Towards Sustainability in Hydraulic Machinery Manufacturing by 3D Printing

Abstract

1. Introduction

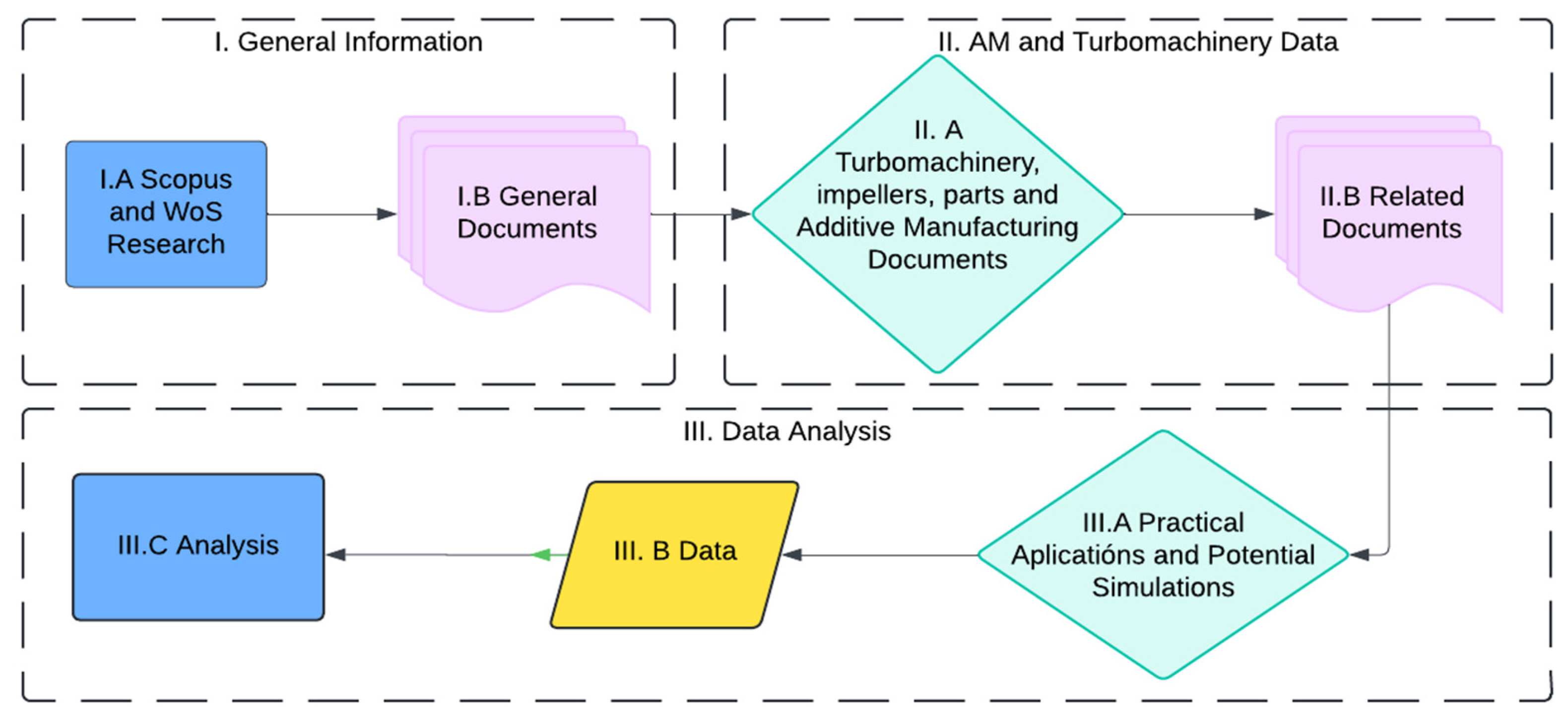

2. Materials and Methods

2.1. I. General Information

2.2. II. AM and Turbomachinery Data

2.3. III. Data Analysis

3. Results and Discussion

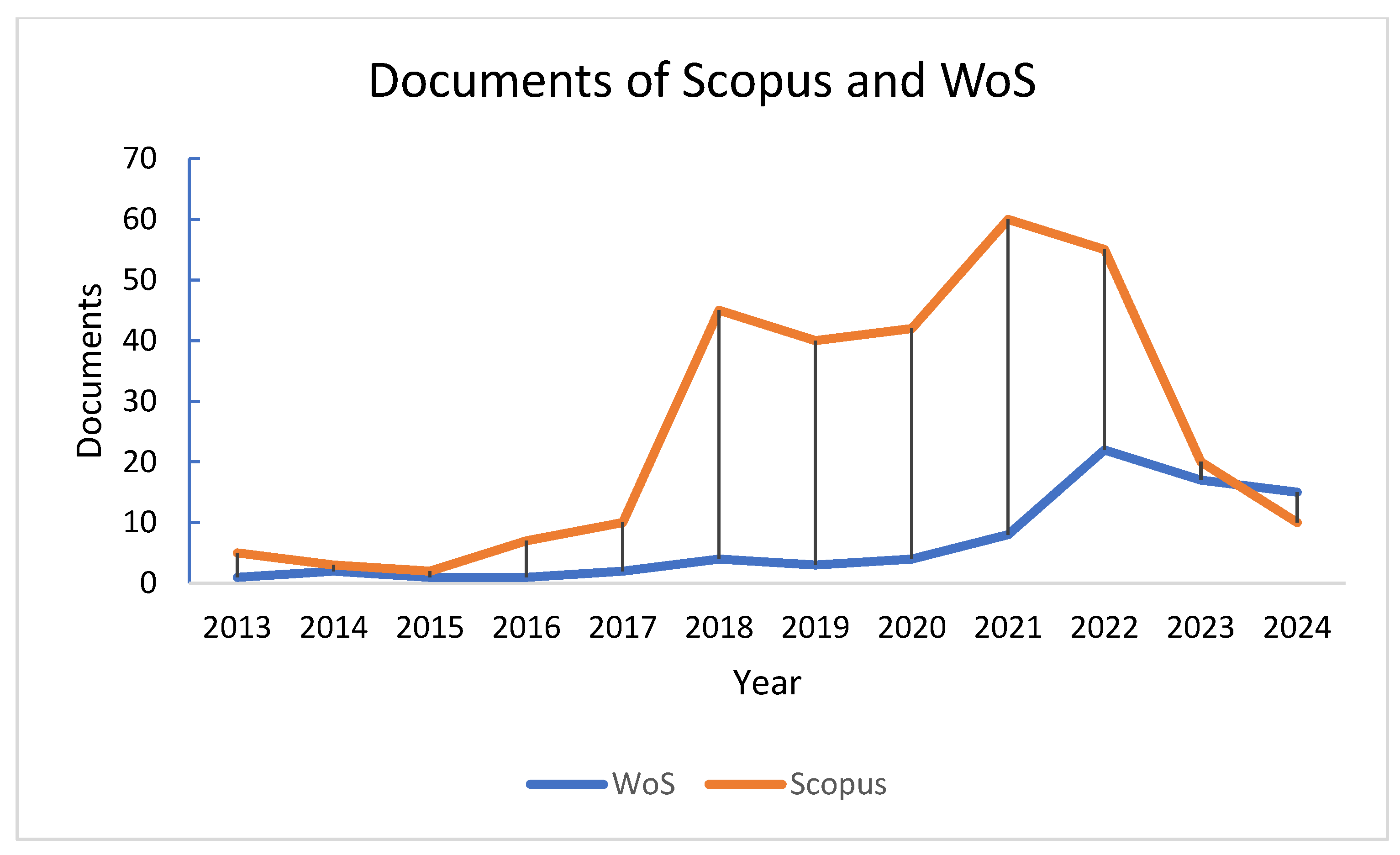

3.1. I. General Information

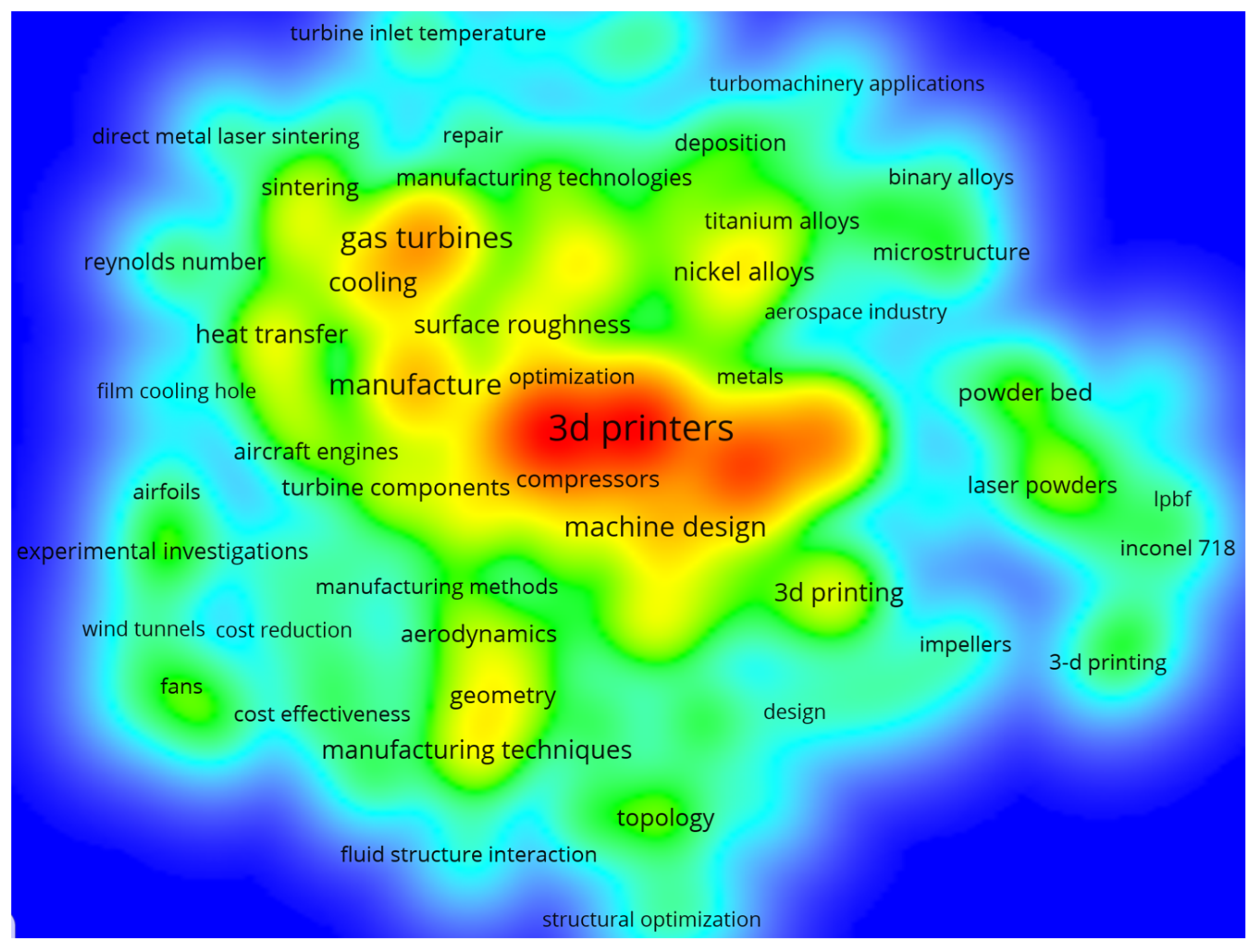

3.2. II. AM and Turbomachinery Data

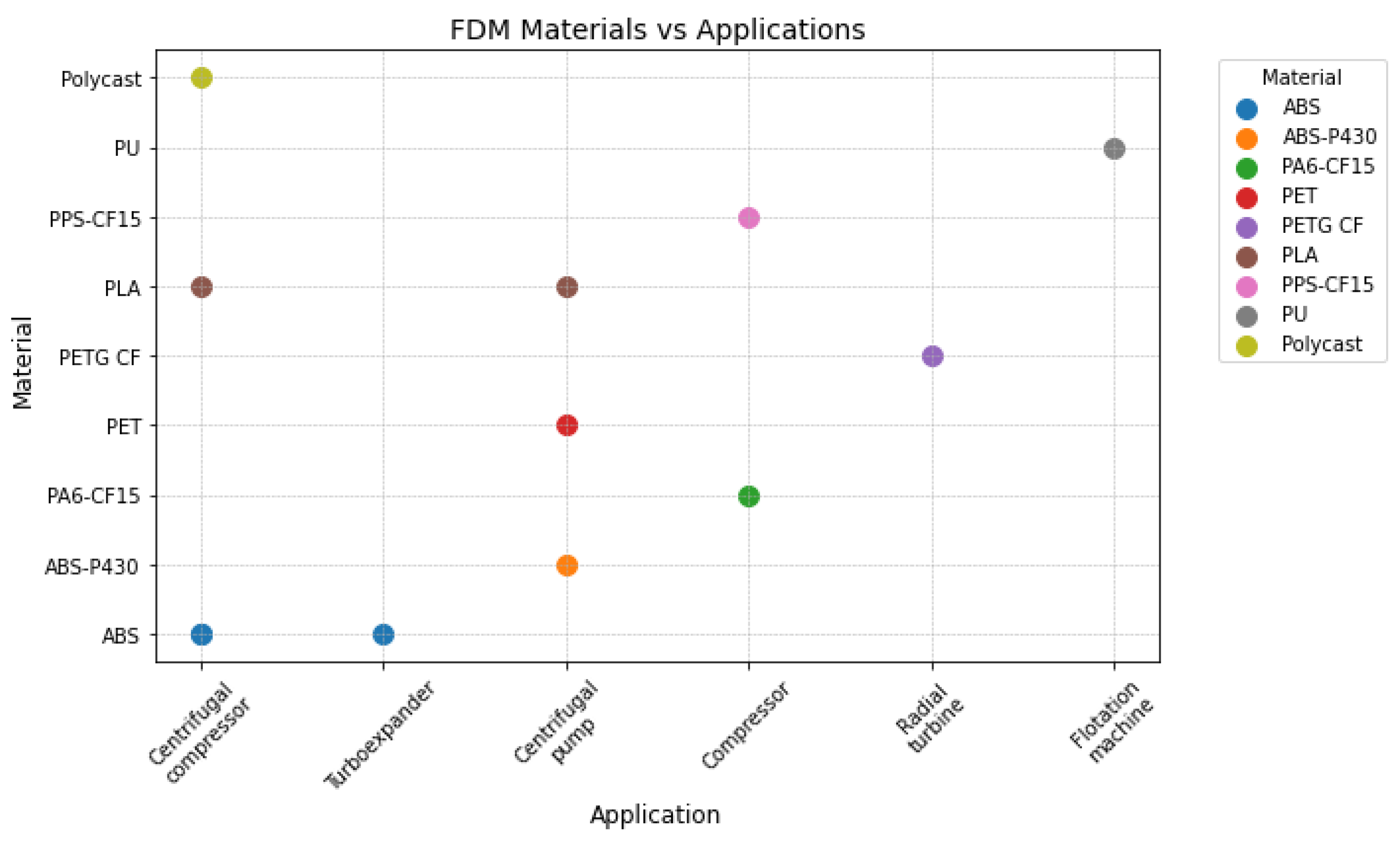

3.3. III. Data Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Acronyms

| ABS | Acrylonitrile Butadiene Styrene |

| AFM | Abrasive Flow Machining |

| AM | Additive Manufacturing |

| BJP | Binder Jetting Printing |

| BMD | Bound Metal Deposition |

| CNC | Computed Numeric Control |

| CRC | Corrosion Resistance Classes |

| CRCI | Corrosion Resistance Cost Index |

| DLP | Digital Light Processing |

| DMLS | Direct Metal Laser Sintering |

| EBM | Electron Beam Melting |

| FDM | Fused Deposition Modeling |

| HIPS | High-Impact Polystyrene |

| IIoT | Industrial Internet of Things |

| IN718 | Inconel 718 |

| LPBF | Laser Powder Bed Fusion |

| LMD | Laser Metal Deposition |

| MJ | MultiJet |

| MJF | Multi Jet Fusion |

| MTG | Micro Gas Turbine |

| PA | Polyamide |

| PA6-CF15 | Polyamide 6 reinforced with 15% carbon fiber |

| PCMs | Polymeric Composite Materials |

| PEEK | Polyether-ether-ketone |

| PET | Polyethylene Terephthalate |

| PETG | Polyethylene Terephthalate Glycol |

| PPS | Polyphenylene sulfide |

| PPS-CF15 | Polyphenylene sulfide reinforced with 15% carbon fiber |

| PU | Polyurethane |

| SDGs | Sustainable Development Goals |

| SiC | Silicon Carbide |

| SLA | Stereolithography |

| SLM | Selective Laser Melting |

| SMC | Soft Magnetic Composite |

| SLS | Selective Laser Sintering |

| SS | Stainless Steel |

| WDE | Water Droplet Erosion |

| sCO2 | Supercritical CO2 |

| WAAM | Wire Arc Additive Manufacturing |

References

- Lagha, M.; Duplaa, S.; Binder, N.; Carbonneau, X. Unified Classification and Characterization of Axial Turbomachines and Propellers. In Proceedings of the 13th International Symposium on Experimental Computational Aerothermodynamics of Internal Flows, Okinawa, Japan, 7–11 May 2017; p. 1. [Google Scholar]

