CFD Analysis of the Effects of a Barrier in a Hydrogen Refueling Station Mock-Up Facility during a Vapor Cloud Explosion Using the radXiFoam v2.0 Code

Abstract

:1. Introduction

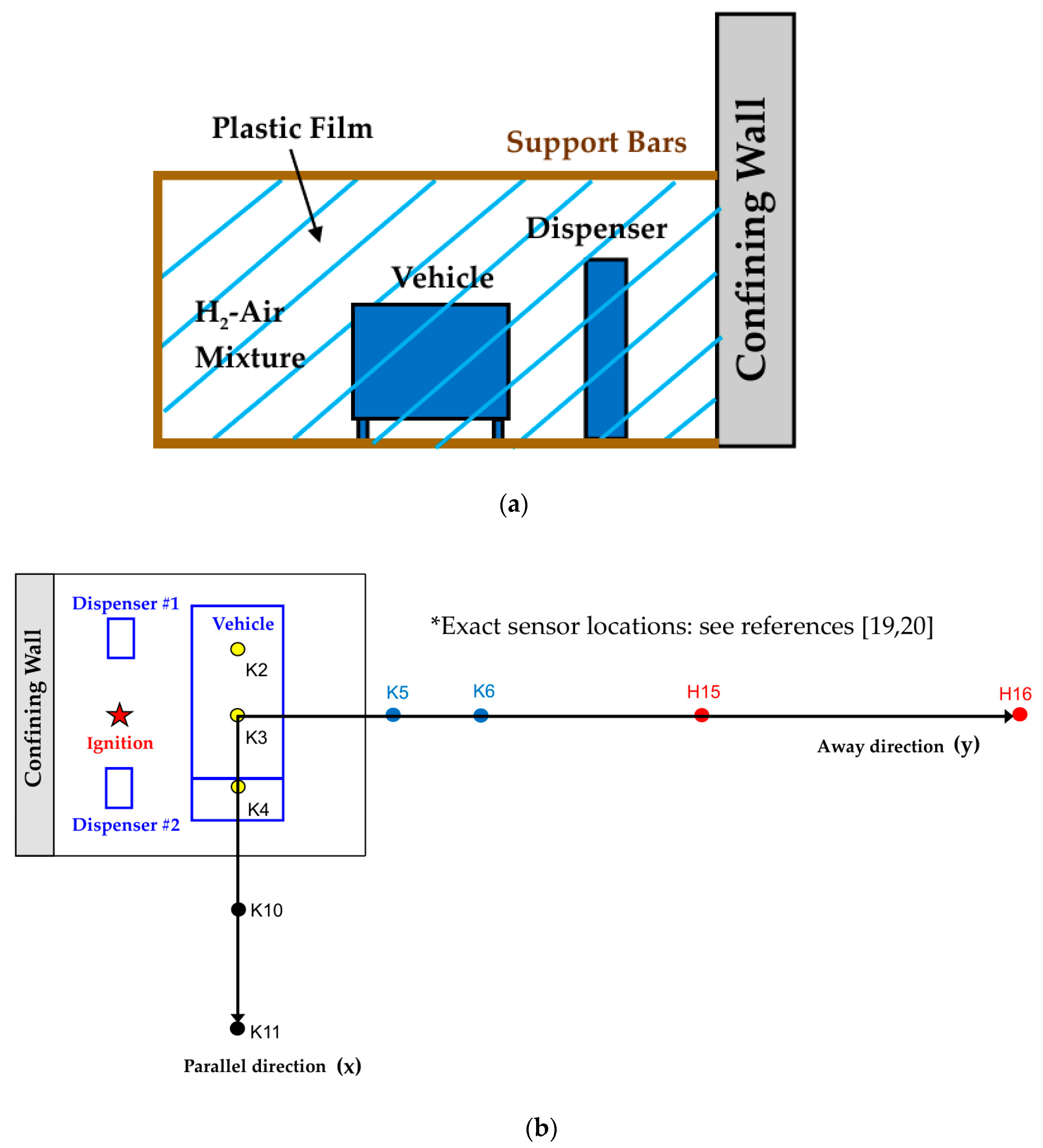

