Integration of Renewable-Energy-Based Green Hydrogen into the Energy Future

Abstract

:1. Introduction

- Electricity Generation: Green hydrogen can be used as a clean fuel source in power plants, where it is converted into electricity through fuel cells.

- Transportation: Green hydrogen is suitable as a fuel for vehicles, including automobiles, buses, trains, and trucks. It can be stored in fuel tanks and converted into electricity within the vehicle using fuel cells.

- Industrial Applications: Industries that require hydrogen as a fuel or raw material, such as fertilizer, chemical, and glass manufacturing, can benefit from the use of green hydrogen.

- Aviation: Green hydrogen shows promise as a fuel for aircraft, particularly in hybrid aircraft that utilize a combination of batteries and fuel cells to convert it into electricity.

- Cost: The production of green hydrogen using renewable electricity is currently more expensive compared to other hydrogen production methods. This is primarily due to the costs associated with water analysis, hydrogen storage, and the establishment of renewable energy infrastructure networks.

- Infrastructure: The widespread adoption of green hydrogen requires the development of a new infrastructure for its storage, distribution, and utilization across various applications. Building this infrastructure entails significant investment.

- Efficiency: Fuel cells used for converting hydrogen into electricity are less efficient compared to alternative energy conversion mechanisms. As a result, larger amounts of hydrogen consumption are necessary to generate the same quantity of electricity.

- Safety: The utilization of green hydrogen demands stringent safety measures for storage, transportation, and usage. Specialized techniques are necessary to prevent hydrogen leakage and ensure careful handling.

- Water Analysis Techniques: New technologies with improved efficiency and lower costs are being developed for water analysis, making green hydrogen production more cost competitive.

- Hydrogen Storage Techniques: Advances are being made in the development of storage technologies that offer high efficiency and low costs, such as hydrogen storage through hydride salts.

- Fuel Cells: Ongoing advancements in fuel cell technology aim to enhance efficiency and reduce costs, making the use of green hydrogen more effective for electricity generation and vehicle operation.

- Infrastructure: Investments are being made to establish a new infrastructure for the distribution and utilization of green hydrogen, including renewable energy networks and integration with existing natural gas networks.

- Safety Control: Innovative technologies are being developed to enhance safety measures in the storage, transportation, and utilization of green hydrogen, thereby improving the overall user experience.

- Hydrothermal Gasification: Clean coal technology utilizing hydrothermal gasification to convert coal into hydrogen gas. This hydrogen can then be used as a clean fuel, powering fuel cells to generate electricity.

- High-Temperature Fuel Cells: High-temperature fuel cells making use of the heat generated from used hydrogen fuel to produce electricity, thereby improving fuel efficiency and reducing emissions.

- Energy Storage Systems: Energy storage systems involving the use of batteries to store energy derived from the conversion of hydrogen to electricity. This stored energy can be utilized later to generate electricity as needed.

- Solid Film Fuel Cells: Ultra-clean fuel cells employing solid film technology to efficiently convert hydrogen into electricity while maintaining low emissions.

- Waste-to-Hydrogen Technologies: Waste treatment technologies can be utilized to produce green hydrogen. Organic waste can be converted into hydrogen gas through processes such as biodegradation or pyrolysis.

- Environmental Benefits: Green hydrogen is a clean fuel that does not produce harmful emissions, contributing to environmental health and improved air quality.

- Renewable and Sustainable: Green hydrogen can be produced using renewable energy sources like solar and wind energy, making it a sustainable option for meeting various energy needs.

- High Energy Conversion Efficiency: Green hydrogen is highly efficient at energy conversion. It can be used in fuel cells to generate electricity more efficiently compared to traditional fuels.

- Easy Storage and Transportation: Green hydrogen can be easily stored and transported through existing natural gas networks, making it suitable for use in industries and vehicles.

- High Production Costs: The production of green hydrogen entails high costs, including the expense of producing solar or wind energy and analyzing water to obtain hydrogen.

- Infrastructure Requirements: The use of green hydrogen necessitates the development of infrastructure for storage and transportation. This requires significant investments and ongoing development efforts.

- Safety Concerns: Green hydrogen can be dangerous if mishandled or if there is a leakage. Proper handling and adherence to safety procedures are essential.

- Technological Development: The utilization of green hydrogen relies on advanced technologies for storage, transportation, and usage. Developing these technologies and making them commercially viable requires time and effort.

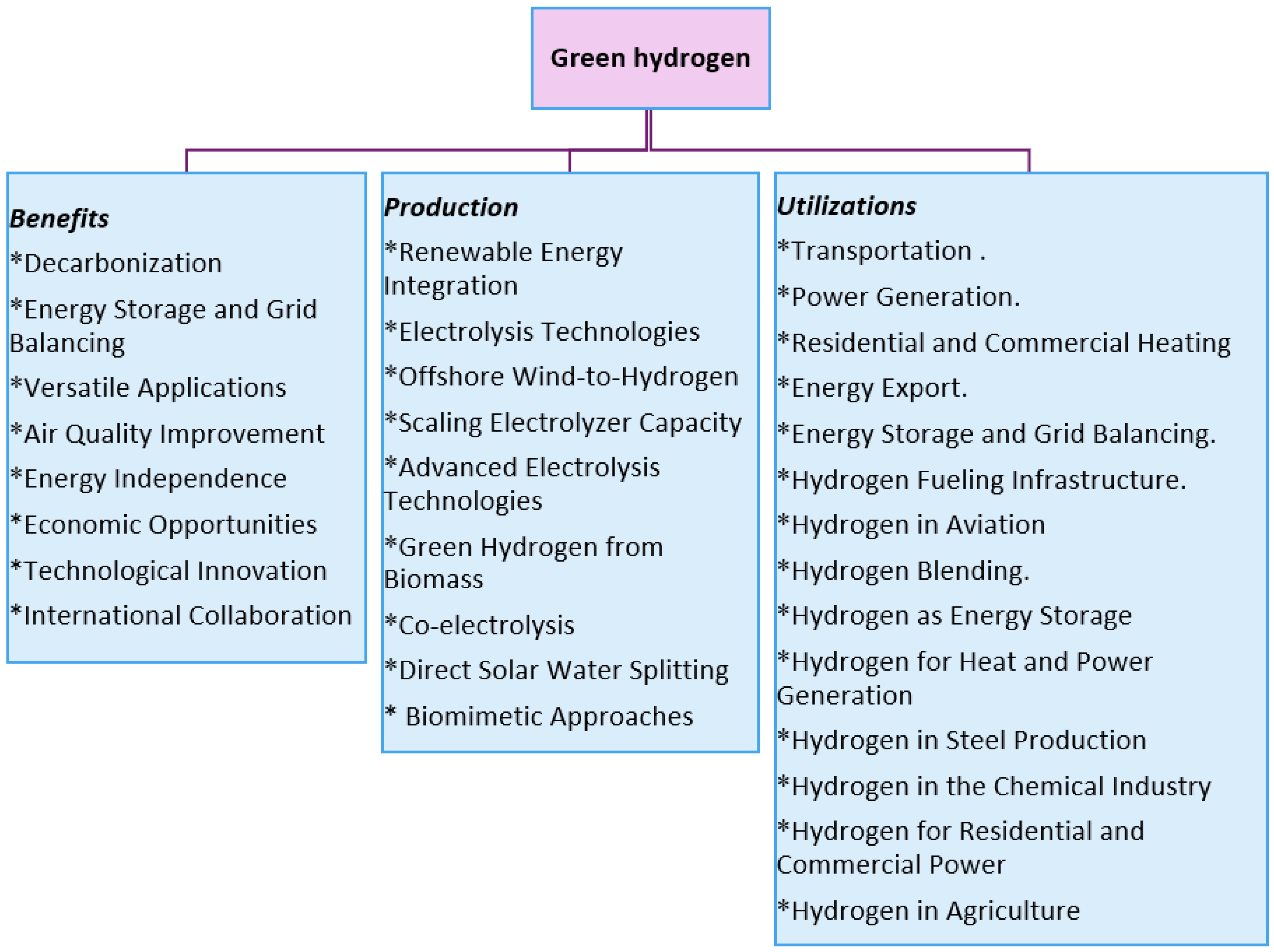

- Highlighting the Importance of Green Hydrogen: The manuscript aims to emphasize the significance of green hydrogen as a key solution in achieving a sustainable energy future. It will shed light on its unique characteristics, including its ability to be produced through renewable energy sources and its potential to decarbonize various sectors.

- Examining the Integration of Renewable Energy Sources: The manuscript will delve into the integration of renewable energy sources, such as solar and wind power, in the production of green hydrogen. It will explore the technological advancements, challenges, and opportunities associated with this integration process.