- Singh, A.; Sharma, D. Efficiency Enhancement in Turbomachinery: Bridging Numerical Modeling and Experimental Validation for Fluid Dynamics Advancements. J. Sustain. Urban Futures 2023, 13, 1–15. [Google Scholar]

- Srinivas, G.; Raghunandana, K.; Shenoy, B.S. Recent Developments in Turbomachinery Component Materials and Manufacturing Challenges for Aero Engine Applications. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Melbourne, Australia, 15–16 September 2018; IOP Publishing: Bristol, UK, 2018; Volume 314, p. 012012. [Google Scholar]

- Patel, M.; Kumar, A.; Pardhi, B.; Pal, M. Abrasive, Erosive and Corrosive Wear in Slurry Pumps—A Review. Int. Res. J. Eng. Technol. 2020, 7, 2188–2195. [Google Scholar]

- Yonezawa, K.; Nakai, G.; Takayasu, M.; Sugiyama, K.; Sugita, K.; Umezawa, S.; Ohmori, S. Influence of Blade Corrosion on Aerodynamic Characteristics of a Gas Turbine. Energy 2021, 230, 120665. [Google Scholar] [CrossRef]

- Linden, D. Know Your Turbomachinery’s Operating Environment! In Proceedings of the 47th Turbomachinery Symposium, Houston, TX, USA, 18–20 September 2018; Turbomachinery Laboratory, Texas A&M Engineering Experiment Station: College Station, TX, USA, 2018. [Google Scholar]

- Yang, S.; Gao, S.; Xue, W.; Wu, B.; Duan, D. Phenomenological Modeling of Wear Mechanisms between Nickel-Based Superalloy Blades and Ceramic-Based Abradable Coatings in Turbomachines. J. Mater. Res. Technol. 2023, 27, 4191–4203. [Google Scholar] [CrossRef]

- Di, J.; Wang, S.; Yan, X.; Cai, L.; Xie, Y. Experimental Investigation on Effect of Surface Strengthening Process and Roughness on Water Droplet Erosion Behavior in Turbomachinery. Tribol. Int. 2021, 153, 106647. [Google Scholar] [CrossRef]

- Torner, B.; Wurm, F.-H. Influence of Zonal Surface Roughness on the Pump Characteristics of a Turbopump. In Proceedings of the 15th European Conference on Turbomachinery Fluid dynamics & Thermodynamics, Budapest, Hungary, 24–28 April 2023; European Turbomachinery Society: Florence, Italy, 2023. [Google Scholar]

