Optimal Allocation Method for Energy Storage Capacity Considering Dynamic Time-of-Use Electricity Prices and On-Site Consumption of New Energy

Abstract

1. Introduction

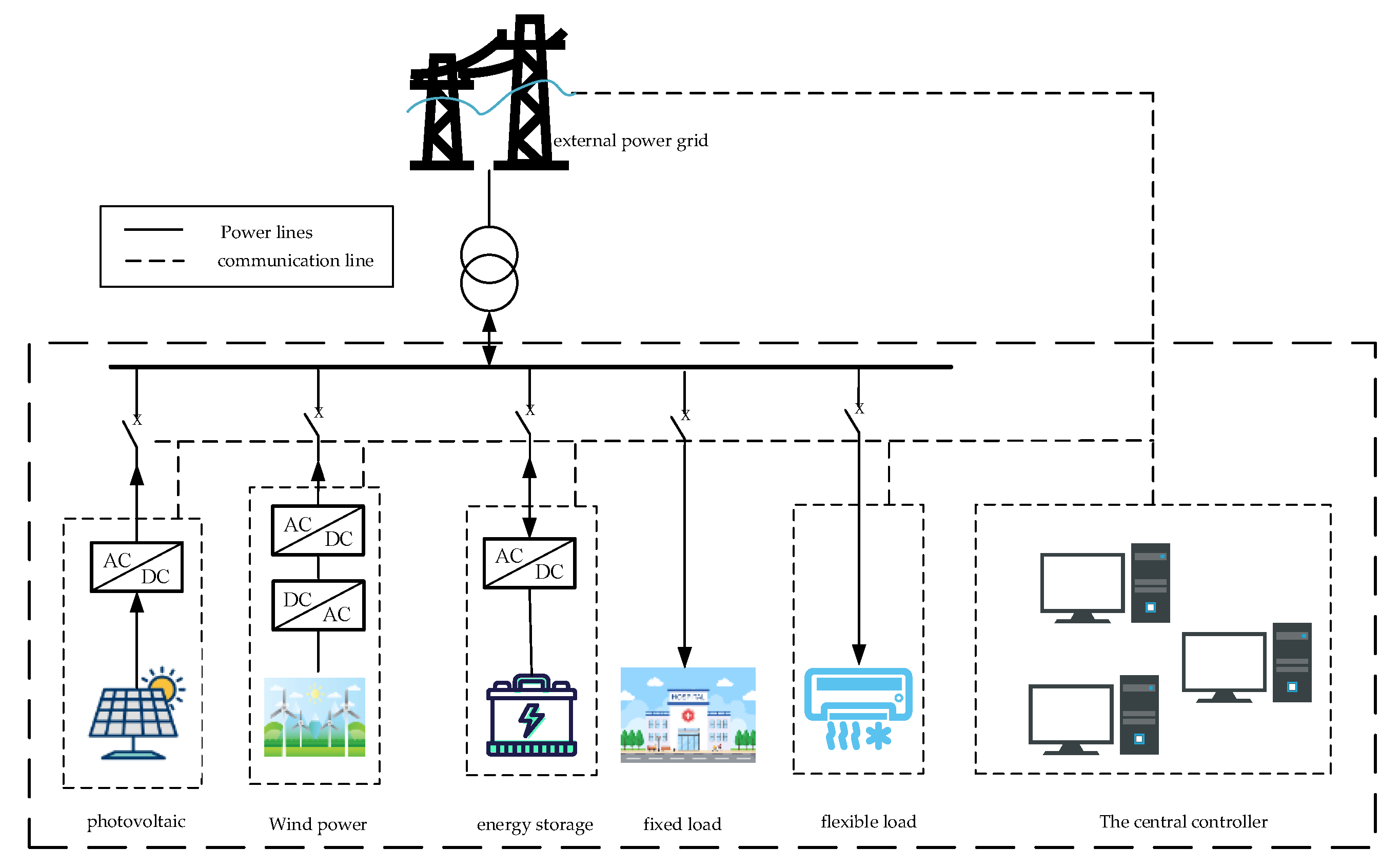

2. Structure of Wind and Solar Energy Storage System

3. Demand Response Model Considering Time Division and Price Optimization

3.1. Time Period Division Based on Fuzzy C-Means Clustering

3.2. Price Setting

4. Build a Coordinated Optimization Model for Time-of-Use Electricity Prices and Energy Storage Capacity

4.1. External Revenue Model Considering Demand-Side Response

4.1.1. Objective Function

4.1.2. Constraints

- (1)

- The total load after the user participates in demand response will remain unchanged, and the load change in any time period will be controlled within a certain range to ensure the power demand of the user.

