Study on the Influence of Fluid Pulsation on Hydraulic Impactor Performance in Drilling Engineering

Abstract

:1. Introduction

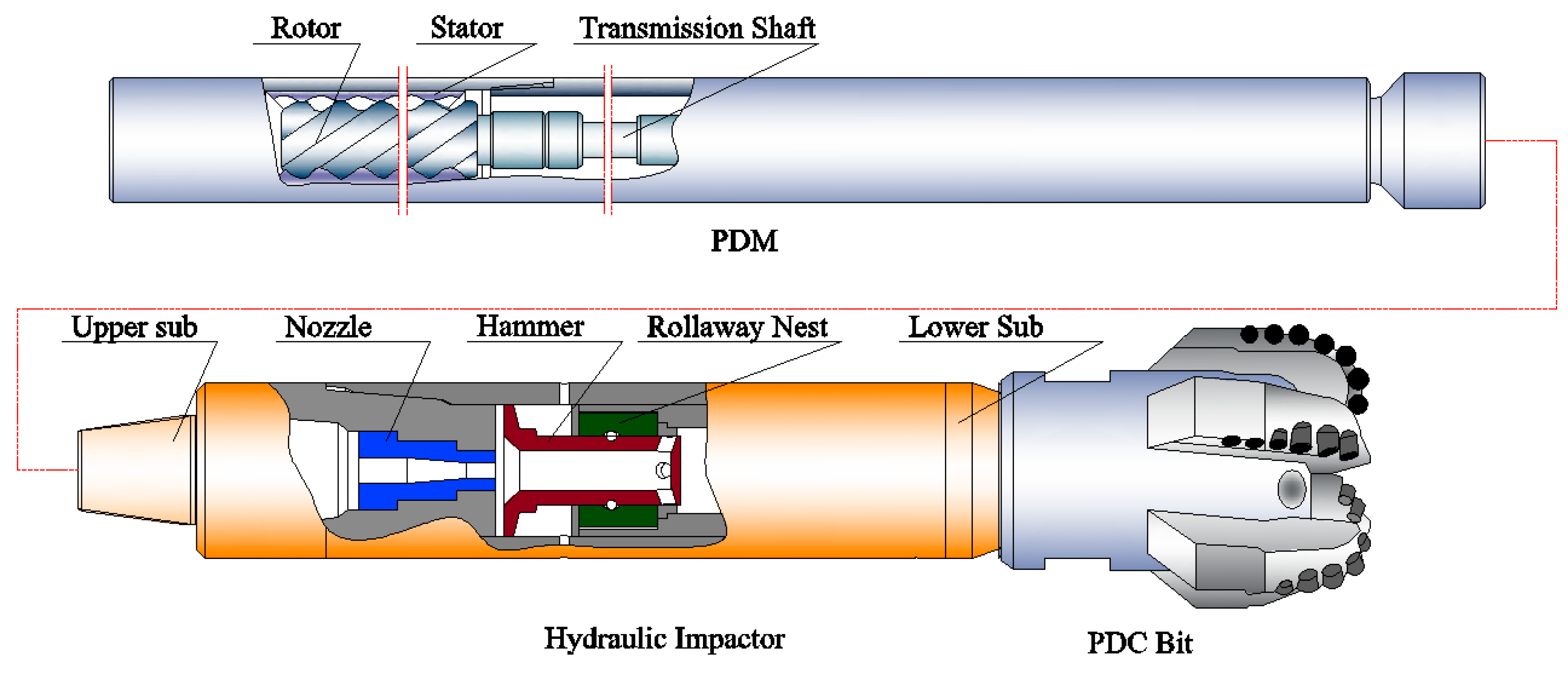

2. Hydraulic Impactor

3. Optimization of Hydraulic Impactor

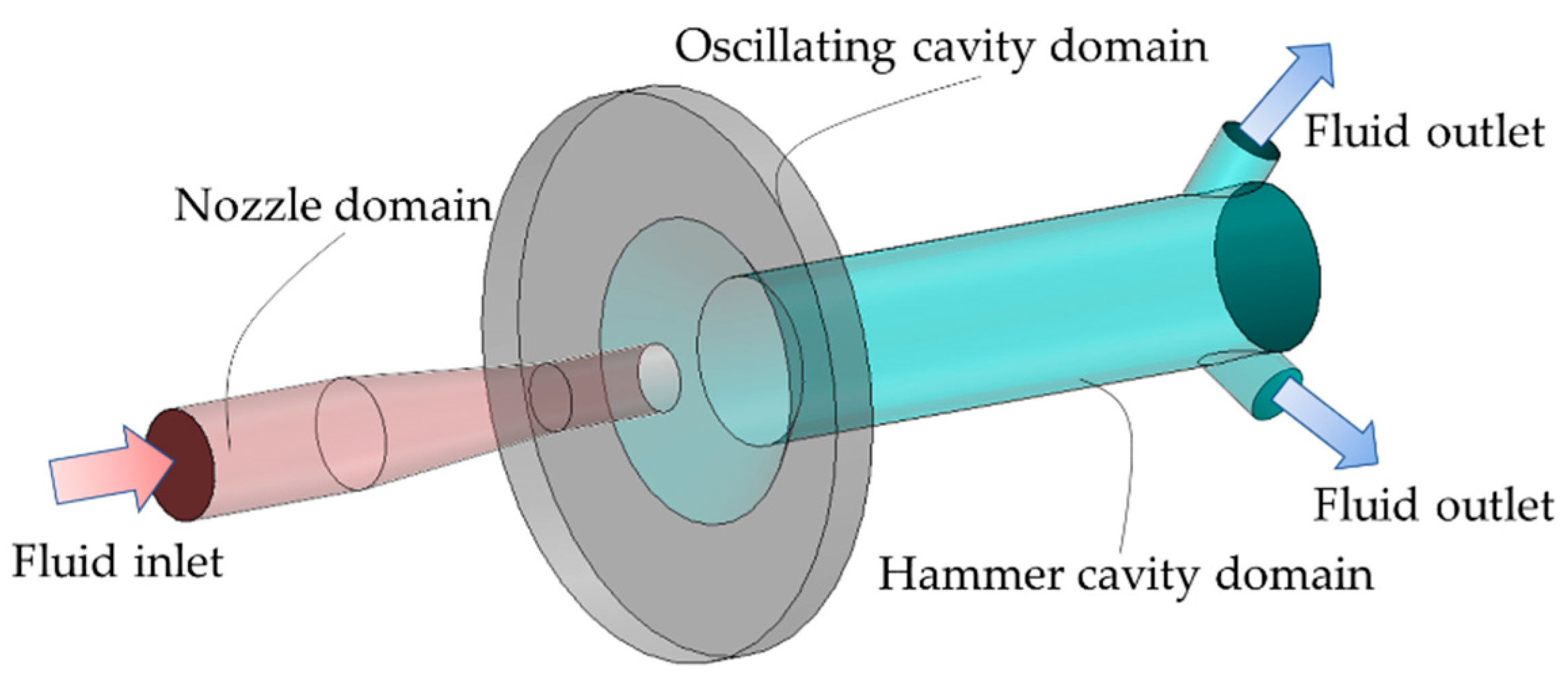

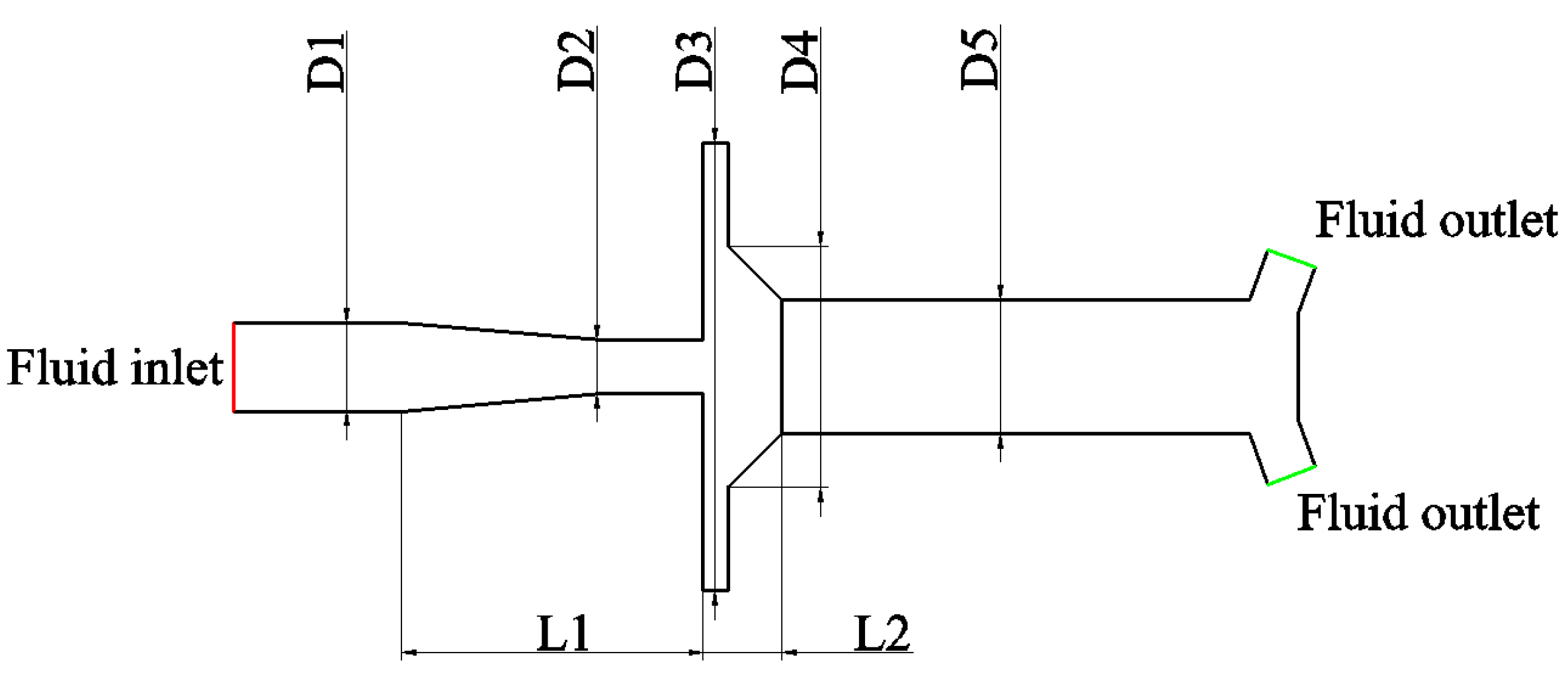

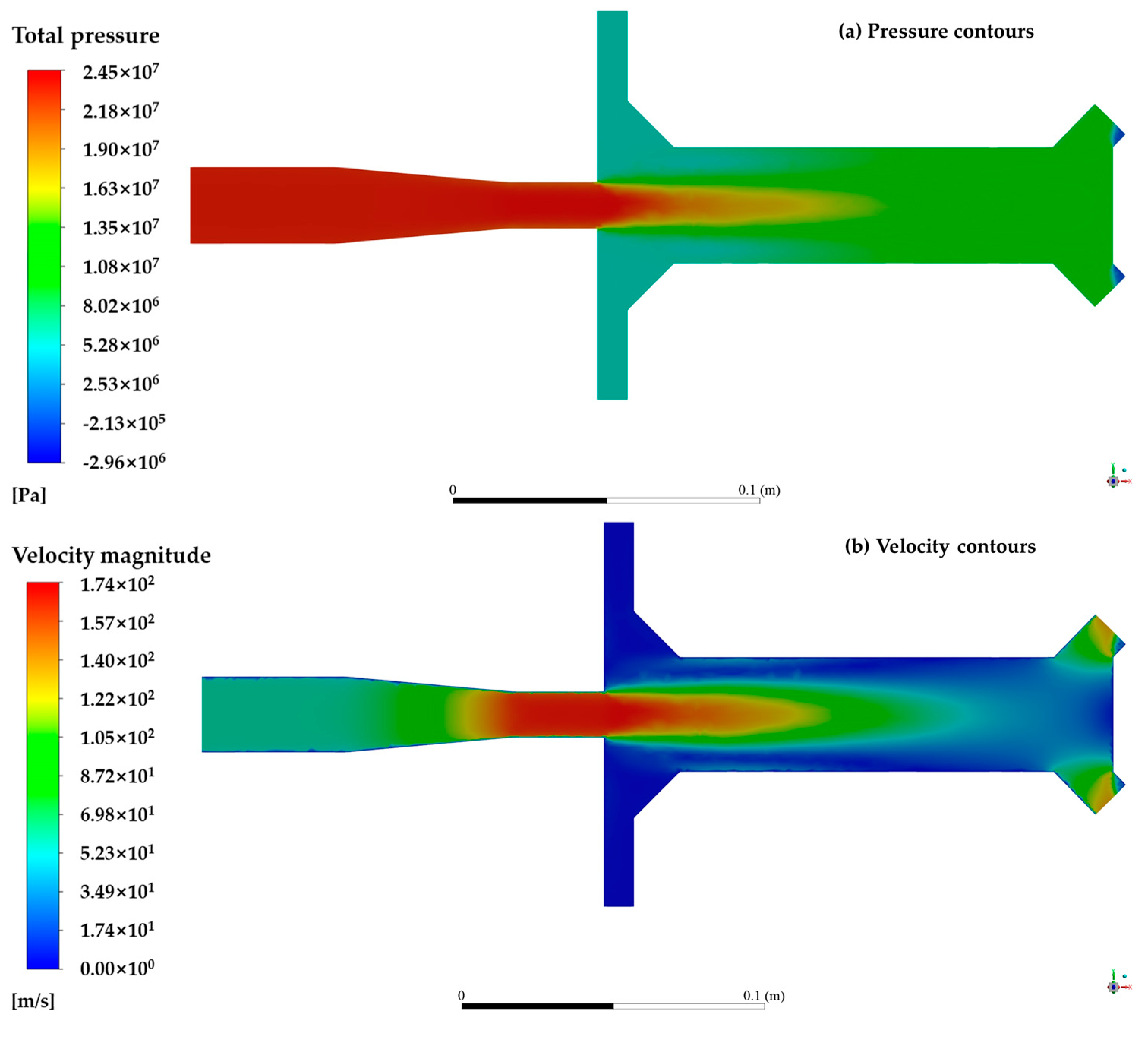

3.1. Numerical Simulation Method

- (1)

- Numerical model

- (2)

- Computational fluid dynamics method

- (3)

- Inlet fluid fluctuation parameters.

- (1)

- The properties of drilling fluid in the actual drilling environment were considered in the simulation. Thus, the fluid medium is set as water, but the density is set as 1.2 g/cm3, which belongs to compressible fluid.

