1. Introduction

Sandblasting is a versatile process for roughening, cleaning or smoothing surfaces. The first sandblasting process was patented (as abrasive) [

1] on 18 October 1870 by Benjamin Chew Tilghman. Since then, the sandblasting process has been used for surface preparation (as a method), resurfacing, surface preparation before painting, creating surface texture [

2,

3,

4,

5], fossil preparation (paleontological preparation technique) [

6], removing surface coatings [

2], etc. In addition, it can be easily applied to developing technological products. For example, it is used as a finishing process to increase the surface quality of the products produced in additive manufacturing [

7], and to obtain a clean surface and micro-mechanical retention in the field of dentistry [

8].

Another application area of sandblasting is adhesive bonding joints. It is one of the preferred surface pre-treatments to increase the area to be bonded and ensure wettability [

1,

9,

10,

11]. It is known that the surface formed after sandblasting increases the bond strength in adhesive bonding joints [

4,

10,

11,

12,

13,

14,

15,

16].

In abrasive blasting, there are different types of abrasive materials classified in the mineral, agricultural, synthetic and metallic categories [

17]. Although sand is mostly preferred, glass, metal, dry ice, coconut shells or plant shells are also used as abrasive materials [

18]. Although sandblasting has a wide usage area, it has some drawbacks. According to the nature of the work to be done, special balls made of materials such as silica, basalt, etc. are used in the sandblasting process. These balls create a time-dependent solid particle erosion by creating a repeated impact effect, especially in the nozzle [

19,

20]. The remaining iron-based abrasives on the material surface cause rust formation [

21]. In addition, iron-based powders have an ignition risk during processing [

22]. Another disadvantage is the health problems that sandblasting operators are exposed to. One of the main health problems is silicosis, which occurs as a result of exposure to respirable crystalline silica, and this has a fatal effect [

23,

24]. Due to the reasons stated above, it is of great importance to use a powder that can reduce the aforementioned drawbacks, as an alternative to the traditional powders used in sandblasting.

Rudawska et al. [

25] investigated the effect of sandblasting on the surface properties of C45 carbon steel. In the experiments, different sandblasting pressures (1, 2 and 4 bar) and abrasive material groups (brown fused alumina, brown fused alumina, white fused alumina, glass beads), each of which had different granulation, were used. All experiments were performed at a 100 mm distance from the surface at a right angle for 1 min. Surface roughness (Ra) values were taken from three different positions on each sandblasted surface. The surfaces subjected to sandblasting with glass beads had the smallest roughness. It was found that the surface roughness obtained with brown fused alumina (2.5–3.5 µm) on the surface of the steel material with a sandblasting pressure of 2 bar was approximately two times higher than the others. The results showed that surface roughness was more affected by changes in sandblasting pressure, depending on the type of abrasive used. It has been understood that surfaces with different roughness parameters and surface properties were formed with the sandblasting application.

Bresson et al. [

26] applied different surface pre-treatments to improve bonding properties. For the sandblasting process, they used F80 white corundum with a grain size of 150–212 µm and F60 corundum abrasive with a grain size of 212–300 µm. The sandblasting pressure was 4 bar, and the corundum grains were sprayed onto the sandblasting surface with a contact angle of 30°. The effect of the distance of the nozzle to the part in the sandblasting process was investigated, and 10 and 35 cm sandblasting distances were used. While Ra = 3.94 ± 0.18 µm was obtained for a 10 cm distance and F60 abrasive, Ra = 3.99 ± 0.40 µm was obtained for 35 cm. These roughness values were higher than the values obtained with F80 corundum abrasive.

Balza et al. [

27] sandblasted titanium material at a 90° angle with Al

2O

3 particles from a distance of 0.1 m. Air pressure was chosen as 0.3 MPa, particle size was 420–600 µm and sandblasting times were 2, 3, 4, 6, 7, and 10 s. It was observed that the optimum roughness value was 3.4 μm at 7 s of sandblasting, and this value decreased to 3.1 μm when the time was increased to 10 s. It was stated that prolonged sandblasting times were associated with a tendency to decrease roughness.

