Abstract

Biotechnology is increasingly being used as a tool to replace traditional production methods due to concerns about the increasing damage caused by global warming. Bacteria, yeasts, fungi, and microalgae are microorganisms able to transform residues into value-added bioproducts. They produce microbial biomass that can result in the production of several products, such as biofuels, microbial proteins, fatty acids, bioactive polysaccharides, carotenoids, industrial enzymes, polyhydroxyalkanoates, and biofertilizers, among others. To improve microbial biomass and lipid yield, modern genetic engineering techniques can be applied as a way of optimizing processes and conditions. This review aims to explore the latest trends and technological advances in microbial biomass and lipid production, including optimization strategies for cultivation conditions and the use of genetic engineering to enhance yields and efficiency. It also discusses the challenges and future prospects for scaling up production for industrial applications. The potential of microbial lipids to contribute to a sustainable bioeconomy, as well as their applications in renewable energy and food industries, underscores their importance in a world increasingly seeking alternatives to fossil fuel dependence and unsustainable agricultural practices.

1. Introduction

Lipids play essential roles in several biological and industrial functions, being crucial for both the health of organisms and for commercial applications. Biologically, lipids are components of cell membranes, ensuring the structural integrity of cells and facilitating the transportation of substances. In addition, they act as a source of energy for organisms and can be precursors of essential hormones [1]. They are utilized industrially in the production of biodiesel, as ingredients in nutritional supplements, and as components in the formulation of creams, lotions, and pharmaceuticals [2]. Traditionally, lipids are found in meat fats, dairy products, fish oils, vegetable oils, nuts, and seeds [3]. In the last few years, microbial lipids have emerged as a sustainable and innovative alternative to traditional lipids. Produced from microorganisms such as yeast and fungi, these lipids offer several advantages, including faster and more efficient production, a lower environmental impact, and the ability to be cultivated on a variety of substrates, such as agricultural waste.

The production of microbial biomass and lipids has increasingly attracted industrial interest due to its potential application in various sectors. Among the markets interested in these technologies, we can highlight the biofuels industry and food and chemical products. According to Grand View Research, the global biodiesel market was valued at USD 32.09 billion and is expected to grow at a compound annual growth rate (CAGR) of 10% from 2022 to 2030 [4]. In the biofuels industry, leveraging oleaginous microorganisms—including bacteria, yeasts, fungi, and microalgae—enables the production of lipids that can be transformed into biodiesel, reducing dependence on conventional vegetable oils [5].

In addition, the application of microbial lipids in the food industry has gained prominence, particularly in the production of omega-3 fatty acids and other functional lipids used in supplements and enriched foods [6]. Polyunsaturated fatty acids (PUFAs) are fatty acids with more than one double bond in their chemical structure. They are categorized as n-3 (ω-3) and n-6 (ω-6), depending on the location of the first double bond at the methyl end of the fatty acid chain. PUFAs are recognized as active components that promote health. Among the health benefits, the development and function of the brain, nerves, and eyes, cardioprotective effects, anti-inflammatory and anticancer properties, vitamin absorption, cholesterol regulation, and potential beneficial effects on the immune system stand out [7]. Another product that is now produced in a microbial way is cocoa butter, whose price has increased to over USD 8000 per ton since the 1980s [8].

Regarding the protein sector for human and animal food, single-cell proteins (SCPs) have also gained prominence. SCPs are dry cells that can be used to produce microbial meat, supplements, and protein-rich ingredients for animal and human feed [9]. These proteins can be produced from agricultural waste or by-products from the food industry [10], mainly with the help of fungal strains. Yeast biomass is rich in essential amino acids, making it an excellent option for animal feed, especially in poultry and swine diets [5]. Microalgae such as Spirulina and Chlorella are widely used in animal nutrition due to their high nutritional content, which includes proteins, vitamins, and essential fatty acids. These microalgae are especially popular in feed for fish and other aquatic organisms [11]. Additionally, Spirulina and Chlorella are gaining recognition in human nutrition due to their remarkable health benefits. They are rich in high-quality proteins, providing all essential amino acids, which makes them an excellent alternative for plant-based diets. Furthermore, both microalgae are packed with vitamins such as B1, B2, B3, and B12, as well as minerals like iron, magnesium, and calcium [12]. Their antioxidant and anti-inflammatory properties help reduce oxidative stress and may lower the risk of chronic diseases [13]. The SCP global market size was valued at around USD 13.1 billion in 2022 and is estimated to reach USD 75.9 billion by 2032, which is a reflection of population growth in food demand [14].

Technological innovations, such as gene editing by CRISPR/Cas9, have made it possible to modify microorganisms to increase lipid production and improve the efficiency of fermentation processes [15]. In addition, advances in bioprocessing, including the optimization of fermenter operating modes, have shown a potential to increase the production of microbial biomass [16]. The use of substrates from agricultural waste and industrial by-products not only improves process efficiency but also promotes sustainability, contributing to the circular economy [17]. Nevertheless, significant challenges remain to be addressed. The high production and operational costs, particularly concerning lipid recovery, pose substantial barriers to the economic feasibility of these technologies [18]. In addition, market acceptance of products intended for supplementation and human nutrition that are derived from genetically modified organisms also presents a challenge, requiring efforts to educate consumers and ensure the safety of these products [19].

In this review, we will explore the advances in biomass and lipid production by microbes, presenting the processes and the bioproducts generated from biomass and lipids and the challenges surrounding this area of research. Furthermore, we will discuss the potential of microbial lipids in various applications, including biofuels, food supplements, and pharmaceuticals, highlighting the importance of optimizing production processes to enhance yields and efficiency. Additionally, we will also conduct a comprehensive search of patents related to these processes and products, examining the innovations that have emerged in this field and analyzing trends and prospects in this evolving field. Ultimately, this review aims to provide a comprehensive overview of microbial biomass and lipid production, emphasizing their significance in promoting sustainability and contributing to a circular economy.

2. Microbial Biomass Production

2.1. Bacterial Biomass

The composition of bacterial biomass is variable and depends on several factors [20]. Generally, proteins make up 50–83% of the dry weight, and this high protein content makes bacterial biomass a promising alternative to traditional protein sources. Bacterial biomass contains all the essential amino acids necessary for human and animal nutrition. The amino acid profile is similar to that of fishmeal, making it a valuable ingredient in animal feed. Taran and Asadi, in 2014 [21], produced bacterial biomass using Haloarcula sp. IRU1 and achieved 76.4% single-cell protein relative to the cell dry weight under optimal conditions. However, bacteria have a high nucleic acid content, typically ranging from 15% to 16%. This high content can be harmful to humans and may lead to health issues. Furthermore, bacterial biomass contains carbohydrates, lipids, vitamins, and minerals [22].

Bacterial biomass production for lipid generation has garnered significant attention due to its potential in biofuels and sustainable energy sources. Certain bacteria, such as Rhodococcus opacus, Acinetobacter calcoaceticus, and Acinetobacter spp., have the ability to accumulate intracellular lipids, primarily in the form of triacylglycerols (TAGs), which can be efficiently converted into biodiesel [23]. Compared to traditional oil crops, lipid-producing bacteria offer faster growth rates, higher yields per biomass unit, and the ability to thrive on a variety of carbon sources, including waste products from industrial processes [24]. This versatility in substrate utilization not only enhances the economic feasibility of bacterial lipid production but also contributes to waste valorization and circular economy practices.

Oleaginous microbes are defined as those that store over 20% of their biomass in the form of lipids, generally TAGs, which can reach 70% of the total biomass. Though the utilization of bacteria for biofuel production is still limited compared to other sources, it is important to recognize the underlying potential of the group to this end [25]. R. opacus, A. calcoaceticus, and Acinetobacter spp. are able to accumulate 87% of their dry biomass in oil content. Other than those, species such as Streptomyces sp., Nocardia sp., Mycobacterium sp., Dietzia sp., Gordionia sp., Serratia sp., and Bacillus sp. have also been classified as oleaginous due to TAGs accumulation [24,26]. Their biomass composition varies according to growth conditions. For instance, R. opacus can generate high lipid levels (over 80%) when utilizing simple sugars and aromatic compounds, but its lipid production decreases when grown on more complex lignin-based substrates [27].

In bacteria, TAG accumulation is a result of cell stress. Its biochemical route can be described in two distinct steps: (1) a growing phase in a carbon-rich environment, in which nutrients are mainly destined for biomass synthesis; (2) an oleaginous phase, initiated when the availability of an essential nutrient, commonly nitrogen, is limited. This causes biomass growth to be interrupted. Though the assimilation of carbon is continued, its excess is directed towards the synthesis and accumulation of storage lipids, such as TAGs [28]. Hence, the choice of substrate significantly influences lipid accumulation, which is decisive for establishing economic viability.

Bacteria can utilize various carbon sources, including glucose, sucrose, and organic acids. Glucose is easily metabolized by various different species of bacteria and normally renders adequate amounts of lipid accumulation [29,30]. However, its relatively high cost might be an impediment to process scale-up. Alternatively, low-cost substrates, such as industrial and agricultural wastes, offer an economically viable route and increase the sustainability of the industrial platform. The challenge lies in identifying, among these residues, high-quality carbon sources that allow for high-cell-density batches of bio-oil-producing bacteria.

