Integration of Thermal Solar Power in an Existing Combined Cycle for a Reduction in Carbon Emissions and the Maximization of Cycle Efficiency

Abstract

1. Introduction

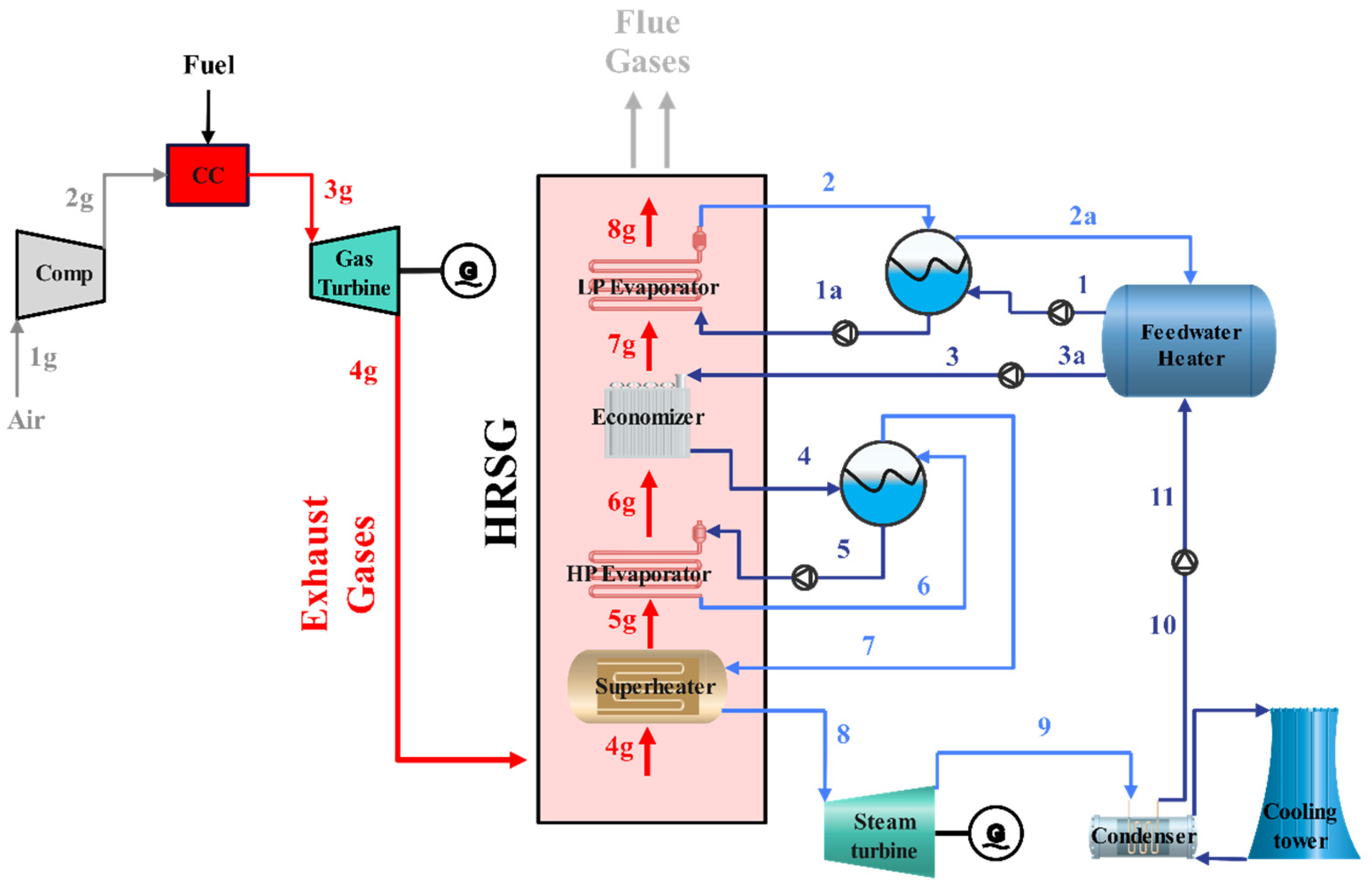

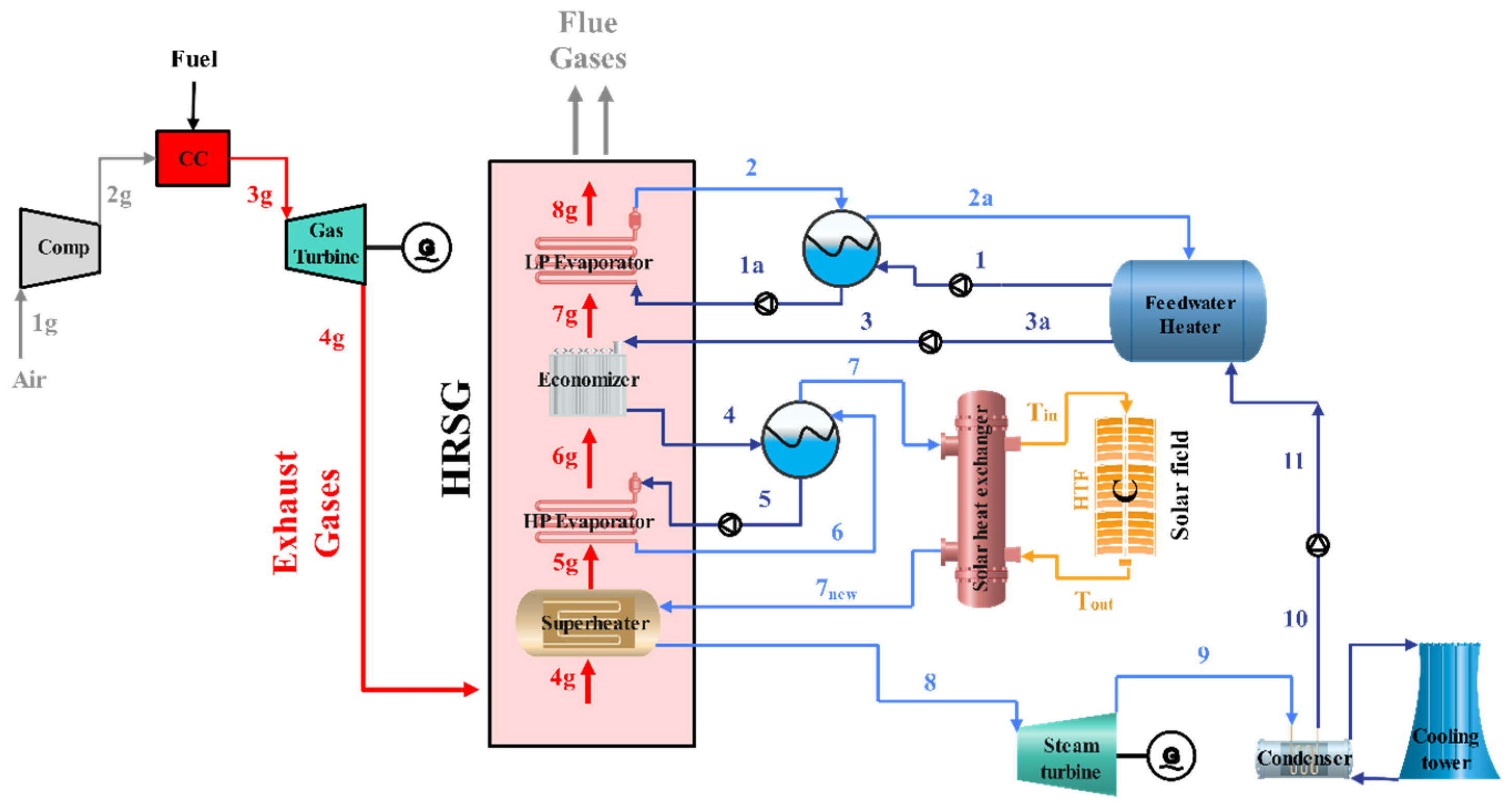

2. Thermodynamic Model of the Original Combined Cycle

2.1. Description of the Combined Cycle

2.2. Thermodynamic Model

2.3. Validation of the Model

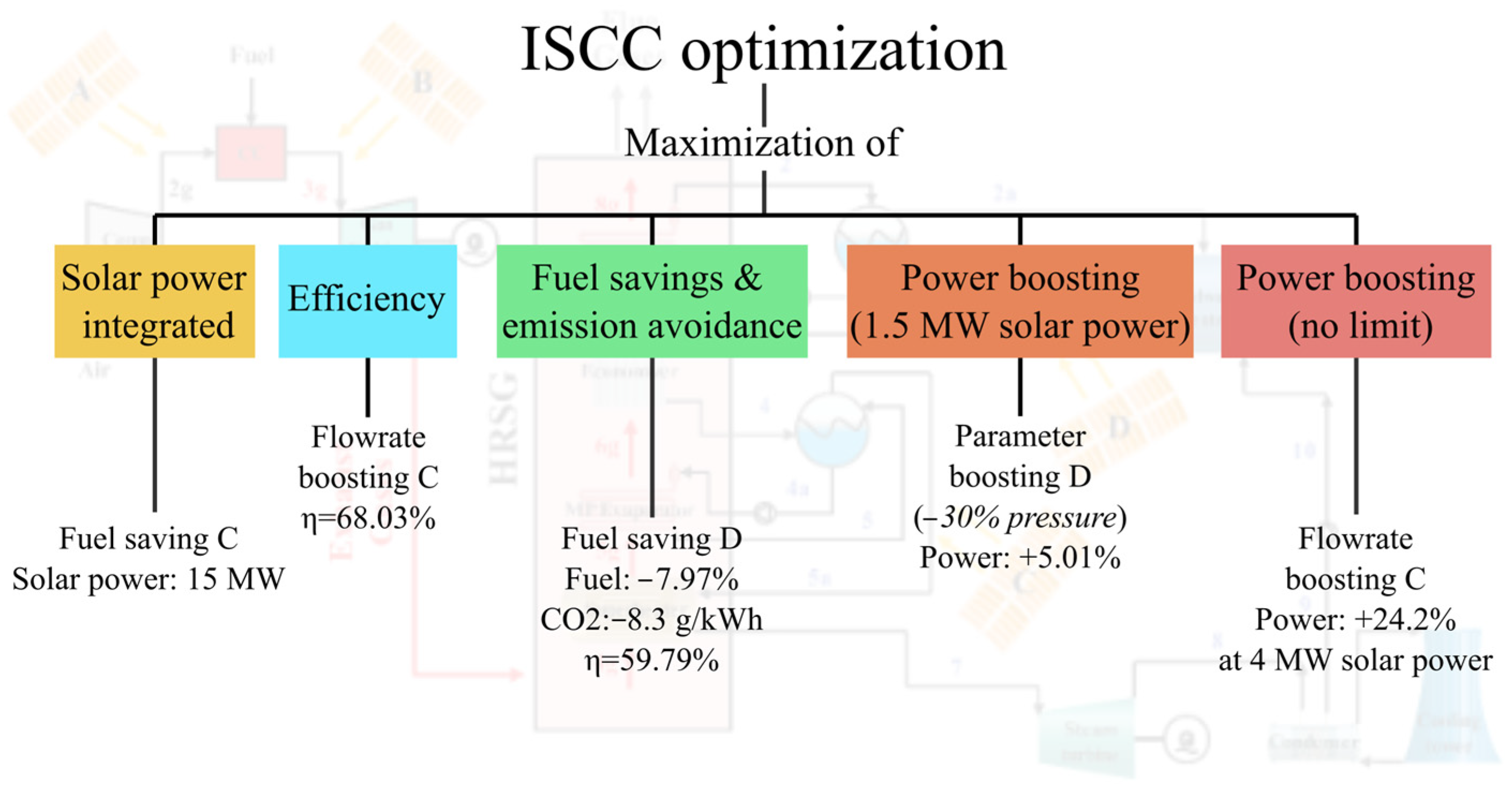

3. Study of Solar Power Integration (ISCC)

3.1. Fuel-Saving Mode

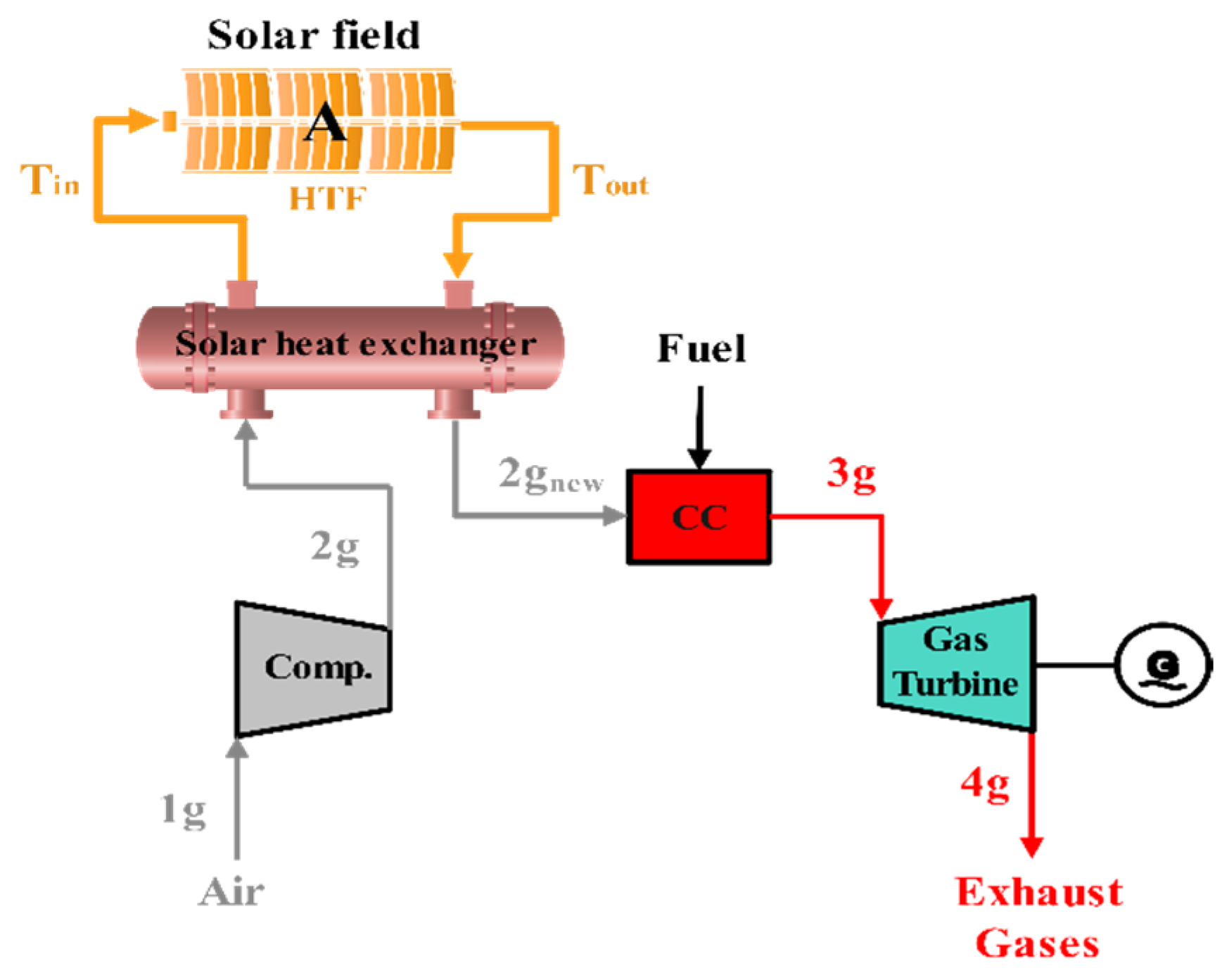

3.1.1. Gas Cycle Integration

- Mass flowrates of fuel and air are altered depending on the solar thermal power;

- Compression specific work is constant;

- Gas turbine inlet and outlet conditions are constant;

- The turbine specific work is constant;

- The top gas cycle output power is constant;

- The mass flowrate of fuel is reduced;

- The bottom steam cycle is unaffected;

- The ISCC overall output power remains constant.

- (a)

- Case A: After air compressor

- (b)

- Case B: After combustion chamber

3.1.2. Steam Cycle Integration

- (a)

- Case C: Integration before superheater

- (b) Case D: Integration at economizer

3.2. Power-Boosting Mode

3.2.1. Gas Cycle Integration

- Air and gas mass flowrates change depending on the integrated solar thermal power;

- Fuel mass flowrate is steady;

- Compression work increases;

- Gas turbine inlet and outlet conditions are constant;

- The total output power of the upper gas cycle increases;

- The bottom steam cycle is unaffected. The ISCC overall output power increases.