- Alqallaf, J.; Teixeira, J.A. Blade Roughness Effects on Compressor and Engine Performance—A CFD and Thermodynamic Study. Aerospace 2021, 8, 330. [Google Scholar] [CrossRef]

- Radgolchin, M.; Anbarsooz, M. Fatigue Failure of Centrifugal Compressor Impellers: A Comprehensive Review. Eng. Fail. Anal. 2023, 153, 107592. [Google Scholar] [CrossRef]

- Doshi, S.; Katoch, A.; Suresh, A.; Razak, F.A.; Datta, S.; Madhavan, S.; Zanhar, C.M.; Gundabattini, E. A Review on Vibrations in Various Turbomachines Such as Fans, Compressors, Turbines and Pumps. J. Vib. Eng. Technol. 2021, 9, 1557–1575. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, T.; Meng, Y.; Zhang, D.; Xie, Y. Integrated Optimization for Design and Operation of Turbomachinery in a Solar-Based Brayton Cycle Based on Deep Learning Techniques. Energy 2022, 252, 123980. [Google Scholar] [CrossRef]

- Gou, L.; Zeng, X.; Wang, Z.; Han, G.; Lin, C.; Cheng, X. A Linearization Model of Turbofan Engine for Intelligent Analysis towards Industrial Internet of Things. IEEE Access 2019, 7, 145313–145323. [Google Scholar] [CrossRef]

- Xie, R.; Chen, M.; Liu, W.; Jian, H.; Shi, Y. Digital Twin Technologies for Turbomachinery in a Life Cycle Perspective: A Review. Sustainability 2021, 13, 2495. [Google Scholar] [CrossRef]

- Brun, K. Turbomachinery for Carbon Dioxide Transport and Storage. In Offshore Technology Conference; OTC: Hollister, MO, USA, 2023; p. D011S010R001. [Google Scholar]

- Cetin, T.H.; Zhu, J. Aerodynamic Design and Optimization of SCO2 Turbomachinery: Two-Stage Optimization Approach. Energy Convers. Manag. 2023, 297, 117711. [Google Scholar] [CrossRef]

- Reddy, T.R.; Priyadarsini, C.I.; Navaneetha, R. Design and Analysis of Impeller Using Corrosion Resistant Materials. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2021; Volume 2317. [Google Scholar]

- Wang, Y.; Li, W.; He, T.; Liu, H.; Han, C.; Zhu, Z. Experimental Study on the Influence of Particle Diameter, Mass Concentration, and Impeller Material on the Wear Performance of Solid–Liquid Two-Phase Centrifugal Pump Blade. Front. Energy Res. 2022, 10, 893385. [Google Scholar] [CrossRef]

- Bandi, S.; Banka, J.; Kumar, A.; Rai, A.K. Effects of Sediment Properties on Abrasive Erosion of a Centrifugal Pump. Chem. Eng. Sci. 2023, 277, 118873. [Google Scholar] [CrossRef]

- Shen, Z.; Chu, W.; Li, X.; Dong, W. Sediment Erosion in the Impeller of a Double-Suction Centrifugal Pump—A Case Study of the Jingtai Yellow River Irrigation Project, China. Wear 2019, 422–423, 269–279. [Google Scholar] [CrossRef]

- Mirmahdi, E. Defects in Turbine Impeller Blades with Non-Destructive Testing: Modeling, Ultrasonic Waves, Defect Analysis. J. Inst. Eng. (India) Ser. C 2021, 102, 1395–1401. [Google Scholar] [CrossRef]

- Li, X.; Zeng, X.; Zhao, Z.; Zhang, X.; Yan, Q.; Zhang, Y.; Wen, Y.; Yang, X.; Mao, F. Fast-flowing LBE Corrosion of the SiC Pump Impeller: Numerical and Experimental Investigations. Int. J. Appl. Ceram. Technol. 2023, 20, 436–450. [Google Scholar] [CrossRef]

- ElJersifi, A.; Chbihi, A.; Semlal, N.; Bouaouine, H.; Naamane, S. Failure Analysis of a High Chromium Carbon Steel Impeller Operating in Phosphoric Acid Slurry. Wear 2021, 476, 203660. [Google Scholar] [CrossRef]

- Li, L.; Ren, Y.; Chang, S.; Li, M.; Lin, S.; Wang, M. Evaluation of the ATI 718Plus Repaired by Laser Metal Deposition under Heat Treatment Regimes: Microstructures, Mechanical Properties, and Their Heterogeneity. Mater. Sci. Eng. A 2023, 885, 145540. [Google Scholar] [CrossRef]

- Kan, K.; Binama, M.; Chen, H.; Zheng, Y.; Zhou, D.; Su, W.; Muhirwa, A. Pump as Turbine Cavitation Performance for Both Conventional and Reverse Operating Modes: A Review. Renew. Sustain. Energy Rev. 2022, 168, 112786. [Google Scholar] [CrossRef]

- Zhu, D.; Xiao, R.; Liu, W. Influence of Leading-Edge Cavitation on Impeller Blade Axial Force in the Pump Mode of Reversible Pump-Turbine. Renew. Energy 2021, 163, 939–949. [Google Scholar] [CrossRef]

- Zhang, F.; Tao, R.; Zhu, D.; Wu, Y.; Jin, F.; Xiao, R. Anti-Cavitation Leading-Edge Profile Design of Centrifugal Pump Impeller Blade Based on Genetic Algorithm and Decision Tree. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 279. [Google Scholar] [CrossRef]

- Fei, Z.; Zhang, R.; Xu, H.; Feng, J.; Mu, T.; Chen, Y. Energy Performance and Flow Characteristics of a Slanted Axial-Flow Pump under Cavitation Conditions. Phys. Fluids 2022, 34, 035121. [Google Scholar] [CrossRef]

- Pokharel, N.; Ghimire, A.; Thapa, B.; Thapa, B.S. Wear in Centrifugal Pumps with Causes, Effects and Remedies: A Review. IOP Conf. Ser. Earth Environ. Sci. 2022, 1037, 012042. [Google Scholar] [CrossRef]

- Li, W.; Li, S.; Ji, L.; Zhao, X.; Shi, W.; Agarwal, R.K.; Awais, M.; Yang, Y. A Study on the Cavitation and Pressure Pulsation Characteristics in the Impeller of an LNG Submerged Pump. Machines 2021, 10, 14. [Google Scholar] [CrossRef]

- Kelley, C.R.; Lopp, G.K.; Kauffman, J.L. Optimizing Piezoelectric Material Location and Size for Multiple-Mode Vibration Reduction of Turbomachinery Blades. J. Vib. Acoust. 2021, 143, 021007. [Google Scholar] [CrossRef]

- Jia, X.Q.; Li, S.Y.; Miu, H.J.; Yang, T.; Rao, K.; Wu, D.Y.; Cui, B.L.; Ou, J.L.; Zhu, Z.C. Carbon Nanomaterials: A New Sustainable Solution to Reduce the Emerging Environmental Pollution of Turbomachinery Noise and Vibration. Front. Chem. 2020, 8, 683. [Google Scholar] [CrossRef]

- Nie, D.; Chen, X.; Wu, Q.; Liu, Y. Stress Corrosion Cracking Behaviors of FV520B Stainless Steel Used in a Failed Compressor Impeller. Eng. Fail. Anal. 2020, 116, 104701. [Google Scholar] [CrossRef]

- Fitriyana, D.F.; Anis, S.; Al Qudus, A.R.; Lakuy, M.A.N.; Ismail, R.; Nugroho, S.; Haryadi, G.D.; Bayuseno, A.P.; Siregar, J.P. The Effect of Post-Heat Treatment on The Mechanical Properties of FeCrBMnSi Coatings Prepared by Twin Wire Arc Spraying (TWAS) Method on Pump Impeller From 304 Stainless Steel. J. Adv. Res. Fluid Mech. Therm. Sci. 2022, 93, 138–147. [Google Scholar] [CrossRef]

- Kyaramyan, K.A.; Nochovnaya, N.A.; Zakharova, N.S.; Kashapov, O.S. Microstructure and Mechanical Properties of the Material and the Surface Residual Stresses of Compressor Impeller Blades Made of a VT41 Titanium Alloy Depending on the Initial State and Incomplete Annealing Conditions. Russ. Metall. (Met.) 2021, 2021, 1587–1593. [Google Scholar] [CrossRef]

- Mamazhonov, M.; Shakirov, B.; Matyakubov, B.; Makhmudov, A. Polymer Materials Used to Reduce Waterjet Wear of Pump Parts. J. Phys. Conf. Ser. 2022, 2176, 012048. [Google Scholar] [CrossRef]

- Zirak, N.; Shirinbayan, M.; Deligant, M.; Tcharkhtchi, A. Toward Polymeric and Polymer Composites Impeller Fabrication. Polymers 2021, 14, 97. [Google Scholar] [CrossRef] [PubMed]

- Soori, M.; Jough, F.K.G.; Dastres, R.; Arezoo, B. Sustainable CNC Machining Operations, a Review. Sustain. Oper. Comput. 2024, 5, 73–87. [Google Scholar] [CrossRef]

- Kantaros, A.; Petrescu, F.I.T.; Brachos, K.; Ganetsos, T.; Petrescu, N. Evaluating Benchtop Additive Manufacturing Processes Considering Latest Enhancements in Operational Factors. Processes 2024, 12, 2334. [Google Scholar] [CrossRef]

- Dalpadulo, E.; Petruccioli, A.; Gherardini, F.; Leali, F. A Review of Automotive Spare-Part Reconstruction Based on Additive Manufacturing. J. Manuf. Mater. Process. 2022, 6, 133. [Google Scholar] [CrossRef]

- Hedayati, R.; Stulova, V. 3D Printing for Space Habitats: Requirements, Challenges, and Recent Advances. Aerospace 2023, 10, 653. [Google Scholar] [CrossRef]

- Hegab, H.; Khanna, N.; Monib, N.; Salem, A. Design for Sustainable Additive Manufacturing: A Review. Sustain. Mater. Technol. 2023, 35, e00576. [Google Scholar] [CrossRef]