2. Hydrogen-Air Explosion Test in a HRS Mock-Up Facility

2.1. Test Facility and Conditions

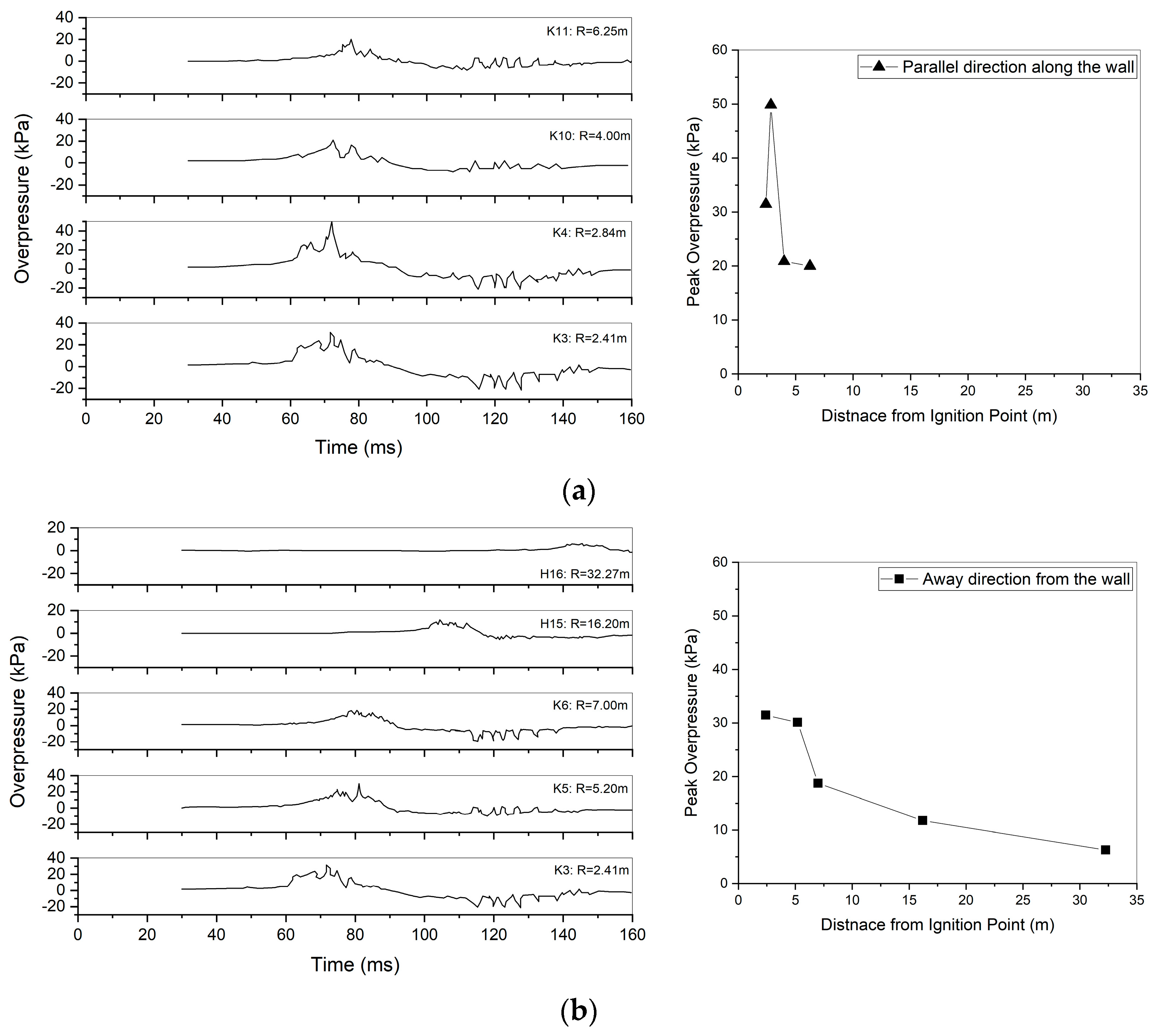

2.2. Discussion on Test Results

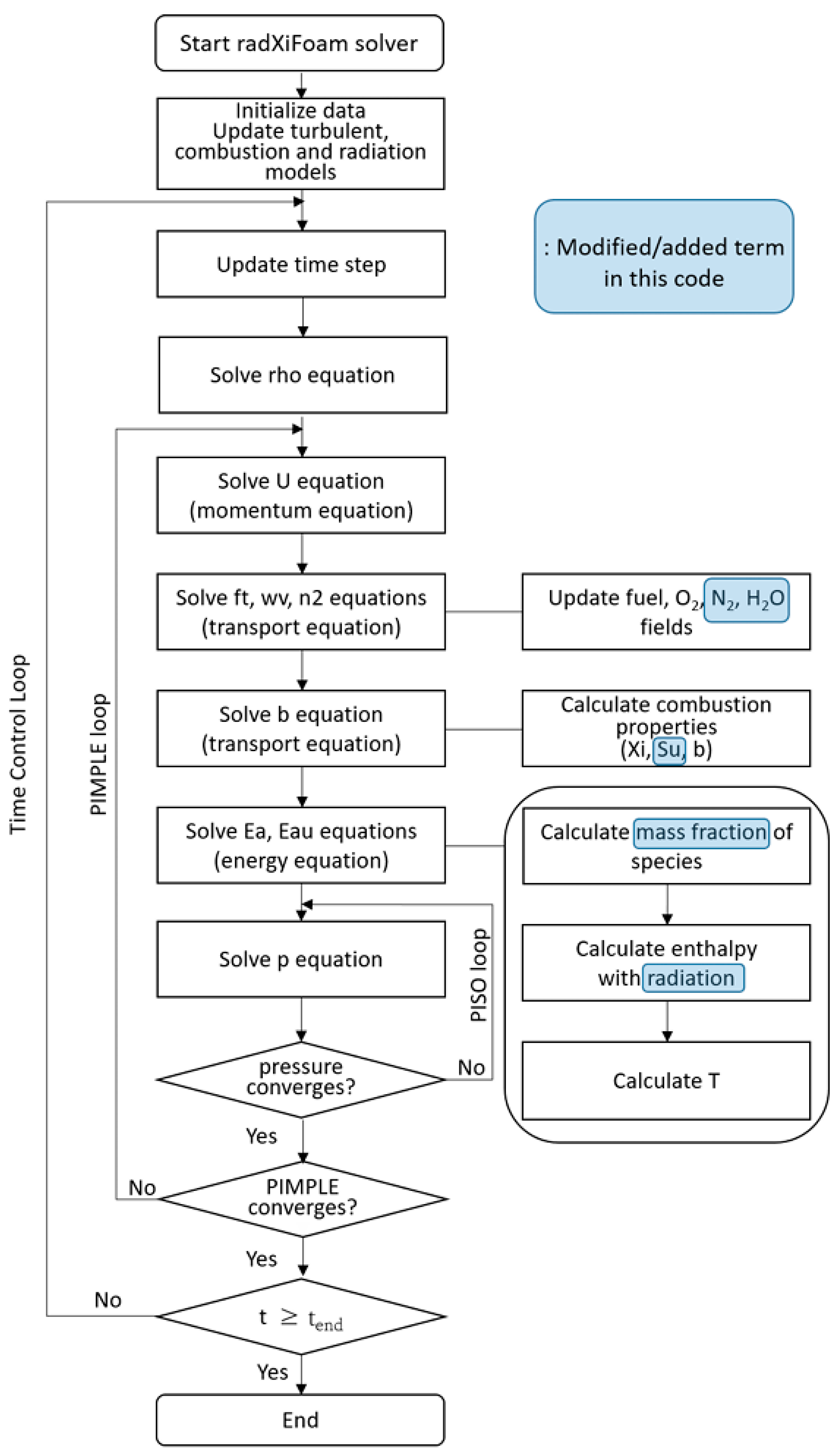