- (2)

- The inlet of the self-oscillation cavity was regarded as the velocity inlet, which simulates the situation with and without considering the PDM. Based on the application experience, the drilling fluid flow rate is 30 L/s, and the velocity condition is 3.57 m/s when the entrance of the self-oscillation cavity is not considered. When the PDM is considered, the entrance velocity is:

- (3)

- The exit boundary of the self-oscillation cavity was set at atmospheric pressure of 101.3 kpa, the fluid wall used the wall function method condition, and the solid surface used the non-slip boundary condition.

- (4)

- The SIMPLE algorithm was used to solve the equations of pressure and momentum, turbulent dissipation rate, and turbulent kinetic energy. The SIMPLE algorithm, also known as semi-implicit method for pressure-linked equations, was proposed by Patankar and Spalding in 1972. The simplicity, stability, convergence, and versatility of the SIMPLE algorithm make it one of the commonly used methods in computational fluid dynamics.

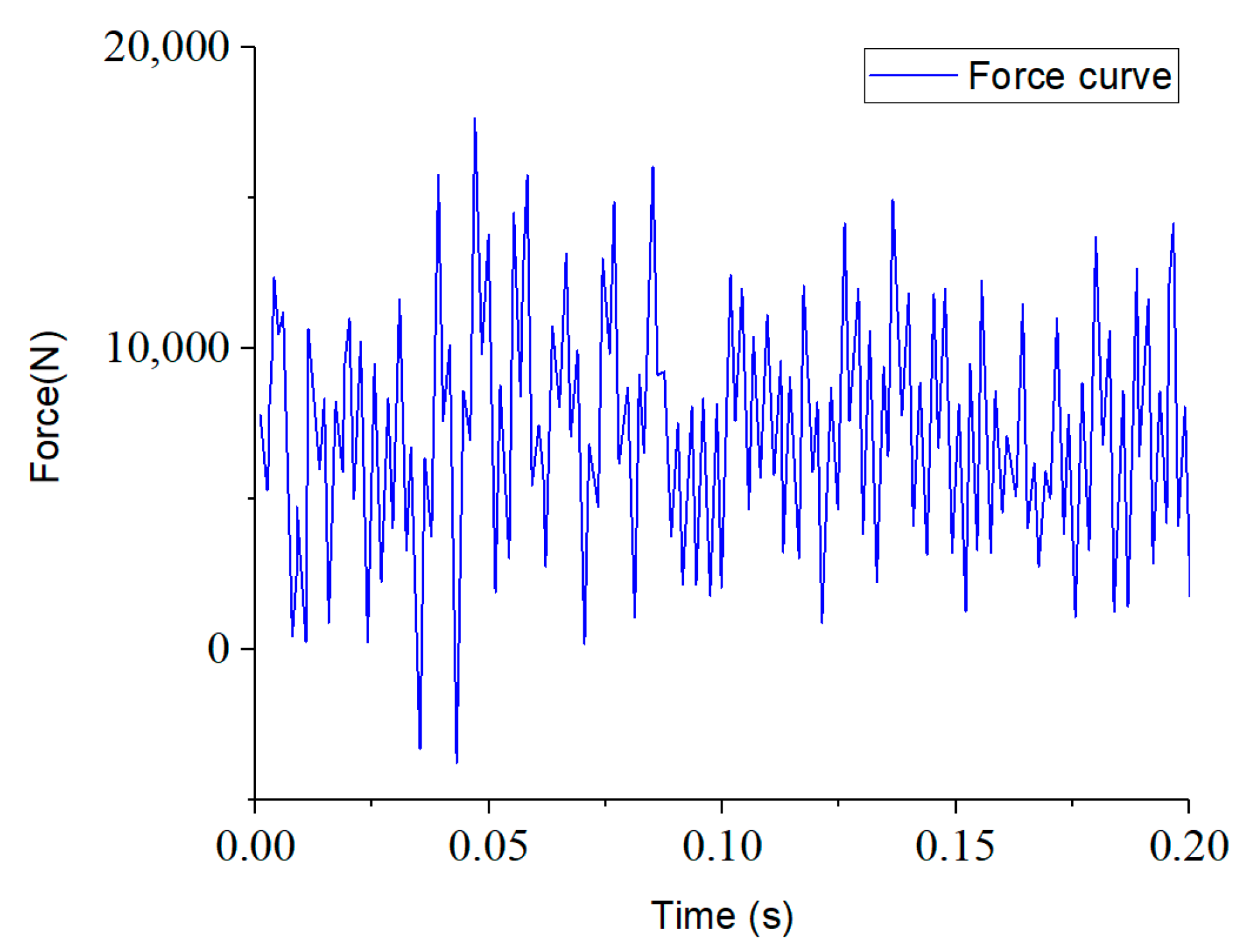

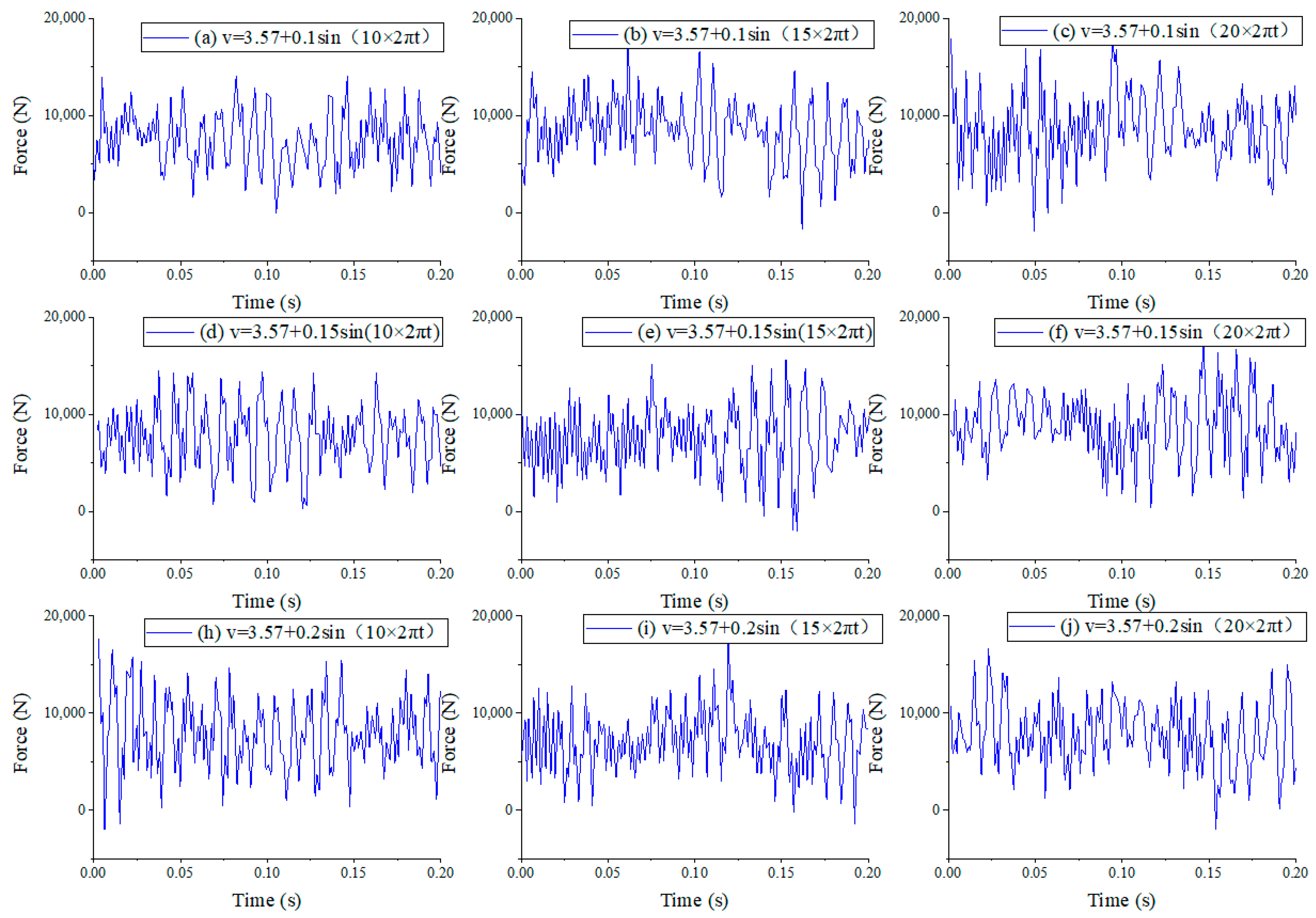

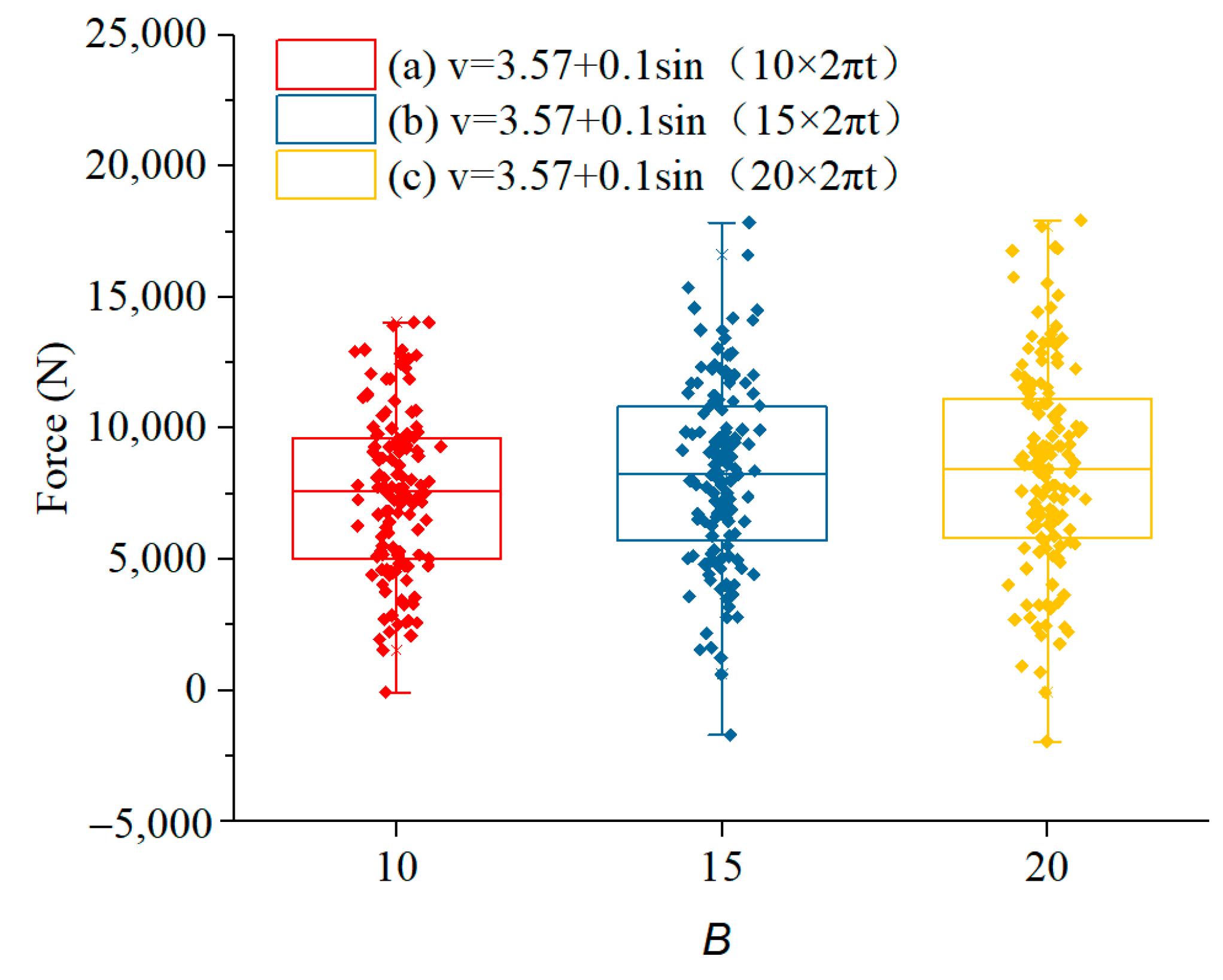

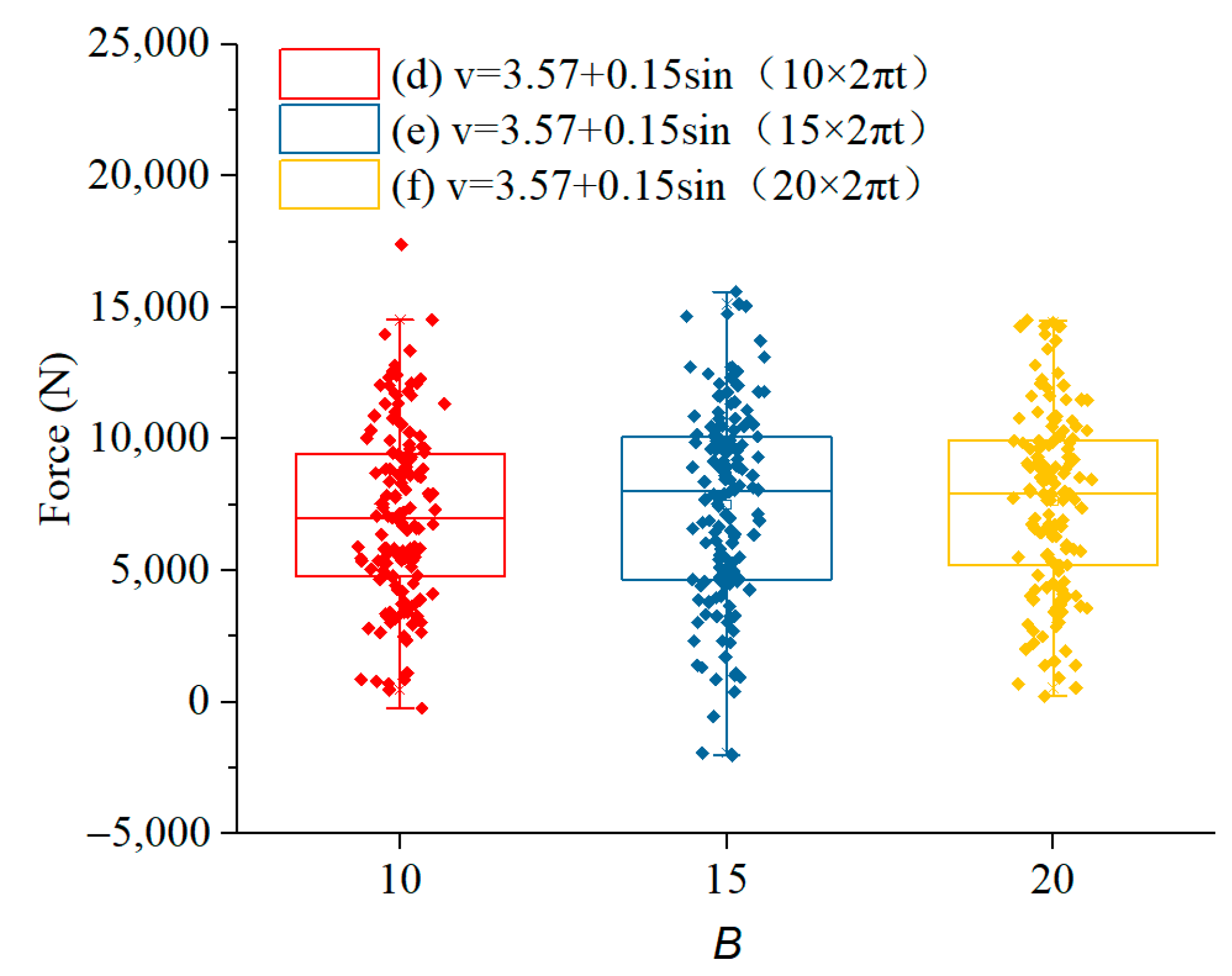

3.2. Influence of Fluid Pulsation

3.3. Optimized Results

4. Field Tests

- (1)

- Well 1: Φ311.2mm PDC bit + Φ245 mm Impactor + Φ244 mm PDM + Φ203 Non- magnetic drill collar (MWD) + Φ309 mm Stabilizer + Φ203 mm Drill collar + Joint (NC61 × NC56) + Φ178 mm Drill collar + 410 × DS55 + Φ139.7 mm Drill pipe;

- (2)

- Well 2: Φ311.2mm PDC bit + Φ245 mm hydraulic impactor + PDM + Joint (731 × NC560) + Φ228.6 mm Drill collar + Φ308 mm Stabilizer + Joint (NC561 × 630) + Φ203 mm Non magnetic drill collar (MWD) + Joint (631 × NC560) + Φ203 mm Drill collar + Joint (NC561 × 520) + Φ139.7 mm Heavy weight drill pipe + Joint (521 × DS550) + Φ139.7 mm Drill pipe.

5. Conclusions

- (1)