Several studies report lipid production by R. opacus using biomass hydrolysates as a substrate, particularly sugarcane bagasse. The research conducted by Mahmood and Singh [31] demonstrated that the strain R. opacus DSM 43205 is capable of accumulating lipids up to 64.47% of its cell dry weight (CDW) when cultured in a medium containing sugarcane bagasse hydrolysate. The lipid productivity achieved was 0.015 g/L/h. These values are significantly higher than those reported in other studies using different substrates and microorganisms. On the other hand, Mondala et al. [32] utilized sugarcane bagasse hydrolysate as a carbon source to stimulate oil production by activating sludge microbial cultures. Pre-cultivation of microorganisms in a high xylose concentrated medium was necessary so that they could be acclimated for assimilating xylose, the main component of the hydrolysate. Furthermore, pre-cultivation allowed for a high cellular concentration, which mitigated potential growth inhibition caused by bagasse hydrolysis byproducts. The study observed lipid accumulation ranging from 40% to 47% of the CDW under a high C:N ratio following feeding with bagasse hydrolysate. The authors further suggest that a sequential fed-batch strategy using hydrolysate with and without nutrient supplementation may be ideal for achieving high cell density and lipid accumulation while minimizing dilution.

Though a decent strategy, the use of lignocellulosic sources demands an extra step of raw material pre-treatment, which allows the bacteria to have access to fermentable sugars. Ongoing research aims to establish efficient and affordable pre-treatment methods to break down lignin materials. Various methods, such as organosolv pre-treatment, oxygen oxidation, laccase supplementation, and alkaline or alkaline–peroxide pre-treatment, demonstrate varying degrees of effectiveness. The optimal method depends on factors such as the type of biomass, the microbial strain used, and the economic feasibility of the process [27]. The literature highlights that the pre-treatment of lignocellulosic biomass, particularly lignin, is crucial for enhancing microbial lipid production.

Moreover, different batch processes can significantly influence lipid accumulation by bacteria, primarily through the controlled management of nutrient availability and growth conditions. Fed-batch fermentation emerges as particularly effective due to its ability to extend the growth phase and optimize nutrient limitations, leading to higher lipid yields compared to traditional batch processes. In a fed-batch process, nutrients are added gradually over time, allowing for extended bacterial growth and controlled nutrient limitation [33]. By carefully regulating the supply of nitrogen and carbon sources, fed-batch cultivation can enhance lipid accumulation, as bacteria can switch from biomass growth to lipid storage more efficiently.

For instance, Thanapimmetha et al. demonstrated the advantage of employing a fed-batch over a batch strategy for the cultivation of R. opacus PD630 and lipid accumulation in a modified salt-medium containing glycerol as the carbon source [34]. The specific feeding profile used in the study involved supplementing the culture with ammonium acetate on the first day, followed by acetic acid on the second and third days, and then alternating between the two feedings until the end of the cultivation. This approach was designed to prevent nitrogen limitation, enhance glycerol consumption, and consequently promote both growth and metabolite production. One of the key benefits of the batch-feeding strategy was the ability to modulate pH levels without the need for external control. Feeding with ammonium acetate initially raised the pH, while subsequent feeding with acetic acid neutralized this effect, thereby creating a self-regulating pH cycle within an optimal range for the growth of R. opacus. This illustrates how a carefully designed feeding profile can enhance metabolite production and optimize conditions such as the pH, demonstrating the potential of fed-batch cultivation to significantly improve lipid yields in bacterial systems like R. opacus.

On the other hand, in a continuous batch process, nutrients are continuously supplied, and cells are constantly harvested, maintaining the bacteria in a dynamic state. This method allows for the constant monitoring and optimization of growth conditions, improving the overall yield of lipids over time [35]. This process can be tailored to maximize lipid accumulation by modifying environmental conditions like carbon source availability, pH, oxygen levels, and temperature.

Gupta et al. explored three different bioreactor operation modes: fed-batch, continuous, and continuous cell recycling, aiming to determine the most effective method for maximizing lipid production and chemical oxygen demand (COD) removal from dairy wastewater using R. opacus [36]. In terms of lipid accumulation, the continuous culture with cell recycling yielded the best results, reaching a lipid concentration of 3.4 g/L, with a COD removal efficiency of 97%, while fed-batch and the continuous culture reached lipid concentrations of 1.1 g/L and 1.8 g/L, respectively. The high lipid production is attributed to the increased biomass in the bioreactor caused by cell recycling [37]. This approach highlights the potential for integrating bioprocesses to improve sustainability in industrial applications.

In summary, optimizing microbial biomass production conditions is critical for maximizing lipid accumulation in bacterial systems like R. opacus and Acinetobacter spp. These oleaginous bacteria exhibit significant potential for sustainable biofuel production due to their ability to utilize diverse carbon sources, including waste products, and efficiently convert them into lipids. Among the various bioprocess strategies, fed-batch and continuous cell recycling modes have proven particularly effective. Additionally, the use of low-cost substrates such as sugarcane bagasse hydrolysate demonstrates the potential for integrating circular economy practices into microbial lipid production. By carefully managing nutrient availability and growth conditions, these processes offer scalable solutions for bio-oil production, contributing to advancements in sustainable energy technologies.

2.2. Fungi Biomass

The composition of fungal biomass exhibits significant variability and is heavily influenced by the cultivation medium, environmental conditions, and the age of the fungal strain. Typically, polysaccharides dominate the composition, representing up to 80% of the dry weight of fungal biomass [38]. Among the polysaccharides found in fungal biomass, glucans, chitosan, and polyuronides are particularly noteworthy [39]. Generally, proteins constitute 3% to 20% of the dry weight of the biomass and play a fundamental role in adhesion and providing hydrophobic properties. Kam et al. [40] demonstrate that certain species of fungi, such as Aspergillus niger, can produce SCP-rich biomass, with protein content reaching 52%. Lipids represent around 1% to 10% of the fungal biomass dry weight. They serve as energy storage material and structural components of the cell membrane [41]. Fungi can accumulate lipids in the form of triglycerides, free fatty acids, polar lipids, sterols, hydrocarbons, and pigments.

Fungal species known for their ability to accumulate lipids are increasingly being studied for applications in biodiesel production and other biotechnological processes. Among the species used to produce lipids, Mucor circinelloide is recognized for its significant lipid production, especially when cultivated under aerobic conditions and high glucose concentrations [42]. Aspergillus terreus is identified as one of the most potent lipid producers, accumulating up to 38.33% lipids of its dry biomass weight under optimized culture conditions. Its fatty acid profile is rich in oleic and stearic acids, making it a promising candidate for biodiesel feedstock [43].

Similar to A. terreus, A. niger has been shown to effectively accumulate lipids, with studies indicating significant lipid production under specific nutrient conditions [44]. It is often screened alongside other Aspergillus species for its potential in biodiesel applications. Aspergillus flavus also demonstrates considerable lipid accumulation capabilities and is often included in studies assessing the potential of various fungi for sustainable biodiesel production [45]. Trichoderma viride is known for its ability to synthesize lipids and can achieve lipid accumulation of about 32% of its dry biomass weight when grown on nitrogen-deficient media, highlighting its potential in biotechnological applications [46]. Trichoderma harzianum species has also been studied for lipid production, achieving around 17% lipid accumulation under specific growth conditions, although it generally produces less biomass compared to T. viride [47].

Fungal lipid accumulation generally occurs in two stages: cell proliferation and lipid accumulation [48]. During the cell proliferation process, fungi actively grow and multiply [49]. In this stage, fungal cells rapidly consume available nutrients in the growth medium, primarily carbon sources. The metabolic processes are predominantly focused on cell division and biomass increase. As the process progresses, the conditions shift towards lipid accumulation. This stage typically occurs when nitrogen sources are depleted while carbon sources remain abundant. In these circumstances, the fungi halt substantial cell proliferation and shift their metabolic emphasis toward the production of lipids [50]. Fungi produce lipids by converting surplus carbohydrates via innovative fatty acid biosynthesis pathways. The transition to lipid synthesis is facilitated by the availability of acetyl-CoA, which is derived from carbohydrate metabolism [51]. The accumulated lipids are stored as TAGs, which serve as energy reserves for the fungi. This accumulation can be influenced by various factors, including temperature, pH, and the presence of metal ions that can enhance or inhibit lipid production [52].

Some factors must be considered when trying to produce fungal biomass and/or fungal lipids. To accumulate lipids, the carbon-to-nitrogen (C/N) ratio is critical. Higher ratios promote lipid accumulation, while lower ratios support biomass growth. To achieve optimal lipid production, the C/N ratio must be greater than 20 but may decline at ratios exceeding 70 [48]. Furthermore, macronutrients such as phosphorus and potassium and micronutrients like zinc and magnesium are essential for optimal growth and lipid synthesis [50]. Fungi have specific temperature ranges that optimize their growth rates. For example, some species exhibit increased proliferation at temperatures around 25 °C but may transition to a different growth form (e.g., yeast to mycelium) at higher temperatures (37 °C) to adapt to environmental changes [53]. The acidity or alkalinity of the growth medium can influence enzyme activity and nutrient availability, thereby affecting cell division and overall growth rates [54]. Adequate oxygen levels are crucial for aerobic fungi as they rely on oxidative metabolism for energy production. Inadequate levels of oxygen can significantly hinder growth rates and disrupt metabolic pathways [55].

The fungal production of lipids can be carried out using two main methods. Submerged fermentation (SF) involves the growth of microorganisms in a nutrient-enriched liquid medium, where agitation is used to ensure medium homogenization. Solid-state fermentation (SSF), on the other hand, occurs through the growth of microorganisms on the surface of a solid substrate, usually agro-industrial residues. Compared to SSF, SF provides a more controlled environment. This allows for more precise monitoring of critical parameters, such as temperature, pH, dissolved oxygen, and nutrient levels, enhancing the overall fermentation process [56]. This process control is crucial to optimizing microbial growth and the production of biomass and lipids. The environment provided by the bioreactors used in SF significantly reduces the risk of contamination by undesirable microorganisms [57]. Moreover, this technology is already widely used and well-established in the bioprocess industry. This technological maturity translates into more efficient and reliable processes for large-scale lipid production.