3. Development of the radXiFoam v2.0 Solver

3.1. Modification of Libraries

3.2. Calculation Procedure of the radXiFoam Solver

3.3. Validation Analysis of the radXiFoam v2.0 Code

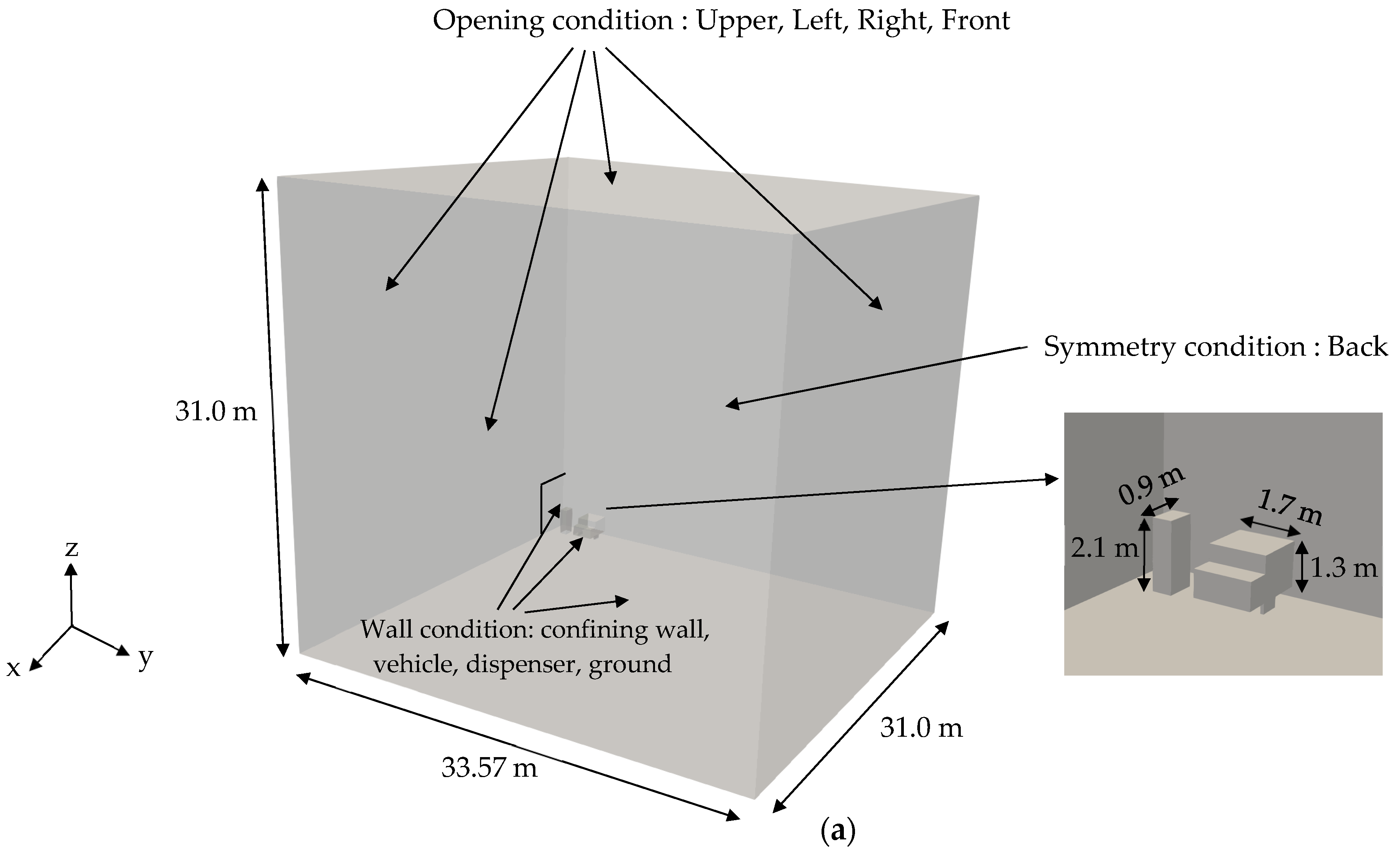