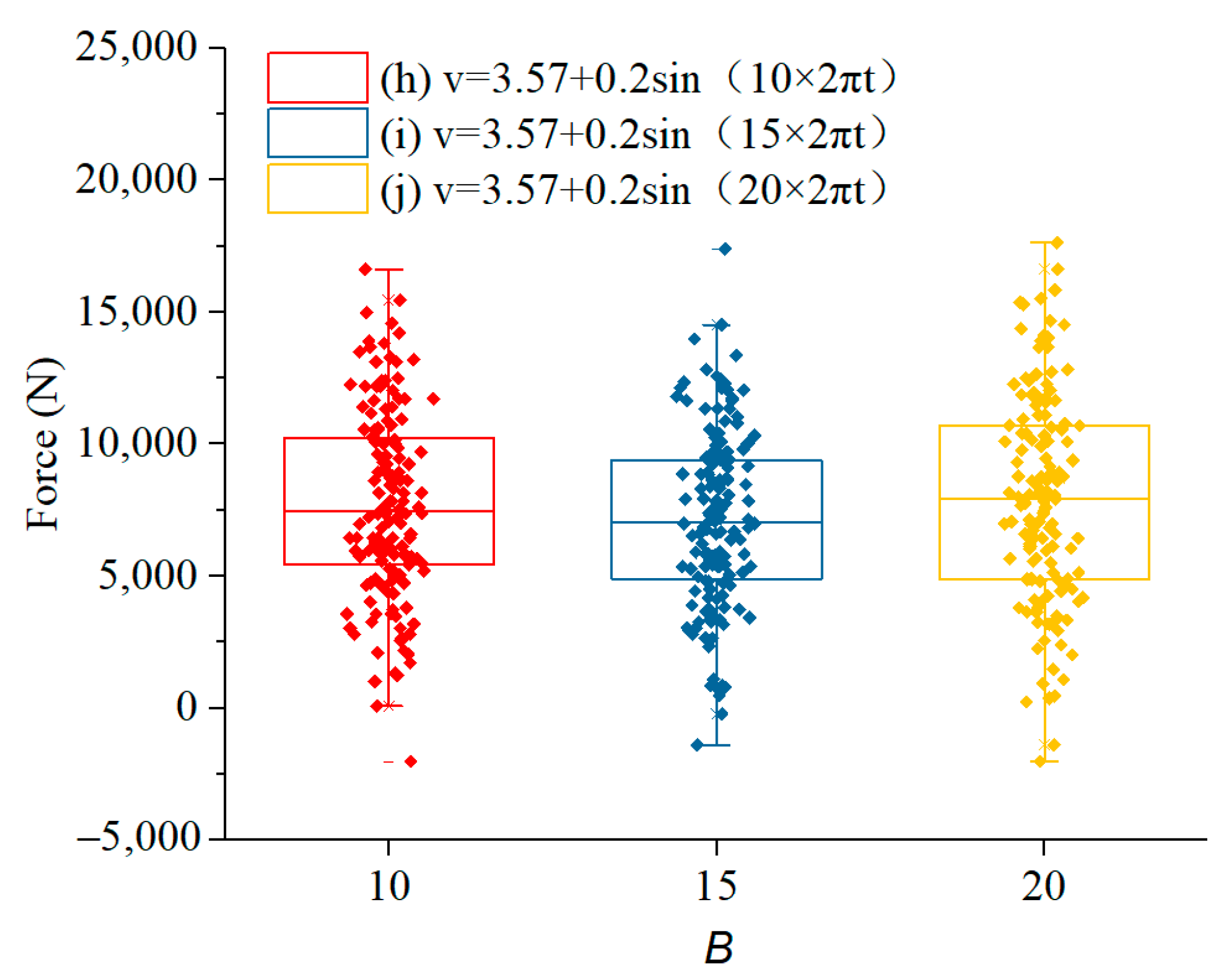

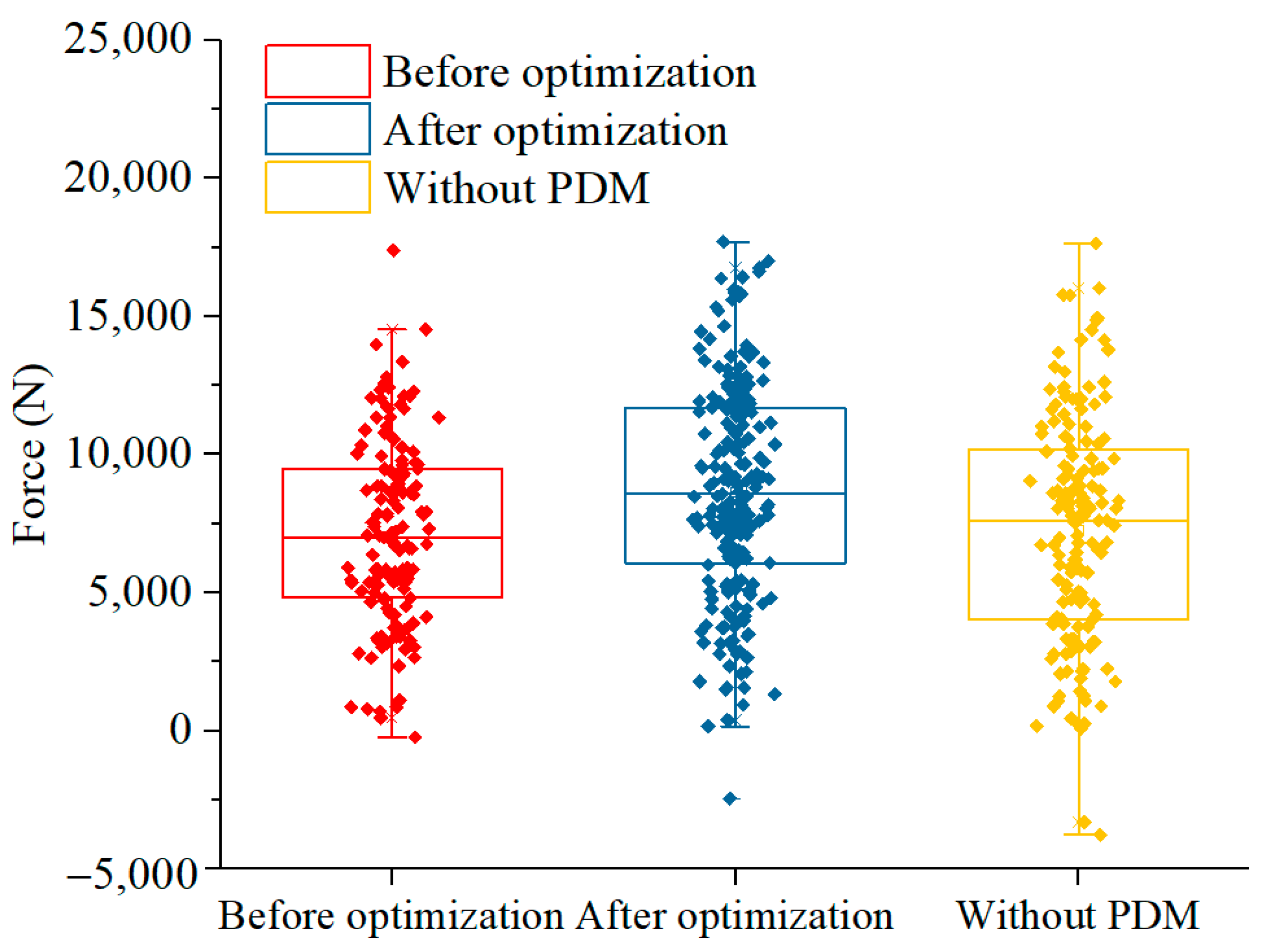

- The fluid pulsation of the PDM has a negative effect on the performance parameters of the hydraulic impactor. As the fluctuation frequency of the inlet fluid increases, the impact values become more scattered, and the median and upper quartile values increase. On the other hand, as the fluctuation amplitude of the inlet fluid increases, there is a tendency for the dispersion of the impact values to decrease, and the median and upper quartile values show a downward trend. The negative effect of inlet fluid fluctuation can be eliminated by optimizing the hydraulic structure of the impactor. The median and upper quartile values of the impact force increase by 28.6% and 24.4%, respectively.

- (2)