Isa et al. [

28] investigated the mechanical properties of the ASTM A516 Grade 70 steel material and its effect on the fatigue life of the material. ASTM A516 Grade 70 steel material was blasted with 0.3 mm SAE G-80 for 15, 25, 35 and 45 min. By changing the time, significant differences occurred in terms of hardness value and grain size. It was also proven that the sandblasting process significantly increased the fatigue life and tensile strength of the material.

Ourahmoune et al. [

29] investigated the effect of sandblasting on the adhesion of PEEK (Poly Ether Ether Ketone) thermoplastic material and carbon fiber (CF)- and glass (GF)-reinforced PEEK material. In all experiments, sandblasting was carried out with a ceramic nozzle of 8 mm diameter, at 5 bar, at an angle of 90°, and with a constant distance value of 80 mm. Sandblasting time was changed from 5 s to 45 s. Furthermore, 98% of commercial alumina (Al

2O

3) powder was used as an abrasive in three different particle sizes (50 µm, 110 µm and 250 µm). It was observed that the roughness parameters tended to stabilize after 5 s of sandblasting, regardless of the particle size used. In addition, the presence of a fiber structure has important effects in the sandblasted material. It was also observed that CF-reinforced PEEK and GF-reinforced PEEK composites had a higher roughness level than the PEEK material.

Rudawska et al. [

18] sandblasted three different aluminum alloys (EN AW-2024 TO, EN AW-2219 TO and EN AW-2014 T4) using calcined bauxite content (named EB F54 aloxite) at three different blasting pressures (0.41 MPa, 0.51 MPa and 0.56 MPa). The grain size of EB F54 aloxite was between 355 and 300 μm. The time was 60 s and the distance was 200 mm. The Ra surface roughness values measured before sandblasting were 0.42 µm for EN AW-2024 TO, 0.35 µm for EN AW-2219 TO, and 0.28 µm for EN AW-2014 T4, respectively.

Tshimanga et al. [

30] blasted Grade 304L austenitic stainless steel with four different abrasives of varying granulation: garnet, aluminum oxide, steel grit, and platinum grit. The characterization of the surface morphology created by the process was investigated. The highest surface roughness (18.2 µm) was obtained in steel grit, while the lowest surface roughness (7.8 µm) was obtained in aluminum oxide.

In this study, the usability of organic waste materials in powder form in the sandblasting process was investigated. Organic materials are biodegradable, environmentally safe, non-toxic, renewable and sustainable. They eliminate the problem of silicosis disease, especially caused by breathing [

31]. In addition, since organic abrasives do not reduce the life of the blasting nozzle [

32,

33], process differences due to nozzle wear will be prevented. Moreover, since organic abrasives do not react chemically with the surface, unwanted formations such as rust, etc., will not occur. The organic materials used are environmentally friendly as they will be obtained from recycling. When the literature is examined, it is seen that there are many studies on the effects of blasting pressure, blasting time, blasting distance, and abrasive material type, which are among the blasting process parameters. However, to the best knowledge of the researchers, there are no studies on abrasive blasting where waste materials are used as abrasives. Therefore, the aim of this study is to examine the use of waste materials as abrasive materials in the abrasive blasting process. For this reason, three different organic materials (walnut shell, olive pomace and mussel shell) and three different sizes (38, 45 and 63 µm) obtained by recycling were used. By using the Taguchi experimental design, the effects of powder type, powder size, blasting distance, and blasting time on the roughness of the blasted surface were investigated.

2. Method

2.1. Experimental Samples

DX51D + Z quality galvanized steel material (EN 10346:2015) with dimensions of 100 × 25 × 1.5 mm was used for experimental studies. The samples were cleaned by wiping with acetone and drying without any treatment.

The chemical composition of the experimental samples is given in

Table 1, and their mechanical properties are given in

Table 2. Values are taken from the manufacturer’s catalogs [

34].