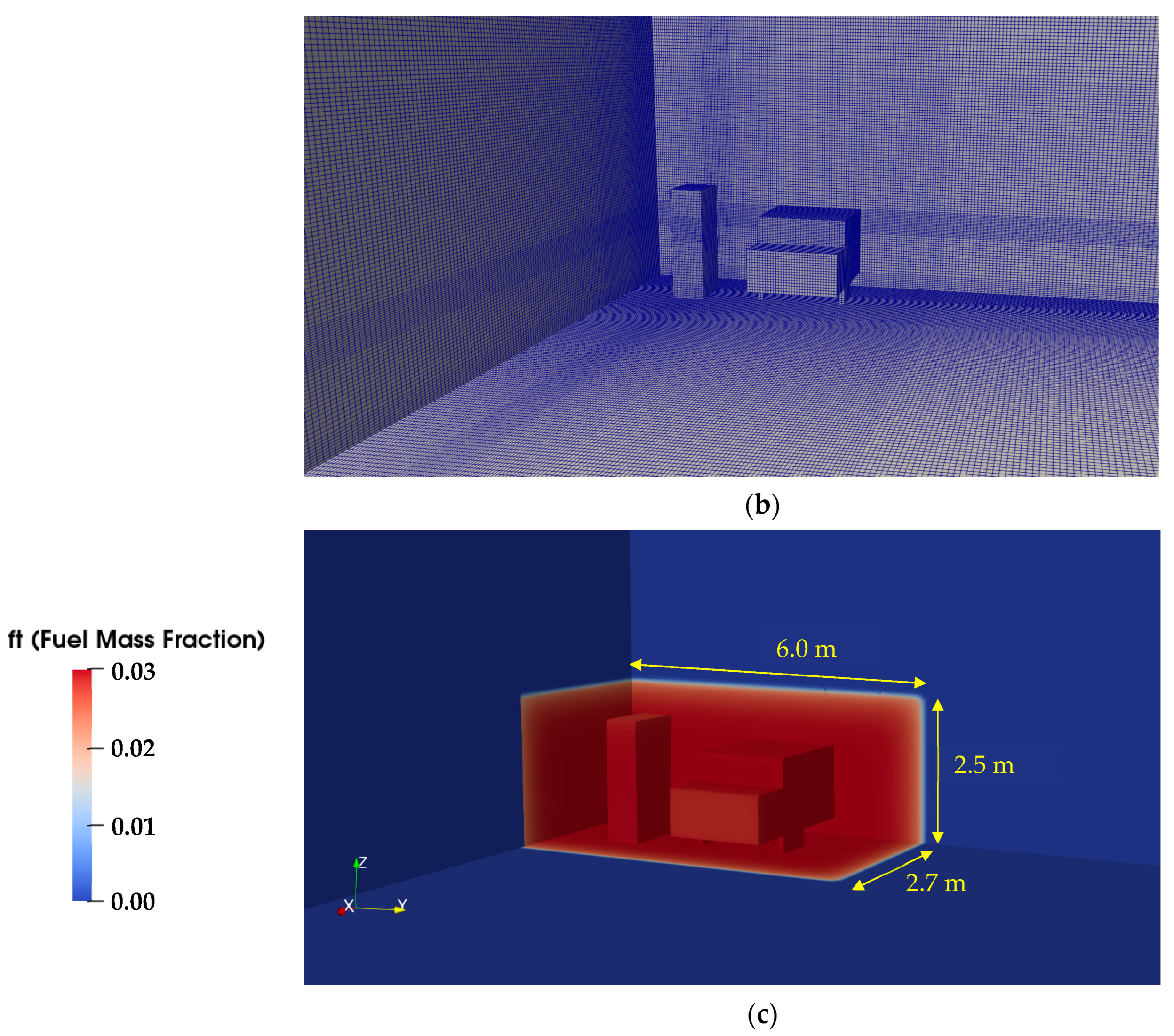

3.3.1. Grid Model with Initial and Boundary Conditions

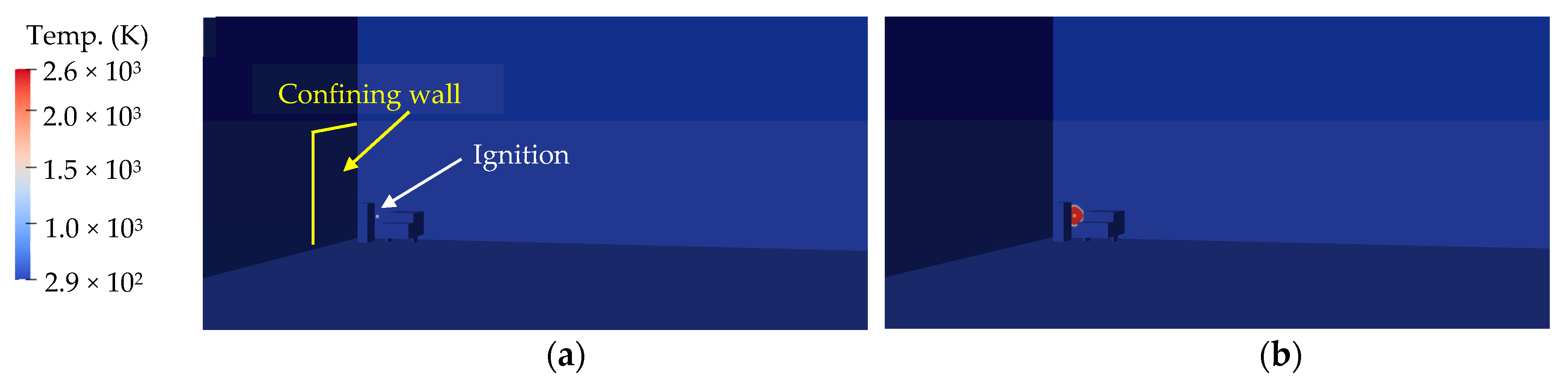

3.3.2. Analysis Methodology

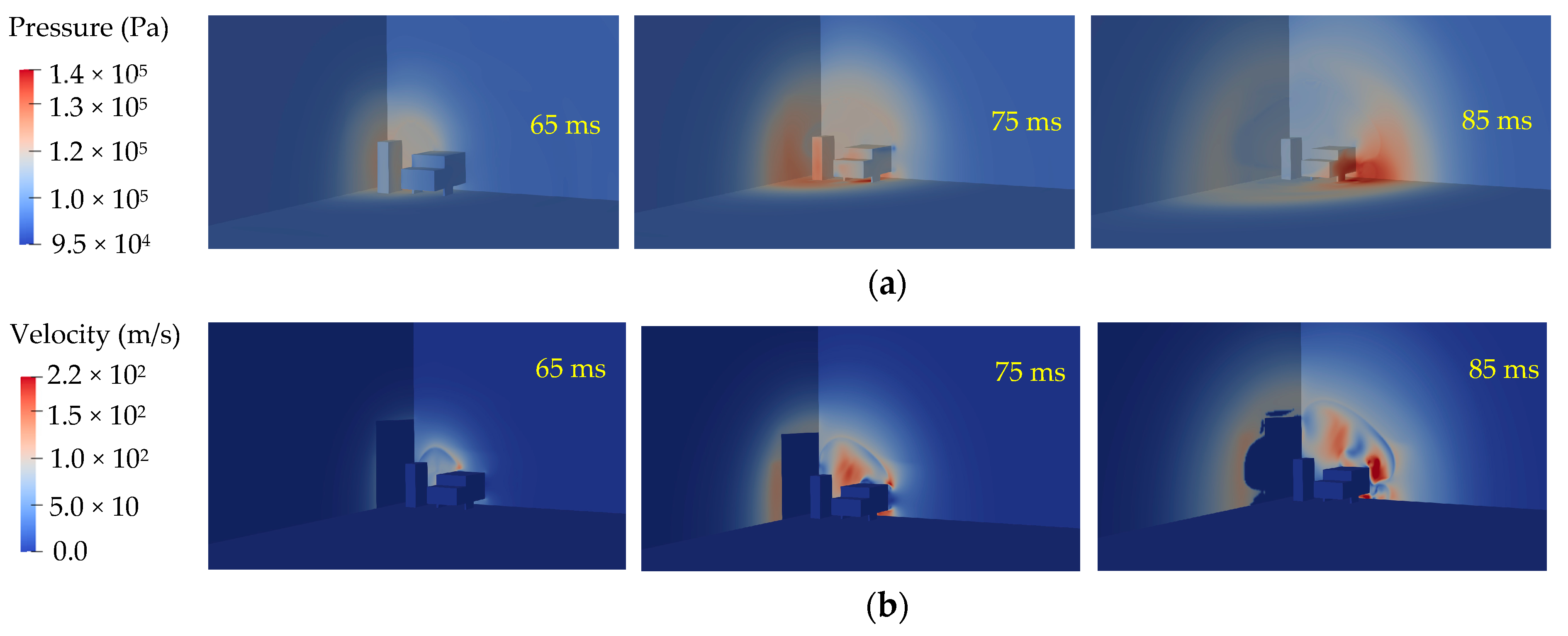