- Liu, W.; Liu, X.; Liu, Y.; Wang, J.; Evans, S.; Yang, M. Unpacking Additive Manufacturing Challenges and Opportunities in Moving towards Sustainability: An Exploratory Study. Sustainability 2023, 15, 3827. [Google Scholar] [CrossRef]

- Chyr, G.; DeSimone, J.M. Review of High-Performance Sustainable Polymers in Additive Manufacturing. Green Chem. 2023, 25, 453–466. [Google Scholar] [CrossRef]

- Jiang, J.; Fu, Y.-F. A Short Survey of Sustainable Material Extrusion Additive Manufacturing. Aust. J. Mech. Eng. 2023, 21, 123–132. [Google Scholar] [CrossRef]

- Calignano, F.; Mercurio, V. An Overview of the Impact of Additive Manufacturing on Supply Chain, Reshoring, and Sustainability. Clean. Logist. Supply Chain 2023, 7, 100103. [Google Scholar] [CrossRef]

- Kantaros, A.; Ganetsos, T.; Petrescu, F.I.T.; Ungureanu, L.M.; Munteanu, I.S. Post-Production Finishing Processes Utilized in 3D Printing Technologies. Processes 2024, 12, 595. [Google Scholar] [CrossRef]

- Ge, J.; Pillay, S.; Ning, H. Post-Process Treatments for Additive-Manufactured Metallic Structures: A Comprehensive Review. J. Mater. Eng. Perform. 2023, 32, 7073–7122. [Google Scholar] [CrossRef]

- Jin, L.; Zhai, X.; Wang, K.; Zhang, K.; Wu, D.; Nazir, A.; Jiang, J.; Liao, W.-H. Big Data, Machine Learning, and Digital Twin Assisted Additive Manufacturing: A Review. Mater. Des. 2024, 244, 113086. [Google Scholar] [CrossRef]

- Peng, S.; Li, T.; Wang, X.; Dong, M.; Liu, Z.; Shi, J.; Zhang, H. Toward a Sustainable Impeller Production: Environmental Impact Comparison of Different Impeller Manufacturing Methods. J. Ind. Ecol. 2017, 21, S216–S229. [Google Scholar] [CrossRef]

- Andrearczyk, A.; Bagiński, P.; Klonowicz, P. Numerical and Experimental Investigations of a Turbocharger with a Compressor Wheel Made of Additively Manufactured Plastic. Int. J. Mech. Sci. 2020, 178, 105613. [Google Scholar] [CrossRef]

- Parize, H.; Tardelli, J.D.C.; Bohner, L.; Sesma, N.; Muglia, V.A.; Dos Reis, A.C. Digital versus Conventional Workflow for the Fabrication of Physical Casts for Fixed Prosthodontics: A Systematic Review of Accuracy. J. Prosthet. Dent. 2022, 128, 25–32. [Google Scholar] [CrossRef]

- Hernández, F.; Fragoso, A. Fabrication of a Stainless-Steel Pump Impeller by Integrated 3D Sand Printing and Casting: Mechanical Characterization and Performance Study in a Chemical Plant. Appl. Sci. 2022, 12, 3539. [Google Scholar] [CrossRef]

- Yang, Z.; Zhu, L.; Ning, J.; Wang, S.; Xue, P.; Xu, P.; Dun, Y.; Xin, B.; Zhang, G. Revealing the Influence of Ultrasound/Heat Treatment on Microstructure Evolution and Tensile Failure Behavior in 3D-Printing of Inconel 718. J. Mater. Process. Technol. 2022, 305, 117574. [Google Scholar] [CrossRef]

- Popa, I.-F.; Dobromirescu, C.; Vintila, I.S.; Tinca, I.; Mihai, D.; Canache, A.M.; Crunteanu, D.E. Hydraulic Performance Comparison of Centrifugal Closed Impellers Fabricated by Means of Additive Manufacturing and Classical Machining for Space Active Thermal Control Systems of Satellites. Applied Sciences 2024, 14, 9448. [Google Scholar] [CrossRef]

- Makivskyi, O.S.; Kondus, V.Y.; Pitel, J.; Sotnyk, M.I.; Andrusiak, V.O.; Polkovnychenko, V.V.; Mushtai, M.V. The Influence of the Design Features of the Submersible Pump Rotor on the Vibration Reliability. J. Eng. Sci. 2024, 11, D1–D9. [Google Scholar] [CrossRef]

- Cooper, C.; Booth, A.; Britten, N.; Garside, R. A Comparison of Results of Empirical Studies of Supplementary Search Techniques and Recommendations in Review Methodology Handbooks: A Methodological Review. Syst. Rev. 2017, 6, 1–16. [Google Scholar] [CrossRef] [PubMed]

- Aguinis, H.; Ramani, R.S.; Alabduljader, N. Best-Practice Recommendations for Producers, Evaluators, and Users of Methodological Literature Reviews. Organ. Res. Methods 2023, 26, 46–76. [Google Scholar] [CrossRef]

- Alexander, P.A. Methodological Guidance Paper: The Art and Science of Quality Systematic Reviews. Rev. Educ. Res. 2020, 90, 6–23. [Google Scholar] [CrossRef]

- Scopus. Scopus—Document Search. Available online: https://www.scopus.com/standard/marketing.uri (accessed on 27 June 2024).

- WoS. Web of Science. WoS.; Clarivate: London, UK, 2020. [Google Scholar]

- VOSviewer. VOSviewer—Visualizing Scientific Landscapes. Available online: https://www.vosviewer.com/ (accessed on 27 June 2024).

- Jiménez, M.; Romero, L.; Domínguez, I.A.; Espinosa, M.d.M.; Domínguez, M. Additive Manufacturing Technologies: An Overview about 3D Printing Methods and Future Prospects. Complexity 2019, 2019, 9656938. [Google Scholar] [CrossRef]

- Systèmes, D. Introduction to 3D Printing–Additive Processes. Dassault Syst. 2018. [Google Scholar] [CrossRef]

- Adiaconitei, A.; Vintila, I.S.; Mihalache, R.; Paraschiv, A.; Frigioescu, T.; Vladut, M.; Pambaguian, L. A Study on Using the Additive Manufacturing Process for the Development of a Closed Pump Impeller for Mechanically Pumped Fluid Loop Systems. Materials 2021, 14, 967. [Google Scholar] [CrossRef]

- Meli, E.; Rindi, A.; Ridolfi, A.; Furferi, R.; Buonamici, F.; Iurisci, G.; Corbò, S.; Cangioli, F. Design and Production of Innovative Turbomachinery Components via Topology Optimization and Additive Manufacturing. Int. J. Rotating Mach. 2019, 2019, 9546831. [Google Scholar] [CrossRef]

- Allison, T.C.; Rimpel, A.M.; Moore, J.J.; Wilkes, J.C.; Pelton, R.; Wygant, K. Manufacturing and Testing Experience with Direct Metal Laser Sintering for Closed Centrifugal Compressor Impellers. In Proceedings of the 43rd Turbomachinery Symposium, Houston, TX, USA, 23–25 September 2014; Texas A&M University, Turbomachinery Laboratories: College Station, TX, USA, 2014. [Google Scholar]

- Meli, E.; Furferi, R.; Rind, A.; Ridolfi, A.; Volpe, Y.; Buonamici, F. A General Framework for Designing 3D Impellers Using Topology Optimization and Additive Manufacturing. IEEE Access 2020, 8, 60259–60269. [Google Scholar] [CrossRef]

- Lea, H.G.; Wooding, R.S.; Kuhr, S.; Rotella, J.; Córdova, J.L. Characterization of Properties of Laser Powder Bed Fusion Three-Dimensional-Printed Inconel 718 for Centrifugal Turbomachinery Applications. J. Eng. Gas Turbine Power 2023, 145, 061017. [Google Scholar] [CrossRef]

- Jia, D.; Li, F.; Zhang, Y. 3D-Printing Process Design of Lattice Compressor Impeller Based on Residual Stress and Deformation. Sci. Rep. 2020, 10, 600. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Li, F.; Jia, D. Residual Stress and Deformation Analysis of Lattice Compressor Impeller Based on 3D Printing Simulation. Mech. Adv. Mater. Struct. 2022, 29, 717–731. [Google Scholar] [CrossRef]

- Guo, J.; Wang, Y.; Wang, Y.; Peng, S.; Wang, F. Simulation Study on the Energy Utilization Efficiency of a Turbine Impeller Based on a Selective Laser Melting Process. Appl. Sci. 2023, 13, 10657. [Google Scholar] [CrossRef]

- Singh, S.P.; Gupta, R.K.; Agarwal, A. Processing and Characterization of Al-Si-Mg Alloy Made through 3D Printing and Comparison with Equivalent Cast Alloy. Mater. Today Proc. 2022, 67, 422–430. [Google Scholar] [CrossRef]

- Auyeskhan, U.; Lee, T.; Park, Y.; Kim, D.; Kim, N.; Kim, C.-S.; Kim, D.-H. Design Study for Performance Improvement of a Hybrid Pico Pelton Turbine and Its Additive Manufacturing Using a Laser Powder Bed Fusion Method. Int. J. Interact. Des. Manuf. (IJIDeM) 2024, 18, 107–117. [Google Scholar] [CrossRef]

- Qu, A.; Li, F. Influence of 3D Printing on Compressor Impeller Fatigue Crack Propagation Life. Int. J. Mech. Sci. 2023, 245, 108107. [Google Scholar] [CrossRef]

- Raghavan, S.; Dzugan, J.; Rzepa, S.; Podany, P.; Soh, N.; Hao, L.J.; Khan, N. Effect of Post-Treatment on Local Mechanical Properties of Additively Manufactured Impellers Made of Maraging Steel. Rapid. Prototyp. J. 2023, 29, 594–611. [Google Scholar] [CrossRef]

- Ponticelli, G.S.; Tagliaferri, F.; Venettacci, S.; Horn, M.; Giannini, O.; Guarino, S. Re-Engineering of an Impeller for Submersible Electric Pump to Be Produced by Selective Laser Melting. Appl. Sci. 2021, 11, 7375. [Google Scholar] [CrossRef]