Another crucial factor is the efficiency of mass transfer. SF processes provide efficient agitation of the fermentation medium, ensuring a more uniform distribution of nutrients. Aeration can also be controlled by adjusting the amount of oxygen required for microbial growth and the production of the desired product. SF generally results in higher biomass yields due to better nutrient solubility and accessibility [58]. For instance, studies show that certain fungi produce more biomass in SF compared to SSF due to optimal growth conditions [59].

Although SF offers valuable advantages for the production of fungal biomass and lipids, SSF remains the most recommended mode of operation. Lipid production by SSF has several advantages over SF, particularly regarding economic and sustainability aspects [60]. SSF allows the use of agro-industrial residues as a fermentation substrate, which are significantly cheaper than the pure substrates used in SF. Examples of such residues include sugarcane bagasse and soybean hulls [61]. Furthermore, solid-state processes demand considerably less water, leading to decreased energy consumption for both mixing and aeration. SSF does not require sophisticated bioreactors, simplifying infrastructure and reducing the implementation costs of the production plant [62]. Regarding the suitability of filamentous fungi for the fermentation environment [63], SSF allows the simulation of the natural environment of these fungi, which generally show greater efficiency in lipid production compared to yeasts [64]. The bioprocess is also consolidated, as enzyme production, biomass hydrolysis, and fermentation occur in a single system.

2.3. Yeast Biomass

The main yeast genera used in lipid production are Yarrowia, Candida, Rhodotorula, Rhodosporidium, Cryptococcus, Trichosporon, and Lipomyces [65]. Of all the known yeast species, less than 30 can accumulate more than 20% of their biomass as intracellular lipids, which qualifies them as oleaginous yeasts [66]. The most studied species for lipid production are Yarrowia lipolytica, Rhodotorula glutinis, Rhodosporidium toruloides, Cryptococcus curvatus, and Lipomyces starkeyi. However, high productivity has also been obtained with other species, such as Trichosporon fermentans [67].

The dry biomass of oleaginous yeasts is generally composed of 40–60% proteins, which are rich in essential amino acids and are an important source of protein for animal feed and human food. A total of 20–30% are lipids that can be used in the production of biodiesel or as functional ingredients in foods. A total of 10–20% are carbohydrates, and these carbohydrates may include glycogen, mannan, and other polysaccharides [68]. Cui et al. [69] produced SCP from Y. lipolytica, reaching a biomass production of 20.1 g/L with 47.5% crude protein. The strain had the introduction of the exo-inulinase gene from Kluyveromyces marxianus, which allowed the yeast to grow on media containing inulin. Gao et al. [70] produced biomass containing 56.42% of crude protein using soy molasses as a substrate. The biomass and SCP produced can be used in animal and human feed, as well as in supplement composition.

The production of biomass and lipids in yeast is significantly impacted by a variety of factors that shape cellular metabolism and enhance the efficiency of synthesizing valuable compounds. When there is excess carbon in the medium, whether from sources such as glucose, sucrose, glycerol, or fatty acids, lipid accumulation may be induced, especially under conditions of the limitation of other nutrients [71]. Nitrogen limitation, for example, is one of the most important factors for lipid accumulation since yeast diverts excess carbon from protein production and cell growth (biomass) to lipid synthesis. This results in the increased production of TAGs, the main storage lipids in cells [72].

TAGs are the most abundant type of lipid found in oleaginous yeasts, typically representing 80% to 90% of the total lipid content [73]. Their structure consists of a glycerol molecule linked to three fatty acids. In addition, the high C/N ratio favors lipid accumulation [74]. Oleaginous yeast has a high activity of lipogenic pathways. Enzymes such as glycerol-3-phosphate acyltransferase (GPAT) and diacylglycerol acyltransferase (DGAT) play critical roles in the incorporation of fatty acids into TAGs [75].

Oxygen availability affects lipid metabolism, especially for the synthesis of unsaturated fatty acids, which require oxygen. Under aerobic conditions, yeasts accumulate lipids, mainly TAGs, since oxygen plays a fundamental role in the oxidation of carbohydrates in the Krebs cycle [76]. Studies show that yeast types such as Y. lipolytica present a higher production of lipids under aerobic conditions due to the increased activity of ATP-citratolyase, which converts citrate into acetyl-CoA, the precursor molecule for the synthesis of fatty acids [75]. Under anaerobic conditions, the production of lipids by oleaginous yeasts is significantly reduced. This occurs because oxygen is an essential cofactor in several enzymes involved in the synthesis of fatty acids. Without oxygen, yeasts redirect their metabolism to alcoholic fermentation or other fermentative pathways, prioritizing the production of ethanol and other fermentative products instead of lipids. The absence of oxygen also results in a lack of sufficient ATP for lipid synthesis since the production of ATP via fermentation is much less efficient than through aerobic respiration [77,78]. In certain scenarios, low oxygen levels (microaeration) may be beneficial for lipid production. Microaeration can provide sufficient oxygen to keep oxygen-dependent enzymes active without stimulating oxidative metabolism to the point where all available carbon is consumed for cell growth rather than lipid synthesis [79,80].

Phosphorus is essential for cell growth and the production of phospholipids, which are essential components of cell membranes [81]. Oxygen limitation can affect both growth and lipid production. Environmental conditions, such as the temperature and pH of the medium, also affect the efficiency of yeast metabolism [82]. Optimized temperatures (generally between 28 °C and 32 °C) favor the biosynthesis of biomass and lipids. Changes in pH can influence fatty acid metabolism and cell permeability [83]. Yeasts, such as Y. lipolytica and Rhodotorula, require oxygen for lipid synthesis, especially for the production of unsaturated fatty acids [84]. Adequate aeration favors biomass accumulation, but oxygen limitation can, in some cases, stimulate lipid accumulation, depending on the yeast species [85].

Bioreactor operating modes (batch, fed-batch, and continuous) differ significantly in their control dynamics and productivity, directly affecting the production of yeast-derived biomass and lipids. Fed-batch fermentation allows for the controlled addition of nutrients over time, which helps to maintain optimal growth conditions for yeast. This approach prevents nutrient depletion and supports sustained yeast activity, leading to higher biomass and lipid production [86]. By gradually feeding substrates, fed-batch systems can minimize the inhibitory effects of high substrate concentrations that may occur in batch processes. This helps to improve overall fermentation performance and product yields [87].

High initial concentrations of the carbon source, although potentially desirable for high lipid yields, can inhibit cell growth in the early phase of batch cultivation. This effect can be pronounced in yeasts that are sensitive to high substrate concentrations. This inhibition can lead to a prolonged lag phase and reduce total biomass and lipid production. Additionally, insufficient nitrogen levels in the culture medium, which are critical for stimulating lipid accumulation, may hinder cell growth throughout batch cultivation. Since nitrogen is an essential nutrient for cell growth, its early depletion in the culture medium can impair biomass production, consequently limiting the final lipid yield, even if the intention is to direct metabolism toward lipid production [88].

Batch fermentation is straightforward to set up and operate, requiring less complex equipment and fewer control systems compared to continuous or fed-batch processes. This simplicity can lead to lower initial capital costs and easier maintenance. Since all ingredients are added at once and the fermentation runs to completion before harvesting, there is a reduced risk of contamination that can occur with continuous systems where media is constantly added. Fed-batch is effective in maximizing biomass production and then promoting lipid accumulation in oleaginous yeasts, especially under nitrogen-limited conditions [89].

Studies have shown that fed-batch fermentation can lead to higher lipid concentrations compared to batch fermentation due to better substrate utilization and reduced inhibitory effects [90]. Fed-batch systems require careful monitoring and control of nutrient additions, which can complicate the operation and increase the likelihood of errors. This complexity may necessitate skilled personnel to manage the process effectively, leading to higher operational costs. Prolonged exposure of yeast to high cell concentrations and potential inhibitors can occur in fed-batch systems. This accumulation can negatively affect yeast performance and reduce overall fermentation efficiency [91].

In continuous mode, the environment is constantly maintained, allowing cells to adapt and thrive, which can lead to higher biomass concentrations and lipid yields over time [90]. This mode allows for sustained production without the downtime associated with batch processes. Continuous feeding of nutrients ensures that yeast cells are always in an optimal growth phase, leading to higher overall productivity [92]. This method offers the advantage of a constant C/N ratio and constant production yields at a steady state [88]. Continuous operation facilitates better nutrient management, as fresh substrates can be supplied while waste products are removed regularly. This reduces the risk of nutrient depletion and toxic accumulation, which can hinder growth. This can lead to higher lipid content in the biomass, making it suitable for biodiesel production and other applications [93].

However, continuous systems require sophisticated control mechanisms to maintain optimal conditions, such as nutrient concentrations and pH levels. This complexity can lead to higher operational costs and the need for skilled personnel to manage the process effectively. In addition, the continuous introduction of fresh media and removal of culture broth increases the risk of contamination by undesirable microorganisms. This can compromise product quality and yield, necessitating stringent sterilization protocols. Lipid production is lower compared to other operating modes, as the continuous system favors cell growth rather than the accumulation of lipid reserves [94].

2.4. Microalgae Biomass

Microalgae biomass composition varies significantly across species and growth conditions. Protein content ranges from 18 to 56%, lipids from 7 to 48%, and carbohydrates from 15 to 46% of dry weight [95]. Microalgae are rich in essential amino acids and polyunsaturated fatty acids, including EPA and DHA [96]. Oliveira et al. produced an SCP-rich biomass from Spirulina maxima, reaching 71% of protein content [97]. Microalgae also contain valuable pigments like carotenoids and chlorophyll [37]. Of course, there are significant phylogenetic differences that reflect on the macromolecular composition (protein, lipid, carbohydrate) of the microalgae [95]).