- (2)

- The implementation of time-of-use tariff has changed users’ electricity consumption habits to a certain extent and reduced their comfort. Therefore, it is necessary to ensure the economy of users’ participation in demand response, so as to mobilize users’ enthusiasm for electricity consumption. It is stipulated that the total electricity cost before users’ participation in demand response should not be greater than the total electricity cost when users do not participate in demand response.

- (3)

- Improper time-of-use electricity prices can lead to peak–valley inversion or insufficient response, so it is necessary to constrain the peak–valley electricity price ratio.

- (4)

- Marginal cost constraint in valley time

4.2. Internal Multi-Objective Model Considering the Daily Life Loss Cost of Energy Storage

4.2.1. Energy Storage Cycle Life Loss Model

- (1)

- Battery discharge depth

- (2)

- Equivalent number of cycles model

- (3)

- The equivalent cycle life of energy storage is

- (4)

- The daily cycle life loss cost of energy storage is

4.2.2. Daily Cost of Energy Storage throughout Its Entire Life Cycle

4.2.3. Objective Function

4.2.4. Constraints

- (1)

- Power balance constraints

- (2)

- Transmission power constraints of interconnection lines

- (3)

- Energy storage operation constraints

- (4)

- Limited by factors such as investment funds and site conditions, the power and capacity of energy storage are constrained

4.2.5. Optimal Scheduling Strategy for Wind and Solar Energy Storage Systems

5. Model Solving Algorithms and Processes

5.1. Solution Algorithm

5.1.1. Multi-Objective Particle Swarm Optimization Algorithm

5.1.2. Choosing the Compromise Optimal Solution

5.2. Energy Storage Charging and Discharging Verification

- (1)

- First, based on the decision variables of energy storage capacity and maximum charging and discharging power at the lower level, and on the principle that the initial state of charge of energy storage is equal to the end time , the maximum state of charge and minimum state of charge that should be constrained for each time period , ... are derived.

- (2)

- Detect and correct and

- (3)

- Detect and correct and based on, , , until equal .

5.3. Solution Flowchart

6. Example Analysis

6.1. Example Parameter Description

6.2. Optimization Configuration Results under Different Typical Weather Conditions

6.3. Analysis of Simulation Results

6.3.1. Analysis of On-Site Consumption of New Energy

6.3.2. Economic Analysis

6.3.3. Optimization Results of Different Penalty Factors

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Koohi-Fayegh, S.; Rosen, M.A. A review of energy storage types, applications and recent developments. J. Energy Storage 2020, 27, 101047. [Google Scholar] [CrossRef]

- Beshir, M.J.; Farag, A.S.; Cheng, T.C. New comprehensive reliability assessment framework for power systems. Energy Convers. Manag. 1999, 40, 975–1007. [Google Scholar] [CrossRef]

- Tushar, M.H.K.; Zeineddine, A.W.; Assi, C. Demand-side management by regulating charging and discharging of the ev, ess, and utilizing renewable energy. IEEE Trans. Ind. Inform. 2018, 14, 117–126. [Google Scholar] [CrossRef]

- Snoussi, J.; Elghali, S.B.; Benbouzid, M.; Mimouni, M.F. Optimal sizing of energy storage systems using frequency-separation-based energy management for fuel cell hybrid electric vehicles. IEEE Trans. Veh. Technol. 2018, 67, 9337–9346. [Google Scholar] [CrossRef]

- Khezri, R.; Mahmoudi, A.; Haque, M.H. Impact of optimal sizing of wind turbine and battery energy storage for a grid-connected household with/without an electric vehicle. IEEE Trans. Ind. Inform. 2022, 18, 5838–5848. [Google Scholar] [CrossRef]

- Li, F.; Li, X.; Zhang, B.; Li, Z.; Lu, M. Multiobjective optimization configuration of a prosumer’s energy storage system based on an improved fast nondominated sorting genetic algorithm. IEEE Access 2021, 9, 27015–27025. [Google Scholar] [CrossRef]

