Study on SiO2 Nanofluid Alternating CO2 Enhanced Oil Recovery in Low-Permeability Sandstone Reservoirs

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Instruments

2.2. Experimental Methods

2.2.1. Characterization of Nanoparticles

2.2.2. Zeta Potential Analysis

2.2.3. Particle Size Test

2.2.4. Emulsifying Properties

2.2.5. Contact Angle Test

2.2.6. Core Flooding Experiment

3. Results and Discussion

3.1. Performance Measurements

3.2. Oil Flooding Tests

3.2.1. Different Injection Methods

3.2.2. Different Slug Sizes

3.2.3. Different Slug Ratios

3.2.4. Flooding in Cores with Different Permeabilities

4. Conclusions

- Both SiO2-I and SiO2-II exhibit good sphericity and monodispersity, with excellent dispersion stability in the aqueous phase, and they demonstrate good emulsification properties with the oil phase.

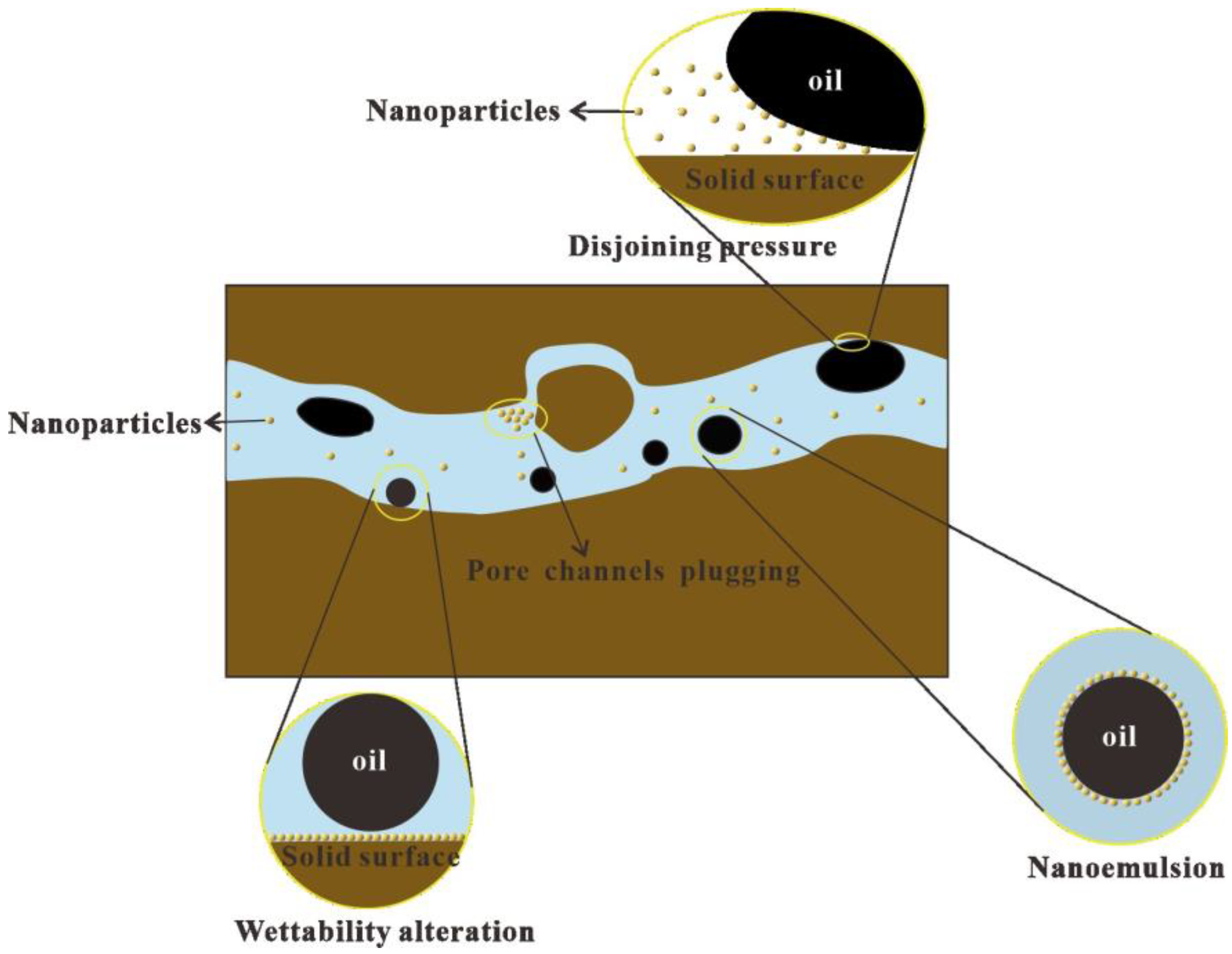

- Compared to other conventional oil displacement methods, the SiO2-I nanofluid alternating CO2 flooding scheme shows the most favorable performance, achieving a recovery rate of up to 67.65%. Contact angle experiments reveal that SiO2 nanoparticles have the capability to modify the wettability of hydrophilic solid surfaces, converting them into hydrophilic surfaces. During the oil displacement process, SiO2 nanoparticles enhance pore connectivity and oil mobility in rock formations through pore-filling, wettability alteration, and emulsification, thereby increasing oil displacement efficiency. The viscosity of the displaced crude oil was found to be the lowest in the SiO2-I alternating CO2 flooding scenario. The dissolution and expansion effects of CO2 provided dynamic support for the displacement process with nanoscale SiO2, leading to a synergistic enhancement. This combination significantly improved the efficiency of nanofluid alternating CO2 flooding and effectively increased the oil recovery rate in low-permeability reservoirs.