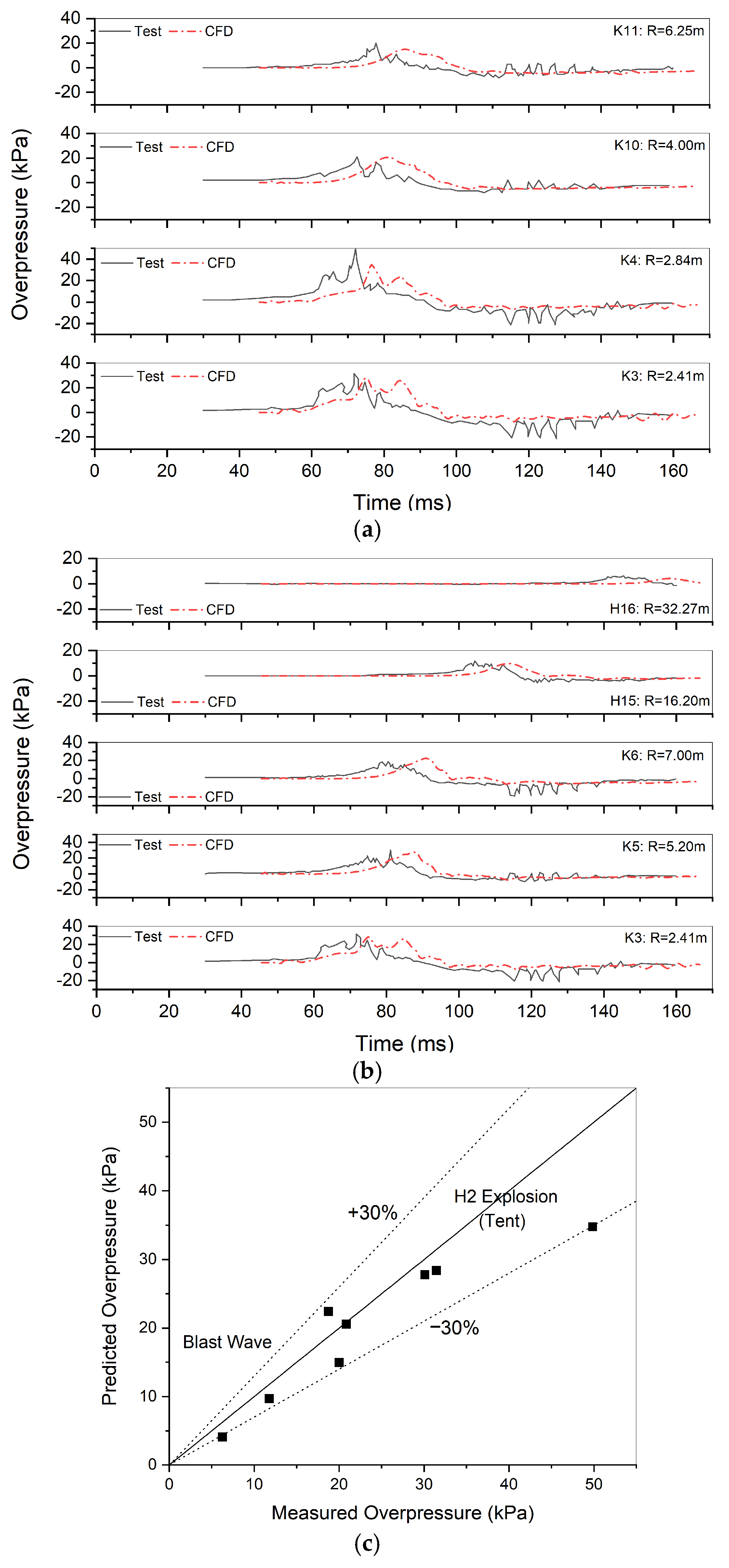

3.3.3. Discussion on the Calculation Results

4. CFD Sensitivity Calculation of the Effect of the Barrier Existence

4.1. Sensitivity Calculation Conditions

