A New Fast Calculating Method for Meshing Stiffness of Faulty Gears Based on Loaded Tooth Contact Analysis

Abstract

:1. Introduction

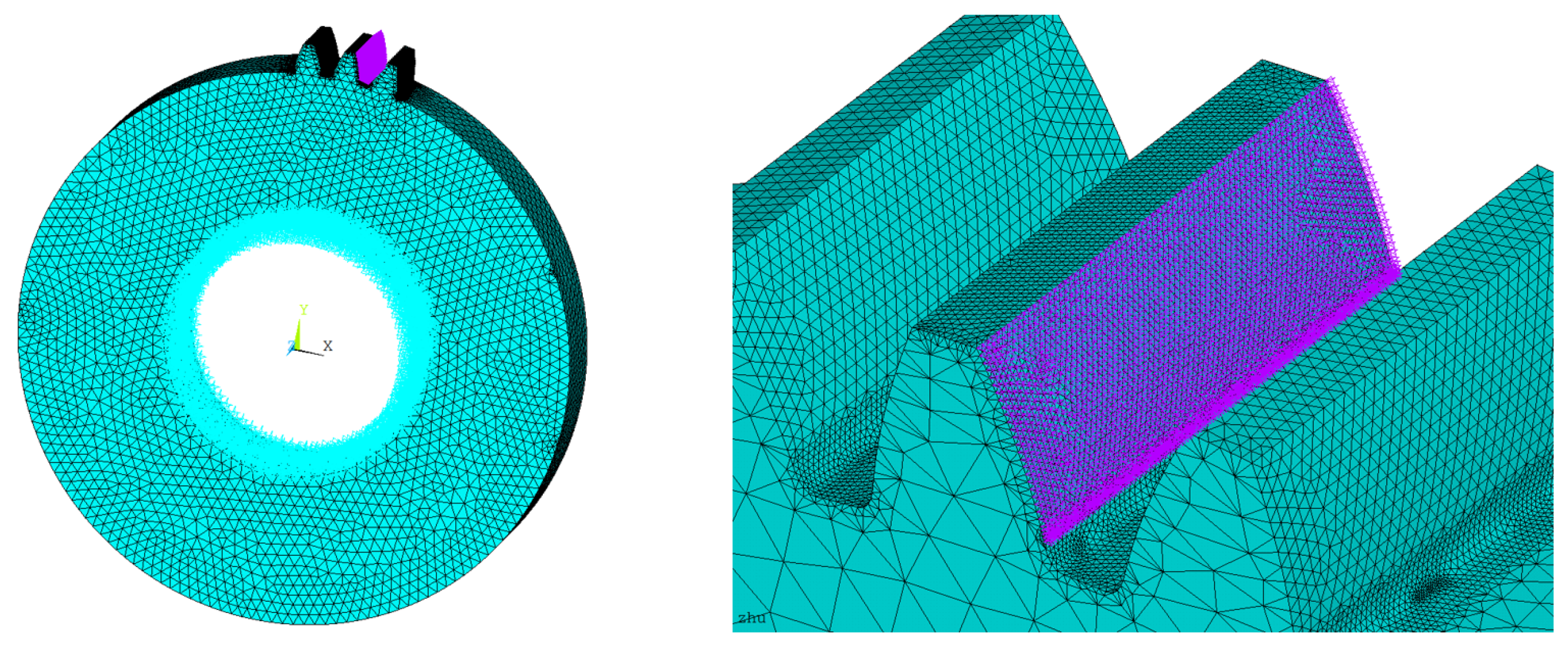

2. Loaded Tooth Contact Analysis Method

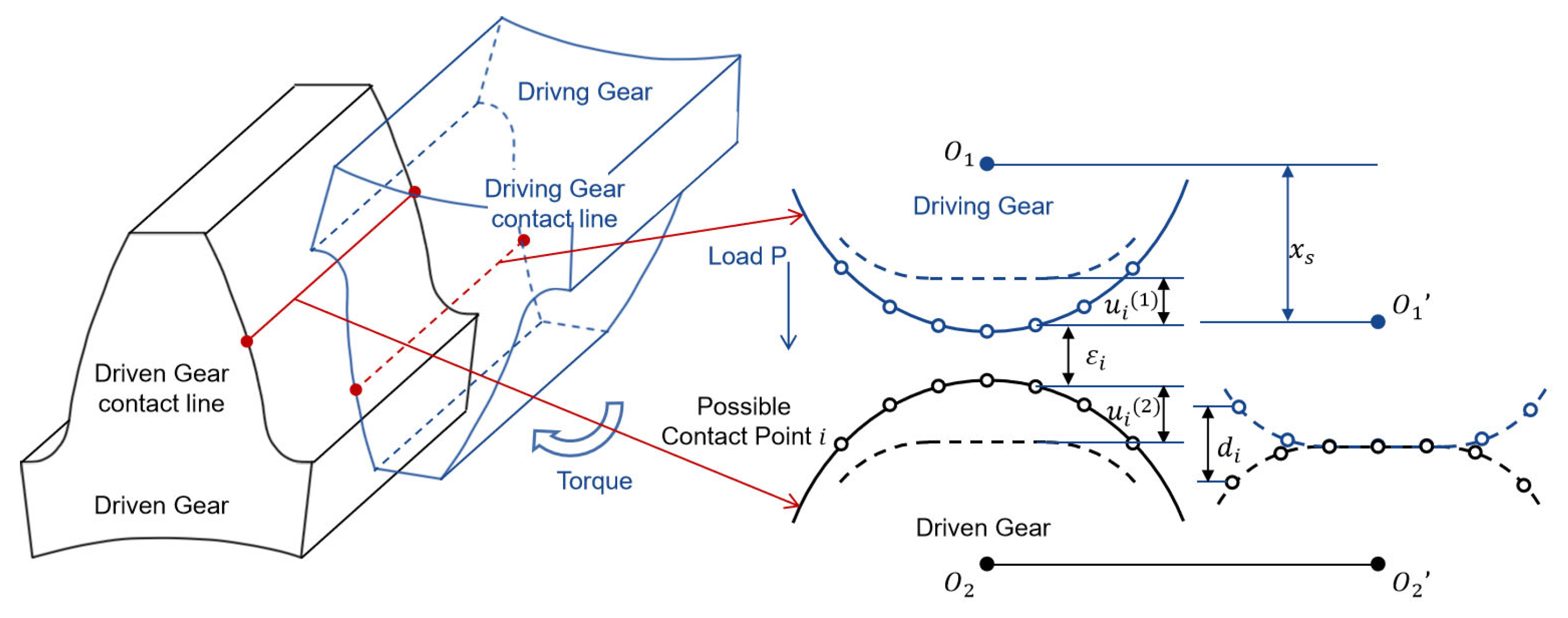