- Assessing the Environmental and Economic Benefits: The manuscript will evaluate the environmental benefits of green hydrogen, including its contribution to reducing greenhouse gas emissions and mitigating climate change. Furthermore, it will analyze the economic opportunities and market potential associated with the widespread adoption of green hydrogen technologies.

- Exploring Applications and Sectoral Integration: The manuscript will explore the diverse range of applications for green hydrogen across various sectors, such as transportation, industry, and power generation. It will examine how green hydrogen can be effectively integrated into existing energy systems, fostering a sustainable and resilient energy future.

- Identifying Policy, Regulatory, and Technological Implications: The manuscript will discuss the policy frameworks, regulatory mechanisms, and technological advancements required to facilitate the widespread adoption of green hydrogen. It will address the challenges and opportunities associated with scaling up production, storage, and distribution infrastructure.

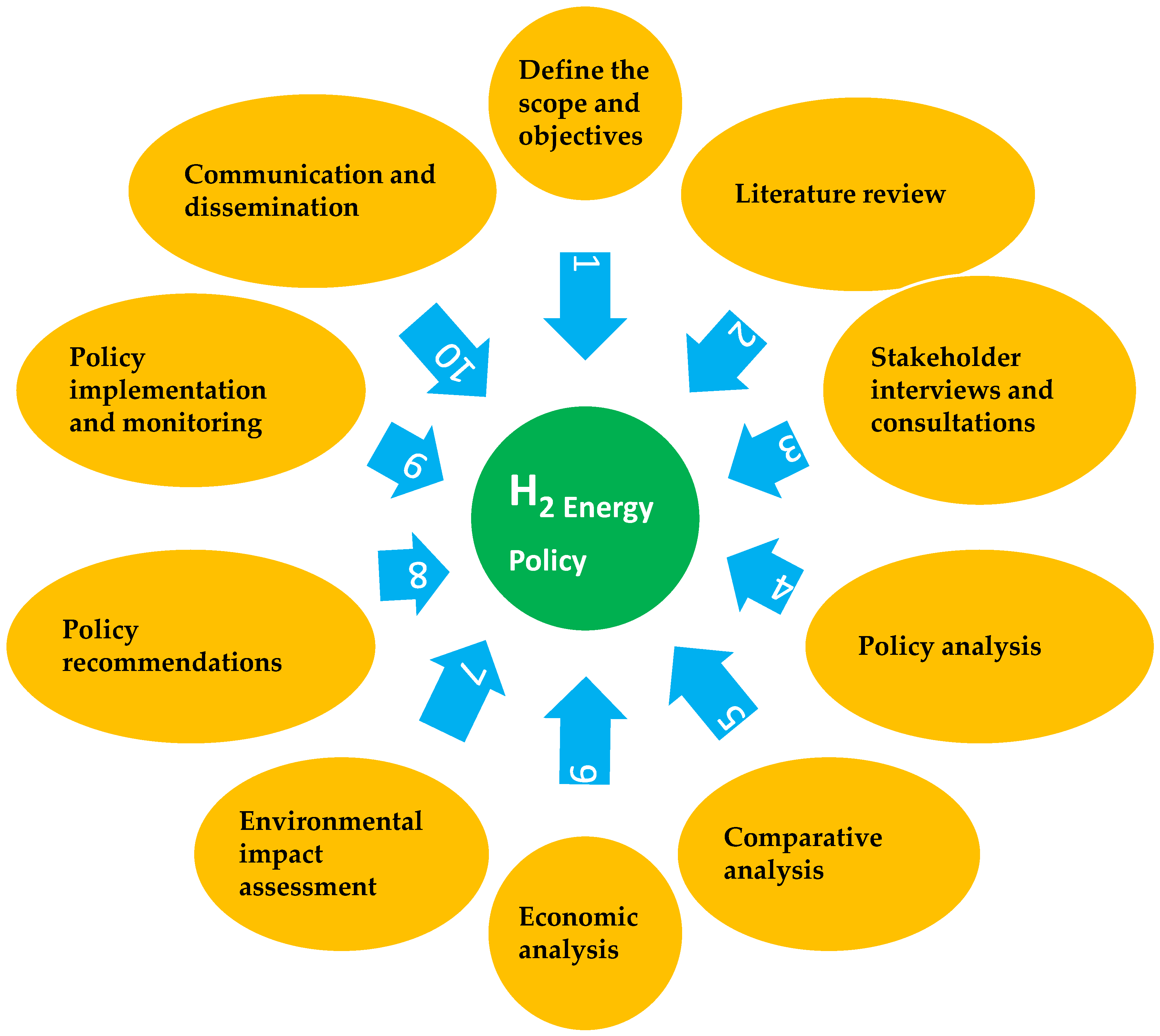

2. Green Hydrogen Energy Policy Review Methodology

2.1. Methodology

2.2. Methods of Hydrogen Production

3. Results of Water Electrolysis

3.1. Chemical Equation

3.2. Electrolysis Techniques

- Alkaline Electrolysis: Alkaline electrolysis is a well-established and widely used method for producing hydrogen through water electrolysis. In this method, a solution of potassium or sodium hydroxide serves as the electrolyte, and the electrodes are typically made of nickel or nickel-plated materials. Alkaline electrolysis operates at relatively high temperatures (60–90 °C) and pressures (1–30 bar). It is commonly employed in large-scale industrial applications due to its relatively low cost and high efficiency. However, the corrosive nature of the electrolyte can lead to electrode degradation over time, limiting its use.

- Polymer Electrolyte Membrane (PEM) Electrolysis: PEM electrolysis is a more advanced method of hydrogen production through water electrolysis. It utilizes a solid polymer electrolyte membrane to separate the anode and cathode compartments, and platinum-based catalysts are employed on both sides of the membrane to facilitate the electrochemical reactions. PEM electrolysis operates at lower temperatures (30–80 °C) and pressures (1–10 bar) compared to alkaline electrolysis. It offers higher efficiency and faster response times. PEM electrolysis is particularly suitable for small-scale applications like fuel cell vehicles or portable power systems due to its compact size and low maintenance requirements.

- Solid Oxide Electrolysis: Solid oxide electrolysis is a relatively new and still-developing method for hydrogen production through water electrolysis. It employs a solid oxide electrolyte to separate the anode and cathode compartments, with a high-temperature ceramic material serving as the electrode. Solid oxide electrolysis operates at high temperatures (600–1000 °C), enabling higher efficiency and faster reaction rates. However, maintaining the high temperature requires significant energy input. Solid oxide electrolysis is still in the experimental stage, but holds potential for offering high efficiency and scalability for large-scale industrial applications.

3.3. Electrolysis Performance Calculation

- Electrolysis Efficiency Calculation: One crucial calculation is determining the efficiency of the electrolysis, which measures the ratio of the energy required to produce a specific quantity of hydrogen to the energy contained within that hydrogen. The efficiency of electrolysis can be computed using the following equation:

- 2.

- Renewable Energy Integration Optimization: Another important aspect is the integration of renewable energy sources, such as solar or wind power, into the green hydrogen production process. Optimization techniques are employed to determine the optimal size and location of renewable energy sources, as well as the optimal operation of the electrolysis and hydrogen storage systems. The goal is to maximize the utilization of renewable energy and minimize costs. For instance, studies conducted by the National Renewable Energy Laboratory (NREL) have shown that the ideal combination of solar and wind power for green hydrogen production varies depending on the location and specific requirements of the hydrogen production process.

- 3.

- Life Cycle Assessment (LCA): Life cycle assessment involves a comprehensive analysis of the environmental impacts associated with a product or process throughout its entire life cycle, from raw material extraction to end-of-life disposal. LCAs are employed to optimize the design and operation of green hydrogen production systems, aiming to minimize environmental impacts and enhance sustainability. For instance, an LCA study conducted by the International Energy Agency (IEA) revealed that the environmental impacts of green hydrogen production depend on various factors, including the electricity source used for electrolysis, the type and source of water employed, and the transportation and storage methods used for hydrogen.

3.4. Green Hydrogen Optimization Techniques

- Techno-Economic Analysis (TEA): Techno-economic analysis (TEA) is a method used to evaluate the economic feasibility of a technology or process, taking into account both technical and economic factors. TEA can be used to optimize the design and operation of green hydrogen production systems, to minimize costs and maximize profitability. For example, TEA can be used to evaluate different electrolysis technologies, renewable energy sources, and hydrogen storage options, and to determine the optimal size and configuration of the production system [31,32].

