Prediction Model of Fouling Thickness of Heat Exchanger Based on TA-LSTM Structure

Abstract

:1. Introduction

2. Theoretical Foundations

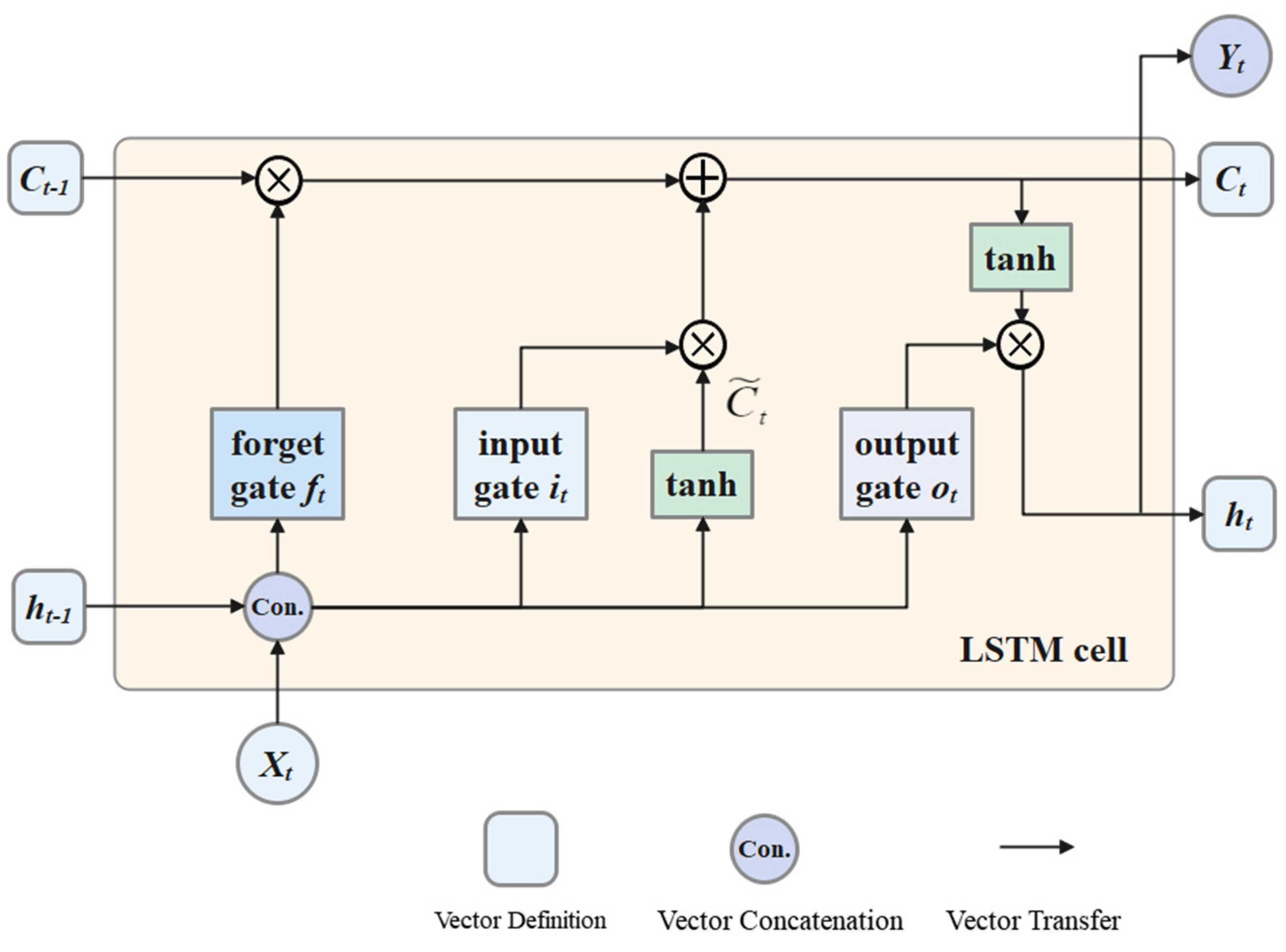

2.1. Long and Short-Term Memory Networks

2.2. Attention Mechanisms

- (1)

- Encoder: converts the input sequence into an intermediate representation, e.g., processed using the LSTM model.