2.1. Coordination Conditions for Meshing Deformation of Gear Pairs

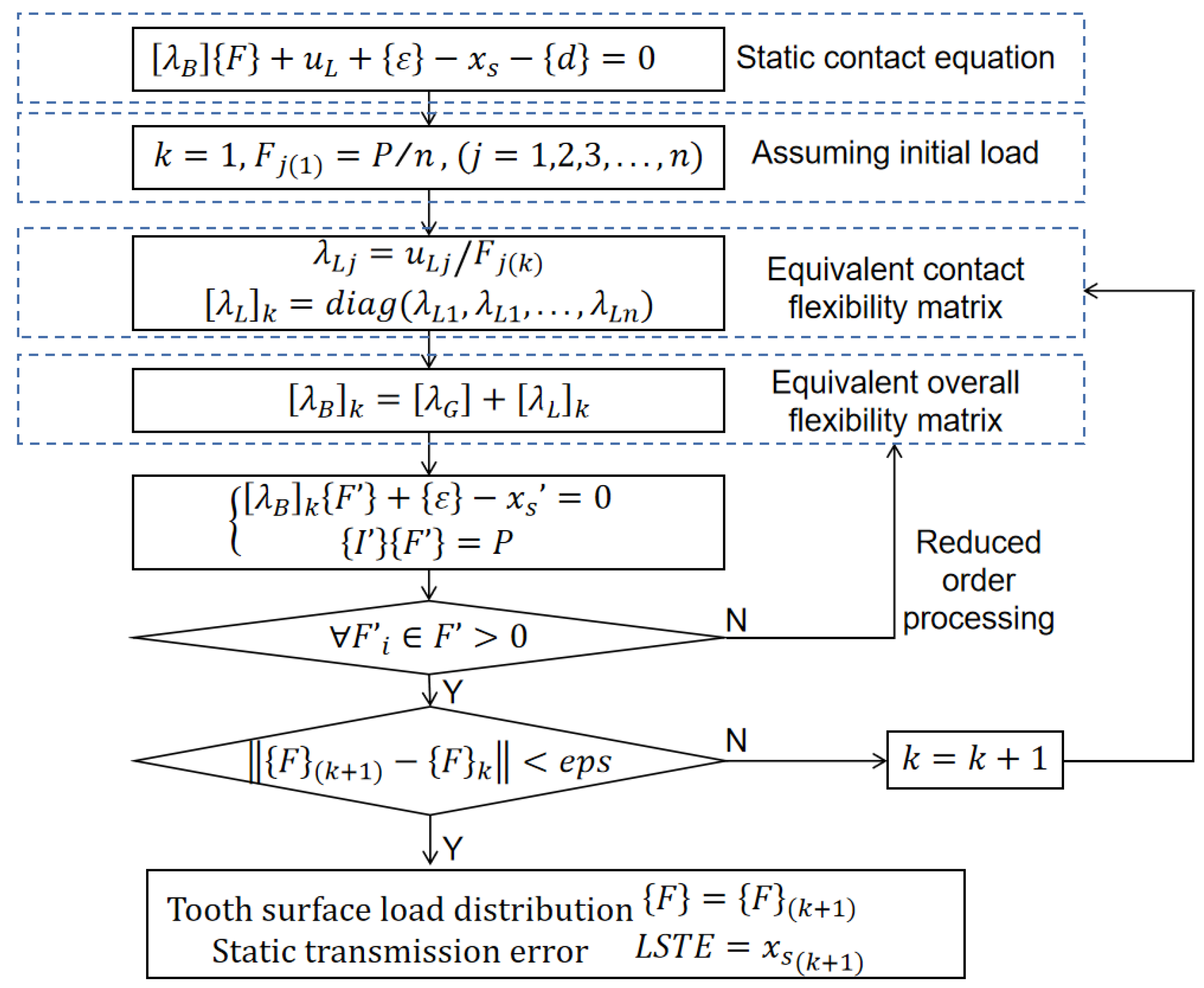

2.2. Iterative Algorithm for Solving Coordination Deformation Equation

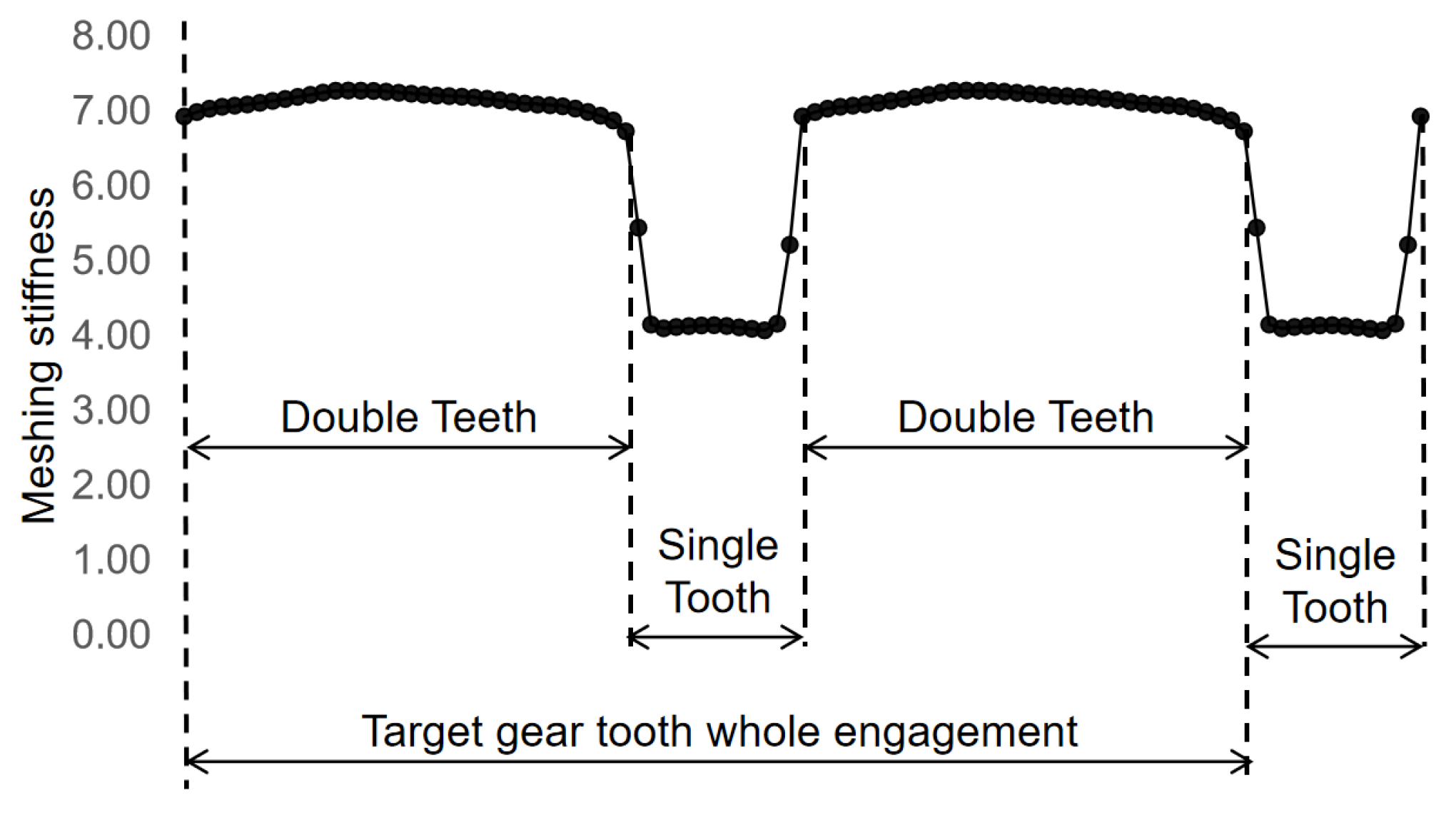

3. Calculation of the Faulty Gears Meshing Stiffness Based on LTCA

