1. Introduction

The construction of a digital twin (DT) platform for the array antenna assembly process is a key link for manufacturing enterprises to achieve intelligent manufacturing. The DT assembly platform can achieve autonomous decision-making, self-assembly production, equipment interconnection, automatic perception, data fusion, real-time performance prediction and visualization in the assembly process. As the bridge connecting the physical world and virtual world of DT, data is a crucial part of achieving virtual-real mapping and online decision-making for digital twins. Further, data collection and sensing are important means to carry the data flow of the DT of the array antenna assembly process. The Internet of Things (IoT) in the workshop, through the use of various sensing devices and corresponding perception technologies, collects real-time data from workshop personnel, equipment, materials, the assembly processes, assembly quality, work environment, etc., and sends it back through the network. This process of data transmission realizes ubiquitous connections between objects and persons, and completes the intelligent identification, perception, and control of workshop monitoring objects. However, there are often a large number of heterogeneous data sources with different formats in the physical assembly site. When collecting information on various production factors at the manufacturing site, it will input a large amount of raw data, which usually contain errors such as abnormalities, duplicates, out-of-order sequences, omissions and incompleteness. How to realize the fusion modeling of multi-source heterogeneous data, maintain real-time mapping of virtual workshops, and adapt to the business needs of DT workshops is key to realizing a DT-driven performance prediction of the array antenna assembly process.

Data collection refers to the process of using intelligent collection devices and corresponding collection technology to obtain information about objects in the physical world [

1]. Data collection for complex product assembly processes is an important link between physical workshops and virtual workshops, and collection equipment is key to achieving this link. Typically, data collection devices have high real-time performance. It can use their own perception mechanisms to instantly collect on-site information, presenting the data to users through a display interface, storing and transmitting collected records and through certain data preprocessing analysis functions to reduce subsequent calculations. With the development of computer and internet technology, IoT technology supported by data collection technology and collection equipment has gradually developed. The IoT is a network that connects various networks to exchange information and communicate through sensing devices according to agreed protocols to achieve intelligent identification, tracking, monitoring, and management [

2,

3]. With the wide application of the IoT and computer technology, scholars have conducted cumulative research on workshop data collection. Zhang [

4] proposed the concept of the Internet of Manufacturing Things (IoMT), which is used to perceive real-time manufacturing data of manufacturing items such as operators, machines, pallets and materials. Wan Fen [

5] designed and implemented multi-source heterogeneous data collection and virtual-real accurate mapping of the satellite assembly process based on the IoT platform. In addition, with the development of information technology and modern networks, wireless sensor network (WSN) technology [

6,

7,

8,

9] has become increasingly mature and has gradually developed. The WSN has changed the way for information collection and plays a crucial role in the application of the IoT. It has attracted attention in various fields around the world. The WSN could sense, detect, and collect information about the observed object within its sensing range. It can obtain object information and preprocesses it, and transmits it to the host computer for user use. Zhang [

10] proposed an artificial intelligence wireless data collection platform based on embedded operating systems which realized wireless data collection and USB interface transmission. In addition, Zhang [

11] proposed a mobile data collection algorithm based on clustering Dubins smooth curves and used WSN to divide multiple non-overlapping clustering intervals. The minimum spanning tree routing method is adopted within the cluster to realize the wireless multihop data transmission of sensor nodes. With the development of communication technology, the development of industrial site data collection systems and related communication protocols and collection standards are becoming more and more mature [

12,

13,

14,

15]. Jiao [

16] designed a network architecture for workshop data perception and transmission based on the OPC protocol, collecting energy consumption data and realizing information statistical supervision for the entire forging production process, aimed at the characteristics of multi-source heterogeneous data in forging workshops and the existence of information islands between equipment. Furthermore, Marcos [

17] designed a completely configurable SoC-based IR-UWB data collection and algorithm testing platform. Similarly, Xiong [

18], relying on the Industrial IoT and OPC UA communication technology, designed a data collection information model based on OPC UA, established a real-time data collection framework for digital twin workshops, and applied it to a certain aerospace structure production line. G. Martinov [

19] studied the application of OPC UA technology to monitor the working status of CAN servo drives, collecting drive parameter information through the CAN system’s OPC UA server, and connecting to mainstream OPC UA clients to monitor and solve problems.

In the field of data collection for DT workshops, domestic and foreign scholars have conducted relevant research on data collection networks, data quality analysis, data fusion and integration, data security, and privacy. Wang [

20] proposed a sustainable data collection and management method to meet the efficient data flow requirements of digital twin models and optimize data fidelity and latency metrics. This method involves collecting a large amount of data from IoT devices through proxies and introducing a blockchain-based framework for shared and sustainable digital twin management. Garg [

21] developed and designed a DT framework for nonlinear multi-degree-of-freedom dynamic systems to summarize and predict future responses. In terms of data collection, traditional sensing techniques were used to collect data on acceleration, displacement, and velocity, and DT was used to receive and apply data. In the digitalization and intelligent construction of the power grid, the technical system formed by digital twin technology based on high-precision data acquisition and real-time data transmission can effectively provide new ideas for the digital transformation of the distribution network. In terms of data collection for the construction of a digital twin system in the power grid, the stable operation of data collection and transmission is ensured through interface protocols, interactive security technologies, and communication integration [

22,

23]. Duan [

24] successfully achieved data collection from lower-level devices and real-time data reading based on communication protocols such as RS-485 in the digital twin system of a blade rotor test bench, ultimately achieving equipment monitoring and an evaluation of the blade rotor test bench. Zhou [

25] used an industrial IoT platform as a data bus for device access, data management, and system integration in the twin workshop, achieving the comprehensive data collection of various production elements such as personnel, equipment, software, materials, and environment. Based on the above, a 3D visualization monitoring system for the seal production workshop was developed. Additionally, with the support of OPC UA technology, researchers have integrated and transmitted heterogeneous data from digital twin workshops using OPC UA technology [

26,

27,

28]. However, most studies focus on the visualization monitoring system of digital twins and the collected data are mostly results data. Real-time data requirements are not high enough to meet the performance online prediction needs for quality assessment in scenarios such as array antenna assembly.