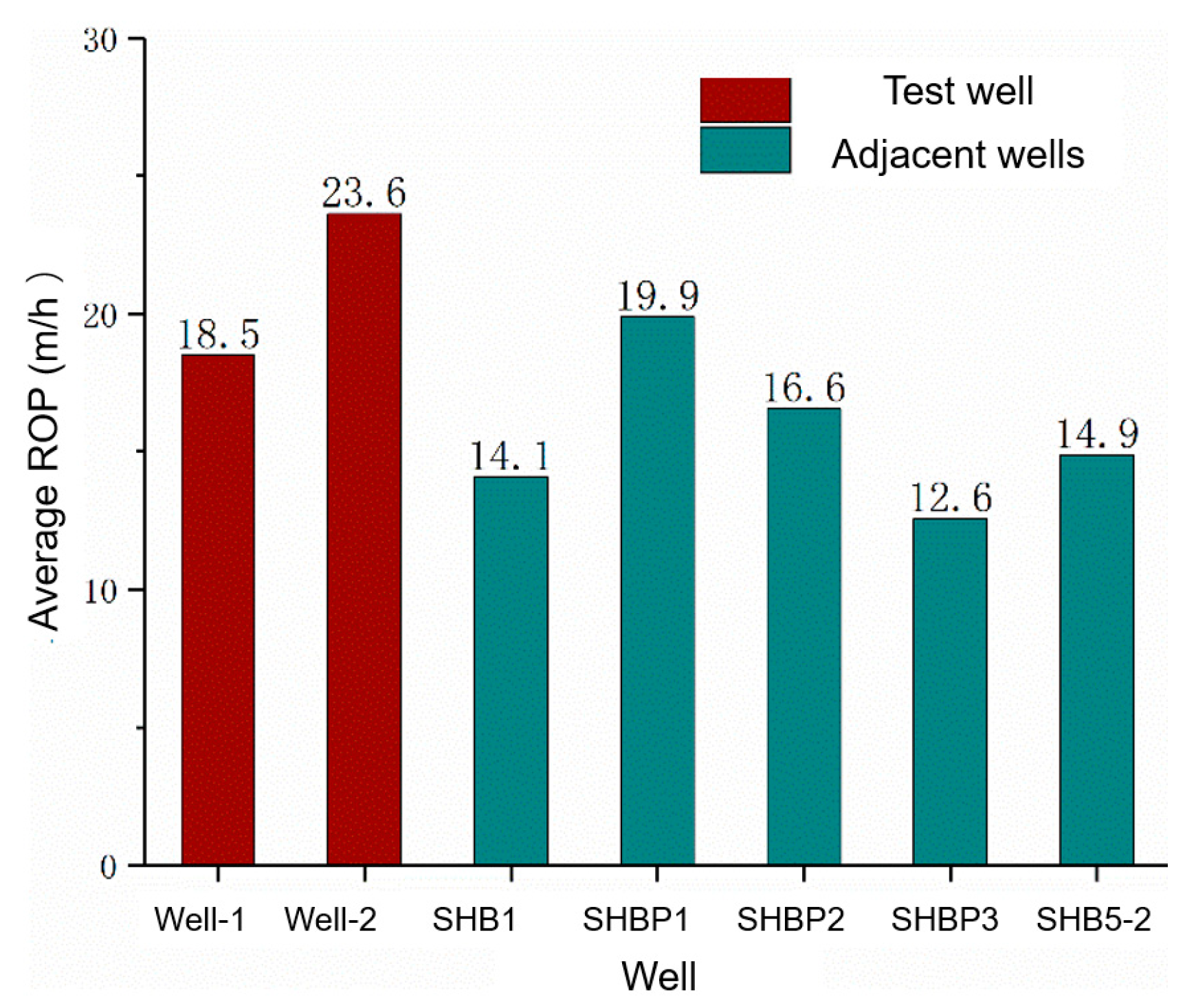

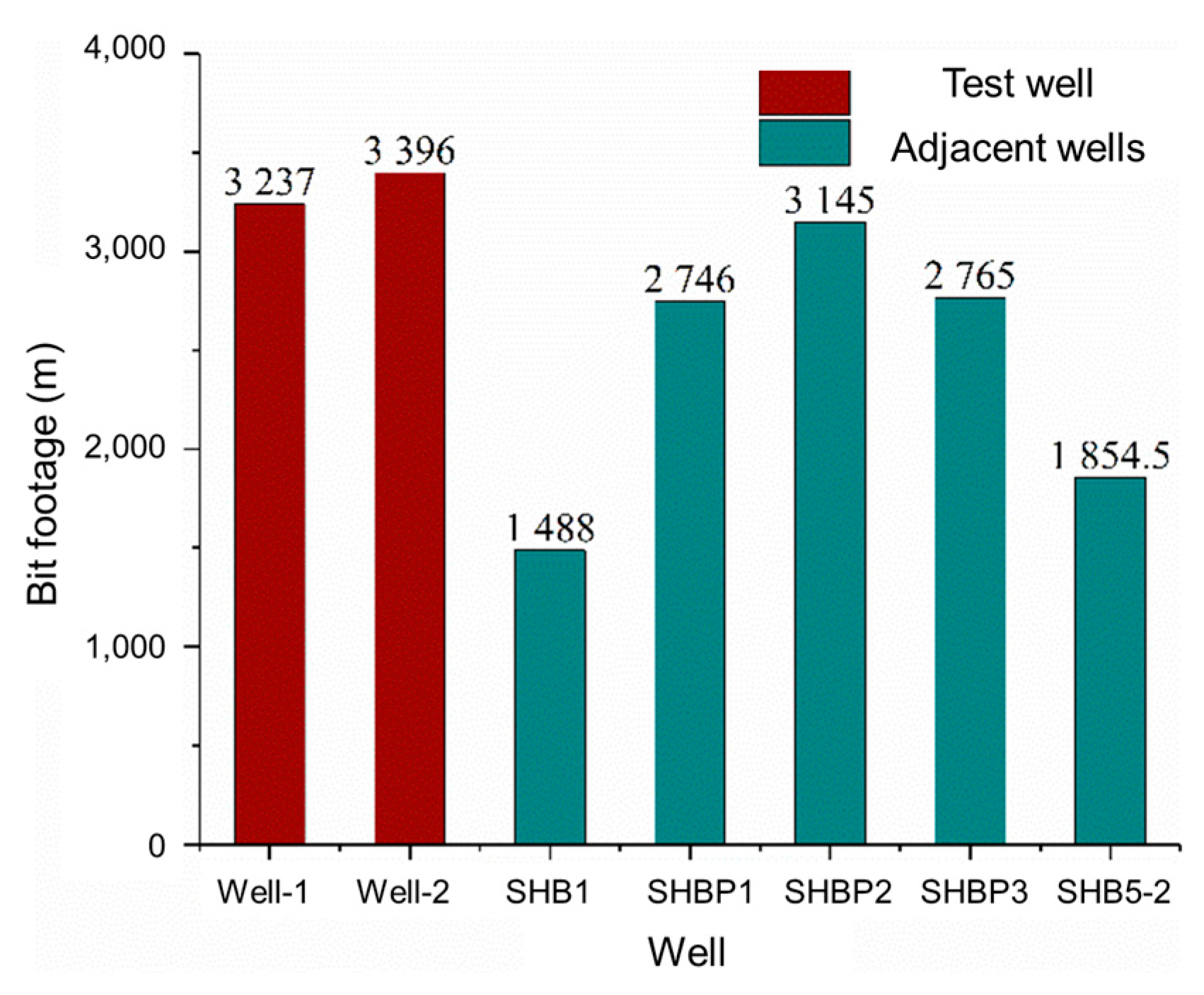

- Two field tests are carried out in 2 wells in the shallow formation. The results indicate that the fluid fluctuation generated in the PDM can restrain the performance of the impactor and that the impact force can be increased by 24.4% to 28.6% through optimization design. The field tests also show that this technique can further improve the drilling efficiency and rotating stability of the polycrystalline diamond compact (PDC) bit, and the rate of penetration (ROP) and bit footage increase by 32.5% and 34.6%, respectively.

- (3)

- In future research, we suggest focusing research on the optimization of bit and drilling parameters with the aim of popularizing and applying this novel technique.

- (4)

- This technique has the potential for application in directional wells. In conventional PDM directional drilling processes, issues like drag and unstable toolface are often encountered. By placing the impactor below the PDM, it can improve drilling speed and drilling stability, thus offering the prospect of reducing drag and stabilizing the toolface.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zou, C.; Yang, Z.; Dong, D.; Zhao, Q.; Chen, Z.; Feng, Y.; Li, J.; Wang, X. Formation, distribution and prospect of unconventional hydrocarbons in source rock strata in China. Earth Sci. 2022, 47, 1517–1533. [Google Scholar]

- Boulesteix, K.; Poyatos-More, M.; Flint, S.; Taylor, K.; Hodgson, D. Transport and deposition of mud in deep-water environments: Processes and stratigraphic implications. Sedimentology 2019, 66, 2894–2925. [Google Scholar] [CrossRef]

- Li, G.; Zhu, R. Progress, challenges and key issues of unconventional oil and gas development of CNPC. China Pet. Explor. 2020, 25, 1–13. [Google Scholar]

- Li, G.; Tian, S.; Zhang, Y. Research progress on key technologies of natural gas hydrate exploitation by cavitation jet drilling of radial wells. Pet. Sci. Bull. 2020, 5, 349–365. [Google Scholar]

