Effect of Crude Oil Quality on Properties of Hydrocracked Vacuum Residue and Its Blends with Cutter Stocks to Produce Fuel Oil

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Physical and Chemical Characterization of Studied Oils

2.2.2. Application of Intercriteria Analysis to the Data Generated in This Study

3. Results

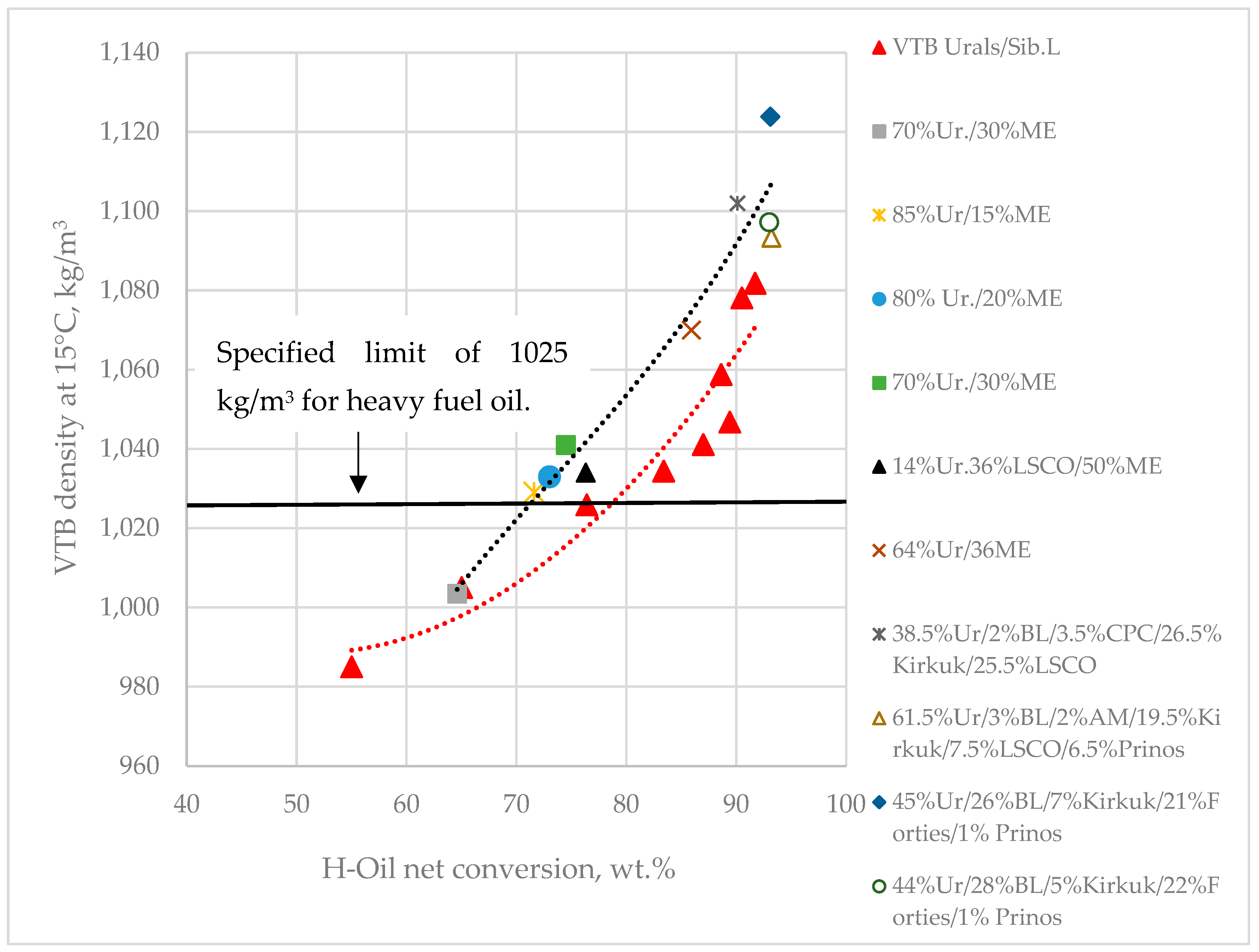

3.1. Variation of Density of H-Oil VTB and Total Sediment Potential of Its Blends with FCC HCO as Partially Blended Fuel Oil (PBFO)

3.2. Density of the Blends of H-Oil VTB Produced from the Three Studied Crude Mixtures with the Cutter Stocks FCC LCO, HCO, SLO, and FCCPT Diesel

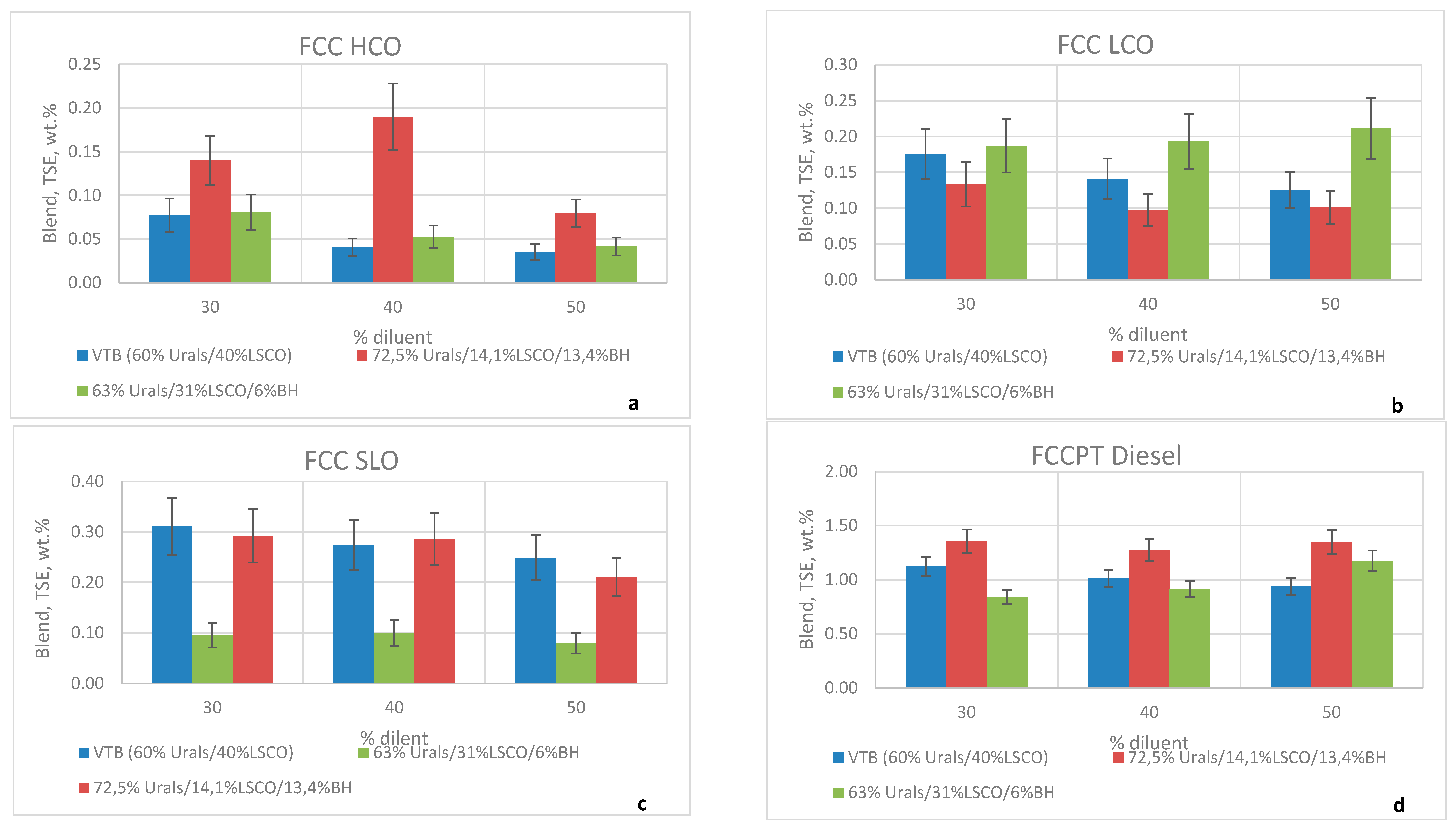

3.3. Sediment Content in the Blends of H-Oil VTB Produced from the Three Studied Crude Mixtures with the Cutter Stocks FCC LCO, HCO, SLO, and FCCPT Diesel