- Life Cycle Assessment (LCA): Life cycle assessment (LCA) is a method used to evaluate the environmental impacts of a product or process throughout its entire life cycle, from raw material extraction to end-of-life disposal. LCA can be used to optimize the design and operation of green hydrogen production systems, to minimize environmental impacts and maximize sustainability. For example, LCA can be used to evaluate the greenhouse gas emissions, water use, and other environmental impacts of different electrolysis technologies, renewable energy sources, and hydrogen storage options [33,34].

- Supply chain optimization: Supply chain optimization is a method used to optimize the production and distribution of a product, taking into account factors such as cost, efficiency, and environmental impacts. Supply chain optimization can be used to optimize the design and operation of green hydrogen production systems, to minimize costs and minimize environmental impacts. For example, supply chain optimization can be used to determine the optimal location of the production facility, the optimal transportation routes and modes, and the optimal distribution network [35,36].

- Control system optimization: Control system optimization is a method used to optimize the control and operation of a process or system, taking into account factors such as efficiency, safety, and reliability. Control system optimization can be used to optimize the design and operation of green hydrogen production systems, to maximize efficiency and minimize costs. For example, control system optimization can be used to optimize the operation of the electrolysis and hydrogen storage system, to minimize energy consumption and maximize hydrogen production [37].

3.5. Green Hydrogen Production Estimation until 2050

- Europe: The European Union has set a target of producing 40 GW of green hydrogen by 2030, and 10 million tonnes of renewable hydrogen by 2030. According to a report by the Hydrogen Council, Europe could produce up to 800 TWh of hydrogen per year by 2050, with a potential market size of up to EUR 630 billion per year.

- China: China has set a target of producing 5 million tonnes of hydrogen per year by 2025, with a focus on green hydrogen produced from renewable energy sources. According to a report by the International Energy Agency (IEA), China could produce up to 60 million tonnes of hydrogen per year by 2050, with a potential market size of up to USD 150 billion per year.

- United States: The United States has set a target of producing 5 GW of hydrogen by 2030, with a focus on green hydrogen produced from renewable energy sources. According to a report by the Hydrogen Council, the United States could produce up to 25% of the world’s hydrogen demand by 2050, with a potential market size of up to USD 140 billion per year.

- Japan: Japan has set a target of producing 300,000 tonnes of hydrogen per year by 2030, with a focus on green hydrogen produced from renewable energy sources. According to a report by the Hydrogen Council, Japan could produce up to 20% of the world’s hydrogen demand by 2050, with a potential market size of up to USD 80 billion per year.

- Australia: Australia has set a target of producing hydrogen at a cost of less than AUD 2 per kilogram by 2030, with a focus on green hydrogen produced from renewable energy sources. According to a report by the Australian Renewable Energy Agency (ARENA), Australia could produce up to 10% of the world’s hydrogen demand by 2050, with a potential market size of up to AUD11 billion per year.

4. Leading Countries in This Field

4.1. Summary of the Current Production and Utilization of Green Hydrogen

4.1.1. Countries

- Germany: Germany aims to become a global leader in hydrogen technologies. It has set a target of producing 5 gigawatts (GW) of electrolytic hydrogen by 2030 and 10 GW by 2040. The country is investing in research, infrastructure, and projects to support the production and utilization of green hydrogen across various sectors.

- Australia: Australia has significant potential for green hydrogen production due to its abundant renewable energy resources. The country aims to become a major exporter of green hydrogen and has several projects underway. The Australian government has set a target of producing hydrogen at less than AUD 2 per kilogram by 2030, making it cost-competitive with other energy sources.

- Japan: Japan is a major consumer of hydrogen and has ambitious goals for hydrogen utilization. The country aims to have 800,000 fuel cell vehicles and 5.3 million residential fuel cells in operation by 2030. Japan is also investing in hydrogen infrastructure, including hydrogen refueling stations and hydrogen-powered trains.

- Netherlands: The Netherlands has set a target to have 500 megawatts (MW) of electrolyze capacity by 2025 and 3–4 GW by 2030. The country is focusing on developing hydrogen clusters, integrating hydrogen into industrial processes, and establishing hydrogen infrastructure for transport and energy storage.

- United States: The United States is actively promoting the production and utilization of green hydrogen. The Department of Energy has launched the Hydrogen Shot initiative, aiming to reduce the cost of clean hydrogen by 80% to USD 1 per kilogram by 2030. The country has several projects and pilot plants for green hydrogen production, particularly in regions with abundant renewable energy resources like California and the Gulf Coast.

- Chile: Chile has vast renewable energy potential, particularly in solar and wind power. The country aims to become a leading exporter of green hydrogen. It plans to install 5 GW of electrolyze capacity by 2025, and aims to produce the cheapest green hydrogen in the world. Chile is also developing hydrogen-production facilities and exploring export opportunities to countries like Japan, South Korea, and Europe.

- Saudi Arabia: Saudi Arabia, known for its abundant solar resources, is investing in green hydrogen production. The country aims to become a major global player in the green hydrogen market and has plans to develop projects totaling over 4 GW of electrolyze capacity. Saudi Arabia intends to leverage its existing infrastructure and expertise in the energy sector to produce, store, and export green hydrogen.

- South Korea: South Korea has a strong focus on green hydrogen as part of its energy transition strategy. The country aims to produce 5.26 million tons of hydrogen per year by 2040, with a significant portion coming from renewable sources. South Korea is also promoting the use of hydrogen in transportation, industry, and power generation, and is investing in research and development to advance hydrogen technologies.

- India:

- -

- Green Hydrogen Production: India has been focusing on renewable energy deployment and has set a target of 450 GW of renewable energy capacity by 2030. This commitment to renewables provides a strong foundation for green hydrogen production. The government has launched the National Hydrogen Mission, aiming to scale up hydrogen production and promote its use in various sectors.

- -

- Transportation Sector: India is exploring the use of green hydrogen in transportation. The government has plans to develop hydrogen fueling infrastructure and promote the adoption of hydrogen-powered vehicles. Initiatives include the development of hydrogen-powered buses, cars, and two-wheelers, as well as the establishment of hydrogen refueling stations.

- -

- Industrial Applications: Industries in India, such as steel, cement, and chemicals, are exploring the utilization of green hydrogen to decarbonize their operations. Green hydrogen can be used as a reducing agent or heat source, replacing fossil fuels in industrial processes. This transition can significantly reduce greenhouse gas emissions in these sectors.

- Canada:

- -

- Abundant Renewable Resources: Canada possesses vast renewable energy resources, including hydro, wind, and solar power. These resources can be harnessed to produce green hydrogen through electrolysis. Several projects are underway to develop large-scale electrolysis facilities powered by renewable energy, enabling the production of green hydrogen.

- -

- Export Potential: Canada aims to leverage its green hydrogen production capacity for domestic use as well as for export. The country has the advantage of being well positioned to supply green hydrogen to international markets, including the United States and Europe. The export of green hydrogen can contribute to Canada’s economic growth and support global decarbonization efforts.

- -

- Industry Transition: The Canadian government is working with industries such as steel, mining, and oil sands to explore the integration of green hydrogen in their operations. This includes using green hydrogen as a reducing agent in steelmaking, replacing carbon-intensive processes. The adoption of green hydrogen in these industries can help reduce their carbon footprint and support the country’s climate goals.

- China:

- -

- Hydrogen Economy Plans: China has set ambitious targets to become a global leader in the hydrogen economy. The country aims to expand its hydrogen production capacity, with a focus on both blue and green hydrogen. China has plans to develop large-scale hydrogen production projects, including coal gasification with carbon capture and storage (CCS), as well as renewable-energy-powered electrolysis facilities.

- -

- Transportation and Mobility: China is exploring the use of hydrogen fuel cells and hydrogen combustion technologies in transportation. The country has been investing in the development of hydrogen-powered buses, trucks, and even trains. The goal is to reduce emissions in the transportation sector and promote the adoption of hydrogen-powered vehicles.

- -

- Industrial Applications: China is exploring the utilization of hydrogen in various industries, including steel, chemicals, and refining. Green hydrogen can be used as a reducing agent or feedstock in these sectors, replacing fossil fuels and reducing carbon emissions. China’s focus on hydrogen in industries aligns with its broader efforts to achieve carbon neutrality.

- Russian Federation:

- -

- Natural Gas Resources: The Russian Federation has abundant natural gas reserves, which can be used as a feedstock for hydrogen production. The country is exploring the production of blue hydrogen by reforming natural gas with carbon capture and storage (CCS) technologies. This approach can reduce the carbon footprint of hydrogen production in the country.