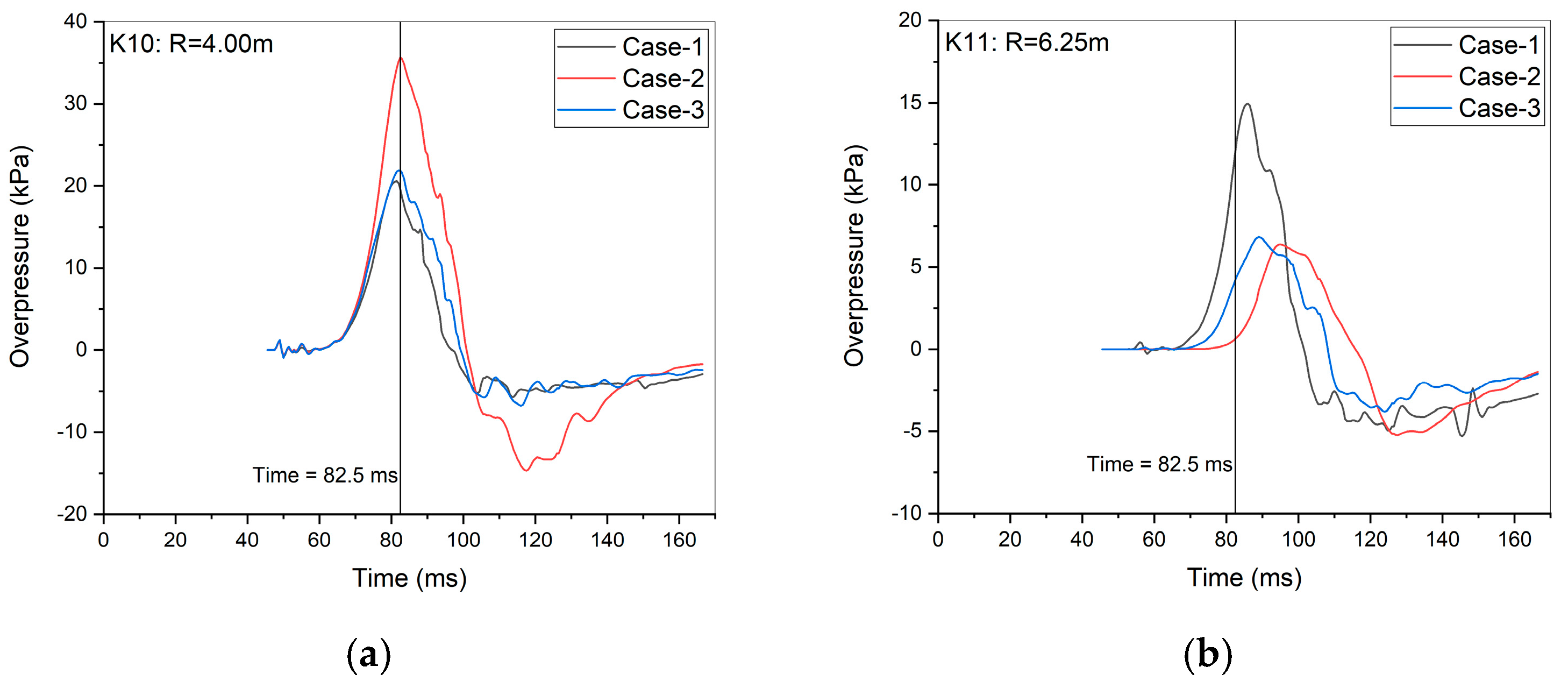

4.2. Discussion on the CFD Calculation Results

5. Conclusions

6. Future Studies

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Variable | Definition | Unit |