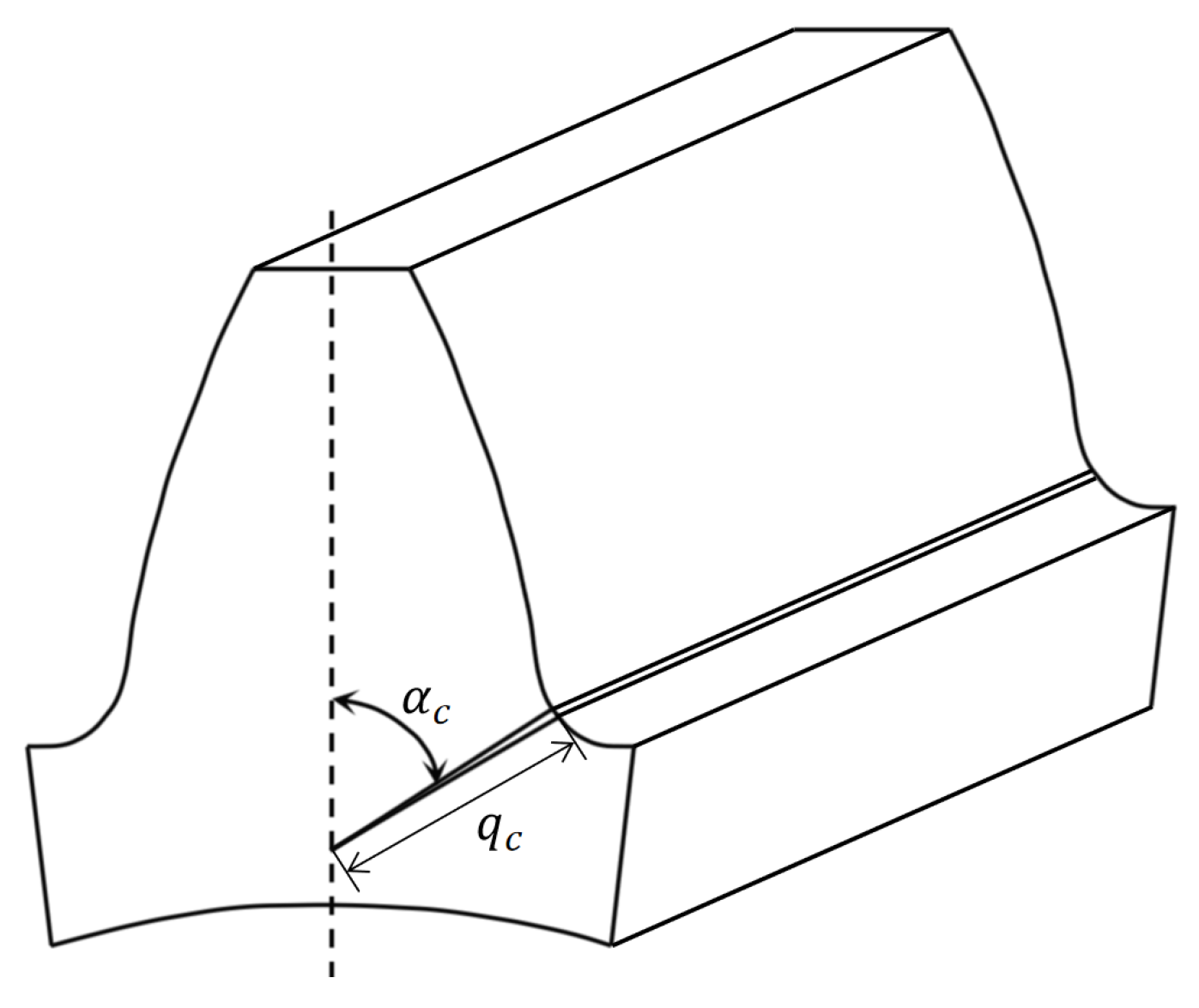

3.1. Meshing Stiffness Calculation Method for Crack Gear Pairs

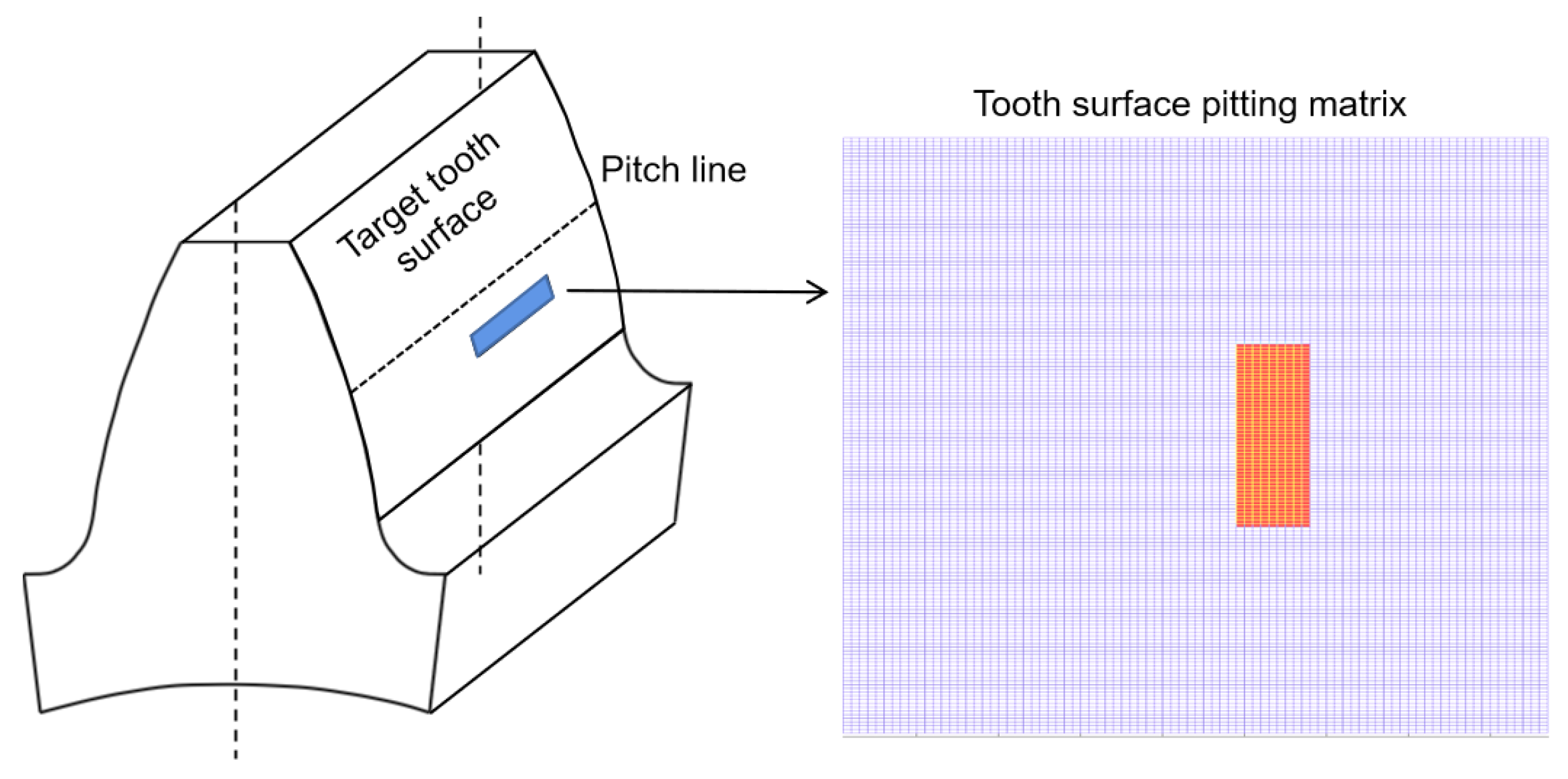

3.2. Meshing Stiffness Calculation Method for Pitting Gear Pairs

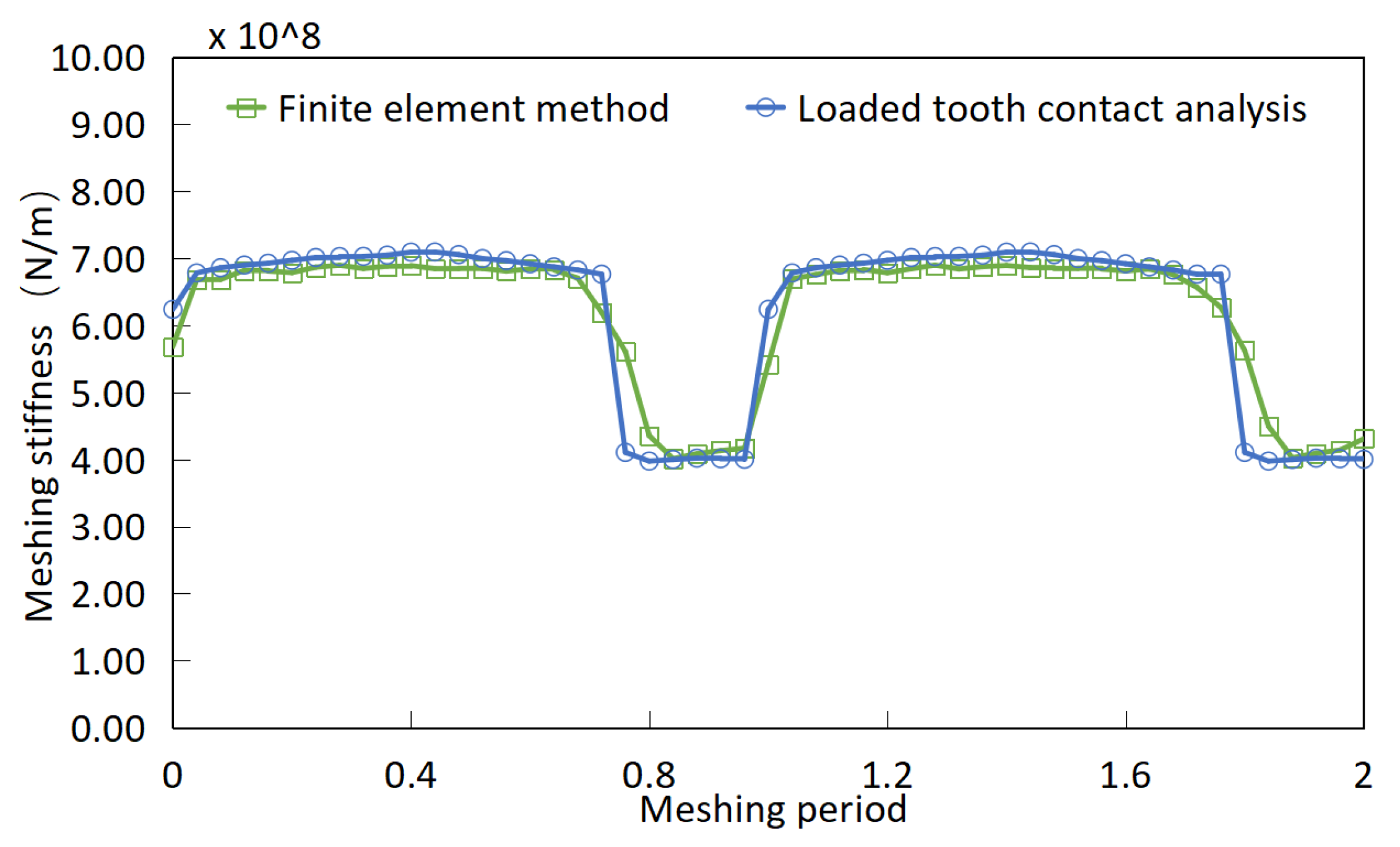