- Huber, M.; Ess, J.; Hartmann, M.; Würms, A.; Rettberg, R.; Kränzler, T.; Löffel, K. Process Setup for Manufacturing of a Pump Impeller by Selective Laser Melting. In Industrializing Additive Manufacturing, Proceedings of the Additive Manufacturing in Products and Applications-AMPA2017 1, Zurich, Switzerland, 13–15 September 2017; Springer: Berlin/Heidelberg, Germany, 2018; pp. 252–263. [Google Scholar]

- Zhang, Y.; Li, F.; Jia, D. Lightweight Design and Static Analysis of Lattice Compressor Impeller. Sci. Rep. 2020, 10, 18394. [Google Scholar] [CrossRef]

- Wu, S.-T.; Huang, P.-W.; Chang, T.-W.; Jiang, I.-H.; Tsai, M.-C. Application of Magnetic Metal 3-D Printing on the Integration of Axial-Flow Impeller Fan Motor Design. IEEE Trans. Magn. 2020, 57, 8201205. [Google Scholar] [CrossRef]

- Bauer, D. Additive Manufacturing of Cryogenic Pump Impellers. In Proceedings of the Asia Turbomachinery & Pump Symposium, Lumpur, Malaysia, 23–26 May 2022; Turbomachinery Laboratory, Texas A&M Engineering Experiment Station: College Station, TX, USA, 2022. [Google Scholar]

- Kim, E.-H.; Choi, H.-H.; Jung, Y.-G. Fabrication of a Ceramic Core for an Impeller Blade Using a 3D Printing Technique and Inorganic Binder. J. Manuf. Process. 2020, 53, 43–47. [Google Scholar] [CrossRef]

- Chivel, Y.; Sudarev, A.; Konakov, V. Additive Manufacturing Technology of Ceramic Turbomachines. In Proceedings of the European Congress and Exhibition on Powder Metallurgy. European PM Conference Proceedings, Hamburg, Germany, 9–13 October 2016; The European Powder Metallurgy Association: Sandviken, Sweden, 2016; pp. 1–6. [Google Scholar]

- Bin, L.I.; Huimin, L.; Yuhang, Z.; Yaxin, C.; Ming, Z.; Qinming, W.U.; Yong, Y. Research on Precision Casting Process and Performance of Impeller Based on SLS. J. Xihua Univ. (Nat. Sci. Ed.) 2023, 42, 71–77. [Google Scholar]

- Špale, J.; Novotny, V.; Novotný, J. Experimental Development of Additively Manufactured Turboexpanders towards an Application in the ORC. In Proceedings of the Heat Powered Cycles Conference, Bilbao, Spain, 10–13 April 2022. [Google Scholar]

- Wang, D.; Dong, A.; Zhu, G.; Shu, D.; Sun, J.; Li, F.; Sun, B. Rapid Casting of Complex Impeller Based on 3D Printing Wax Pattern and Simulation Optimization. Int. J. Adv. Manuf. Technol. 2019, 100, 2629–2635. [Google Scholar] [CrossRef]

- Sudarev, A.; Konakov, V.; Chivel, Y. Selective Laser Sintering of Ceramic Turbomachine Components. Procedia CIRP 2018, 74, 264–267. [Google Scholar] [CrossRef]

- Badum, L.; Prochaska, T.; Schwentenwein, M.; Cukurel, B. Ceramic and Metal Additive Manufacturing of Monolithic Rotors From SiAlON and Inconel and Comparison of Aerodynamic Performance for 300W Scale Microturbines. J. Eng. Gas Turbine Power 2024, 146, 021006. [Google Scholar] [CrossRef]

- Stümpfl, D.; Ráž, K.; Streit, P.; Weiß, A.P. Additive manufacturing for fast prototyping of a velocity compounded radial re-entry turbine. In Proceedings of the 7th International Seminar on ORC Power System (ORC2023), Seville, Spain, 4–6 September 2023; pp. 13–22. [Google Scholar]

- Liverani, A.; Caligiana, G.; Frizziero, L.; Francia, D.; Donnici, G.; Dhaimini, K. Design for Six Sigma (DFSS) for Additive Manufacturing Applied to an Innovative Multifunctional Fan. Int. J. Interact. Des. Manuf. (IJIDeM) 2019, 13, 309–330. [Google Scholar] [CrossRef]

- Adach, M.; Sokołowski, P.; Piwowarczyk, T.; Nowak, K. Study on Geometry, Dimensional Accuracy and Structure of Parts Produced by Multi Jet Fusion. Materials 2021, 14, 4510. [Google Scholar] [CrossRef]

- Tan, X.; Kok, Y.; Tor, S.B.; Chua, C.K. Application of Electron Beam Melting (EBM) in Additive Manufacturing of an Impeller. In Proceedings of the 1st International Conference on Progress in Additive Manufacturing (Pro-AM 2014), Singapore, 26–28 May 2014. [Google Scholar]

- Klocke, F.; Klink, A.; Veselovac, D.; Aspinwall, D.K.; Soo, S.L.; Schmidt, M.; Schilp, J.; Levy, G.; Kruth, J.-P. Turbomachinery Component Manufacture by Application of Electrochemical, Electro-Physical and Photonic Processes. CIRP Ann. 2014, 63, 703–726. [Google Scholar] [CrossRef]

- Mandil, G.; Le, V.T.; Paris, H.; Suard, M. Building New Entities from Existing Titanium Part by Electron Beam Melting: Microstructures and Mechanical Properties. Int. J. Adv. Manuf. Technol. 2016, 85, 1835–1846. [Google Scholar] [CrossRef]

- Wang, P.; Nai, M.L.S.; Lu, S.; Bai, J.; Zhang, B.; Wei, J. Study of Direct Fabrication of a Ti-6Al-4V Impeller on a Wrought Ti-6Al-4V Plate by Electron Beam Melting. Jom 2017, 69, 2738–2744. [Google Scholar] [CrossRef]

- Kahhal, P.; Jo, Y.-K.; Park, S.-H. Recent Progress in Remanufacturing Technologies Using Metal Additive Manufacturing Processes and Surface Treatment. Int. J. Precis. Eng. Manuf. Green Technol. 2024, 11, 625–658. [Google Scholar] [CrossRef]

- Michaud, M.; Milan, P.J.; Vo, H.D. Low-Cost Rotating Experimentation in Compressor Aerodynamics Using Rapid Prototyping. Int. J. Rotating Mach. 2016, 2016, 8518904. [Google Scholar] [CrossRef]

- Derrick, S.; Rauen, J.; Rodriguez, J.; Aller, B. The Dual Impeller Drive System (DIDS). In Proceedings of the ASEE North Central Sectional Conference, Pittsburgh, PA, USA, 27 March 2010; Marshall University: Pittsburgh, PA, USA, 2010; pp. 4C1–4C8. [Google Scholar]

- Geiselhart, M. Design for Manufacturing and Characterization of Small-Scale Turbomachinery Impellers; Technical University of Denmark: Kongens Lyngby, Denmark, 2021. [Google Scholar]

- Leicht, B.T.; Bohan, B.T.; Schauer, F.; Kemnitz, R.; Rueschhoff, L.M.; Lam, B.; Kemp, J.W.; Costakis, W. Manufacturing a Ceramic Turbine Rotor for a Compact Jet Engine. J. Turbomach. 2023, 145, 081009. [Google Scholar] [CrossRef]

- Zhao, J.; Chu, W.; Song, T.; Bi, L.; Liu, J.; Han, Z.; Wang, Y.; Zhou, Q.; Li, L. Digital Light Processing of High-Strength Si3N4 Ceramics: Role of Particle Grading on Slurries Curing and Mechanical Properties. Ceram Int. 2024, 50, 22722–22732. [Google Scholar] [CrossRef]

- Ivanovich, S.M.; Dmitrievich, K.A.; Aleksandrovna, K.I.; Konstantinovich, S.F. Study of Impeller Design Parameters Effect on the Axial Thrust of a Centrifugal Electric Pump Assembly. Sib. Aerosp. Mag. 2020, 21, 389–399. [Google Scholar]

- Zhu, X.; Tong, X.; Wang, F. Rapid Investment Casting Technology of Closed Impeller Based on Digital Light Processing (DLP) 3D Printing. Spec. Cast. Nonferrous Alloys 2021, 41, 1370–1374. [Google Scholar]

- González Barrio, H. Metholology for Hybrid Manufacturing of Turbomachinery Integral Rotary Components in Thermoresistant Super Alloys. Ph.D. Thesis, Universidad del País Vasco-Euskal Herriko Unibertsitatea, Leioa, Spain, 2019. [Google Scholar]

- Soo, A.; Ali, S.M.; Shon, H.K. 3D Printing for Membrane Desalination: Challenges and Future Prospects. Desalination 2021, 520, 115366. [Google Scholar] [CrossRef]

- Li, C.; Wu, B.; Zhang, Z.; Zhang, Y. A Novel Process Planning Method of 3+ 2-Axis Additive Manufacturing for Aero-Engine Blade Based on Machine Learning. J. Intell. Manuf. 2023, 34, 2027–2042. [Google Scholar] [CrossRef]

- Pfeil, A.; Siegfarth, M.; Pusch, T.P.; Barbé, L.; Geiskopf, F.; Renaud, P. Design and Experimental Characterization of Hydraulically Actuated Revolute Joint Based on Multimaterial Additive Manufacturing. J. Mech. Des. 2022, 144, 055001. [Google Scholar] [CrossRef]

- Jiang, C.; Fleck, B.A.; Lipsett, M.G. Rapid Wear Modelling in a Slurry Pump Using Soft 3D Impeller Material. Energies 2020, 13, 3264. [Google Scholar] [CrossRef]