With the development of data collection technology, real-time data collection from digital workshop equipment has become possible. However, the development of traditional data collection operations also encounters bottleneck issues such as large data storage volumes, high collection speed frequencies, and complex structures. Various types of underlying equipment also bring the following difficulties to workshop data collection and transmission: (1) For intelligent IoT workshops, there are many types of underlying equipment and their communication protocols are different, which makes the cost of integrating the data collection and communication system of the workshop huge. (2) The goal pursued by the workshop information management system is the unified management of data communication at all levels. However, the information transmission from different protocols in various workshop information management systems increases the difficulty of a unified management. (3) Due to the lack of a unified communication protocol, the workshop’s Manufacturing Execution System can only passively integrate various different communication protocols during its design, thereby adapting to the underlying equipment, which undoubtedly increases the difficulty of system development and hinders the entire workshop’s informatization construction. Therefore, it is urgent for IoT technology to achieve the intelligent identification, perception, and control of monitoring objects in digital twin workshops for complex product assembly.

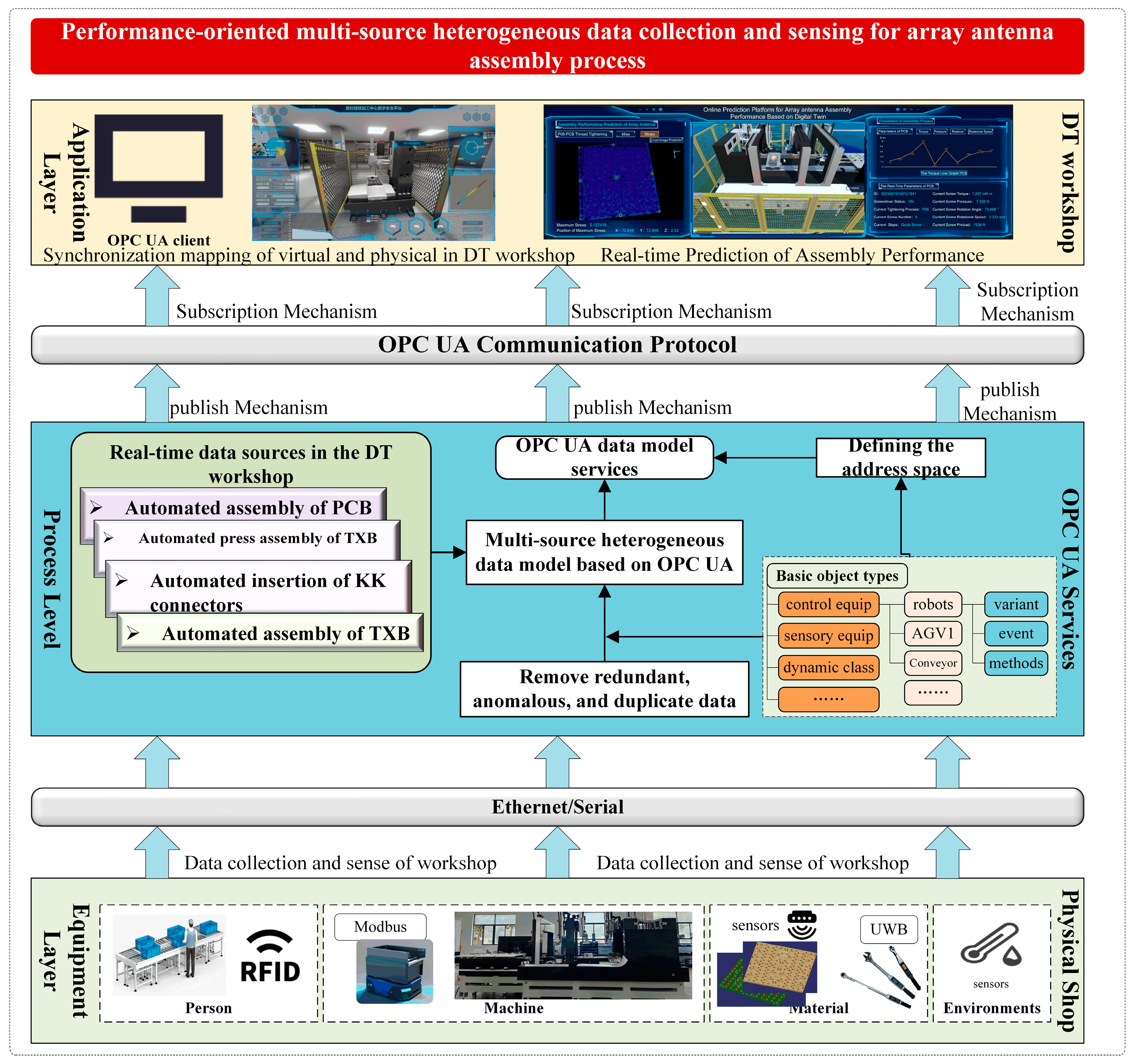

Based on the above difficulties in data collection and transmission, this paper designs a data integration method based on OPC UA. Firstly, in a pre-assembly scenario for assembly performance, the process flow and data source characteristics of the array antenna assembly process are analyzed and a data collection and transmission scheme based on OPC UA is designed. Secondly, an array antenna assembly process technology information model is established and data perception and transmission are realized to solve the challenges of complex data structure, high real-time requirements, and data heterogeneity in DT workshops. Finally, the proposed method and model are applied to the performance prediction platform of the array antenna assembly process based on DT, realizing the process data perception of the array antenna assembly process. Meanwhile, based on the assembly process data, the performance prediction and visualization of each assembly link of the array antenna are achieved, improving the assembly quality and efficiency of the array antenna.

