Study on the Effectiveness of the Integral Emergency Response System for Coal Mine Water Hazard Accidents Based on Combination Weighting

Abstract

:1. Introduction

2. Construction of the Effectiveness Measurement Index System

2.1. Connotation of the Integrated Emergency Response System for Coal Mine Water Hazard Accidents

2.2. Construction of the Effectiveness Measurement Index System for the Integrated Emergency Response System for Coal Mine Water Hazard Accidents

2.3. Determination of Combination Weights of the Effectiveness Measurement Indexes for Emergency Response System

2.3.1. AHP Method for Determining Subjective Weights of Measurement Indexes

2.3.2. Entropy Method for Determining Objective Weights of Measurement Indexes

2.3.3. AHP and Entropy Methods for Determining Combination Weights by Establishing a Combination Weighting Model

2.4. Grading of Emergency Response System Effectiveness for Coal Mine Water Hazard Accidents

3. Construction of a Fuzzy Evaluation Model for the Effectiveness of Integrated Emergency Response System for Coal Mine Water Hazard Accidents

3.1. Establishment of a Dimensionless Original Data Matrix

3.2. Calculation of the TOPSIS Model

4. Empirical Analysis on Coal Mines

4.1. Data Source and Processing

4.2. Questionnaire Reliability and Validity Test

4.3. Result Analysis

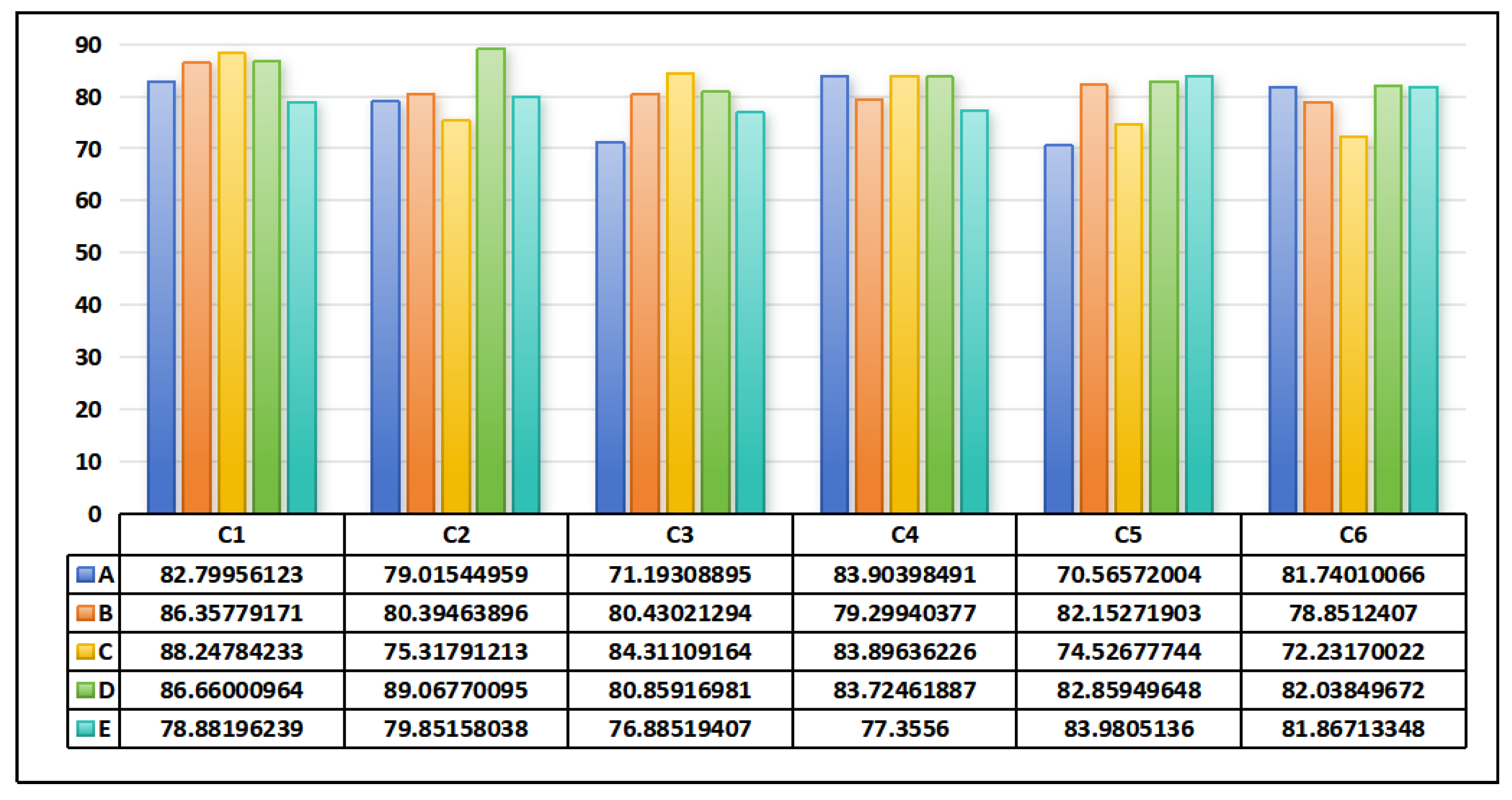

4.3.1. Scores-Based Comprehensive Evaluation

- (1)

- the average comprehensive score of the A Coal Mine, B Coal Mine, and E Coal Mine, which belong to the Coking Coal Group, is 79.91, with a standard deviation of 1.05;

- (2)

- that of the C Coal Mine and D Coal Mine, which are members of Henan Coal Chemical Group, is 82.07, with a standard deviation of 2.05.

4.3.2. Determination of Effectiveness Scores and Evaluation of Capability Grades

5. Conclusions

- (1)

- The efficiency measurement index system of the comprehensive emergency response system for coal mine water disaster accidents can be divided into two parts: normal emergency service capacity and non-normal emergency response capacity, and is then detailed into six secondary indexes, including accident information transmission, emergency command and control, emergency rescue and mitigation, emergency management dimension, personnel team dimension, and prevention and preparedness dimension. It is further divided into 27 three-level indexes, which can avoid the general concept of coal mine accidents and make the evaluation more targeted.