- -

- Industrial Applications: Russia is exploring the utilization of hydrogen in industries such as steel and chemicals. Hydrogen can be used as a reducing agent in steelmaking, replacing coal or coke. The use of hydrogen in these industries can help reduce greenhouse gas emissions and support Russia’s climate goals.

- -

- Research and Development: Russia is actively involved in the research and development of advanced electrolysis technologies for green hydrogen production. This includes exploring high-temperature electrolysis and solid oxide electrolysis cells (SOEC), which can enhance the efficiency and cost effectiveness of hydrogen production.

- South Africa:

- -

- Renewable Energy Potential: South Africa has significant renewable energy resources, including solar and wind power. The country is exploring the production of green hydrogen through electrolysis powered by renewable energy sources. This can enable the utilization of renewable energy surpluses and support the transition to a low-carbon economy.

- -

- Industrial Decarbonization: South Africa is exploring the use of green hydrogen in industries such as mining and steel. By replacing fossil fuels with green hydrogen, these industries can reduce their carbon emissions and contribute to sustainable development. The use of green hydrogen as a reducing agent in steelmaking, for example, can help decarbonize the steel industry.

- -

- Power Generation and Energy Storage: South Africa is investigating the use of green hydrogen for power generation and energy storage. Hydrogen can be used in fuel cells to generate electricity, providing clean and reliable power. Additionally, excess renewable energy can be used to produce hydrogen, which can then be stored and converted back to electricity when needed, supporting grid stability and energy storage.

4.1.2. Industries

- Transportation: The transportation sector is increasingly adopting green hydrogen as a zero-emission fuel. Fuel cell electric vehicles (FCEVs) powered by hydrogen are being developed and deployed by automakers such as Toyota, Hyundai, and BMW. There are also initiatives to use hydrogen for heavy-duty vehicles, buses, and trains.

- Power Generation: Green hydrogen can be used in power plants to generate electricity with zero carbon emissions. Hydrogen can be combusted directly in gas turbines or used in fuel cells to produce electricity. Several countries are exploring the use of hydrogen in their power generation mix to decarbonize the electricity sector.

- Industrial Applications: Industries such as steel, chemicals, and refineries are exploring the use of green hydrogen to decarbonize their processes. Hydrogen can be used as a feedstock, a reducing agent, or a source of heat in various industrial applications. Pilot projects and collaborations are underway to integrate hydrogen into industrial processes and reduce carbon emissions.

- Energy Storage: Green hydrogen can be stored and used as a form of energy storage, helping to balance intermittent renewable energy sources. Excess renewable energy can be used to produce hydrogen through electrolysis, which can then be stored and converted back to electricity or other forms of energy when needed.

- Refining and Petrochemicals: The refining and petrochemical industries are exploring the use of green hydrogen to reduce carbon emissions. Hydrogen can be used as a cleaner alternative to fossil fuels in various refining processes, such as desulfurization and hydrocracking. The transition to green hydrogen in these industries can help decarbonize their operations and reduce their environmental footprint.

- Aviation: The aviation industry is investigating the use of green hydrogen as a sustainable fuel for aircraft. Hydrogen-powered aircraft, either through combustion or fuel cells, have the potential to significantly reduce greenhouse gas emissions compared to traditional jet fuels. Several companies and research institutions are working on developing hydrogen-powered aircraft and infrastructure.

- Residential Heating: Green hydrogen can be used for residential heating applications, replacing natural gas or other carbon-intensive fuels. Hydrogen boilers and fuel cells can provide heat and hot water with zero carbon emissions. Pilot projects are underway in various countries to explore the feasibility and effectiveness of using hydrogen for residential heating.

- Energy Export: Countries with abundant renewable energy resources, such as Australia and Chile, are exploring the export of green hydrogen to international markets. Green hydrogen can be transported as a commodity in the form of compressed or liquefied hydrogen, enabling countries to share their renewable energy potential with regions that have limited renewable resources.

- Energy Storage and Grid Balancing: Green hydrogen can play a crucial role in energy storage and grid balancing. Excess renewable energy can be used to produce hydrogen through electrolysis during periods of low demand. The hydrogen can be stored and then converted back to electricity through fuel cells or combustion when demand exceeds supply, helping to stabilize the grid and ensure a reliable energy supply.

4.2. Green Hydrogen Production Using Renewable Energy

4.3. Green Hydrogen Application in Different Industries

4.4. Key Aspects of the Benefits of Green Hydrogen Production and Utilization

5. Innovative Methods of Producing and Using Green Hydrogen

- Power-to-Gas (P2G): P2G technology allows for the conversion of excess renewable energy into hydrogen. When the supply of renewable energy exceeds the demand, the surplus electricity is used to power electrolyzes, which split water into hydrogen and oxygen. The produced hydrogen can be stored and used later when renewable energy generation is low or as a clean fuel for transportation, heating, or industrial processes.

- Biomass Conversion: Biomass can be converted into hydrogen through gasification or pyrolysis processes. Gasification involves heating biomass in a controlled environment to produce a synthesis gas (syngas) consisting of hydrogen, carbon monoxide, and other gases. The syngas can then be further processed to extract hydrogen. Pyrolysis, on the other hand, involves heating biomass in the absence of oxygen, which produces bio-oil, syngas, and char. Hydrogen can be extracted from the syngas component.

- Photo Electrochemical (PEC) Water Splitting: PEC water splitting utilizes specialized semiconductor materials to directly convert solar energy into hydrogen. These materials are capable of absorbing sunlight and initiating the water-splitting reaction within the cell, generating hydrogen and oxygen. PEC technology offers the potential for efficient and direct solar-driven hydrogen production, eliminating the need for external electricity sources.

- Hydrogen Fuel Cells: Hydrogen fuel cells are devices that generate electricity through an electrochemical reaction between hydrogen and oxygen. Hydrogen is supplied to the anode and oxygen (usually from the air) is supplied to the cathode of the fuel cell. The reaction produces electricity, heat, and water as byproducts. Fuel cells are a versatile technology that can be used in various applications, including transportation (e.g., fuel cell vehicles) and stationary power generation for buildings or remote off-grid locations.

- 5.

- Electrolysis: Electrolysis is a process that uses electricity to split water molecules into hydrogen and oxygen. By passing an electric current through water, the hydrogen ions (H+) are attracted to the negative electrode (cathode), where they gain electrons to form hydrogen gas (H2). Oxygen is simultaneously produced at the positive electrode (anode). When the electricity used in the electrolysis process comes from renewable energy sources such as solar or wind, electrolysis can be a green and sustainable method of hydrogen production [52].

- 6.

- Plasma Arc Decomposition: Plasma arc decomposition, also known as plasma reforming, involves the use of high temperatures generated by an electric arc to break down natural gas (methane) into hydrogen and carbon monoxide. The process occurs in a plasma reactor, where the intense heat dissociates the methane molecules, releasing hydrogen gas. If the electricity used for the plasma arc decomposition is generated from renewable sources, this method can be considered a green hydrogen production method.

- 7.

- Thermolysis: Thermolysis is a hydrogen production method that involves the decomposition of a chemical compound, such as water or hydrocarbons, through the application of heat. By subjecting the compound to high temperatures, the molecular bonds are broken, resulting in the release of hydrogen gas. The heat required for thermolysis can be obtained from renewable energy sources to ensure the production process is environmentally friendly.

- 8.

- Thermochemical Processes: Thermochemical processes utilize chemical reactions and heat to produce hydrogen. These processes typically involve the use of metal oxides or metal hydrides as catalysts. During the thermochemical reactions, the catalysts absorb heat and undergo chemical transformations, releasing hydrogen gas as a byproduct. Thermochemical processes offer the potential for efficient hydrogen production, especially when coupled with renewable energy sources.

- 9.

- Hybrid Thermochemical Cycles: Hybrid thermochemical cycles combine different thermochemical reactions to achieve efficient hydrogen production. These cycles often involve multiple steps, including the use of high temperatures, chemical reactions, and catalysts. By coupling different reactions and optimizing the cycle, hybrid thermochemical processes aim to improve the overall efficiency and feasibility of hydrogen production.

- 10.

- Photo-Electrolysis: Photo-electrolysis involves using sunlight to drive the electrolysis process for hydrogen production. Specifically, specialized semiconductor materials are used as photo electrodes to absorb sunlight and directly convert solar energy into electricity, which is then used to split water into hydrogen and oxygen. Photo-electrolysis offers the potential for direct and sustainable solar-driven hydrogen production.

- 11.

