A Hybrid Ultrasonic Membrane Anaerobic System (UMAS) Development for Palm Oil Mill Effluent (POME) Treatment

Abstract

:1. Introduction

2. Materials and Procedures

2.1. The POME

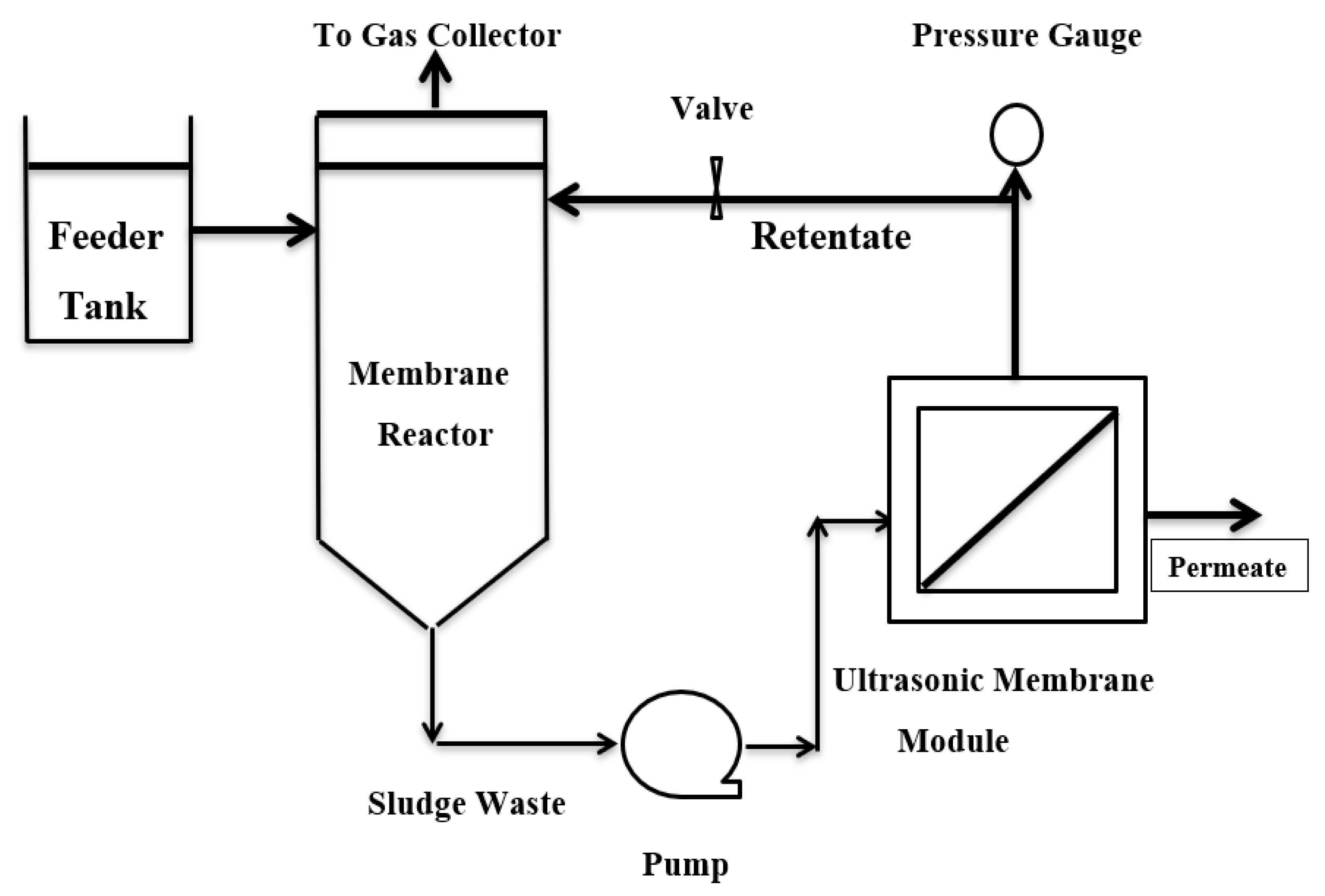

2.2. The Bioreactor Operation

2.3. Mechanisms of Ultrasonic Transducers

2.4. Ultrasonic Cleaner Mechanics

2.5. The Ultrasonic Generator

3. Results and Discussion