- (2)

- AHP method and entropy method are used to combine and empower the measurement indicators of the emergency response system of water disaster accidents in coal mine enterprises. TOPSIS evaluation model is introduced to build a comprehensive evaluation model of the emergency response ability of water disaster accidents in coal mine enterprises, which avoids too strong subjective thoughts and too simple methods, and enriches the evaluation methods of coal mine accident emergency response ability.

- (3)

- Taking five coal mines under Henan Coking Coal Group as examples, the empirical evaluation of water disaster emergency response system was carried out. According to the evaluation results, the comprehensive evaluation of water disaster emergency response system efficiency of Guhanshan Mine and Zhongma Cun Mine was in “average”, while the comprehensive evaluation of water disaster emergency response system efficiency of Jiulishan Mine, Zhaogu No.1 Mine and Zhaogu II mine was in “good”. The evaluation results are consistent with the actual situation, indicating that the evaluation model constructed in this paper has good practical significance, can evaluate the efficiency of the emergency response system of water disaster accidents in coal mines scientifically and effectively and provide a new way to improve the efficiency evaluation of the emergency response system of water disaster accidents in coal mines.

- (4)

- To comprehensively evaluate the effectiveness of the emergency response system for water disaster accidents in five coal mines, with the purpose of finding out the deficiencies in the emergency response for water disaster accidents, and taking corresponding rectification measures to improve their overall emergency response capability. Of course, this paper also has some limitations. First of all, there are many factors affecting the emergency response efficiency of coal mine water disaster accidents, so how to scientifically and reasonably select the evaluation index needs further in-depth research. Secondly, there are many evaluation methods for coal mine emergency response capability, and more excellent evaluation methods should be combined. In the future, a more perfect and reasonable evaluation model should be built to continuously optimize and improve.