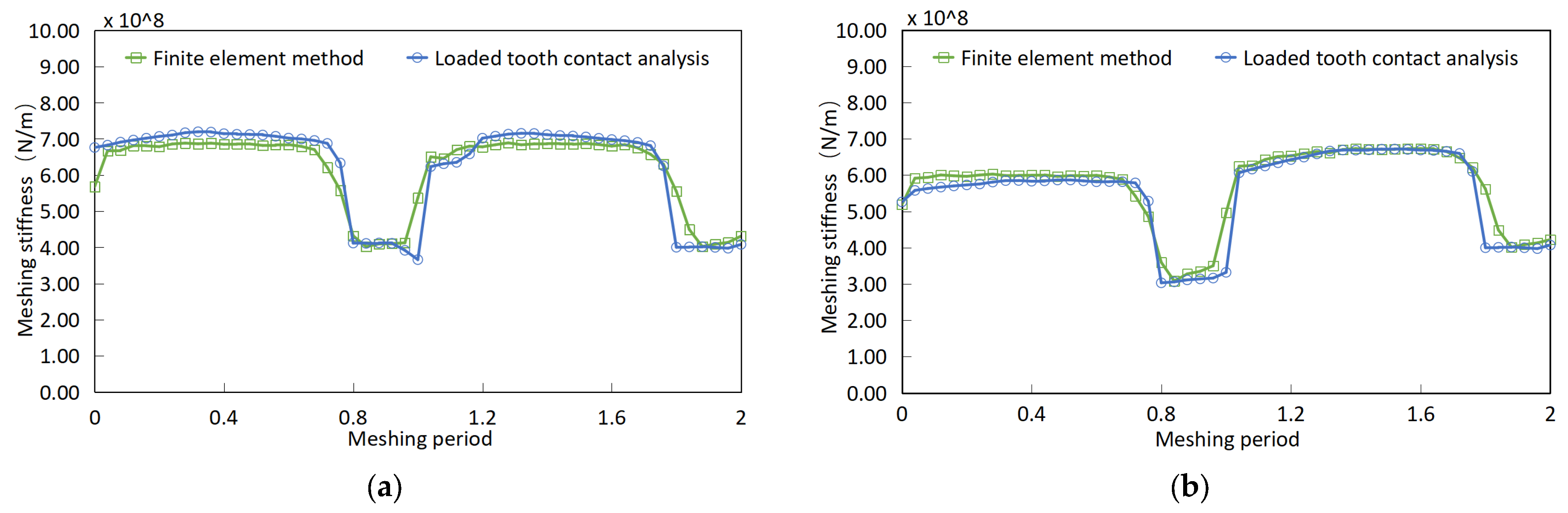

3.3. Verification of Meshing Stiffness Calculation Results

4. Research on Parameters Sensitivity of Fault Degradation

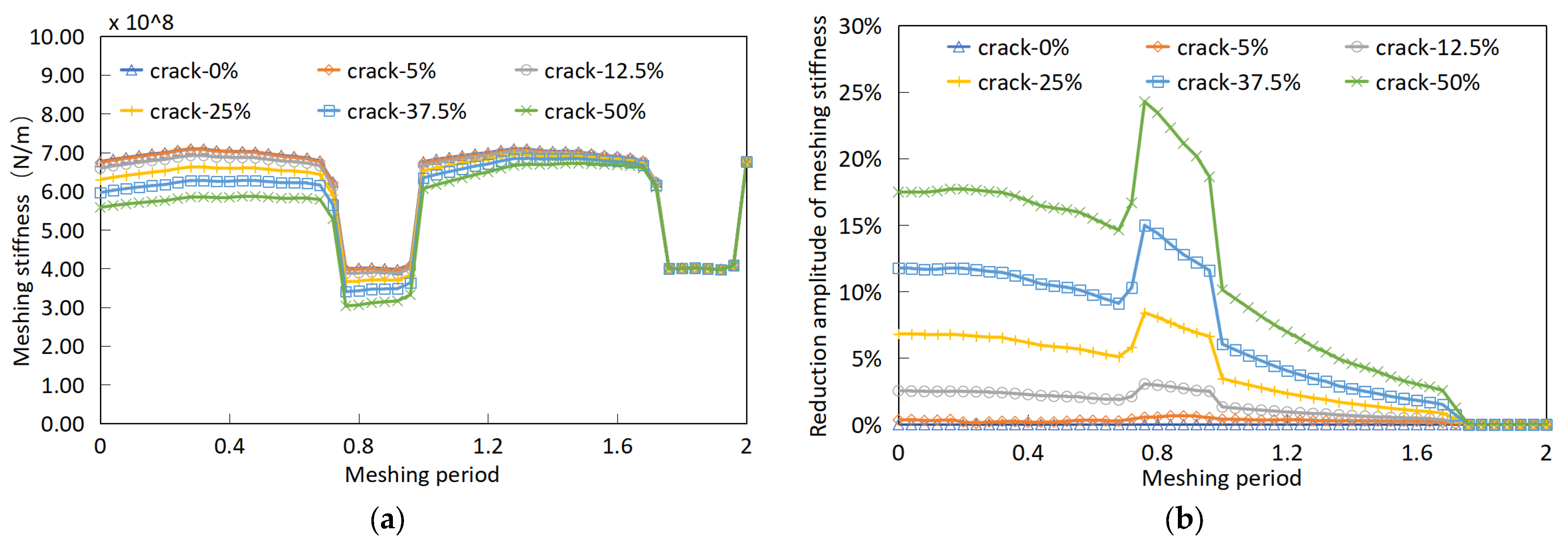

4.1. Parameters Sensitivity Study of Meshing Stiffness on Crack Degradation