- Artificial Photosynthesis: Artificial photosynthesis is an emerging field that seeks to replicate the process of natural photosynthesis in plants to produce hydrogen. It involves using specialized materials and catalysts to capture sunlight and initiate chemical reactions that produce hydrogen from water. Artificial photosynthesis holds promise for renewable and sustainable hydrogen production, but it is still an area of ongoing research and development.

6. Green Hydrogen Challenges, Recommendations, Expectations and Observations

6.1. Challenges

- Hydrogen Energy Loss: Implementation of green hydrogen is associated with a loss of about 30% of its energy content due to hydrogen liquefaction. This means that each unit of hydrogen produced equals only 70% of the available energy.

- Storage of Liquid Hydrogen (LH2): Storing liquid hydrogen is challenging due to the low storage temperature required (−253 °C under 1 bar) and the need for an effective isolation system.

- Hydrogen Safety: Because of hydrogen’s flammability and potential for dilution of oxygen, hydrogen can pose a threat to human safety.

- High energy density: Hydrogen has a wide combustible limit range, low boiling point, low temperature, rate, content and flash rate. In addition, the heating value of hydrogen (LHV) is as low as 120 MJ/kg, which is three times the heating value of heavy fuel oil. This high energy density must be handled carefully to avoid accidents.

- Technical Challenges: Green hydrogen technology faces technical difficulties associated with high temperature and high pressure, which makes its storage difficult.

- Cost: The cost of hydrogen gas must be reduced to be competitive. Achieving a cost of USD 2 per kilogram is a competitive goal.

- Electricity Demand: The production and application of green hydrogen requires a large amount of electricity. To support these applications, renewable energy production such as offshore wind and solar energy must be increased.

- Offshore Wind Capacity: support is needed for such an application. Therefore, in the next 30 years, and every year, offshore wind energy should be developed more than in the last 20 years.

- Infrastructure: The establishment of a comprehensive infrastructure for the production, storage, transportation, and distribution of green hydrogen is a significant challenge. It requires the development of hydrogen production facilities, hydrogen refueling stations, and pipelines or other means of transporting hydrogen to end-users.

- Scaling Up Production: Scaling up the production of green hydrogen to meet the demand for various sectors such as transportation, industry, and power generation poses a challenge. Currently, the production of green hydrogen is limited, and significant investments and advancements are required to increase production capacity.

- Electrolysis Technology: The primary method for producing green hydrogen is through electrolysis, which involves using electricity to split water molecules into hydrogen and oxygen. The efficiency and cost effectiveness of electrolysis technology need further improvements to make green hydrogen more commercially viable.

- Availability of Renewable Energy: The production of green hydrogen relies on a consistent and abundant supply of renewable energy sources such as wind and solar power. However, the intermittent nature of these energy sources poses challenges in ensuring a continuous and reliable supply of electricity for hydrogen production.

- International collaboration: The implementation of green hydrogen requires international collaboration and cooperation due to the global nature of the energy transition. Harmonizing standards, sharing best practices, and establishing cross-border infrastructure are essential for the widespread adoption of green hydrogen.

- Regulatory Rramework: Developing a supportive regulatory framework is crucial for the successful deployment of green hydrogen. This includes policies and incentives that promote investment in green hydrogen projects, facilitate research and development, and address safety and environmental concerns.

- Public awareness and acceptance: Promoting public awareness and acceptance of green hydrogen is vital. Educating the public about the benefits and potential of green hydrogen, addressing safety concerns, and fostering a positive perception of hydrogen as a clean energy source are important for its widespread adoption.

6.2. Recommendations

- Consider Hydrogen as Part of Energy Transition Efforts: It is true that green hydrogen can be a sustainable solution in the long run. There should be a focus by the government and the private sector on supporting the green hydrogen market and promoting its use in various sectors such as transportation, industry and energy.

- Focusing on Green Hydrogen as a Long-Term Supply Option: It is clear that producing green hydrogen based on renewable energy is a sustainable option in the long term. Governments and companies should focus on developing these technologies, enhancing their availability and reducing their production costs to make green hydrogen more competitive.

- Comprehensive integration: It is true that the various aspects of integration in the hydrogen value chain deserve special attention. From production to distribution, storage and use, the integration of all these processes must be enhanced to achieve maximum efficiency and environmental benefits.

- Ensure Efficient Supply and Use of Hydrogen: Appropriate technology and infrastructure must be developed to deal with storage and transportation losses and achieve the highest efficiency in hydrogen use. Advanced and innovative storage and transportation technology can contribute to this goal. Therefore, joint action between governments, companies and the international community must continue to promote the use of clean hydrogen and achieve a sustainable energy transition.

- Japan: Japan is considered one of the leading countries in the field of green hydrogen. Japan aims to achieve a hydrogen-based society by 2050, and is investing in developing the technology and infrastructure needed to produce and use green hydrogen.

- Germany: Germany is making ambitious plans to promote green hydrogen as part of its energy strategy. The German government is promoting the production and sustainable use of green hydrogen in sectors such as transport and industry.

- The Netherlands: The Netherlands seeks to become one of the leading countries in the production of green hydrogen. The Netherlands is investing in green hydrogen projects and working to provide the necessary infrastructure to promote the use of green hydrogen in transport and industry.

- South Korea: South Korea is one of the leading countries in the field of green hydrogen. South Korea is investing in developing technology related to green hydrogen and aims to increase its use in transportation and industry. These countries are making significant investments in developing technology and infrastructure related to green hydrogen, and are expected to continue to make significant progress in this field in the coming years.

6.3. Expectations

- Industries such as the iron and steel industry and the chemical industry can benefit from using clean hydrogen to decarbonize production processes and reduce emissions. Pure hydrogen can be used as a reducing agent in the steel industry, and it can also be used as an energy source in other high-temperature industrial applications.

- In the transportation sector, clean hydrogen can be used in fuel cells or internal combustion engines to power vehicles. Pure hydrogen is considered a supplement to electric vehicles in the field of long-distance charging.

- Hydrogen can play an important role in the energy system as energy storage and resilience services. Hydrogen can be produced from excess electricity generated from renewable sources, and stored for use in periods of excess demand [70].

- Hydrogen can also be injected into the existing natural gas transmission and distribution network as a potential alternative to reducing carbon emissions in building gas consumption [71]. However, it should be noted that these prospects and potential uses of clean hydrogen are dependent on technology development, availability of adequate infrastructure, and costs of production and use [72].

6.4. Observations

- Potential and Benefits: Green hydrogen has the potential to play a crucial role in integrating renewable energy sources into the energy future. It offers a versatile and carbon-neutral energy carrier that can be produced using renewable electricity. The integration of green hydrogen can help address the intermittency and storage challenges associated with renewables, thereby enabling a more reliable and resilient energy system.

- Environmental Impact: Green hydrogen production offers a sustainable alternative to conventional hydrogen production methods, which often rely on fossil fuels. By utilizing renewable energy sources, green hydrogen can significantly reduce greenhouse gas emissions, air pollution, and dependence on finite fossil fuel resources.

- Technological Advancements: Ongoing research and development efforts are focused on improving the efficiency and cost effectiveness of green hydrogen production, storage, and utilization technologies. Advancements in electrolysis technology, catalysts, and infrastructure development are key areas of progress that will further enhance the viability of green hydrogen as a mainstream energy solution.

- Infrastructure Requirements: The widespread adoption of green hydrogen would necessitate the development of a robust infrastructure, including hydrogen production facilities, storage systems, and distribution networks. Collaboration among governments, industries, and research institutions is essential to facilitate the necessary investments and infrastructure planning.

- Economic Viability: While the costs of green hydrogen production have been decreasing, further efforts are needed to make it economically competitive with conventional energy sources. Technological advancements, economies of scale, and supportive policies can contribute to reducing the costs and enhancing the economic feasibility of green hydrogen.

- Policy and Regulatory Support: Governments play a pivotal role in creating a favorable environment for the growth of green hydrogen. Supportive policies, such as financial incentives, research funding, and carbon pricing mechanisms, can accelerate the deployment of green hydrogen technologies and stimulate market demand.

- Collaboration and Knowledge Sharing: Collaboration among stakeholders, including researchers, policymakers, industries, and communities, is vital for the successful integration of green hydrogen into the energy future. Sharing knowledge, best practices, and lessons learned from pilot projects and real-world deployments can facilitate the widespread adoption of green hydrogen technologies.

- Scalability and Deployment: As green hydrogen technologies continue to develop, it is essential to assess their scalability and deployment potential. Scaling up production, storage, and distribution infrastructure to meet increasing demand will require careful planning and coordination among stakeholders. Identifying suitable locations for large-scale green hydrogen projects and optimizing supply chains will be critical for successful deployment.