3.2.2. Steam Cycle Integration

3.3. Solar Field Technology Selection

4. Results

4.1. Fuel-Saving Mode

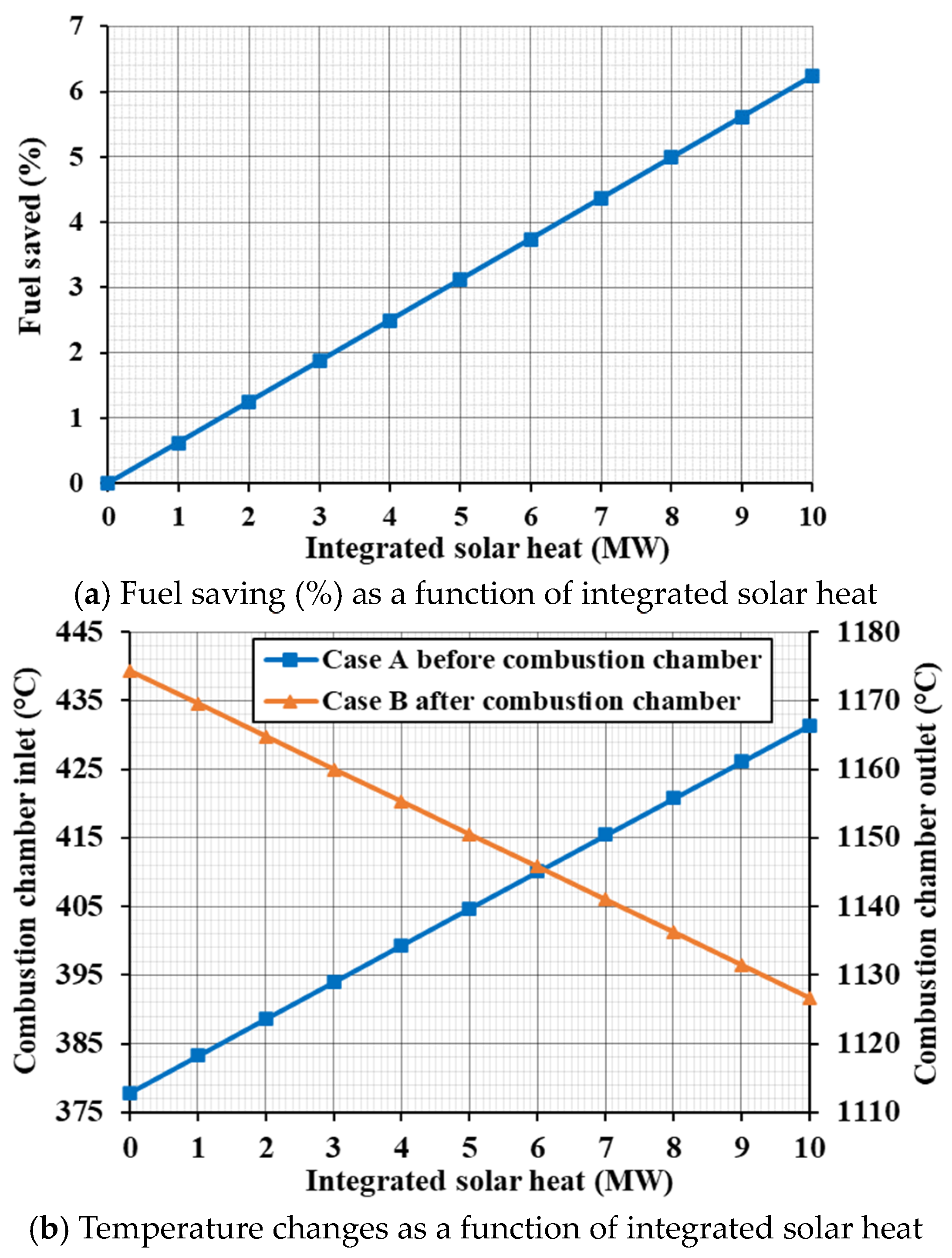

4.1.1. Gas Cycle Integration

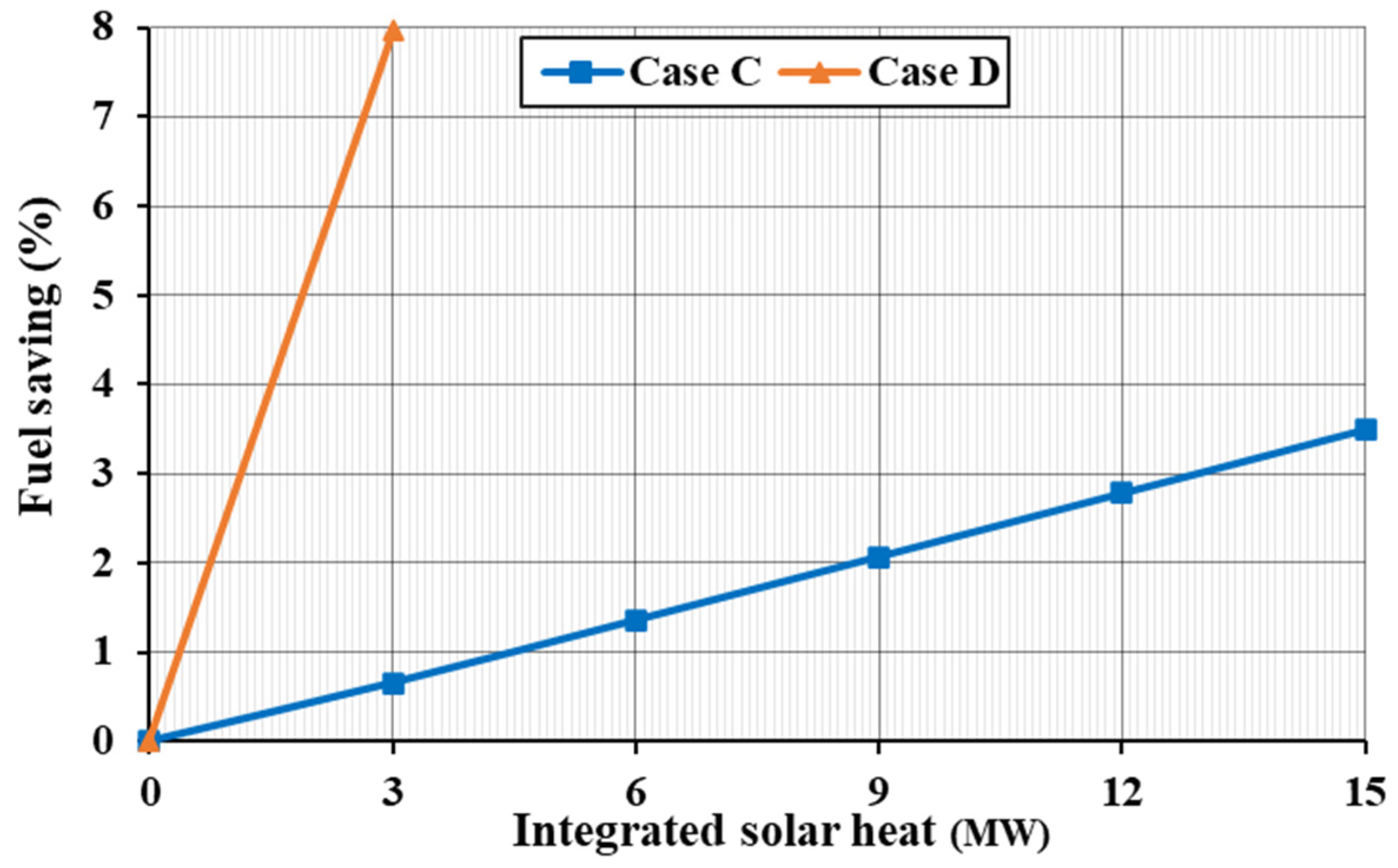

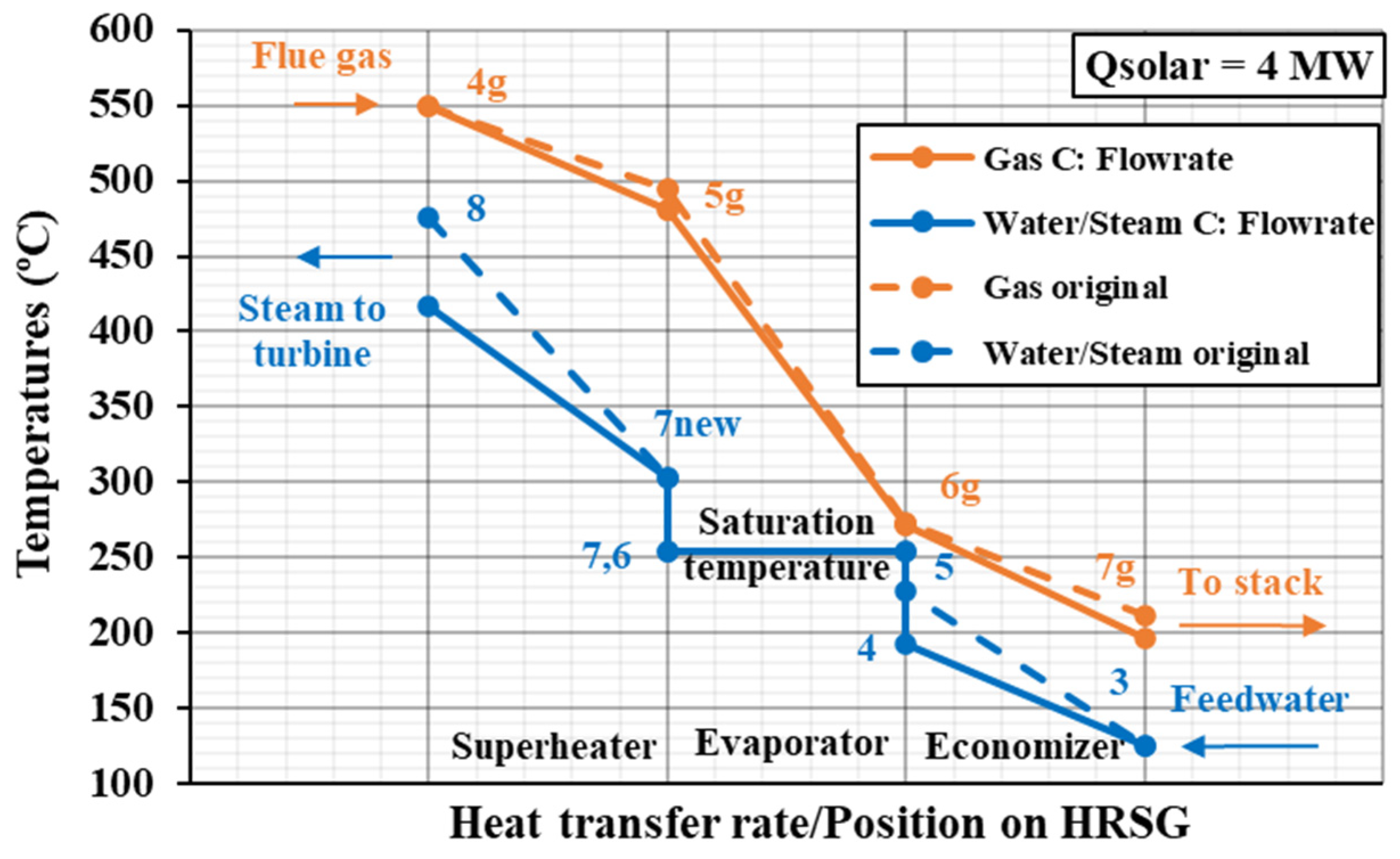