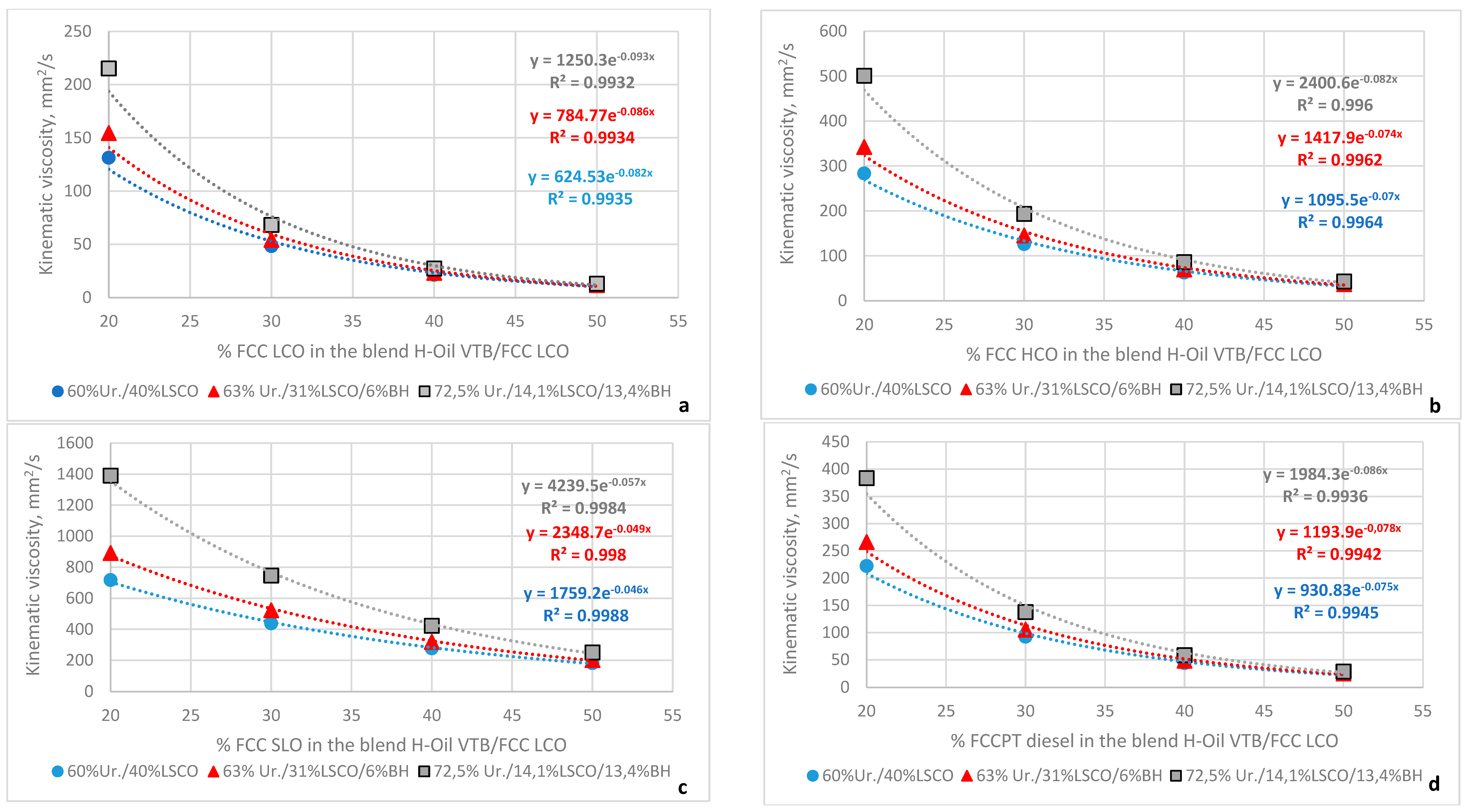

3.4. Viscosity Variation in the Blends of H-Oil VTB Produced from the Three Studied Crude Mixtures with Alteration of the Content of the Cutter Stocks FCC LCO, HCO, SLO, and FCCPT Diesel in the Mixtures