- Smaller gas and water slugs lead to better performance in alternating nanofluid and CO2 flooding. However, when the gas and water slugs are too small, their influence on the development effect of alternating nanofluid and CO2 flooding becomes insignificant and may instead increase operational costs in field applications. Both excessive and inadequate gas–water slug ratios can adversely impact the development effect, primarily due to the rapid increase in the water cut or gas–oil ratio. The experimental study on the gas–water slug ratio reveals that the best development effect is achieved with a gas–water slug ratio of 1:1 in nanofluid alternating CO2 flooding.

- Alternating nanofluid and CO2 flooding demonstrates a superior oil recovery factor in low-permeability rock formations. Low-permeability rock formations with small pores and poor pore connectivity allow smaller particles to facilitate more efficient transport through the porous media. SiO2 nanoparticles can fill pores, enhance pore connectivity, reduce residual oil trapping, and increase oil mobility and oil recovery factors. Therefore, alternating nanofluid and CO2 flooding performs exceptionally well in low-permeability rock formations, a conclusion supported by wettability measurement results.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kulkarni, M.M.; Rao, D.N. Experimental investigation of miscible and immiscible Water-Alternating-Gas (WAG) process performance. J. Pet. Sci. Eng. 2005, 48, 1–20. [Google Scholar] [CrossRef]

- Muggeridge, A.; Cockin, A.; Webb, K.; Frampton, H.; Collins, I.; Moulds, T.; Salino, P. Recovery rates, enhanced oil recovery and technological limits. Philosophical Transactions of the Royal Society A: Mathematical. Phys. Eng. Sci. 2014, 372, 20120320. [Google Scholar]

- Hu, W.R. Current status and future of low permeability oil and gas in China. China Eng. Sci. 2009, 11, 29–37. [Google Scholar]

- Yang, X.; Zhao, W.; Zou, C.; Chen, M.; Guo, Y. Genetic mechanism of low-permeability reservoirs and formation and distribution of high-quality reservoirs. Acta Pet. Sin. 2007, 4, 57–61. [Google Scholar]

- Hu, Z.; Ba, Z.; Xiong, W.; Gao, S.; Luo, R. Analysis of Micro Pore Structure of Low Permeability Reservoirs. J. Daqing Pet. Inst. 2006, 3, 51–53. [Google Scholar]

