1. Introduction

Decanter centrifuges are continuously operating centrifuges that are frequently used for solid–liquid separation. For example, they find use on an industrial scale in the chemical or food industry, but also in wastewater treatment and mining. Due to their complex design and the high speeds at which decanter centrifuges rotate, the experimental investigation of the separation processes in the apparatus is difficult. This complicates the design and dimensioning of the centrifuge as well as the determination of ideal operating conditions, which entails high costs [

1].

At this point, numerical simulations help to increase the understanding of the process and optimize the design of the centrifuges and the separation process. On the one hand, dynamic real-time models exist, which cannot resolve the process directly, but provide a fast estimation of the process behavior with low computational effort by means of additional assumptions. For the compensation of the necessary model reduction, the flow and material behavior are modeled by suitable material and machine functions. On the other hand, there are resolved flow simulations that give more detailed insights into the physical behavior of centrifuges. In computational fluid dynamics (CFD), the flow pattern of the continuous phase is described by the solution of the Navier–Stokes equations and is thus resolved temporally and spatially. There are different methods for modeling the disperse phase: In Eulerian–Eulerian two-phase flows, the dispersed phase is also treated as a fluid, and additional conservation equations are solved. Supplemental source terms allow the momentum exchange between the two phases to be taken into account. In the Eulerian–Lagrange method, the dispersed phase is modeled using discrete moving particles on a co-moving coordinate system. The motion of the particles results from the forces acting on the particles due to, for example, fluid flow and particle–particle interactions. But again, the momentum exchange between the phases requires additional source terms. The disadvantage of resolved simulations is the high computational time, which is further increased by the additional source terms for the consideration of the interaction between the continuous and dispersed phases.

The literature contains a number of real-time models: Stickland et al. [

2] developed a model for the simulation of batch centrifuges, tubular centrifuges and the cylindrical part of decanter centrifuges. It is based on a one-dimensional numerical model for discontinuous bucket centrifuges. Thereby, three different domains of behavior exist: clarified fluid, sedimentation, and sediment compression. To represent the unsteady behavior, the conservation equations of momentum and mass are described with the Runge–Kutta method and linked to the flux density function based on the work of Kynch [

3]. The consideration of the material behavior enables a realistic simulation of the process. Building on the idea of flow sheet simulation [

4,

5], numerical models require a model reduction to simulate unit operations in real time. This makes it possible to model individual apparatuses as well as entire process chains [

6]. Applied to a solid bowl centrifuge, it is possible to calculate the separation efficiency and the sediment build-up. Thereby, this model also takes into account the geometry of the apparatus and machine functions. Gleiß et al. [

7] and Menesklou [

8] have developed such a model for decanter centrifuges. Empirical equations and model assumptions allow the characterization of the separation process. To describe the stratified flow patterns, a parabolic velocity profile was assumed. To describe the transport of the sediment or its efficiency, the authors introduce an additional factor that ranges from 0 to 1, where 0 stands for no transport and 1 for complete transport. To take into account the influence of local flow effects on the separation behavior, Menesklou [

8] extended the dynamic model with a neural network. The literature presents various hypotheses regarding the flow in decanter centrifuges: some assume a parabolic flow profile [

7], others plug flow [

9]. Furthermore, experiments have shown that backflow may occur immediately above the sediment [

10,

11]. Bai et al. [

12,

13] have also developed a dynamic model for decanter centrifuges and propose a new flow model that combines the parabolic flow profile and the backflow above the sediment according to a model proposed by Amirante and Catalano [

14]. The calculation of the cut size of the particle system is performed by different drag models as a function of the Reynolds number. The models already presented [

7,

8,

12,

13,

14] solely model the sedimentation and sediment formation. Furthermore, it is unclear whether the material is transportable or not. Bell et al. [

15] have developed a mathematical model that describes sediment transport in decanter centrifuges, taking into account the power, torque, and necessary axial force of the screw to ensure transportability. The model was validated for granular products with data from Reif and Stahl [

16].