4. Discussion

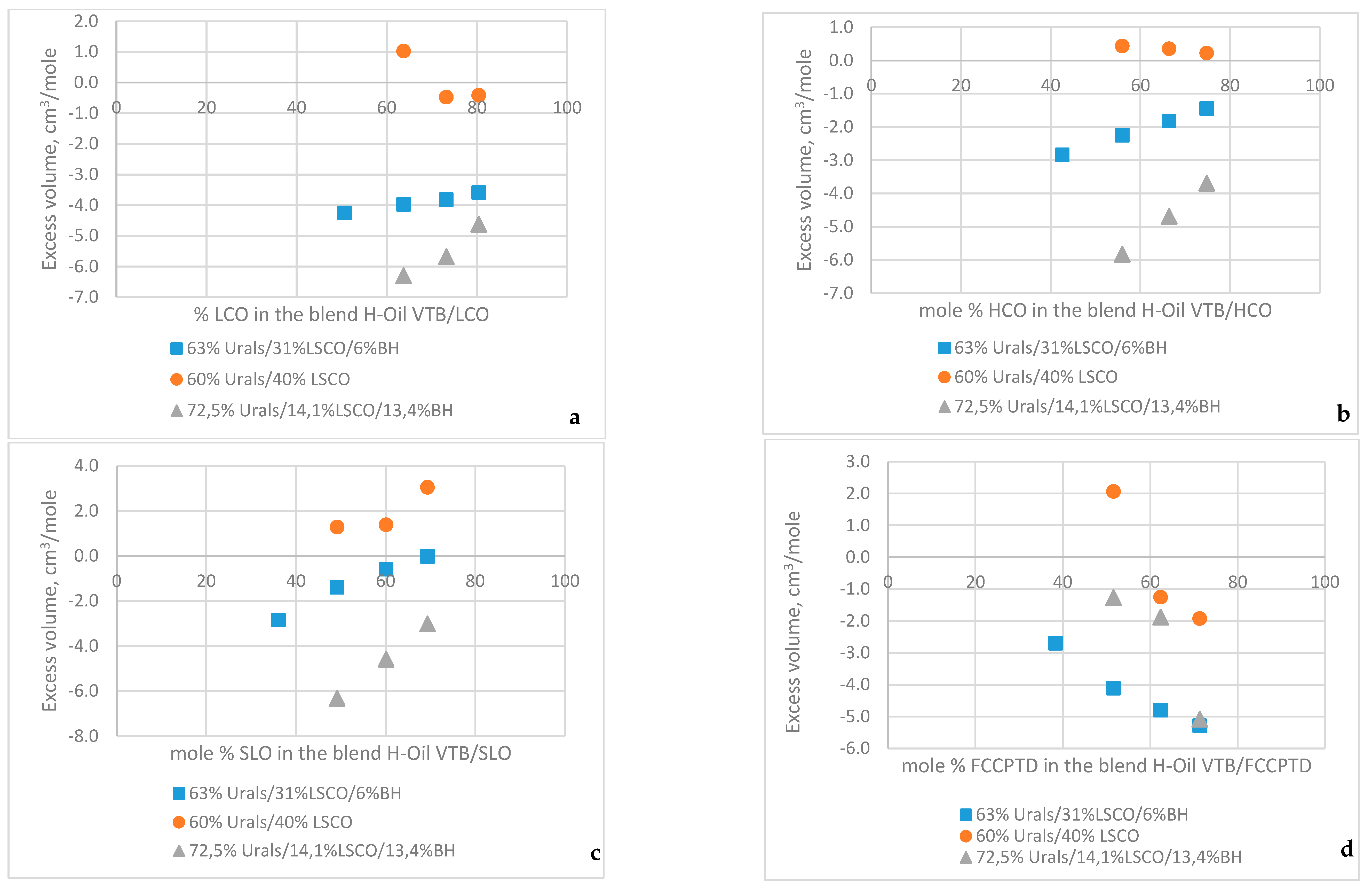

4.1. Variation of the Molar Excess Volume of the Blends of H-Oil VTBs with the Cutter Stocks

4.2. Sediment Content in the Blends of H-Oil VTBs with the Cutter Stocks

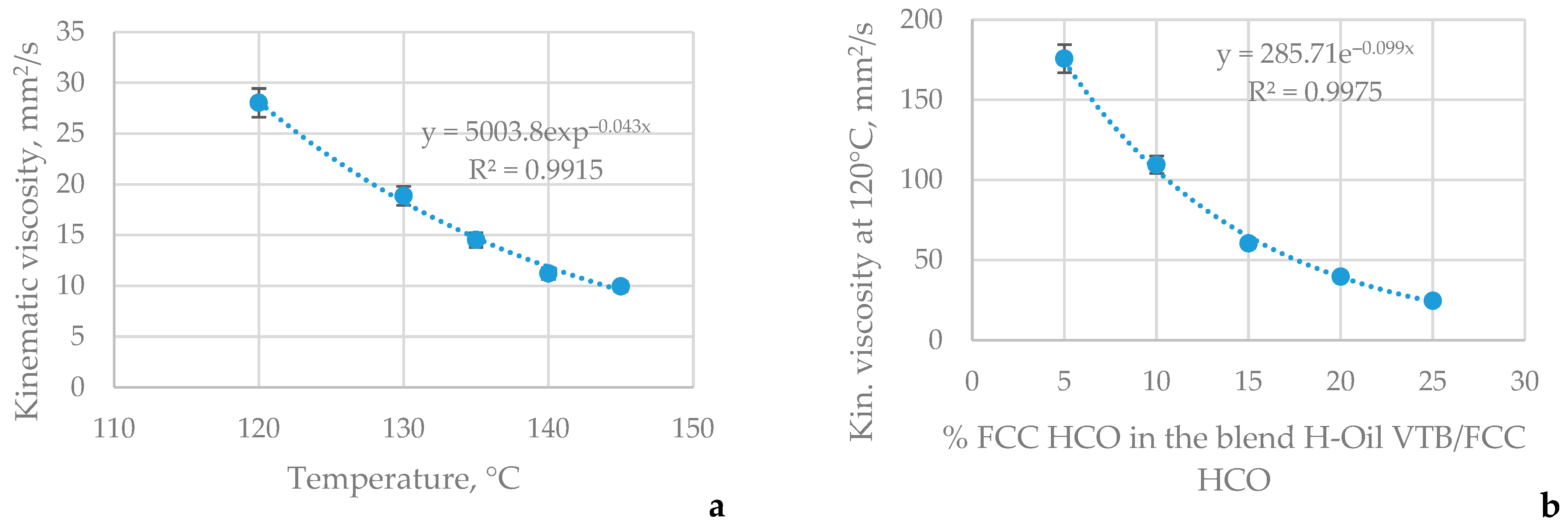

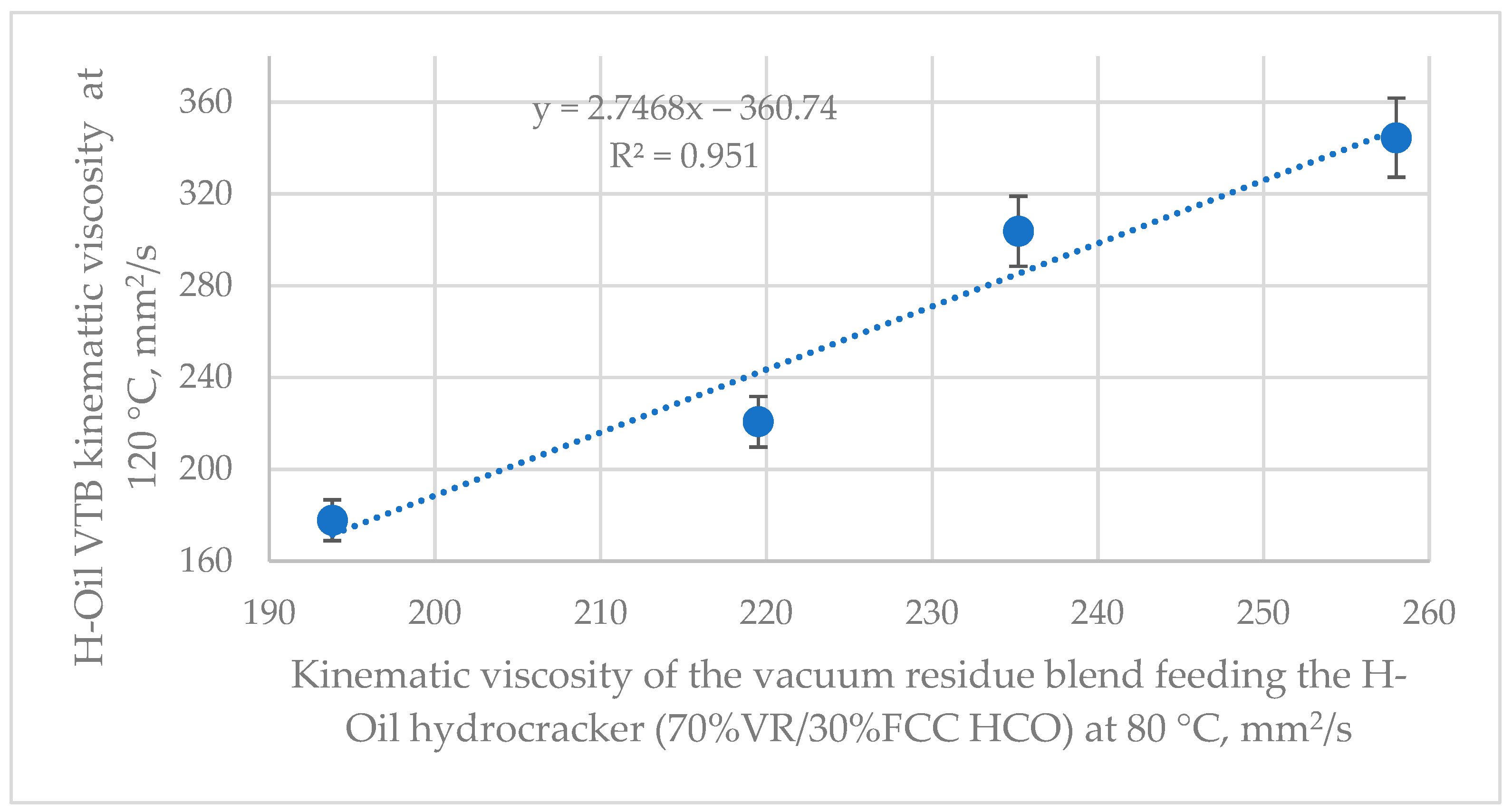

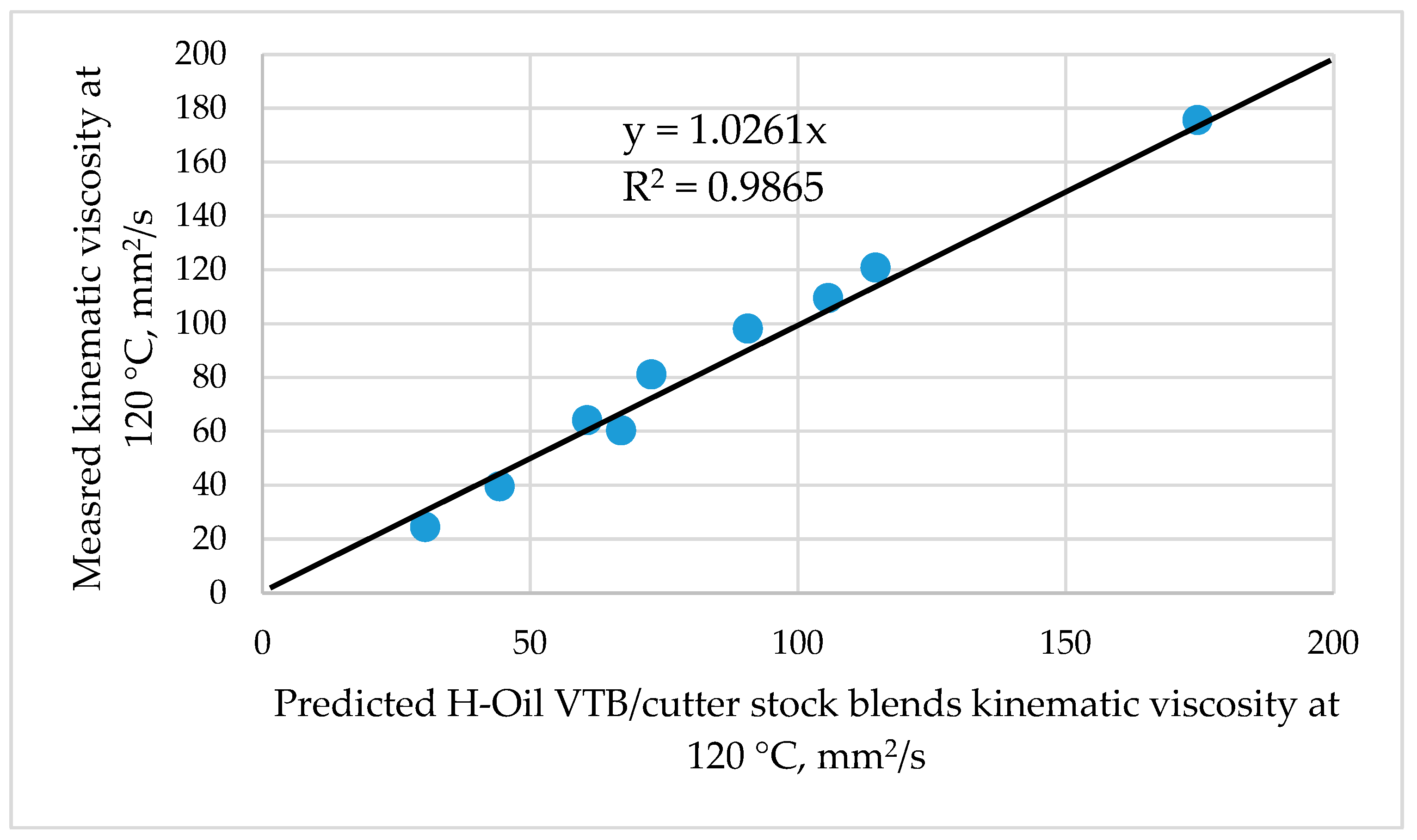

4.3. Viscosity Dependence of H-Oil VTB on the Viscosity of the Processed Vacuum Residue Blend in the H-Oil Hydrocracker and Prediction of Viscosity of the Blends H-Oil VTB/Cutter Stocks

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Aro | Content of aromatic compounds, wt.% |

| Asp | Content of asphaltenes, wt.% |

| ATB | Atmospheric tower bottom product |

| BH | Basrah heavy crude oil |

| C5-asp | Content of n-pentane asphaltenes, wt.% |

| C7-asp | Content of n-heptane asphaltenes, wt.% |

| EBVRHC | Ebullated vacuum residue hydrocracking |

| FBP | Final boiling point, °C |

| FCC | Fluid catalytic cracking |

| FCCPT | Fluid catalytic cracking pretreater |

| HAGO | Heavy atmospheric gas oil |

| HCO | Heavy cycle oil |

| HTSD | High-temperature simulated distillation |

| HVGO | Heavy vacuum gas oil |

| IBP | Initial boiling point, °C |

| Kw | Watson characterization factor |

| LCO | Light cycle oil |

| LSCO | Light Siberian crude oil |

| LHSV | Liquid hourly space velocity, h−1 |

| LNB | LUKOIL Neftohim Burgas |

| LVGO | Light vacuum gas oil |

| MW | Molar weight, g/mol |

| PBFO | Partially blended fuel oil |

| Res | Content of resins, wt.% |

| SAR-AD | Patented method for separation of SAR (saturates, aromatics, and resins) combined with Asphaltene Determinator (AD) |

| SARA | Saturates, aromatics, and resins |

| SLO | Slurry oil |

| TBP | True boiling point, °C |

| TSE | Total sediment existent content, wt.% |

| TSP | Total sediment potential content, wt.% |

| VE | Excess molar volume, m3 |

| VGO | Vacuum gas oil |

| VTB | Vacuum tower bottom product |

| VR | Vacuum residue |

| WABT | Weight average bed temperature, °C |

| ∆V | Relative changes in volume |

| χi | Mole fraction of the individual component i, mol/mol |

| Mi | Molar mass of the individual component i, g/mol |

| Voi | Molar volume of the individual component i, m3/mol |

| ρi | Density of the individual component i, g/m3 |

| mi | Mass fraction of the individual component i |

| ϕ1 | Volume fraction of the cutter stock. |

References

- Treese, S.; Jones, D.; Pujado, P. Handbook of Petroleum Processing; Springer: Cham, Switzerland, 2020. [Google Scholar]

- Panariti, N.; Rispoli, G. The first EST Commercial Unit: Achieving the goal of residue conversion. In Proceedings of the 13th International Bottom of the Barrel Conference, Istanbul, Turkey, 14–15 May 2015. [Google Scholar]