- Daabo, A.M.; Hassan, A.A.; Bashir, M.A.; Hamza, H.; Salim, S.; Koprulu, A.; Badawy, T.; Mahmoud, S.; Al-Dadah, R. Experimental Study and 3D Optimization of Small-Scale Solar-Powered Radial Turbine Using 3D Printing Technology. Machines 2023, 11, 817. [Google Scholar] [CrossRef]

- Nishida, M.; Negishi, T.; Sakota, D.; Kosaka, R.; Maruyama, O.; Hyakutake, T.; Kuwana, K.; Yamane, T. Properties of a Monopivot Centrifugal Blood Pump Manufactured by 3D Printing. J. Artif. Organs 2016, 19, 322–329. [Google Scholar] [CrossRef] [PubMed]

- Udroiu, R.; Nedelcu, A.; Deaky, B. Rapid Manufacturing by Polyjet Technology of Customized Turbines for Renewable Energy Generation. Environ. Eng. Manag. J. 2011, 10, 1387–1394. [Google Scholar] [CrossRef]

- Aruna Prabha, K.; Sai Rohit, P.; Nitturi, S.C.; Nithin, B. Manufacturing of 3 D Shrouded Impeller of a Centrifugal Compressor on 3D-Printing Machine Using FDM Technology. In Proceedings of the Materials Science and Engineering Conference Series, Bapatla, Andhra, 7–8 May 2021; Volume 1012, p. 012039. [Google Scholar]

- Tamburrino, F.; Barone, S.; Paoli, A.; Razionale, A.V. Post-Processing Treatments to Enhance Additively Manufactured Polymeric Parts: A Review. Virtual Phys. Prototyp. 2021, 16, 221–254. [Google Scholar] [CrossRef]

- Micha Premkumar, T.; Pushpak, V.; Vamsi Krishna, K.; Govardhan Reddy, D.; Sudheer Kumar, N.; Hariram, V.; Seralathan, S.; Nakandhrakumar, R.S. Design and Fusion Deposit Modelling of Radial Flow Centrifugal Pump. Mater. Today Proc. 2020, 33, 3497–3503. [Google Scholar] [CrossRef]

- Choe, C.-M.; Yang, W.-C.; Kim, U.-H.; Ri, B.-G.; Om, M.-S. Manufacture of Centrifugal Compressor Impeller Using FDM and Investment Casting. Int. J. Adv. Manuf. Technol. 2022, 118, 173–181. [Google Scholar] [CrossRef]

- Sedykh, L.V.; Borisov, P.V.; Pashkov, A.N.; Gorbatyuk, N.V.; Surkova, R.Y.; Mamatkulov, Z.K. Development of Flotation Machine Impeller on the Basis of Additive Technologies. Steel Transl. 2021, 51, 308–313. [Google Scholar] [CrossRef]

- Jabłońska, M.; Jurczak, W.; Ozimina, D.; Adamiak, M. Increasing the Operational Reliability of a Ship by Using a Composite Impeller in the Event of Hydrophore Pump Failure. Eksploat. I Niezawodn. 2023, 25. [Google Scholar] [CrossRef]

- Daniyan, I.A.; Muvunzi, R.; Fameso, F.; Mpofu, K.; Ale, F. Computer Aided Modelling and Investigation of the Performance of a Pump Impeller Produced Using Fused Deposition Modelling. In Proceedings of the 2023 14th International Conference on Mechanical and Intelligent Manufacturing Technologies (ICMIMT), Cape Town, South Africa, 26–28 May 2023; pp. 244–249. [Google Scholar]

- Sitte, D.; Sutanto, H. Performance Analysis of Hydraulic Machines Using Impellers Made from Conventional Steel and 3D Printing Co-Polymer. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Sanya, China, 12–14 November 2021; IOP Publishing: Bristol, UK, 2021; Volume 1115, p. 012049. [Google Scholar]

- Polák, M. Behaviour of 3D Printed Impellers in Performance Tests of Hydrodynamic Pump. In Proceedings of the 7th International Conference on Trends in Agricultural Engineering, Prague, Czech Republic, 17–20 September 2019; pp. 17–20. [Google Scholar]

- Do, T.; Bauder, T.J.; Suen, H.; Rego, K.; Yeom, J.; Kwon, P. Additively Manufactured Full-Density Stainless Steel 316L with Binder Jet Printing. In Proceedings of the International Manufacturing Science and Engineering Conference, College Station, TX, USA, 18–22 June 2018; American Society of Mechanical Engineers: New York, NY, USA, 2018; Volume 51357, p. V001T01A017. [Google Scholar]

- Jayawardane, H.; Davies, I.J.; Gamage, J.R.; John, M.; Biswas, W.K. Investigating the ‘Techno-Eco-Efficiency’Performance of Pump Impellers: Metal 3D Printing vs. CNC Machining. Int. J. Adv. Manuf. Technol. 2022, 121, 6811–6836. [Google Scholar] [CrossRef]

- Sinha, A.; Swain, B.; Behera, A.; Mallick, P.; Samal, S.K.; Vishwanatha, H.M.; Behera, A. A Review on the Processing of Aero-Turbine Blade Using 3D Print Techniques. J. Manuf. Mater. Process. 2022, 6, 16. [Google Scholar] [CrossRef]

- Pakle, S.; Jiang, K. Design of a High-Performance Centrifugal Compressor with New Surge Margin Improvement Technique for High Speed Turbomachinery. Propuls. Power Res. 2018, 7, 19–29. [Google Scholar] [CrossRef]

- Zinchenko, A.; Baiul, K.; Krot, P.; Khudyakov, A.; Vashchenko, S.; Banasiewicz, A.; Wróblewski, A. Materials Selection and Design Options Analysis for a Centrifugal Fan Impeller in a Horizontal Conveyor Dryer. Materials 2021, 14, 6696. [Google Scholar] [CrossRef]

- Sun, X.; Yan, Y.; Zhang, L.; Ma, G.; Liu, Y.; Yu, Y.; An, Q.; Tao, S. Direct 3D Printing of Reactive Agitating Impellers for the Convenient Treatment of Various Pollutants in Water. Adv. Mater. Interfaces 2018, 5, 1701626. [Google Scholar] [CrossRef]

- Mansour, G.; Papageorgiou, V.; Tzetzis, D. Carbon Fiber Polymer Reinforced 3D Printed Composites for Centrifugal Pump Impeller Manufacturing. Technologies 2024, 12, 48. [Google Scholar] [CrossRef]

- Jurković, K.; Schauperl, Z.; Šolić, S.; Bauer, B. Numerical Simulation of Sand Casting of Stainless Steel Pump Impeller. Metals 2024, 14, 435. [Google Scholar] [CrossRef]

- Kennedy, F.E.; Ye, Y.; Baker, I.; White, R.R.; Barry, R.L.; Tang, A.Y.; Song, M. Development of a New Cryogenic Tribotester and Its Application to the Study of Cryogenic Wear of AISI 316 Stainless Steel. Wear 2022, 496–497, 204309. [Google Scholar] [CrossRef]

- De Bartolomeis, A.; Newman, S.T.; Biermann, D.; Shokrani, A. State-of-the-Art Cooling and Lubrication for Machining Inconel 718. J. Manuf. Sci. Eng. 2021, 143, 050801. [Google Scholar] [CrossRef]

- Raddatz, M.; Holländer, D.; Gampe, U. Innovative Material Testing Based on Small-Scale Specimens and Application for Turbomachinery Components. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 2017; Volume 50923, p. V07AT31A004. [Google Scholar]

- Córdova, J.L. Additive Manufacturing of Centrifugal Impellers for Solid Oxide Fuel Cell Anode Offgas Recycle Blowers. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 2022; Volume 86052, p. V007T17A027. [Google Scholar]

- Pegues, J.W.; Shao, S.; Shamsaei, N.; Sanaei, N.; Fatemi, A.; Warner, D.H.; Li, P.; Phan, N. Fatigue of Additive Manufactured Ti-6Al-4V, Part I: The Effects of Powder Feedstock, Manufacturing, and Post-Process Conditions on the Resulting Microstructure and Defects. Int. J. Fatigue 2020, 132, 105358. [Google Scholar] [CrossRef]

- Wang, J.; Sama, S.R.; Lynch, P.C.; Manogharan, G. Design and Topology Optimization of 3D-Printed Wax Patterns for Rapid Investment Casting. Procedia Manuf. 2019, 34, 683–694. [Google Scholar] [CrossRef]

- Rettberg, R.; Kraenzler, T. Hybrid Manufacturing: A New Additive Manufacturing Approach for Closed Pump Impellers. In Industrializing Additive Manufacturing, Proceedings of the AMPA2020, Zurich, Switzerland, 1–3 September 2020; Springer: Cham, Switzerland, 2021; pp. 146–159. [Google Scholar]

- Li, H.; Zhang, Y. Lightweight Design of the Transonic Centrifugal Impeller Based on Fluid–Structure Coupling. Phys. Fluids 2022, 34, 107109. [Google Scholar] [CrossRef]

- Kanesund, J.; Brodin, H.; Johansson, S. High Temperature Corrosion Influence on Deformation and Damage Mechanisms in Turbine Blades Made of IN-792 during Service. Eng. Fail. Anal. 2020, 110, 104388. [Google Scholar] [CrossRef]

- Zhuk, Y. Nanostructured CVD W/WC Coating Protects Steam and Gas Turbine Blades Against Water Droplet Erosion. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 2022; Volume 86052, p. V007T17A003. [Google Scholar]

- Soffel, F.; Lin, Y.; Keller, D.; Egorov, S.; Wegener, K. Laser Remelting Process Simulation and Optimization for Additive Manufacturing of Nickel-Based Super Alloys. Materials 2021, 15, 177. [Google Scholar] [CrossRef] [PubMed]

- Menon, N.; Mahdi, T.H.; Basak, A. Microstructure of IN738LC Fabricated Using Laser Powder Bed Fusion Additive Manufacturing. J. Turbomach. 2022, 144, 031011. [Google Scholar] [CrossRef]