Feller et al. compared the biochemical composition of five different microalgae. It was found that the green microalgae Chlorella vulgaris and Scenedesmus spp. exhibited notably high protein contents, with values of 56.1% and 49.0%, respectively. Additionally, these species also stood out for their lipid contents, achieving the highest levels among the microalgae studied, with C. vulgaris at 12.5% and Scenedesmus spp. at 12.1%. In terms of fatty acid composition, Spirulina platensis and Phaeodactylum tricornutum were rich in saturated fatty acids, particularly palmitic acid, while Porphyridium cruentum was characterized by high monounsaturated fatty acid content. Conversely, Scenedesmus spp. and C. vulgaris had elevated levels of polyunsaturated fatty acids, which highlights their diverse macromolecular profiles [98].

Different algae species exhibit varying growth rates and biomass accumulation capacities. Selecting an appropriate species with a high growth rate and strong biomass accumulation potential is crucial. For instance, C. vulgaris is known for its high biomass productivity and ability to accumulate lipids, especially under nitrogen deprivation conditions [98]. Furthermore, combining nitrogen deficiency with carbon enrichment in heterotrophic cultures can be an effective strategy to increase biomass and lipid accumulation. While traditional autotrophic cultivation relies on sunlight and CO2 for algae growth, heterotrophic cultivation uses organic carbon sources in the absence of light. This method can significantly boost biomass production by achieving higher cell densities and faster growth rates in a shorter time. Heterotrophic cultivation also allows greater flexibility as it can be performed in conventional fermenters, reducing the need for expensive photobioreactors, lowering production costs, and removing the dependence on sunlight, enabling continuous production regardless of weather or seasonal change [99].

In contrast to lipid-producing bacteria, microalgae are much more explored in that sense. This is due to the versatility of microalgal lipids, which opens up multiple routes for sustainable applications across various industries. They may be converted into fatty acid methyl esters (FAME) for use in biofuels; used in dietary supplements and functional foods, providing an alternative to fish oils; utilized in the pharmaceutical industry for drug development or as ingredients in cosmetic products due to their skin-nourishing properties; and used as raw material for producing bioplastics and other biochemicals [100]. Microalgae lipid is, hence, a focal point in efforts to promote renewable resources and reduce environmental impact.

Lipid production in microalgae is favored under stress conditions, in which TAG is accumulated as an energy storage compound [101]. One of the most powerful triggers for lipid accumulation in microalgae is nutrient limitation, especially of nitrogen and phosphorus. This scarcity compels the organisms to adapt their metabolism to conserve energy and resources, mirroring the responses observed in bacteria [102]. Moreover, extreme temperatures can also act as stressors. For instance, temperatures above the optimal growth range may lead to cell damage and increased lipid production as a survival strategy, while low temperatures may enhance unsaturated fatty acid production [103]. Additionally, protective mechanisms that result in lipid accumulation can be triggered by excessive lighting, salinity stress, pH variations, and chemical exposure [104]. Understanding how microalgae respond to these stresses allows for the optimization of cultivation strategies that maximize lipid accumulation while avoiding compromising the growth and viability of the algae.

The study of Morowvat and Ghasemi investigates the heterotrophic cultivation of the microalga C. vulgaris using glucose as a carbon source in shake flasks and stirred-tank bioreactors as an alternative to traditional autotrophic cultivation, with the aim of improving biomass and lipid production for biodiesel. It was found that cell growth was significantly higher in the heterotrophic culture, particularly with increased glucose concentration in the medium. The biomass productivity was 3.68 times greater than in autotrophic conditions, with total lipid content reaching 44% of dry cell weight after 21 days. In bioreactors, heterotrophic cultivation further improved results, achieving a biomass concentration of 4.95 g/L and a total lipid content of 2.18 g/L after just 5 days. These findings demonstrate the potential of heterotrophic cultivation to enhance biomass and lipid production. However, the authors recognize that the use of glucose as a carbon source may not be economically feasible and therefore suggest the employment of alternative and cheaper carbon sources [99].

In that context, heterotrophic cultivations may be leveraged to utilize waste materials as carbon sources, offering a more sustainable pathway for producing microalgal lipids. In a more synergistic approach, heterotrophic and autotrophic cultivations can be combined in what is called mixotrophic cultivation. By leveraging the benefits of both light-driven and organic carbon utilization, mixotrophy enhances growth rates and overall productivity [105]. This makes it an attractive option for large-scale microalgal biomass production, especially in applications aimed at biofuel generation and other biotechnological processes.

Hang et al. explored the benefits of mixotrophic cultivation of Chlamydomonas reinhardtii using treated wastewater (nitrogen and phosphorous source) supplemented with either acetate, fructose, glucose, molasses, sucrose, or corn steep liquor (CSL) (carbon source) as low-cost culture media to enhance biomass and lipid production for biodiesel. The addition of organic carbon sources significantly increased biomass and lipid production compared to purely phototrophic conditions, with the exception of glucose and sucrose. Molasses provided the highest growth rate, followed by acetate and CSL, while acetate resulted in the highest lipid content, followed by molasses and CSL. The findings suggest that mixotrophic cultivation not only provides a sustainable and economical alternative to traditional methods but also leverages organic waste as a nutrient source, positioning C. reinhardtii as a viable candidate for biodiesel production [106].

Similarly, Jasimone et al. investigated the dual objectives of lipid production and wastewater treatment using microalgae cultivated in urban wastewater. The study examines how varying light intensities and nutrient concentrations affect the biomass growth rate of microalgae, their efficiency in removing nutrients like nitrogen and phosphorus, their ability to self-flocculate for sedimentation, and their lipid accumulation. This approach addresses two critical issues: reducing pollution from wastewater and providing a sustainable source of biomass for energy production. Results showed that higher light intensity enhanced biomass growth, while lower light levels improved self-flocculation efficiency. Increased nutrient concentrations improved biomass production but decreased flocculation efficiency, with optimal lipid accumulation occurring at low initial nutrient levels. Overall, the findings highlight the significant impact of light and nutrient management on achieving effective wastewater treatment alongside maximizing lipid yields in microalgae cultivation [107].

In Table 1, the main characteristics of the three types of cultivation discussed are highlighted.

Table 1.

Cultivation of microalgae by trophic mode employed.

Regarding autotrophic cultivation, light intensity and duration are essential as they drive photosynthesis. The optimal light and dark photoperiods for maximizing microalgae biomass growth can vary depending on the species of microalgae and the specific cultivation conditions. However, general trends and recommendations can be outlined based on research findings. A light/dark cycle of 18 h light to 6 h dark (18:6) is often cited as optimal for maximizing biomass production in several microalgae species, including C. vulgaris and Desmodesmus subspicatus) [108,109]. This cycle allows for metabolic processes that promote lipid synthesis. In the absence of light, microalgae harness their stored carbohydrates to produce lipids, especially when nutrients are scarce. This metabolic transformation is crucial for optimizing lipid accumulation within the cells.

The effectiveness of different wavelengths in combination with photoperiods in biomass growth has also been explored. For instance, using mixed wavelengths (e.g., blue and green light) for specific durations can enhance growth performance, indicating that not just duration but also the quality of light matters [110]. Moreover, it has been shown that different microalgal species exhibit varying responses to light intensity.

Ho et al. investigated the optimization of lipid production in a newly isolated marine microalga, Chlamydomonas sp. JSC4, focusing on light intensity and nitrogen depletion as key factors. Through experiments with different light intensities, the authors found that the specific growth rate of Chlamydomonas sp. JSC4 increased with light intensity up to a saturation point. Beyond this intensity, growth was inhibited, suggesting a delicate balance between light supply and photoinhibition. However, in order to promote lipid accumulation, optimized light intensity had to be combined with nitrogen depletion. The optimal combination of high light intensity (300 μmol m−2 s−1) for robust growth and nitrogen depletion for lipid accumulation resulted in a maximum lipid productivity of 328 mg L−1 d−1 and a lipid content of 34.1%. Further studies performed indicated that sufficient light supply promotes the formation of essential precursors for TAG synthesis, leading to increased lipid accumulation [111].

Another important factor that drives photosynthesis is the presence of CO2. Higher concentrations of CO2 generally enhance microalgae growth and biomass production by providing more inorganic carbon for photosynthesis. Numerous studies have shown that CO2 supplementation can significantly boost both biomass and lipid productivity, with optimal concentrations usually falling between 2% and 6% [112,113,114]. For instance, Omar Faruque et al. found the highest lipid content (31.6%) at 6% CO2 in Scenedesmus dimorphus, while Chen et al. found 6% CO2 to be optimal for Nannochloropsis salina [115,116].

Nevertheless, excessive CO2 levels can negatively impact microalgae growth, leading to growth inhibition or even cell death. This is often due to factors such as medium acidification, which lowers pH and disrupts optimal growth conditions, enzymatic activity alterations that affect essential metabolic pathways like photosynthesis, and nutrient imbalances due to over-prioritization of carbon fixation [117]. To optimize CO2 uptake, strategies such as optimizing CO2 concentrations and improved aeration methods are key to maximizing biomass and lipid yields in microalgae cultivation systems enriched with CO2. For instance, by employing sequential bioreactors or special aerators that generate smaller bubbles, the dissolution and utilization of CO2 can significantly increase [118].

From a sustainable perspective, CO2 supply can be combined with flue gas treatment, an industrial waste stream. Flue gas CO2 has shown promise as a sustainable carbon source for microalgal cultivation, offering both environmental and economic benefits, as studies have demonstrated that various microalgae species can effectively utilize flue gas CO2 for growth and biomass production [119,120]. The capture and utilization of CO2 from flue gases emitted by thermal power plants and other industries present a promising opportunity to reduce greenhouse gas emissions while providing a sustainable carbon source for microalgae cultivation. However, the high concentrations of CO2 and other potentially toxic compounds in flue gases can inhibit the growth of some microalgae species.