- Energy Transition Synergies: Green hydrogen can contribute to the broader energy transition by integrating with other renewable energy technologies and systems. For example, coupling green hydrogen production with wind or solar farms can help balance electricity supply and demand, maximize renewable energy utilization, and provide additional revenue streams for renewable energy project developers.

- Technological Challenges: Despite advancements, there are still technological challenges that need to be addressed. For instance, improving the efficiency of electrolysis processes, reducing the cost of catalyst materials, and enhancing hydrogen storage methods are areas that require ongoing research and development efforts. Innovations in these areas can further enhance the viability and competitiveness of green hydrogen.

- International Collaboration: Given the global nature of climate change and energy transition, international collaboration is crucial. Sharing best practices, research findings, and collaborating on joint projects can accelerate the development and deployment of green hydrogen technologies. International agreements and partnerships can also facilitate cross-border trade and cooperation, driving the growth of a global green hydrogen market.

- Social and Economic Implications: The transition to a green hydrogen-based energy system will have social and economic implications. It has the potential to create new job opportunities, particularly in industries related to green hydrogen production, infrastructure development, and hydrogen-based applications. However, it is important to ensure a just transition, providing support for affected communities and workers in fossil fuel-dependent industries.

- Public Awareness and Acceptance: Public awareness and acceptance of green hydrogen will play a crucial role in its successful integration. Educating the public about the benefits, potential applications, and environmental impacts of green hydrogen can foster support and drive consumer demand. Transparent communication about safety measures and addressing any misconceptions can also instill confidence among stakeholders.

- Life Cycle Assessment: Conducting a comprehensive life cycle assessment of green hydrogen is essential to evaluate its overall environmental impact. This assessment should consider the entire life cycle, including the production, distribution, and utilization stages, to determine its carbon footprint and potential environmental benefits compared to conventional energy sources.

- Electrolysis with Renewable Energy Sources: One of the most economical methods of green hydrogen production is through electrolysis powered by renewable energy sources such as solar, wind, or hydroelectric power. By utilizing abundant and low-cost renewable energy, electrolysis can produce green hydrogen with minimal carbon emissions. This method can be properly utilized by strategically locating electrolysis facilities near renewable energy generation sites, optimizing the use of excess renewable energy during off-peak hours, and implementing grid-balancing strategies.

- Biomass Gasification: Biomass gasification is another cost-effective method for green hydrogen production. Biomass feedstocks, such as agricultural residues or dedicated energy crops, can be gasified to produce a syngas, which is then converted into hydrogen through various processes. This method offers the advantage of utilizing organic waste materials and providing an additional revenue stream for the agricultural sector. Proper utilization involves establishing biomass supply chains, optimizing gasification technologies, and ensuring sustainable sourcing practices.

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- DOE. MEGA-BIO: Bioproducts to Enable Biofuels Award. Office of Energy Efficiency & Renewable Energy. 2017. Available online: https://www.energy.gov/eere/articles/energy-department-announces-additional-mega-bio-bioproducts-enable-biofuels-award (accessed on 15 June 2023).

- Zimmermann, A.W.; Wunderlich, J.; Müller, L.; Buchner, G.A.; Marxen, A.; Michailos, S.; Armstrong, K.; Naims, H.; McCord, S.; Styring, P.; et al. Techno-economic assessment guidelines for CO2 utilization. Front. Energy Res. 2020, 8, 5. [Google Scholar] [CrossRef]

- Moni, S.M.; Mahmud, R.; High, K.; Carbajales-Dale, M. Life cycle assessment of emerging technologies: A review. J. Ind. Ecol. 2020, 24, 52–63. [Google Scholar] [CrossRef]

- Buchner, G.A.; Zimmermann, A.W.; Hohgr-ave, A.E.; Schomacker, R. Technoeconomic assessment framework for the chemical industry—Based on technology readiness levels. Ind. Eng. Chem. Res. 2018, 57, 8502–8517. [Google Scholar] [CrossRef]

- Thomassen, G.; Van Dael, M.; Van Passel, S.; You, F. How to assess the potential of emerging green technologies? Towards a prospective environmental and technoeconomic assessment framework. Green Chem. 2019, 21, 4868–4886. [Google Scholar] [CrossRef]

- Wunderlich, J.; Armstrong, K.; Buchner, G.A.; Styring, P.; Schomäcker, R. Integration of techno-economic and life cycle assessment: Defining and applying integration types for chemical technology development. J. Clean. Prod. 2021, 287, 125021. [Google Scholar] [CrossRef]

- Ueckerdt, F.; Bauer, C.; Dirnaichner, A.; Everall, J.; Sacchi, R.; Luderer, G. Potential and risks of hydrogen-based e-fuels in climate change mitigation. Nature Clim. Chang. 2021, 11, 384–393. [Google Scholar] [CrossRef]

- Li, R.; Wang, W.; Xia, M. Cooperative planning of active distribution system with renewable energy sources and energy storage systems. IEEE Access 2017, 6, 5916–5926. [Google Scholar] [CrossRef]

- Ayodele, T.R.; Munda, J.L. The potential role of green hydrogen production in the South Africa energy mix. J. Renew. Sustain. Energy 2019, 11, 044301. [Google Scholar] [CrossRef]

- Gondal, I.A.; Masood, S.A.; Khan, R. Green hydrogen production potential for developing a hydrogen economy in Pakistan. Int. J. Hydrogen Energy 2018, 43, 6011–6039. [Google Scholar] [CrossRef]

- Kakoulaki, G.; Kougias, I.; Taylor, N.; Dolci, F.; Moya, J.; Jäger-Waldau, A. Green hydrogen in Europe—A regional assessment: Substituting existing production with electrolysis powered by renewables. Energy Convers. Manag. 2021, 228, 113649. [Google Scholar] [CrossRef]

- IRENA, G.D.; Taibi, E.; Miranda, R. Hydrogen: A Renewable Energy Perspective. In International Renewable Energy Agency, Abu Dhabi; IRENA: Masdar City, United Arab Emirates, 2019. [Google Scholar]

- Armaroli, N.; Barbieri, A. The Hydrogen Dilemma in Italy’s Energy Transition. 2021. Available online: https://www.nature.com/articles/d43978-021-00109-3 (accessed on 15 June 2023).

- Ritchie, H.; Roser, M.; Rosado, P. CO2 and greenhouse gas emissions. In Our World in Data; Oxford Martin School: Oxford, UK, 2020. [Google Scholar]

- de Oliveira, A.C.L.; Tótola, L.A.; Lorentz, J.F.; Silva, A.A.; de Assis, L.R.; dos Santos, V.J.; Calijuri, M.L. Spatial analysis of energy indicators and proposition of alternative generation sources for the Brazilian territory. J. Clean. Prod. 2022, 356, 131894. [Google Scholar] [CrossRef]

- Chien, F.; Kamran, H.W.; Albashar, G.; Iqbal, W. Dynamic planning, conversion, and management strategy of different renewable energy sources: A sustainable solution for severe energy crises in emerging economies. Int. J. Hydrogen Energy 2021, 46, 7745–7758. [Google Scholar] [CrossRef]

- Noussan, M.; Raimondi, P.P.; Scita, R.; Hafner, M. The role of green and blue hydrogen in the energy transition-A technological and geopolitical perspective. Sustainability 2021, 13, 298. [Google Scholar] [CrossRef]

- Ajanovic, A.; Sayer, M.; Haas, R. The economics and the environnmental benignity of different colors of hydrogen. Int. J. Hydrogen Energy 2022, 2, 94. [Google Scholar]

- Hermesmann, M.; Muller, T.E. Green turquoise, blue, or grey? Environnmentally friendly hydrogen production in transforming energy systems. Prog. Energy Combust. Sci. 2022, 90, 100996. [Google Scholar] [CrossRef]

- Navas-Anguita, Z.; Garcia-Gusano, D.; Dufour, J.; Iribarren, D. Rvisiting the role of steam methane reforming with CO2 capture and storage for long-term hydrogen production. Sci. Total Environ. 2021, 771, 145432. [Google Scholar] [CrossRef]

- Nikolaidis, P.; Poullikkas, A. A comparative overview of hydrogen production processes. Renew. Sustain. Energy Rev. 2017, 67, 597–611. [Google Scholar] [CrossRef]

- IRENA. Green hydrogen: A guide to mpolicy Marking. In International Renewable Energy Agency; IRENA: Masdar City, United Arab Emirates, 2020; ISBN 978-92-9260-286-4. [Google Scholar]

- IEA. The Future of Hydrogen. Available online: https://www.hydrogenexpo.com/media/9370/the_future_of_hydrogen_iea.pdf (accessed on 15 June 2023).

