The Industrial Digital Energy Twin as a Tool for the Comprehensive Optimization of Industrial Processes

Abstract

:1. Introduction

2. Digital Twins for Energy Efficiency Improvement of the Industrial Process

2.1. The Challenge of Improving Energy Efficiency in the Manufacturing Industry

2.2. Digital Twins Usage for Energy Efficiency Optimization in Manufacturing Environments

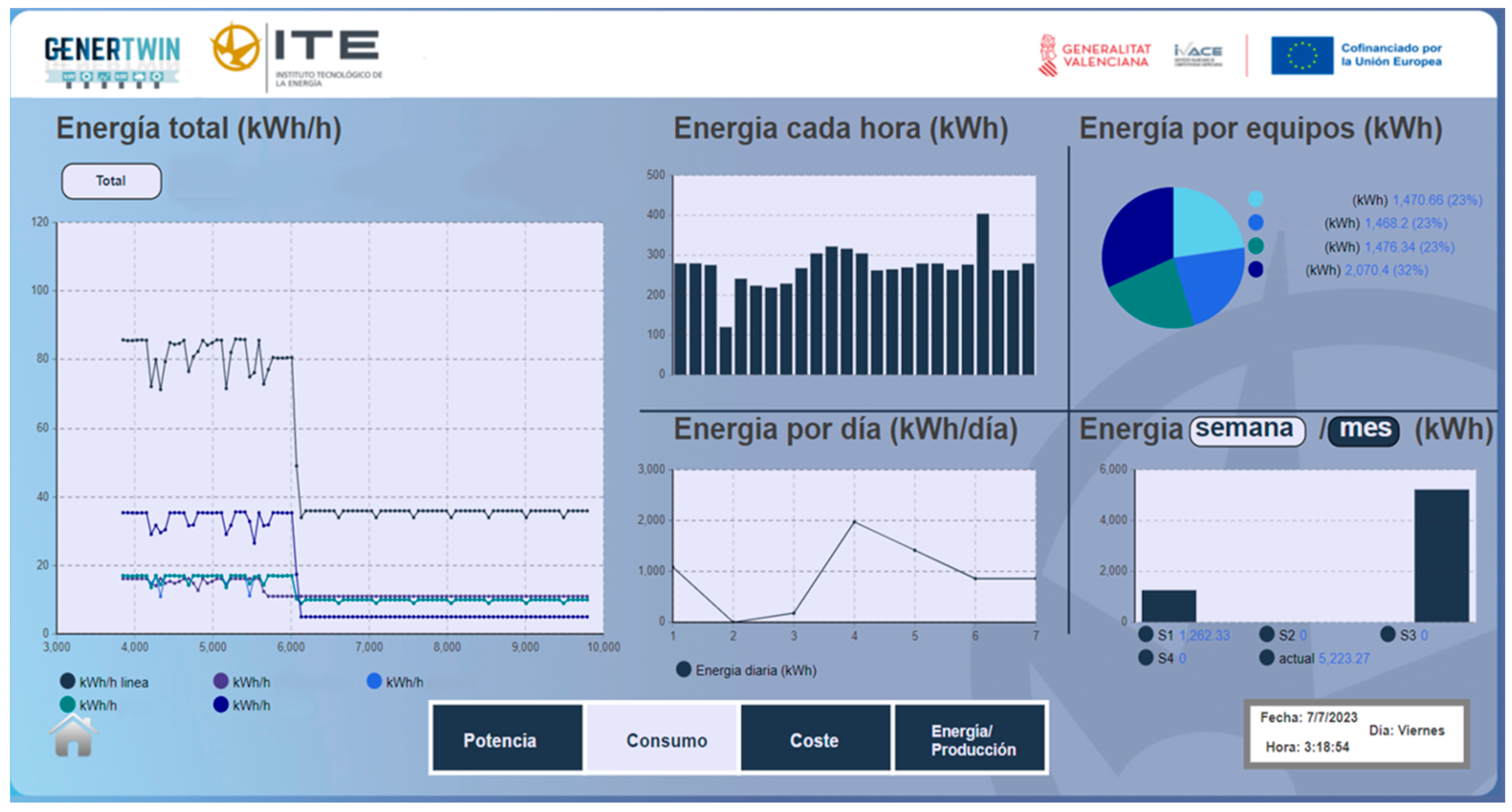

2.3. Project GENERTWIN

2.4. Constraints and Challenges

3. Digital Twin Development

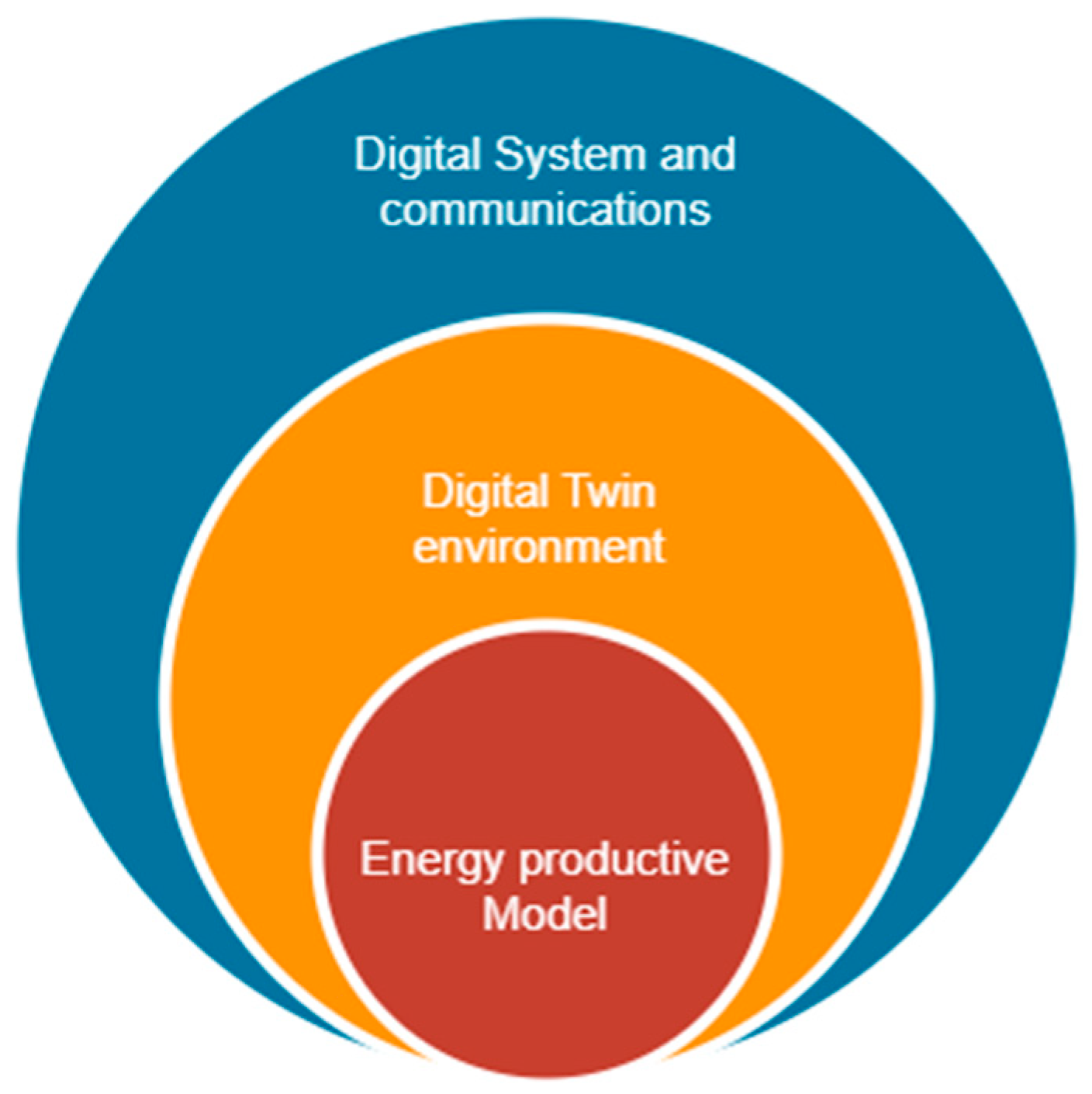

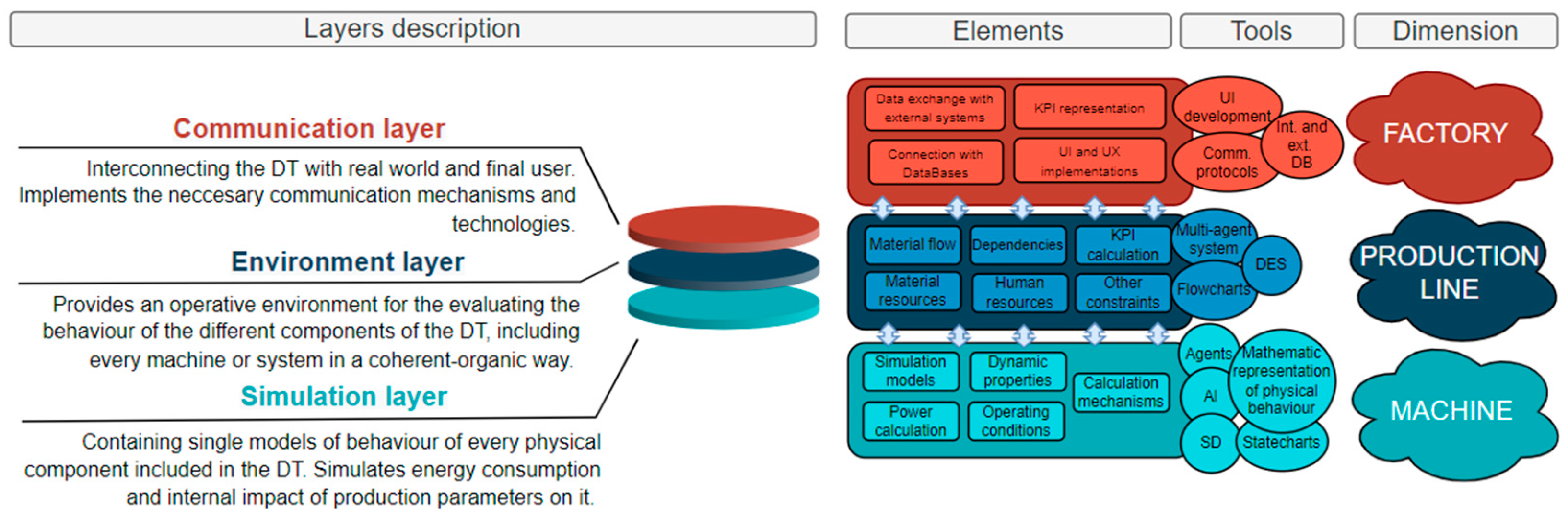