Paylou et al. conducted a study focused on identifying and evaluating CO2-tolerant microalgae species for use in 3G biorefineries by analyzing biomass growth and biomolecule accumulation, including lipids. The authors carried out cultivation experiments using 13 microalgae species from Greek collections in flasks and bioreactors to assess their tolerance to 10% CO2, representing the upper limit found in flue gas mixtures. The strain Stichococcus sp. Wild-TUC was identified as a promising candidate for 3G biorefineries due to its high CO2 tolerance, rapid growth, and high carbohydrate and protein productivity. However, the authors noted that the biomass yields were lower than those reported in the literature for lower CO2 concentrations, highlighting the importance of optimizing cultivation conditions to maximize biomass production under high CO2 levels [121].

In such a context, it becomes clear that understanding the intricate balance of light intensity, CO2 concentration, and nutrient management is crucial for maximizing microalgal growth and lipid accumulation. As research continues to identify effective species and optimize cultivation techniques, microalgae are poised to play a vital role in promoting renewable resources and reducing the environmental impact of industrial processes, making them a key player in the transition toward a more sustainable future. Table 2 below presents a comparative analysis of the production of each type of microorganism.

Table 2.

Production of biomass and lipids and lipid profiles of key oil-producing microbial species.

The analysis presented in Table 2 demonstrates that oleaginous fungi and yeasts have a superior performance in the production of biomass and lipids compared to bacteria and microalgae. This superiority can be attributed to the intrinsic capacity of these microorganisms to metabolize a wide range of substrates, resulting in high yields of both biomass and lipids. The main fatty acids synthesized by these microorganisms include palmitic acid (C16:0), oleic acid (C18:1), and linoleic acid (C18:2). These fatty acids are widely valued in several commercial applications. Palmitic acid is frequently used in the food, cosmetic, and pharmaceutical industries due to its emulsifying and stabilizing properties. Oleic acid, in turn, is a fundamental component of olive oil, known for its benefits to cardiovascular health, in addition to being used in cosmetics and cleaning products. Linoleic acid, classified as an essential fatty acid, is crucial for human nutrition and also has applications in the formulation of food and cosmetic products [136].

In addition, some microorganisms have the ability to synthesize less common fatty acids, such as α-linoleic acid (C18:3), γ-linoleic acid (C18:3), hexadecadienoic acid (C16:2), hexadecatrienoic acid (C16:3) and myristic acid (C14:0). α-linoleic acid, for example, is an essential fatty acid recognized for its anti-inflammatory properties, arousing considerable interest in nutrition and disease prevention [90]. γ-linoleic acid is often used in dietary supplements and can help manage conditions such as arthritis [137]. Hexadecadienoic and hexadecatrienoic acids have potential applications in the biofuel industry, given their chemical structure that favors more efficient conversion into biodiesel [138]. Myristic acid, in turn, is used in the cosmetics industry and is present in several personal care products [139].

The lipid production by fungi and yeasts not only showcases remarkable yield advantages but also highlights their substantial commercial and industrial potential. The diversification of applications of the fatty acids produced emphasizes the importance of continuing research and optimization in fermentation processes involving these microorganisms.

3. Microbial Lipids Production

3.1. Impact of Microbial Lipids

The production of microbial lipids offers several advantages over traditional sources such as vegetable oils and animal fats, particularly in terms of production efficiency and environmental impact. Table 3 summarizes these comparisons, highlighting key factors such as production efficiency, environmental impact, raw material use, and cost-effectiveness. In terms of efficiency, microbial lipids have shorter production cycles, ranging from days to weeks, whereas traditional sources depend on longer, seasonal cycles, making microbial lipid production more stable and less susceptible to climatic variations.

Moreover, microbial lipid production requires significantly fewer natural resources, such as land and water, than traditional sources. Microorganisms like algae can thrive in saline or wastewater environments, reducing the demand for freshwater resources in water-scarce regions. This capability is particularly beneficial in areas where freshwater use needs to be minimized [140]. Another important advantage is that microorganisms can be cultivated on non-arable land, avoiding competition with food crops, which allows for higher-density cultivation without the need for fertile soil [141].

A distinctive feature of microbial lipids is their ability to utilize non-edible by-products, such as agricultural waste or glycerol, as feedstocks. This reduces competition with food production and contributes to a circular bioeconomy [142]. Additionally, microbial lipid production has the potential to lower the carbon footprint associated with fuel production by using CO2 from industrial emissions or atmospheric sources. Microorganisms such as algae and bacteria can convert carbon into lipids through photosynthesis or fermentation processes, sequestering carbon and helping to mitigate greenhouse gas emissions [143]. When integrated with existing industrial processes, microbial lipid production can result in a net reduction in emissions, contributing to a more positive environmental impact.

Furthermore, microbial lipid production can effectively promote waste valorization by transforming organic waste materials, such as food processing and agricultural residues, into valuable lipids. This not only reduces landfill usage but also contributes to efficient waste management and lowers the environmental impact associated with waste disposal [140].

While microbial lipids offer numerous benefits, they still face challenges related to cost-effectiveness and scalability. Traditional lipid production benefits from established infrastructure and economies of scale, making it more financially advantageous at present. However, with advancements in fermentation technologies and the reduction in costs associated with bioreactors and feedstock optimization, microbial lipids are expected to become increasingly competitive. Although scalability remains a challenge, ongoing technological advancements hold the potential for microbial lipid production to become a viable and sustainable alternative to traditional lipid sources in the future.

Table 3.

Comparison between microbial lipids and traditional lipid sources.

Table 3.

Comparison between microbial lipids and traditional lipid sources.

| Aspect | Traditional Lipids | Microbial Lipids | Ref. |

|---|---|---|---|

| Production Efficiency | Seasonal and climate-dependent. | Independent of seasons or climate | [144] |

| Long production cycles (e.g., months to years). | Short production cycles (e.g., days to weeks). | ||

| Environmental impact | High land and water usage for crops or livestock. | Minimal land use; can utilize non-arable areas. | [145,146] |

| Associated with deforestation and biodiversity loss. | Lower ecological footprint; utilizes waste substrates. | ||

| Raw material | Edible feedstocks (e.g., soy, palm, animals). | Can use waste or non-edible feedstocks (e.g., glycerol, lignocellulose). | [144] |

| Cost-effectiveness | Relatively lower cost for established production methods. | Currently higher production costs due to scalability and process optimization challenges. | [147] |

| Vulnerable to market fluctuations (e.g., crop yields, feed costs). | Potential for cost reduction with technological advances. | [148] | |

| Scalability | Well-established and large-scale industrial infrastructure. | Emerging technology; scalability still a challenge. | [100] |

| Limitations | Environmental degradation and limited resource availability. | Requires further development to achieve economic parity. | [148,149] |

| Ethical concerns with animal fat production. | Public acceptance of microbial-derived products. | [6] |