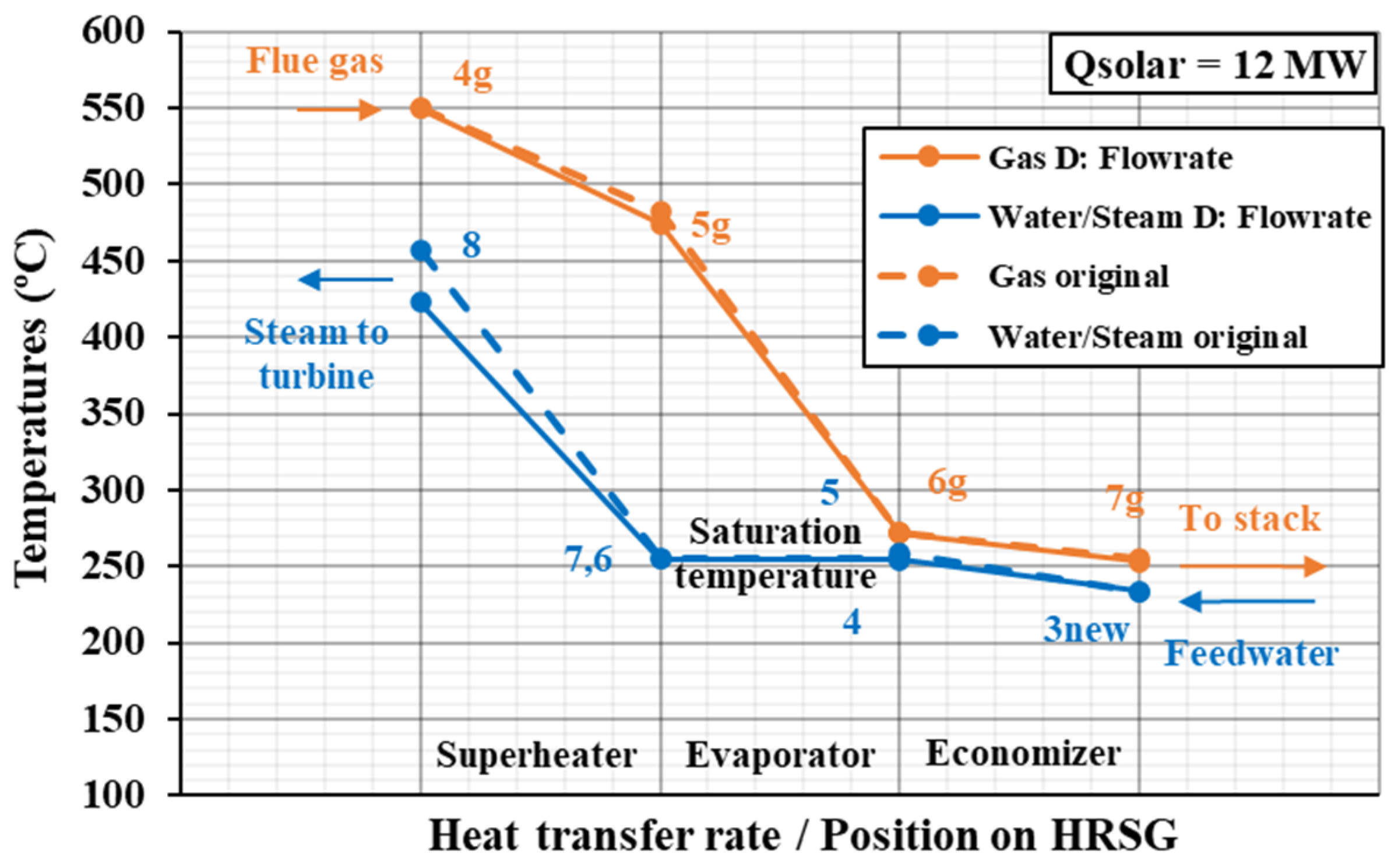

4.1.2. Steam Cycle Integration

4.2. Power-Boosting Mode

4.2.1. Gas Cycle Integration

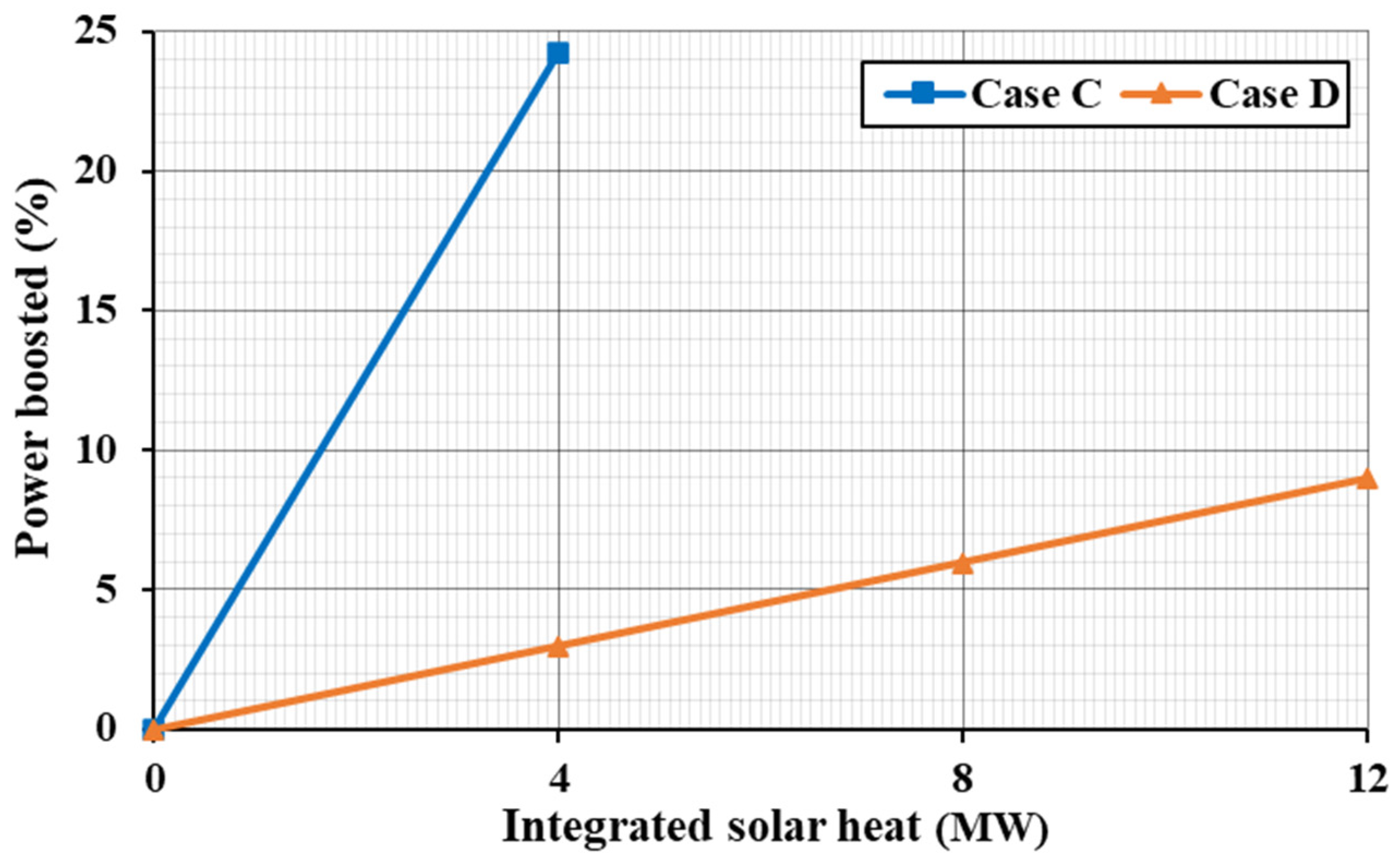

4.2.2. Steam Cycle Integration: Flowrate Boosting

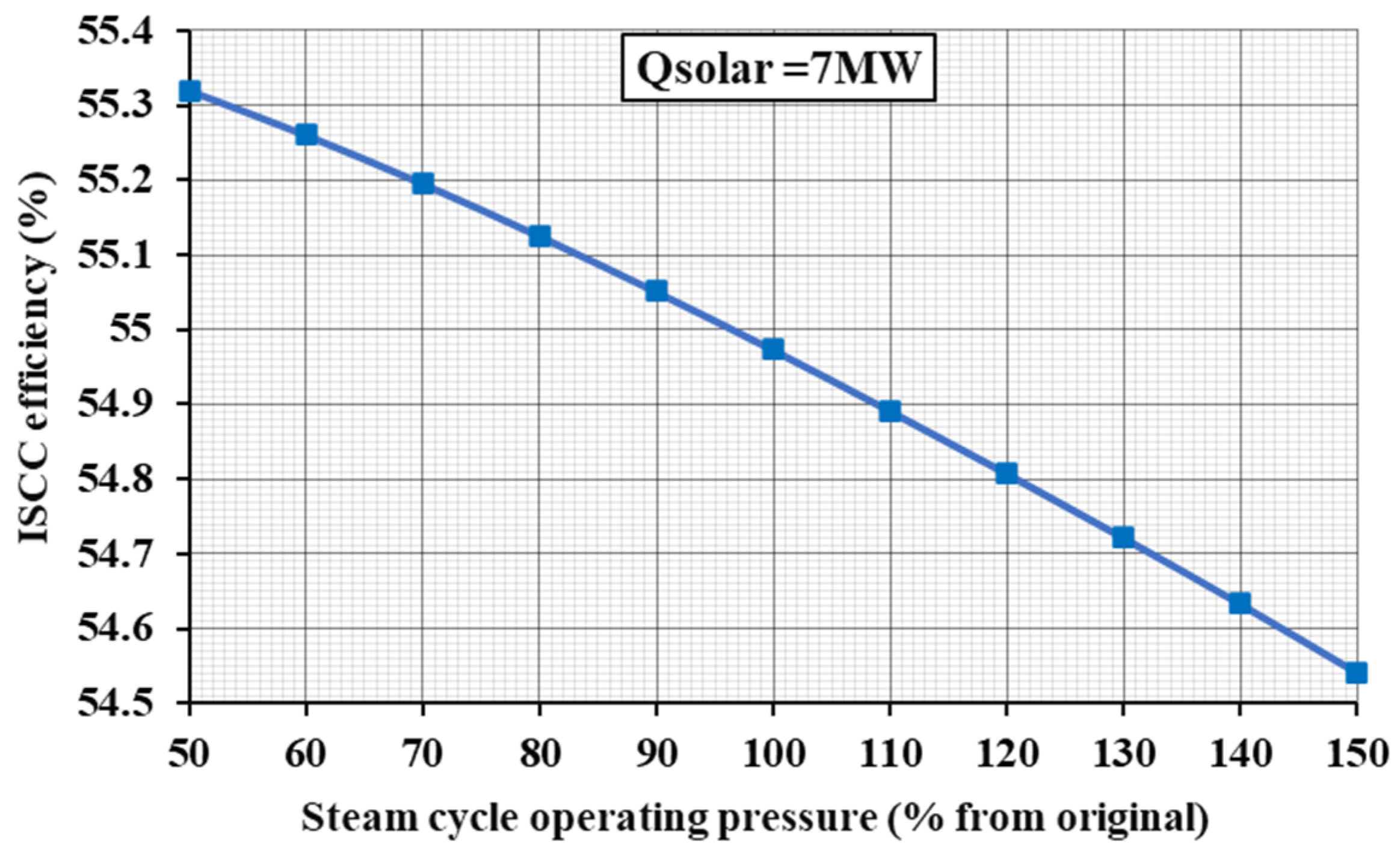