The flow of the continuous phase in the apparatus has a direct effect on the movement of the particulate phase; thus, the flow conditions significantly influence the separation. To better understand the interplay between flow and separation behavior, resolved simulations are essential: Romaní Fernández and Nirschl [

17] proposed a coupled CFD–DEM method for the simulation of a solid bowl centrifuge. CFD provides the simulation of the flow of air and water, while DEM serves to model the movement of the particles. However, the computational effort rises with increasing particle number. The simulation of finely dispersed particle systems (<20

) and their consolidation behavior would obviously require a high computational effort. For this reason, Hammerich et al. [

18] developed a multi-phase simulation model for tubular centrifuges. The multi-phase system was treated as a mixed phase, with additional transport equations solved for the solid volume fraction. The model takes into account the consolidation and rheological behavior of the sediment. The sediment build-up over time has a strong influence on the flow conditions, which is in agreement with experimental data. Due to solver-internal algorithms and equations, the model is not applicable to complex geometries, such as the decanter centrifuge. Zhu et al. [

19] studied the solids distribution in a decanter centrifuge with a steady-state simulation. The simulation was performed with the software Fluent and the continuous and dispersed phases were calculated with the Eulerian–Eulerian method. The simulation results were compared with experiments. However, the simulated solids fraction was higher than expected (>85

). Kang et al. [

20] also modeled the multi-phase system with the Eulerian two-phase model. A multi-parameter optimization indicates possibilities for improving the separation performance in decanter centrifuges. For this purpose, geometrical properties, such as window size and the presence of a gap, were varied. Garrido et al. [

21] have shown that the sedimentation–consolidation process in centrifuges can be described by a single partial differential equation using solely one scalar, the solids volume fraction. Therefore, it is necessary to define initial and boundary conditions. Batch centrifuge tests [

22,

23] are used for validation, whereby the model achieved a good agreement. Based on these results, Baust et al. [

24] have coupled the partial differential equation with the conservation equations for the flow in CFD. Material functions provide the basis for modeling to consider the interactions between the continuous and dispersed phases. In contrast to the solver of Hammerich et al. [

18], the partial differential equation for the volume fraction of the solids allows the simulation of complex geometries. Moreover, additional equations, as in the conventional Euler–Euler or Euler–Lagrange models, are not necessary, which is why the computation time is comparatively moderate.

The specific objective of this study was to apply the solver developed by Baust et al. [

24] to a decanter centrifuge. The variation of the operating parameters served to verify the model in order to test whether it reproduces different characteristics of clarification and dewatering in decanter centrifuges. Experiments on a laboratory centrifuge were used for validation. The resolved simulation also provided insight into the flow processes in the apparatus. By studying the different velocity components, it was possible to identify and describe different flow phenomena in the apparatus. Furthermore, this study proposes to derive a transport efficiency from CFD data.

3. Results and Discussion

In this work, the simulation method presented by Baust et al. [

24] was used for the first time to simulate the separation process in a decanter centrifuge. First, the simulation results were compared with experimental data. Since the simulation method models solely monodisperse slurries, the solids volume fraction of the cake served as a validation parameter. The centrate was not considered.

Section 3.1 describes the startup procedure of the decanter centrifuge. Next,

Section 3.2 presents the validation data. The flow behavior is discussed in

Section 3.3. Finally,

Section 3.4 proposes a way to derive a transport efficiency for the sediment transport using the simulation method.

3.1. Startup Procedure of the Decanter Centrifuge

Figure 7 shows the startup procedure of the decanter centrifuge by visualizing different time steps. The color scale marks the solid volume fraction in the apparatus. To obtain a detailed impression, a logarithmic scaling was selected. In the beginning (

0

), there are no particles in the centrifuge (a). The slurry flows into the apparatus via four inlets. In the simulation shown, the volume flow is

24

, and the solids volume fraction of the feed is

. At 3000 rpm, a maximum C-value of 402 g is present on the inner wall of the bowl. The differential speed of the screw is

rpm. According to the acting centrifugal force, the particles settle toward the inner wall of the bowl and form the sediment (b). The gel point lies at