- Wang, D.; Shi, D.; Li, X.; Chen, G. Analysis of the main contradiction mechanism and reasonable well spacing in the development of low-permeability sandstone reservoirs. Pet. Explor. Dev. 2003, 1, 87–89. [Google Scholar]

- Ali, J.A.; Kolo, K.; Manshad, A.K.; Mohammadi, A.H. Recent advances in application of nanotechnology in chemical enhanced oil recovery: Effects of nanoparticles on wettability alteration, interfacial tension reduction, and flooding. Egypt. J. Pet. 2018, 27, 1371–1383. [Google Scholar] [CrossRef]

- Li, B.; Zhang, D.; Lin, S.; Liu, F.; Li, Z. Indoor experimental study on frozen gel foam system. Spec. Petrochem. 2013, 30, 21–25. [Google Scholar]

- Mahdavi, S.; James, L.A. High pressure and high-temperature study of CO2 saturated-water injection for improving oil displacement; mechanistic and application study. Fuel 2020, 262, 116442. [Google Scholar] [CrossRef]

- Aghdam, K.A.; Moghaddas, J.S.; Moradi, B.; Dabiri, M.; Hassanzadeh, M. Maximizing the oil recovery through miscible water alternating gas (WAG) injection in an Iranian oil reservoir. Pet. Sci. Technol. 2013, 31, 2431–2440. [Google Scholar] [CrossRef]

- Wang, L.; Zhao, Q.; Li, Z. Experimental investigation of carbon dioxide flooding in heavy oil reservoirs for enhanced oil recovery. Energy Rep. 2022, 8, 10754–10761. [Google Scholar] [CrossRef]

- Ghafoori, A.; Shahbazi, K.; Darabi, A.; Soleymanzadeh, A.; Abedini, A. The experimental investigation of nitrogen and carbon dioxide water-alternating-gas injection in a carbonate reservoir. Pet. Sci. Technol. 2012, 30, 1071–1081. [Google Scholar] [CrossRef]

- Salehi, M.M.; Safarzadeh, M.A.; Sahraei, E.; Nejad, S.A. Comparison of oil removal in surfactant alternating gas with water alternating gas, water flooding and gas flooding in secondary oil recovery process. J. Pet. Sci. Eng. 2014, 120, 86–93. [Google Scholar] [CrossRef] [PubMed]

- Cao, X.; Lu, G.; Wang, J.; Zhang, D.; Ren, M. Current Status and Future Research Directions of CO2 Enhanced Oil Recovery Technology in Shengli Oilfield. Reserv. Eval. Dev. 2020, 10, 51–59. [Google Scholar]

- Zhang, R.; Li, X.; Li, X.; Niu, M.; Li, R. Evaluation of CO2 flooding effect and characteristics of reservoir damage in low-permeability heterogeneous multi-layer reservoirs. Pet. Geol. Recovery Effic. 2022, 19, 121–127. [Google Scholar]

- Li, M.; Guan, H.; Hu, S.; Wang, X.; Li, Q.; Yuan, S. Parameter Optimization of CO2 Huff-n-Puff and Non-Huff-n-Puff Water-Gas Alternating Injection in Ultra-Low Permeability Reservoirs. Unconv. Oil Gas 2021, 8, 60–66. [Google Scholar]

- Zhang, M.; Zhao, F.; Lu, G.; Hou, J.; Song, L.; Feng, H.; Zhang, D. Adaptation Limits of Gas-Water Alternating to Improve CO2 Enhanced Oil Recovery Effect. Oilfield Chem. 2020, 37, 279–286. [Google Scholar]

- Lu, C.; Song, L.; Shang, F.; Yang, L.; Yang, R.; Guo, P.; Du, J. Study on Rational Displacement Method and Parameters Experiment of High-Temperature and High-Pressure Carbonate Reservoirs. J. Shaanxi Univ. Sci. Technol. 2022, 40, 96–101. [Google Scholar]