6. Discussion

- (1)

- In the area of accident information transmission, the coal mine water hazard accident source management should be strengthened as far as possible in order to reduce the probability of accidents. Starting from upgrading their abilities to identify hazards, coal mines are encouraged to focus on strengthening their capabilities of predicting water detection and release, as well as on sourcing the causes of water hazard accident, with a view to refining technologies on accident prediction and early warning, reporting accident information more timely, and ensuring the smooth transmission of accident information continuously and effectively. To increase collaboration with meteorological, water conservancy, flood prevention, and other departments, establish a disaster weather warning and prevention mechanism, pay close attention to the warning information of disaster weather forecasting, timely grasp information on heavy rainfall and flood hazards that may jeopardize the production of coal mines, and take safety precautions. In the meantime, it is also necessary to strengthen information communication with adjacent mines in the surrounding area, when it is found that the water damage of the mine may affect the adjacent mine, an immediate warning is issued to the adjacent mine.

- (2)

- In the emergency command and control, coal mining enterprises are advised to deepen the multidimensional efforts concept and the integrated establishment of water hazard accident underground personnel timely evacuation systems. Greater efforts should be made to enhance the emergency command and control quality of the coal mine personnel, and accelerate the design of scientific and reasonable emergency broadcasting systems. Coal mining should vigorously carry out accident drills, take advantage of safety training, and exchange learning and other opportunities in order to standardize the process steps, such as accident identification and control, emergency command agency activation, disaster relief command coordination, clear start-up criteria, and command departing.

- (3)

- In the emergency relief and mitigation, one should adhere to the “fast, effective, detract” course of action, committed to creating a skilled, rapid action rescue team. With the emphasis of building special and combined emergency rescue teams, set up emergency material reserves and infrastructure emergency temporary deployment points, master rescue technology and equipment, and optimize the current rescue plan. Water damage in coal mines may cause secondary disasters, such as secondary water burst and toxic and harmful gas leakages. Therefore, rescue programs should be systematically built with expert guidance. Perform accident emergency rescue and mitigation work need to pay attention to the combination of peace and war. In other words, the capacity-building of emergency services and the capacity of emergency responses should are both enhanced. What calls for special attention is the operational status of the security monitoring system and the video monitoring system, both of which play an irreplaceable role in guaranteeing the scientificity and effectiveness of emergency rescue and mitigation.

- (4)

- In the emergency management dimension, the emergency response capacity of coal mine water accident mainly depends on the frequency of emergency drills, the scientific nature of emergency preparedness planning and modification drills, the completeness of various systems at all levels, and the proficiency of personnel cooperation. It is recommended that coal mining enterprises organize special drills for water hazards in accordance with the provisions of the “Regulations on Water Prevention and Control” [44] in order to improve the proficiency of material deployment and personnel coordination. Coal mining enterprises are supposed to invest more funds in safety technology based on their actual situation, and establish and optimize management systems of different levels including emergency response systems for water hazard accidents, emergency material reserve management systems, responsibility systems for preventing and controlling water hazard accidents, and water disaster investigation and treatment systems. Besides, it is a must to clarify the responsibilities of the personnel involved with the intention of greatly avoiding disorderly and inefficient emergency response.

- (5)

- In the personnel dimension, coal mining enterprises are expected to increase their knowledge concerning water hazard accidents, clarify a concept of safe development, standardize daily production, and commit themselves to creating a sound situation featuring unified knowledge, belief, and actions for all employees. Set up incentive mechanisms of reward and punishment: employ punishment mechanisms to strengthen the knowledge and skills of personnel in water hazard accidents, and use rewards to inspire employees to learn. At the same time, strengthen the construction of enterprise safety cultures, cultivate the internal safety motivation of employees, and create a good production safety atmosphere.

- (6)

- In the prevention preparedness dimension, coal mining enterprises should strengthen ties with universities and scientific research institutes, update existing drainage and drainage technology equipment, introduce advanced equipment for mining, monitoring, warning, etc., actively introduce geophysical satellite systems to monitor groundwater flows, and deploy seismic sensors to detect underground bumps. In order to judge groundwater flow and verify the rationality of mine drainage systems, and to improve the graded control ability of underground water hazard risk, all-round improvement of the coal mine water accident detection system and early warning capabilities are desired.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- National Development and Reform Commission. Coal Industry Development “13th Five-Year Plan”; National Energy Administration: Beijing, China, 2016. Available online: http://www.nea.gov.cn/2016-12/30/c_135944439.htm (accessed on 30 December 2016).