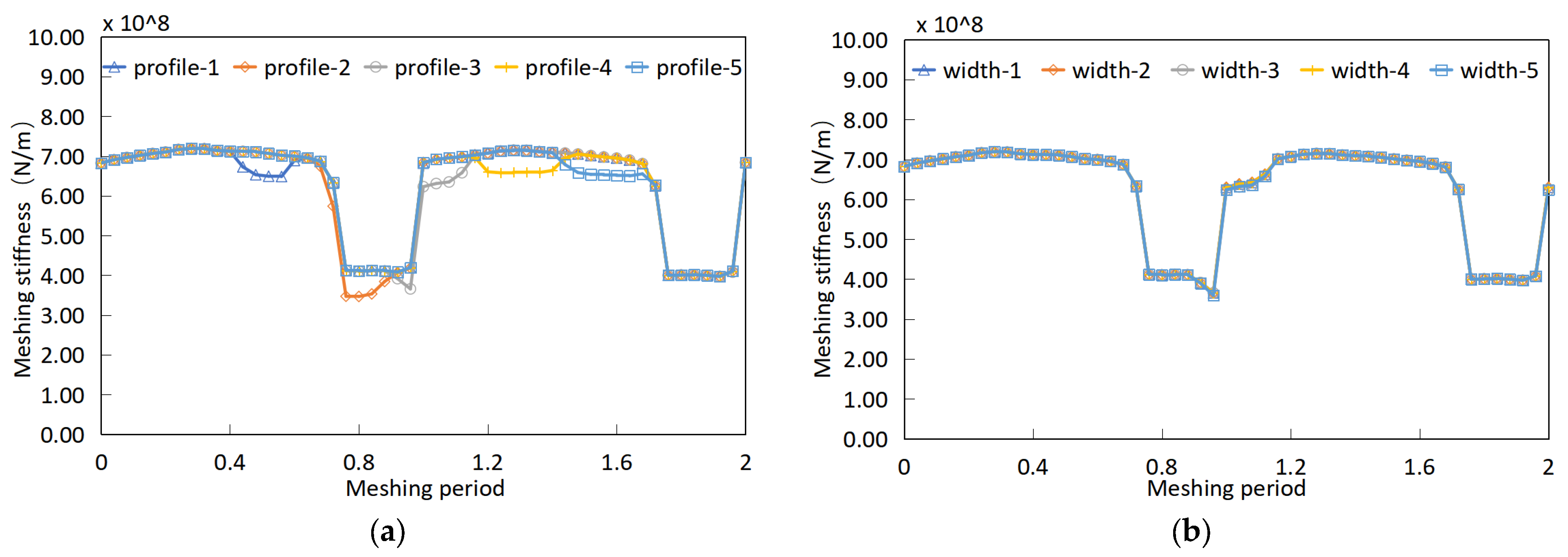

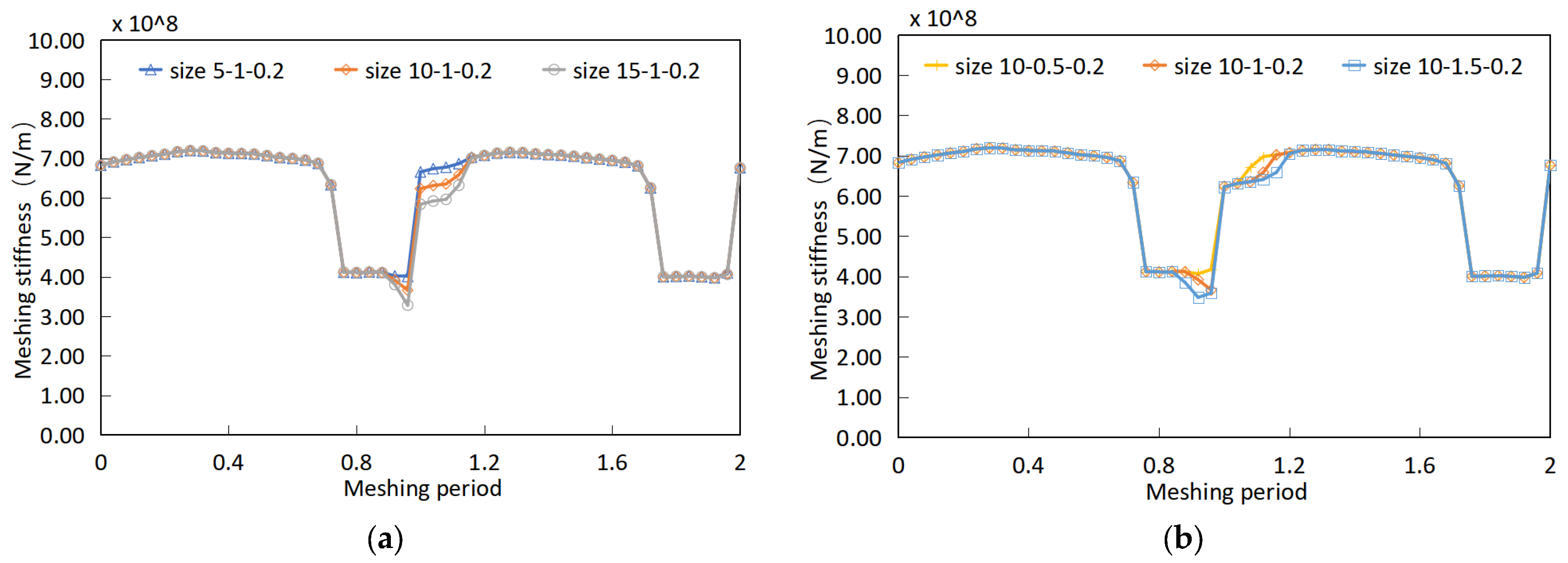

4.2. Parameters Sensitivity Study of Meshing Stiffness on Pitting Degradation

5. Conclusions

- (1)

- The simulation results show that the improved method has many advantages when compared with the other methods for calculating the meshing stiffness of faulty gear pairs. It can ensure high computational accuracy, significantly improve computational efficiency, reduce the time cost of engineering research, and achieve efficient modeling of fault transmission systems.