, which means that sediment is present in the regions colored red. In contrast, blue colors represent a steadily decreasing solid volume fraction smaller than

. In this case, the sediment forms primarily in the inlet area. The differential movement of the screw transports the sediment up the cone segment by segment. At time step

20

, the sediment is in the first segment of the cone (b); at time

40

, it is in the third segment (c); and at time

60

, it is in the last segment (d). Finally, the sediment reaches the outlet and is discharged (e). As time progresses, a sediment formation is also noticeable in the cylindrical part of the apparatus. The screw transport leads to a pushing of the cake into a triangular to trapezoidal shape [

24]. In the present case, however, the buoyancy of the fine particles and the neglect of the air phase provides a curvature of the sediment. The liquid to be clarified flows in the opposite direction toward the weir. Thereby, unseparated particles still have the chance to be separated. A part of the dispersed phase is not separated or accumulates immediately before the weir. Here, the sediment is swirled up from time to time (e–f).

Section 3.3 quantifies the observed flow effects in the zone before the weir. Due to the moving screw, the particles accumulate on the screw flights. As a result, there are fewer particles in the center of the screw channel, and the solids volume fraction is correspondingly lower. The simulation shows, however, that particles also accumulate behind the screw flights against the transport direction. This behavior may be explained by the disk stirrer effect, which is caused by the disturbing impact of the differential movement of the screw [

36]. Assuming that the pitch of the screw approaches zero, the screw turns into individual separated disks and thus becomes a multi-disk stirrer. In the case of leading screws, the fluid elements close to the disk assume a higher speed than those further away. Due to the increasing centrifugal acceleration, they experience a higher mass force and move radially outward. As a result, the specifically heavier disperse phase accumulates on the flights of the screw. The higher the differential speed, the greater the effect. In this context, it is conceivable that particles that have already been separated may be stirred up again.

Section 3.3 shows and discusses this flow phenomena quantitatively.

Figure 8 shows the average solids volume fraction

of the sediment in the individual screw segments. On the left, the temporal course is plotted (a). What can be clearly seen is the sediment reaching the individual segments step by step. The four inlets are located in segments 6 and 7, which is the reason the sediment is detectable here first. Since one of the four inlets is very close to the cone, the sediment is found in segment 8 at approximately the same time. The transport of the sediment is also recognizable; about every ten seconds the sediment reaches a new screw segment. At the beginning, the course shows a comparatively increased solid volume fraction of the sediment in part of the screw segments (no. 8, 9, 10, 11). It is conceivable that a steady state between the sediment being transported up the cone and the sediment flowing back down the cone is initially established during the start-up phase. Over time, the solids volume fraction of the sediment in the individual segments stabilizes and is quasi-constant. On the right, the average solids volume fraction in the individual segments is shown. The solids volume fraction of the sediment increases toward the cone. The reason for this may be that the yield point must first be exceeded. The transition between cylindrical and conical part is located in segment 8. In the last three segments, the solids volume fraction decreases again. The orange dashed line represents the solid volume fraction measured in the experiment at the outlet of the apparatus. The standard deviation is highlighted in a lighter orange. The simulated data fall into the range of the experimental measurement accuracy.

3.2. Validation of the Simulation Results

The series of experiments focuses on the variation of important process parameters to investigate their influence on the experimental results and verify whether the simulations correctly reflect the respective dependencies. For this purpose, the operating parameters, rotational speed, and differential speed of the centrifuge, as well as the inlet conditions, such as the volumetric flow rate, were varied. All experiments were carried out at least three times. At this point, it should also be noted that the material functions derived from the experiments represent an idealized state. For example, reallocation in the sediment is not captured by the laboratory experiments.