- Ge, L.T.; Ye, G.J.; Gang, H.L. Hydrogeology of Coal Fields in China; Coal Industry Press: Beijing, China, 2001; pp. 1–12. [Google Scholar]

- Wang, H.; Liu, B. Control Technology of Mine Water Damage; Coal Industry Press: Beijing, China, 2007; pp. 90–127. [Google Scholar]

- Zeng, Y.; Wu, Q.; Zhao, S.; Miao, Y.W.; Zhang, Y.; Mei, A.S.; Meng, S.H.; Liu, X.X. Characteristics, causes, and prevention measures of coal mine water hazard accidents in China. Coal Sci. Technol. 2023, 51, 1–14. [Google Scholar]

- David, T. Rock fracture spacings, openings, and porosities. J. Soil Mech. Found. Div. 1968, 94, 73–91. [Google Scholar] [CrossRef]

- Louis, C. Groundwater flow in rock masses and its influence on stability. Rock Mech. Res. 1969. [Google Scholar]

- Meng, S.; Gao, Y.; Lu, A.H. Theory and Method of Mine Water Inrush Risk Assessment; Science Press: Beijing, China, 2001; pp. 74–77. [Google Scholar]

- Kong, H.L.; Miao, X.X.; Wang, L.Z.; Zhang, Y.; Chen, Z.Q. Analysis of the harmfulness of water-inrush from coal seam floor based on seepage instability theory. J. China Univ. Min. Technol. 2007, 17, 453–458. [Google Scholar] [CrossRef]

- Vutukuri, V.S.; Singh, R.N. Mine inundation-case histories. Mine Water Environ. 1994, 14, 107–130. [Google Scholar] [CrossRef]

- Yan, Z.; Zhang, H.; Du, P. Application of SVM in analyzing the headstream of gushing water in coal mine. J. China Univ. Min. Technol. 2006, 16, 433–438. [Google Scholar] [CrossRef]

- Wang, S. Research on construction of theoretical model of coal mine accident cause. Coal Sci. Technol. 2007, 12, 106–108. [Google Scholar] [CrossRef]

- Zhang, Z.L.; Gao, Y.; Wu, Q.; Wei, S.M. Technical system of three-dimensional control of mine water damage. J. China Coal Soc. 2013, 38, 378–383. [Google Scholar] [CrossRef]

- Zhao, B.F. Control of mine water disaster based on MATLAB fuzzy clustering analysis. Coal Sci. Technol. 2013, 41, 89–92. [Google Scholar] [CrossRef]

- Miao, Y.W.; Ye, L. Analysis and prevention countermeasures of coal mine water disaster in China in 2020. China Coal 2021, 47, 51–54. [Google Scholar]

- Sun, W.J.; Han, Q.; Li, S.Q. Analysis on water inrush accidents in China’s coal mines 2000–2015. Coal Eng. 2017, 49, 95–98. [Google Scholar]

- Wei, J.C.; Xiao, L.L.; Niu, C.; Yin, H.Y.; Shi, L.Q.; Han, J.; Duan, F.T. Characteristics analysis of the correlation factors of China mine water hazard accidents in 2001–2013. China Sci. 2015, 10, 336–341. [Google Scholar]

- Yin, S.X.; Wang, Y.; Li, W. Cause, countermeasures and solutions of water hazards in coal mines in China. Coal Geol. Explor. 2023, 51, 20. [Google Scholar]

- Zhang, P.; Li, F.; Zhu, H.; Niu, H.; Li, X. Statistical analysis and prevention countermeasures of coal mine accidents from 2008 to 2020. Min. Saf. Environ. Prot. 2022, 49, 128–134. [Google Scholar]

- Bascetin, A.; Adiguzel, D.; Eker, H.; Tuylu, S. The investigation of geochemical and geomechanical properties in surface paste disposal by pilot-scale tests. Int. J. Min. Reclam. Environ. 2022, 36, 537–551. [Google Scholar] [CrossRef]

- Jia, X.; He, R.M.; Yao, H. Study on law of mining-induced surface crack affected to surface water in Shendong Mining Area. Coal Sci. Technol. 2017, 45, 17–22. [Google Scholar]