3.2. Integrated Metabolic Pathway

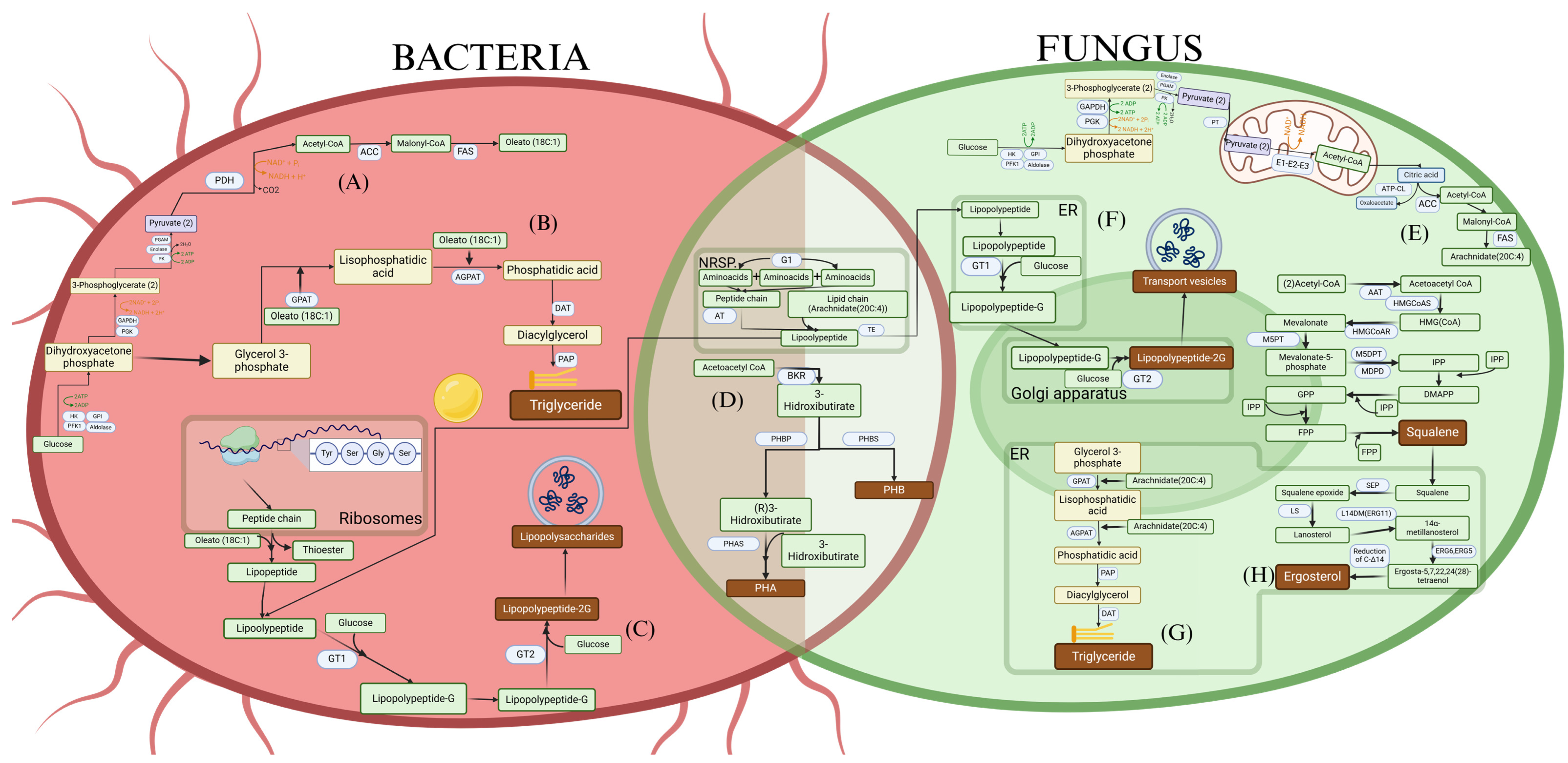

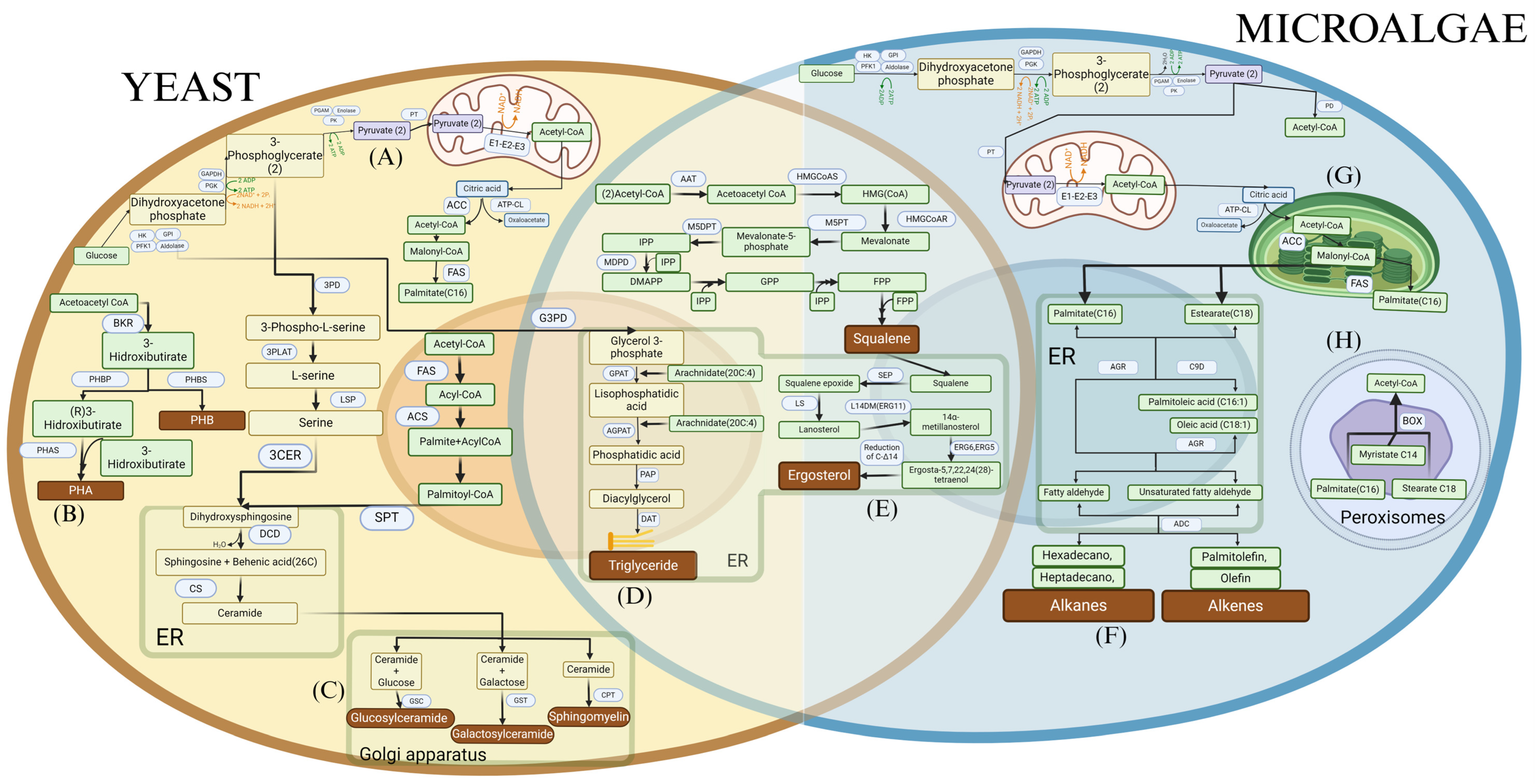

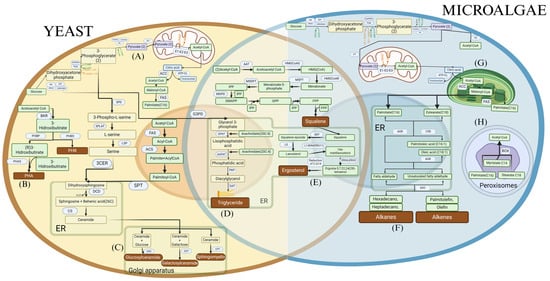

The production of microbial lipids involves a series of interconnected metabolic pathways, where primary metabolites, such as glucose or acetate, are converted into energy reserves and structural lipids. A central point in this process is the synthesis of acetyl-CoA, which serves as a precursor for various lipid biosynthesis routes. The production of acetyl-CoA can occur through different pathways depending on the microorganism type and environmental conditions (Figure 1A and Figure 2A,H). During glucose metabolism, pyruvate decarboxylation is essential: glucose is initially converted into pyruvate, which is subsequently transformed into acetyl-CoA. In eukaryotic organisms, such as yeasts, fungi, and microalgae, this process takes place in the mitochondria; however, the acetyl-CoA required for lipid biosynthesis is exported to the cytosol through specific transporters. In bacteria, the conversion occurs in the cytoplasm, facilitating the direct utilization of acetyl-CoA for lipid synthesis [150].

Figure 1.

Metabolic pathways for (A) Production of acetyl-CoA and fatty acids from glucose in bacteria. (B) Production of triglycerides in bacteria. (C) Production of lipopeptides in bacteria from ribosomes and NRPS (non-ribosomal peptide synthetases). (D) Production of polyhydroxyalkanoates (PHA) and polyhydroxybutyrates (PHB) from acetyl-CoA in bacteria and fungi. (E) Production of acetyl-CoA and fatty acids from glucose in fungi. (F) Production of lipopeptides in fungi from NRPS. (G) Production of triglycerides in fungi. (H) Production of squalene and ergosterol from acetyl-CoA in fungi.

Figure 2.

Metabolic pathways for (A) Production of acetyl-CoA and fatty acids from glucose in yeasts. (B) Production of polyhydroxyalkanoates (PHA) and polyhydroxybutyrates (PHB) from acetyl-CoA. (C) Production of sphingolipids in yeasts. (D) Production of triglycerides in yeasts and microalgae. (E) Production of squalene and ergosterol in yeasts and microalgae. (F) Production of hydrocarbons in yeasts. (G) Production of acetyl-CoA and fatty acids in microalgae. (H) Production of acetyl-CoA in microalgae through peroxisomal degradation.

Fatty acid synthesis is another key process for lipid production, where acetyl-CoA is incorporated into elongation cycles catalyzed by the fatty acid synthase (FAS) complex (Figure 1E and Figure 2G). Each cycle adds two carbon units, generating saturated and unsaturated fatty acids that can be incorporated into triglycerides, phospholipids, and other lipid compounds. Conditions favoring this route include the availability of carbon-rich sources and nitrogen limitation, as nitrogen restriction activates anabolic pathways and promotes the accumulation of storage lipids. Oleaginous microorganisms, such as Y. lipolytica and R. toruloides, exhibit a high capacity to store lipids under such conditions, reaching up to 70% of their dry weight in lipids [151].

In addition to fatty acids, other metabolic products, such as squalene, ergosterol, and polyhydroxyalkanoates (PHAs), are synthesized from acetyl-CoA-derived precursors. Squalene and ergosterol, for instance, are products of the mevalonate pathway and are involved in the production of sterols and isoprenoid compounds, essential for cell membrane structure (Figure 1H and Figure 2E) [152,153]. Maximizing the production of these compounds requires an optimal supply of acetate or glucose, along with the fine-tuning of pH and temperature. PHAs, which serve as carbon reserves in bacteria, accumulate primarily under conditions of carbon excess and nutrient limitation (such as nitrogen or phosphorus), enabling the synthesis of these biopolymers with industrial applications in bioplastics production [154] (Figure 1D and Figure 2B).