| awv | Absorption coefficient of water vapor | [−] |

| b | Reaction progress variable | [−] |

| E | Emission contribution | [−] |

| ft | Fuel mixture fraction | [−] |

| G | Radiation intensity | [W/m2] |

| h | Enthalpy | [J/kg] |

| K | Thermal conductivity | [W/m·K] |

| kwv | Absorption coefficient of water vapor depending on the gas temp. | [−] |

| p | Pressure | [Pa] |

| q | Heat flux | [W/m2] |

| Si | Source/Sink of species-i | [kg/m2·s] |

| Su | Laminar flame speed | [m/s] |

| Sct | Turbulent Schmidt number | [−] |

| T | Temperature | [K] |

| U | Velocity | [m/s] |

| Yi | Species-i mass fraction | [−] |

| μt | Turbulence effective viscosity | [kg/m·s] |

| ρ | Density | [kg/m3] |

| σSB | Stefan-Boltzmann constant | [W/m2·K4] |

| φ | Fuel equivalent ratio | [−] |

| Subscripts | ||

| eff | Effective | |

| o | Reference condition | |

| u | Unburned | |

| wv | Water vapor | |

References

- Kim, K.S. Development of Design Technology and Safety Standard in the Protection Wall for Blast Mitigations in a Hydrogen Station; Research Plan Report, No. 20215810100020; Korea Gas Safety Corporation: Eumseong, Republic of Korea, 2021. [Google Scholar]

- Chuncheon District Prosecutors’ Office, Gangneung Branch. Investigation Results for the Hydrogen Tank Explosion in Gangwon Techno Park; Press Release Report; Chuncheon District Prosecutors’ Office, Gangneung Branch: Gangneung, Republic of Korea, 2019. [Google Scholar]

- Lee, Y.C. Powerful explosion, directed fragments into nearby building. MBC News, 24 September 2019. [Google Scholar]

- KGS FP216; Facility/Technical/Inspection Code for Fuel Vehicles Refueling by Type of On-Site Hydrogen Production. Korea Gas Safety Corporation: Eumseong, Republic of Korea, 2020.

- KGS FP217; Facility/Technical/Inspection Code for Fuel Vehicles Refueling by Type of Compressed Hydrogen Delivery. Korea Gas Safety Corporation: Eumseong, Republic of Korea, 2020.

- Kang, H.-S.; Hwang, J.-W.; Yu, C.-H. A database extension for a safety evaluation of a hydrogen refueling station with a barrier using a CFD analysis and a machine learning method. Processes 2023, 11, 3025. [Google Scholar] [CrossRef]

- Kwon, D.; Choi, S.K.; Yu, C. Improved Safety by Crossanalyzing quantitative risk assessment of hydrogen refueling stations. Int. J. Hydrogen Energy 2022, 47, 10788–10798. [Google Scholar] [CrossRef]

- OpenCFD Ltd. OpenFOAM-v2112 User Guide; Technical Report; ESI: Rungis, France, 2021; Available online: https://www.openfoam.com (accessed on 6 August 2024).

- CFD Direct Ltd. Notes on Computational Fluid Dynamics: General Principles; CFD Direct Ltd.: Reading, UK, 2024; Available online: https://doc.cfd.direct/notes/cfd-general-principles (accessed on 6 August 2024).

- Kang, H.-S.; Kim, S.-M.; Kim, J. Safety issues of a hydrogen refueling station and a prediction for an overpressure reduction by a barrier using OpenFOAM software for an SRI explosion test in an open space. Energies 2022, 15, 7556. [Google Scholar] [CrossRef]

- Myilsamy, D.; Oh, C.-B. Computational study of a high-pressure hydrogen storage tank explosion at different heights from the ground. Int. J. Hydrogen Energy 2024, 50, 1245–1260. [Google Scholar] [CrossRef]

- KOSHA P-31-2001; Predictive Methods for Accident Damage. Korea Occupational Safety and Health Agency: Ulsan, Republic of Korea, 2001.

- NRC RG 1.91; Evaluations of Explosion Postulated to Occur at Nearby Facilities and on Transportation Routes Near Nuclear Power Plants. Nuclear Regulatory Commission: Rockville, MD, USA, 2021.

- Shen, R.; Jiao, Z.; Parker, T.; Sun, Y.; Wang, Q. Recent application of computational fluid dynamics (CFD) in process safety and loss prevention: A review. J. Loss Prev. Process Ind. 2020, 67, 104252. [Google Scholar] [CrossRef]

- Kim, S.M.; Kang, H.S.; Choi, K.S. radXiFoam v1.0; VCE Solver; KAERI: Daejeon, Republic of Korea; Available online: https://github.com/ksm0226/radXiFoam (accessed on 6 August 2024).

- Groethe, M.A.; Colton, J.D. FY01 Annual Report on Hydrogen Safety in the World Energy Network; Technical Report; SRI: Menlo Park, CA, USA, 2002. [Google Scholar]

- Groethe, M.A. FY02 Annual Report on Hydrogen Safety in the World Energy Network; Technical Report; SRI: Menlo Park, CA, USA, 2002. [Google Scholar]

- Kang, H.S.; Choi, K.-S. Report-I for Creating a Database of an Explosion Accident in a Liquefied Hydrogen Refueling Station; Technical Report; KAERI: Daejeon, Republic of Korea, 2023. [Google Scholar]

- Shirvill, L.C.; Roberts, T.A.; Royle, M.; Willoughby, D.B.; Gautier, T. Safety studies on high-pressure hydrogen vehicle refueling stations: Releases into a simulated high-pressure dispensing area. Int. J. Hydrogen Energy 2012, 37, 6949–6964. [Google Scholar] [CrossRef]

- Shirvill, L.C.; Royle, M.; Roberts, T.A. Hydrogen releases ignited in a simulated vehicle refueling environment. In Proceedings of the 2nd International Conference on Hydrogen Safety, San Sebastian, Spain, 11–13 September 2007. [Google Scholar]

- Turns, S.R. An Introduction to Combustion, 2nd ed.; McGraw-Hill, Inc.: Singapore, 2000. [Google Scholar]