- Dreillard, M.; Marques, J.; Barbier, J.; Feugnet, F. Deep conversion of vacuum residue while limiting sediment formation. In Proceedings of the Petrophase Conference, The Chateaux at Deer Valley, Uta, Park City, UT, USA, 11 July 2018. [Google Scholar]

- Stratiev, D.; Nenov, S.; Shishkova, I.; Georgiev, B.; Argirov, G.; Dinkov, R.; Yordanov, D.; Atanassova, V.; Vassilev, P.; Atanassov, K. Commercial investigation of the ebullated-bed vacuum residue hydrocracking in the conversion range of 55–93%. ACS Omega 2020, 51, 33290–33304. [Google Scholar] [CrossRef] [PubMed]

- Bellussi, G.; Rispoli, G.; Landoni, A.; Millini, R.; Molinari, D.; Montanari, E.; Moscotti, D.; Pollesel, P. Hydroconversion of heavy residues in slurry reactors: Developments and perspective. J. Catal. 2013, 308, 189–200. [Google Scholar] [CrossRef]

- Stratiev, D.; Shishkova, I.; Dinkov, R.; Dobrev, D.; Argirov, G.; Yordanov, D. The Synergy between Ebullated Bed Vacuum Residue Hydrocracking and Fluid Catalytic Cracking Processes in Modern Refining—Commercial Experience; Professor Marin Drinov Publishing House of Bulgarian Academy of Sciences: Sofia, Bulgaria, 2022; ISBN 978-619-245-234-6. [Google Scholar]

- Yang, C.; Du, F.; Zheng, H.; Chung, K.H. Hydroconversion characteristics and kinetics of residue narrow fractions. Fuel 2005, 84, 675–684. [Google Scholar] [CrossRef]

- Dinkov, R.; Kirilov, K.; Stratiev, D.; Sharafutdinov, I.; Dobrev, D.; Nguyen-Hong, D.; Chapot, S.; Le-coz, J.F.; Burilkova, A.; Bakalova, D.; et al. Feasibility of bitumen production from unconverted vacuum tower bottom from H-Oil ebullated bed residue hydrocracking. Ind. Eng. Chem. Res. 2018, 57, 2003–2013. [Google Scholar] [CrossRef]

- Marques, J.; Maget, S.; Verstraete, M.J.J. Improvement of ebullated-bed effluent stability at high conversion operation. Energy Fuels 2011, 25, 3867–3874. [Google Scholar] [CrossRef]

- Robert, E.C.; Merdrignac, I.; Rebours, B.; Harlé, V.; Kressmann, S.; Colyar, J. Contribution of analytical tools for the understanding of sediment formation: Application to H-Oil® Proces. Pet. Sci. Technol. 2003, 21, 615–627. [Google Scholar] [CrossRef]

- Nakashima, N. Update on H-Oil Unit Fouling Mitigation Study; Criterion EB Workshop: Vancouver, BC, Canada, 2018. [Google Scholar]

- Bannayan, M.A.; Lemke, H.K.; Stephenson, W.K. Fouling mechanisms and effect of process conditions on deposit formation in H-Oil. Stud. Surf. Sci. Catal. 1996, 100, 273–281. [Google Scholar]

- Manek, E.; Haydary, J. Hydrocracking of vacuum residue with solid and dispersed phase catalyst: Modeling of sediment formation and hydrodesulfurization. Fuel Process. Technol. 2017, 159, 320–327. [Google Scholar] [CrossRef]

- Respini, M.; Ekres, S.; Wright, B.; Žajdlík, R. Strategies to control sediment and coke in a hydrocracker. Pet. Technol. Q. 2013, 18, 23–35. [Google Scholar]

- Kunnas, J.; Ovaskainen, O.; Respini, M. Mitigate fouling in ebullated-bed hydrocrackers. Hydrocarb. Process. 2010, 10, 59–64. [Google Scholar]