- (2)

- Calculate attention weights: given the current decoder state and intermediate representations, calculates the weights or distributions for each input element, indicating the degree of importance.

- (3)

- Weighted summation: weighted summation of intermediate representations based on attention weights to obtain weighted information.

- (4)

- Decoder: generates the current output based on the weighting information as well as the previous memory, while updating the decoder status and previous memory.

- (5)

- Repeat steps two through four until the complete output sequence is generated.

2.3. Two-Layer LSTM Neural Network

3. Introduction to the Model

- (1)

- The input sequence is processed through the first LSTM layer to produce the hidden state, , and cell state sequences, .

- (2)

- A soft attention mechanism is introduced in the first LSTM layer to compute attention weights and attention up and down vectors.

- (3)

- The attention up and down vectors, , are combined with the hidden state of the first LSTM layer, , to be merged to get the new hidden state, .

- (4)

- The new hidden state, is used to perform further processing and input the second LSTM layer.

- (5)

- Further operations are performed in the second LSTM layer to obtain the final hidden state sequence, and the cell state sequence, .

- (6)

- Predictions are obtained by the final sequence of hidden states, .

4. Experimentation

4.1. Subjects and Samples

4.2. Experimental Platform and Experimental Environment

4.3. Experimental Model Evaluation Metrics

- 1.

- Mean Absolute Percentage Error (MAPE)

- 2.

- Mean Absolute Error (MAE)

- 3.

- Root Mean Square Error (RMSE)

4.4. Experimental Steps

4.5. Analysis of Forecast Results

5. Conclusions

- The paper selects four main factors, namely ambient temperature, air conditioning system inlet pressure, primary heat exchanger outlet pressure, and secondary heat exchanger outlet pressure, which affect the growth of heat exchanger fouling. This multi-feature input method effectively represents the fouling growth environment.

- By introducing the attention mechanism to calculate the time series and adaptively allocate weights based on the input information, the model improves its robustness and generalization ability. This process aligns with the growth process of heat exchanger fouling over time, thereby significantly enhancing the prediction accuracy of the model.

- This model utilizes a two-layer LSTM structure along with an attention mechanism. This design not only enhances the model’s expressive capability but also enables it to capture longer time dependencies, resulting in improved performance.

- When comparing the errors between the predicted values of the three models and the experimental true values, it is observed that the BP model performs the worst, followed by the LSTM model, and the present model performs the best. The predicted value curve of the present model demonstrates the closest fit to the real value curve and exhibits the most stable behavior without abnormal fluctuations. Furthermore, the evaluation indexes (MAPE, MAE, and RMSE) of the TA-LSTM model show an improvement of over 40% compared to those of the common LSTM model. This improvement validates the reliability and stability of the TA-LSTM model, which fulfills the requirements of engineering practice. Consequently, the TA-LSTM model can play a significant role in the field of heat exchanger fouling growth detection and heat exchanger descaling.

6. Prospects and Challenges

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| BP | Back propagation |

| LSTM | Long short-term memory |

| TA-LSTM | Time-aware long short-term memory |

| Forget gate | |

| Input gate | |

| Output gate | |

| Input vector at the current moment | |

| Hidden state at the current moment | |

| New hidden state | |

| Final hidden state | |

| Current cell status | |

| New candidate cell states | |

| Final cell state | |

| The hidden state of the previous moment | |

| The state of the cell at the previous moment | |

| Weight matrix of forget gate | |

| Weight matrix of | |

| Weight matrix of | |

| Output gate matrix for | |

| Bias vector of forget gate | |

| Bias vector of the input gate | |

| Bias matrix | |

| Bias vector of the output gate | |

| σ | Sigmoid activation function |

| tanh | Hyperbolic tangent activation function |

| HAM | Hard attention mechanism |

| SAM | Soft attention mechanism |

| MAPE | Mean absolute percentage error |

| MAE | Mean absolute error |

| RMSE | Root mean square error |

References

- Liu, J. A review of research on the current status and future trend of heat exchanger development. China Equip. Eng. 2022, 510, 261–263. [Google Scholar]