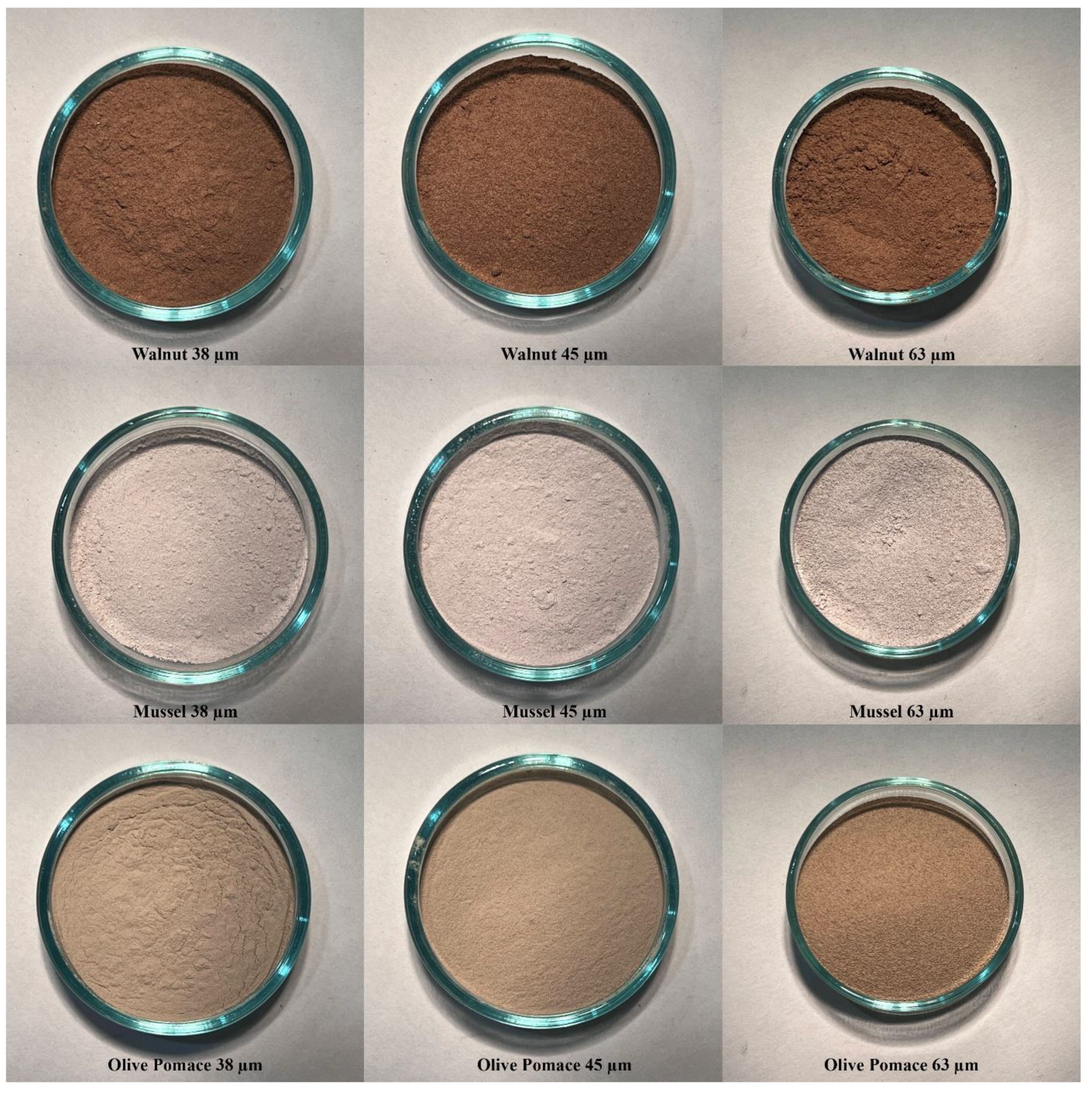

2.2. Abrasive Powders

Mussel shell, olive pomace and walnut shell powders (three different kinds) in three different sizes as 38, 45 and 63 µm were used as abrasive. The grinded powders of 38, 45 and 63 µm are given in

Figure 1 as olive pomace, walnut shell and mussel shell, respectively.

Organic abrasives have an irregular, jagged structure. These properties of the abrasives used are shown in

Table 3.