- Su, Y.; Lu, B.; Liu, Y.; Zhou, Y.; Liu, X.; Liu, W.; Zang, Y. Status and research suggestions on the drilling and completion technologies for onshore deep and ultra deep wells in China. Oil Drill. Prod. Technol. 2020, 42, 527–542. [Google Scholar]

- Jia, C.; Pang, X. Research processes and main development directions of deep hydrocarbon geological theories. Acta Pet. Sin. 2015, 36, 1457–1469. [Google Scholar]

- Chen, X.; Gao, D.; Guo, G.; Feng, Y. Real-time optimization of drilling parameters based on mechanical specific energy for rotating drilling with positive displacement motor in the hard formation. J. Nat. Gas Sci. Eng. 2016, 35, 686–694. [Google Scholar] [CrossRef]

- Detournay, E.; Defourny, P. A phenomenological model for the drilling action of drag bits. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1992, 29, 13–23. [Google Scholar] [CrossRef]

- Jaime, M.; Zhou, Y.; Lin, J.; Gamwo, I. Finite element modeling of rock cutting and its fragmentation process. Int. J. Rock Mech. Min. Sci. 2015, 80, 137–146. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.; Ni, H.; Wang, X.; Wang, P.; Li, N. Numerical study of the compound vertical and horizontal impact cutting with a single PDC cutter. Energy Rep. 2020, 6, 1520–1527. [Google Scholar] [CrossRef]

- Liu, S.; Ni, H.; Zhang, H.; Wang, Y.; Li, N.; Lyu, J.; Xie, H. Numerical study on optimal impact angle of a single PDC cutter in impact rock cutting. Energy Rep. 2021, 7, 4172–4183. [Google Scholar] [CrossRef]

- Liu, S.; Ni, H.; Jin, Y.; Zhang, H.; Wang, Y.; Huang, B.; Hou, W. Experimental study on drilling efficiency with compound axial and torsional impact load. J. Pet. Sci. Eng. 2022, 219, 111060. [Google Scholar] [CrossRef]

- Deen, C.; Wedel, R.; Nayan, A.; Mathison, S.; Hightower, G. Application of a Torsional Impact Hammer to Improve Drilling Efficiency. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 30 October–2 November 2011. [Google Scholar]

- Xu, Z.; Jin, Y.; Hou, B.; Don, J.; Pang, H.; Lu, Y. Rock Breaking Model Under Dynamic Load with the Application of Torsional and Axial Percussion Hammer. In Proceedings of the International Petroleum Technology Conference, Bangkok, Thailand, 14–16 November 2016. [Google Scholar]