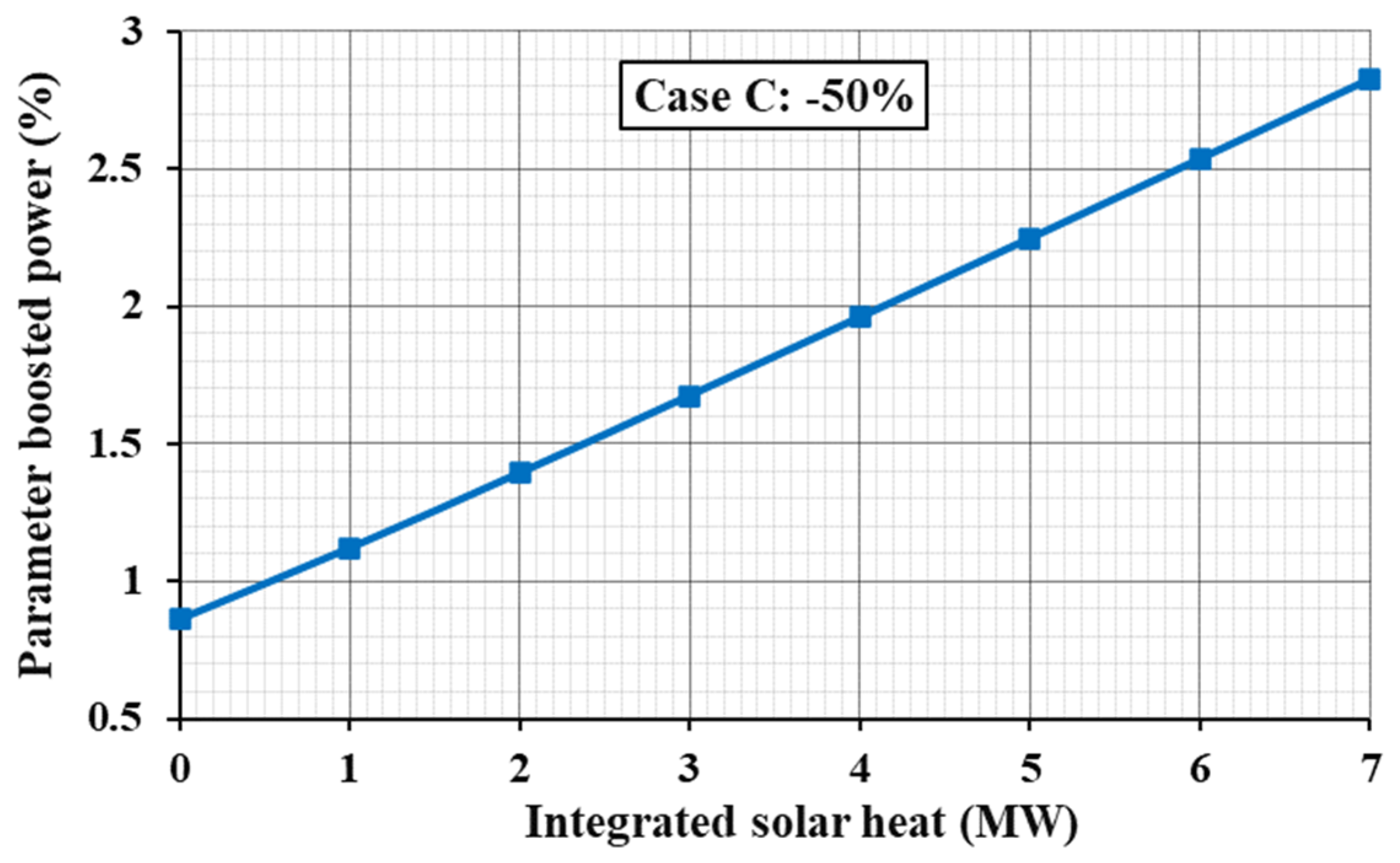

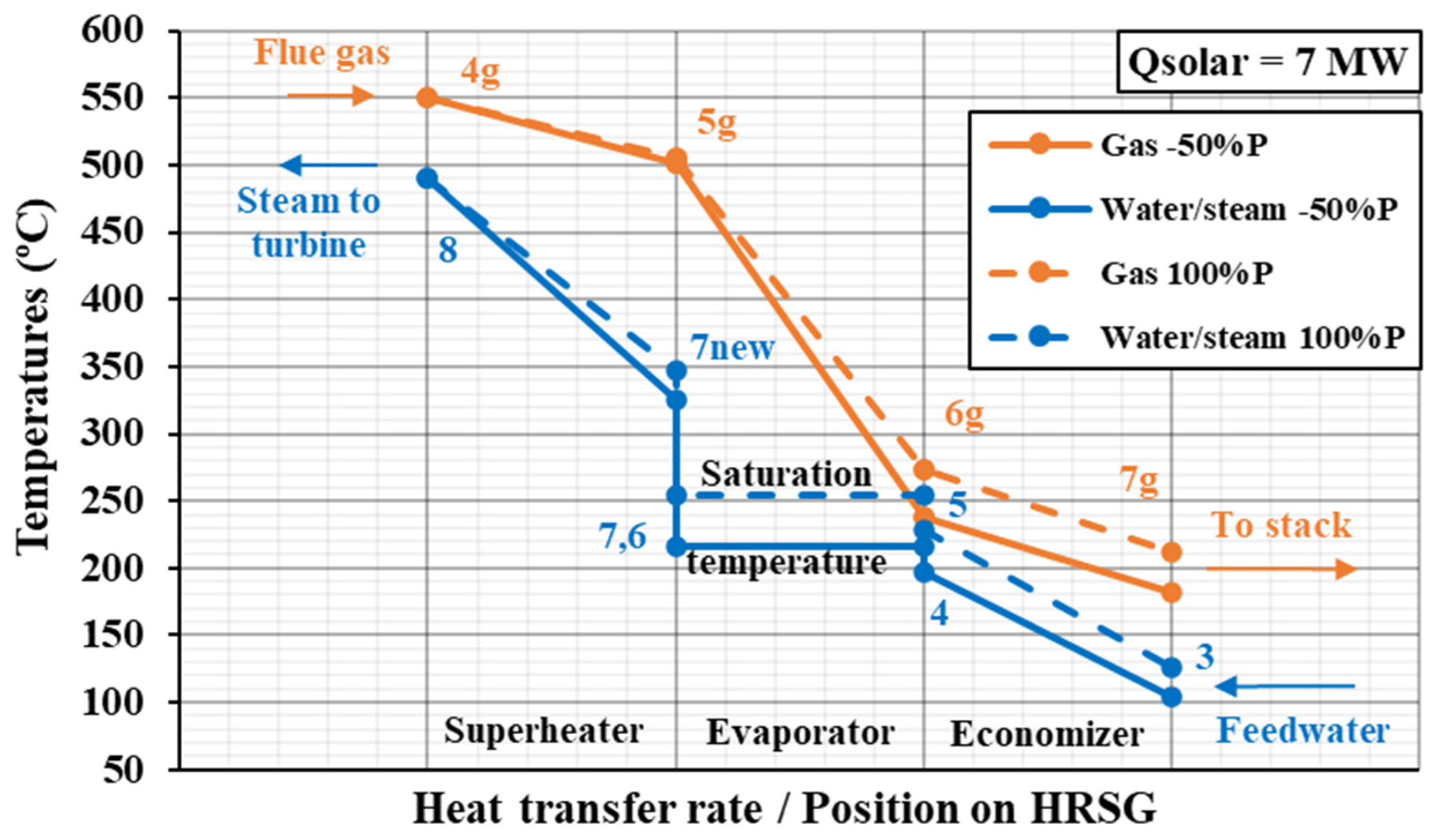

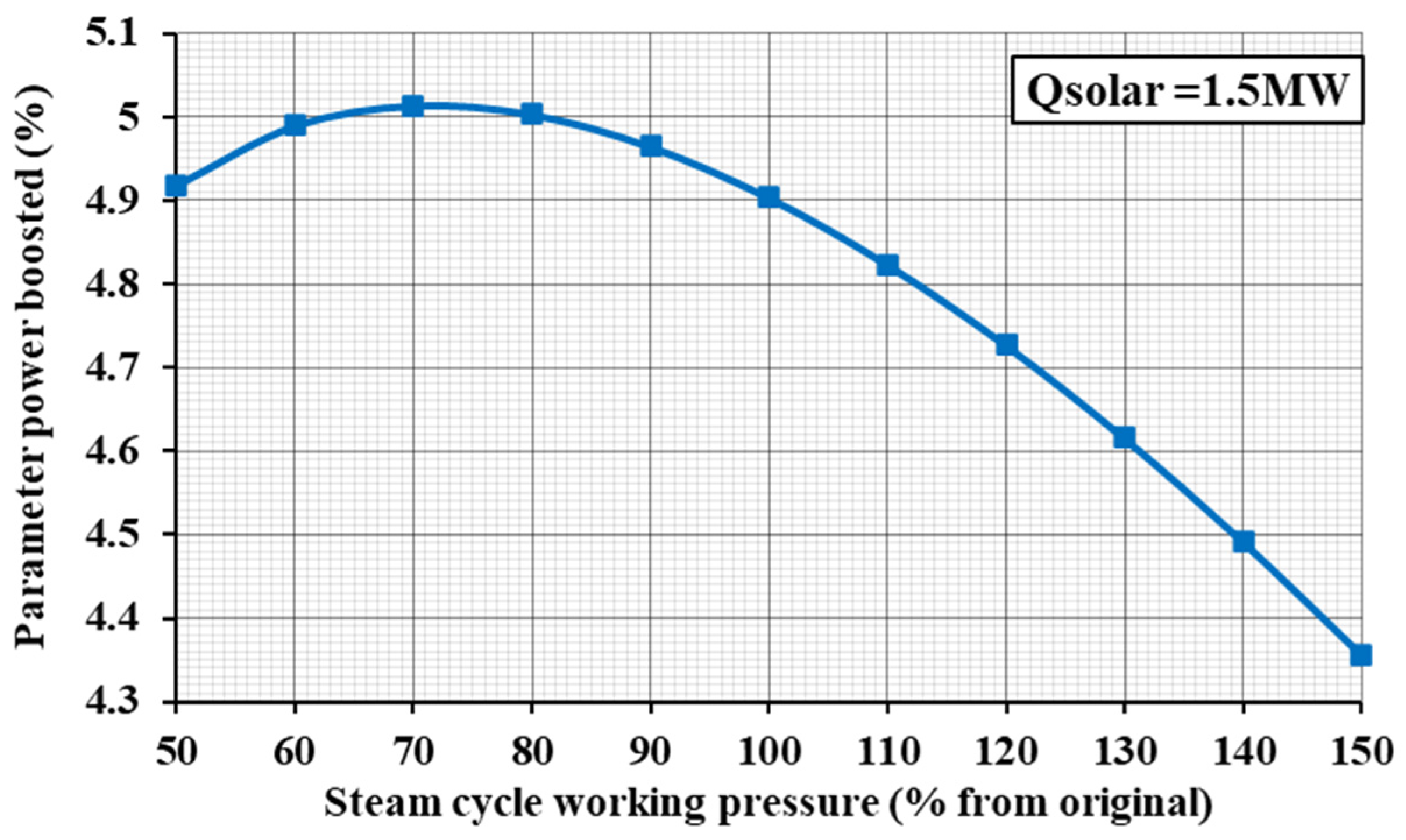

4.2.3. Steam Cycle Integration: Parameter Boosting

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. Detailed Results of Each Studied Configuration