3.1. Basic Architecture

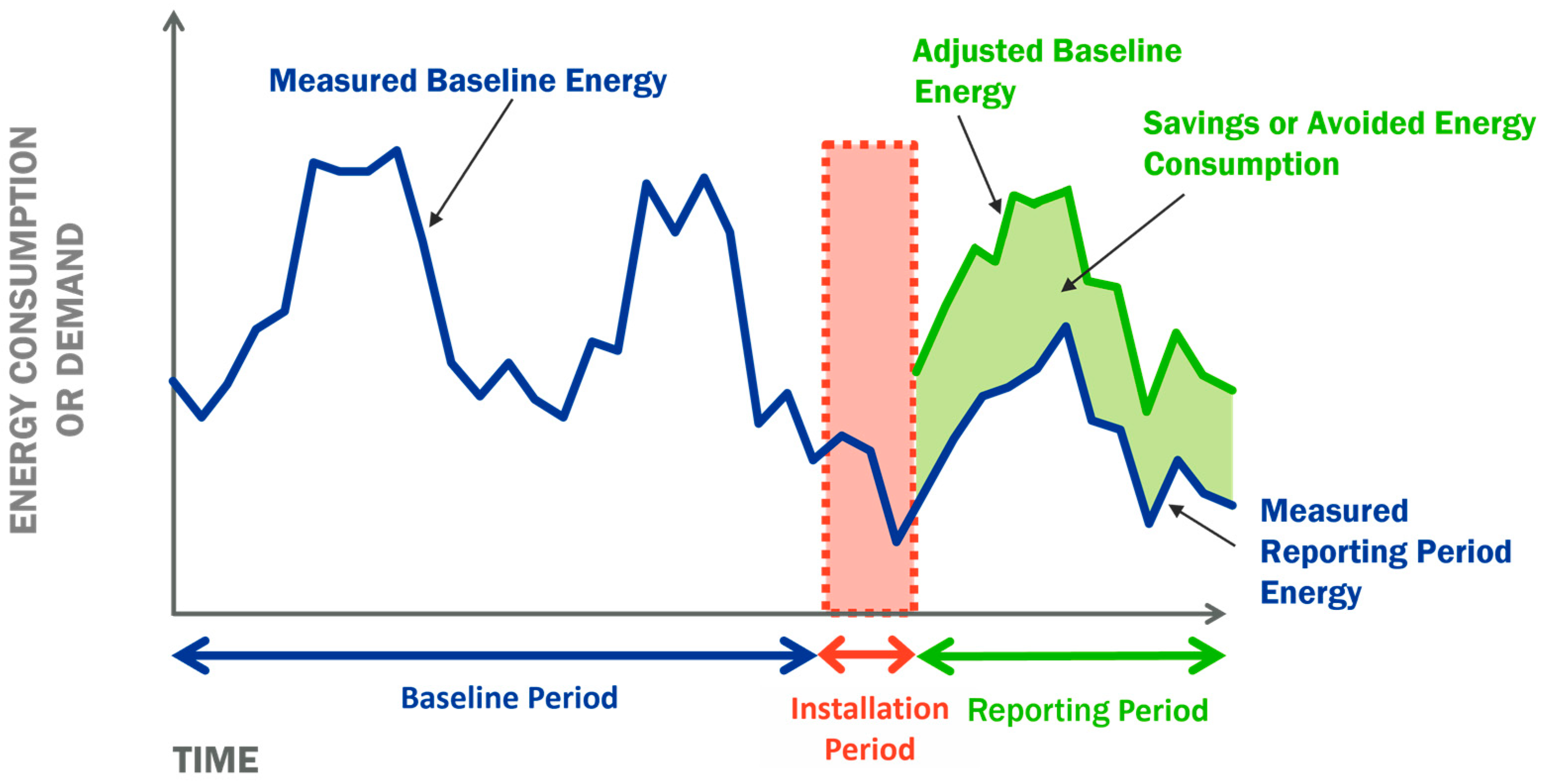

3.2. The DT Implementation Process

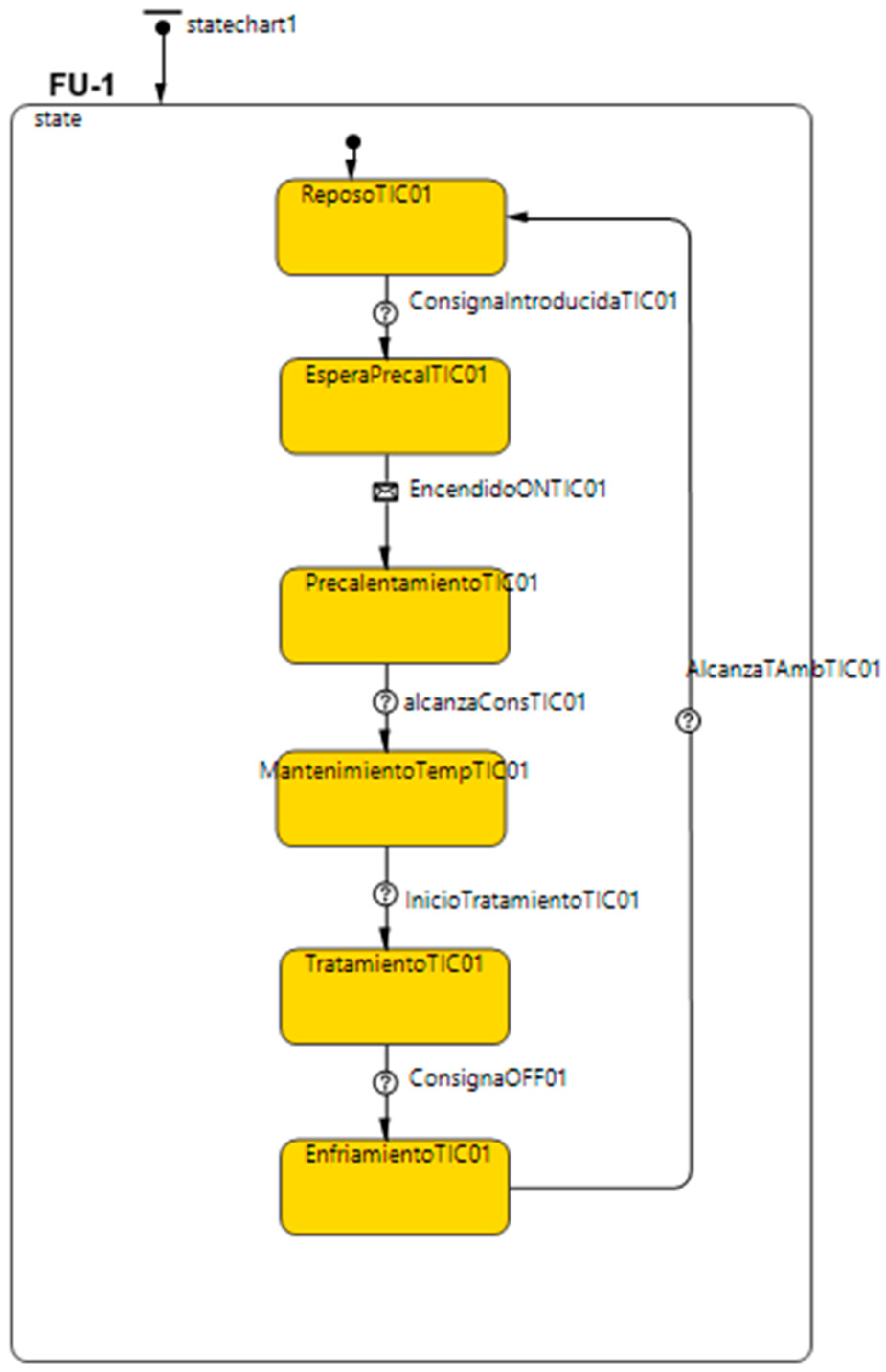

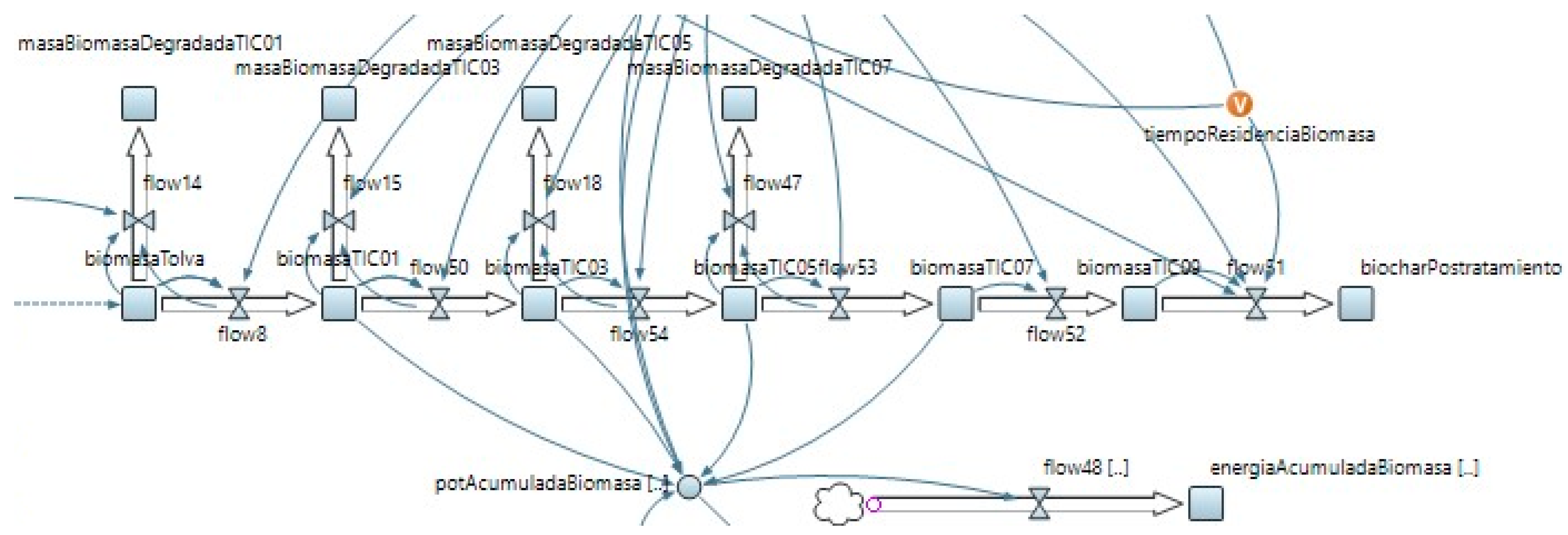

3.3. Functionalities and Examples of Implementation

3.4. Application and Impact

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Grieves, M. Digital Twin: Manufacturing Excellence through Virtual Factory Replication; White Paper; Michael W. Grieves, LLC: Cocoa Beach, FL, USA, 2014; pp. 1–7. [Google Scholar]

- May, G.; Stahl, B.; Taisch, M.; Kiritsis, D. Energy management in manufacturing: From literature review to a conceptual framework. J. Clean. Prod. 2017, 167, 1464–1489. [Google Scholar] [CrossRef]

- International Organization for Standardization. Energy Management Systems-Requirements with Guidance for Use (ISO 50001). 2018. Available online: https://www.iso.org/standard/69426.html (accessed on 31 July 2023).