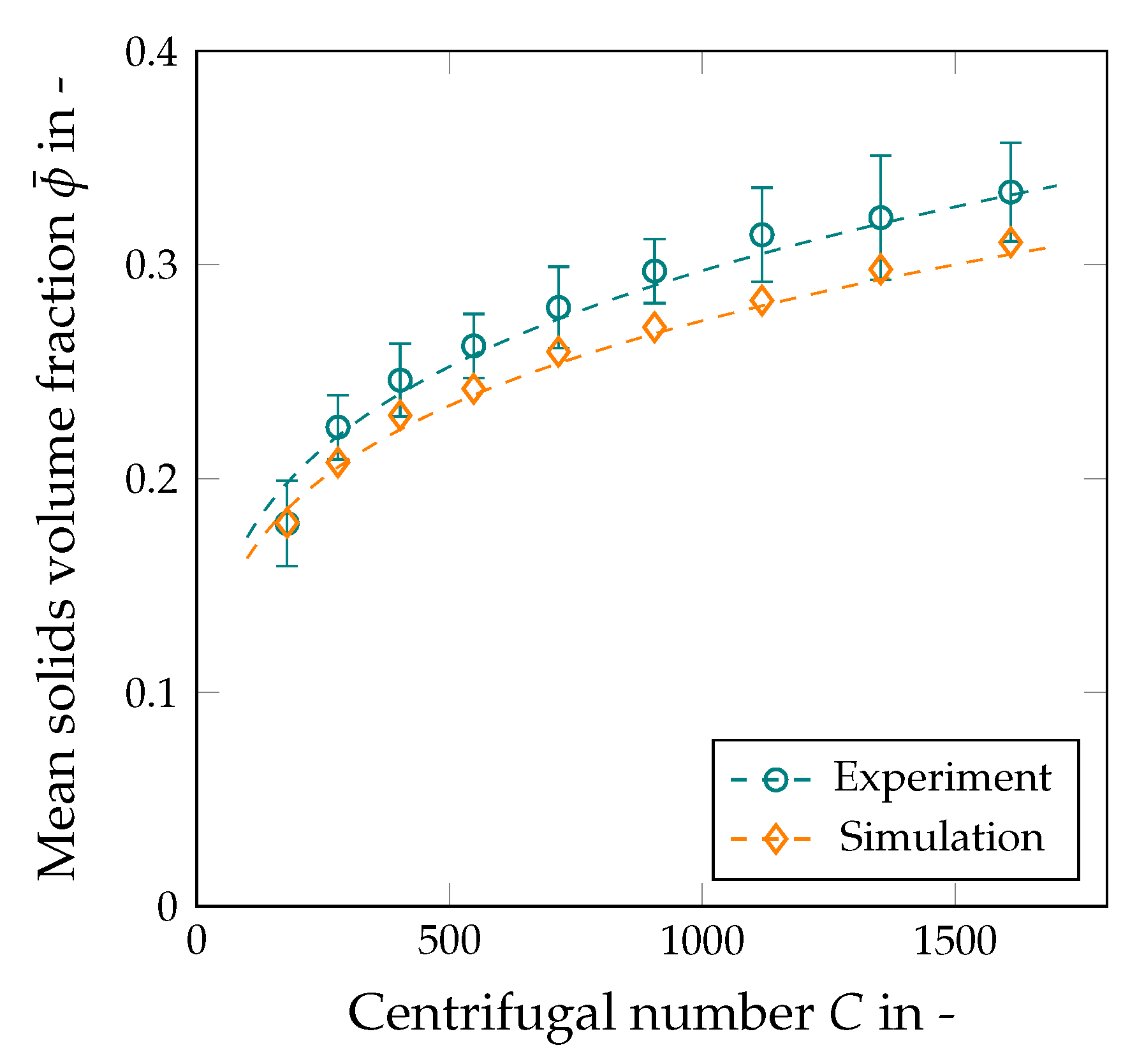

Figure 9 shows the solids volume fraction of the sediment plotted against the centrifugal number

C. In the results presented, the solids volume fraction at the inlet was constant at

, the differential velocity was

rpm, and the volumetric flow rate was constant at

24

, which corresponds to a Reynolds number of

. The volume flow spread evenly across the four inlets. Blue refers to the experimental data, orange to the simulated results. As expected, the solids concentration in the sediment increases with the growing centrifugal number. The reason is that as the rotational speed increases, the centrifugal acceleration and thus the forces acting on the sediment rise (

), resulting in a greater compaction of the sediment. The simulation reproduces the experimental data well. The inaccuracy of the experimental measurements overlaps with the range of the simulated results. At higher speeds, the simulation tends to underestimate the solids volume fractions in the sediment determined in the experiment. This may be related to additional shear compression in the apparatus [

37,

38]. The material function used to describe the consolidation behavior does not take into account the effect of shear stresses and considers solely the stresses acting in the normal direction.