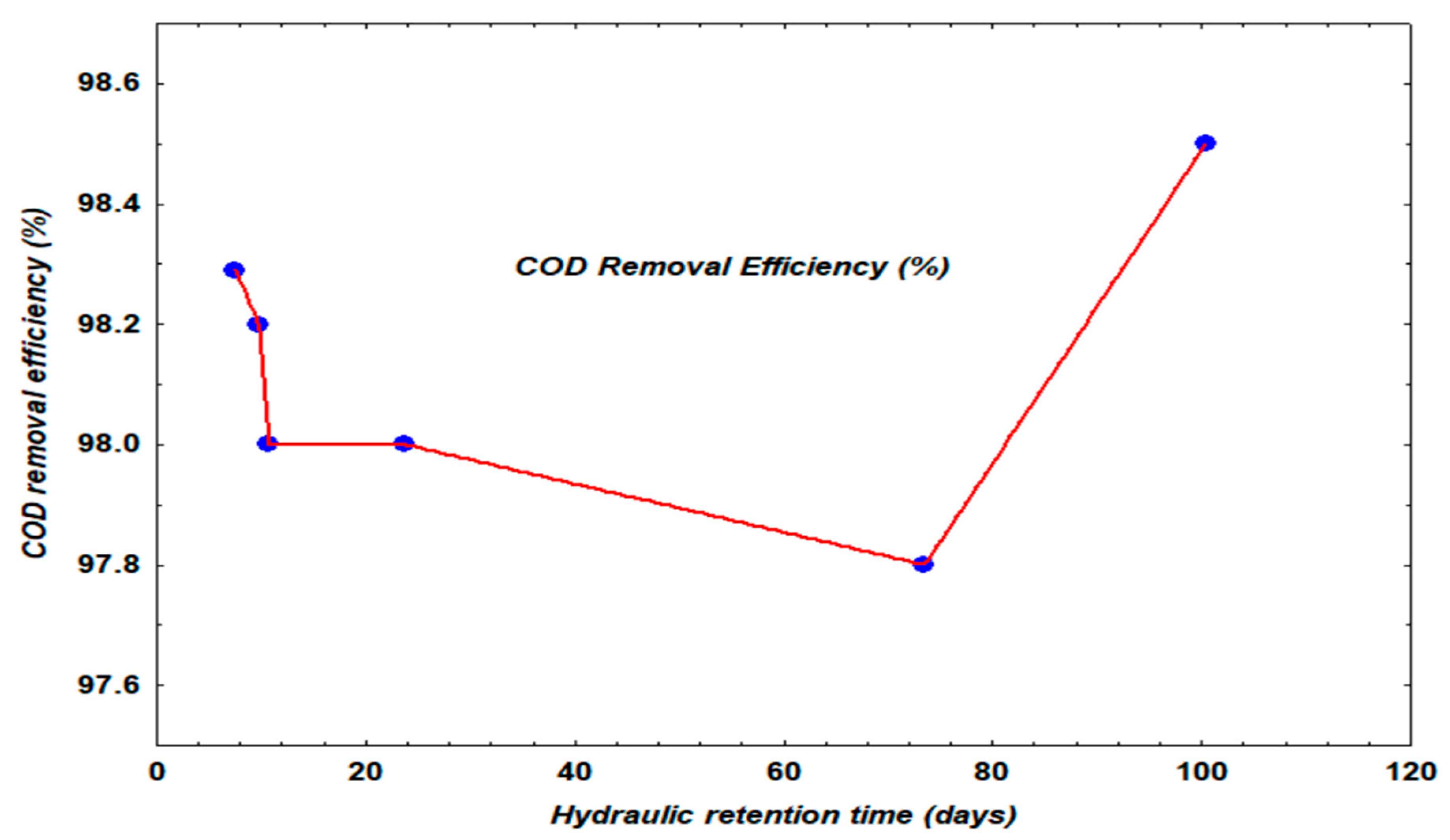

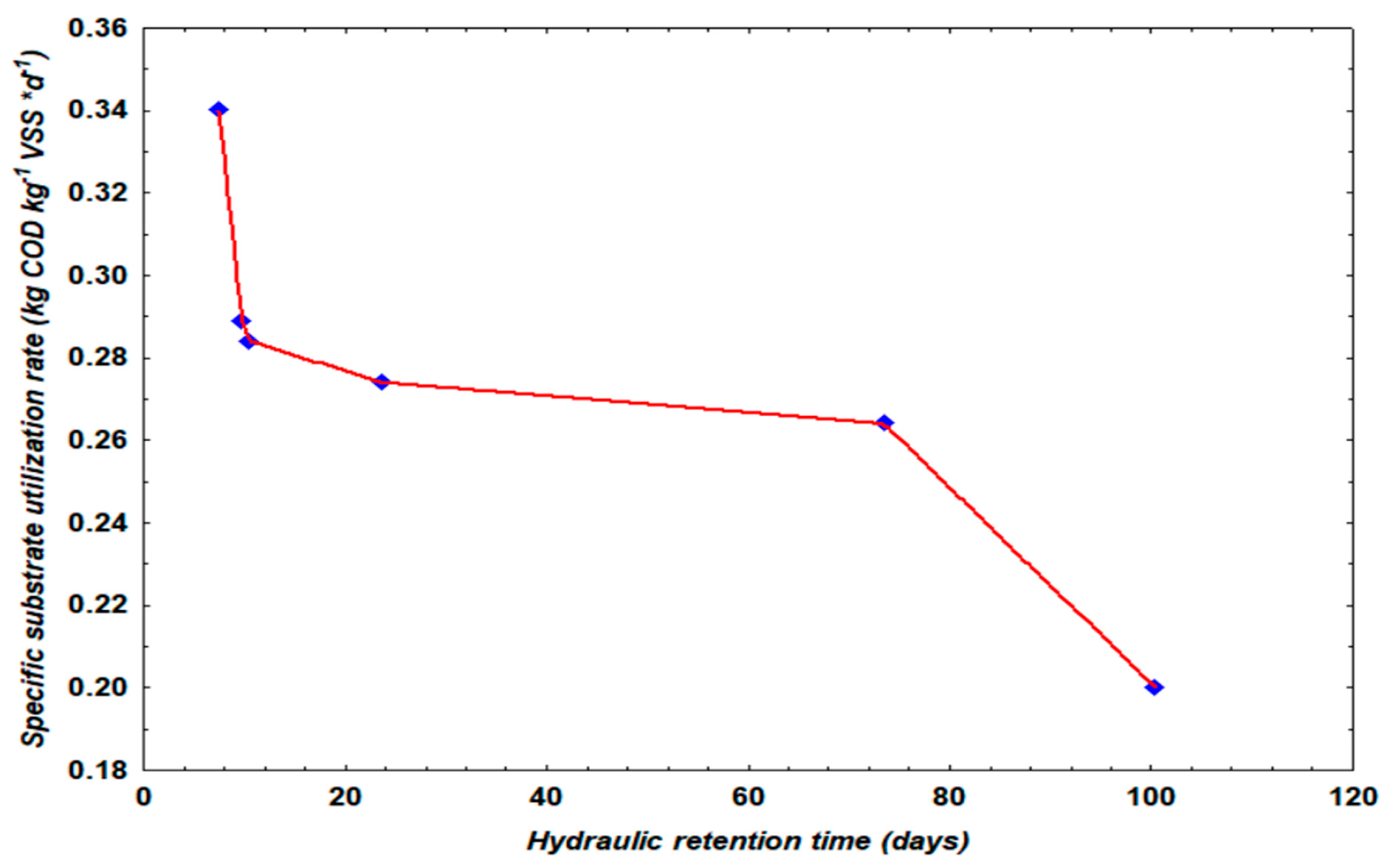

3.1. The Performance of the Semi-Continuous UMAS

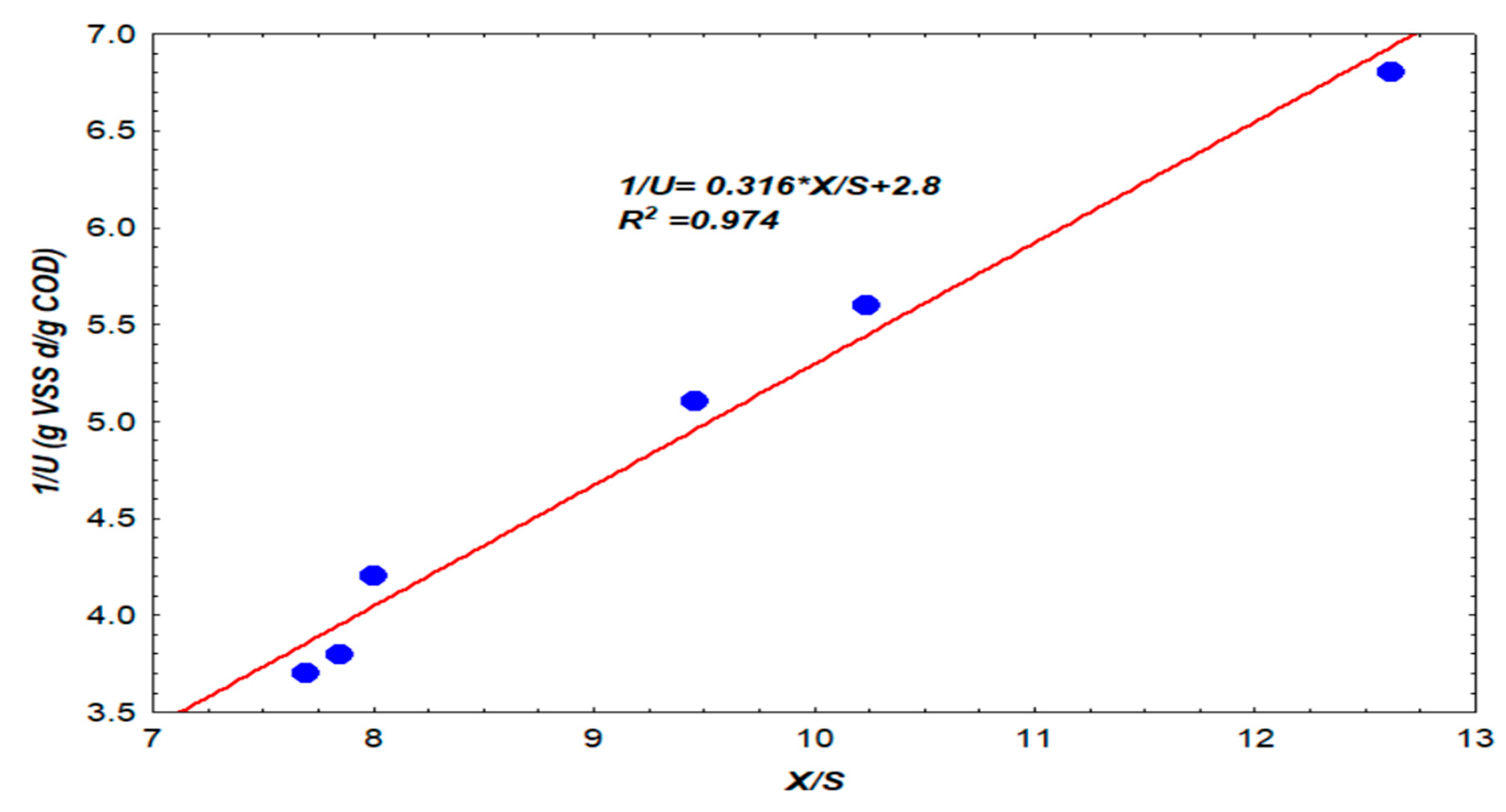