- Khezri, R.; Mahmoudi, A.; Haque, M.H. Optimal capacity of solar pv and battery storage for australian grid-connected households. IEEE Trans. Ind. Appl. 2020, 56, 5319–5329. [Google Scholar] [CrossRef]

- Wu, J.; Ding, M.; Zhang, J. Capacity configuration method of energy storage system for wind farm based on cloud model and k-means clustering. Automat. Electron. Power Syst. 2018, 42, 67–73. [Google Scholar]

- El-Bidairi, K.S.; Duc Nguyen, H.; Jayasinghe, S.D.G.; Mahmoud, T.S.; Penesis, I. A hybrid energy management and battery size optimization for standalone microgrids: A case study for flinders island, australia. Energy Convers. Manag. 2018, 175, 192–212. [Google Scholar] [CrossRef]

- Kong, X.; Wang, H.; Li, N.; Mu, H. Multi-objective optimal allocation and performance evaluation for energy storage in energy systems. Energy 2022, 253, 124061. [Google Scholar] [CrossRef]

- Cai, J.; Xu, Q.; Yuan, X.; Wang, X. Configuration strategy of large-scale battery storage system orienting wind power consumption based on temporal scenarios. High Volt. Eng. 2019, 45, 993–1001. [Google Scholar]

- Barrera-Santana, J.; Sioshansi, R. An optimization framework for capacity planning of island electricity systems. Renew. Sustain. Energy Rev. 2023, 171, 112955. [Google Scholar] [CrossRef]

- Naderipour, A.; Ramtin, A.R.; Abdullah, A.; Marzbali, M.H.; Nowdeh, S.A.; Kamyab, H. Hybrid energy system optimization with battery storage for remote area application considering loss of energy probability and economic analysis. Energy 2022, 239, 122303. [Google Scholar] [CrossRef]

- Nazir, M.S.; Abdalla, A.N.; Wang, Y.; Chu, Z.; Jie, J.; Tian, P.; Jiang, M.; Khan, I.; Sanjeevikumar, P.; Tang, Y. Optimization configuration of energy storage capacity based on the microgrid reliable output power. J. Energy Storage 2020, 32, 101866. [Google Scholar] [CrossRef]

- Pires, A.L.G.; Rotella Junior, P.; Rocha, L.C.S.; Peruchi, R.S.; Janda, K.; Miranda, R.D.C. Environmental and financial multi-objective optimization: Hybrid wind-photovoltaic generation with battery energy storage systems. J. Energy Storage 2023, 66, 107425. [Google Scholar] [CrossRef]

- Premadasa, P.N.D.; Silva, C.M.M.R.; Chandima, D.P.; Karunadasa, J.P. A multi-objective optimization model for sizing an off-grid hybrid energy microgrid with optimal dispatching of a diesel generator. J. Energy Storage 2023, 68, 107621. [Google Scholar] [CrossRef]

- Kou, L.; Ji, Y.; Wu, M.; Niu, G. Optimal configuration of multi-energy complementary system considering full life cycle. Electric Power 2020, 53, 75–82. [Google Scholar]

- Yan, N.; Zhang, B.; Li, W.; Ma, S. Hybrid energy storage capacity allocation method for active distribution network considering demand side response. IEEE Trans. Appl. Supercond. 2019, 29, 1–4. [Google Scholar] [CrossRef]

- Murty, V.V.S.N.; Kumar, A. Optimal energy management and techno-economic analysis in microgrid with hybrid renewable energy sources. J. Mod. Power Syst. Clean Energy 2020, 8, 929–940. [Google Scholar] [CrossRef]

- Honarmand, H.A.; Rashid, S.M. A sustainable framework for long-term planning of the smart energy hub in the presence of renewable energy sources, energy storage systems and demand response program. J. Energy Storage 2022, 52, 105009. [Google Scholar] [CrossRef]

- Kiptoo, M.K.; Lotfy, M.E.; Adewuyi, O.B.; Conteh, A.; Howlader, A.M.; Senjyu, T. Integrated approach for optimal techno-economic planning for high renewable energy-based isolated microgrid considering cost of energy storage and demand response strategies. Energy Convers. Manag. 2020, 215, 112917. [Google Scholar] [CrossRef]