2. Difficulties and Framework of Data Integration in DT Workshop

The DT workshop is an effective means for holographic monitoring, precise analysis, and real-time decision-making in the workshop under the background of intelligent manufacturing. Real-time and efficient multi-source heterogeneous data collection and fusion, as well as virtual and real workshop interaction based on perceptual data, are the core factors driving the operation of the digital twin workshops. With the continuous development and improvement of DT technology, the real-time, reliability, and professional solution requirements of DT platforms for workshop data collection are increasing. In the construction of a DT assembly platform, physical workshop data collection still faces the following prominent challenges:

- (1)

The industrial protocol standards are not unified and the data structure is complex, making it difficult to apply data sensing in the assembly process.

Workshop data has the characteristics of a large volume, high frequency collection speed, and heterogeneity. Additionally, the equipment for different manufacturing tasks has different characteristics. In the field of industrial data collection, there are various industrial protocol standards such as Modbus, Profibus, CAN, Profinet, Ethernet IP, etc. Furthermore, the production and integration vendors of various workshop equipment will also develop various private industrial protocols. These non-unified protocol standards result in incompatible data problems. In addition, the information exchange between equipment and external computers is limited, resulting in the inability to share data information and forming “data islands”, which cannot form an organic whole and cannot be fully utilized. Hence, how to implement the collection of heterogeneous data in a physical workshop and establish a unified data collection system is a difficult factor that urgently needs to be solved in the construction of a digital twin platform for array antenna assembly.

- (2)

Industrial data collection cannot guarantee real-time requirements and the data collection solutions are not comprehensive enough.

The real-time requirements for data collection in DT workshops are constantly increasing. Traditional data collection technologies are unable to guarantee the real-time collection and uploading of important information in high-precision, low-latency industrial scenarios, making it difficult to meet the virtual-real linkage of DT workshops and the rapid prediction and decision-making needs driven by data. In addition, most data collection solutions have certain specificities towards data collection. Some solutions focus on collecting workshop production data information, while some solutions focus on collecting the operational data of workshop equipment. It is difficult to comprehensively collect complete data information by these data collection solutions.

- (3)

It is difficult to utilize multi-source heterogeneous data in the workshop and it is impossible to realize data sharing.

The physical information fusion of the DT workshop needs not only to realize the interconnection and effective cooperation of the four major elements of people, machines, objects, and environment within the workshop, but also to accurately depict all production activities in the workshop. As research into the DT workshop gradually deepens, due to problems such as vague unified model descriptions of multi-source heterogeneous data in the workshop, it becomes very difficult to achieve interconnection and an efficient integrated transmission between multi-source heterogeneous data in the physical workshop, as well as the perception fusion of the four major elements of people, machines, objects, and environment. This has become a critical bottleneck hindering the real-time virtual-real mapping of DT workshops.

This paper focuses on the problems, such as non-unified industrial protocol standards, complex data structures, difficulties in guaranteeing real-time requirements for data collection, and incomplete collection schemes, faced by array antenna assembly workshop data perception. Firstly, different collection methods for different equipment in the workshop are distinguished and a data collection design is carried out according to the actual situation of the equipment to solve the problem of data convergence from heterogeneous equipment. Secondly, a unified DT workshop data model is constructed and OPC UA communication technology is introduced to realize the collection and interconnection of multi-source heterogeneous data in the physical workshop. At the same time, in response to the fact that it is difficult to utilize multi-source heterogeneous data in the workshop and impossible to achieve data sharing, a fusion method based on the data layer, feature layer, and decision layer is proposed, reducing the ambiguity of data and improving the stability of the digital twin system through establishing a unified data model. Finally, on the basis of data interconnection standards and norms, a DT workshop data access interface based on OPC UA services is designed to realize the subscription of the DT platform to physical workshop data. The technical route of multi-source heterogeneous data collection, sensing, and fusion in the array antenna assembly process is shown in

Figure 1.