- Dörr, M.; Wahren, S.; Bauernhansl, T. Methodology for energy efficiency on process level. Procedia CIRP 2013, 7, 652–657. [Google Scholar] [CrossRef]

- Dolge, K.; Kubule, A.; Blumberga, D. Composite index for energy efficiency evaluation of industrial sector: Sub-sectoral comparison. Environ. Sustain. Indic. 2020, 8, 100062. [Google Scholar] [CrossRef]

- Xiong, S.; Ma, X.; Ji, J. The impact of industrial structure efficiency on provincial industrial energy efficiency in China. J. Clean. Prod. 2019, 215, 952–962. [Google Scholar] [CrossRef]

- Asociación Europea de la Industria Cerámica. Hoja de Ruta de la Industria Cerámica, 2050. Available online: https://www.ascer.es/verDocumento.ashx?documentoId=2714&tipo=pdf (accessed on 20 July 2023).

- Leng, J.; Wang, D.; Shen, W.; Li, X.; Liu, Q.; Chen, X. Digital twins-based smart manufacturing system design in Industry 4.0: A review. J. Manuf. Syst. 2021, 60, 119–137. [Google Scholar] [CrossRef]

- Tekinerdogan, B.; Verdouw, C. Systems architecture design pattern catalog for developing digital twins. Sensors 2020, 20, 5103. [Google Scholar] [CrossRef] [PubMed]

- Maeyer, C.; Markopoulos, P. Future outlook on the materialisation, expectations and implementation of Digital Twins in healthcare. In Proceedings of the 34th British HCI Conference (HCI2021), London, UK, 20–21 July 2021. [Google Scholar] [CrossRef]

- Nasirahmadi, A.; Hensel, O. Toward the Next Generation of Digitalization in Agriculture Based on Digital Twin Paradigm. Sensors 2022, 22, 498. [Google Scholar] [CrossRef] [PubMed]

- Opoku, D.; Perera, S.; Osei-Kyei, R.; Rashidi, M. Digital twin application in the construction industry: A literature review. J. Build. Eng. 2021, 40, 102726. [Google Scholar] [CrossRef]

- Schoonenberg, W.; Farid, A. A Dynamic Production Model for Industrial Systems Energy Management. In Proceedings of the 2015 IEEE International Conference on Systems, Man, and Cybernetics, Hong Kong, China, 9–12 October 2015; pp. 1–7. [Google Scholar] [CrossRef]

- Mo, F.; Rehman, H.U.; Monetti, F.M.; Chaplin, J.C.; Sanderson, D.; Popov, A.; Maffei, A.; Ratchev, S. A framework for manufacturing system reconfiguration and optimisation utilising digital twins and modular artificial intelligence. Robot. Comput.-Integr. Manuf. 2023, 82, 102524. [Google Scholar] [CrossRef]

- Yu, W.; Patros, P.; Young, B.; Klinac, E.; Walmsley, T.G. Energy digital twin technology for industrial energy management: Classification, challenges and future. Renew. Sustain. Energy Rev. 2022, 161, 112407. [Google Scholar] [CrossRef]

- Zhang, C.; Xu, W.; Liu, J.; Liu, Z.; Zhou, Z.; Pham, D. A Reconfigurable Modeling Approach for Digital Twin-based Manufacturing System. Procedia CIRP 2019, 83, 118–125. [Google Scholar] [CrossRef]

- Fang, K.; Uhan, N.; Zhao, F.; Sutherland, J.W. A new approach to scheduling in manufacturing for power consumption and carbon footprint reduction. J. Manuf. Syst. 2011, 30, 234–240. [Google Scholar] [CrossRef]

- Zhang, Z.; Tang, R.; Peng, T.; Tao, L.; Jia, S. A method for minimizing the energy consumption of machining system: Integration of process planning and scheduling. J. Clean. Prod. 2016, 137, 1647–1662. [Google Scholar] [CrossRef]