- Mohseni, S.; Brent, A.C.; Kelly, S.; Browne, W.N.; Burmester, D. Strategic design optimisation of multi-energy-storage-technology micro-grids considering a two-stage game-theoretic market for demand response aggregation. Appl. Energy 2021, 287, 116563. [Google Scholar] [CrossRef]

- Zhu, C.; Lu, W.; Zhao, W.; Hong, Z.; Chen, C. On-site energy consumption technologies and prosumer marketing for distributed poverty alleviation photovoltaic linked to agricultural loads in china. IEEE Access 2020, 8, 191561–191573. [Google Scholar] [CrossRef]

- Sun, Y.; Cui, C.; Lu, J.; Hao, J.; Liu, X. Non-intrusive load monitoring method based on delta feature extraction and fuzzy clustering. Automat. Electron. Power Syst. 2017, 41, 86–91. [Google Scholar]

- Karapetyan, A.; Khonji, M.; Chau, S.C.; Elbassioni, K.; Zeineldin, H.; El-Fouly, T.H.M.; Al-Durra, A. A competitive scheduling algorithm for online demand response in islanded microgrids. IEEE Trans. Power Syst. 2021, 36, 3430–3440. [Google Scholar] [CrossRef]

- Muthirayan, D.; Kalathil, D.; Poolla, K.; Varaiya, P. Mechanism design for demand response programs. IEEE Trans. Smart Grid 2020, 11, 61–73. [Google Scholar] [CrossRef]

- Li, C.; Xu, Z.; Ma, Z. Optimal time-of-use electricity price model considering customer demand response. Proc. CSU-EPSA 2015, 27, 11–16. [Google Scholar]

- Wang, K.; Qiao, Y.; Xie, L.; Li, J.; Lu, Z.; Yang, H. A fuzzy hierarchical strategy for improving frequency regulation of battery energy storage system. J. Mod. Power Syst. Clean Energy 2021, 9, 689–698. [Google Scholar] [CrossRef]

- Tran, D.; Khambadkone, A.M. Energy management for lifetime extension of energy storage system in micro-grid applications. IEEE Trans. Smart Grid 2013, 4, 1289–1296. [Google Scholar] [CrossRef]

- Zhu, L.; Hu, W. Short term wind speed prediction based on vmd and dbn combined model optimized by improved sparrow intelligent algorithm. IEEE Access 2022, 10, 92259–92272. [Google Scholar] [CrossRef]

- Zhang, C.; Ding, S. A stochastic configuration network based on chaotic sparrow search algorithm. Knowl. -Based Syst. 2021, 220, 106924. [Google Scholar] [CrossRef]

- Cui, Y.F.; Geng, Z.Q.; Zhu, Q.X.; Han, Y.M. Review: Multi-objective optimization methods and application in energy saving. Energy 2017, 125, 681–704. [Google Scholar] [CrossRef]

- Qu, B.; Li, C.; Liang, J.; Yan, L.; Yu, K.; Zhu, Y. A self-organized speciation based multi-objective particle swarm optimizer for multimodal multi-objective problems. Appl. Soft Comput. 2020, 86, 105886. [Google Scholar] [CrossRef]

- Fei, Z.S.; Li, B.; Yang, S.S.; Xing, C.W.; Chen, H.B.; Hanzo, L. A survey of multi-objective optimization in wireless sensor networks: Metrics, algorithms, and open problems. IEEE Commun. Surv. Tutor. 2017, 19, 550–586. [Google Scholar] [CrossRef]

| Parameter | Numerical Value | Parameter | Numerical Value |

|---|---|---|---|

| Penalty cost coefficient | 0.1 | Cross elasticity coefficient | 0.03 |

| Ciscounted rate | 5% | cp (RMB/kW) | |

| Kp | 2 | (kW) | 600 |

| Maximum number of charges and disCharges for energy storage | 5000 | (kW) | −600 |

| Carbon trading price (RMB/1000 kg) | 15 | cE (RMB/kW) | |

| , | 0.95 | Operation and maintenance Costs (RMB/kW h) | 50 |

| 0.9 | 2500 | ||

| 0.2 | 500 | ||

| initial value | 0.5 | Carbon reduction per unit of New energy (kg/kW·h) | 0.16 |