- Matsushita, K.; Marafi, A.; Hauser, A.; Stanislaus, A. Relation between relative solubility of asphaltenes in the product oil and coke deposition in residue hydroprocessing. Fuel 2004, 83, 1669–1674. [Google Scholar] [CrossRef]

- Stanislaus, A.; Hauser, A.; Marafi, M. Investigation of the mechanism of sediment formation in residual oil hydrocracking process through characterization of sediment deposits. Catal. Today 2005, 109, 167–177. [Google Scholar] [CrossRef]

- Marafi, M.; Al-Barood, A.; Stanislaus, A. Effect of Diluents in Controlling Sediment Formation during Catalytic Hydrocracking of Kuwait Vacuum Residue. A Pet. Sci. Technol. 2005, 23, 899–908. [Google Scholar] [CrossRef]

- Tirado, A.; Ancheyta, J. A batch reactor study of the effect of aromatic diluents to reduce sediment formation during hydrotreating of heavy oil. Energy Fuels 2018, 32, 60–66. [Google Scholar] [CrossRef]

- García, F.O.; Mar-Juárez, E.; Hernández, P.S. Controlling Sediments in the Ebullated Bed Hydrocracking Process. Energy Fuels 2012, 26, 2948–2952. [Google Scholar] [CrossRef]

- Stratiev, D.; Dinkov, R.; Shishkova, I.; Sharafutdinov, I.; Ivanova, N.; Mitkova, M.; Yordanov, D.; Rudnev, N.; Stanulov, K.; Artemiev, A.; et al. What is behind the high values of hot filtration test of the ebullated bed residue H-Oil hydrocracker residual oils? Energy Fuels 2016, 30, 7037–7054. [Google Scholar] [CrossRef]

- Almukhtar, R.; Hammoodi, S.I.; Majdi, H.S.; Sukkar, K.A. Managing Transport Processes in Thermal Cracking to Produce High-Quality Fuel from Extra-HeavyWaste Crude Oil Using a Semi-Batch Reactor. Processes 2022, 10, 2077. [Google Scholar] [CrossRef]

- Alvarez, A.E.; Ovalles, E.; Rodríguez, M.C.; Rodríguez, A.F.; Castillo, P.J.; Rivas, J.C.; Reyes-Ortíz, O.J.; Rincón-Morantes, J.F. Adhesion quality and rheological properties of unmodified and nano-modified asphalt residues derived from paving-heavy crude oils. DYNA 2019, 86, 357–366. [Google Scholar]

- Ahmad, I.; Sohail, S.M.; Khan, H.; Ahmad, W.; Gul, K.; Khan, R.; Yasin, A. Study on Atmospheric Distillation of Some Plain and Chemically Dispersed Crude Oils: Comparison of Yields and Fuel Quality of Distillate Fractions. Energy Fuels 2018, 32, 181–190. [Google Scholar] [CrossRef]

- Waziri, M.; Audu, A.; Alex, B. A comparison of the quality of low pour fuel oils (LPFO) blended from Nigerian and foreign crude oils. Petrol. Sci. Technol. 2014, 32, 1473–1479. [Google Scholar] [CrossRef]

- Jarullah, A.T.; Mujtaba, I.M.; Wood, A.S. Improving fuel quality by whole crude oil hydrotreating: A kinetic model for hydrodeasphaltenization in a trickle bed reactor. Appl. Energy 2012, 94, 182–191. [Google Scholar] [CrossRef]

- Rathore, V.; Brahma, R.; Thorat, T.S.; Rao, P.V.C.; Choudary, N.V. Assessment of crude oil blends. Pet. Technol. Q. 2011, 16, 111–117. [Google Scholar]

- Kumar, R.; Voolapalli, R.K.; Upadhyayula, S. Prediction of crude oil blends compatibility and blend optimization for increasing heavy oil processing. Fuel Process. Technol. 2018, 177, 309–327. [Google Scholar] [CrossRef]

- Frecon, J.; Le-Bars, D.; Rault, J. Flexible upgrading of heavy feedstocks. Pet. Technol. Q. 2019, Q1, 1–11. [Google Scholar]

- Stratiev, D.; Shishkova, I.; Dinkov, R.; Nenov, S.; Sotirov, S.; Sotirova, E.; Kolev, I.; Ivanov, V.; Ribagin, S.; Atanassov, K.; et al. Prediction of Petroleum Viscosity from Molecular Weight and Density. Fuel 2023, 331, 125679. [Google Scholar] [CrossRef]

- Adams, J.J.; Rovani, J.F.; Planche, J.-P.; Loveridge, J.; Literati, A.; Shishkova, I.; Palichev, G.; Kolev, I.; Atanassov, K.; Nenov, S.; et al. SAR-AD Method to Characterize Eight SARA Fractions in Various Vacuum Residues and Follow Their Transformations Occurring during Hydrocracking and Pyrolysis. Processes 2023, 11, 1220. [Google Scholar] [CrossRef]

- Stratiev, D.; Shishkova, I.; Nikolova, R.; Tsaneva, T.; Mitkova, M.; Yordanov, D. Investigation on precision of determination of SARA analysis of vacuum residual oils from different origin. Pet. Coal 2016, 58, 109–119. [Google Scholar]

- Stratiev, D.; Sotirov, S.; Sotirova, E.; Nenov, S.; Dinkov, R.; Shishkova, I.; Kolev, I.V.; Yordanov, D.; Vasilev, S.; Atanassov, K.; et al. Prediction of Molecular Weight of Petroleum Fluids by Empirical Correlations and Artificial Neuron Networks. Processes 2023, 11, 426. [Google Scholar] [CrossRef]

- Stratiev, D.; Dinkov, R.; Tavlieva, M.; Shishkova, I.; Palichev, G.N.; Ribagin, S.; Atanassov, K.; Stratiev, D.D.; Nenov, S.; Pilev, D.; et al. Correlations of HTSD to TBP and Bulk Properties to Saturate Content of a Wide Variety of Crude Oils. Processes 2023, 11, 420. [Google Scholar] [CrossRef]

- Stratiev, D.; Nenov, S.; Nedanovski, D.; Shishkova, I.; Dinkov, R.; Stratiev, D.D.; Stratiev, D.D.; Sotirov, S.; Sotirova, E.; Atanassova, V.; et al. Empirical Modeling of Viscosities and Softening Points of Straight-Run Vacuum Residues from Different Origins and of Hydrocracked Unconverted Vacuum Residues Obtained in Different Conversions. Energies 2022, 15, 1755. [Google Scholar] [CrossRef]

- Stratiev, D.; Shishkova, I.; Palichev, G.N.; Atanassov, K.; Ribagin, S.; Nenov, S.; Nedanovski, D.; Ivanov, V. Study of Bulk Properties Relations to SARA Composition Data of Various Vacuum Residues Employing Intercriteria Analysis. Energies 2022, 15, 9042. [Google Scholar] [CrossRef]

- Coquelet, C.; Auger, E.; Valtz, A. Density and Excess Volume for Four Systems Involving Eugenol and Furan. J. Solution Chem. 2019, 48, 455–488. [Google Scholar] [CrossRef]

- Qin, A.; Hoffman, D.E.; Munk, P. Excess Volumes of Mixtures of Alkanes with Carbonyl Compounds. J. Chem. Eng. Data 1992, 37, 55–61. [Google Scholar] [CrossRef]

- Atanassov, K.; Mavrov, D.; Atanassova, V. Intercriteria decision making: A new approach for multicriteria decision making, based on index matrices and intuitionistic fuzzy sets. Issues Intuit. Fuzzy Sets Gen. Nets 2014, 11, 1–8. [Google Scholar]

- Atanassov, K.; Atanassova, V.; Gluhchev, G. Intercriteria analysis: Ideas and problems. Notes Intuit. Fuzzy Sets 2015, 21, 81–88. [Google Scholar]

- Atanassov, K. Index Matrices: Towards an Augmented Matrix Calculus; Springer: Cham, Switzerland, 2014. [Google Scholar]

- Doukovska, L.; Atanassova, V.; Sotirova, E.; Vardeva, I.; Radeva, I. Defining Consonance Thresholds in InterCriteria Analysis: An Overview. In Intuitionistic Fuzziness and Other Intelligent Theories and Their Applications; Hadjiski, M., Atanassov, K., Eds.; Studies in Computational Intelligence; Springer: Berlin/Heidelberg, Germany, 2019; Volume 757, pp. 161–179. [Google Scholar]