- Hu, H.; Zhang, L.; Huang, W.; Li, G. Classification and development trend of automotive heat exchanger. Automot. Eng. 2015, 3, 15–17. [Google Scholar] [CrossRef]

- Zhang, X. Development status and future development trend of heat exchanger industry. Mass Invest. Guide 2019, 1–5. [Google Scholar]

- Gao, G.; Zhang, X.; Li, C. Current status of research and development of heat exchanger. Contemp. Chem. Res. 2016, 83–84. [Google Scholar]

- Liu, J. Exploration of future development trend of heat exchanger industry. China Mark. 2016, 3, 61+64. [Google Scholar] [CrossRef]

- Hu, B.; Xia, Z. Development status and outlook of China’s heat exchanger industry. Comput. Prod. Circ. 2017, 12, 1. [Google Scholar]

- Lv, M.; Yang, X.; Zhang, Y.; Zhuang, Y. Analysis of the current situation of heat exchanger and classification application. Contemp. Chem. Ind. 2018, 47, 582–584. [Google Scholar]

- Yin, X.; Chen, Y.; Song, Y. Progress in the study of fouling characteristics in heat exchangers. Chem. Equip. Technol. 2021, 42, 1–6. [Google Scholar]

- Shang, Y.; Cai, X.; Liu, X.; Zhang, J.; Xiao, D.; Ouyang, Z.; Zhang, Y.; Zhang, W. Research on the implementation program of on-line cleaning of heat exchangers. Petrochem. Equip. 2012, 41, 4–7. [Google Scholar]

- Epstein, N. Fouling in Heat Exchangers. In Proceedings of the International Heat Transfer Conference 6, Toronto, ON, Canada, 7–11 August 1978. [Google Scholar] [CrossRef]

- Li, Y. Research on Fouling Growth Characteristics of Direct Sewage Source Heat Pump; Xi’an University of Architecture and Technology: Xi’an, China, 2015. [Google Scholar]

- Garrett-Price, B.A.; Smith, S.A.; Watts, R.L. Industrial Fouling: Problem Characterization, Economic Assessment, and Review of Prevention, Mitigation and Accommodation Techniques; Pacific Northwest National Lab.: Richland, WA, USA, 1984. [Google Scholar]

- Lin, W. Characterization of Enhanced Heat Transfer and Descaling by Pulsating Flow and Wall Vibration; Wuhan University of Technology: Wuhan, China, 2015. [Google Scholar]

- Ibrahim, H.A.H. Fouling in Heat Exchangers; INTECH Open Access Publisher: Vienna, Austria, 2012. [Google Scholar]

- Steinhagen, R.; Steinhagen, H.M.; Maani, K. Problems and costs due to heat exchangers fouling in New Zealand industries. Heat Transf. Eng. 1993, 14, 19–30. [Google Scholar] [CrossRef]

- Yang, L. Preventing heat exchanger fouling and reducing economic losses. Chem. Eng. Equip. 2009, 69–71. [Google Scholar]

- Wu, Y. Electromagnetic Field Analysis and Experimental Study of High Frequency Electromagnetic Water Processor; Chongqing University: Chongqing, China, 2012. [Google Scholar]

- Ma, G.; Pan, C.; Xu, J. Experimental study of descaling based on different growth stages of sewage heat exchanger fouling. Renew. Energy 2021, 39, 31–36. [Google Scholar]

- Duan, P. Research on Online Anti-Scaling and Descaling Technology of Heat Exchanger; Zhejiang University: Hangzhou, China, 2008. [Google Scholar]

- Jie, L. Experimental Study on the Performance of Oil-Scaled Heat Exchanger Equipment and Online Descaling Technology; Taiyuan University of Technology: Taiyuan, China, 2011. [Google Scholar]

- Liu, Z.; Tan, C.; Liu, Y.; Li, H.; Cui, B.; Zhang, X. A Study of a Domain-Adaptive LSTM-DNN-Based Method for Remaining Useful Life Prediction of Planetary Gearbox. Processes 2023, 11, 2002. [Google Scholar] [CrossRef]