- Ma, S.; Zhang, Y.; Lv, J.; Yang, H.; Wu, J. Energy-cyber-physical system enabled management for energy-intensive manufacturing industries. J. Clean. Prod. 2019, 226, 892–903. [Google Scholar] [CrossRef]

- Keshari, A.; Sonsale, A.N.; Sharma, B.K.; Pohekar, S.D. Discrete event simulation approach for energy efficient resource management in paper pulp industry. Procedia CIRP 2018, 78, 2–7. [Google Scholar] [CrossRef]

- Kant, G.; Sangwan, K. Predictive Modelling for Energy Consumption in Machining Using Artificial Neural Network. Procedia CIRP 2015, 37, 205–210. [Google Scholar] [CrossRef]

- Holler, J.; Tsiatsis, V.; Mulligan, C.; Karnouskos, S.; Avesand, S.; Boyle, D. From Machine-to-Machine to the Internet of Things: Introduction to a New Age of Intelligence; Elsevier Science: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Ferreno-González, S. Aproximación Metodológica a la Implantación del Gemelo Digital en Buques. Available online: https://ruc.udc.es/dspace/bitstream/handle/2183/30974/FerrenoGonzalez_Sara_TD_2022.pdf?sequence=2 (accessed on 31 July 2023).

- Schroeder, G.N.; Steinmetz, C.; Rodrigues, R.N.; Henriques, R.V.B.; Rettberg, A.; Pereira, C.E. A methodology for digital twin modeling and deployment for industry 4.0. Proc. IEEE 2020, 109, 556–567. [Google Scholar] [CrossRef]

- Efficiency Valuation Organization: International Performance Measurement and Verification Protocol (IPMVP). Available online: https://evo-world.org/en/products-services-mainmenu-en/protocols/ipmvp (accessed on 31 July 2023).

| Application Case | Energy Cost Improvement (%) | Considerations |

|---|---|---|

| Ceramic industry process | 4 | Low flexibility |

| Glass industry process | 37 | High flexibility |

| Simulation Nº | Type of Simulation | Description | KPI (kWh/Unit) | Impact * |

|---|---|---|---|---|

| S1 | Constant period—3 working days | Baseline | 0.526 | 0% |

| S2 | Constant period—3 working days | Increasing procedure time + 40 s | 0.542 | 3.1% |

| S3 | Constant period—3 working days | Increasing losses by 4.5% | 0.527 | 0.2% |

| S4 | Constant period—3 working days | Variation in operator speed | 0.53 | 0.8% |

| S5 | Constant production—10,000 units | Baseline | 0.527 | 0% |

| S6 | Constant production—10,000 units | Increasing procedure time + 40 s | 0.542 | 3.0% |

| S7 | Constant production—10,000 units | Increasing losses by 4.5% | 0.528 | 0.3% |

| S8 | Constant production—10,000 units | Variation in operator speed | 0.529 | 0.6% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rubio-Rico, A.; Mengod-Bautista, F.; Lluna-Arriaga, A.; Arroyo-Torres, B.; Fuster-Roig, V. The Industrial Digital Energy Twin as a Tool for the Comprehensive Optimization of Industrial Processes. Processes 2023, 11, 2353. https://doi.org/10.3390/pr11082353

Rubio-Rico A, Mengod-Bautista F, Lluna-Arriaga A, Arroyo-Torres B, Fuster-Roig V. The Industrial Digital Energy Twin as a Tool for the Comprehensive Optimization of Industrial Processes. Processes. 2023; 11(8):2353. https://doi.org/10.3390/pr11082353

Chicago/Turabian StyleRubio-Rico, Alejandro, Fernando Mengod-Bautista, Andrés Lluna-Arriaga, Belén Arroyo-Torres, and Vicente Fuster-Roig. 2023. "The Industrial Digital Energy Twin as a Tool for the Comprehensive Optimization of Industrial Processes" Processes 11, no. 8: 2353. https://doi.org/10.3390/pr11082353

APA StyleRubio-Rico, A., Mengod-Bautista, F., Lluna-Arriaga, A., Arroyo-Torres, B., & Fuster-Roig, V. (2023). The Industrial Digital Energy Twin as a Tool for the Comprehensive Optimization of Industrial Processes. Processes, 11(8), 2353. https://doi.org/10.3390/pr11082353