- (2)

- The stiffness calculation results of crack and pitting faults indicate that the meshing stiffness decreases more severely under crack faults, manifested as a decrease in the whole meshing stiffness of cracked gear teeth. However, the variation of the meshing stiffness of the gear pair under pitting faults is slightly different from the cracked gear pair, manifested as a decrease in the meshing stiffness when the pitting area is meshing, with a limited reduction amplitude in the entire meshing stiffness.

- (3)

- The meshing stiffness of the gear pair is closely related to the length of the actual meshing contact line. The growth of pitting along the tooth width direction will lead to a decrease in the actual length of the meshing contact line, resulting in a greater decrease in meshing stiffness; the growth of pitting along the tooth profile direction will lead to a longer duration of the short contact line, resulting in a longer duration of the decrease in meshing stiffness.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kan, K.; Binama, M.; Chen, H.; Zheng, Y.; Zhou, D.; Su, W.; Muhirwa, A. Pump as turbine cavitation performance for both conventional and reverse operating modes: A review. Renew. Sustain. Energy Rev. 2022, 168, 112786. [Google Scholar] [CrossRef]

- Kan, K.; Chen, H.; Zheng, Y.; Zhou, D.; Binama, M.; Dai, J. Transient characteristics during power-off process in a shaft extension tubular pump by using a suitable numerical model. Renew. Energy 2021, 164, 109–121. [Google Scholar] [CrossRef]

- Chang, L.; Liu, G.; Zheng, Y.; Ding, Y.F. A modified method for determining mesh stiffness of gears based on finite element method and elastic contact theory. Hangkong Dongli Xuebao 2014, 29, 682–688. [Google Scholar]

- Zhang, C.; Dong, H.; Wang, D.; Dong, B. A new effective mesh stiffness calculation method with accurate contact deformation model for spur and helical gear pairs. Mech. Mach. Theory 2022, 171, 104762. [Google Scholar] [CrossRef]

- Ma, H.; Pang, X.; Feng, R.; Zeng, J.; Wen, B. Improved time-varying mesh stiffness model of cracked spur gears. Eng. Fail. Anal. 2015, 55, 271–287. [Google Scholar] [CrossRef]

- Mohammed, O.D.; Rantatalo, M.; Aidanpää, J.-O. Improving mesh stiffness calculation of cracked gears for the purpose of vibration-based fault analysis. Eng. Fail. Anal. 2013, 34, 235–251. [Google Scholar] [CrossRef]

- Liang, X.; Zuo, M.J.; Pandey, M. Analytically evaluating the influence of crack on the mesh stiffness of a planetary gear set. Mech. Mach. Theory 2014, 76, 20–38. [Google Scholar] [CrossRef]

- Yang, L.; Wang, L.; Yu, W.; Shao, Y. Investigation of tooth crack opening state on time varying meshing stiffness and dynamic response of spur gear pair. Eng. Fail. Anal. 2021, 121, 105181. [Google Scholar] [CrossRef]

- Luo, Y.; Baddour, N.; Liang, M. Dynamical modeling and experimental validation for tooth pitting and spalling in spur gears. Mech. Syst. Signal Process. 2019, 119, 155–181. [Google Scholar] [CrossRef]

- Mohamed, A.; Sassi, S.; Paurobally, M.R. Numerical simulation of one-stage gearbox dynamics in the presence of simultaneous tooth cracks. In Proceedings of the 24th International Congress on Sound and Vibration, ICSV 2017, London, UK, 23–27 July 2017. [Google Scholar]

- Lei, Y.; Liu, Z.; Wang, D.; Yang, X.; Liu, H.; Lin, J. A probability distribution model of tooth pits for evaluating time-varying mesh stiffness of pitting gears. Mech. Syst. Signal Process. 2018, 106, 355–366. [Google Scholar] [CrossRef]

- Chen, Z.; Zhai, W.; Shao, Y.; Wang, K.; Sun, G. Analytical model for mesh stiffness calculation of spur gear pair with non-uniformly distributed tooth root crack. Eng. Fail. Anal. 2016, 66, 502–514. [Google Scholar] [CrossRef]

- Cui, L.; Huang, J.; Zhai, H.; Zhang, F. Research on the meshing stiffness and vibration response of fault gears under an angle-changing crack based on the universal equation of gear profile. Mech. Mach. Theory 2016, 105, 554–567. [Google Scholar] [CrossRef]

- Mohammed, O.D.; Rantatalo, M. Dynamic response and time-frequency analysis for gear tooth crack detection. Mech. Syst. Signal Process. 2016, 66–67, 612–624. [Google Scholar] [CrossRef]

- Chen, Z.; Shao, Y. Dynamic Features of a Planetary Gear System with Tooth Crack Under Different Sizes and Inclination Angles. J. Vib. Acoust. 2013, 135, 031004. [Google Scholar] [CrossRef]

- Chen, Z.; Shao, Y. Dynamic simulation of spur gear with tooth root crack propagating along tooth width and crack depth. Eng. Fail. Anal. 2011, 18, 2149–2164. [Google Scholar] [CrossRef]

- Jiang, H.; Shao, Y.; Mechefske, C.K. Dynamic characteristics of helical gears under sliding friction with spalling defect. Eng. Fail. Anal. 2014, 39, 92–107. [Google Scholar] [CrossRef]

- Han, L.; Qi, H. Influences of tooth spalling or local breakage on time-varying mesh stiffness of helical gears. Eng. Fail. Anal. 2017, 79, 75–88. [Google Scholar] [CrossRef]