- Stratiev, D.; Nedelchev, A.; Shishkova, I.; Ivanov, A.; Sharafutdinov, I.; Nikolova, R.; Mitkova, M.; Yordanov, D.; Rudnev, N.; Belchev, Z.; et al. Dependence of visbroken residue viscosity and vacuum residue conversion in a commercial visbreaker unit on feedstock quality. Fuel Process. Technol. 2015, 138, 595–604. [Google Scholar] [CrossRef]

- Stratiev, D.; Shishkova, I.; Nedelchev, A.; Kirilov, K.; Nikolaychuk, E.; Ivanov, A.; Sharafutdinov, I.; Veli, A.; Mitkova, M.; Tsaneva, T.; et al. Investigation of relationships between petroleum properties and their impact on crude oil compatibility. Energy Fuels 2015, 29, 7836–7854. [Google Scholar] [CrossRef]

- Stratiev, D.S.; Sotirov, S.; Shishkova, I.; Nedelchev, A.; Sharafutdinov, I.; Vely, A.; Mitkova, M.; Yordanov, D.; Sotirova, E.; Atanassova, V.; et al. Investigation of relationships between bulk properties and fraction properties of crude oils by application of the Intercriteria analysis. Petrol. Sci. Technol. 2016, 34, 1113–1120. [Google Scholar] [CrossRef]

- Stratiev, D.; Shishkova, I.; Dinkov, R.; Kolev, I.; Argirov, G.; Ivanov, V.; Ribagin, S.; Atanassova, V.; Atanassov, K.; Stratiev, D.; et al. Intercriteria analysis to diagnose the reasons for increased fouling in a commercial ebullated bed vacuum residue hydrocracker. ACS Omega 2022, 7, 30462–30476. [Google Scholar] [CrossRef]

- Georgiev, B.E.; Stratiev, D.S.; Argirov, G.S.; Nedelchev, A.; Dinkov, R.; Shishkova, I.K.; Ivanov, M.; Atanassov, K.; Ribagin, S.; Nikolov Palichev, G.; et al. Commercial Ebullated Bed Vacuum Residue Hydrocracking Performance Improvement during Processing Difficult Feeds. Appl. Sci. 2023, 13, 3755. [Google Scholar] [CrossRef]

- Yarranton, H. Prediction of crude oil saturate content from a simdist assay. Energy Fuels 2022, 36, 8809–8817. [Google Scholar] [CrossRef]

- Lim, S.H.; Go, K.S.; Nho, N.S.; Kim, Y.K.; Kwon, E.H.; Kwang, H.K.; Lee, J.G. Reaction characteristics and sediment formation of slurry phase hydrocracking with vacuum residue in a bench-scale bubble column reactor. J. Pet. Sci. Eng. 2021, 196, 107713. [Google Scholar] [CrossRef]

- Sundaram, K.M.; Mukherjee, U.; Baldassari, M. Thermodynamic Model of Sediment Deposition in the LC-FINING Process. Energy Fuels 2008, 22, 3226–3236. [Google Scholar] [CrossRef]

- Gray, M.R.; Yarranton, H.W.; Chacón-Patiño, M.L.; Rodgers, R.P.; Bouyssiere, B.; Giusti, P. Distributed properties of asphaltene nanoaggregates in crude oils: A review. Energy Fuels 2021, 35, 18078–18103. [Google Scholar] [CrossRef]

- Vargas, F.M.; Tavakkoli, M.; Boggara, M.; Garcia-Bermudes, M.; Evangelista, R.; Melendez, A.; Wang, F.; Sisco, C.; Mathew, N.T.; Prasad, S.; et al. Advances in Understanding Asphaltene Precipitation and Deposition. In Proceedings of the 15th International Conference on Petroleum Phase Behavior and Fouling, Galveston, TX, USA, 8–12 June 2014. [Google Scholar]

- Khaleel, A.T.; Sisco, C.J.; Tavakkoli, M.; Vargas, F. An Investigation of the effect of asphaltene polydispersity on asphaltene precipitation and deposition tendencies. Energy Fuels 2022, 36, 8799–8808. [Google Scholar] [CrossRef]

- Stratiev, D.S. Novelties in Thermal and Catalytic Processes at Production of Modern Fuels. Ph.D. Thesis, Burgas University “Assen Zlatarov”, Burgas, Bulgaria, 2010. [Google Scholar]

| Crude Origin | Urals | Basrah H | LSCO | Kirkuk | |

|---|---|---|---|---|---|

| Crude density at 15 °C | kg/m3 | 877.0 | 905.0 | 854.0 | 879.9 |

| Crude sulphur | wt.% | 1.53 | 3.86 | 0.57 | 2.88 |

| Crude kin. viscosity at 40 °C | mm2/s | 12.6 | 37.2 | 10.8 | 11.8 |

| Crude Sat. | wt.% | 58.4 | 46.5 | 62.3 | 57.7 |

| Crude Aro. | wt.% | 35.2 | 38.7 | 31.4 | 34.2 |

| Crude Res. | wt.% | 2.6 | 5.1 | 3.1 | 2.2 |

| Crude Asp(C7) | wt.% | 3.8 | 9.7 | 3.2 | 6.0 |

| Crude Asp(C5) | wt.% | 6.3 | 14.8 | 6.3 | 8.1 |

| IBP–180 °C | TBP, wt.% | 15.0 | 15.7 | 20.0 | 20.9 |

| 180–240 °C | TBP, wt.% | 8.7 | 7.8 | 9.1 | 9.0 |

| 240–360 °C | TBP, wt.% | 21.0 | 17.7 | 23.1 | 19.5 |

| 360–550 °C | TBP, wt.% | 30.3 | 25.9 | 29.6 | 24.5 |

| >550 °C | TBP, wt.% | 23.9 | 31.9 | 17.3 | 25.1 |

| Urals | Basrah Heavy | Siberian Light | Recycle | Kirkuk | ||

|---|---|---|---|---|---|---|

| VR density at 15 °C | kg/m3 | 997.0 | 1071 | 993.0 | 1035.9 | 10,540 |

| VR Concarbon | wt.% | 17.5 | 28.9 | 14 | 23.5 | 25.2 |

| VR sulphur | wt.% | 3.0 | 7.1 | 1.58 | 1.15 | 5.9 |

| Sat (LNB) | wt.% | 25.6 | 12.3 | 25.0 | 15.2 | |

| Aro (LNB) | wt.% | 52.5 | 54.1 | 61.1 | 55.4 | |

| Res (LNB) | wt.% | 7.8 | 5.8 | 6.1 | 5.0 | |

| C7-asp (LNB) | wt.% | 14.1 | 27.7 | 7.8 | 18.0 | 24.3 |

| C5-asp (LNB) | wt.% | 17.6 | 37 | 15.5 | 25.7 | 33.1 |

| Kin. vis. * | mm2/s | 220.9 | 731.9 | 149.1 | 308 | |

| Soft. point, °C | wt.% | 40.1 | 68.6 | 28.9 | 38.9 | 58.1 |

| Sat (SAR-AD) | wt.% | 18.2 | 7.4 | 21.2 | 21.5 | 9.5 |

| Aro 1 (SAR-AD) | wt.% | 7.0 | 6.5 | 9.4 | 8.4 | 6.6 |

| Aro 2 (SAR-AD) | wt.% | 20.7 | 23.9 | 19.4 | 20.3 | 23.3 |

| Aro 3 (SAR-AD) | wt.% | 33.0 | 38.9 | 32.2 | 39.7 | 39.2 |

| Resins (SAR-AD) | wt.% | 14.0 | 13.4 | 13.4 | 4.2 | 10.2 |

| CyC6 (SAR-AD) | wt.% | 2.4 | 3.0 | 1.3 | 0.14 | 2.3 |

| Toluene (SAR-AD) | wt.% | 4.4 | 6.6 | 2.9 | 5.28 | 8.4 |

| CH2Cl2 (SAR-AD) | wt.% | 0.1 | 0.3 | 0.1 | 0.53 | 0.5 |

| Total Asp (SAR-AD) | wt.% | 6.9 | 9.9 | 4.4 | 5.95 | 11.2 |

| Date | 18 July 2022 | 29 August 2022 | 3 October 2022 | 5 May 2023 |

|---|---|---|---|---|

| 60% Urals/ 40% LSCO | 72.5% Urals/ 14.1% LSCO/ 13.4% BH | 63% Urals/ 31% LSCO/ 6% BH | 78% Urals/ 2.5% LSCO/19.5% Kirkuk | |