| Electricity selling price | 0.58 | (RMB/kW·h) | 0.12 |

| Electricity purchase price | 0.69 | (RMB/kW·h) | 1.2 |

| Coefficient of self elasticity | −0.2 | /Year | 20 |

| Parameter | Period of Time | Electricity Price (RMB/kW·h) |

|---|---|---|

| Peak period | 07:00–11:00, 17:00–21:00 | 0.96 |

| Peacetime period | 12:00–16:00, 22:00–23:00 | 0.58 |

| Valley period | 00:00–6:00 | 0.27 |

| Typical Daily Scenario | On Site Consumption Rate of New Energy | ||

|---|---|---|---|

| Peak period | 07:00–11:00, 17:00–21:00 | 285 | 210 |

| Peacetime period | 12:00–16:00, 22:00–23:00 | 1194 | 136 |

| Valley period | 00:00–6:00 | 826 | 192 |

| Scene | On Site Consumption Rate of New Energy/% | ||

|---|---|---|---|

| 1 | 91.55% | 0 | 0 |

| 2 | 95.67% | 0 | 0 |

| 3 | 93.89% | 1194 | 210 |

| 4 | 97.93% | 1194 | 210 |

| Before and after Optimization | Maximum Load/kW | Minimum Load/kW | Peak–Valley Difference of Load/kW | Net Load Peak Valley Difference/kW |

|---|---|---|---|---|

| Before optimization | 1356.3 | 458.6 | 897.7 | 646.9 |

| After optimization | 1339 | 547 | 792 | 411.4 |

| Variation | −17.3 | 88.4 | −105.7 | −235.5 |

| Scene | System Benefits | Consumer Electricity Consumption | Revenue from Selling Electricity to the Power Grid | Cost of Purchasing Electricity from the Power Grid | Penalty for Contact Line Fluctuations | Daily Loss Cost of Energy Storage |

|---|---|---|---|---|---|---|

| 1 | 10,354 | 14,301 | 1124.9 | 1514.9 | 3612.1 | 0 |

| 2 | 11,914 | 13,238 | 576.17 | 863.19 | 1092.5 | 0 |

| 3 | 7046.4 | 14,301 | 985.51 | 1426.3 | 5197.7 | 1670.9 |

| 4 | 10,527 | 13,238 | 276.12 | 560.53 | 856.43 | 1625.7 |

| Different Scenarios | Returns and Volatility Penalties | Different Penalty Factors | ||

|---|---|---|---|---|

| 0.1 | 0.01 | 0.001 | ||

| Scenario 1 | System benefits | 10,354 | 13,605 | 13,930 |

| Volatility Penalties | 3612.1 | 361.21 | 36.12 | |

| Scenario 2 | System benefits | 11,914 | 12,897 | 12,995 |

| Volatility Penalties | 1092.5 | 109.25 | 10.93 | |

| Scenario 3 | System benefits | 7046.4 | 11,725 | 12,192 |

| Volatility Penalties | 5197.7 | 519.77 | 51.98 | |

| Scenario 4 | System benefits | 10,527 | 11,297 | 11,374 |

| Volatility Penalties | 856.43 | 85.64 | 8.56 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, W.; Zhang, X.; Zhu, L.; Li, Z. Optimal Allocation Method for Energy Storage Capacity Considering Dynamic Time-of-Use Electricity Prices and On-Site Consumption of New Energy. Processes 2023, 11, 1725. https://doi.org/10.3390/pr11061725

Hu W, Zhang X, Zhu L, Li Z. Optimal Allocation Method for Energy Storage Capacity Considering Dynamic Time-of-Use Electricity Prices and On-Site Consumption of New Energy. Processes. 2023; 11(6):1725. https://doi.org/10.3390/pr11061725

Chicago/Turabian StyleHu, Wei, Xinyan Zhang, Lijuan Zhu, and Zhenen Li. 2023. "Optimal Allocation Method for Energy Storage Capacity Considering Dynamic Time-of-Use Electricity Prices and On-Site Consumption of New Energy" Processes 11, no. 6: 1725. https://doi.org/10.3390/pr11061725

APA StyleHu, W., Zhang, X., Zhu, L., & Li, Z. (2023). Optimal Allocation Method for Energy Storage Capacity Considering Dynamic Time-of-Use Electricity Prices and On-Site Consumption of New Energy. Processes, 11(6), 1725. https://doi.org/10.3390/pr11061725