3. Performance-Oriented Array Antenna Assembly Process Analysis

3.1. Data Source Analysis of Array Antenna Assembly Process

Data collection is the premise and foundation for realizing the virtual-real mapping of the array antenna assembly process and predicting assembly performance. The array antenna generates a large amount of data during the entire assembly process; the data sources come from the entire assembly process, such as the production equipment, sensors, control equipment, upper computer, etc. The data generated by different assembly process links are also different, affecting the array antenna assembly performance differently. Therefore, the data collection and transmission of assembly process parameters has become the key to influencing array antenna assembly performance. In terms of the entire assembly process of the array antenna, its assembly process parameters mainly include torque and pressure in the screw fastening process, fastening order, screw fastening angle, flatness of the plate, insertion force of electrical connectors, concentricity, parallelism, and pressing force of the antenna board, etc. The above process data present the following characteristics:

- (1)

Diversity and High Capacity

Due to the complexity of the array antenna assembly process, various types of assembly equipment are involved and there are differences in data protocols and data interfaces between devices. The data source has various forms and types, such as physical parameters like temperature, humidity, pressure collected by sensors, equipment operating status and fault information, and various original data such as processes and production plans. These data come from a variety of sources, types, time frequencies, and accuracies, and even need to handle unstructured data such as text, images, and videos. In addition, with the continuous upgrading of workshop equipment and processes, the amount of data will continue to increase. Hence, the workshop needs to have enough storage capacity to store these data and back up and protect these data at any time. At the same time, the speed of data collection and transmission also needs to meet high-capacity requirements to ensure real-time and continuity. Therefore, the workshop needs to have efficient capabilities for data collection, transmission, storage, and management.

- (2)

Data Generation Rapidly

In the assembly process of the array antenna, due to the widespread application of highly automated production equipment and sensor networks, it is possible to collect, monitor, control, and feedback various production data in real-time. These devices can continuously generate a large amount of production data with a high automation, faster speed, and accuracy. These data have high time accuracy, even reaching the millisecond level. Therefore, the speed at which assembly workshop data is generated is extremely fast, which requires digital workshops to adopt efficient data processing methods, as well as the strict control and management of data quality and real-time aspects, to ensure the accuracy and reliability of production data. In addition, the performance prediction system of the array antenna assembly process based on digital twin technology also has a high real-time requirement for the collected data. Therefore, the real-time prediction of the performance indicators of array antenna assembly by a digital twin system can be ensured only when the data collected and transmitted have a strong timeliness.

- (3)

Strong Correlation with Assembly Process

The data collection in the assembly workshop is a key link to provide accurate data support and decision support for the assembly process. During the data collection process of the assembly workshop, various information about the assembly process can be acquired and summarized, including assembly parameters, the status of machines and equipment, etc., and these data play an important role in the assembly process. Data collection can be achieved in various ways, such as manual recording, automatic sensors, computer monitoring, etc. By collecting and uploading data in real-time, changes in the assembly process can be captured promptly, such as changes in assembly process performance, machine failures, changes in production progress, etc., thereby helping to formulate targeted manufacturing decisions. At the same time, the array antenna assembly process also needs to rely on the data from the assembly workshop and it is necessary to analyze and process the collected data to adjust assembly process parameters, improve efficiency, and ensure quality. Therefore, data collection in the assembly workshop and the array antenna assembly process together constitutes one of the most important links in the production process. Only by continuously innovating data collection, analysis, and processing can more accurate and efficient data support be provided for the assembly process, making the production process faster and more efficient, and obtaining greater benefits.

Based on the above characteristics, it is known that the assembly process parameters have a direct impact on the assembly performance of the array antenna. Therefore, it is necessary to strictly control the process parameters during the assembly process and collect assembly data from each process link in real time to ensure that each parameter can meet the requirements. In addition, using data analysis and other techniques to calculate the performance changes of the array antenna assembly process in real time can thereby improve the overall performance of the array antenna. The assembly flow of the array antenna is shown in

Figure 2.

The overall assembly process of array antennas can be divided into four steps: (1) automated assembly of function board components; (2) automated assembly of KK connectors; (3) automated press-fitting of antenna board components; (4) automated assembly of antenna board components. In assembly step (1), this process will affect the stress deformation of the function board components and the reliability of the solder joints due to the screw tightening between the function board components and the heat dissipation board. Therefore, it is necessary to collect relevant process parameters, including the flatness of the function board, the tightening torque of screws, the pressure applied during tightening, and the tightening order. In assembly step (2), for thin-walled parts like KK connectors, the insertion displacement, angle, and size of the insertion force of the connector easily affect the structure and electromagnetic transmission performance of the connector, thereby causing varying degrees of impact on the overall assembly performance of the array antenna. Therefore, the process parameters that need to be collected in this assembly link include the insertion and extraction force of the connector, the depth of the connector’s insertion, concentricity, and parallelism. In assembly step (3), the press-fit pressure of the antenna board will be transmitted to the function board components and KK connectors, causing deformation of the function board components and KK connectors, and affecting the reliability of the solder joints and connections. Therefore, it is necessary to collect changes during the automatic press-fitting process of the antenna board. In assembly step (4), considering the impact of the screw tightening process on the structural deformation of the function board components and antenna board components, solder joints, and antenna patch radiation performance, it is necessary to collect critical process parameters such as the flatness of the antenna board components, screw tightening torque, pressure applied during tightening, tightening order, and antenna patch offset. The data sources for the performance-oriented array antenna assembly process are shown in

Figure 3.

3.2. Analysis of Equipment Sources in the Assembly Process of Array Antennas

According to the analysis of the array antenna assembly process in

Section 3.1, the underlying data sources for the array antenna assembly process based on DT come from different equipment resources, which can be specifically divided into perception resources, execution resources, and control resources. Perception resources include basic sensors such as pressure sensors and torque sensors that convert perceived information into basic electrical signals. Execution resources include assembly equipment using general or special communication protocols, such as guide rail slides, three-dimensional scanners, tightening modules, and insertion modules. Control resources include PLCs, controllers, and other assembly resources that support standard communication protocols and communication interfaces, and realize information interaction with other assembly equipment and production control. Based on the different protocol types and interface types supported by the above resource devices, the commonly used data collection methods can be divided into data collection based on analog/digital signals, data collection based on Ethernet interfaces, data collection based on serial interfaces, and data collection based on dedicated protocols, as shown in

Table 1.