| WABT of 1st reactor, °C | 428 | 430 | 429 | 430 |

| WABT of 2nd reactor, °C | 428 | 432 | 431 | 430 |

| ∆T 1st reactor | 77 | 90 | 80 | 95 |

| ∆T 2nd reactor | 40 | 43 | 34 | 51 |

| Residence time, h | 5.47 | 5.3 | 5.12 | 7.96 |

| VR in the H-Oil feed, wt.% | 72.9 | 81.8 | 67.1 | 76.5 |

| VGO in the feed, wt.% | 13.14 | 4.6 | 14.9 | 1.7 |

| Recycle, % of fresh feed | 0 | 0 | 0 | 12.1 |

| Gas yield, wt.% | 6.37 | 7.05 | 5.64 | 8.86 |

| Naphtha yield, wt.% | 5.86 | 5.74 | 5.92 | 7.58 |

| Diesel yield, wt.% | 35.47 | 34.53 | 37.03 | 44.92 |

| VGO yield, wt.% | 36.51 | 34.00 | 40.60 | 30.07 |

| VTB yield, wt.% | 15.82 | 18.02 | 10.61 | 8.70 |

| H2S yield, wt.% | 1.93 | 2.88 | 2.15 | 3.10 |

| Net conversion, wt.% | 76.0 | 77.8 | 76.50 | 88.7 |

| ATB, TSE, wt.% | 0.19 | 0.22 | 0.10 | 0.07 |

| PBFO, TSP, wt.% | 0.09 | 0.07 | 0.09 | 0.03 |

| FCCPT Diesel | LCO | HCO | SLO | |

|---|---|---|---|---|

| Density at 15 °C, kg/m3 | 884.6 | 935.0 | 1036 | 1112.1 |

| Sulphur, wt.% | 0.0582 | 0.174 | 0.715 | 0.773 |

| Simulated distillation, % mass | ASTM D-2887 | |||

| IBP | 180 | 138 | 202 | 227 |

| 5 | 237 | 169 | 257 | 311 |

| 10 | 267 | 188 | 275 | 336 |

| 20 | 302 | 206 | 295 | 361 |

| 30 | 323 | 220 | 306 | 380 |

| 40 | 338 | 230 | 319 | 395 |

| 50 | 349 | 234 | 328 | 410 |

| 60 | 359 | 250 | 342 | 426 |

| 70 | 369 | 255 | 354 | 443 |

| 80 | 378 | 267 | 368 | 462 |

| 90 | 391 | 279 | 391 | 488 |

| 95 | 402 | 290 | 410 | 507 |

| FBP | 430 | 333 | 452 | 540 |

| Kw | 11.7 | 10.35 | 9.88 | 9.65 |

| Kinematic viscosity at 80 °C, mm2/s | 2.97 | 1.42 | 4.42 | 33.35 |

| MW, g/mole | 267 | 162 | 224 | 294 |

| H-Oil VTB Properties | 60% Urals/ 40% LSCO | 72.5% Urals/ 14.1% LSCO/ 13.4% BH | 63% Urals/ 31% LSCO/ 6% BH |

|---|---|---|---|

| Density at 15 °C, kg/m3 | 1025.9 | 1046.9 | 1035.9 |

| Sulfur, wt.% | 0.897 | 1.522 | 1.153 |

| Concarbon content, wt.% | 20.7 | 26.9 | 23.5 |

| Specific viscosity at 120 °C, °E | 24.0 | 46.5 | 29.8 |

| Kinematic viscosity at 120 °C, mm2/s | 178 | 345 | 221 |

| Kinematic viscosity at 80 °C, °mm2/s * | 2172 | 5772 | 2989 |

| Softening point, °C | 34.9 | 45.7 | 38.9 |

| C7 asphaltenes, wt.% | 16.1 | 27.6 | 18 |

| C5 asphaltenes, wt.% | 22.6 | 32.2 | 25.7 |

| MW, g/mole | 668 | 663 | 664 |

| HTSD, wt.% (ASTM D-7169) | |||

| IBP 0.5 | 473 | 407 | 349 |

| 10 | 527 | 514 | 513 |

| 30 | 570 | 565 | 566 |

| 50 | 603 | 598 | 600 |

| 70 | 643 | 638 | 638 |

| 90 | 706 | 697 | 696 |

| 95 | 761 | 719 | 715 |

| FBP 99.5 | 959 | 774 | 773 |

| Recovery, % | 94.9 | 91.2 | 97.3 |

| Mass % | χ1 | ϕ1 | ρ kg/m3 | ∆ρ kg/m3 | VE cm3/mol | ΔV | χ1 | ϕ1 | ρ kg/m3 | ∆ρ kg/m3 | VE cm3/mol | ΔV |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LCO (1) + VTB (60% Urals/40% LSCO) (2) | HCO (1) + VTB (60% Urals/40% LSCO) (2) | |||||||||||

| 30 | 0.637 | 0.320 | 994.0 | −2.9 | 1.027 | 0.0029 | 0.560 | 0.300 | 1.0278 | −1.1 | 0.435 | 0.0079 |

| 40 | 0.732 | 0.422 | 0.9892 | 1.7 | −0.478 | −0.0017 | 0.664 | 0.400 | 1.028.9 | −1.1 | 0.353 | 0.0069 |

| 50 | 0.804 | 0.523 | 0.9800 | 1.6 | −0.414 | −0.0016 | 0.748 | 0.500 | 1.030.2 | −0.8 | 0.225 | 0.0056 |

| SLO (1) + VTB (60% Urals/40% LSCO) (2) | FCCPT Diesel (1) + VTB (60% Urals/40% LSCO) (2) | |||||||||||

| 30 | 0.492 | 0.283 | 1.047.3 | −3.0 | 1.284 | 0.0022 | 0.516 | 0.332 | 974.9 | −4.0 | 2.065 | 0.0033 |

| 40 | 0.601 | 0.381 | 1.055.1 | −4.0 | 1.390 | 0.0024 | 0.624 | 0.436 | 967.3 | 3.0 | −1.255 | −0.0023 |

| 50 | 0.693 | 0.480 | 1.058.7 | −9.0 | 3.051 | 0.0054 | 0.713 | 0.537 | 954.8 | 5.0 | −1.922 | −0.0034 |

| LCO (1) + VTB (63% Urals/31% LSCO/6% BH) (2) | HCO (1) + VTB (63% Urals/31% LSCO/6% BH) (2) | |||||||||||

| 20 | 0.506 | 0.217 | 1.017 | 3.0 | −4.256 | −0.0029 | 0.426 | 0.200 | 1.034.2 | −2.0 | −2.841 | 0.0017 |

| 30 | 0.637 | 0.322 | 1.008.5 | 5.0 | −3.971 | −0.0050 | 0.560 | 0.300 | 1.034.6 | −1.0 | −2.248 | 0.0013 |

| 40 | 0.732 | 0.425 | 1.000.3 | 7.0 | −3.816 | −0.0072 | 0.664 | 0.400 | 1.035.1 | −1.0 | −1.820 | 0.0009 |

| 50 | 0.804 | 0.526 | 991.8 | 9.0 | −3.586 | −0.0090 | 0.748 | 0.500 | 1.035.5 | 0.0 | −1.445 | 0.0005 |

| SLO (1) + VTB (63% Urals/31% LSCO/6% BH) (2) | FCCPT Diesel (1) + VTB (63% Urals/31% LSCO/6% BH) (2) | |||||||||||

| 20 | 0.361 | 0.189 | 1.047.8 | −2.0 | −2.844 | 0.0020 | 0.383 | 0.226 | 999.5 | −2.0 | −2.697 | 0.0018 |

| 30 | 0.492 | 0.285 | 1.053.4 | −4.0 | −1.392 | 0.0031 | 0.516 | 0.334 | 987.8 | 2.0 | −4.112 | −0.0020 |

| 40 | 0.601 | 0.383 | 1.060.1 | −5.0 | −0.591 | 0.0034 | 0.624 | 0.438 | 975.3 | 6.0 | −4.799 | −0.0043 |

| 50 | 0.693 | 0.482 | 1.067.2 | −5.0 | −0.024 | 0.0034 | 0.713 | 0.539 | 962.9 | 9.0 | −5.287 | −0.0062 |

| LCO (1) + VTB (72.5% Urals/14.1% LSCO/13.4% BH) (2) | HCO (1) + VTB (72.5% Urals/14.1% LSCO/13.4% BH) (2) | |||||||||||