- Stella, P.; Ceccanti, F.; Cappuccini, F.; Bellacci, M.; Kemble, S.; Biccari, D.V.; Masi, G. Powder Metallurgy and Additive Manufacturing for Compressors and Pumps: A New Manufacturing Paradigm for Corrosion and Heat Resistant Alloys. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 31 October–3 November 2022; SPE: Kuala Lumpur, Malaysia, 2022; p. D031S082R001. [Google Scholar]

- Andrearczyk, A.; Konieczny, B.; Sokołowski, J. Additively Manufactured Parts Made of a Polymer Material Used for the Experimental Verification of a Component of a High-Speed Machine with an Optimised Geometry—Preliminary Research. Polymers 2020, 13, 137. [Google Scholar] [CrossRef]

- Katiyar, P.C.; Singh, B.P.; Chhabra, M.; Kumar, N.; Parle, D. Analysis of Tensile Strength of Thin ABS Specimens 3-D Printed in Various Build Orientations for Turbomachinery Applications. Int. J. Interact. Des. Manuf. (IJIDeM) 2024, 1–13. [Google Scholar] [CrossRef]

- Vyacheslav, S.; Iurii, M.; Ilya, K. Prototyping Centrifugal Microcompressors Using Additive Technology. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2023; Volume 2833. [Google Scholar]

- Warner, J.; Celli, D.; Scott-Emuakpor, O.; George, T.; Tomlin, T. Fused Deposition Modeling Fabrication Evaluation of a TI-6AL-4V Centrifugal Compressor. J. Eng. Gas Turbine Power 2023, 145, 031008. [Google Scholar] [CrossRef]

- Iyankumar, R.; Mohanavel, V.; Vinoth, N.; Vinoth, T. Modeling and Assessment of Pump Impeller. Mater. Today Proc. 2020, 33, 3226–3233. [Google Scholar] [CrossRef]

- Jiang, C. Investigating Impeller Wear and Its Effect on Pump Performance Using Soft Materials. Master’s Thesis, University of Alberta, Edmonton, AB, Canada, 2019. [Google Scholar]

- Akdemir, B.; Kayisoglu, B.; Kocoglu, S. Effect of Impeller Materials on Centrifugal Pump Characteristics. Agric. Mech. Asia Afr. Lat. Am. 2006, 37, 62. [Google Scholar]

- Fernández, S.; Jiménez, M.; Porras, J.; Romero, L.; Espinosa, M.M.; Domínguez, M. Additive Manufacturing and Performance of Functional Hydraulic Pump Impellers in Fused Deposition Modeling Technology. J. Mech. Des. 2016, 138, 024501. [Google Scholar] [CrossRef]

- Bauer, A.P. Design, Development, and Testing of a Low Cost, Additively-Manufactured, Centrifugal Compressor, Air Force Institute of Technology. 2020. Available online: https://scholar.afit.edu/etd/3208 (accessed on 21 November 2024).

- Boccini, E.; Furferi, R.; Governi, L.; Meli, E.; Ridolfi, A.; Rindi, A.; Volpe, Y. Toward the Integration of Lattice Structure-Based Topology Optimization and Additive Manufacturing for the Design of Turbomachinery Components. Adv. Mech. Eng. 2019, 11, 1687814019859789. [Google Scholar] [CrossRef]

- Castro, M.T.; Ocon, J.D. Novel Designs of Blade Mixer Impellers from the Discrete Element Method and Topology Optimization. Chem. Eng. J. 2024, 490, 151863. [Google Scholar] [CrossRef]

- Sword, J.I.; Galloway, A.; Toumpis, A. Analysis of Environmental Impact and Mechanical Properties of Inconel 625 Produced Using Wire Arc Additive Manufacturing. Sustainability 2024, 16, 4178. [Google Scholar] [CrossRef]

| Keyword | Boolean Operator | Keyword |

|---|---|---|

| Impellers | AND/OR | Printers/3D Printing/Additive Manufacturing |

| Turbomachinery | AND/OR | Printers/3D Printing/Additive Manufacturing |

| DMLS-LPBF-SLM | AND/OR | Impellers/Turbomachinery/Turbomachines |

| FDM | AND/OR | Impellers/Turbomachinery/Turbomachines |

| SLS | AND/OR | Impellers/Turbomachinery/Turbomachines |

| DLP | AND/OR | Impellers/Turbomachinery/Turbomachines |

| Polyjet | AND/OR | Impellers/Turbomachinery/Turbomachines |

| SLA | AND/OR | Impellers/Turbomachinery/Turbomachines |

| BJP | AND/OR | Impellers/Turbomachinery/Turbomachines |

| BMD | AND/OR | Impellers/Turbomachinery/Turbomachines |

| EBM | AND/OR | Impellers/Turbomachinery/Turbomachines |

| MJF | AND/OR | Impellers/Turbomachinery/Turbomachines |

| LMD | AND/OR | Impellers/Turbomachinery/Turbomachines |

| Additive Manufacturing | AND/OR | Impellers/Turbomachinery/Turbomachines |

| Process | Material | References |

|---|---|---|

| SLS | SS 304 (HIPS-Stainlees steel), SiC-Si (BN)-Al2O3, Mullite (3Al2O3·2SiO2), PS, Nylon | [83,84,85,86,88,135] |

| SLA | ABS, Resina | [86,99] |

| DLP | Si3N4, Photopolymer, Al2O3, Si3N5 | [101,102,103] |

| LMD | AISI316L | [136] |

| MJF | PA12GB (Nylon y 40% vidrio) | [90] |

| Polyjet | PC, FullCure 720 (Clear Resin), RGD 525 (Stratasys material), VeroGray | [109,110,111,112] |

| FDM | ABS-P430, PLA, ABS, PU, Polycast, PET, PLA, PA6-CF15, PPS-CF15, ABS, PETG CF | [78,86,113,115,116,117,118,119,120,121,128] |

| BMD–BJP | AISI316L, Quartz (SiO2) | [83,123] |

| EBM | Ti-6Al-4V | [93,96] |

| DMLS-LPBF-SLM | AlSi10Mg, 17-4 PH Stainless Steel, Ti-6Al-4V, Inconel 718, Inconel 625, AISI316L, FV520B-I, FeSiCr Martensitic Steel, SUS316L | [66,67,68,69,70,71,72,73,75,76,77,78,79,80,81,82,86,137] |

| Material | Mils per Year—mpy | Corrosion Resistance | CRCI 1 | CRC 2 |

|---|---|---|---|---|

| SS 304 (HIPS-Stainless Steel) | 2–20 mpy (in seawater) | Medium | 0.75–1.0 | CRC2 |

| SiC-Si (BN)-Al2O3, Mullite | <0.1 mpy | High | >1.0 | CRC3 |

| PS (Polystyrene) | Low resistance, not used in corrosive environments | Low | - | CRC1 |

| Nylon | 0.1–1 mpy (in diluted acids) | Low | 0.8–0.9 | CRC2 |

| ABS | 1–10 mpy (depending on the medium) | Low | 0.6–0.8 | CRC1 |

| Resin | Depends on type, generally low | Low | 0.5–0.7 | CRC2 |

| Si3N4 (Silicon Nitride) | <0.1 mpy | High | >1.0 | CRC4 |

| Photopolymer | Depends on type, generally low | Low | 0.4–0.7 | CRC2 |

| Al2O3 (Aluminum Oxide) | <0.1 mpy | High | >1.0 | CRC3 |

| Si3N5 | <0.1 mpy | High | >1.0 | CRC4 |

| AISI316L (Stainless Steel) | 0.5–5 mpy (in seawater) | High | 0.9–1.0 | CRC3 |

| PA12GB (Nylon and 40% glass) | Similar to Nylon, 0.1–1 mpy | Low | 0.8–0.9 | CRC2 |

| PC (Polycarbonate) | 1–10 mpy | Low | 0.7–0.9 | CRC2 |

| FullCure 720 (Clear Resin) | - | Low | - | CRC2 |

| RGD 525 (Stratasys material) | - | Low | - | CRC2 |

| VeroGray | - | Low | - | CRC2 |

| ABS-P430 | Similar to ABS, 1–10 mpy | Low | 0.6–0.8 | CRC1 |

| PLA | 1–10 mpy (depending on the medium) | Low | 0.6–0.8 | CRC1 |

| PU (Polyurethane) | 1–10 mpy | Low | 0.6–0.8 | CRC2 |

| Polycast | Similar to ABS | Low | 0.6–0.8 | CRC2 |

| PET | 1–10 mpy (depending on the medium) | Low | 0.7–0.9 | CRC2 |

| PA6-CF15 | Similar to PA6, 1–10 mpy | Low | 0.7–0.9 | CRC2 |

| PPS-CF15 | <0.1 mpy (in acidic media) | Low | 0.9–1.0 | CRC3 |

| PETG CF | Similar to PET, 1–10 mpy | Low | 0.7–0.9 | CRC2 |

| Quartz (SiO2) | <0.1 mpy | High | >1.0 | CRC4 |

| Ti-6Al-4V (Titanium) | <0.1 mpy (in seawater) | High | >1.0 | CRC4 |

| AlSi10Mg (Aluminum Alloy) | 1–5 mpy (in saline environments) | Medium | 0.8–0.9 | CRC2 |

| 17-4 PH Stainless Steel | 0.5–5 mpy (in seawater) | High | 0.9–1.0 | CRC3 |

| Inconel 718 | <0.1 mpy (in acidic or saline environments) | Very High | >1.0 | CRC4 |

| Inconel 625 | <0.1 mpy (in acidic or saline environments) | Very High | >1.0 | CRC4 |

| FV520B-I | 1–10 mpy | Medium | 0.8–0.9 | CRC3 |

| FeSiCr (Iron-Silicon-Chromium Alloy) | <0.1 mpy | High | >1.0 | CRC3 |

| Martensitic Steel | 5–20 mpy (in saline environments) | Medium | 0.6–0.8 | CRC2 |