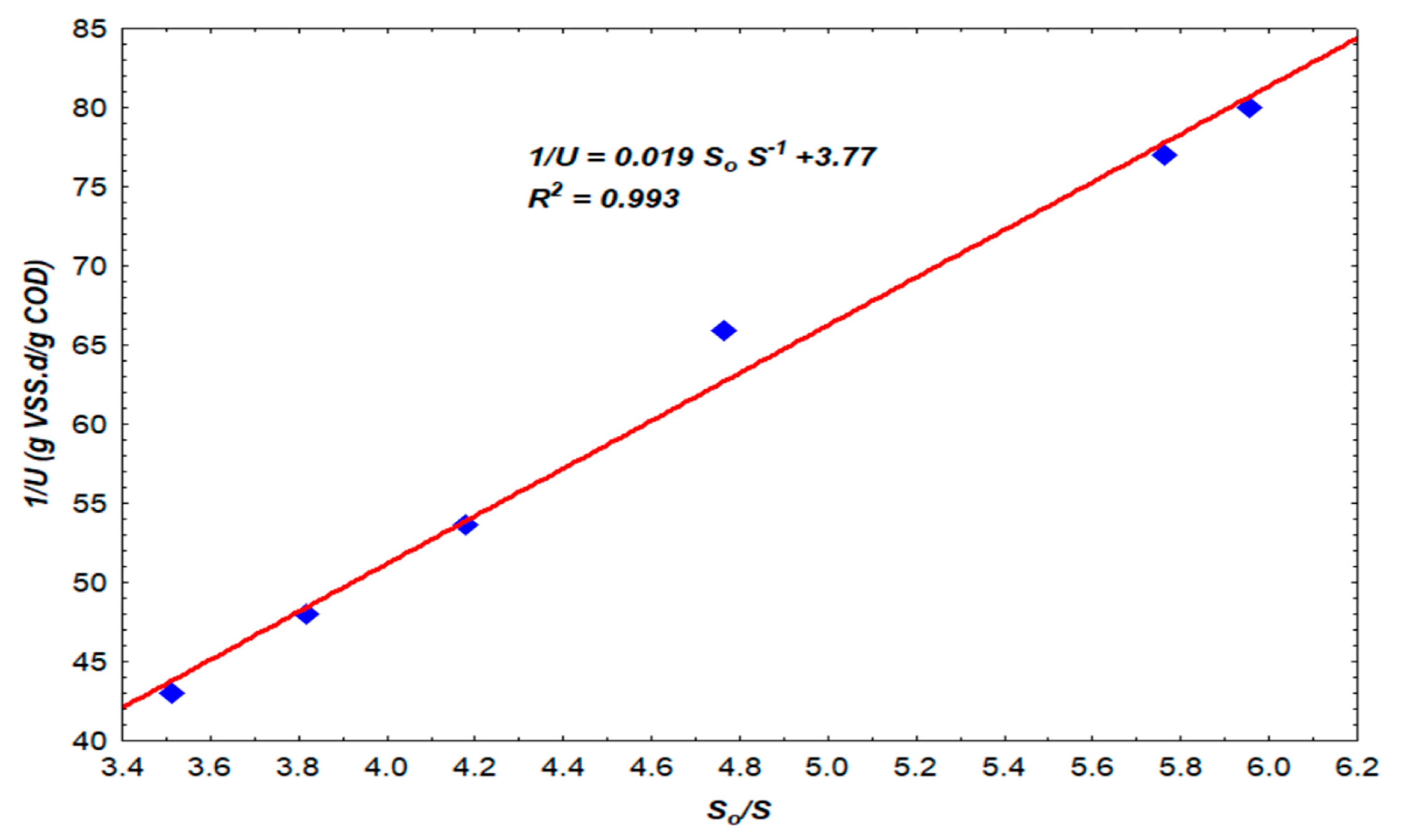

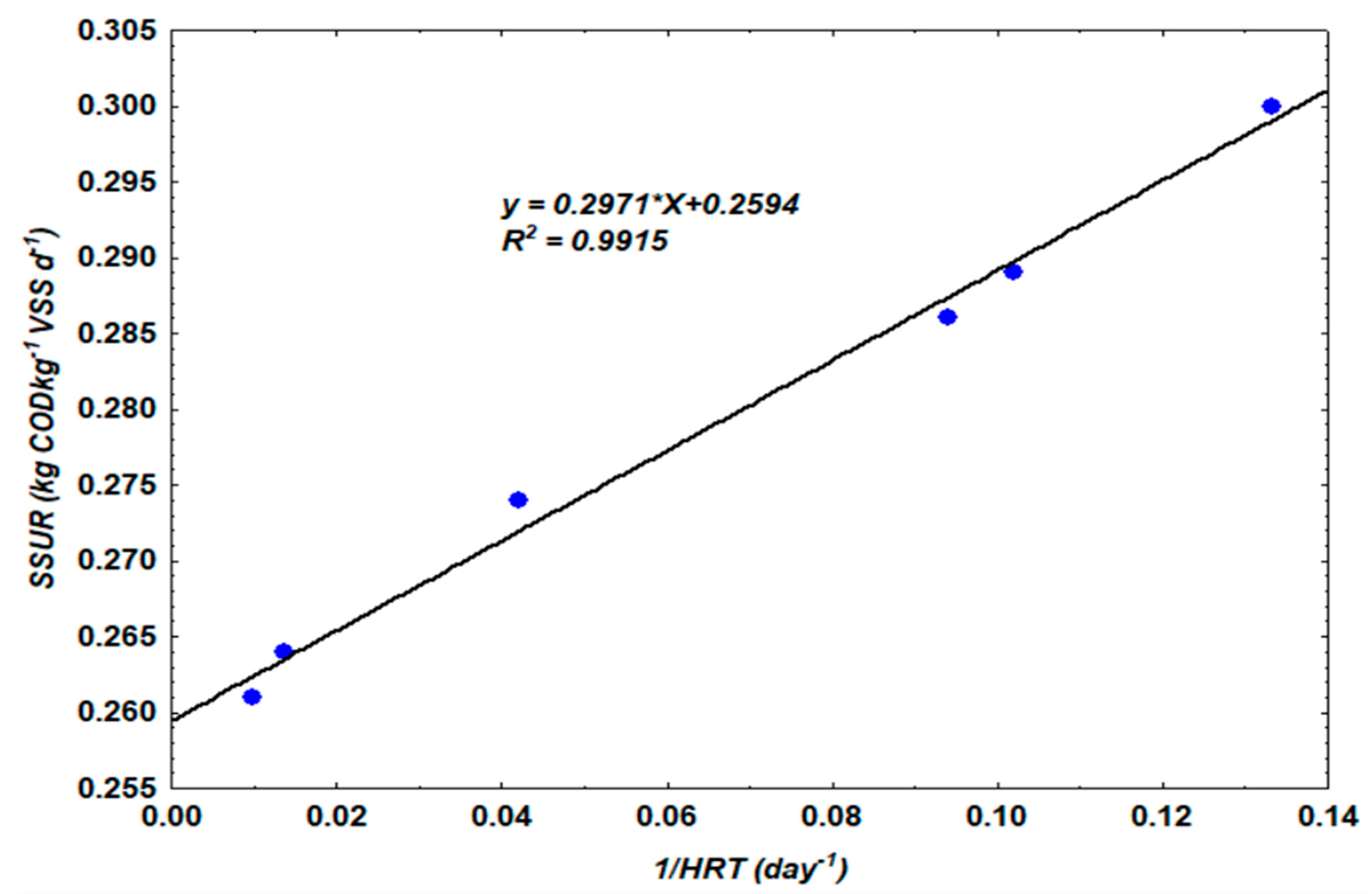

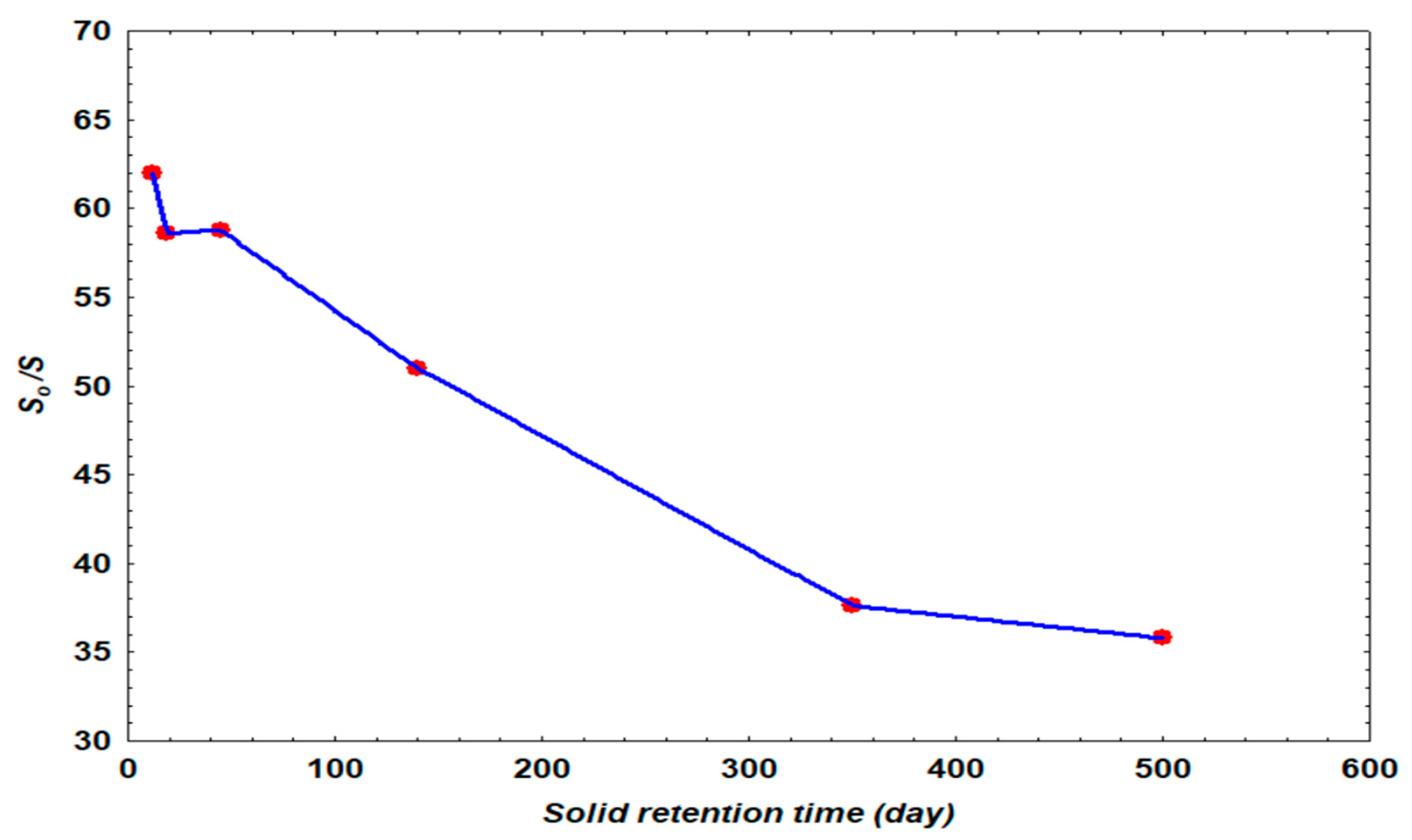

3.2. Bio-Kinetic Coefficients Determination