- Staysko, R.; Francis, B.; Cote, B. Fluid Hammer Drives Down Well Costs. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, Amsterdam, The Netherlands, 1–3 March 2011. [Google Scholar]

- Fowell, R.J.; Tecen, O. Studies in Water Jet Assisted Drag Tool Rock Excavation. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1984, 21, A199. [Google Scholar]

- Tutluoglu, L.; Hood, M.; Barton, C. Investigation of the Mechanisms of Water Jet Assistance on The Rock Cutting Process. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1984, 21, 75. [Google Scholar]

- Luiz, F.P.F. A bit-rock interaction model for rotary percussive drilling. Int. J. Rock Mech. Min. Sci. 2011, 48, 827–835. [Google Scholar]

- Zhou, X.; Zhang, J.; Zhang, D. Application of TorkBuster in Yuanba Area. Drill. Prod. Technol. 2012, 35, 15–17. [Google Scholar]

- Peng, M.; Li, S.; Wu, S.; Zhang, Y.; Wang, M.; Wang, K.; Fang, H. Application of Torsional Impact Hammer in Tahe Oil Field. Fault-Block Oil Gas Field 2012, 19, 622–625. [Google Scholar]

- Cheng, R.; Ge, Y.; Wang, H.; Ni, H.; Zhang, H.; Sun, Q. Self-Oscillation Pulsed Percussive Rotary Tool Enhances Drilling Through Hard Igneous Formations. In Proceedings of the IADC/SPE Asia Pacific Drilling Technology Conference and Exhibition, Tianjin, China, 9–11 July 2012. [Google Scholar]

- Li, W.; Wu, B.; Huang, G.; Yu, F.; Ni, H. Study on the main controlling factors and formation mechanism of motion states of bottom hole assembly in slightly-deviated wells. J. Energy Resour. Technol. 2022, 144, 123001. [Google Scholar] [CrossRef]

- Li, W.; Huang, G.; Ni, H.; Yu, F.; Huang, B.; Jiang, W. Experimental study and mechanism analysis of the motion states of bottom hole assembly during rotary drilling. J. Pet. Sci. Eng. 2020, 195, 107859. [Google Scholar] [CrossRef]

| PDM Type | Recommended Flow Rate (L/s) | Rotational Speed (rpm) | Maximum Torque (N·m) | Output Torque (N·m) |

|---|---|---|---|---|

| LZ197x7.0L-6-840 | 7.75–15.50 | 139–277 | 1814 | 1366 |

| 4LZ197x7.0L-840 | 17.00–34.00 | 85–170 | 10,367 | 7340 |

| 5LZ197x7.0L-4-840 | 18.55–37.08 | 79–158 | 6700 | 5022 |

| 5LZ197x7.0L-5-840 | 18.55–37.08 | 79–158 | 8866 | 6277 |

| 5LZ197x7.0L-6-840 | 18.55–37.08 | 79–158 | 10,640 | 7533 |

| 9LZ197x7.0L-4-840 | 21.12–42.23 | 72–145 | 8315 | 6260 |

| 7LZ197x7.0L-5-840 | 20.50–41.00 | 75–150 | 10,197 | 7220 |

| C9LZ197x7.0L-4-1050 | 25.17–50.47 | 67–135 | 12,743 | 9022 |

| PDM Type | Fluctuation Frequency/Hz | PDM Type | Fluctuation Frequency/Hz |

|---|---|---|---|

| LZ197x7.0L-6-840 | 4.6~9.2 | 5LZ197x7.0L-6-840 | 7.9~15.8 |

| 4LZ197x7.0L-840 | 7.1~14.2 | 9LZ197x7.0L-4-840 | 12~24.2 |

| 5LZ197x7.0L-4-840 | 7.9~15.8 | 7LZ197x7.0L-5-840 | 10~20 |

| 5LZ197x7.0L-5-840 | 7.9~15.8 | C9LZ197x7.0L-4-1050 | 11.2~22.5 |

| Flow Factor | Mean Value/(N) | Amplitude/(N) | |

|---|---|---|---|

| A/(m/s) | B/(Hz) | ||

| 0 | 0 | 7181 | 5564 |

| 0.1 | 10 | 7460 | 4664 |

| 0.1 | 15 | 8467 | 5132 |

| 0.1 | 20 | 8542 | 5386 |

| 0.15 | 10 | 7691 | 5033 |

| 0.15 | 15 | 7487 | 5144 |

| 0.15 | 20 | 8811 | 4974 |

| 0.2 | 10 | 7968 | 5470 |

| 0.2 | 15 | 7154 | 4638 |

| 0.2 | 20 | 7782 | 5079 |

| No. | D4/(mm) | L1/(mm) | L2/(mm) |

|---|---|---|---|

| 1 | 62 | 91 | 31 |

| 2 | 62 | 95 | 35 |

| 3 | 62 | 99 | 39 |

| 4 | 66 | 95 | 39 |

| 5 | 66 | 99 | 31 |

| 6 | 66 | 91 | 35 |

| 7 | 70 | 99 | 35 |

| 8 | 70 | 91 | 31 |

| 9 | 70 | 95 | 39 |

| Compare values | 66 | 95 | 35 |

| / | D1/(mm) | D2/(mm) | D3/(mm) | L1/(mm) | D4/(mm) | L2/(mm) | D5/(mm) | Median Force/(N) | Upper Quartile Force/(N) | |

|---|---|---|---|---|---|---|---|---|---|---|

| Before | 32 | 24 | 96 | 95 | 66 | 35 | 43 | 7029 | 9471 | |

| After | 32 | 24 | 96 | 95 | 70 | 39 | 43 | 9038 | 11,785 | |

| Well Section/m | Density/(g·cm−3) | Shear Modulus/GPa | μ | Uniaxial Compressive Strength/MPa |

|---|---|---|---|---|

| 3000~4800 | 2.19 | 81.0 | 0.23 | 40.02 |

| Well | Bit Type | Well Section/m | Density/(g·cm−3) | WOB/kN | RPM/(r·min−1) | Flow Rate/(L·s−1) | Bit Footage/m | Drilling Time/h | ROP/(m·h−1) |

|---|---|---|---|---|---|---|---|---|---|

| Well-1 | SF56H3 | 1104~4341 | 1.27 | 100 | 50 + PDM | 47 | 3237 | 175 | 18.5 |

| Well-2 | SI516MHBPX | 1221~4617 | 1.25 | 80 | 60 + PDM | 55 | 3396 | 143.7 | 23.63 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, H.; Li, W.; Xiao, H.; Wang, Y.; Chen, W.; Liu, W. Study on the Influence of Fluid Pulsation on Hydraulic Impactor Performance in Drilling Engineering. Processes 2023, 11, 2392. https://doi.org/10.3390/pr11082392

Cui H, Li W, Xiao H, Wang Y, Chen W, Liu W. Study on the Influence of Fluid Pulsation on Hydraulic Impactor Performance in Drilling Engineering. Processes. 2023; 11(8):2392. https://doi.org/10.3390/pr11082392

Chicago/Turabian StyleCui, Haibo, Wei Li, Hongbing Xiao, Yufei Wang, Wei Chen, and Wenting Liu. 2023. "Study on the Influence of Fluid Pulsation on Hydraulic Impactor Performance in Drilling Engineering" Processes 11, no. 8: 2392. https://doi.org/10.3390/pr11082392