- Christensen, J.; Stenby, E.; Skauge, A. Review of WAG field experience. SPE Reserv. Eval. Eng. 2001, 4, 97–106. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, H.; Ma, L.; Liu, Y.; Zhang, L. Performance evaluation and mechanism with different CO2 flooding modes in tight oil reservoir with fractures. J. Pet. Sci. Eng. 2020, 188, 106950. [Google Scholar] [CrossRef]

- Chaturvedi, K.R.; Ravilla, D.; Kaleem, W.; Jadhawar, P.; Sharma, T. Impact of low salinity water injection on CO2 storage and oil recovery for improved CO2 utilization. Chem. Eng. Sci. 2021, 229, 116127. [Google Scholar] [CrossRef]

- Ding, S.; Wang, L.; Li, M.; Zhang, W.; Liu, H.; Sun, J. Study on Control Technology of Carbon Dioxide Flooding Gas Channeling in Low Permeability Reservoir. In Proceedings of the International Field Exploration and Development Conference; Springer: Singapore, 2021; pp. 2786–2794. [Google Scholar]

- Rezk, M.; Allam, N. Impact of nanotechnology on enhanced oil recovery: A mini-review. Ind. Eng. Chem. Res. 2019, 58, 16287–16295. [Google Scholar] [CrossRef]

- Crews, J.; Huang, T. Performance enhancements of viscoelastic surfactant stimulation fluids with nanoparticles. In Proceedings of the Europec/EAGE Conference and Exhibition, SPE, Rome, Italy, 9–12 June 2008; p. 113533. [Google Scholar]

- Kanj, M.; Funk, J.; Al-Yousif, Z. Nanofluid coreflood experiments in the ARAB-D. In Proceedings of the SPE Saudi Arabia Section Technical Symposium, SPE, Al-Khobar, Saudi Arabia, 9–11 May 2009; p. 126161. [Google Scholar]

- Lan, Q.; Yang, F.; Zhang, S.; Liu, S.; Xu, J.; Sun, D. Synergistic effect of silica nanoparticle and cetyltrimethyl ammonium bromide on the stabilization of O/W emulsions. Colloids Surf. A 2007, 302, 126–135. [Google Scholar] [CrossRef]

- Li, S.; Dan, D.; Lau, H.; Hadia, N.; Torsæter, O.; Stubbs, L. Investigation of wettability alteration by silica nanoparticles through advanced surface-wetting visualization techniques. In Proceedings of the SPE Annual Technical Conference and Exhibition, SPE, Calgary, AB, Canada, 30 September–2 October 2019; p. D031S040R002. [Google Scholar]

- Yuan, W.; Liu, X.; Wei, H.; Liu, J.; Yang, H.; Hu, S.; Li, Y.; Wang, D. Research and application effect ofpolymeric microsphere in Wen-10 of Sinopec Zhongyuan Oil ûeld. Inner Mong. Petrochem 2010, 12, 122–126. [Google Scholar]

- Li, X.; Ying, Z.; Jia, Y.; Liu, X.; Yang, T.; Ma, L. Application of nanosphere deep profile control and displacement technology in Chanqing oilfield. Oilfield Chem 2012, 29, 419–422. [Google Scholar]

- Tian, Q.; Wang, L.; Tang, Y.; Liu, C.; Ma, C.; Wang, T. Research and Application of Nano Polymer Microspheres Diversion Technique of Deep Fluid. In Proceedings of the SPE International Oilfield Nanotechnology Conference and Exhibition, SPE, Noordwijk, The Netherlands, 12–14 June 2012; p. 156999. [Google Scholar]

- Al-Shargabi, M.; Davoodi, S.; Wood, D.; Al-Musai, A.; Rukavishnikov, V.; Minaev, K. Nanoparticle applications as beneficial oil and gas drilling fluid additives: A review. J. Mol. Liq. 2022, 352, 118725. [Google Scholar] [CrossRef]

- Ershadi, M.; Alaei, M.; Rashidi, A.; Ramazani, A.; Khosravani, S. Carbonate and sandstone reservoirs wettability improvement without using surfactants for Chemical Enhanced Oil Recovery. Fuel 2015, 153, 408–415. [Google Scholar] [CrossRef]