- Carmo, M.; Fritz, D.L.; Mergel, J.; Stolten, D. A comprehensive review on PEM water electrolysis. Int. J. Hydrogen Energy 2013, 38, 4901–4934. [Google Scholar] [CrossRef]

- Imasiku, K.; Farirai, F.; Olwoch, J.; Agbo, S.N. A Policy Review of Green Hydrogen Economy in Southern Africa. Sustainability 2021, 13, 13240. [Google Scholar] [CrossRef]

- Md, M.R.; Mohammed, A.; Hamid, N.M. Danish Hydrogen production by water electrolysis: A review of alkaline water electrolysis, PEM water electrolysis and high temperature water electrolysis. Int. J. Eng. Adv. Technol. 2015, 4, 2249–8958. [Google Scholar]

- Sapountzi, F.M.; Gracia, J.M.; Fredriksson, H.O.; Niemantsverdriet, J.H. Electrocatalysts for the generation of hydrogen, oxygen and synthesis gas Prog. Energy Combust. Sci. 2017, 58, 1–35. [Google Scholar] [CrossRef]

- Shiva, K.S.; Himabindu, V. Hydrogen production by PEM water electrolysis—A review. Mater. Sci. Energy Technol. 2019, 2, 442–454. [Google Scholar]

- Renee, C. Report of Energy: Why We Need Green Hydrogen? State of the Planet; Columbia Climate School: New York, NY, USA, 2021. [Google Scholar]

- Egeland-Eriksen, T.; Jonas, F.J.; Øystein, U.; Sabrina, S. Simulating offshore hydrogen production via PEM electrolysis using real power production data from a 2.3 MW floating offshore wind turbine. Int. J. Hydrogen Energy 2023, 48, 28712–28732. [Google Scholar] [CrossRef]

- Iribarren, D.; Peters, J.F.; Dufour, J. Life cycle assessment of transportation fuels from biomass pyrolysis. Fuel 2012, 97, 812–821. [Google Scholar] [CrossRef]

- Aspentech. Process Simulation Software. 2021. Available online: https://www.aspentech.com/en# (accessed on 18 March 2021).

- Bennion, E.P.; Ginosar, D.M.; Moses, J.; Agblevor, F.; Quinn, J.C. Lifecycle assessment of microalgae to biofuel: Comparison of thermochemical processing pathways. Appl. Energy 2015, 154, 1062–1071. [Google Scholar] [CrossRef]

- Quinn, J.C.; Smith, T.G.; Downes, C.M.; Quinn, C. Microalgae to biofuels lifecycle assessment—Multiple pathway evaluation. Algal Res. 2014, 4, 116–122. [Google Scholar] [CrossRef]

- Reuß, M. Seasonal storage and alternative carriers: A flexible hydrogen supply chain model. Appl. Energy 2017, 200, 290–302. [Google Scholar] [CrossRef]

- Emonts, B. Flexible sector coupling with hydrogen: A climate-friendly fuel supply for road transport. Int. J. Hydrogen Energy 2019, 44, 12918–12930. [Google Scholar] [CrossRef]

- Löhndorf, N.; Wozabal, D.; Minner, S. Optimizing trading decisions for hydro storage systems using approximate dual dynamic programming. Oper. Res. 2013, 61, 810–823. [Google Scholar] [CrossRef]

- EIA. Renewable Energy Explained. Available online: https://www.eia.gov/energyexplained/renewable-sources/ (accessed on 6 May 2021).

- Stuart, D.C.W.; Laura, E.; Zhehan, W.; Changlong, W.; Joseph, M.; Andrew, F. Evaluating the economic fairways for hydrogen production in Australia. Int. J. Hydrogen Energy 2021, 46, 35985–35996. [Google Scholar]

- ARUP. Australian Hydrogen Hubs Study: Technical Study; Technical Report; COAG Energy Council Hydrogen Working Group: Canberra, Australia, 2019. [Google Scholar]

- Dawood, F.; Shafiullah, G.M.; Anda, M. A hover view over Australia’s Hydrogen Industry in recent history: The necessity for a Hydrogen Industry Knowledge-Sharing Platform. Int. J. Hydrogen Energy 2020, 45, 32916–32939. [Google Scholar] [CrossRef]

- European Commission. A hydrogen strategy for a climate-neutral Europe. In Communication from the Commission to the European Parliament, the Council, the European Economic and Social Com-Mittee and the Committee of the Regions; European Commission: Brussels, Belgium, 2020; Volume 53. [Google Scholar] [CrossRef]

- Japan External Trade Organization (JETRO). Diesel Generators in the Delhi Metropolitan Area Will Be Banned in Principle from October Onward (India). 2022. Available online: https://www.jetro.go.jp/biznews/2022/08/21ca073dc706c416.html (accessed on 22 January 2023).

- Pathak, K. Greenko to Supply 250K Tonnes Green Ammonia to Germany’s Uniper, 1st Indian Co to Start Exports from 2025. The Economic Times. 2023. Available online: https://economictimes.indiatimes.com/industry/renewables/germany-based-uniper-signs-pact-with-greenko-to-source-green-ammonia-from-india/articleshow/97698964.cms (accessed on 12 February 2023).

- IHI Corporation (IHI). IHI and Partners to Explore Ammonia Co-Firing at Indian Thermal Power Plant as Part of Japanese NationalProject. 2022. Available online: https://www.ihi.co.jp/en/all_news/2022/resources_energy_environment/1198023_3488.html (accessed on 13 February 2023).

- Government of Canada. Uranium and Nuclear Power Facts. 28 July 2020. Available online: https://natural-resources.canada.ca/our-natural-resources/minerals-mining/minerals-metals-facts/uranium-and-nuclear-power-facts/20070 (accessed on 15 June 2023).

- Ministry of Finance of China; Ministry of Industry and Information Technology of China; Ministry of Science and Technology of China; National Development and Reform Commission of China; National Energy Administration. Guanyu Kaizhan Ranliao Dianchi Qiche Shifan Yingyong de Tongzhi (Notice of the Pilot Application of Fuel Cell Vehicles). 16 September 2020. Available online: http://www.gov.cn/zhengce/zhengceku/2020-09/21/content_5545221.htm (accessed on 28 July 2022).

- State Council of China. Guowuyuan Guanyu Jiakuai Peiyu He Fazhan Zhanluexing Xinxing Chanye De Jueding (Decision on Accelerating the Development of Strategic Emerging Industries). 10 October 2010. Available online: http://www.gov.cn/zwgk/2010-10/18/content_1724848.htm (accessed on 28 July 2022).

- Abe, J.O.; Popoola, A.P.I.; Ajenifuja, E.; Popoola, O.M. Hydrogen energy, economy and storage: Review and recommendation. Int. J. Hydrogen Energy 2019, 44, 15072–15086. [Google Scholar] [CrossRef]

- Hnát, J.; Plevová, M.; Žitka, J.; Paidar, M.; Bouzek, K. Anion-selective materials with 1, 4 diazabicyclo [2.2.2] octane functional groups for advanced. Electrochim. Acta 2017, 248, 547–555. [Google Scholar]

- Di, L.G.; Olufemi, O.A.; Kumar, A. Blending blue hydrogen with natural gas for direct consumption: Examining the effect of hydrogen concentration on transportation and well-to-combustion greenhouse gas emissions. Int. J. Hydrogen Energy 2021, 46, 19202–19216. [Google Scholar] [CrossRef]

- Ministry of Trade and Energy Industry. The Present and Future of Renewable Energy, 1st Investment Briefing for the Korean Newdeal Policy. Republic of Korea: Ministry of Trade. 2020. Available online: https://english.moef.go.kr/ (accessed on 22 November 2022).

- Muhammed, N.S.; Haq, B.; Shehri, D.A.; Al-Ahmed, A.; Rahman, M.M.; Zaman, E. A review on underground hydrogen storage: Insight into geological sites, influencing factors and future outlook. Energy Rep. 2022, 8, 461–499. [Google Scholar] [CrossRef]

- Norihiko, I. Research and Development of Gas Turbine Using Ammonia as Fuel. J. 2022. Available online: https://www.jstage.jst.go.jp/article/sekiyu/2022/0/2022_10/_article/-char/en (accessed on 22 January 2023).

- New Energy and Industrial Technology Development Organization (NEDO). Green Innovation Fund Project/Hydrogen Production by Water Electrolysis Using Electricity Derived from Renewable Energies and Other Sources: Report of the WG for FY2022. 2022. Available online: https://www.meti.go.jp/shingikai/sankoshin/green_innovation/energy_structure/pdf/009_05_00.pdf (accessed on 22 January 2023).