| 30 | 0.637 | 0.324 | 1.015.4 | 5.0 | −6.300 | −0.0047 | 0.560 | 0.302 | 1.043.8 | 0.0 | −5.822 | −0.0002 |

| 40 | 0.732 | 0.427 | 1.006.6 | 7.0 | −5.678 | −0.0074 | 0.664 | 0.402 | 1.043.4 | 1.0 | −4.688 | −0.0008 |

| 50 | 0.804 | 0.528 | 995.7 | 8.0 | −4.618 | −0.0079 | 0.748 | 0.503 | 1.042.7 | 1.0 | −3.685 | −0.0012 |

| SLO (1) + VTB (72.5% Urals/14.1% LSCO/13.4% BH) (2) | FCCPT Diesel (1) + VTB (72.5% Urals/14.1% LSCO/13.4% BH) (2) | |||||||||||

| 30 | 0.492 | 0.287 | 1.064.8 | −1.0 | −6.312 | 0.0006 | 0.516 | 0.337 | 981.8 | −10.0 | −1.259 | 0.0084 |

| 40 | 0.601 | 0.386 | 1.070.3 | −2.0 | −4.576 | 0.0012 | 0.624 | 0.441 | 968.7 | −7.0 | −1.880 | 0.0050 |

| 50 | 0.693 | 0.485 | 1.075.6 | −3.0 | −3.015 | 0.0018 | 0.713 | 0.542 | 962.4 | 3.0 | −5.081 | −0.0025 |

| Amount of Cutter Stocks in Percent of the Blend H-Oil VTB/Cutter Stock Needed to Achieve Blend Viscosity of 110 mm2s | |||

|---|---|---|---|

| Cutter Stock | H-Oil VTB 60% Urals/40% LSCO | H-Oil VTB 63% Urals/31% LSCO/6% BH | H-Oil VTB 72.5% Urals/14.1% LSCO/13.4% BH |

| LCO | 21.2 | 22.8 | 26.1 |

| HCO | 32.8 | 34.5 | 37.6 |

| FCCPT | 28.5 | 30.6 | 33.6 |

| SLO | 60.3 | 62.5 | 64.1 |

| Nu | Urals, % | LSCO, % | BH, % | LCO (TSE) | HCO (TSE) | SLO (TSE) | FCCPTD (TSE) | LCO (VE) | HCO (VE) | SLO (VE) | FCCPTD (VE) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Urals, % | 1.00 | 0.00 | 1.00 | 0.33 | 0.67 | 0.33 | 0.67 | 0.00 | 0.00 | 0.00 | 0.33 |

| LSCO, % | 0.00 | 1.00 | 0.00 | 0.67 | 0.33 | 0.33 | 0.00 | 1.00 | 1.00 | 1.00 | 0.67 |

| BH, % | 1.00 | 0.00 | 1.00 | 0.33 | 0.67 | 0.33 | 0.67 | 0.00 | 0.00 | 0.00 | 0.33 |

| LCO (TSE) | 0.33 | 0.67 | 0.33 | 1.00 | 0.00 | 0.00 | 0.00 | 0.67 | 0.67 | 0.67 | 0.33 |

| HCO (TSE) | 0.67 | 0.33 | 0.67 | 0.00 | 1.00 | 0.67 | 0.67 | 0.33 | 0.33 | 0.33 | 0.67 |

| SLO (TSE) | 0.33 | 0.33 | 0.33 | 0.00 | 0.67 | 1.00 | 0.33 | 0.33 | 0.33 | 0.33 | 0.67 |

| FCCPTD (TSE) | 0.67 | 0.00 | 0.67 | 0.00 | 0.67 | 0.33 | 1.00 | 0.00 | 0.00 | 0.00 | 0.33 |

| LCO (VE) | 0.00 | 1.00 | 0.00 | 0.67 | 0.33 | 0.33 | 0.00 | 1.00 | 1.00 | 1.00 | 0.67 |

| HCO (VE) | 0.00 | 1.00 | 0.00 | 0.67 | 0.33 | 0.33 | 0.00 | 1.00 | 1.00 | 1.00 | 0.67 |

| SLO (VE) | 0.00 | 1.00 | 0.00 | 0.67 | 0.33 | 0.33 | 0.00 | 1.00 | 1.00 | 1.00 | 0.67 |

| FCCPTD (VE) | 0.33 | 0.67 | 0.33 | 0.33 | 0.67 | 0.67 | 0.33 | 0.67 | 0.67 | 0.67 | 1.00 |

| Nu | Urals, % | LSCO, % | BH, % | LCO (TSE) | HCO (TSE) | SLO (TSE) | FCCPTD (TSE) | LCO (VE) | HCO (VE) | SLO (VE) | FCCPTD (VE) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Urals, % | 0.00 | 1.00 | 0.00 | 0.67 | 0.33 | 0.33 | 0.00 | 1.00 | 1.00 | 1.00 | 0.67 |

| LSCO, % | 1.00 | 0.00 | 1.00 | 0.33 | 0.67 | 0.33 | 0.67 | 0.00 | 0.00 | 0.00 | 0.33 |

| BH, % | 0.00 | 1.00 | 0.00 | 0.67 | 0.33 | 0.33 | 0.00 | 1.00 | 1.00 | 1.00 | 0.67 |

| LCO (TSE) | 0.67 | 0.33 | 0.67 | 0.00 | 1.00 | 0.67 | 0.67 | 0.33 | 0.33 | 0.33 | 0.67 |

| HCO (TSE) | 0.33 | 0.67 | 0.33 | 1.00 | 0.00 | 0.00 | 0.00 | 0.67 | 0.67 | 0.67 | 0.33 |

| SLO (TSE) | 0.33 | 0.33 | 0.33 | 0.67 | 0.00 | 0.00 | 0.00 | 0.33 | 0.33 | 0.33 | 0.00 |

| FCCPTD (TSE) | 0.00 | 0.67 | 0.00 | 0.67 | 0.00 | 0.00 | 0.00 | 0.67 | 0.67 | 0.67 | 0.33 |

| LCO (VE) | 1.00 | 0.00 | 1.00 | 0.33 | 0.67 | 0.33 | 0.67 | 0.00 | 0.00 | 0.00 | 0.33 |

| HCO (VE) | 1.00 | 0.00 | 1.00 | 0.33 | 0.67 | 0.33 | 0.67 | 0.00 | 0.00 | 0.00 | 0.33 |

| SLO (VE) | 1.00 | 0.00 | 1.00 | 0.33 | 0.67 | 0.33 | 0.67 | 0.00 | 0.00 | 0.00 | 0.33 |

| FCCPTD (VE) | 0.67 | 0.33 | 0.67 | 0.67 | 0.33 | 0.00 | 0.33 | 0.33 | 0.33 | 0.33 | 0.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kolev, I.; Stratiev, D.; Shishkova, I.; Atanassov, K.; Ribagin, S.; Sotirov, S.; Sotirova, E.; Stratiev, D.D. Effect of Crude Oil Quality on Properties of Hydrocracked Vacuum Residue and Its Blends with Cutter Stocks to Produce Fuel Oil. Processes 2023, 11, 1733. https://doi.org/10.3390/pr11061733

Kolev I, Stratiev D, Shishkova I, Atanassov K, Ribagin S, Sotirov S, Sotirova E, Stratiev DD. Effect of Crude Oil Quality on Properties of Hydrocracked Vacuum Residue and Its Blends with Cutter Stocks to Produce Fuel Oil. Processes. 2023; 11(6):1733. https://doi.org/10.3390/pr11061733

Chicago/Turabian StyleKolev, Iliyan, Dicho Stratiev, Ivelina Shishkova, Krassimir Atanassov, Simeon Ribagin, Sotir Sotirov, Evdokia Sotirova, and Danail D. Stratiev. 2023. "Effect of Crude Oil Quality on Properties of Hydrocracked Vacuum Residue and Its Blends with Cutter Stocks to Produce Fuel Oil" Processes 11, no. 6: 1733. https://doi.org/10.3390/pr11061733

APA StyleKolev, I., Stratiev, D., Shishkova, I., Atanassov, K., Ribagin, S., Sotirov, S., Sotirova, E., & Stratiev, D. D. (2023). Effect of Crude Oil Quality on Properties of Hydrocracked Vacuum Residue and Its Blends with Cutter Stocks to Produce Fuel Oil. Processes, 11(6), 1733. https://doi.org/10.3390/pr11061733