The accumulation of triglycerides primarily occurs through the esterification of fatty acids with glycerol-3-phosphate, forming triacylglycerols that are stored in lipid bodies [155]. The efficiency of this process depends not only on enzymatic activity but also on the cell’s energy balance. Through fermentative processes, such as fed-batch, it is possible to maximize both biomass production and lipid accumulation, particularly under nitrogen-limited conditions and high carbon concentrations. The use of agro-industrial residues, such as residual glycerol, is being explored as a sustainable strategy to enhance economic feasibility and reduce production costs. Due to their ability to store triglycerides, yeasts are considered prime candidates for biofuel production [156]. Many fungi are used to produce omega-3 fatty acids and other high-value oils thanks to their ability to store unsaturated fatty acids (Figure 1G) [157]. Microalgae, on the other hand, are known for their ability to store triglycerides under adverse conditions, specifically when nutrients like nitrogen are scarce, allowing them to survive unfavorable conditions (Figure 2D). In bacteria, unlike eukaryotic cells, triglycerides are not as abundant (Figure 1B) [158]. Only oleaginous bacteria can accumulate oils in their cellular structures, where they can synthesize and store triglycerides as carbon and energy reserves, such as Rhodococcus and Acinetobacter [159].

3.3. Conditions and Optimization Processes

Optimal parameters for microbial lipid production can significantly enhance the yield and efficiency of the process. Inoculum concentration directly affects microbial growth rate. A very low inoculum can result in a long lag phase, delaying the onset of biomass and lipid production. On the other hand, an excessively high inoculum can lead to rapid nutrient depletion, limiting growth and lipid production [125,160]. The ideal inoculum concentration for Rhodotorula kratochvilovae was determined to be 10% (v/v), which resulted in a maximum dry biomass of 14.28 g/L and a lipid yield of 5.32 g/L. Lower inoculum concentrations led to longer lag phases, while concentrations above 10% resulted in a decrease in lipid yield [160].

Chemical factors, such as a high C/N ratio (typically above 100) [161], are essential to stimulate lipid production, as nitrogen limitation combined with excess carbon triggers the accumulation of TAGs as energy reserves. R. toruloides was able to accumulate up to 60% intracellular lipids when cultivated on xylose with a C/N ratio of 120 [162]. In addition, the choice of carbon source can significantly impact lipid production. Different carbon sources influence microbial metabolic pathways and lipid synthesis rates. Simple sugars, like glucose and sucrose, are more easily metabolized than complex carbohydrates, such as starch. The carbon source can significantly affect lipid production, with glycerol yielding higher lipid levels than sugars like xylose and glucose. Glycerol, for example, can produce up to 69% lipid yield from consumed carbon, making it one of the most effective substrates for lipid synthesis [74]. Sucrose has proven to be a superior carbon source compared to glucose and xylose for lipid production in R. toruloides [163].

The nitrogen source plays a key role in microbial lipid production by affecting growth dynamics and lipid accumulation. Inorganic nitrogen sources, such as sodium nitrate (NaNO3), are more effective in enhancing lipid production than organic sources like urea or ammonium sulfate. For example, Crypthecodinium cohnii produced 26.9% lipid content with NaNO3 [164]. The optimal carbon-to-nitrogen (C/N) ratio is crucial, with ratios between 30 and 120 being effective for R. toruloides, leading to increased lipid accumulation at higher ratios. Nitrogen limitation, such as high C/N ratios, can induce metabolic pathways that enhance lipid production, as seen in Y. lipolytica. Common nitrogen sources like ammonium sulfate and ammonium nitrate support high lipid yields, while urea has emerged as a sustainable alternative with similar results. Sodium nitrate, ammonium nitrate, ammonium sulfate, and urea are all considered optimal for boosting microbial lipid production [165].

The pH of the cultivation medium is a critical factor for the optimal performance of lipid-producing strains. pH variations can trigger undesirable responses and reduce process yields. It is important to note that the optimal pH range may vary depending on the strain, but it is generally between four and six. For Saitozyma podzolica DSM 27192, a pH of four was ideal for lipid production, while a pH of six resulted in a 50% reduction in lipid yield [161].

Physical and environmental factors also impact lipid production. Cultivation temperature, like pH, can affect strain performance and may even inactivate it. Assessing the microorganism’s tolerance range and its optimal growth temperature can lead to higher yields. Aeration, another key factor, is essential for the growth and metabolism of many oleaginous microorganisms. Optimizing the airflow rate in an airlift bioreactor enhanced lipid production by Candida tropicalis ASY2. Proper agitation ensures the homogeneity of the culture medium, nutrient availability, and oxygen transfer, influencing both growth and lipid production [166].

Process optimization can benefit from various tools that assist in experimental design and result prediction. Response surface methodology (RSM) is a powerful statistical technique used to simultaneously optimize multiple parameters. In the study by Thangavelu et al., RSM was employed to determine the optimal conditions for starch content, yeast extract, and airflow rate for lipid production in a bioreactor. This approach also enabled the optimization of the biomass-to-methanol ratio, catalyst concentration, and reaction time to maximize FAME yield in the transesterification process [166]. Similarly, mathematical modeling can be used to predict lipid yield and optimize cultivation conditions. In a study with Aspergillus wentii Ras101, the LINGO optimization program was applied to predict maximum lipid production by considering process variables [167]. Genetic modification of oleaginous microorganisms is another optimization strategy, capable of enhancing lipid production and altering fatty acid composition to improve biodiesel properties [142].

4. Lipids Extraction Process

Most lipids produced by oleaginous microorganisms consist of short- and long-chain fatty acids, ranging from 6 to 36 carbon atoms, and can be classified as saturated (SUFA), monounsaturated (MUFA), or PUFA, depending on the number of double bonds in the carbon chain [25,168,169]. Yeasts, microalgae, filamentous fungi, and bacteria can produce oils rich in SUFA and MUFA, which have strong applicability in biofuel production. Others, such as microalgae and thraustochytrids, are excellent sources of PUFA, with applications in nutraceutical production [25].

The extraction of microbial lipids is a vital process that enables the accessibility of intracellular lipids, paving the way for their recovery for various applications. Nonetheless, achieving lipid recovery on an industrial scale poses significant challenges. This difficulty arises from the fact that lipids are not stored in uniform compartments and possess varying polarities; some are polar, such as phospholipids, while others are nonpolar, like triacylglycerols [25].

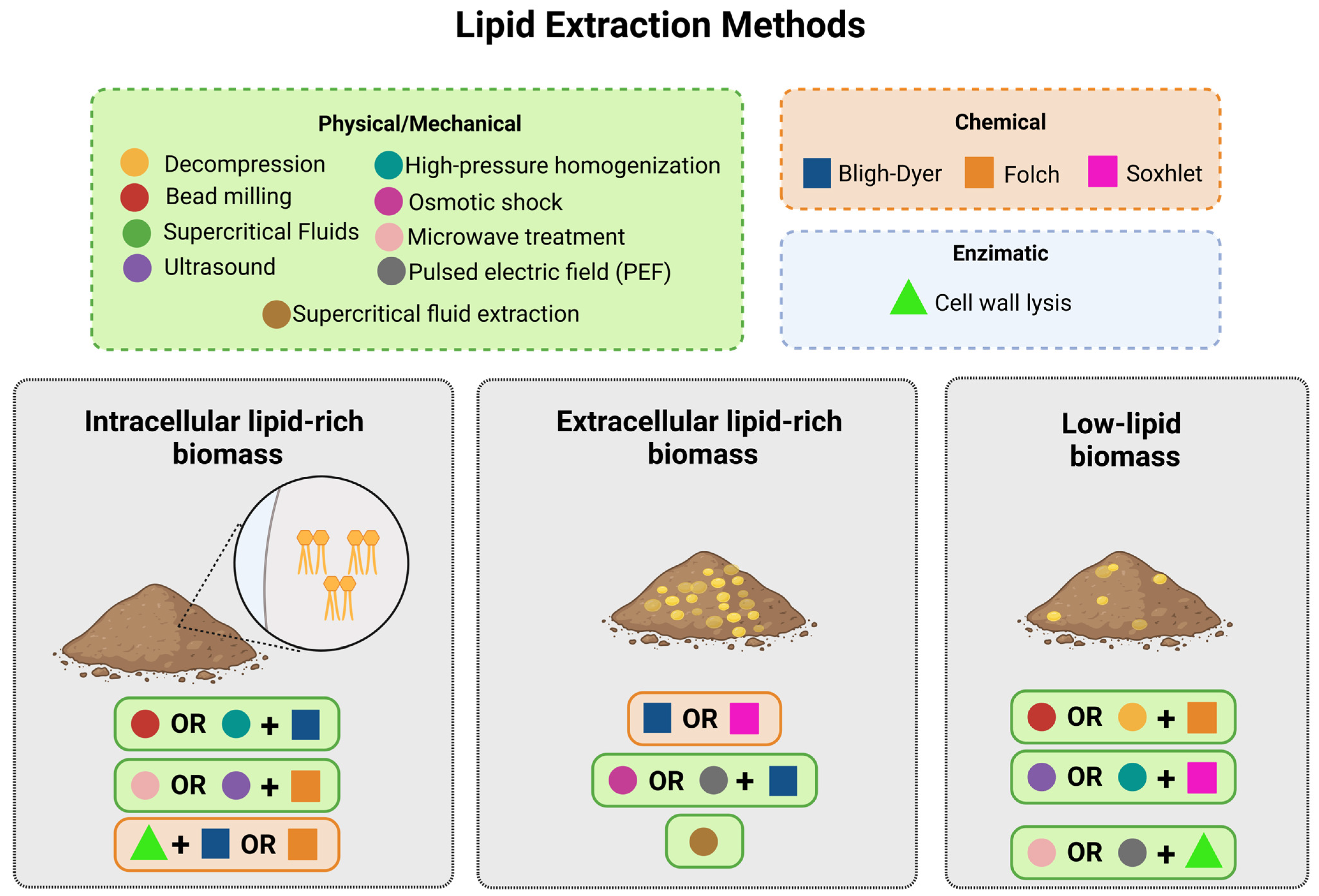

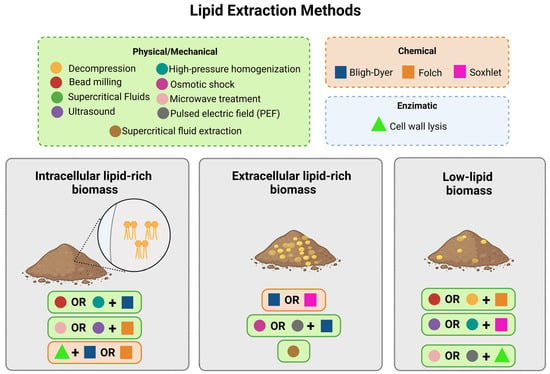

Lipids can be synthesized either intracellularly or extracellularly, which affects the type of extraction method and the complexity of the process. The extraction of extracellular lipids can be easily performed using physical processes, such as centrifugation or filtration, while intracellular lipids require a pre-treatment step (Figure 3) [170].