- Lu, Z.; Guo, Y.N.; Li, G.Q.; Wang, L.; Li, F.Z.; Zhang, Z. Water quality and health risk of surface water, groundwater and mine water in Shendong mining area. Saf. Environ. Eng. 2023, 30, 222–234. [Google Scholar] [CrossRef]

- Li, Q.M.; Zhai, L.J.; Fu, Y.J.; Ma, X.F.; Tang, Y.B.; Li, J.Y.; Li, H.; Meng, Y.P.; Ma, Y.L. A Study on Coal Mining Aquifer Destruction Mode in North China Typed Coalfields. Coal Geol. China 2012, 24, 38–43. [Google Scholar] [CrossRef]

- Cao, Z.G.; He, R.M.; Wang, X.F. Coal Mining Affected to Underground Water and Underground Water Storage and Utilization Technology. Coal Sci. Technol. 2014, 42. 113–116+128. [Google Scholar] [CrossRef]

- Ning, J.H.; Jia, X.R. Discussion on Working Grade Determination Method for Environmental Impact Assessment of Groundwater in Coal Mine area. Coal Geol. Explor. 2004, 32, 153–154. [Google Scholar] [CrossRef]

- Fan, L.M.; Kou, G.D.; Jiang, Z.Q.; Wang, Z.Z. The variation law of groundwater flow field during the mining process of shallow buried coal seam. Shaanxi Coal 2003, 1, 26–28. [Google Scholar]

- Dong, S.N.; Hu, W.Y. Basic characteristics and main controlling factors of coal mine water hazard in China. Coal Geol. Explor. 2007, 5, 34–38. [Google Scholar]

- Wu, Q.; Shen, J.J.; Wang, Y. Mining techniques and engineering application for “Coal-Walter” dual-resources mine. J. China Coal Soc. 2017, 42, 8–16. [Google Scholar] [CrossRef]

- Wang, S.M.; Huang, Q.X.; Fan, L.M.; Yang, Z.Y.; Shen, T. Study on overburden aquclude and water protection mining regionazation in the ecological fragile mining area. J. China Coal Soc. 2010, 35, 7–14. [Google Scholar] [CrossRef]

- Zhao, P.M.; Guo, Q.L. Experimental research on the permeability of high-rank coal under a varying stress and its influencing factors. Int. J. Coal Geol. 2013, 162, 108–117. [Google Scholar] [CrossRef]

- Dong, S.Z.; Gang, W.F.; Yu, D.L.; Li, Q.M. Field trials of aquifer protection in longwall mining of shallow coal seams in China. Int. J. Rock. Mech. Min. 2010, 47, 908–914. [Google Scholar] [CrossRef]

- Qiang, S.; Ji, X.Z.; Nan, Z. Study and discussion of short-strip coal pillar recovery with cemented paste backfill. Int. J. Rock. Mech. Min. 2018, 104, 147–155. [Google Scholar] [CrossRef]

- Zhen, H.; Zhen, Q.J.; Shu, Y.Z.; Zi, W.Q.; Ding, T.C. Characterizing the hydraulic conductivity of rock formations between deep coal and aquifers. Int. J. Rock. Mech. Min. 2014, 71, 12–18. [Google Scholar] [CrossRef]

- Hua, G.; Liang, Y.; Bao, T.S.; Qing, D.Q.; Jun, H.X. Mining-induced strata stress changes, fractures and gas flow dynamics in multi-seam longwall mining. Int. J. Rock. Mech. Min. 2012, 54, 129–139. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, H.T.; Guo, L.; Du, P.Y.; Li, L.W.; Li, R.J.; Tang, X.F. Spatial distribution of soil heavy metal Cu content using Cokriging interpolation model combined with principal component analysis. J. Huazhong Agric. Univ. 2016, 35, 60–69. [Google Scholar] [CrossRef]

- Zhang, G.F.; Yang, L.R.; QU, M.K.; Chen, H.L. Interpolation of daily mean temperature by using geographically weighted regression-Kriging. Chin. J. Appl. Ecol. 2015, 26, 1531–1535. [Google Scholar] [CrossRef]

- Hu, W.Y. Water inflows prediction technique of water inflow from roof aquifer during extraction of shallow seam. Coal Geol. Explor. 2016, 44, 91–96. [Google Scholar] [CrossRef]