- Lau, H.; Yu, M.; Nguyen, Q. Nanotechnology for oilfield applications: Challenges and impact. J. Pet. Sci. Eng. 2017, 157, 1160–1169. [Google Scholar] [CrossRef]

- Singh, S.; Ahmed, R. Vital role of nanopolymers in drilling and stimulations fluid applications. In Proceedings of the SPE Annual Technical Conference and Exhibition, SPE, Florence, Italy, 19–22 September 2010; p. 130413. [Google Scholar]

- Aziz, H.; Muther, T.; Khan, M.; Syed, F. A review on nanofluid water alternating gas (N-WAG): Application, preparation, mechanism, and challenges. Arab. J. Geosci. 2021, 14, 1416. [Google Scholar] [CrossRef]

- Chen, B.; Reynolds, A.C. Ensemble-based optimization of the water-alternating-gas-injection process. SPE J. 2016, 21, 0786–0798. [Google Scholar] [CrossRef]

- Cheraghian, G. A new thermal method concept for IOR from oil reservoir using optimized in-situ combustion. In Proceedings of the 78th EAGE Conference and Exhibition, Online, 30 May–2 June 2016; pp. 1–3. [Google Scholar]

- Cheraghian, G.; Tardasti, S. Improved Oil Recovery by the Efficiency of Nano-particle in Imbibition Mechanism. In Proceedings of the 2nd EAGE International Conference KazGeo, Almaty, Kazakhstan, 29–31 October 2012; European Association of Geoscientists & Engineers: Utrecht, The Netherlands, 2012; p. 315. [Google Scholar]

- Ju, B.; Fan, T.; Ma, M. Enhanced oil recovery by flooding with hydrophilic nanoparticles. China Particuol. 2006, 4, 41–46. [Google Scholar] [CrossRef]

- Cheraghian, G.; Nezhad, S.; Kamari, M.; Hemmati, M.; Masihi, M.; Bazgir, S. Effect of nanoclay on improved rheology properties of polyacrylamide solutions used in enhanced oil recovery. J. Pet. Explor. Prod. Technol. 2014, 5, 189–196. [Google Scholar] [CrossRef]

- Cheraghian, G.; Nezhad, S.S.K.; Kamari, M.; Hemmati, M.; Masihi, M.; Bazgir, S. Adsorption polymer on reservoir rock and role of the nanoparticles, clay and SiO2. Int. Nano Lett. 2014, 4, 114. [Google Scholar] [CrossRef]

- Le, N.; Pham, D.; Le, K.; Nguyen, P. Design and screening of synergist ic blends of SiO2 nanoparticles and surfactants for enhanced oil recovery in high-temperature reservoirs. Adv. Nat. Sci. Nanosci. Nanotechnol. 2011, 2, 35013–35019. [Google Scholar] [CrossRef]

- Raj, I.; Qu, M.; Xiao, L.; Hou, J.; Li, Y.; Liang, T.; Zhao, M. Ultralow concentration of molybdenum disulfide nanosheets for enhanced oil recovery. Fuel 2019, 251, 514–522. [Google Scholar] [CrossRef]

- Eltoum, H.; Yang, Y.; Hou, J. The effect of nanoparticles on reservoir wettability alteration: A critical review. Pet. Sci. 2021, 18, 136–153. [Google Scholar] [CrossRef]

- Alomair, O.; Matar, K.; Alsaeed, Y. Experimental study of enhanced-heavy-oil recovery in Berea sandstone cores by use of nanofluids applications. SPE Reserv. Eval. Eng. 2015, 18, 387–399. [Google Scholar] [CrossRef]

- Rezvani, H.; Khalilnezhad, A.; Ganji, P.; Kazemzadeh, Y. How ZrO2 nanoparticles improve the oil recovery by affecting the interfacial phenomena in the reservoir conditions. J. Mol. Liq. 2018, 252, 158–168. [Google Scholar] [CrossRef]