| Mass Flowrates | Original CC | ISCC Case A | ISCC Case B |

|---|---|---|---|

| Air to fuel ratio | 50 | 53.39 | 53.39 |

| Turbine gas flowrate (kg/s) | 174.7 | 174.7 | 174.7 |

| Air flowrate (kg/s) | 171.28 | 171.49 | 171.49 |

| Fuel flowrate (kg/s) | 3.42 | 3.21 | 3.21 |

| Fuel saving (%) | -- | 6.23 | 6.23 |

| LP evaporator mass flowrate (kg/s) | 5 | 5 | 5 |

| HP evaporator mass flowrate (kg/s) | 25 | 25 | 25 |

| Operating temperatures | Original CC | ISCC Case A | ISCC Case B |

| Compressor inlet (°C) | 24 | 24 | 24 |

| Combustion chamber inlet (°C) | 378 | 431 | 378 |

| Gas turbine inlet (°C) | 1174 | 1174 | 1174 |

| Gas turbine outlet (°C) | 549 | 549 | 549 |

| Solar heat integration | Original CC | ISCC Case A | ISCC Case B |

| Integrated solar heat (MW) | -- | 10 | |

| Cycle efficiency | Original CC | ISCC Case A | ISCC Case B |

| Gas turbine cycle (%) | 39.84 | 39.85 | |

| Combined cycle (%) | 56.13 | 56.15 | |

| Cycle power breakdown | Original CC | ISCC Case A | ISCC Case B |

| Compressor (kW) | 62,450 | 62,450 | 62,450 |

| Gas turbine (kW) | 126,727 | 126,727 | 126,727 |

| Gas cycle (kW) | 64,277 | 64,277 | 64,277 |

| Steam cycle (kW) | 26,292 | 26,292 | 26,292 |

| Total net power (kW) | 90,569 | 90,569 | 90,569 |

| Back work ratio (%) | 49.279 | 49.279 | 49.279 |

| Specific work per unit fuel mass flow (kJ/kg) | 26,439 | 28,198 | 28,198 |

| CO2 emissions (Mt/year) | 0.2971 | 0.2785 | 0.2785 |

| CO2 emissions saved (kg CO2/kWh) | -- | 0.0064 | 0.0064 |

| Mass Flowrates | Original CC | ISCC Case C | ISCC Case D |

|---|---|---|---|

| Air to fuel ratio | 50 | 50 | 50 |

| Turbine gas flowrate (kg/s) | 174.7 | 168.59 | 160.7 |

| Air flowrate (kg/s) | 171.28 | 165.28 | 157.61 |

| Fuel flowrate (kg/s) | 3.42 | 3.3 | 3.15 |

| Fuel saving (%) | -- | 3.49 | 7.97 |

| LP evaporator mass flowrate (kg/s) | 5 | 5 | 5 |

| HP evaporator mass flowrate (kg/s) | 25 | 25 | 25 |

| Operating temperatures | Original CC | ISCC Case C | ISCC Case D |

| Compressor inlet (°C) | 24 | 24 | 24 |

| Combustion chamber inlet (°C) | 378 | 378 | 378 |

| Gas turbine inlet (°C) | 1174 | 1174 | 1174 |

| Gas turbine outlet (°C) | 549 | 549 | 549 |

| Solar heat integration | Original CC | ISCC Case C | ISCC Case D |

| Integrated solar heat (MW) | -- | 15 | 3 |

| Cycle efficiency | Original CC | ISCC Case C | ISCC Case D |

| Gas turbine cycle (%) | 39.84 | 39.84 | 39.84 |

| Combined cycle (%) | 56.13 | 53.06 | 59.79 |

| Cycle power breakdown | Original CC | ISCC Case C | ISCC Case D |

| Compressor (kW) | 62,450 | 60,266 | 57,471 |

| Gas turbine (kW) | 126,727 | 122,294 | 116,622 |

| Gas cycle (kW) | 64,277 | 62,028 | 59,152 |

| Steam cycle (kW) | 26,292 | 28,542 | 31,417 |

| Total net power (kW) | 90,569 | 90,569 | 90,569 |

| Back work ratio (%) | 49.279 | 49.279 | 49.279 |

| Specific work per unit fuel mass flow (kJ/kg) | 26,439 | 27,399 | 28,730 |

| CO2 emissions (Mt/year) | 0.2971 | 0.2867 | 0.2734 |

| CO2 emissions saved (kg CO2/kWh) | -- | 0.0035 | 0.0083 |

| Mass Flowrates | Original CC | ISCC Case A | ISCC Case B |

|---|---|---|---|

| Air to fuel ratio | 50 | 53.2 | |

| Turbine gas flowrate (kg/s) | 174.7 | 185.68 | |

| Air flowrate (kg/s) | 171.28 | 182.25 | |

| Fuel flowrate (kg/s) | 3.42 | 3.42 | 3.42 |

| LP evaporator mass flowrate (kg/s) | 5 | 5 | 5 |

| HP evaporator mass flowrate (kg/s) | 25 | 25 | 25 |

| Operating temperatures | Original CC | ISCC Case A | ISCC Case B |

| Compressor inlet (°C) | 24 | 24 | 24 |

| Combustion chamber inlet (°C) | 378 | 430 | 378 |

| Gas turbine inlet (°C) | 1174 | 1174 | 1174 |

| Gas turbine outlet (°C) | 549 | 549 | 549 |

| Solar heat integration | Original CC | ISCC Case A | ISCC Case B |

| Integrated solar heat (MW) | -- | 10 | |

| Cycle efficiency | Original CC | ISCC Case A | ISCC Case B |

| Gas turbine cycle (%) | 39.84 | 39.83 | |

| Combined cycle (%) | 56.13 | 55.19 | |

| Cycle power breakdown | Original CC | ISCC Case A | ISCC Case B |

| Compressor (kW) | 62,450 | 66,455 | |

| Gas turbine (kW) | 126,727 | 134,693 | |

| Gas cycle (kW) | 64,277 | 68,239 | |

| Steam cycle (kW) | 26,292 | 26,323 | |

| Total net power (kW) | 90,569 | 94,562 | |

| Power boosted (%) | -- | 4.41 | |

| Back work ratio (%) | 49.279 | 49.33 | |

| Specific work per unit fuel mass flow (kJ/kg) | 26,439 | 27,605 | |

| Mass Flowrates | Original CC | ISCC Case C | ISCC Case D |

|---|---|---|---|

| Air to fuel ratio | 50 | 50 | 50 |

| Turbine gas flowrate (kg/s) | 174.7 | 174.7 | 174.7 |

| Air flowrate (kg/s) | 171.28 | 171.28 | 171.28 |

| Fuel flowrate (kg/s) | 3.42 | 3.42 | 3.42 |

| LP evaporator mass flowrate (kg/s) | 5 | 9.17 | 6.54 |

| HP evaporator mass flowrate (kg/s) | 25 | 45.84 | 32.72 |

| Operating temperatures | Original CC | ISCC Case C | ISCC Case D |

| Compressor inlet (°C) | 24 | 24 | 24 |

| Combustion chamber inlet (°C) | 378 | 378 | 378 |

| Gas turbine inlet (°C) | 1174 | 1174 | 1174 |

| Gas turbine outlet (°C) | 549 | 549 | 549 |

| Inlet steam temperature (°C) | 457 | 416.5 | 423 |

| Pinch temperature (°C) | 17.5 | 17.3 | 17 |

| Economizer outlet temperature (°C) | 228 | 192.5 | 254.5 |

| Approach temperature (°C) | 28 | 62 | 0.5 |

| Operating pressures | Original CC | ISCC Case C | ISCC Case D |

| Inlet steam pressure (bar) | 43 | 43 | 43 |

| LP evaporator pressure (bar) | 2.4 | 2.4 | 2.4 |

| Condenser pressure (bar) | 0.08 | 0.08 | 0.08 |

| Solar heat integration | Original CC | ISCC Case C | ISCC Case D |

| Integrated solar heat (MW) | -- | 4 | 12 |

| Cycle efficiency | Original CC | ISCC Case C | ISCC Case D |

| Gas turbine cycle (%) | 39.84 | 39.84 | 39.84 |

| Combined cycle (%) | 56.13 | 68.03 | 56.93 |

| Cycle power breakdown | Original CC | ISCC Case C | ISCC Case D |

| Compressor (kW) | 62,450 | 62,450 | 62,450 |

| Gas turbine (kW) | 126,727 | 126,727 | 126,727 |

| Gas cycle (kW) | 64,277 | 64,277 | 64,277 |

| Steam cycle (kW) | 26,292 | 48,214 | 34,412 |

| Total net power (kW) | 90,569 | 112,491 | 98,689 |

| Power boosted (%) | -- | 24.2 | 8.96 |

| Back work ratio (%) | 49.279 | 49.279 | 49.279 |