- Tie, L.; Ting, T.M.; Xue, H.S.; Yu, G.L.; Ji, Q.S.; Ming, C. A study on a water-inrush incident at Laohutai coalmine. Int. J. Rock. Mech. Min. 2013, 59, 151–159. [Google Scholar] [CrossRef]

- Gao, L.; Wu, Q.; Li, Y.; Ding, D.; Hao, Y.; Cui, Y.; Sun, H. How prepared are hospitals’ emergency management capacity? Factors influencing efficiency of disaster rescue. Disaster Med. Public Health Prep. 2018, 12, 176–183. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Zhang, S.; Zhang, Z.; Meng, Q. Estimating Added Values of the Integrated Emergency Response System for Airport Accident: Improved Responsiveness and Increased Service Capacity. Math. Probl. Eng. 2018, 2018, 3960242. [Google Scholar] [CrossRef]

- Ordu, M.; Der, O. Polymeric Materials Selection for Flexible Pulsating Heat Pipe Manufacturing Using a Comparative Hybrid MCDM Approach. Polymers 2023, 15, 2933. [Google Scholar] [CrossRef]

- Zhou, Q.C.; Zhang, H.Q.; Jiao, Y.; Yu, B.; Guo, J. Evaluation of the risk of water inrush from coal roof based on combination weighting method. Sci. Technol. Eng. 2022, 22, 3497–3503. [Google Scholar]

- Chen, G.B.; Teng, P.C.; Li, T.; Wang, C.Y.; Chen, S.J.; Zhang, G.H. Evaluation model of rock burst in coal mine and its application. J. Taiyuan Univ. Technol. 2021, 52, 966–973. [Google Scholar]

- Kumar, A.; Sah, B.; Singh, A.R.; Deng, Y.; He, X.; Kumar, P.; Bansal, R.C. A review of multi criteria decision making (MCDM) towards sustainable renewable energy development. Renew. Sust. Energ. Rev. 2017, 69, 596–609. [Google Scholar] [CrossRef]

- The Central People’s Government of the People’s Republic of China. Rules on Water Control in Coal Mines. 2018. Available online: https://www.gov.cn/zhengce/zhengceku/2018-12/31/content_5448431.htm (accessed on 31 December 2018).

| Target Layer | Criterion Layer | Sub-Criterion Layer | Index Level | AHP Weight | Entropy Method Weight | Combined Weight |

|---|---|---|---|---|---|---|

| Efficiency measurement index system of comprehensive emergency response system for coal mine flooding accident | B1 Responsiveness | C1 Accident information transmission | Hazard identification capability C11 | 0.0419 | 0.0378 | 0.03985 |

| Prediction ability of water exploration and release C12 | 0.0496 | 0.0541 | 0.05185 | |||

| Water damage cause analysis capacity C13 | 0.0463 | 0.0490 | 0.04765 | |||

| Accident information alarm capability C14 | 0.0371 | 0.0356 | 0.03635 | |||

| Accident information reporting ability C15 | 0.0325 | 0.0309 | 0.0317 | |||

| C2 Emergency command and control | Accident identification and control handling capability C21 | 0.0341 | 0.0309 | 0.0325 | ||

| The emergency broadcast system is scientific C22 | 0.0301 | 0.0356 | 0.03285 | |||

| Emergency command authority activation capability C23 | 0.0445 | 0.0378 | 0.04115 | |||

| Disaster relief command and coordination ability C24 | 0.0381 | 0.0425 | 0.0403 | |||

| C3 Emergency rescue and mitigation | Quality of rescue team C31 | 0.0474 | 0.0464 | 0.0469 | ||

| Medical security level C32 | 0.0299 | 0.0464 | 0.03815 | |||

| Technical support C33 | 0.0315 | 0.0309 | 0.0312 | |||

| Security monitoring system running status C34 | 0.0464 | 0.0309 | 0.03865 | |||

| Video surveillance system running status C35 | 0.0303 | 0.0309 | 0.0306 | |||

| B2 Service capability | C4 Emergency management dimension | Safety input level of coal mine C41 | 0.0253 | 0.0253 | 0.0253 | |

| Completeness of emergency response system C42 | 0.0253 | 0.0283 | 0.0268 | |||

| Perfection of emergency materials reserve management system C43 | 0.0253 | 0.0253 | 0.0253 | |||