A decisive factor for the design of decanter centrifuges is the ratio of residence time and the centrifugal acceleration, whereby the filling level of the centrifuge cannot be neglected. In addition to the rotational speed, the volume flow is therefore an important parameter for the separation.

Figure 10 shows the solids volume fraction of the sediment plotted against the Reynolds number. The rotational velocity is constant with

rpm, which corresponds to a centrifugal number of

and a constant differential velocity

rpm. The solids volume fraction at the inlet is

. Basically, the residence time of the suspension in the apparatus is shorter at higher volume flows. Consequently, the particles have more time to settle, so that even smaller particles may still be separated. Conversely, at the same feed concentration, the absolute input of solids into the centrifuge increases with rising volumetric flow rate. As a result, quantitatively more solids are separated at the same rotational speed, which leads to a higher sediment and thus to a better compaction of the sediment. In the present case, both the experimental and simulation results show no discernible effect of the volumetric flow rate on the solids volume fraction of the sediment, which might be caused by the small volume of the apparatus. This means that the sediment height in the centrifuge is approximately the same for all four volume flows. Since only one particle size is simulated in this study, the centrate was not considered for validation.

The differential rotation of the screw causes the transport of the sediment in the direction of the sediment discharge. Thereby, the differential speed has a significant influence on the residence time of the sediment.

Figure 11 shows the solids volume fraction of the sediment plotted against the differential velocity of the screw. The rotational speed of the bowl is constant with

rpm, which corresponds to a centrifugal number of 715. The volumetric flow rate was constant at

24

, which corresponds to a Reynolds number of

. Also, the inlet concentration was constant with

. The data indicate that with increasing differential speed, the solids volume fraction in the cake decreases as expected. Low differential speeds have the consequence that a higher sediment builds up and compacts stronger due to its own weight. The higher sediment reduces the flow cross-section, which may lead to an increase in the flow velocity and possibly to a poorer separation efficiency. In contrast, higher differential speeds result in a lower sediment height and less compactness. At the same time, a high differential speed shortens the dewatering time on the cone. An excessively high differential speed may lead to the resuspension of particles that have already been separated, resulting in disturbances of the clarification process. In the presented case, the trend of the simulatively determined data agrees well with those from the experiment.

In summary, the validation shows that the simulated results slightly underestimate the experimental data, but reproduce very well the effects of the varied process parameters on the product properties. The underestimation of the experimental data may be explained by the fact that shear compaction was not taken into account when determining the material function for consolidation. In addition, the air phase was neglected and the sediment of the monodisperse fine particle system was further affected by the buoyancy force. Discarding this assumption might have a positive effect on the sediment compaction, but was not further investigated in this work. Nevertheless, the deviation between the simulation and the experimental data is less than 5% and thus within the acceptable margin of error.

3.3. Flow Behavior in the Decanter Centrifuge

The conventional methodology used to design decanter centrifuges is based on mathematical approaches such as the

-theory given by Ambler [

9,

39]. The scale-up is performed by means of a

-parameter, which represents a clarification area equivalent to the thickener. The g-volume approach [

40] is also widely used in the design of centrifuges. Here, the ratio of the clarification volume and the g-force

C is kept constant in relation to the volume flow during scale-up. However, practical experience showed that the experimentally determined results may sometimes deviate significantly from the predicted ones so that pilot tests are necessary for the scale-up. In fact, a superposition of the sedimentation process by the local flow conditions occurs in the apparatus. In this case, CFD helps to investigate the flow conditions in the decanter centrifuge.