- Liu, L.; Li, Y. Research on a Photovoltaic Power Prediction Model Based on an IAO-LSTM Optimization Algorithm. Processes 2023, 11, 1957. [Google Scholar] [CrossRef]

- Li, C.; Qu, Y.; Xia, D.; Zhou, H. A comparative study on the performance of improved models for BP networks. Comput. Eng. Appl. 2003, 120–121+132. [Google Scholar]

- Shao, J. Research on the Generation Method of Two-Layer LSTM Image Description Based on Semantic Weighting; Zhengzhou University: Zhengzhou, China, 2022. [Google Scholar]

- Nana, G. Research on Speech Emotion Recognition Based on Two-Layer CNN-LSTM.; Lanzhou University of Technology: Lanzhou, China, 2022. [Google Scholar]

- Hochreiter, S.; Schmidhuber, J. Long short-term memory. Neural Comput. 1997, 9, 1735–1780. [Google Scholar] [CrossRef]

- Kuo, P.; Huang, C. A high precision artificial neural networks model for short-term energy load forecasting. Energies 2018, 11, 213. [Google Scholar] [CrossRef]

- Li, H.; Sun, J.; Liao, X. A Novel Short-term Load Forecasting Model by TCN-LSTM Structure with Attention Mechanism. In Proceedings of the 4th International Conference on Machine Learning, Big Data and Business Intelligence (MLBDBI), Shanghai, China, 28–30 October 2022; pp. 178–182. [Google Scholar]

- Bahdanau, D.; Cho, K.; Bengio, Y. Neural machine translation by joint learning to align and translate [EB/OL]. arXiv 2015, arXiv:1409.0473v7. [Google Scholar]

- Wang, H.; Shi, J.C.; Zhang, Z. Semantic relation extraction by LSTM based on attention mechanism. Comput. Appl. Res. 2018, 35, 1417–1420+1440. [Google Scholar]

- Ma, F.; Tu, Z.; Zhu, S.; Xiang, M.; Sun, Y.; Fang, Q. Research on LSTM water level prediction model based on improved attention mechanism. Jiangxi Water Resour. Sci. Technol. 2023, 49, 162–166+175. [Google Scholar]

- Li, S. Research on stock trend prediction based on two-layer LSTM model. Technol. Innov. 2021, 175, 50–51. [Google Scholar]

- Leng, T. Stock Price Prediction Analysis Based on Attention Mechanism and LSTM Neural Network; Nanjing University of Science and Technology: Nanjing, China, 2021. [Google Scholar]

- Huang, Y. Research on target cost dynamic control of shipbuilding enterprises under earned value method. Small Medium-Sized Enterp. Manag. Technol. (Low. Lunar) 2021, 657, 118–119. [Google Scholar]

- Xie, R.; Hu, J.; Xie, Y. Analysis of market development trend of ship and marine equipment manufacturing industry. Jiangsu Ship 2018, 35, 1–5+8. [Google Scholar]

- Ma, M. Optimization of Contamination Mechanism and Cleaning Process of Aircraft Air Conditioning Heat Exchanger; Civil Aviation University of China: Tianjin, China, 2016. [Google Scholar]

- Wu, G.; Lin, L.; Yang, X.; Qi, H.; Li, D. Study on the effect of scaling on flow heat transfer in shell-and-tube heat exchangers. Contemp. Chem. Ind. 2014, 43, 1386–1388+1391. [Google Scholar]

- Du, L.Y.; Yu, H.B.; Hou, L.G.; Wang, T.J. Improved BP neural network for aircraft heat exchanger fouling thickness prediction. Comput. Simul. 2020, 37, 27–30. [Google Scholar]

- Hong, J.; Tian, W. Prediction in Catalytic Cracking Process Based on Swarm Intelligence Algorithm Optimization of LSTM. Processes 2023, 11, 1454. [Google Scholar] [CrossRef]

- Li, R.; Li, L. Research on wind power prediction based on LSTM neural network. J. Shenyang Eng. Inst. (Nat. Sci. Ed.) 2023, 19, 14–18. [Google Scholar]