| SUS316L (Stainless Steel) | 0.5–5 mpy (in seawater) | High | 0.9–1.0 | CRC3 |

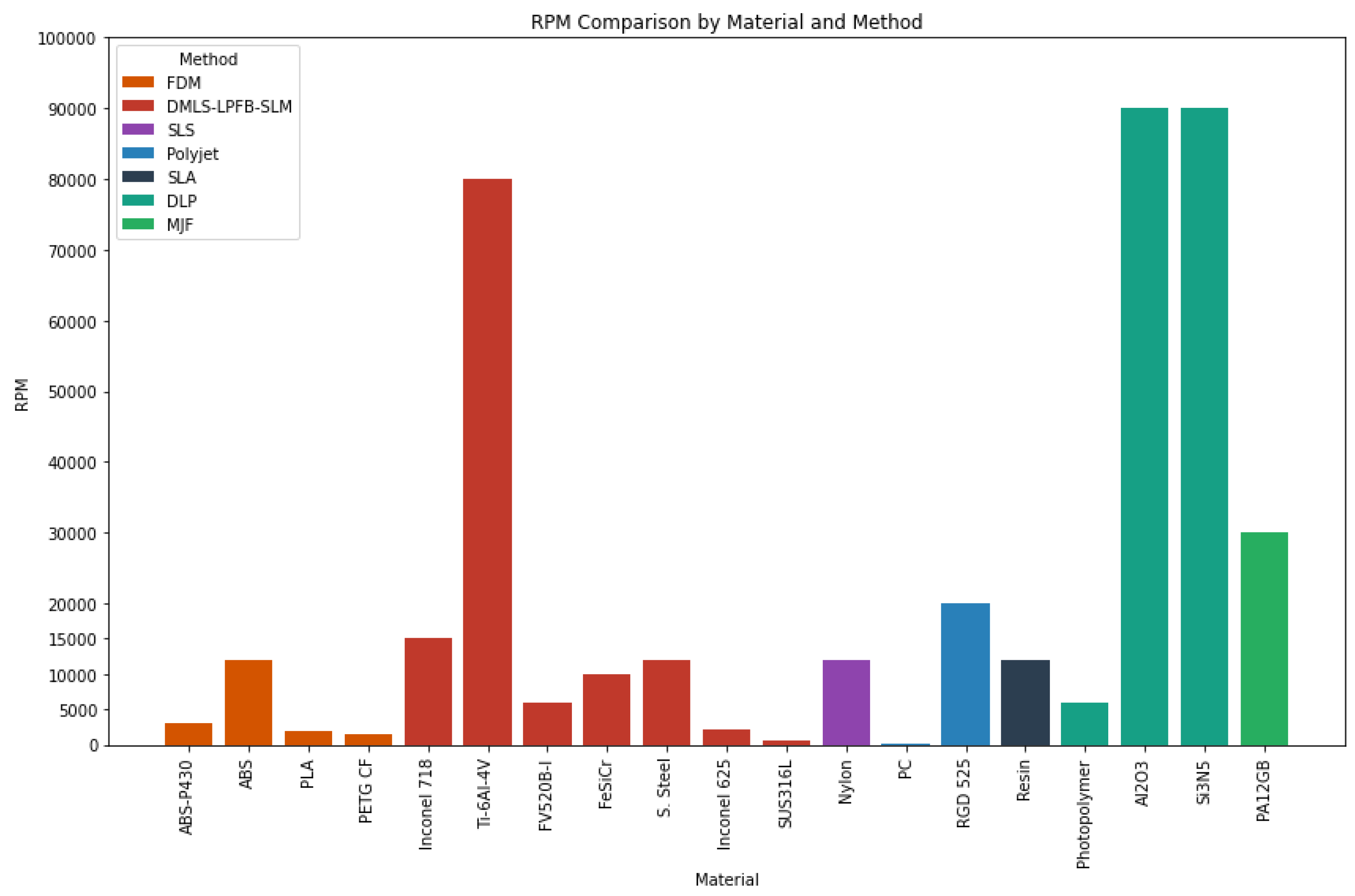

| Material | Method | Application | RPM |

|---|---|---|---|

| PEEK | CNC–3D | High Speed Microturbine | 120,000 |

| PPS | CNC–3D | High Speed Microturbine | 120,000 |

| Aluminum 2014-T6 | Ansys CFD Simulation | Centrifugal Compressor | 230,000 |

| ASTM A36 | Ansys CFD Simulation | Fan | 653 |

| Hardox 450 | Ansys CFD Simulation | Fan | 1225 |

| Aluminum 6061-T6 | Ansys CFD Simulation | Fan | 1002 |

| ABS-P430 | FDM | Generator | 2950 |

| Aluminum 2014-T6 | Ansys CFD Simulation | Compressor | 210,000 |

| Inconel 718 | DMLS-LPFB-SLM | Centrifugal Compressor | 14,700 |

| Inconel 718 | DMLS-LPFB-SLM | Centrifugal Compressor | 15,120 |

| ABS | FDM | Centrifugal Compressor | 2800 |

| ABS-P430 | FDM | Centrifugal Pump | 1450 |

| Ti-6Al-4V | DMLS-LPFB-SLM | Compressor | 80,000 |

| FV520B-I | DMLS-LPFB-SLM | Compressor | 6000 |

| FeSiCr | DMLS-LPFB-SLM | Fan | 10,000 |

| PLA | FDM | Centrifugal Pump | 1900 |

| Nylon | SLS | Turboexpander | 12,000 |

| ABS | FDM | Turboexpander | 12,000 |

| Stainless steel | DMLS-LPFB-SLM | Turboexpander | 12,000 |

| PC | Polyjet | Centrifugal Blood Pump | 50 |

| Resin | SLA | Turboexpander | 12,000 |

| Inconel 625 | DMLS-LPFB-SLM | Compressor | 2200 |

| RGD 525 | Polyjet | Radial Turbine | 20,000 |

| PETG CF | FDM | Radial Turbine | 1450 |

| SUS316L | DMLS-LPFB-SLM | Pelton Turbine | 500 |

| Ti-6Al-4V | DMLS-LPFB-SLM | Compressor | 570 |

| Photopolymer | DLP | Centrifugal Pump | 5900 |

| Al2O3 | DLP | Turbine Rotor | 90,000 |

| Si3N5 | DLP | Turbine Rotor | 90,000 |

| PA12GB | MJF | Radial Turbine | 30,000 |

| AM Technique | Advantages | Disadvantages | Mechanical/Physical Defects |

|---|---|---|---|

| DMLS-LPBF-SLM | High dimensional accuracy, excellent material strength, up to 30% weight reduction, and optimized operational frequencies. | Residual stresses, porosity, lack of fusion, thermal deformation, and high costs. | Residual stresses, porosity, thermal deformation, surface roughness, and lack of fusion. |

| SLS | Significant cost reductions (up to 99.75%), short production times, lighter and more efficient components. | Low density, high surface roughness, and limited material options. | Low density, high surface roughness, and deformation during cooling. |

| EBM | Capable of producing and repairing complex components, high mechanical strength, and relative density of 98%. | High energy consumption, susceptibility to cracking in materials such as Ti-6Al-4V. | Cracking in thin components and loss of properties due to prolonged annealing times. |

| FDM | Cost-effective, efficient for complex geometries, improves performance by 4–6% in materials such as ABS and PETG CF. | Formation of voids, layer adhesion issues, and limitations for high-speed or high-temperature applications. | Delamination between layers, void formation, limited precision, and excessive waste from support structures. |

| DLP | Excellent surface finish, suitable for high-temperature applications using ceramics such as Si3N4. | Material fragility, limited material compatibility, and flow and pressure challenges. | Material fragility, flow and pressure issues, and limited mechanical strength. |

| BMD | Highly eco-efficient, reducing environmental impacts by 54.6% compared to conventional methods. | Scalability issues for industrial applications and material density inconsistencies. | Difficulty in achieving repeatability, interlayer porosity, and limited mechanical strength in complex shapes. |

| MJF | Allows precise control of voxel-specific properties, high resolution, and functional prototypes. | Material restrictions, deformation during cooling, and interlayer porosity. | Interlayer porosity, unprocessed powder particles, and variability in dimensional tolerances. |

| SLA | Ideal for low-load applications, fast and cost-efficient for rotary compressors using ABS and photosensitive resins. | Fragile parts, roughness in vitreous surfaces, and limited mechanical strength. | Fragility, high roughness on vitreous surfaces, and unsuitability for high-load or high-speed components. |

| PolyJet | Capable of producing multi-material components, ideal for wear testing, and small-scale energy applications. | Material compatibility limitations, deformation in high-stress conditions, and restricted scalability. | Deformation in high-rotation speed conditions, wear inconsistencies in testing materials. |

| LMD | Viable for producing closed impellers and other complex shapes, reduces powder consumption, and improves decomposition efficiency. | Higher cost compared to traditional casting processes, limited evidence of large-scale adoption in turbomachinery. | Porosity in deposited layers, residual stresses, and inconsistencies in mechanical properties. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Remache, A.; Pérez-Sánchez, M.; Hidalgo, V.H.; Ramos, H.M.; Sánchez-Romero, F.-J. Towards Sustainability in Hydraulic Machinery Manufacturing by 3D Printing. Processes 2024, 12, 2664. https://doi.org/10.3390/pr12122664

Remache A, Pérez-Sánchez M, Hidalgo VH, Ramos HM, Sánchez-Romero F-J. Towards Sustainability in Hydraulic Machinery Manufacturing by 3D Printing. Processes. 2024; 12(12):2664. https://doi.org/10.3390/pr12122664

Chicago/Turabian StyleRemache, Abel, Modesto Pérez-Sánchez, Víctor Hugo Hidalgo, Helena M. Ramos, and Francisco-Javier Sánchez-Romero. 2024. "Towards Sustainability in Hydraulic Machinery Manufacturing by 3D Printing" Processes 12, no. 12: 2664. https://doi.org/10.3390/pr12122664

APA StyleRemache, A., Pérez-Sánchez, M., Hidalgo, V. H., Ramos, H. M., & Sánchez-Romero, F.-J. (2024). Towards Sustainability in Hydraulic Machinery Manufacturing by 3D Printing. Processes, 12(12), 2664. https://doi.org/10.3390/pr12122664