In

Section 3.1, the startup procedure was shown and described. Thereby, a disk stirring effect was indicated between the screw flights. To investigate this effect and the flow conditions in general in the centrifuge, different slice planes of the centrifuge are discussed. The flow velocity of the slurry along the screw channel comprises the individual components of the velocity-the radial, axial, and tangential velocities. An advantage of CFD is the possibility to analyze the flow components separately. This section focuses on the individual components of the velocity and discusses them. At this point, the most important assumptions should be listed: The solver did not consider the gas phase. The simulation merely included the mixing phase. Moreover, rigid body rotation was assumed. Adhesion conditions were applied to the walls. The incoming fluid was not pre-accelerated, and the region above the weir was made more generous.

In the laboratory decanter centrifuge investigated, the liquid flows along the screw channel towards the overflow weir. Thus, the tangential velocity complies with the main flow direction.

Figure 12 depicts the relative tangential velocity in the decanter centrifuge, which is defined as the absolute deviation from the rigid body rotation. In this case, the centrifuge was cut parallel to the axis of rotation. The segments shown are 5 and 6. Both segments are located in the cylindrical part of the centrifuge. Segment 6 contains one of the inlets. On the inner wall of the bowl, the relative tangential velocity is zero. Along the screw body and the flights, the relative tangential velocity is equal to the circumferential velocity corresponding to the differential speed of the screw. In the simulation, the slurry was not pre-accelerated in the inlet section. For this reason, the relative tangential velocity at the inlet is also zero. The highest velocity occurs in the center of the screw channel. In the present case, a uniform flow profile is formed in the screw channel. The maximum of the relative tangential velocity is about

, and the average velocity is about

. In the inlet segment, the gray colored part indicates that particles have been separated and have formed a sediment. In the sediment zone, the relative tangential velocity decreases significantly.