The real-time data generated during the assembly process of an array antenna serves as a representation of the assembly status and a medium for information exchange within the system. It acts as a bridge connecting the physical workshop and the virtual workshop in a DT assembly performance prediction system. The twin system achieves the mapping between the physical and virtual workshops by acquiring real-time status information from the workshop equipment. Additionally, the DT assembly system can achieve a real-time performance prediction of array antennas under different process parameters based on driven real-time data based on artificial intelligence, deep learning, and other technologies driven by real-time data. This enables a real-time monitoring of the assembly process performance of array antennas and an early warning for abnormal assembly situations. Therefore, the real-time integration of assembly process data serves as the foundation for supporting the stable operation of the DT system. Array antenna assembly involves multiple assembly processes and data collection for each process requires collaboration among numerous heterogeneous devices and systems. This leads to the characteristics of multi-source and heterogeneous assembly process data. Therefore, studying the classification and composition of data sources and analyzing the structure and characteristics of the data are the fundamental basis for achieving the integration of array antenna assembly process data based on DT.

The objective existence of multi-source and heterogeneous data in array antenna assembly based on DT makes it difficult to integrate production resources through a common platform or method. Developing separate control software for each type of production resource or replacing devices to unify the generated production data would require a significant amount of work and incur high costs. Therefore, it is necessary to integrate multiple sources of heterogeneous data to achieve interconnectivity and unified scheduling among production resources. This paper proposes a DT workshop data integration method based on OPC UA to achieve the integration of multi-source and heterogeneous data. It focuses on two key issues: array antenna assembly data acquisition methods and data transmission methods.

4. A Method of Data Integration for DT Workshop Based on OPC UA

4.1. Overview of OPC UA

Open Platform Communications Unified Architecture (OPC UA) is an open and cross-platform communication protocol and architecture used to achieve interoperability between devices and applications in industrial automation systems. OPC UA aims to provide a reliable, secure, and interoperable communication method that enables seamless connection and data exchange among different vendors, devices, and systems, allowing for the monitoring, control, and management of various industrial devices and processes. In the industrial domain, OPC UA exhibits the following characteristics:

- (1)

OPC UA adopts a service-oriented architecture (SOA) which defines a set of standardized services and functional models. These services include data access, event publishing, historical data, security, etc., enabling data transfer and communication between devices.

- (2)

OPC UA uses a unified information model to describe devices, objects, and variables. It provides a hierarchical object structure that represents the hierarchical relationships and attributes of devices, such as devices, subsystems, components, etc. By defining these objects and variables, OPC UA enables data access and control of devices.

- (3)

OPC UA emphasizes the confidentiality, integrity, and availability of data. It provides multiple security mechanisms such as encrypted transmission, authentication, and access control to ensure data security and prevent unauthorized access and manipulation.

- (4)

OPC UA supports various communication protocols, including TCP/IP, HTTPS, and WebSockets, allowing it to operate in different network environments and integrate with existing systems.

- (5)

OPC UA has good scalability, allowing customization and extension based on specific requirements and application scenarios. It defines a set of specifications and interfaces that enable developers to customize new functionalities and services.

- (6)

OPC UA is a cross-platform standard that is not dependent on specific operating systems or hardware platforms. Devices and systems from different vendors can communicate using the common OPC UA interface, achieving interoperability and integration.

OPC UA provides a standardized specification and interface for reliable, secure, and cross-platform communication and data interaction across different platforms, vendors, and network environments. It offers independence and interoperability, allowing it to run on various hardware devices, operating systems, and network protocols, enabling interoperability between different devices. In addition, it boasts powerful security mechanisms, including authentication, data encryption, and integrity protection, ensuring the confidentiality and reliability of communications. Furthermore, OPC UA supports flexible data models and service definitions, accommodating the needs of different industries and application domains from sensors and smart devices to factory-level systems. It provides a reliable solution for data exchange and system integration in industrial automation, laying a solid foundation for interconnectivity and intelligence in the Industrial Internet of Things (IIoT). Most importantly, OPC UA is an open standard that has gained extensive support and adoption, promoting standardization and interoperability in the field of industrial automation. It offers more choices and convenience for system integration, device management, data analytics, and other applications. Thanks to the openness, standardization, security, and flexibility of OPC UA technology, a DT system can achieve device interoperability in data acquisition, meet diverse requirements, ensure data security, and efficiently integrate with other systems. These advantages provide a reliable foundation for the development and operation of a DT system.

4.2. The Process Information Model of Array Antenna Assembly

Based on the principles of an object-oriented design, OPC UA modeling draws upon many best practices from enterprise application integration (EAI) and embedded system domains. The modeling principles of OPC UA include the following aspects:

- (1)

Object-oriented: OPC UA modeling adopts the object-oriented approach, where objects are collections of data and their operations. Attributes represent the characteristics of the object’s state, while methods represent the operations that the object can perform.

- (2)

Establishing a comprehensive object model: OPC UA’s object model provides extensive descriptions for different types of devices and applications, covering various domains.

- (3)

Defining clear naming conventions: namespaces and identifiers form the foundation of OPC UA modeling, requiring the establishment of clear rules to ensure the consistency of objects, attributes, and methods across different systems.

- (4)

Defining specific data types: OPC UA adopts standard data types and categorizes different data types while also allowing for extensions.