- Zhu, R.; Wang, D. Power prediction of photovoltaic system based on LSTM neural network. Electr. Power Technol. Environ. Prot. 2023, 39, 201–206. [Google Scholar]

| Brochure | Serial Number | Environmental Temperature (°C) | Inlet Pressure (Pa) | Initial Temperature (°C) | Secondary Effluent Temperature (°C) | Scale Thickness (mm) |

|---|---|---|---|---|---|---|

| Network training samples | 1 | 35 | 100 | 59 | 38.1 | 0.48 |

| 2 | 25 | 100 | 76 | 53.3 | 0.93 | |

| 3 | 25 | 100 | 97 | 81.0 | 1.12 | |

| 4 | 25 | 30 | 59 | 38.1 | 0.38 | |

| 5 | 35 | 100 | 76 | 53.3 | 0.92 | |

| 6 | 25 | 30 | 97 | 81.0 | 1.08 | |

| 7 | 25 | 60 | 59 | 38.1 | 0.47 | |

| 8 | 25 | 60 | 76 | 53.3 | 0.9 | |

| 9 | 35 | 100 | 97 | 81.0 | 1.07 | |

| 10 | 30 | 30 | 59 | 38.1 | 0.45 | |

| 11 | 30 | 30 | 97 | 81.0 | 1.02 | |

| 12 | 30 | 100 | 59 | 38.1 | 0.5 | |

| 13 | 30 | 100 | 76 | 53.3 | 0.93 | |

| 14 | 30 | 100 | 97 | 81.0 | 1.1 | |

| 15 | 30 | 60 | 59 | 38.1 | 0.45 | |

| 16 | 30 | 60 | 76 | 53.3 | 0.88 | |

| 17 | 35 | 60 | 59 | 38.1 | 0.41 | |

| Sample Network Test | 18 | 35 | 30 | 59 | 38.1 | 0.46 |

| 19 | 35 | 30 | 76 | 53.3 | 0.83 | |

| 20 | 35 | 30 | 97 | 81.0 | 0.99 | |

| 21 | 25 | 100 | 59 | 38.1 | 0.52 | |

| 22 | 25 | 30 | 76 | 53.3 | 0.85 | |

| 23 | 30 | 30 | 76 | 53.3 | 0.91 | |

| 24 | 35 | 60 | 97 | 81.0 | 1.11 | |

| 25 | 35 | 100 | 97 | 81.0 | 1.07 |

| Experimental Environment | Specific Information |

|---|---|

| Operating system | Windows 10 |

| Processing unit | Intel(R) Xeon(R) Platinum 8373C CPU @ 2.60 GHz 2.60 GHz (2 processors) |

| Display card (computer) | NVIDA GeForce RTX 3050 |

| Random access memory (RAM) | 256G |

| Programming language | Python |

| Development environment (computer) | Pytorch |

| Development tool | Pycharm |

| Group | MAPE | RMSE | MAE |

|---|---|---|---|

| BP | 0.07127 | 0.07298 | 0.06157 |

| LSTM | 0.02374 | 0.02049 | 0.01481 |

| TA-LSTM | 0.00231 | 0.00168 | 0.00136 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Sun, L.; Li, H.; Ding, R.; Chen, N. Prediction Model of Fouling Thickness of Heat Exchanger Based on TA-LSTM Structure. Processes 2023, 11, 2594. https://doi.org/10.3390/pr11092594

Wang J, Sun L, Li H, Ding R, Chen N. Prediction Model of Fouling Thickness of Heat Exchanger Based on TA-LSTM Structure. Processes. 2023; 11(9):2594. https://doi.org/10.3390/pr11092594

Chicago/Turabian StyleWang, Jun, Lun Sun, Heng Li, Ruoxi Ding, and Ning Chen. 2023. "Prediction Model of Fouling Thickness of Heat Exchanger Based on TA-LSTM Structure" Processes 11, no. 9: 2594. https://doi.org/10.3390/pr11092594

APA StyleWang, J., Sun, L., Li, H., Ding, R., & Chen, N. (2023). Prediction Model of Fouling Thickness of Heat Exchanger Based on TA-LSTM Structure. Processes, 11(9), 2594. https://doi.org/10.3390/pr11092594