- Mohajeri, M.; Hemmati, M.; Shekarabi, A. An experimental study on using a nanosurfactant in an EOR process of heavy oil in a fractured micromodel. J. Pet. Sci. Eng. 2015, 126, 162–173. [Google Scholar] [CrossRef]

- Wang, Z.; Babadagli, T.; Maeda, N. Preliminary screening and formulation of new generation nanoparticles for stable pickering emulsion in cold and hot heavy-oil recovery. SPE Reserv. Eval. Eng. 2021, 24, 66–79. [Google Scholar] [CrossRef]

- Qi, L.; Song, C.; Wang, T.; Li, Q.; Hirasaki, G.; Verduzco, R. Polymer-coated nanoparticles for reversible emulsification and recovery of heavy oil. Langmuir 2018, 34, 6522–6528. [Google Scholar] [CrossRef] [PubMed]

- Lei, Q.; Luo, J.; Peng, B.; Wang, X.; Xiao, P.; Wang, P.; Geng, X. Mechanism of expanding swept volume by nano-sized oil-displacement agent. Pet. Explor. Dev. 2019, 46, 991–997. [Google Scholar] [CrossRef]

- Jin, Y.; Wang, Z.; Sun, Q.; Li, Y.; Wang, B.; Chen, Y. Research and application of nano-injection technology for tight reservoirs. Spec. Oil Gas Reserv. 2023, 30, 169–174. [Google Scholar]

- Moslan, M.; Wan Sulaiman, W.; Ismail, A.; Jaafar, M.; Ismail, I. Wettability alteration of dolomite rock using nanofluids for enhanced oil recovery. Mater. Sci. Forum 2016, 864, 194–198. [Google Scholar] [CrossRef]

- Nourafkan, E.; Hu, Z.; Wen, D. Nanoparticle-enabled delivery of surfactants in porous media. J. Colloid Interface Sci. 2018, 519, 44–57. [Google Scholar] [CrossRef]

- Ju, B.; Fan, T. Experimental study and mathematical model of nanoparticle transport in porous media. Powder Technol. 2009, 192, 195–202. [Google Scholar] [CrossRef]

- Li, S.; Torsaeter, O. The impact of nanoparticles adsorption and transport on wettability alteration of intermediate wet berea sandstone. In Proceedings of the SPE Middle East Unconventional Resources Conference and Exhibition, Muscat, Oman, 26–28 January 2015. Society of Petroleum Engineers. [Google Scholar]

- Ogolo, N.A.; Olafuyi, O.A.; Onyekonwu, M.O. Enhanced Oil Recovery Using Nanoparticles. In Proceedings of the SPE Saudi Arabia Section Technical Symposium and Exhibition, Al-Khobar, Saudi Arabia, 8–11 April 2012; pp. 12–18. [Google Scholar]

- Al Matroushi, M.; Pourafshary, P.; Al Wahaibi, Y. Possibility of nanofluid/gas alternating injection as an EOR method in an oil field. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, SPE, Abu Dhabi, UAE, 9–12 November 2015; p. D031S054R002. [Google Scholar]

- Salem Ragab, A.; Hannora, A. Comparative investigation of nano particle effects for improved oil recovery–experimental work. In Proceedings of the SPE Kuwait Oil and Gas Show and Conference, SPE, Mishref, Kuwait, 11–14 October 2015. [Google Scholar]

- Wang, K.; Liang, S.; Wang, C. Research of improving water injection effect by using active SiO2 nano-powder in the low-permeability oilfield. Adv. Mater. Res. 2010, 92, 207–212. [Google Scholar] [CrossRef]

- Amrouche, F.; Gomari, S.; Islam, M.; Xu, D. A novel hybrid technique to enhance oil production from oil-wet carbonate reservoirs by combining a magnetic field with alumina and iron oxide nanoparticles. J. Clean. Prod. 2021, 281, 124891. [Google Scholar] [CrossRef]

- Gallo, G.; Erdmann, E. Simulation of viscosity enhanced CO2 nanofluid alternating gas in light oil reservoirs. In Proceedings of the SPE Latin America and Caribbean Petroleum Engineering Conference, SPE, Buenos Aires, Argentina, 17–19 May 2017. [Google Scholar]