- (5)

Establishing flexible access permissions: OPC UA’s security model includes access control, which can be flexibly configured to manage and restrict user, device, or application access to data based on specific needs.

- (6)

Scalability: OPC UA modeling possesses scalability to support new devices and applications, while also accommodating existing devices and applications.

- (7)

Reusability: OPC UA modeling embraces reusability to reduce development costs and improve productivity.

The data collection of a DT workshop based on the OPC UA protocol can address the interoperability issues among different devices and systems in the physical workshop. It provides a stable data foundation for performance-oriented DT systems in array antenna assembly. By defining standardized objects, attributes, and methods, the OPC UA information model can not only describe the basic properties and status of the devices but also define the functionalities and behaviors. This enables the real-time mapping of assembly process parameters from the physical workshop to the twin workshop. In the array antenna assembly process, there are numerous assembly process parameters involved in the physical workshop. To better express the relationship between the data object types of the physical assembly process and the assembly performance, and facilitate the effective transmission of different assembly performance data, three key processes in array antenna assembly are considered for the construction of the process information model: automated assembly of functional boards, automated assembly of antenna boards, and automated insertion of KK connectors. Based on the OPC UA communication protocol, a performance-oriented twin workshop process information model is established, as shown in

Figure 4.

The process information model is the ultimate form of integrating physical and digital information in the assembly of digital twins. Information modeling addresses the challenge of collecting heterogeneous assembly process data from various sources in the workshop, while establishing a unified data transmission method. The performance-oriented twin workshop process information model is divided into two data objects: mechanical component assembly objects and electrical component assembly objects, and “HasComponent” is used to describe their dependencies. Within the mechanical component assembly objects, there are two types: automated assembly data object types for functional board components and automated assembly data object types for antenna board components. These define the different assembly stages of the array antenna and use the “HasTypeDefinition” reference to connect to the corresponding object type. The object types contain production elements such as assembly stages, part numbers, tightening torque, pressure, insertion depth, and insertion displacement, represented by state variables and configuration variables referenced using the “HasProperty” reference. Typically, clients can read or subscribe these variable data based on different characteristic attributes. Additionally, within the object types, there are two methods: “Start” and “Stop”, which can be used to invoke process data. The information model for electrical component objects follows a similar structure to the mechanical component objects and will not be elaborated upon here.

4.3. Implementation of Data Collection Communication for OPC UA

Real-time data collection and interaction are crucial for performance prediction in array antenna assembly based on DT technology. Data collection ensures accurate and timely feedback from the physical system to the DT system to maintain the accuracy of the model. Real-time interaction enables users to quickly interact with the DT system and obtain real-time antenna assembly performance predictions, adjust parameters, or issue commands. This significantly enhances the application value of DT technology, allowing real-time prediction, optimization, and decision-making under rapidly changing process parameters, thereby improving assembly efficiency and quality while reducing costs and risks. The core of OPC UA communication is to establish a reliable communication connection between clients and servers. The client is the entity that requests data or performs operations, while the server is the entity that provides data and performs operations. OPC UA communication relies on a platform-independent protocol stack and adopts a service-oriented architecture, decomposing communication functionality into multiple services that can be combined as needed. Additionally, the OPC UA protocol provides support for security, reliability, flexibility, and other aspects. The communication flow based on the OPC UA architecture is illustrated in

Figure 5.

In OPC UA communication implementation, data is transmitted between the client and server through the network. The client can be various industrial devices, monitoring systems, or applications, while the server acts as the central node that hosts data and provides services. The client and server can establish connection-oriented communication through the OPC UA protocol stack to ensure the reliability and stability of data transmission. Initially, during communication establishment, the client and server perform a connection handshake and security authentication. OPC UA uses a public key/private key mechanism for identity verification to ensure data security during the communication process. Once the connection is established, the client can send read and write requests to the server. Through the OPC UA information model, the client can access and manage data nodes on the server in a hierarchical structure. It can read the values, states, and attributes of the nodes and perform corresponding operations. Additionally, the client can modify the data values of nodes on the server through writing requests, enabling data updates, and controlling operations. In addition to read and write operations, OPC UA also supports a subscription and publishing mechanism for real-time data transmission and notification. The subscription mechanism allows the client to subscribe to nodes of interest and the server periodically sends data updates of the nodes to the subscribers. This real-time notification mechanism keeps the data synchronized between the client and server, reflecting changes in device status promptly.

4.4. Implementation of Data Transmission

When the OPC UA client has collected data, it is necessary to separate the OPC UA data collection service from the DT system because frequent data transmission and processing will cause significant lag and decreased frame rates, and, due to the WebSocket communication method, can realize the active push of the message from the server side to the client side, which has a high real-time performance. Therefore, in order to transfer these data to the DT system, this paper establishes a WebSocket communication between the DT system and OPC UA to realize process data transfer. The main steps of the process are as follows:

- (1)

Transmission carrier of assembly process data

The processes data exhibits characteristics of multiple sources and heterogeneity in terms of structure and type due to the complexity of the array antenna assembly process. When it comes to data transmission, the choice of a suitable data format for transmitting assembly process data becomes crucial to ensure stable data transmission. JavaScript object notation (JSON) file is a platform-independent data format that allows for data exchange between different operating systems, programming languages, and applications. It utilizes a concise text format that is friendly to read and write. It employs a key-value pair structure along with simple arrays and object representations, making the data structure clear and understandable. Therefore, this paper adopts the JSON data format as an intermediate carrier for transmitting process data in the process of array antenna assembly.