- Kuo, K.K. Principles of Combustion, 2nd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2005. [Google Scholar]

- Kim, S.; Kim, J. Effect of radiation model on simulation of water vapor—Hydrogen premixed flame using flamelet combustion model in OpenFOAM. Nucl. Eng. Tech. 2022, 54, 1321–1335. [Google Scholar] [CrossRef]

- Modest, M.F. Radiative Heat Transfer, International Editions; McGraw-Hill, Inc.: Singapore, 1993. [Google Scholar]

- Mossi, A.; Galarca, M.M.; Brittes, R.; Vielmo, H.A.; Franca, F.H.R. Comparison of spectral models in the computation of radiative heat transfer in participating media composed of gases and soot. ABCM J. 2012, 34, 112–119. [Google Scholar] [CrossRef]

- Metghalchi, M.; Keck, J.C. Burning velocities of mixtures of air with methanol, isooctane, and indolence at high pressure and temperature. Combust. Flame 1982, 48, 191–210. [Google Scholar] [CrossRef]

- HP Development Company. High-performance Computing Power from Anywhere. Available online: https://hp.com/us-en/workstations/learning-hub/high-performance-computing-power.html (accessed on 6 August 2024).

- Kang, H.S.; Kim, J.; Hong, S.W.; Kim, S.B. Numerical Analysis for Hydrogen Flame Acceleration during a Severe Accident in the APR1400 Containment Using a Multi-Dimensional Hydrogen Analysis System. Energies 2020, 13, 6151. [Google Scholar] [CrossRef]

- Kang, H.S.; Kim, J.; Hong, S.W. Numerical Analysis for Hydrogen Flame Acceleration during a Severe Accident Initiated by SBLOCA in the APR1400 Containment. Hydrogen 2022, 3, 28–42. [Google Scholar] [CrossRef]

- Kitware Inc. ParaView-v5.11 User Guide; Technical Report; Kitware Inc.: New York, NY, USA, 2023; Available online: https://www.paraview.org (accessed on 6 August 2024).

| Total Tent Vol. (m3) | Mixture Free Vol. (m3) | Partial H2 Pressure | Equivalence Ratio of Mixture | Relative Humidity (%) | Ignition Method | Mixture Temp. (K) |

|---|---|---|---|---|---|---|

| 81.0 | 70.16 | 0.3088 | 1.09 | 42.1 | Electric spark | 302.05 |

| Tent Region (Top View) | Sensor | Distance from Ignition Point (m) | Location (m) | ||

|---|---|---|---|---|---|

| x | y | z | |||

| K3 | 2.41 | 0 | 2.15 | 0.15 |

| K4 | 2.84 | 1.5 | 2.15 | 0.15 | |

| K5 | 5.20 | 0 | 5.2 | 1.25 | |

| K6 | 7.00 | 0 | 7.0 | 1.25 | |

| K10 | 4.00 | 4.0 | 2.15 | 1.25 | |

| K11 | 6.25 | 6.25 | 2.15 | 1.25 | |

| H15 | 16.20 | 0 | 16.2 | 1.5 | |

| H16 | 32.27 | 0 | 32.2 | 3.5 | |

| * Ignition point | - | 0 | 0 | 1.25 | |

| CPU | Parallel Computation Core | Memory | Operating System |

|---|---|---|---|

| Intel Core i9-13900K | 24 | 64 GB (32 GB × 2) | Ubuntu 20.04.6 LTS |

| Parameter | Models |

|---|---|

| ● Open-source software | radXiFoam v2.0 based on OpenFOAM-v2112 |

| ● Thermal–hydraulic solver algorithm | PIMPLE [8] |

| ● Combustion model | Flamelet progress variable |

| ● Turbulence model | k-ω SST |

| ● Wall function | kqR/omega |

| ● CFL number | <0.9 |

| ● Time step size | Approximately 1.0 × 10−7 s to 1.0 × 10−4 s |

| ● Mesh type | Hexahedral |

| ● Mesh size at the far field | ~25 cm |

| ● Ignition model | Hot-spot spherical region model [28,29] |

| Case No. | Barrier Height (m)/Width (m)/Thickness (m)/R (m) | Number of Cells (Grid Model) |

|---|---|---|

| Case–1 | - | 30,432,390 |

| Case–2 | 4.2/6.0/0.2/5.0 | 29,569,168 |

| Case–3 | 2.1/6.0/0.2/5.0 | 29,586,556 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, H.-S.; Choi, K.-S.; Lee, H.-W.; Yu, C.-H. CFD Analysis of the Effects of a Barrier in a Hydrogen Refueling Station Mock-Up Facility during a Vapor Cloud Explosion Using the radXiFoam v2.0 Code. Processes 2024, 12, 2173. https://doi.org/10.3390/pr12102173

Kang H-S, Choi K-S, Lee H-W, Yu C-H. CFD Analysis of the Effects of a Barrier in a Hydrogen Refueling Station Mock-Up Facility during a Vapor Cloud Explosion Using the radXiFoam v2.0 Code. Processes. 2024; 12(10):2173. https://doi.org/10.3390/pr12102173

Chicago/Turabian StyleKang, Hyung-Seok, Keun-Sang Choi, Hyun-Woo Lee, and Chul-Hee Yu. 2024. "CFD Analysis of the Effects of a Barrier in a Hydrogen Refueling Station Mock-Up Facility during a Vapor Cloud Explosion Using the radXiFoam v2.0 Code" Processes 12, no. 10: 2173. https://doi.org/10.3390/pr12102173