| Specific work per unit fuel mass flow (kJ/kg) | 26,439 | 32,840 | 28,810 |

| Mass Flowrates | Original ISCC | ISCC “Case C” (Superheater) | ||||

|---|---|---|---|---|---|---|

| +10% | +20% | +30% | +40% | +50% | ||

| Turbine gas flowrate (kg/s) | 174.7 | |||||

| Air flowrate (kg/s) | 171.27 | |||||

| Fuel flowrate (kg/s) | 3.42 | |||||

| LP evaporator mass flowrate (kg/s) | 5 | |||||

| HP evaporator mass flowrate (kg/s) | 25 | |||||

| Operating temperatures | Original ISCC | +10% | +20% | +30% | +40% | +50% |

| Compressor inlet (°C) | 24 | |||||

| Combustion chamber inlet (°C) | 379 | |||||

| Gas turbine inlet (°C) | 1174 | |||||

| Gas turbine outlet (°C) | 549 | |||||

| Inlet steam temperature (°C) | 491 | 491 | 490.5 | 490.5 | 490 | 489.5 |

| Pinch temperature (°C) | 19.3 | 19 | 18.5 | 18.2 | 17.9 | 17.5 |

| Economizer outlet temperature (°C) | 228 | 232.5 | 237 | 241 | 244.5 | 48 |

| Approach temperature (°C) | 26.5 | 27.5 | 29 | 30 | 31 | 32 |

| Operating pressures | Original ISCC | +10% | +20% | +30% | +40% | +50% |

| Inlet steam pressure (bar) | 2.4 | 2.64 | 2.88 | 3.12 | 3.36 | 3.6 |

| LP evaporator pressure (bar) | 43 | 47.3 | 51.6 | 55.9 | 60.2 | 64.5 |

| Condenser pressure (bar) | 0.08 | |||||

| Solar heat integration | Original ISCC | +10% | +20% | +30% | +40% | +50% |

| Integrated solar heat (MW) | 7 | |||||

| Cycle efficiency | Original ISCC | +10% | +20% | +30% | +40% | +50% |

| Gas turbine cycle (%) | 39.84 | |||||

| Combined cycle (%) | 54.97 | 54.89 | 54.81 | 54.72 | 54.63 | 54.54 |

| Cycle power breakdown | Original ISCC | +10% | +20% | +30% | +40% | +50% |

| Compressor (kW) | 62,450 | |||||

| Gas turbine (kW) | 126,727 | |||||

| Gas cycle (kW) | 64,277 | |||||

| Steam cycle (kW) | 28,265 | 28,128 | 27,987 | 27,843 | 27,694 | 27,539 |

| Total net power (kW) | 92,542 | 92,405 | 92,264 | 92,120 | 91,971 | 91,816 |

| Power boosted (%) | 2.18 | 2.02 | 1.87 | 1.71 | 1.55 | 1.37 |

| Back work ratio (%) | 49.279 | |||||

| Specific work per unit fuel mass flow (kJ/kg) | 27,016 | 26,976 | 26,935 | 26,892 | 26,849 | 26,804 |

| Mass Flowrates | Original ISCC | ISCC “Case C” (Superheater) | ||||

|---|---|---|---|---|---|---|

| −10% | −20% | −30% | −40% | −50% | ||

| Turbine gas flowrate (kg/s) | 174.7 | |||||

| Air flowrate (kg/s) | 171.27 | |||||

| Fuel flowrate (kg/s) | 3.42 | |||||

| LP evaporator mass flowrate (kg/s) | 5 | |||||

| HP evaporator mass flowrate (kg/s) | 25 | |||||

| Operating temperatures | Original ISCC | −10% | −20% | −30% | −40% | −50% |

| Compressor inlet (°C) | 24 | |||||

| Combustion chamber inlet (°C) | 379 | |||||

| Gas turbine inlet (°C) | 1174 | |||||

| Gas turbine outlet (°C) | 549 | |||||

| Inlet steam temperature (°C) | 491 | 491 | 491 | 491 | 491 | 490.5 |

| Pinch temperature (°C) | 19.3 | 19.7 | 20 | 20.5 | 21. | 21.5 |

| Economizer outlet temperature (°C) | 228 | 223 | 218 | 212 | 205 | 197.5 |

| Approach temperature (°C) | 26.5 | 25 | 23.5 | 22 | 20.5 | 18.5 |

| Operating pressures | Original ISCC | −10% | −20% | −30% | −40% | −50% |

| Inlet steam pressure (bar) | 43 | 38.7 | 34.4 | 30.1 | 25.8 | 21.5 |

| LP evaporator pressure (bar) | 2.4 | 2.16 | 1.92 | 1.68 | 1.44 | 1.2 |

| Condenser pressure (bar) | 0.08 | |||||

| Solar heat integration | Original ISCC | −10% | −20% | −30% | −40% | −50% |

| Integrated solar heat (MW) | 7 | |||||

| Cycle efficiency | Original ISCC | −10% | −20% | −30% | −40% | −50% |

| Gas turbine cycle (%) | 39.84 | |||||

| Combined cycle (%) | 54.97 | 55.05 | 55.12 | 55.19 | 55.26 | 55.32 |

| Cycle power breakdown | Original ISCC | −10% | −20% | −30% | −40% | −50% |

| Compressor (kW) | 62,450 | |||||

| Gas turbine (kW) | 126,727 | |||||

| Gas cycle (kW) | 64,277 | |||||

| Steam cycle (kW) | 28,265 | 28,396 | 28,521 | 28,640 | 28,750 | 28,849 |

| Total net power (kW) | 92,542 | 92,673 | 92,798 | 92,917 | 93,027 | 93,126 |

| Power boosted (%) | 2.18 | 2.32 | 2.46 | 2.59 | 2.71 | 2.82 |

| Back work ratio (%) | 49.279 | |||||

| Specific work per unit fuel mass flow (kJ/kg) | 27,016 | 27,054 | 27,091 | 27,125 | 27,157 | 27,186 |

| Mass Flowrates | Original ISCC | ISCC “Case D” (Economizer) | ||||

|---|---|---|---|---|---|---|

| +10% | +20% | +30% | +40% | +50% | ||

| Turbine gas flowrate (kg/s) | 174.7 | |||||

| Air flowrate (kg/s) | 171.27 | |||||

| Fuel flowrate (kg/s) | 3.42 | |||||

| LP evaporator (kg/s) | 5 | |||||

| HP evaporator kg/s) | 25 | |||||

| Operating temperatures | Original ISCC | +10% | +20% | +30% | +40% | +50% |

| Compressor inlet (°C) | 24 | |||||

| Combustion chamber inlet (°C) | 379 | |||||

| Gas turbine inlet (°C) | 1174 | |||||

| Gas turbine outlet (°C) | 549 | |||||

| Inlet steam temperature (°C) | 534 | 534.5 | 535 | 535 | 535 | 534.5 |

| Pinch temperature (°C) | 15 | 15 | 14.5 | 14 | 13.5 | 13.5 |

| Economizer outlet temperature (°C) | 229 | 233 | 236 | 239.5 | 242 | 245 |

| Approach temperature (°C) | 25.5 | 27.5 | 29.5 | 31.5 | 33.5 | 35 |

| Operating pressures | Original ISCC | +10% | +20% | +30% | +40% | +50% |

| Inlet steam (bar) | 43 | 47.3 | 51.6 | 55.9 | 60.2 | 64.5 |

| LP evaporator (bar) | 2.4 | 2.64 | 2.88 | 3.12 | 3.36 | 3.6 |

| Condenser (bar) | 0.08 | |||||

| Solar heat integration | Original ISCC | +10% | +20% | +30% | +40% | +50% |

| Integrated solar heat (MW) | 1.5 | |||||

| Cycle efficiency | Original ISCC | +10% | +20% | +30% | +40% | +50% |

| Gas turbine cycle (%) | 39.84 | |||||

| Combined cycle (%) | 58.34 | 58.3 | 58.24 | 58.18 | 58.65 | 58.04 |

| Cycle power breakdown | Original ISCC | +10% | +20% | +30% | +40% | +50% |

| Compressor (kW) | 62,450 | |||||

| Gas turbine (kW) | 126,727 | |||||

| Gas cycle (kW) | 64,277 | |||||

| Steam cycle (kW) | 30,733 | 30,660 | 30,573 | 30,472 | 30,360 | 30,237 |

| Total net power (kW) | 95,010 | 94,937 | 94,850 | 94,749 | 94,637 | 94,514 |

| Power boosted (%) | 4.9 | 4.82 | 4.72 | 4.61 | 4.49 | 4.35 |

| Back work ratio (%) | 49.279 | |||||

| Specific work per unit fuel mass flow (kJ/kg) | 27,736 | 27,715 | 27,689 | 27,660 | 27,627 | 27,591 |