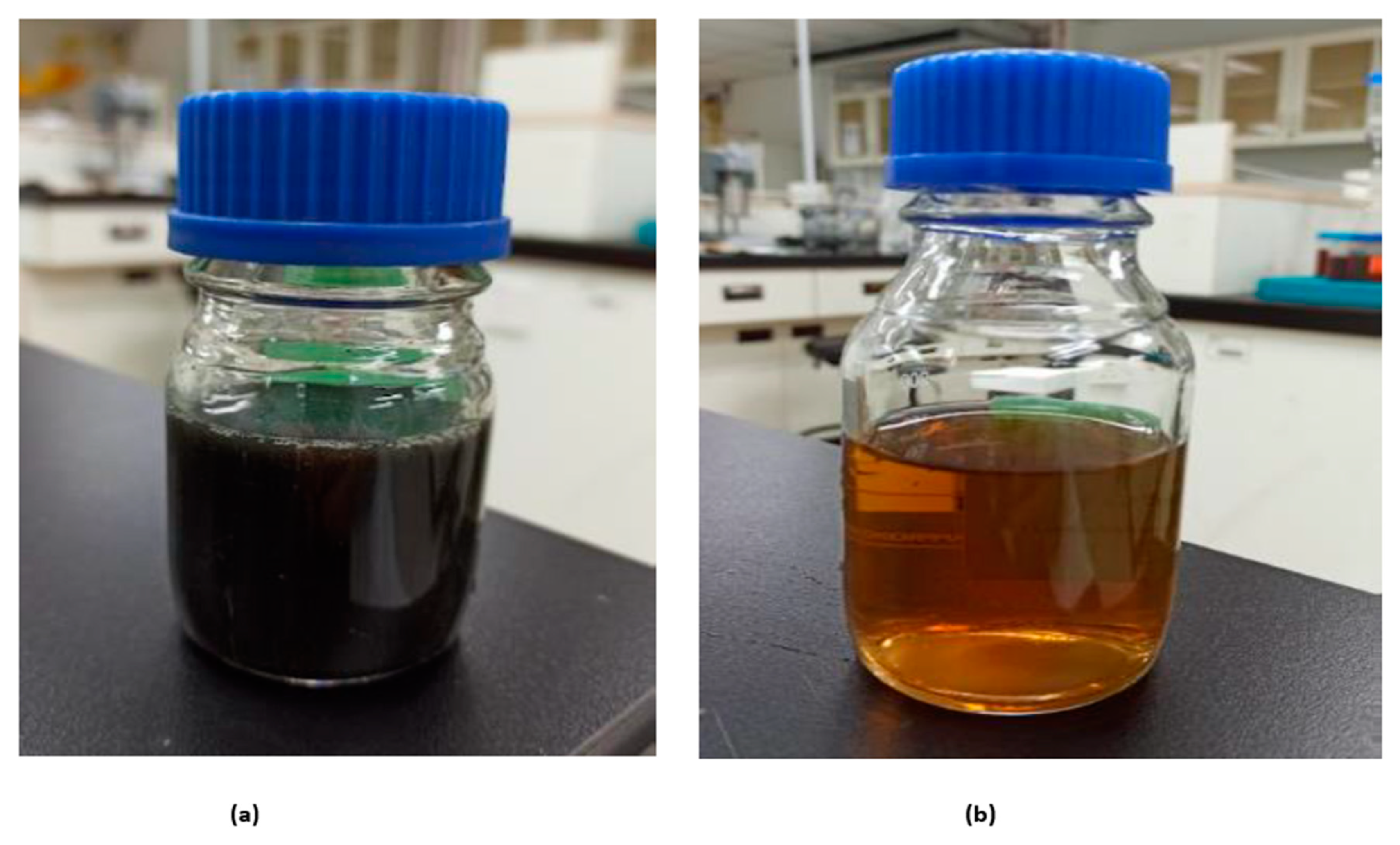

3.3. The Permeate Appearance

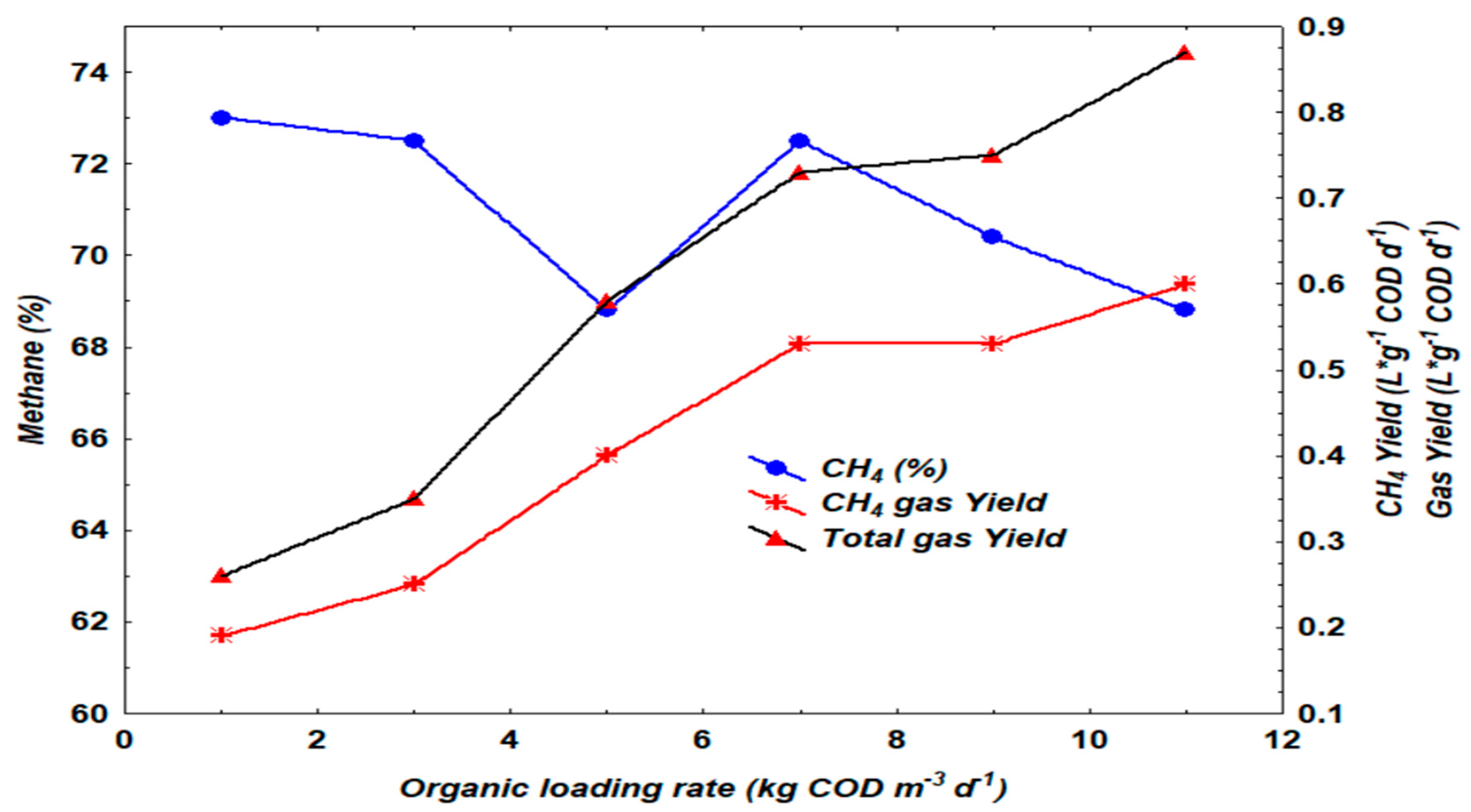

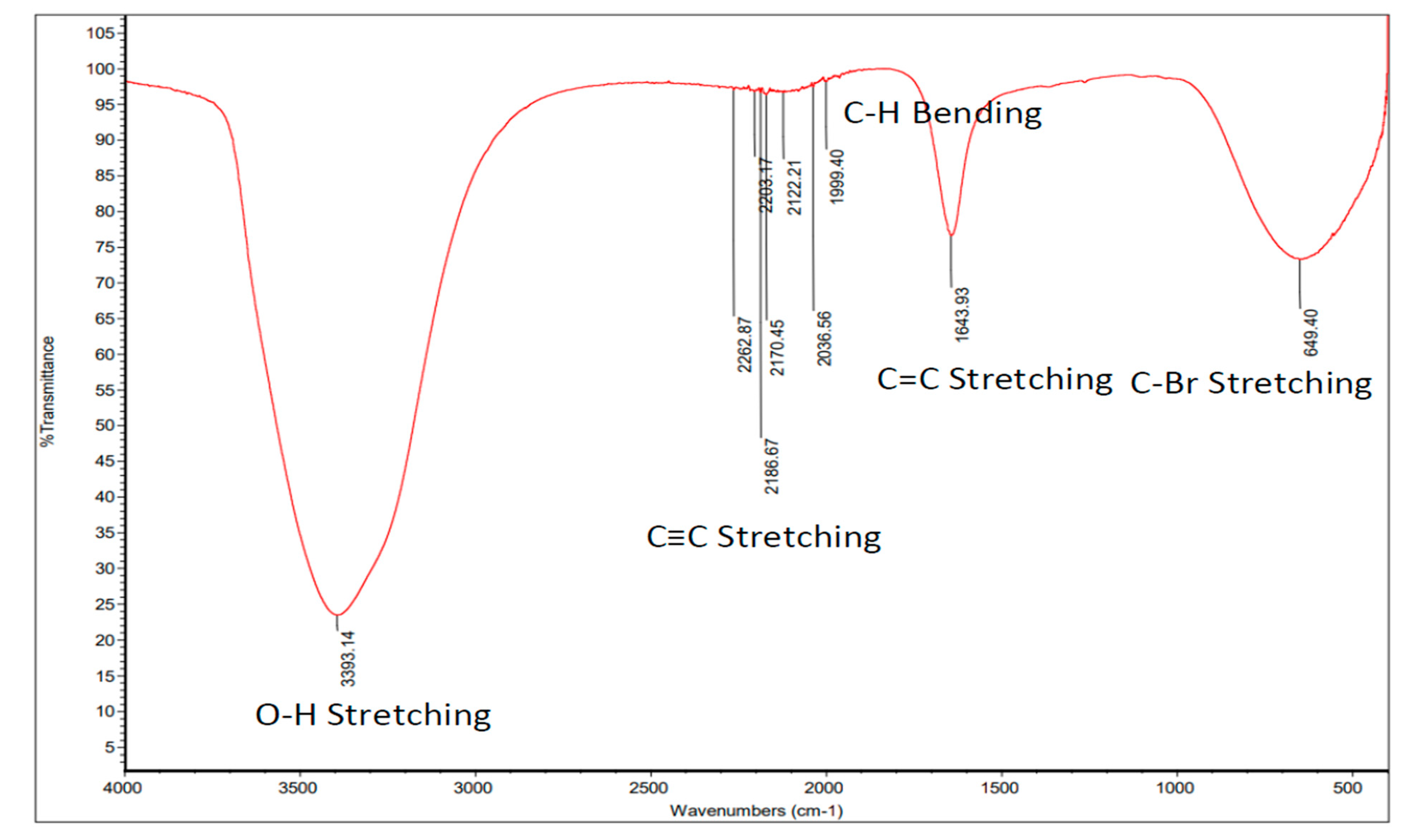

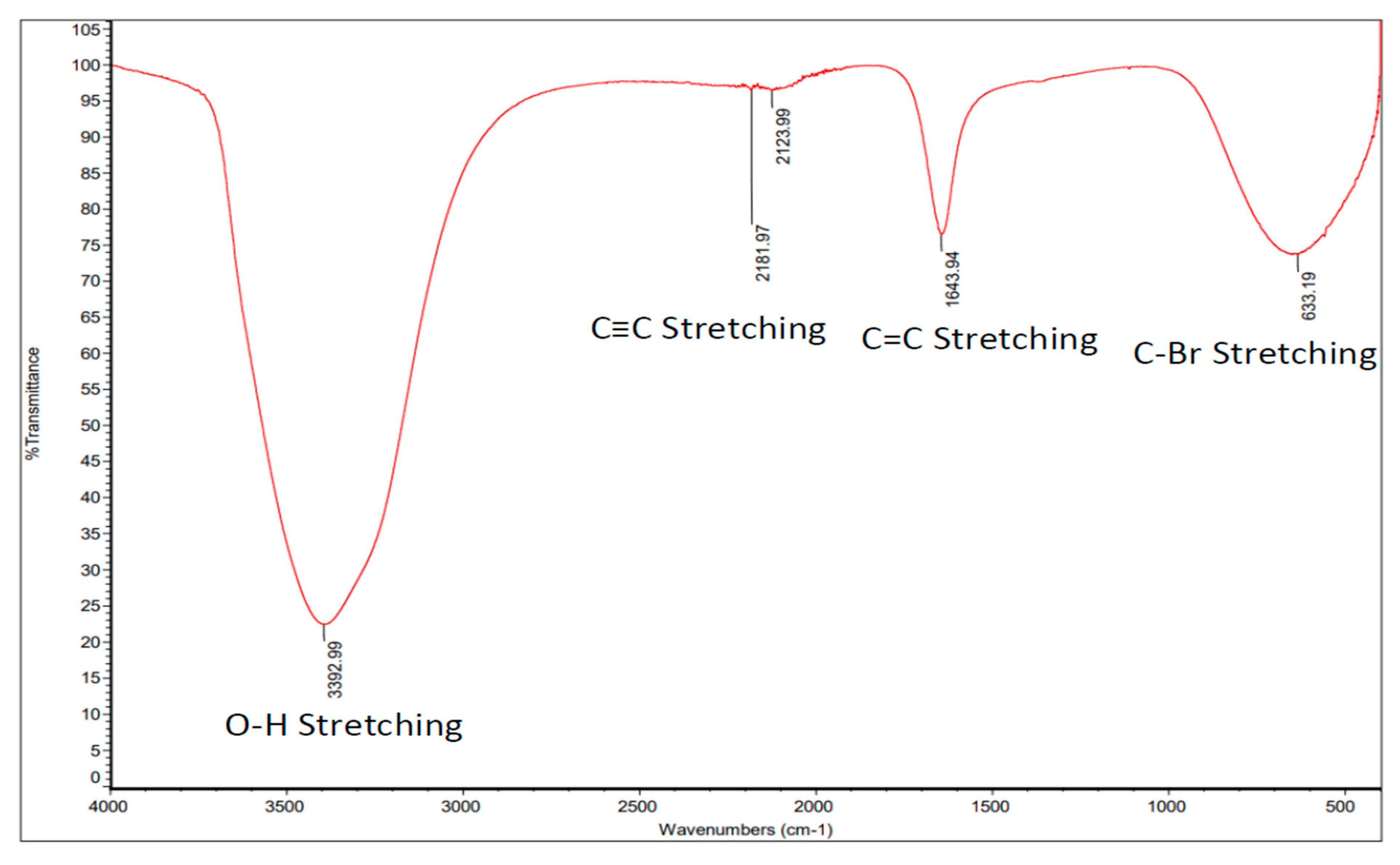

3.4. The Production and Compositions of Natural Gas

3.5. The Production and Compositions of Natural Gas Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| COD | Chemical oxygen demand (mg·L−1) |