- Liang, X.; Zhang, H.; Liu, L.; Zuo, M.J. The influence of tooth pitting on the mesh stiffness of a pair of external spur gears. Mech. Mach. Theory 2016, 106, 1–15. [Google Scholar] [CrossRef]

- Saxena, A.; Parey, A.; Chouksey, M. Time varying mesh stiffness calculation of spur gear pair considering sliding friction and spalling defects. Eng. Fail. Anal. 2016, 70, 200–211. [Google Scholar] [CrossRef]

- Liang, X.; Zuo, M.J.; Feng, Z.; Liu, L. A mesh stiffness evaluation model to reflect tooth pitting growth of a pair of external spur gears. In Proceedings of the 2016 Prognostics and System Health Management Conference (PHM-Chengdu), Chengdu, China, 19–21 October 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Feng, K.; Smith, W.A.; Randall, R.B.; Wu, H.; Peng, Z. Vibration-based monitoring and prediction of surface profile change and pitting density in a spur gear wear process. Mech. Syst. Signal Process. 2021, 165, 108319. [Google Scholar] [CrossRef]

- Vijayakar, S. A combined surface integral and finite element solution for a three-dimensional contact problem. Int. J. Numer. Methods Eng. 1991, 31, 525–545. [Google Scholar] [CrossRef]

- Hedlund, J.; Lehtovaara, A. A parameterized numerical model for the evaluation of gear mesh stiffness variation of a helical gear pair. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2008, 222, 1321–1327. [Google Scholar] [CrossRef]

- Fang, Z. A Model and method for loaded teeth contact analysis (LTCA) of gear teeth. Mech. Transm. 1998, 2–4, 53. [Google Scholar]

- Chang, L.; Liu, G.; Wu, L. A robust model for determining the mesh stiffness of cylindrical gears. Mech. Mach. Theory 2015, 87, 93–114. [Google Scholar] [CrossRef]

- Feng, Z.; Jin, G.; Zhu, R. Calculation and analysis of spur gear meshing stiffness based on LTCA. Mech. Transm. 2019, 43, 78–83, 91. [Google Scholar]

- Cappellini, N.; Tamarozzi, T.; Blockmans, B.; Fiszer, J.; Cosco, F.; Desmet, W. Semi-analytic contact technique in a non-linear parametric model order reduction method for gear simulations. Meccanica 2018, 53, 49–75. [Google Scholar] [CrossRef]

- Chang, L.; Liu, G.; Wu, L. Determination of composite meshing errors and its influence on the vibration of gear system. J. Mech. Eng. 2015, 51, 123–130. [Google Scholar] [CrossRef]

- Chang, L.; He, Z.; Yuan, B.; Song, W. A model for coupling analysis of the nonlinear contact characteristics and dynamics of gear pairs. Hsichiao Tung Ta Hsueh/J. Xi’an Jiaotong Univ. 2022, 56, 1–10. [Google Scholar]

- Yuan, B. Meshing Characteristics and Dynamic Analysis of Marine Gear Systems with High Speed and Heavy Load. Ph.D. Thesis, Northwestern Polytechnical University, Xi’an, China, 2019. [Google Scholar]

- Ding, C.; Zhang, L.; Zhou, F.; Zhu, J.; Zhao, S.K. Theoretical formula for calculation of line-contact elastic contact deformation. Tribology 2001, 21, 135–138. [Google Scholar]

- Chang, L. A Generalized Dynamic Model for Parallel Shaft Gear Transmissions and the Influences of Dynamic Excitations. Ph.D. Thesis, Northwestern Polytechnical University, Xi’an, China, 2014. [Google Scholar]

| Parameter | Module (mm) | Teeth Number | Width (mm) | Pressure Angle (°) | Elastic Modulus (Pa) | Poisson’s Ratio | Power (kW) | Speed (r/min) |

|---|---|---|---|---|---|---|---|---|

| Driving gear | 6 | 45 | 34 | 20 | 2.05 × 1011 | 0.3 | 278.3 | 2640.74 |

| Driven gear | 35 | 3395.24 |

| Type of Gear Pair | Time Consumption (s) | |

|---|---|---|

| Finite Element Method | LTCA Method | |

| Healthy | 35,653.30 | 241.06 |

| Crack | 44,719.41 | 267.08 |

| Pitting | 42,376.48 | 282.96 |

| Gear Crack Parameters | Gear Crack Parameters Settings | |||||

|---|---|---|---|---|---|---|

| Crack length | 0% | 5% | 12.5% | 25% | 37.5% | 50% |

| Crack angle | 75° | 70° | 65° | |||

| Gear Pitting Parameters | Gear Pitting Parameter Settings | ||||

|---|---|---|---|---|---|

| Tooth profile | Profile-1 | Profile-2 | Profile-3 | Profile-4 | Profile-5 |

| Tooth width | Width-1 | Width-2 | Width-3 | Width-4 | Width-5 |

| Pitting size (length-width) | 5 × 1 mm | 10 × 0.5 mm | 10 × 1 mm | 10 × 1.5 mm | 15 × 1 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Wang, H.; Lu, F.; Wang, C.; Zhang, J.; Qin, M. A New Fast Calculating Method for Meshing Stiffness of Faulty Gears Based on Loaded Tooth Contact Analysis. Processes 2023, 11, 2003. https://doi.org/10.3390/pr11072003

Liu Z, Wang H, Lu F, Wang C, Zhang J, Qin M. A New Fast Calculating Method for Meshing Stiffness of Faulty Gears Based on Loaded Tooth Contact Analysis. Processes. 2023; 11(7):2003. https://doi.org/10.3390/pr11072003

Chicago/Turabian StyleLiu, Zhe, Haiwei Wang, Fengxia Lu, Cheng Wang, Jiachi Zhang, and Mingjian Qin. 2023. "A New Fast Calculating Method for Meshing Stiffness of Faulty Gears Based on Loaded Tooth Contact Analysis" Processes 11, no. 7: 2003. https://doi.org/10.3390/pr11072003

APA StyleLiu, Z., Wang, H., Lu, F., Wang, C., Zhang, J., & Qin, M. (2023). A New Fast Calculating Method for Meshing Stiffness of Faulty Gears Based on Loaded Tooth Contact Analysis. Processes, 11(7), 2003. https://doi.org/10.3390/pr11072003