| Mass Flowrates | Original ISCC | ISCC “Case D” (Economizer) | ||||

|---|---|---|---|---|---|---|

| −10% | −20% | −30% | −40% | −50% | ||

| Turbine gas flowrate (kg/s) | 174.7 | |||||

| Air flowrate (kg/s) | 171.27 | |||||

| Fuel flowrate (kg/s) | 3.42 | |||||

| LP evaporator (kg/s) | 5 | |||||

| HP evaporator kg/s) | 25 | |||||

| Operating temperatures | Original ISCC | −10% | −20% | −30% | −40% | −50% |

| Compressor inlet (°C) | 24 | |||||

| Combustion chamber inlet (°C) | 379 | |||||

| Gas turbine inlet (°C) | 1174 | |||||

| Gas turbine outlet (°C) | 549 | |||||

| Inlet steam temperature (°C) | 534 | 533 | 532 | 530 | 527.5 | 524.5 |

| Pinch temperature (°C) | 15 | 15.5 | 16 | 16.5 | 17.5 | 18 |

| Economizer outlet temperature (°C) | 229 | 225 | 221 | 216 | 211 | 205 |

| Approach temperature (°C) | 25.5 | 23 | 20.5 | 18 | 14.5 | 11 |

| Operating pressures | Original ISCC | −10% | −20% | −30% | −40% | −50% |

| Inlet steam (bar) | 43 | 38.7 | 34.4 | 30.1 | 25.8 | 21.5 |

| LP evaporator (bar) | 2.4 | 2.16 | 1.92 | 1.68 | 1.44 | 1.2 |

| Condenser (bar) | 0.08 | |||||

| Solar heat integration | Original ISCC | −10% | −20% | −30% | −40% | −50% |

| Solar heat (MW) | 1.5 | |||||

| Cycle efficiency | Original ISCC | −10% | −20% | −30% | −40% | −50% |

| Gas turbine cycle (%) | 39.84 | |||||

| Combined cycle (%) | 58.34 | 58.38 | 58.4 | 58.4 | 58.39 | 58.35 |

| Cycle power breakdown | Original ISCC | −10% | −20% | −30% | −40% | −50% |

| Compressor (kW) | 62,450 | |||||

| Gas turbine (kW) | 126,727 | |||||

| Gas cycle (kW) | 64,277 | |||||

| Steam cycle (kW) | 30,733 | 30,788 | 30,823 | 30,833 | 30,811 | 30,746 |

| Total net power (kW) | 95,010 | 95,065 | 95,100 | 95,110 | 95,088 | 95,023 |

| Power boosted (%) | 4.9 | 4.96 | 5 | 5.01 | 4.98 | 4.92 |

| Back work ratio (%) | 49.279 | |||||

| Specific work per unit fuel mass flow (kJ/kg) | 27,736 | 27,752 | 27,762 | 27,765 | 27,759 | 27,740 |

References

- U.S Energy Information Administration “EIA”. Energy Institute Statistical Review of World Energy. 2012. Available online: https://ourworldindata.org/ (accessed on 13 November 2024).

- Enerdata. World Energy & Climate Statistics—Yearbook 2024. Available online: https://yearbook.enerdata.net/total-energy/world-consumption-statistics.html (accessed on 1 November 2024).

- Shahabuddin, M.; Bhattacharya, S. Effect of reactant types (steam, CO2 and steam + CO2) on the gasification performance of coal using entrained flow gasifier. Int. J. Energy Res. 2021, 45, 9492–9501. [Google Scholar] [CrossRef]

- Alam, M.T.; Dai, B.; Wu, X.; Hoadley, A.; Zhang, L. A critical review of ash slagging mechanisms and viscosity measurement for low-rank coal and bio-slags. Front. Energy 2021, 15, 46–67. [Google Scholar] [CrossRef]

- REN21. Renewables 2023 Global Status Report: Energy Supply Module. 2023. Available online: https://www.ren21.net/wp-content/uploads/2019/05/GSR-2023_Energy-Supply-Module.pdf (accessed on 13 November 2024).

- Statista. Global Data and Business Intelligence Platform with an Extensive Collection of Statistics. 2023. Available online: https://www.statista.com/ (accessed on 5 August 2024).

- Imteaz, M.A.; Shanableh, A.; Rahman, A.; Ahsan, A. Optimisation of rainwater tank design from large roofs: A case study in Melbourne, Australia. Resour. Conserv. Recycl. 2011, 55, 1022–1029. [Google Scholar] [CrossRef]

- Gielen, D.; Boshell, F.; Saygin, D.; Bazilian, M.D.; Wagner, N.; Gorini, R. The role of renewable energy in the global energy transformation. Energy Strateg. Rev. 2019, 24, 38–50. [Google Scholar] [CrossRef]

- Zhu, L.; Fang, W.; Rahman, S.U.; Khan, A.I. How solar-based renewable energy contributes to CO2 emissions abatement? Sustainable environment policy implications for solar industry. Energy Environ. 2023, 34, 359–378. [Google Scholar] [CrossRef]

- Weldekidan, H.; Strezov, V.; Town, G. Review of solar energy for biofuel extraction. Renew. Sustain. Energy Rev. 2018, 88, 184–192. [Google Scholar] [CrossRef]

- Tsoutsos, T.; Frantzeskaki, N.; Gekas, V. Environmental impacts from the solar energy technologies. Energy Policy 2005, 33, 289–296. [Google Scholar] [CrossRef]

- International Renewable Energy Agency “IRENA”. Future of Solar Photovoltaic. 2019. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2019/Nov/IRENA_Future_of_Solar_PV_2019.pdf (accessed on 25 October 2024).

- U.S. Department of Energy. Solar Parabolic Trough. 2009. Available online: https://www1.eere.energy.gov/ba/pba/pdfs/solar_trough.pdf (accessed on 31 October 2024).

- Rovira, A.; Montes, M.J.; Varela, F.; Gil, M. Comparison of Heat Transfer Fluid and Direct Steam Generation technologies for Integrated Solar Combined Cycles. Appl. Therm. Eng. 2013, 52, 264–274. [Google Scholar] [CrossRef]

- The World Bank. Implementation Completion and Results Report (TF-91289) on A Grand in The Amount of US $49.80 Million to the Arab Republic of Egypt for the Kuraymat Solar Thermal Hybrid Project. 2012. Available online: http://documents.worldbank.org/curated/en/168831468332487486/Main-report (accessed on 13 November 2024).

- Islam, M.T.; Huda, N.; Abdullah, A.B.; Saidur, R. A comprehensive review of state-ofthe-art concentrating solar power (CSP) technologies: Current status and research trends. Renew. Sustain. Energy Rev. 2018, 91, 987–1018. [Google Scholar] [CrossRef]

- Sumayli, H.; El-Leathy, A.; Danish, S.N.; Al-Ansary, H.; Almutairi, Z.; Al-Suhaibani, Z.; Saleh, N.S.; Saeed, R.S.; Alswaiyd, A.; Djajadiwinata, E.; et al. Integrated CSP-PV hybrid solar power plant for two cities in Saudi Arabia. Case Stud. Therm. Eng. 2023, 44, 102835. [Google Scholar] [CrossRef]

- Powell, K.M.; Rashid, K.; Ellingwood, K.; Tuttle, J.; Iverson, B.D. Hybrid concentrated solar thermal power systems: A review. Renew. Sustain. Energy Rev. 2017, 80, 215–237. [Google Scholar] [CrossRef]

- Pramanik, S.; Ravikrishna, R.V. A review of concentrated solar power hybrid technologies. Appl. Therm. Eng. 2017, 127, 602–637. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, G.; Fu, Z. Performance analysis of a novel integrated solar combined cycle with inlet air heating system. Appl. Therm. Eng. 2019, 161, 114010. [Google Scholar] [CrossRef]

- Barakat, S.; Ramzy, A.; Hamed, A.M.; El Emam, S.H. Enhancement of gas turbine power output using earth to air heat exchanger (EAHE) cooling system. Energy Convers. Manag. 2016, 111, 137–146. [Google Scholar] [CrossRef]

- Barigozzi, R.; Franchini, G.; Perdichizzi, A.; Ravelli, S. Simulation of Solarized Combined Cycles: Comparison Between Hybrid GT and ISCC Plants. In Proceedings of the ASME Turbo Expo 2013: Turbine Technical Conference and Exposition, San Antonio, TX, USA, 3–7 June 2013; Volume 4. [Google Scholar] [CrossRef]

- Behar, O. Solar thermal power plants—A review of configurations and performance comparison. Renew. Sustain. Energy Rev. 2018, 92, 608–627. [Google Scholar] [CrossRef]

- Manente, G.; Rech, S.; Lazzaretto, A. Optimum choice and placement of concentrating solar power technologies in integrated solar combined cycle systems. Renew. Energy 2016, 96, 172–189. [Google Scholar] [CrossRef]

- Elmohlawy, A.E.; Ochkov, V.F.; Kazandzhan, B.I. Thermal performance analysis of a concentrated solar power system (CSP) integrated with natural gas combined cycle (NGCC) power plant. Case Stud. Therm. Eng. 2019, 14, 100458. [Google Scholar] [CrossRef]

- Elmohlawy, A.E.; Ochkov, V.F.; Kazandzhan, B.I. Study and prediction the performance of an integrated solar combined cycle power plant. Energy Procedia 2019, 156, 72–78. [Google Scholar] [CrossRef]

- Rovira, A.; Abbas, R.; Sánchez, C.; Muñoz, M. Proposal and analysis of an integrated solar combined cycle with partial recuperation. Energy 2020, 198, 117379. [Google Scholar] [CrossRef]

- Dayem, A.M.A.; Metwally, M.N.; Alghamdi, A.S.; Marzouk, E.M. Numerical Simulation and Experimental Validation of Integrated Solar Combined Power Plant. Energy Procedia 2014, 50, 290–305. [Google Scholar] [CrossRef]

- Muñoz, M.; Rovira, A.; Montes, M.J. Thermodynamic cycles for solar thermal power plants: A review. WIREs Energy Environ. 2022, 11, e420. [Google Scholar] [CrossRef]

- Javadi, M.; Jafari Najafi, N.; Khalili Abhari, M.; Jabery, R.; Pourtaba, H. 4E analysis of three different configurations of a combined cycle power plant integrated with a solar power tower system. Sustain. Energy Technol. Assess. 2021, 48, 101599. [Google Scholar] [CrossRef]

- Hosseini, R.; Soltani, M.; Valizadeh, G. Technical and economic assessment of the integrated solar combined cycle power plants in Iran. Renew Energy 2005, 30, 1541–1555. [Google Scholar] [CrossRef]

- Hajizadeh Aghdam, M.; Khoshgoftar Manesh, M.H.; Khani, N.; Yazdi, M. Energy, Exergy-Based and Emergy-Based Analysis of Integrated Solar PTC with a Combined Cycle Power Plant. Int. J. Thermodyn. 2021, 24, 17–30. [Google Scholar] [CrossRef]

- Binamer, A.O. Al-Abdaliya integrated solar combined cycle power plant: Case study of Kuwait, part I. Renew. Energy 2019, 131, 923–937. [Google Scholar] [CrossRef]

- Ameri, M.; Mohammadzadeh, M. Thermodynamic, thermoeconomic and life cycle assessment of a novel integrated solar combined cycle (ISCC) power plant. Sustain. Energy Technol. Assess. 2018, 27, 192–205. [Google Scholar] [CrossRef]

- Achour, L.; Bouharkat, M.; Behar, O. Performance assessment of an integrated solar combined cycle in the southern of Algeria. Energy Rep. 2018, 4, 207–217. [Google Scholar] [CrossRef]

- Manente, G. High performance integrated solar combined cycles with minimum modifications to the combined cycle power plant design. Energy Covers. Manag. 2016, 111, 186–197. [Google Scholar] [CrossRef]

- Dolores, D.G.; Rafael, A.S.; Galileo, M.C. Estudio del acoplamiento de diferentes configuraciones de ciclo combinado con planta solar de canal parabólico. Ing. Investig. Tecnol. 2015, 16, 253–264. [Google Scholar] [CrossRef][Green Version]

- Egyptian Petrochemicals Company. Available online: www.egy-petrochem.com (accessed on 26 November 2023).

- Math Works. MATLAB Software. Available online: https://www.mathworks.com/products.html?s_tid=nav_products (accessed on 13 November 2024).

- Math Works. Ideal Air Toolbox. Available online: https://www.mathworks.com/matlabcentral/fileexchange/71269-ideal-air-properties-at-constant-pressure-1-atm (accessed on 19 April 2019).