| OLR | Organic loading rate (kg·m−3·d−1) |

| CUF | Cross-flow ultra-filtration membrane |

| SS | Steady state |

| SUR | Substrate utilisation rate (kg·m−3·d−1) |

| TSS | Total suspended solid (mg·L−1) |

| MLSS | Mixed liquid suspended solid (mg·L−1) |

| HRT | Hydraulic retention time (day) |

| SRT | Solids retention time (day) |

| SSUR | Specific substrate utilisation rate (kg·COD·kg−1·VSS·d−1) |

| MAS | Membrane Anaerobic System |

| MLVSS | Mixed liquid volatile suspended Solid (mg·L−1) |

| VSS | Volatile suspended solids (mg·L−1) |

| MWCO | Molecular weight Cut-Off |

| BLR | Biological loading rate |

| U | Specific substrate utilisation rate (SSUR) (g·CODg−1·VSS·d−1) |

| Umax | Specific substrate utilisation rate (SSUR) (g·CODg−1·VSS·d−1) |

| S | Effluent substrate concentration (mg·L−1) |

| So | Influent substrate concentration (mg·L−1) |

| X | Micro-organism concentration (mg·L−1) |

| Maximum specific growth rate (day−1) | |

| k | Maximum substrate utilisation rate (COD·g−1·VSS·day−1) |

| ks | Half velocity coefficient (mg·CODL−1) |

| X | Micro-organism concentration (mg·L−1) |

| b | Specific micro-organism decay rate (day−1) |

| Y | growth yield coefficient (gm·VSS·gm−1·COD) |

| T | time |

| a | Proportionality constant (dimensionless) |

| B | Proportionality constant in Contois model (dimensionless) |

References

- Foong, S.Z.; Chong, M.F.; Ng, D.K. Strategies to promote biogas generation and utilisation from palm oil mill effluent. Process Integr. Optim. Sustain. 2021, 5, 175–191. [Google Scholar] [CrossRef]

- Isaiah, O.O.; Blessing, A.G. Environmental Pollutant of Palm Oil Effluent and Its Management in Okitipupa Area of Ondo State, Nigeria. J. Environ. Prot. Sustain. Dev. 2020, 6, 72–81. [Google Scholar]

- Isa, M.H.; Wong, L.-P.; Bashir, M.J.; Shafiq, N.; Kutty, S.R.M.; Farooqi, I.H.; Lee, H.C. Improved anaerobic digestion of palm oil mill effluent and biogas production by ultrasonication pretreatment. Sci. Total Environ. 2020, 722, 137833. [Google Scholar] [CrossRef] [PubMed]

- Zamri, M.; Hasmady, S.; Akhiar, A.; Ideris, F.; Shamsuddin, A.; Mofijur, M.; Fattah, I.R.; Mahlia, T. A comprehensive review on anaerobic digestion of organic fraction of municipal solid waste. Renew. Sustain. Energy Rev. 2021, 137, 110637. [Google Scholar] [CrossRef]

- Som, A.M.; Yahya, A. Kinetics and performance study of ultrasonic-assisted membrane anaerobic system using Monod Model for Palm Oil Mill Effluent (POME) treatment. Clean. Eng. Technol. 2021, 2, 100075. [Google Scholar]

- Li, W.; Ma, H.; He, R.; Ren, X.; Zhou, C. Prospects and application of ultrasound and magnetic fields in the fermentation of rare edible fungi. Ultrason. Sonochemistry 2021, 76, 105613. [Google Scholar] [CrossRef]

- Logan, M.; Visvanathan, C. Management strategies for anaerobic digestate of organic fraction of municipal solid waste: Current status and future prospects. Waste Manag. Res. 2019, 37, 27–39. [Google Scholar] [CrossRef]

- Mansor, U.; Yahya, A.; Shafie, N.; Roslan, Q.; Manshor, N.; Som, A.; Nour, A.; Hassan, Z.; Yunus, R. An overview of anaerobic treatment processes performance treating palm oil mill effluent (POME)-Past, present and future. Adv. Sci. Lett. 2017, 23, 4179–4183. [Google Scholar] [CrossRef]

- Kumar, A.; Samadder, S. Performance evaluation of anaerobic digestion technology for energy recovery from organic fraction of municipal solid waste: A review. Energy 2020, 197, 117–253. [Google Scholar] [CrossRef]

- Kadier, A.; Wang, J.; Chandrasekhar, K.; Abdeshahian, P.; Islam, M.A.; Ghanbari, F.; Bajpai, M.; Katoch, S.S.; Bhagawati, P.B.; Li, H. Performance optimisation of microbial electrolysis cell (MEC) for palm oil mill effluent (POME) wastewater treatment and sustainable Bio-H2 production using response surface methodology (RSM). Int. J. Hydrogen Energy 2022, 47, 15464–15479. [Google Scholar] [CrossRef]

- Bokhary, A.; Leitch, M.; Liao, B. Effect of organic loading rates on the membrane performance of a thermophilic submerged anaerobic membrane bioreactor for primary sludge treatment from a pulp and paper mill. J. Environ. Chem. Eng. 2022, 10, 107–523. [Google Scholar] [CrossRef]

- Abdulsalam, M.; Che Man, H.; Isma Idris, A.; Faezah Yunos, K.; Zainal Abidin, Z. Treatment of palm oil mill effluent using membrane bioreactor: Novel processes and their major drawbacks. Water 2018, 10, 1165. [Google Scholar] [CrossRef]

- Ramadhani, L.; Damayanti, S.; Sudibyo, H.; Budhijanto, W. Kinetics of anaerobic digestion of palm oil mill effluent (POME) in double-stage batch bioreactor with recirculation and fluidisation of microbial immobilisation media. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 316, p. 012071. [Google Scholar]

- Uma, V.; Usmani, Z.; Sharma, M.; Diwan, D.; Sharma, M.; Guo, M.; Tuohy, M.G.; Makatsoris, C.; Zhao, X.; Thakur, V.K. Valorisation of algal biomass to value-added metabolites: Emerging trends and opportunities. Phytochem. Rev. 2022, 1–26. [Google Scholar] [CrossRef]

- Ayodele, T.; Eshalomi, M. African Case Study: Palm Oil and Economic Development in Nigeria and Ghana; Recommendations for the World Bank’s 2010 Palm Oil Strategy; Initiative for Public Policy Analysis: Lagos, Nigeria, 2010; pp. 1–13. [Google Scholar]

- Nasrin, A.B.; Raman, A.A.A.; Bukhari, N.A.; Sukiran, M.A.; Buthiyappan, A.; Subramaniam, V.; Aziz, A.A.; Loh, S.K. A critical analysis on biogas production and utilisation potential from palm oil mill effluent. J. Clean. Prod. 2022, 361, 132040. [Google Scholar] [CrossRef]

- Dineshbabu, G.; Vijayan, D.; Uma, V.S.; Makut, B.B.; Das, D. Microalgal Systems for Integrated Carbon Sequestration from Flue Gas and Wastewater Treatment. In Application of Microalgae in Wastewater Treatment: Volume 2: Biorefinery Approaches of Wastewater Treatment; Springer: Berlin/Heidelberg, Germany, 2019; pp. 339–370. [Google Scholar]

- Monod, J. Growth of bacteria cultures. Annu. Rev. Microbial. 1949, 3, 371–394. [Google Scholar] [CrossRef]