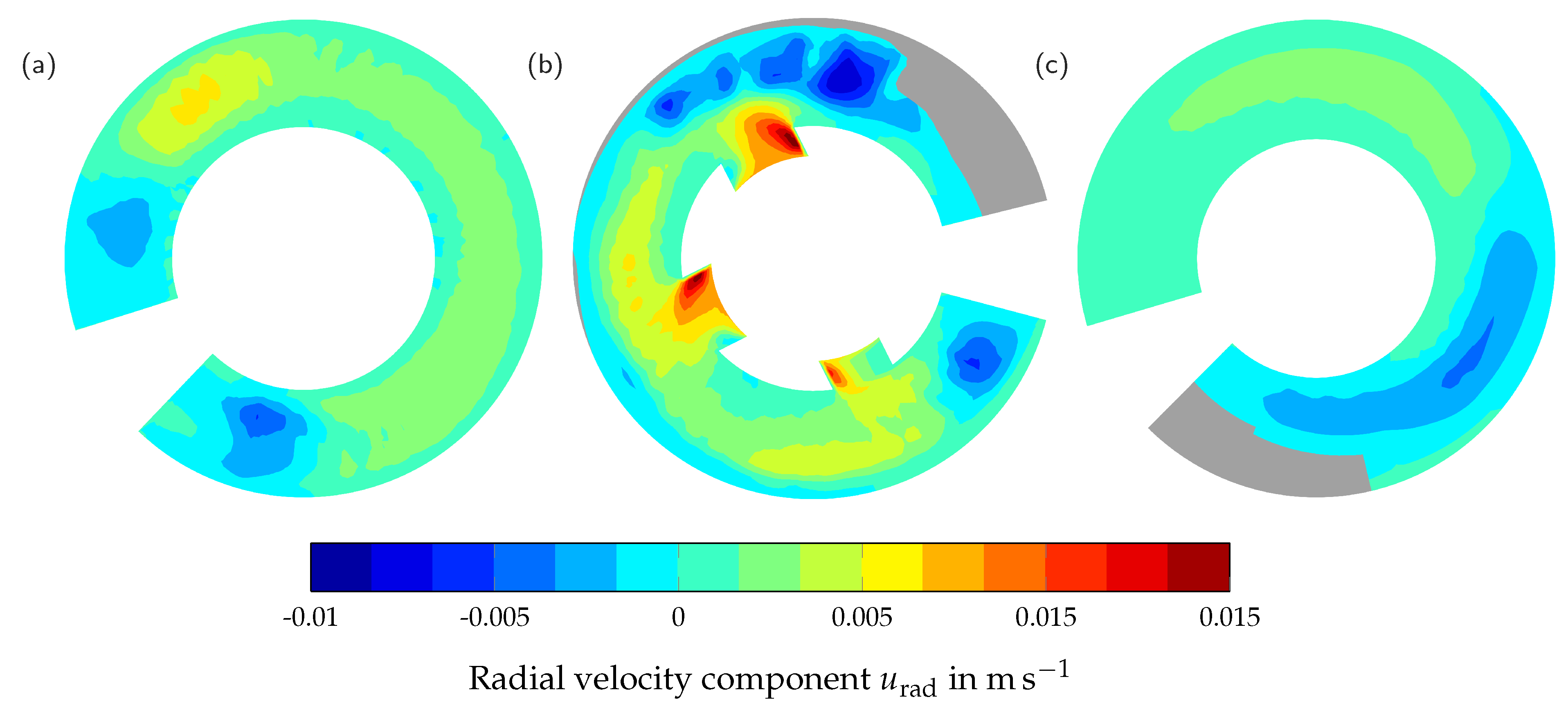

Figure 13 shows cuts orthogonal to the axis of rotation of the radial velocity component in the cylindrical part (a), in the inlet section (b), and in the conical part (c) of the decanter centrifuge at

and

. Positive values point in the direction of the bowl, negative values point in the direction of the screw body. The gray-colored parts represent the sediment. In the cylindrical part (a), no sediment is present. The radial velocity at the flights is opposite to the velocity in the center of the screw channel. This indicates the disk stirrer effect already mentioned in

Section 3.1. The picture in the middle shows the inflow of the slurry (b). At the inlets, the radial velocity is the highest with

. Again, a reverse flow occurs at the flights and close to the sediment. At the pushing flight, the sediment is recognizable (gray). In the sediment itself, the radial velocity is quasi zero. A kind of roller flow takes place in the conical part (c). Stahl [

36] described the same effect on the basis of theoretical considerations and concluded that friction effects cause a stationary roller flow. In summary, the radial velocity in the cylindrical (a) and conical (c) part of the apparatus take values in the range of

and are thus much smaller than the tangential velocity. Furthermore, the vortices are not perpendicular to the axis of rotation. Instead, they follow the screw channel. In the sediment, the radial velocity is quasi zero.

Figure 14 shows cuts orthogonal to the axis of rotation of the axial velocity component in the cylindrical part (a), in the inlet section (b), and in the conical part (c) of the decanter centrifuge at

and

. Positive values point toward the cone, negative values point toward the weir. No sediment is present in the cylindrical part (a). The axial velocities are highest between the pushing screw flank and the screw body and in the diagonally opposite corner between the bowl wall and the pulling flight. This flow profile also indicates the roller flow. The inlet area shows the same effect (b). However, there are more disturbances due to the inlets. The sediment (gray) accumulates at the pressing flight. It has a positive axial velocity, which means that the differential movement of the screw causes its transport toward the solids discharge. The same applies to the sediment in the conical part (c). It is conveyed up the cone. Again, a reverse flow may be observed.

Overall, the superposition of the axial, radial, and tangential velocities results in a complicated three-dimensional steady-state flow. Effects such as a the roller flow are recognizable. Thereby, the characteristics of the current follow the helix-shaped screw channel. The differential movement of the screw transports the sediment towards the solids discharge. Thereby, the solids accumulate at the pushing flight. In addition to the differential speed, the flow may be influenced by properties of the slurry, such as density and viscosity, as well as geometric properties, such as the channel width. The resolved simulations also allow the simulation of larger apparatuses and the investigation of the flow’s influence on the particle separation. In general, it is also conceivable to optimize the geometry of the apparatus, such as inlet and outlet geometry with regard to the interaction between flow and particle separation.