In network communication, process data is typically stored in persistent storage media and needs to be transferred between different nodes. Serialization enables data to be transformed into a specific string format for transmission over the network. Comparatively, deserialization can convert the received strings back to their original data format and allow the recipient to correctly parse and use the data. Therefore, this paper employs the serialization and deserialization methods of JSON files to achieve the conversion between object state information and sequences in the process of transmitting assembly process data in array antenna assembly. To maintain consistency in the structure of the process data, the JSON file format for defining array antenna assembly process parameters is depicted in

Figure 6.

- (2)

Building data transmission services based on WebSocket

To achieve the push of the array antenna assembly process parameter JSON data to the DT system, a WebSocket server needs to be set up. The WebSocket server is created to listen to a specified address and port at first. The server can utilize the functionalities provided by the WebSocket library to handle connection requests and manage connection objects. When a client initiates a connection request, the server goes through a handshake process to ensure the validity of the connection and protocol compatibility. The handshake process is based on the HTTP protocol, typically, where the server verifies crucial information in the request and returns a handshake response as a connection confirmation. Once the handshake is successful, a WebSocket connection can be established between the server and the client, enabling a real-time bidirectional data transfer. The server and client can send data to each other. The key methods and attributes used in building the data transfer service based on WebSocket are shown in

Table 2.

- (3)

Building a data transmission client based on WebSocket

By using a WebSocket client object to specify the server’s address, port, and other necessary connection parameters, it is possible to establish a connection between a DT system and a WebSocket server. The client sends a connection request to the server using the WebSocket protocol and engages in real-time data exchange upon successful connection. JSON data reception and processing events can be achieved through data subscription. The key methods and attribute meanings used in building a WebSocket-based data transmission client are shown in

Table 3.

- (4)

Deserialization of JSON data

During the process of transmitting process data between the DT system and the WebSocket service, the received data is serialized in a JSON format. In order to perform an assembly performance analysis based on the synchronized assembly status of physical entities for the DT model, it is necessary to deserialize the serialized JSON data received from the WebSocket server. In the DT client, the antenna assembly process data type can be defined as an array and marked with deserialization attributes. The deserialization process is commonly implemented by using the “Newtonsoft.Json”, and the “DeserializeObject()” static method from the “JsonConvert” class is called to deserialize the real-time received JSON string and return the deserialized object. The specific implementation method is shown in

Figure 7.

5. Case Application

In the array antenna assembly process of a certain smart manufacturing workshop, due to its complex assembly technology, the dynamic data generated during the assembly process of the array antenna has massive, high-dimensional, multi-source, heterogeneous, and high-noise data characteristics. Among the diverse data source devices, their control systems and data transmission methods are different. If traditional data collection and communication methods are used to achieve a unified integrated management, it will increase the complexity of the array antenna assembly performance prediction DT platform and affect the load balance of the DT system. Therefore, this paper focuses on the array antenna assembly workshop and carries out an application verification of data collection and transmission in the assembly workshop based on OPC UA.

In terms of data collection and transmission in the assembly workshop, this paper adopts the industrial software KEPServer EX to build and configure the OPC UA server. The software integrates a variety of communication protocols and device drivers. It can communicate with different types of devices and provide a data exchange ability with other systems. As known from the analysis of the equipment sources in the assembly process in

Section 3.2, the devices involved in the perception of process data in the array antenna assembly process include pressure sensors, torque sensors, three-dimensional scanners, guide rails sliding tables, tightening modules, inserting modules, PLCs, controllers, etc. When building an OPC UA server, it is necessary to prepare driver programs for each device in KEPServer EX according to the type and communication protocol of the production line equipment. In addition, the connection parameters, communication ports, and device identifiers need to be configured to establish connections with the devices. In addition, device data nodes should be defined. The data nodes are the data sources in the OPC UA server, representing a variable or property in the device. Lastly, the access permissions for data points can be configured, such as defining users’ read and write permissions, ensuring the safety and compliance of data, etc. After completing all configurations, it can open the OPC UA service in KEPServer EX to start listening for client requests and provide data access and exchange functions. The OPC UA client is based on the .NET platform and C# programming language to realize the visual display of the array antenna assembly process data and data transmission. The server and client system for collecting process data in the array antenna assembly based on OPC UA is shown in

Figure 8.

In addition, the workshop data, behaving as a bridge connecting the physical and virtual workshops, are crucial for reflecting the real-time variations and situations of the physical systems via immediate data collection and transmission. This is especially important in rapidly changing environments and demands. The twin model may fail to reflect the changes of the physical system in times when the data collection is not timely or is delayed, leading to deviations between the model and the actual system. Meanwhile, outdated data could result in inaccurate decision-making and a non-adaptability to the current assembly situation, thereby affecting the quality of the antenna array assembly. Therefore, to verify the real-time advantages of the method proposed in this paper in terms of data collection and transmission, the data generated by the physical assembly workshop of the antenna array are tested. The test procedure adopted delay testing; that is, a timestamp was introduced at the data collection point during the assembly process, and the reception timestamp was recorded before the data reached the twin system. Then, the differences between the collection timestamp and the reception timestamp were compared to evaluate the delay situation in the data collection and transmission process. The test results showed that the method proposed in this paper for data collection and transmission in a twin workshop had a time response of 0.005 s under actual workshop application scenarios, as shown in

Figure 9. This meets the requirements for the virtual and real mapping of antenna array assembly and the prediction of related assembly performance indicators, achieving the real-time requirements for virtual and real linkage and the online prediction of assembly performance.