- David, J.J.; Gregor, D. Can Green Hydrogen Production Be Economically Viable under Current Market Conditions. Energies 2020, 13, 6599. [Google Scholar]

- Ibrahim, D. Green methods for hydrogen production. Int. J. Hydrogen Energy 2012, 37, 1954–1971. [Google Scholar]

- Hosseini, S.; Butler, B. An overview of development and challenges in hydrogen powered vehicles. Int. J. Green Energy 2020, 17, 13–37. [Google Scholar] [CrossRef]

- Ball, M.; Wietschel, M. The future of hydrogen–opportunities and challenges. Int. J. Hydrogen Energy 2009, 34, 615–627. [Google Scholar] [CrossRef]

- Birol, F. The Future of Hydrogen—Seizing Today’s Opportunities; International Energy Agency IEA: Paris, France, 2019. [Google Scholar]

- Atilhan, S.; Park, S.; El-Halwagi, M.M.; Atilhan, M.; Moore, M.; Nielsen, R.B. Green hydrogen as an alternative fuel for the shipping industry. Curr. Opin. Chem. Eng. 2021, 31, 100668. [Google Scholar] [CrossRef]

- Rasul, M.; Hazrat, M.; Sattar, M.; Jahirul, M.; Shearer, M. The future of hydrogen: Challenges on production, storage and applications. Energy Convers. Manag. 2022, 272, 116326. [Google Scholar] [CrossRef]

- Abad, A.V.; Dodds, P.E. Green hydrogen characterisation initiatives: Definitions, standards, guarantees of origin, and challenges. Energy Policy 2020, 138, 111300. [Google Scholar] [CrossRef]

- Hague, O. What Are the 3 Main Types of Hydrogen? 2021. Available online: https://www.brunel.net/en/blog/renewable-energy/3-main-types-of-hydrogen (accessed on 30 October 2022).

- Bhagwat, S.; Olczak, M. Green Hydrogen: Bridging the Energy Transition in Africa and Europe; European University Institute: Fiesole, Italy, 2020. [Google Scholar]

- Alverhed, E.; Kåvik, F. The Decoupling Process of CO2 Emissions and Economic Growth: A Comparative Study between the European Union and Middle Income Countries in South and East Asia; Jönköping University: Jönköping, Sweden, 2020. [Google Scholar]

- Megía, P.J.; Vizcaíno, A.J.; Calles, J.A.; Carrero, A. Hydrogen production technologies: From fossil fuels toward renewable sources. A mini review. Energy Fuels 2021, 35, 16403–16415. [Google Scholar] [CrossRef]

- Abdalla, A.M.; Hossain, S.; Nisfindy, O.B.; Azad, A.T.; Dawood, M.; Azad, A.K. Hydrogen production, storage, transportation and key challenges with applications: A review. Energy Convers. Manag. 2018, 165, 602–627. [Google Scholar] [CrossRef]

- Raman, R.; Nair, V.K.; Prakash, V.; Patwardhan, A.; Nedungadi, P. Green-hydrogen research: What have we achieved, and where are we going? Bibliometrics analysis. Energy Rep. 2022, 8, 9242–9260. [Google Scholar] [CrossRef]

- Deloitte, Green Hydrogen: Energizing the Path to Net Zero. Deloitte’s 2023, Global Green Hydrogen Outlook. Available online: https://www.google.com.hk/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwiSqdvBlJOBAxUPs1YBHUkIC-cQFnoECBIQAQ&url=https%3A%2F%2Fwww2.deloitte.com%2Fcontent%2Fdam%2FDeloitte%2Fat%2FDocuments%2Fpresse%2Fat-deloitte-wasserstoffstudie-2023.pdf&usg=AOvVaw0Rwav7NusoVCo-kwVZiMX0&opi=89978449 (accessed on 15 June 2023).

- International Energy Agency. Electricity Consumption—Electricity Information: Overview; International Energy Agency: Paris, France, 2023. [Google Scholar]

- International Energy Agency. Fossil Fuel Subsidies in Clean Energy Transitions: Time for a New Approach? International Energy Agency: Paris, France, 2023. [Google Scholar]

- Federal Ministry of Education and Research. Ariadne-Analysis Securing Hydrogen Imports for Germany: Import Needs, Risks and Strategies on the Way to Climate Neutrality; Federal Ministry of Education and Research: Bonn, Germany, 2022. [Google Scholar]

- Stöckl, F.; Schill, W.P.; Zerrahn, A. Optimal supply chains and power sector benefits of green hydrogen. Sci. Rep. 2021, 11, 14191. [Google Scholar] [CrossRef]

- Li, H.; Cao, X.; Liu, Y.; Shao, Y.; Nan, Z.; Teng, L.; Peng, W.; Bian, J. Safety of hydrogen storage and transportation: An overview on mechanisms, techniques, and challenges. Energy Rep. 2022, 8, 6258–6269. [Google Scholar] [CrossRef]

- Rosenow, J. Is heating homes with hydrogen all but a pipe dream? An evidence review. Joule 2022, 6, 2225–2228. [Google Scholar] [CrossRef]

| Hydrogen Color | Production Technology | Cost | CO2 Emissions |

|---|---|---|---|

| Blue | Steam reforming of natural gas, with carbon capture and storage | Moderate | 9–12 kg CO2/kg H2 |

| Gray | Steam reforming of natural gas, without carbon capture and storage | Low | 16–18 kg CO2/kg H2 |

| Brown | Gasification of coal or other hydrocarbon-rich feedstock | Moderate | 19–25 kg CO2/kg H2 |

| Black | Coal gasification, with hydrogen separation and other gases released into the atmosphere | High | 24–28 kg CO2/kg H2 |

| Green | Electrolysis of water using renewable energy sources | High | Zero CO2 emissions |

| Country | Green Hydrogen Production | Green Hydrogen Utilization | Industries Utilizing Green Hydrogen |

|---|---|---|---|

| Germany | Increasing capacity | Growing adoption | Steel, chemicals, refineries, transportation |

| Australia | Expanding production | Export ambitions | Transportation, industry, export markets |

| Japan | Scaling up production | Diverse applications | Transportation, power generation, industry, residential heating |

| Netherlands | Offshore wind integration | Building infrastructure | Transportation, industrial processes, power generation |

| United States | Rapidly increasing | Developing markets | Transportation, power generation, industry, heating and cooling |

| Chile | Developing capacity | Mining industry | Mining operations, heavy-duty vehicles, industrial applications |

| Saudi Arabia | Investing in production | Industrial applications | Petrochemicals, ammonia production, transportation |

| South Korea | Expanding production | Developing hydrogen economy | Transportation, power generation, industry, heating, and cooling |

| India | Expanding production | Transportation, power generation, industry | Transportation, power generation, industry, heating, and cooling |

| Canada | Growing production | Transportation, industry, export markets | Transportation, industry, export markets, power generation |

| China | Scaling up production | Transportation, power generation, industry | Transportation, power generation, industry, heating, and cooling |

| Russian Federation | Developing capacity | Transportation, industry, power generation | Transportation, industry, power generation |

| South Africa | Early-stage development | Transportation, mining industry | Transportation, mining industry, industrial applications |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marouani, I.; Guesmi, T.; Alshammari, B.M.; Alqunun, K.; Alzamil, A.; Alturki, M.; Hadj Abdallah, H. Integration of Renewable-Energy-Based Green Hydrogen into the Energy Future. Processes 2023, 11, 2685. https://doi.org/10.3390/pr11092685

Marouani I, Guesmi T, Alshammari BM, Alqunun K, Alzamil A, Alturki M, Hadj Abdallah H. Integration of Renewable-Energy-Based Green Hydrogen into the Energy Future. Processes. 2023; 11(9):2685. https://doi.org/10.3390/pr11092685

Chicago/Turabian StyleMarouani, Ismail, Tawfik Guesmi, Badr M. Alshammari, Khalid Alqunun, Ahmed Alzamil, Mansoor Alturki, and Hsan Hadj Abdallah. 2023. "Integration of Renewable-Energy-Based Green Hydrogen into the Energy Future" Processes 11, no. 9: 2685. https://doi.org/10.3390/pr11092685

APA StyleMarouani, I., Guesmi, T., Alshammari, B. M., Alqunun, K., Alzamil, A., Alturki, M., & Hadj Abdallah, H. (2023). Integration of Renewable-Energy-Based Green Hydrogen into the Energy Future. Processes, 11(9), 2685. https://doi.org/10.3390/pr11092685