For mussel powders, waste Mediterranean Mussel (mytilus galloprovincialis) shells were used. Calcium carbonate is a commonly used as filler in polymer material. While the chemical composition of mussel shell contains 95.7% CaO, this ratio is 99.1% in commercial CaCO

3. Since mussel shells contain a similar amount of CaO to commercial CaCO

3, it is appropriate to use them as an additive material [

33].

Olive pomace is the residue remaining after olives are crushed. It was obtained from a company operating in the Aegean region (Turkey). Walnut shells were also obtained from people who consumed walnuts. They had a specific gravity of 1.2–1.4 [

35].

After the waste materials were dried in the oven, they were ground in a ring mill and sieved in a sieve shaker.

Moreover, 25 µm alumina was used to make comparisons on the surfaces after abrasive blasting. Aluminum oxide is an abrasive material with a Mohs Hardness = 9 and high resistance to abrasion.

2.3. Process Parameters

The organic powders used in abrasive blasting were sprayed from a distance of 5, 10, and 15 cm. Blasting time was chosen as 10, 20 and 30 s. Three different types of powder sizes of 38, 45 and 63 µm were used. The sandblasting pen was held at an angle of 90° to the samples to be sandblasted. A sandblasting machine with two pen types was used. The nozzle material was carbide and the nozzle diameter was 1.2 mm. The blasting pressure was kept constant at 6 bar.

Two different experiments were performed using aluminum oxide powder to compare with Taguchi validation experiments. In the first one, a 5 cm distance and 30 s blasting time were used, while a 10 cm distance and 20 s blasting time were used in the second one. Then, the surface roughness values obtained from Taguchi, and “larger is better” and “smaller is better” validation experiments were compared.

The roughness values were measured in accordance with ISO (2021) 21920-2 [

37] using the Mitutoyo SJ-301 profilometer device. The surface roughness of the samples was found by averaging the values measured from five different positions before and after abrasive blasting. The experiment was conducted with three replications.

2.4. Design of Experiments

Abrasive blasting is a method used in a wide variety of fields as a complementary process. The abrasive blasting process is affected by the particle size of the abrasive, the application pressure, the application time, and the blasting distance [

38,

39,

40]. The inappropriateness of the parameters specified in the abrasive blasting process may cause excessive material loss [

41,

42]. In addition, there are problems in biocompatibility if abrasive residues remain in surface polishing or roughening processes after blasting. Therefore, the use of natural abrasives will provide advantages in terms of both cost and compatibility.

In the first stage of the abrasive blasting process, the samples prepared were fixed by placing them on the clamping apparatus. Then, the abrasives to be used were placed in the abrasive blasting chamber by adjusting the sandblasting distance. Finally, abrasive blasting was carried out on the surface of the samples within the specified time. In the study, an experimental design was made using the Taguchi method. In the experimental designs, two separate designs were made according to the “smaller is better” and “larger is better” characteristics, and signal-to-noise ratios (

S/

N) were calculated. The reason for this is that user expectations in the abrasive blasting process differ according to the application area. Control factors and levels are given in

Table 4.

The experiment design was arranged with the four factors of distance, time, powder type and grain size, and each factor had three levels. The factors and the values of the levels of the factors are given in

Table 5.

The first step of the Taguchi method is to select a proper orthogonal array based on the number of parameters and levels selected as control factors [

43]. In the study, the total degrees of freedom (DOF) for four factors, each of which has three levels, was eight. Therefore, the L9 (3

3) array, which is a three-level Taguchi orthogonal array (TOA) with at least eight DOFs, was selected. The L9 orthogonal array is given in

Table 5.

In the Taguchi method, the experimental results are converted to the signal-to-noise ratio (S/N) to determine the amount of deviation from the desired value. The S/N ratio for surface roughness is calculated by the following formula:

Larger is better characteristic:

Smaller is better characteristic:

where “

n” is the number of tests and “

yi” is the value of the experimental result of the test.

In addition, an analysis of variance (ANOVA) test was also performed to determine the statistical effects of the processing parameters. With S/N and ANOVA analysis, the most appropriate variation of the process parameters can be determined according to the determined values. Finally, a validation experiment was conducted to verify the optimal process parameters obtained from the parameter design.