In terms of the application of array antenna assembly performance prediction in DT, based on the data collection and data transmission methods in

Section 4, a large amount of real-time data are collected from the assembly site by using the OPC UA interface. In the DT system, a DT model that is highly consistent with the actual assembly process is constructed using the collected data. On one hand, the model reflects various environmental conditions, operation steps, and potential problems that may occur in the real assembly process, realizing a digital mirror of the assembly workshop’s operation process. On the other hand, based on the process data of the assembly process, the online pre-diction of the reliability of solder joints, electromagnetic transmission, sub-array radiation performance, stress–strain prediction of PCB and other performance indicators of the array antenna assembly process and the visualization of assembly performance are realized, as shown in

Figure 10.

6. Discussion

The twin workshop data collection has advantages such as openness, interoperability, flexibility, real-time capability, reliability, security, and network independence based on OPC UA. These advantages can improve the efficiency and quality of data integration and promote the application of DT technology in array antenna assembly. In the process of the integration and transmission of heterogeneous data from physical workshops, twin workshop data collection based on OPC UA has the following advantages:

Firstly, in terms of information modeling, OPC UA defines a unified information model to describe devices, objects, variables, etc. This unified information model can bridge the heterogeneity of different devices and systems, enabling them to exchange and share data in a consistent manner. As long as devices adhere to the OPC UA information model, the data interoperability, regardless of the communication protocol used, can be achieved. Additionally, OPC UA provides the concept of an adapter layer which can map different communication protocols to the standardized interfaces of OPC UA. With the adapter layer, devices using different communication protocols in the workshop can be connected to the OPC UA network and exchange data with others. In this way, even if the communication protocol changes, only the adapter layer needs to be updated without modifying the entire system architecture. Moreover, through gateway technology, data conversion and transmission can be achieved between the OPC UA network and other communication protocols. Gateways can convert data from different protocols and pass it to the OPC UA network or other protocol networks. This gateway technology enables interconnection between different communication protocols and handles data from multiple heterogeneous sources. Lastly, OPC UA provides extensibility, allowing customization and expansion based on specific requirements and application scenarios. If there is a need to support new communication protocols or handle the data formats of specific devices, OPC UA can be extended to meet it. This flexible extensibility enables OPC UA to adapt to evolving communication protocols and device types.

However, despite the many advantages of twin workshop data integration methods and process information models based on OPC UA, there are also limitations and potential drawbacks:

- (1)

OPC UA is a powerful and flexible standard, but it also means that configuring and managing OPC UA servers, clients, and related security settings can be relatively complex.

- (2)

Despite the interoperability and cross-platform features provided by the OPC UA standard, there are still compatibility issues between different devices and systems in practical applications. Some devices or systems may require additional development work to integrate with OPC UA.

- (3)

Using OPC UA for data integration may require significant computing and networking resources. Especially in large-scale workshop environments, processing a large amount of real-time data and ensuring its reliable transmission and storage might burden the system.

- (4)

The OPC UA standard is an evolving standard and new versions and changes may emerge over time. This will require system upgrades and adaptations to maintain compatibility with the latest standards.

- (5)

In practical applications, there are various devices and systems in the workshop environment, and their data formats, communication protocols, interfaces, etc., may vary. Integrating these heterogeneous systems requires additional development and customization, which can significantly increase the cost of twin workshop construction.

7. Conclusions

Based on the actual requirements of the development of the array antenna assembly DT system, this paper analyzed the process link and process data characteristics of the array antenna assembly in view of targeting the existence of a large number of heterogeneous data sources with different formats at the physical assembly workshop. On this basis, an array antenna assembly process information model based on OPC UA is constructed, and reliable communication between the OPC UA server and client is established to realize the perception of assembly process data. At the same time, the data transmission from the OPC UA client to the DT system is realized by using the WebSocket protocol, completing the instantiation of the array antenna assembly DT workshop. The real-time process data of the assembly process reflects the status of array antenna assembly. Meanwhile, based on assembly process data, the performance prediction and visualization of each assembly link of the array antenna are realized, improving the quality and efficiency of array antenna assembly.

By analyzing the data collection, transmission, and application in the array antenna assembly process of the twin workshop, there are some practical challenges and factors to consider when using the twin workshop data collection method and model based on OPC UA: (1) As there are various types of equipment and systems in the actual workshop environment, these devices and systems may use different communication protocols, interfaces, and data formats. In the face of this diversity, it is necessary to identify and adapt to the data sources during twin data collection to ensure the accurate acquisition and parsing of information from each data source. (2) The real-time nature of manufacturing data in the twin workshop is very important. However, due to network delays and data transmission reasons, it is impossible to guarantee that all data can be transmitted and updated in real-time. Therefore, it is necessary to properly evaluate the real-time needs of the data according to specific application scenarios and requirements, and use relevant intelligent algorithms, edge computing, and other technologies for corresponding optimization and adjustment. (3) Different devices and systems may generate data at different frequencies and accuracies, and the quality of the data may also vary. When establishing a digital twin model, it is necessary to consider how to handle and compensate for data differences between different data sources, as well as how to ensure the consistency and accuracy of the data. (4) The manufacturing workshop has constantly changing and expanding environments, equipment, and systems. Therefore, the scalability of the digital twin system needs to be considered to integrate new devices easily, support new communication protocols and data formats, and carry out system upgrades and evolution. (5) The data collection method based on OPC UA may require a lot of computing and network resources. In practical applications, it is necessary to evaluate the resource consumption of the system, optimize performance, and ensure the stability and reliability of the system.