Figure 3.

The figure presents combinations of lipid extraction techniques for different types of biomasses, adjusted according to the location of the lipids. For intracellular lipid-rich biomass, it is essential to disrupt the cells by combining mechanical methods, such as bead milling or high-pressure homogenization, with or without chemical methods like Bligh–Dyer or Folch, or by applying enzymatic lysis followed by chemical extraction. In extracellular lipid-rich biomass, chemical techniques like Soxhlet or Bligh–Dyer are sufficient but can be enhanced with physical processes such as osmotic shock or supercritical fluids. For low-lipid biomass, more intensive combinations are required: mechanical methods (ultrasound or microwave treatment) assist in cell disruption, followed by chemical techniques such as Soxhlet to ensure maximum recovery of dispersed lipids.

One effective pre-treatment method for biomass to optimize mass transfer and enhance the efficiency of downstream processing of intracellular lipids involves disrupting or weakening the microbial cell wall [26]. This disruption can be achieved by two routes: using wet or dry biomass. The wet biomass route uses organic solvent extraction and is more advantageous than the dry biomass route due to reduced costs associated with lower energy demands. However, depending on the material, this disruption may be affected by lipid accessibility, mass transfer, and emulsion formation. The dry biomass route relies on physical damage to the microbial cell wall in the presence of a co-solvent [23,170].

Cell disruption represents one of the main obstacles to achieving the economic feasibility of microbial lipid production. Therefore, the choice of the optimal cell disruption and lipid extraction method depends on the structure of the oleaginous microorganism [25,171]. There are various methods available for lipid recovery at a laboratory scale, including chemical, physical, and enzymatic methods [171].

4.1. Chemical Process of Lipid Extraction

Organic solvent extraction is one of the most widely used chemical methods for extracting lipids from microbial sources, as it promotes cell disruption without requiring additional pre-treatment due to the affinity of lipids for organic solvents [172]. The efficiency of the solvent extraction process depends on the proper selection of the solvent, the solubility of lipids in the chosen solvent, and the ability to separate complex lipids from other macromolecules [173].

The Bligh–Dyer and Folch methods are the most commonly used techniques for microbial lipid extraction, utilizing methanol and chloroform as solvents, which have a high affinity for and solubility in polar lipids, resulting in high lipid recovery yields [172]. The Folch method is specifically designed for small sample sizes, whereas the Bligh–Dyer method is commonly utilized for extracting lipids from samples that are high in moisture and low in fat. Both techniques make use of a methanol-chloroform mixture for effective extraction [173]. In these methods, the dry biomass of the microorganism is homogenized or mixed with a chloroform and methanol solution in a 2:1:0.8 ratio and then filtered through a tube. The addition of a potassium chloride solution to this mixture promotes the distribution of lipids into two phases: an aqueous phase (top) and an organic phase (bottom), with chloroform containing the lipids due to the salting-out effect [25,174]. Phase separation can be carried out using a decantation funnel or centrifugation, and lipids are recovered by evaporating the chloroform. However, disadvantages include the high toxicity and health risks associated with the solvents, as well as the multiple steps involved, which complicate their use at both laboratory and industrial scales [173].

Martinez-Burgos et al. used soybean hulls rich in lignocellulosic residues as a carbon source for biolipid production by Lipomyces starkeyi LPB 53. These authors obtained 42.5% lipids from a maximum lyophilized cell biomass concentration of 26.5 g/L using a chloroform and methanol solution. The extracted oil was composed of oleic, palmitic, palmitoleic, linoleic, and stearic fatty acids [175].

Another widely utilized technique is the Soxhlet method, which uses hexane as its organic solvent. This method is applied to solid samples, which are subjected to several washing cycles with the solvent at high temperatures. It is often combined with mechanical pressing or expeller extraction methods, allowing for greater lipid extraction efficiency from the residual cake. However, large quantities of solvents are required, and lipids are recovered by distillation, achieving yields of up to 95%. Disadvantages include the long extraction time (~6 h), the potential for thermal degradation of unsaturated fatty acids, and the need for large volumes of solvent [176].

Due to the growing demand for extraction methods that utilize green technologies and solvents with minimal environmental impact, bio-solvents have emerged. Breil et al. demonstrated that a combination of ethyl acetate and ethanol in a 1.794:0.784 (w/w) ratio, using 0.08 g of wet sample, was more efficient for lipid extraction from the yeast Y. lipolytica IFP29. This was followed by the addition of water (containing 0.8% KCl) and ethyl acetate in a 1:2 (v/v) ratio to separate the aqueous and organic phases. These results suggest that the classic extraction system is as efficient as the alternative system in terms of lipid yield from microbial tissues, regardless of their apparent hydrophilicity [174].

4.2. Physical and Mechanical Process of Lipid Extraction

Physical and mechanical techniques for disrupting the cell wall in oleaginous microorganisms offer energy-efficient solutions but face several drawbacks, including limitations to small-scale applications and reduced overall efficiency. Among the methods employed are decompression, bead milling, high-pressure homogenization, osmotic shock, microwave treatment, ultrasound, pulsed electric fields, supercritical CO2 extraction, and drying [6].

Cell disruption by decompression involves mixing microbial cells with a pressurized supercritical gas, followed by a sudden release of pressure, which causes cell expansion and rupture due to changes in pressure. Various gases can be used, such as nitrogen or carbon dioxide. Carbon dioxide is highly efficient under optimized conditions of pressure (40 atm), temperature (40 °C), and time (3 h) in wet yeast cells. In contrast, nitrogen, although inert and pH-neutral, exhibits low efficiency in wet yeast cells due to its low solubility in water [6,177].

Among mechanical methods, bead milling is simple and highly efficient, making it suitable for yeasts, bacteria, algae, and filamentous fungi. This method disrupts microbial cells through the abrasive action of small glass or stainless-steel beads, releasing lipids. The ideal bead diameter is 0.5 mm for most microorganisms; however, for bacteria, smaller beads (0.1 mm) improve cell disruption efficiency. One significant advantage of this method is the straightforward removal of the beads through gravitational force, followed by lipid recovery via solvent extraction [178].

High-pressure homogenization employs pressures between 150 and 200 MPa to effectively disrupt cell structures. One of the primary benefits of this technique is its scalability and versatility for a wide range of microorganisms. However, it is important to note that filamentous fungi can pose a challenge, as their mycelial structure may lead to valve blockages. This method can increase lipid extraction yield by up to four times compared to solvent extraction. Furthermore, its combination with bead milling enhances lipid extraction while reducing energy consumption [178].

Osmotic shock exposes microbial cells to a high osmotic pressure medium using high concentrations of solutes, such as salts or sugars. Cell lysis occurs as water migrates into the cell, increasing internal pressure. However, microorganisms with rigid cell walls resist lysis and undergo only weakening. Additionally, the high cost of additives limits the application of this method on a small scale [179].

Microwave treatment has a high potential for cell disruption as electromagnetic waves (300 MHz to 300 GHz) interact with water molecules in cellular compartments, causing water to heat, expand, and increase internal pressure, leading to cell rupture. This method is advantageous due to its speed, safety, low cost, and industrial scalability without the need for pre-drying. However, the heat generated may degrade the quality of the extracted lipids, particularly unsaturated fatty acids [6,178].

Ultrasound is a method that accelerates the extraction process by interacting with the solvent and matrix through the periodic collapse of cavitation bubbles. This method involves cavitation effects that destroy cells and enhance lipid mass transfer. It is compatible with various materials, such as plants, microalgae, animals, and fungi, improving extraction efficiency and lipid quality [180].

The combination of extraction methods with bio-solvents, such as ethanol and ethyl acetate, can improve extraction yield, lipid purity, and composition, including fatty acid content in algae. However, the Folch method was more efficient for the extraction of polar lipids (glycolipids and phospholipids) and pigments (chlorophylls and carotenoids). Conversely, bio-solvents reduced SFAs and PUFAs [181].

In another study, the combination of hexane/isopropanol and ultrasound-assisted extraction for lipids from microalgae Nannochloropsis resulted in similar lipid, free fatty acid, and pigment extraction efficiencies compared to the control protocol using chloroform/methanol (1:1 v/v). The success of ultrasound-assisted extraction is largely attributed to the ultrasound-induced temperature increase. However, the scalability of this method remains challenging for industrial implementation [182].

Pulsed electric field (PEF) technology is an innovative, non-thermal extraction method that enhances industrial oil extraction through environmentally friendly processes. By improving mass transfer at lower temperatures and shorter extraction times, PEF significantly reduces energy and solvent usage. This technology works by applying brief, high-voltage electrical pulses that disrupt microbial cell membranes, increasing their permeability. As a result, PEF facilitates the extraction of intracellular compounds, including lipids, while also allowing for higher incorporation of health-promoting phytochemicals, such as antioxidants, thus enhancing oxidative stability [183,184].