- Math Works. XSteam Toolbox. Available online: https://www.mathworks.com/matlabcentral/fileexchange/9817-x-steam-thermodynamic-properties-of-water-and-steam (accessed on 19 April 2019).

- World Nuclear Association. Heat Values of Various Fuels. Available online: https://world-nuclear.org/information-library/facts-and-Figures/heat-values-of-various-fuels.aspx (accessed on 22 December 2023).

- Bergman, T.L.; Lavine, A.S.; Incropera, F.P.; Dewitt, D.P. Heat Exchangers. In Fundamentals of Heat and Mass Transfer, 7th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2011; pp. 706–747. [Google Scholar]

- “Recognized Document of the Regulation of Thermal Installations in Buildings (RITE)” Joint Resolution of the Ministries of Industry, Energy and Tourism, and the Ministry of Public Works. CO2 Emission Factors and Passage Coefficients to Primary Energy. Available online: https://energia.gob.es/desarrollo/EficienciaEnergetica/RITE/Reconocidos/Reconocidos/Otrosdocumentos/Factores_emision_CO2.pdf (accessed on 15 October 2023).

- World Weather & Climate Information. 2023. Available online: https://weather-and-climate.com/average-monthly-hours-Sunshine,Alexandria,Egypt (accessed on 20 July 2023).

- Solutia. Therminol VP-1: Vapor Phase/Liquid Phase Heat Transfer Fluid. Available online: http://twt.mpei.ac.ru/tthb/hedh/htf-vp1.pdf (accessed on 18 July 2021).

- Ruegamer, T.; Kamp, H.; Kuckelkorn, T.; Schiel, W.; Weinrebe, G.; Nava, P.; Riffelmann, K.; Richert, T. Molten Salt for Parabolic Trough Applications: System Simulation and Scale Effects. Energy Procedia 2014, 49, 1523–1532. [Google Scholar] [CrossRef]

- Barlev, D.; Vidu, R.; Stroeve, P. Innovation in concentrated solar power. Sol. Energy Mater. Sol. Cells. 2011, 95, 2703–2725. [Google Scholar] [CrossRef]

- Kalogirou, S.A. Solar thermal collectors and applications. Prog. Energy Combust. Sci. 2004, 30, 231–295. [Google Scholar] [CrossRef]

| Gas Cycle | Steam Cycle | ||

|---|---|---|---|

| Ambient temperature | 24 °C | Steam inlet pressure | 43 bar |

| Ambient pressure | 1 bar | Steam inlet temperature | 457 °C |

| Combustion chamber inlet temperature | 379 °C | LP evaporator pressure | 2.4 bar |

| Turbine pressure | 15.7 bar | Condenser pressure | 0.08 bar |

| Turbine inlet temperature | 1174 °C | Economizer outlet temperature | 228 °C |

| Turbine exhaust temperature | 549 °C | LP evaporator mass flowrate | 5 kg/s |

| Exhaust mass flowrate | 174.7 kg/s | HP evaporator mass flowrate | 25 kg/s |

| Operating & Design Conditions | Model | EPC Power Plant |

|---|---|---|

| Gas turbine cycle | ||

| Air mass flowrate, kg/s | 171.2 | 171.2 |

| Air to fuel ratio | 50 | 50 |

| Pressure ratio, rp | 15.7 | 15.7 |

| Turbine inlet temperature, °C | 1174 | 1100 |

| Exhaust temperature, °C | 549 | 540 |

| Power output, MW | 90,569 | 90,569 |

| Top gas cycle efficiency, % | 39.84% | 39.84% |

| Steam Turbine cycle | ||

| LP steam mass flowrate, kg/s | 5 | 5 |

| HP steam mass flowrate, kg/s | 25 | 25 |

| Turbine inlet pressure, bar | 43 | 43 |

| Power output, MW | 26,292 | 26,292 |

| Bottom steam cycle efficiency, % | 27.1 | NA |

| Heat recovery steam generator (HRSG) | ||

| Pinch point temperature, K | 17.5 | 17.5 |

| Approach temperature, K | 28 | 28 |

| Stack temperature, °C | 160 | 172 |

| (UA) Feedwater heater, kW/K | 449 | NA |

| (UA) Low-pressure evaporator, kW/K | 164.5 | NA |

| (UA) Economizer, kW/K | 175.5 | NA |

| (UA) High-pressure evaporator, kW/K | 475 | NA |

| (UA) Superheater, kW/K | 84.5 | NA |

| Combined cycle | ||

| Total output power, MW | 90,569 | 90,569 |

| Efficiency, % | 56.13 | 56.13 |

| Collector Type | Parabolic Trough Collectors (PTC) | Parabolic Dish Reflectors (PDR) | Heliostat Field Collectors (Solar Power Tower) |

|---|---|---|---|

| Description | Parabolic sheet of reflective material.Linear receiver (metal pipe with heat transfer fluid) | Large reflective parabolic dish with stirring high engine receiver at focal point | Large heliostat field with tall tower in its center. Receiver: water/HTF boiler at top |

| Operating range (°C) | 50–400 | 150–1500 | 300–2000 |

| Relative cost | Low | Very high | High |

| Concentration ratio 1 | 15–45 | 100–1000 | 150–1500 |

| Tracking | One-Axis | Two-Axis | Two-Axis |

| Efficiency (%) | ~18 | ~30 | ~25–28 |

| Mass Flowrates | Original CC | ISCC Case A | ISCC Case B |

|---|---|---|---|

| Fuel flowrate (kg/s) | 3.42 | 3.21 | |

| Fuel saving (%) | -- | 6.23 | |

| Solar heat integration | Original CC | ISCC Case A | ISCC Case B |

| Integrated solar heat (MW) | -- | 10 | |

| Cycle efficiency | Original CC | ISCC Case A | ISCC Case B |

| Gas turbine cycle (%) | 39.84 | 39.85 | |

| Combined cycle (%) | 56.13 | 56.15 | |

| Cycle power breakdown | Original CC | ISCC Case A | ISCC Case B |

| Gas cycle (kW) | 64,277 | 64,277 | 64,277 |

| Steam cycle (kW) | 26,292 | 26,292 | 26,292 |

| Total net power (kW) | 90,569 | 90,569 | 90,569 |

| Specific work per fuel unit mass flow (kJ/kg) | 26,439 | 28,198 | 28,198 |

| CO2 emissions (Mt/year) | 0.2971 | 0.2785 | 0.2785 |

| CO2 emissions saved (kg CO2/kWh) | - | 0.0064 | 0.0064 |

| Mass Flowrates | Original CC | ISCC Case C | ISCC Case D |

|---|---|---|---|

| Fuel flowrate (kg/s) | 3.42 | 3.3 | 3.15 |

| Fuel saving (%) | -- | 3.49 | 7.97 |

| Solar heat integration | Original CC | ISCC Case C | ISCC Case D |

| Integrated solar heat (MW) | -- | 15 | 3 |

| Cycle efficiency | Original CC | ISCC Case C | ISCC Case D |

| Gas turbine cycle (%) | 39.84 | 39.84 | 39.84 |

| Combined cycle (%) | 56.13 | 53.06 | 59.79 |

| Cycle power breakdown | Original CC | ISCC Case C | ISCC Case D |

| Compressor (kW) | 62,450 | 60,266 | 57,471 |

| Gas turbine (kW) | 126,727 | 122,294 | 116,622 |

| Gas cycle (kW) | 64,277 | 62,028 | 59,152 |

| Steam cycle (kW) | 26,292 | 28,542 | 31,417 |

| Total net power (kW) | 90,569 | 90,569 | 90,569 |

| Specific work per unit fuel mass flow (kJ/kg) | 26,439 | 27,399 | 28,730 |

| CO2 emissions (Mt/year) | 0.2971 | 0.2867 | 0.2734 |

| CO2 emissions saved (kg CO2/kWh) | -- | 0.0035 | 0.0083 |

| Solar Heat Integration | Original CC | ISCC Case C | ISCC Case D |

|---|---|---|---|

| Integrated solar heat (MW) | -- | 10 | |

| Cycle efficiency | Original CC | ISCC Case C | ISCC Case D |

| Gas turbine cycle (%) | 39.84 | 39.83 | |

| Combined cycle (%) | 56.13 | 55.19 | |

| Cycle power breakdown | Original CC | ISCC Case C | ISCC Case D |

| Compressor (kW) | 62,450 | 66,455 | |

| Gas turbine (kW) | 126,727 | 134,693 | |

| Gas cycle (kW) | 64,277 | 68,239 | |

| Steam cycle (kW) | 26,292 | 26,323 | |

| Total net power (kW) | 90,569 | 94,562 | |

| Power boosted (%) | -- | 4.41 | |

| Back work ratio (%) | 49.279 | 49.33 | |

| Specific work per unit fuel mass flow (kJ/kg) | 26,439 | 27,605 | |

| Mass Flowrates | Original CC | ISCC Case C | ISCC Case D |

|---|---|---|---|

| LP evaporator mass flowrate (kg/s) | 5 | 9.17 | 6.54 |

| HP evaporator mass flowrate (kg/s) | 25 | 45.84 | 32.72 |

| Solar heat integration | Original CC | ISCC Case C | ISCC Case D |

| Integrated solar heat (MW) | -- | 4 | 12 |

| Cycle efficiency | Original CC | ISCC Case C | ISCC Case D |

| Gas turbine cycle (%) | 39.84 | 39.84 | 39.84 |

| Combined cycle (%) | 56.13 | 68.03 | 56.93 |

| Cycle power breakdown | Original CC | ISCC Case C | ISCC Case D |

| Gas cycle (kW) | 64,277 | 64,277 | 64,277 |

| Steam cycle (kW) | 26,292 | 48,214 | 34,412 |

| Total net power (kW) | 90,569 | 112,491 | 98,689 |

| Power boosted (%) | -- | 24.2 | 8.96 |

| Specific work per unit fuel mass flow (kJ/kg) | 26,439 | 32,840 | 28,810 |

| Strategy | Considerations/Recommendations for Solar Thermal Power Integration | ||

|---|---|---|---|

| Fuel saving | A |

| |

| B |

| ||

| C |

| ||

| D |

| ||

| Power boosting | A |

| |

| B |

| ||

| C | Flowrate |

| |

| Parameter |

| ||

| D | Flowrate |

| |

| Parameter |

| ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdelhalim, A.M.; Meana-Fernández, A.; Suarez-Ramon, I. Integration of Thermal Solar Power in an Existing Combined Cycle for a Reduction in Carbon Emissions and the Maximization of Cycle Efficiency. Processes 2024, 12, 2557. https://doi.org/10.3390/pr12112557

Abdelhalim AM, Meana-Fernández A, Suarez-Ramon I. Integration of Thermal Solar Power in an Existing Combined Cycle for a Reduction in Carbon Emissions and the Maximization of Cycle Efficiency. Processes. 2024; 12(11):2557. https://doi.org/10.3390/pr12112557

Chicago/Turabian StyleAbdelhalim, Adham Mohamed, Andrés Meana-Fernández, and Ines Suarez-Ramon. 2024. "Integration of Thermal Solar Power in an Existing Combined Cycle for a Reduction in Carbon Emissions and the Maximization of Cycle Efficiency" Processes 12, no. 11: 2557. https://doi.org/10.3390/pr12112557

APA StyleAbdelhalim, A. M., Meana-Fernández, A., & Suarez-Ramon, I. (2024). Integration of Thermal Solar Power in an Existing Combined Cycle for a Reduction in Carbon Emissions and the Maximization of Cycle Efficiency. Processes, 12(11), 2557. https://doi.org/10.3390/pr12112557