| Framework of the responsibility system for preventing and controlling water C44 | 0.0283 | 0.0253 | 0.0268 | |||

| Contingency plan preparation, training, and exercise rationality C45 | 0.0283 | 0.0283 | 0.0283 | |||

| C5 Personnel team dimension | Knowledge level of water damage accidents C51 | 0.0303 | 0.0283 | 0.0293 | ||

| Safety accident attitude concept C52 | 0.0407 | 0.0427 | 0.0417 | |||

| Code of conduct for work safety C53 | 0.0283 | 0.0283 | 0.0283 | |||

| C6 Prevention of preparation dimension | Rationality of mine drainage system C61 | 0.0493 | 0.0483 | 0.0488 | ||

| Water safety training and warning education level C62 | 0.0387 | 0.0366 | 0.03765 | |||

| Emergency rescue equipment and materials level C63 | 0.0472 | 0.0503 | 0.04875 | |||

| Spatial accessibility of emergency supplies C64 | 0.0425 | 0.0412 | 0.04185 | |||

| Emergency response exercise and summary normative C65 | 0.0508 | 0.0521 | 0.05145 |

| Evaluation Level | Rank Scale | Equal Efficiency Score Interval |

|---|---|---|

| optimal | I | (0.9, 1.0] |

| good | II | (0.8, 0.9] |

| normal | III | (0.7, 0.8] |

| range | IV | (0.6, 0.7] |

| Very bad | V | [0, 0.6] |

| Number of Copies Issued | Recycled Copies | Recovery | Effective Copies | Effective Recovery |

|---|---|---|---|---|

| 190 | 185 | 97.37% | 183 | 96.32% |

| Variable (Layer/Level) | Klonbach Coefficient | Item |

|---|---|---|

| Accident information transfer | 0.906 | 5 |

| Emergency command and control | 0.954 | 4 |

| Emergency rescue and mitigation | 0.944 | 5 |

| Emergency management dimension | 0.971 | 5 |

| Personnel team dimension | 0.917 | 3 |

| Preventive preparedness dimension | 0.978 | 5 |

| Overall questionnaire | 0.987 | 27 |

| Variable (Layer/Level) | KMO | Bartlett Sphericity Test | ||

|---|---|---|---|---|

| Exponent | Approximate Chi-Square | Degree of Freedom | Significance | |

| Accident information transfer | 0.755 | 242.547 | 10 | 0.000 |

| Emergency command and control | 0.818 | 298.787 | 6 | 0.000 |

| Emergency rescue and mitigation | 0.826 | 203.129 | 5 | 0.000 |

| Emergency management dimension | 0.754 | 201.075 | 10 | 0.000 |

| Personnel team dimension | 0.712 | 150.939 | 3 | 0.000 |

| Preventive preparedness dimension | 0.844 | 584.668 | 10 | 0.000 |

| Symbol | Comprehensive Integral | Positive Ideal Solution Distance | Negative Ideal Solution Distance | Relative Proximity | Sort Result |

|---|---|---|---|---|---|

| A | 78.78 | 7.544 | 0.000 | 0.000 | 5 |

| B | 81.31 | 3.960 | 3.584 | 0.475 | 2 |

| C | 80.02 | 0.000 | 7.544 | 1.000 | 3 |

| D | 84.12 | 5.790 | 1.754 | 0.232 | 1 |

| E | 79.64 | 6.329 | 1.216 | 0.161 | 4 |

| Symbol | Responsiveness B1 | Ranking | Symbol | Service Capability B2 | Ranking |

| A | 0 | 5 | A | 0.58457 | 3 |

| B | 0.65216 | 3 | B | 0.54529 | 4 |

| C | 0.74226 | 2 | C | 0 | 5 |

| D | 1 | 1 | D | 1 | 1 |

| E | 0.08996 | 4 | E | 0.74660 | 2 |

| Symbol | Accident Information Transmission C1 | Ranking | Symbol | Emergency Command and Control C2 | Ranking |