- Ragab, A.M.; Hannora, A.E. An experimental investigation of silica nano particles for enhanced oil recovery applications. In Proceedings of the SPE North Africa Technical Conference and Exhibition, SPE, Cairo, Egypt, 14–15 September 2015; p. 175829. [Google Scholar]

- Mo, D.; Jia, B.; Yu, J.; Liu, N.; Lee, R. Study nanoparticle-stabilized CO2 foam for oil recovery at different pressure, temperature, and rock samples. In Proceedings of the SPE Improved Oil Recovery Symposium, SPE, Tulsa, OK, USA, 12–16 April 2014; p. 169110. [Google Scholar]

- Lee, J.; Huang, J.; Babadagli, T. Visual support for heavy-oil emulsification and its stability for cold-production using chemical and nano-particles. In Proceedings of the SPE Annual Technical Conference and Exhibition, SPE, Calgary, AB, Canada, 30 September–2 October 2019; p. 196023. [Google Scholar]

- Lee, J.; Babadagli, T. Optimal design of pickering emulsions for heavy-oil recovery improvement. J. Dispers. Sci. Technol. 2020, 41, 2048–2062. [Google Scholar] [CrossRef]

| Ion | Concentration, mg/L |

|---|---|

| Na+ | 9625.19 |

| Ca2+ | 380.03 |

| Mg2+ | 1300.33 |

| Cl− | 16,000.42 |

| SO42− | 3000.50 |

| HCO3− | 160.46 |

| Total | 30,466.93 |

| Number | Length /cm | Diameter /cm | Permeability /mD | Porosity /% | Average Permeability /mD | Average Porosity/% |

|---|---|---|---|---|---|---|

| 1 | 6.25 | 2.20 | 2.58 | 33.15 | 2.49 | 33.05 |

| 2 | 6.25 | 2.20 | 2.34 | 34.28 | ||

| 3 | 6.25 | 2.20 | 2.56 | 31.71 | ||

| 4 | 6.25 | 2.20 | 185.65 | 31.85 | 196.88 | 31.57 |

| 5 | 6.25 | 2.20 | 206.43 | 32.37 | ||

| 6 | 6.25 | 2.20 | 198.55 | 30.48 |

| Low-Permeable Core Injection | Viscosity/mPa·s |

|---|---|

| Viscosity of crude oil in preliminary test | 43.37 |

| SiO2-I alternating CO2 | 35.21 |

| SiO2-II alternating CO2 | 36.47 |

| WAG | 38.55 |

| Water | 43.28 |

| CO2 | 38.83 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, J.; Fu, M.; Li, M.; He, H.; Hou, B.; Chen, L.; Liu, W. Study on SiO2 Nanofluid Alternating CO2 Enhanced Oil Recovery in Low-Permeability Sandstone Reservoirs. Processes 2023, 11, 2758. https://doi.org/10.3390/pr11092758

Hu J, Fu M, Li M, He H, Hou B, Chen L, Liu W. Study on SiO2 Nanofluid Alternating CO2 Enhanced Oil Recovery in Low-Permeability Sandstone Reservoirs. Processes. 2023; 11(9):2758. https://doi.org/10.3390/pr11092758

Chicago/Turabian StyleHu, Jiani, Meilong Fu, Minxuan Li, Honglin He, Baofeng Hou, Lifeng Chen, and Wenbo Liu. 2023. "Study on SiO2 Nanofluid Alternating CO2 Enhanced Oil Recovery in Low-Permeability Sandstone Reservoirs" Processes 11, no. 9: 2758. https://doi.org/10.3390/pr11092758

APA StyleHu, J., Fu, M., Li, M., He, H., Hou, B., Chen, L., & Liu, W. (2023). Study on SiO2 Nanofluid Alternating CO2 Enhanced Oil Recovery in Low-Permeability Sandstone Reservoirs. Processes, 11(9), 2758. https://doi.org/10.3390/pr11092758