3.4. Deriving a Transport Efficiency

The sediment build-up in decanter centrifuges is based on two different aspects, the sediment formation due to the centrifugal forces within the apparatus and the sediment transport resulting from a differential speed between the screw and the bowl. At this point, it should be mentioned, that there is no generally applicable method for describing the transport behavior of liquid-saturated sediments. Current models are restricted to the description of the transport velocity in the axial direction, which depends on the differential speed, the helix angle, and a friction coefficient. The friction coefficient is determined experimentally, although it is normally not measurable. One goal of this work is to determine a theoretical value simulatively, which describe the sediment transport in the decanter centrifuges. For this purpose, a transport efficiency is derived from the simulative data, which can be adopted for flowsheet simulations. Thereby, the axial velocity of the sediment plays an important role.

The axial velocity allows us to derive the transport efficiency

, meaning how well the sediment will be transported within and out of the apparatus. For this purpose, the axial velocity is related to the screw pitch

and the differential speed

.

To determine the transport efficiency, the axial velocity of each grid cell is averaged according to its volume fraction with respect to the sediment volume. For the set material properties of kaolin, the average transport efficiency is 0.22. Simulations where the sediment has no yield point exhibit a transport efficiency of zero. In this case, the dispersed phase flows as the clarified liquid along the inner wall of the bowl toward the weir. The transport processes in the decanter itself are highly complex. In reality, the actual rheological behavior may be supplemented by gliding. The gliding may raise the transport rate in the apparatus. However, the solver does not reproduce this behavior.

4. Conclusions and Outlook

This article is the first to present the simulation of a decanter centrifuge using the numerical solver of Baust et al. [

24], which is based on the work of Garrido et al. [

21] and Hammerich et al. [

18], and provides an insight into the separation process in decanter centrifuges. For the validation, experiments were carried out on a laboratory-scale decanter centrifuge. The variation of the rotational speed, the differential speed, and the volume flow rate served to run different operating points. Sediment samples were taken at each operating point to determine the solids volume fraction. The model system used was a kaolin suspension consisting of kaolin and deionized water. The geometry of the centrifuge was generated using the ANSYS DesignModeler, and the required mesh refinement was identified by means of a mesh independence study. Preliminary simulations with a test case were carried out to ensure that the sediment was actually transported up the cone out of the apparatus. The simulation shows the sedimentation and sediment formation. Thereby, the solids accumulate on the pushing screw and are transported to the solids discharge by the differential movement of the screw.

Both the experimental results and the simulation show that the rotational speed mainly affects the sediment compaction. Furthermore, the results indicate an influence of the differential speed on the solids content in the sediment. In contrast, the variation of the volume flow shows no influence on the residual moisture of the sediment for the material considered. However, the decanter centrifuge used on a laboratory scale is small relative to typical machines used in industry. A transfer to a larger apparatus would be interesting. Since the simulation method merely supports the modeling of monodisperse slurries, an extension is planned to enable the simulation of polydisperse particle systems as well. The simulation of different particle size classes allows the determination of the separation efficiency as well as the numerical investigation of separation processes such as the classification.

The work shows that the simulation confirms the experimental results and reflects the expected trends. However, the simulation tended to slightly underestimate the solids volume fraction of the sediment. The reason for this probably lies in the shear compaction of the sediment caused by the differential motion of the screw, which was not taken into account. Furthermore, experimental uncertainties in the simulation were not taken into account in this work. However, it can be summarized that the deviations between simulation and experiments are within the accepted margin of error.

In addition, the simulation provides detailed insights into the behavior of the decanter centrifuge. The flow can be visualized and the sediment transport can be observed. Overall, the simulation shows a complex three-dimensional flow. The flow follows the helical screw channel and shows effects such as a roller flow, which Stahl [

36] has already described on the basis of theoretical considerations. Moreover, the numerical method allows the determination of the transport efficiency of the sediment by using the axial velocity of the sediment. The material considered in this study has a transport efficiency of 0.22 with the specified material functions. In general, the results prove that the numerical method developed by Baust et al. [

24] is suitable to study the flow behavior and the influence of flow on the separation performance in decanter centrifuges in the future.