| A | 0.41828 | 4 | A | 0.26892 | 4 |

| B | 0.79819 | 3 | B | 0.36922 | 2 |

| C | 1 | 1 | C | 0 | 5 |

| D | 0.83046 | 2 | D | 1 | 1 |

| E | 0 | 5 | E | 0.32973 | 3 |

| Symbol | Emergency Rescue and Mitigation C3 | Ranking | Symbol | Emergency Management C4 | Ranking |

| A | 0 | 5 | A | 1 | 1 |

| B | 0.70415 | 3 | B | 0.29683 | 4 |

| C | 1 | 1 | C | 0.99883 | 2 |

| D | 0.73658 | 2 | D | 0.97260 | 3 |

| E | 0.43391 | 4 | E | 0 | 5 |

| Symbol | Personnel Team C5 | Ranking | Symbol | Prevention of Preparation C6 | Ranking |

| A | 0 | 5 | A | 0.96957 | 3 |

| B | 0.86374 | 3 | B | 0.67499 | 4 |

| C | 0.29527 | 4 | C | 0 | 5 |

| D | 0.91643 | 2 | D | 1 | 1 |

| E | 1 | 1 | E | 0.98252 | 2 |

| Symbol | Water Hazard Accidents Emergency Response System Effectiveness (A) | Lv. | |||

| A | 0.7878 | normal | |||

| B | 0.8131 | good | |||

| C | 0.8002 | good | |||

| D | 0.8412 | good | |||

| E | 0.7964 | normal | |||

| Symbol | Responsiveness B1 | Lv. | Symbol | Service Capability B2 | Lv. |

| A | 0.7778 | normal | A | 0.7995 | normal |

| B | 0.8270 | good | B | 0.7969 | normal |

| C | 0.8532 | good | C | 0.8270 | good |

| D | 0.8338 | good | D | 0.7608 | normal |

| E | 78.50 | normal | E | 0.8102 | good |

| Symbol | Information Transmission C1 | Lv. | Symbol | Command and Control C2 | Lv. |

| A | 0.8280 | good | A | 0.7902 | normal |

| B | 0.8636 | good | B | 0.8039 | good |

| C | 0.8666 | good | C | 0.8907 | good |

| D | 0.8825 | good | D | 0.7532 | normal |

| E | 0.7888 | normal | E | 0.7985 | normal |

| Symbol | Rescue and Mitigation C3 | Lv. | Symbol | Emergency Management C4 | Lv. |

| A | 0.7419 | normal | A | 0.8390 | good |

| B | 0.8043 | good | B | 0.7930 | normal |

| C | 0.8086 | good | C | 0.8372 | good |

| D | 0.8431 | good | D | 0.8390 | good |

| E | 0.7689 | normal | E | 0.7736 | normal |

| Symbol | Personnel Team C5 | Lv. | Symbol | Prevention of Preparation C6 | Lv. |

| A | 0.7057 | normal | A | 0.8174 | good |

| B | 0.8215 | good | B | 0.7885 | normal |

| C | 0.8286 | normal | C | 0.8204 | good |

| D | 0.7453 | good | D | 0.7223 | normal |

| E | 0.8398 | good | E | 0.8187 | good |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hao, Y.; Yang, H.; Zhang, L.; Sun, C. Study on the Effectiveness of the Integral Emergency Response System for Coal Mine Water Hazard Accidents Based on Combination Weighting. Processes 2024, 12, 235. https://doi.org/10.3390/pr12010235

Hao Y, Yang H, Zhang L, Sun C. Study on the Effectiveness of the Integral Emergency Response System for Coal Mine Water Hazard Accidents Based on Combination Weighting. Processes. 2024; 12(1):235. https://doi.org/10.3390/pr12010235

Chicago/Turabian StyleHao, Yu, Huanhuan Yang, Lijun Zhang, and Chaolun Sun. 2024. "Study on the Effectiveness of the Integral Emergency Response System for Coal Mine Water Hazard Accidents Based on Combination Weighting" Processes 12, no. 1: 235. https://doi.org/10.3390/pr12010235

APA StyleHao, Y., Yang, H., Zhang, L., & Sun, C. (2024). Study on the Effectiveness of the Integral Emergency Response System for Coal Mine Water Hazard Accidents Based on Combination Weighting. Processes, 12(1), 235. https://doi.org/10.3390/pr12010235