- Contois, D.E. Kinetics of bacteria growth: Relationship between pupolation density and space growth rate of continuous cultures. J. Gen Microbiol. 1959, 21, 40–50. [Google Scholar] [CrossRef]

- Chen, Y.R.; Hashimoto, A.G. Substrate Utilization Kinetic Model for Biological Treatment Processes. Biotechnol. Bioeng. 1980, 22, 2081–2095. [Google Scholar] [CrossRef]

- Abdurahman, N.; Rosli, Y.; Azhari, N. Development of a membrane anaerobic system (MAS) for palm oil mill effluent (POME) treatment. J. Desalination 2011, 266, 208–212. [Google Scholar] [CrossRef]

- Pereira, A.H.A. Ultrasonic Cleaning: Overview and State of the Art; ATCP Physical Engineering: San Carlos, Brazil, 2010. [Google Scholar]

- Puskas, W.; Piazza, T. Designer Waveforms. In CleanTech 2000; Witter Publishing/Witter Expositions: Flemington, NJ, USA, 2000. [Google Scholar]

- Paniwnyk, L.; Cobley, A. Ultrasonic Surface Modification of Electronics Materials. Phys. Procedia 2009, 3, 1103–1108. [Google Scholar] [CrossRef]

- Syahin, M.S.; Ghani, W.A.W.A.K.; Loh, S.K. Decolourisation of palm oil mill effluent (POME) treatment technologies: A review. J. Oil Palm Res. 2020, 32, 1–15. [Google Scholar] [CrossRef]

- Fakhru’l-Razi, A.; Noor, M. Treatment of palm oil effluent (POME) with the membrane anaerobic system (MAS). Water Sci. Technol. 1999, 39, 10–11. [Google Scholar] [CrossRef]

- Sindhu, R.; Binod, P.; Pandey, A. Microbial Poly-3-Hydroxybutyrate and Related Copolymers. In Industrial Biorefineries and White Biotechnology; Elsevier: Amsterdam, The Netherlands, 2015; pp. 575–605. [Google Scholar] [CrossRef]

- Yalcinkaya, F.; Boyraz, E.; Maryska, J.; Kucerova, K. A Review on Membrane Technology and Chemical Surface Modification for the Oily Wastewater Treatment. Materials 2020, 13, 493. [Google Scholar] [CrossRef] [PubMed]

- Yasmeen, Z.H.; Abdurahman, N.H.; Hybat, M.S.; Yunus, R.M. The efficiency of membrane anaerobic system (MAS) in treating sugarcane mill effluent (SCME). IOP Conf. Ser. Mater. Sci. Eng. 2019, 702, 012032. [Google Scholar] [CrossRef]

- Abdurahman, H.N.; Rosli, M.Y.; Azhary, H.N. The Performance Evaluation of Anaerobic Methods for Palm Oil Mill Effluent (POME) Treatment: A Review. In International Perspectives on Water Quality Management and Pollutant Control; InTech: London, UK, 2013. [Google Scholar] [CrossRef]

| Kinetic Model | Equation (1) | Equation (2) |

|---|---|---|

| Monod [18] | ||

| Contois [19] | ||

| Chen & Hashimoto [20] |

| Steady-State (SS) | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| COD feed, mg·L−1 | 65,000 | 74,500 | 76,500 | 79,400 | 83,000 | 88,100 |

| COD permeate, mg·L−1 | 1000 | 1980 | 1500 | 1350 | 1450 | 1500 |

| Gas production, L·d−1 | 248.8 | 320 | 360 | 385 | 440 | 460 |

| Total gas yield, L·g−1·COD·d−1 | 0.26 | 0.35 | 0.58 | 0.73 | 0.75 | 0.87 |

| CH4, % | 73 | 72.5 | 68.8 | 72.5 | 70.4 | 68.8 |

| CH4 yield, L·g−1·COD·d−1 | 0.19 | 0.25 | 0.40 | 0.53 | 0.53 | 0.60 |

| MLSS, mg·L−1 | 11,800 | 12,950 | 15,379 | 15,900 | 18,400 | 21,700 |

| MLVSS, mg·L−1 | 8614 | 10,800 | 11,400 | 12,600 | 14,832 | 18,662 |

| VSS, % | 77.40 | 78.60 | 79.50 | 80.80 | 83.00 | 87.00 |

| HRT, d | 100.4 | 73.5 | 23.8 | 10.6 | 9.80 | 7.50 |

| Solid retention time (SRT), d | 500 | 350 | 140 | 44.6 | 18.8 | 12.1 |

| OLR, kg·COD·m−3·d−1 | 1 | 3 | 5 | 7 | 9 | 11 |

| SSUR, kg·COD·kg−1·VSS·d−1 | 0.200 | 0.264 | 0.274 | 0.284 | 0.289 | 0.340 |

| SUR, kg·COD·m−3·d−1 | 0.0430 | 0.9353 | 4.4540 | 6.7501 | 7.8850 | 9.7000 |

| Model | Equation | R2 |

|---|---|---|

| Monod | U−1 = 2025S−1 + 3.61 (kg·COD·kg−1·VSS·d−1) Ks = 498 (mg·COD·L−1) K = 0.350 (g·COD·g−1·VSS·d−1) µmax = 0.259 (d−1) | 99.4% |

| Contois | U−1 = 0.306XS−1 + 2.78 (kg·COD·kg−1·VSS·d−1) B = 0.111 (-) Umax = 0.344 (d−1) ɑ = 0.115 (-) µmax = 0.384 (day−1) K = 0.519 (g·COD·g−1·VSS·d−1) | 99.7% |

| Chen & Hashimoto | U−1 = 0.0190SoS−1 + 3.77 (kg·COD·kg−1·VSS·d−1) K = 0.006 (g·COD·g−1·VSS·d−1) ɑ = 0.006 (-) µmax = 0.277 (d−1) k = 0.374 (g·COD·g−1·VSS·d−1) | 99.5% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdurahman, N.H.; Rosli, Y.M.; Azhari, N.H.; Hayder, G.; Norasyikin, I. A Hybrid Ultrasonic Membrane Anaerobic System (UMAS) Development for Palm Oil Mill Effluent (POME) Treatment. Processes 2023, 11, 2477. https://doi.org/10.3390/pr11082477

Abdurahman NH, Rosli YM, Azhari NH, Hayder G, Norasyikin I. A Hybrid Ultrasonic Membrane Anaerobic System (UMAS) Development for Palm Oil Mill Effluent (POME) Treatment. Processes. 2023; 11(8):2477. https://doi.org/10.3390/pr11082477

Chicago/Turabian StyleAbdurahman, Nour Hamid, Yunus Mohd Rosli, Nour Hamid Azhari, Gasim Hayder, and Ismail Norasyikin. 2023. "A Hybrid Ultrasonic Membrane Anaerobic System (UMAS) Development for Palm Oil Mill Effluent (POME) Treatment" Processes 11, no. 8: 2477. https://doi.org/10.3390/pr11082477

APA StyleAbdurahman, N. H., Rosli, Y. M., Azhari, N. H., Hayder, G., & Norasyikin, I. (2023). A Hybrid Ultrasonic Membrane Anaerobic System (UMAS) Development for Palm Oil Mill Effluent (POME) Treatment. Processes, 11(8), 2477. https://doi.org/10.3390/pr11082477