Advancing PetroChina’s Development Strategies for Low-Permeability Oil Reservoirs

Abstract

:1. Introduction

2. Development Situation and Major Issues

2.1. Basic Development Situation

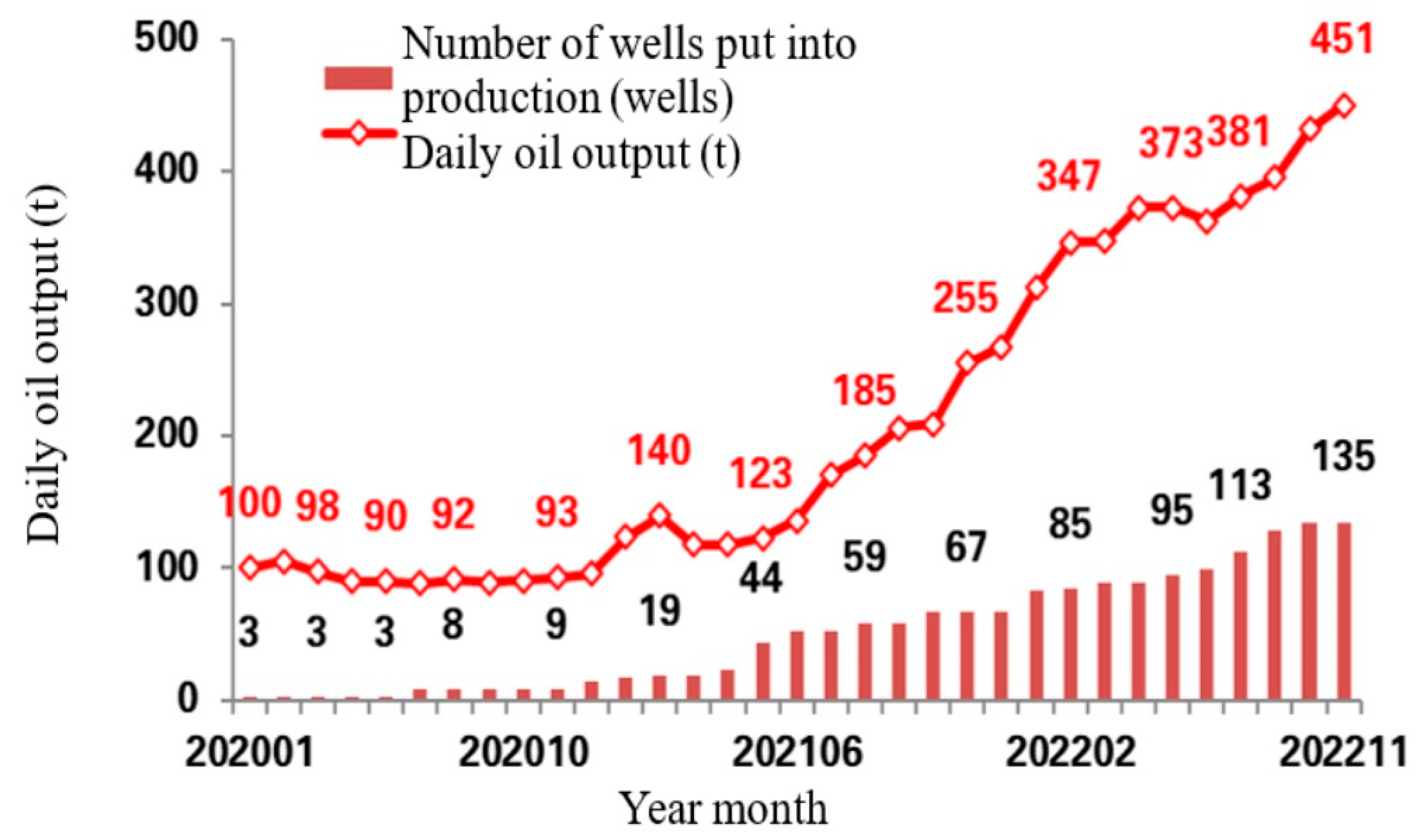

2.2. Overall Development Situation

2.3. Major Common Issues

2.3.1. Deterioration of Resource Quality

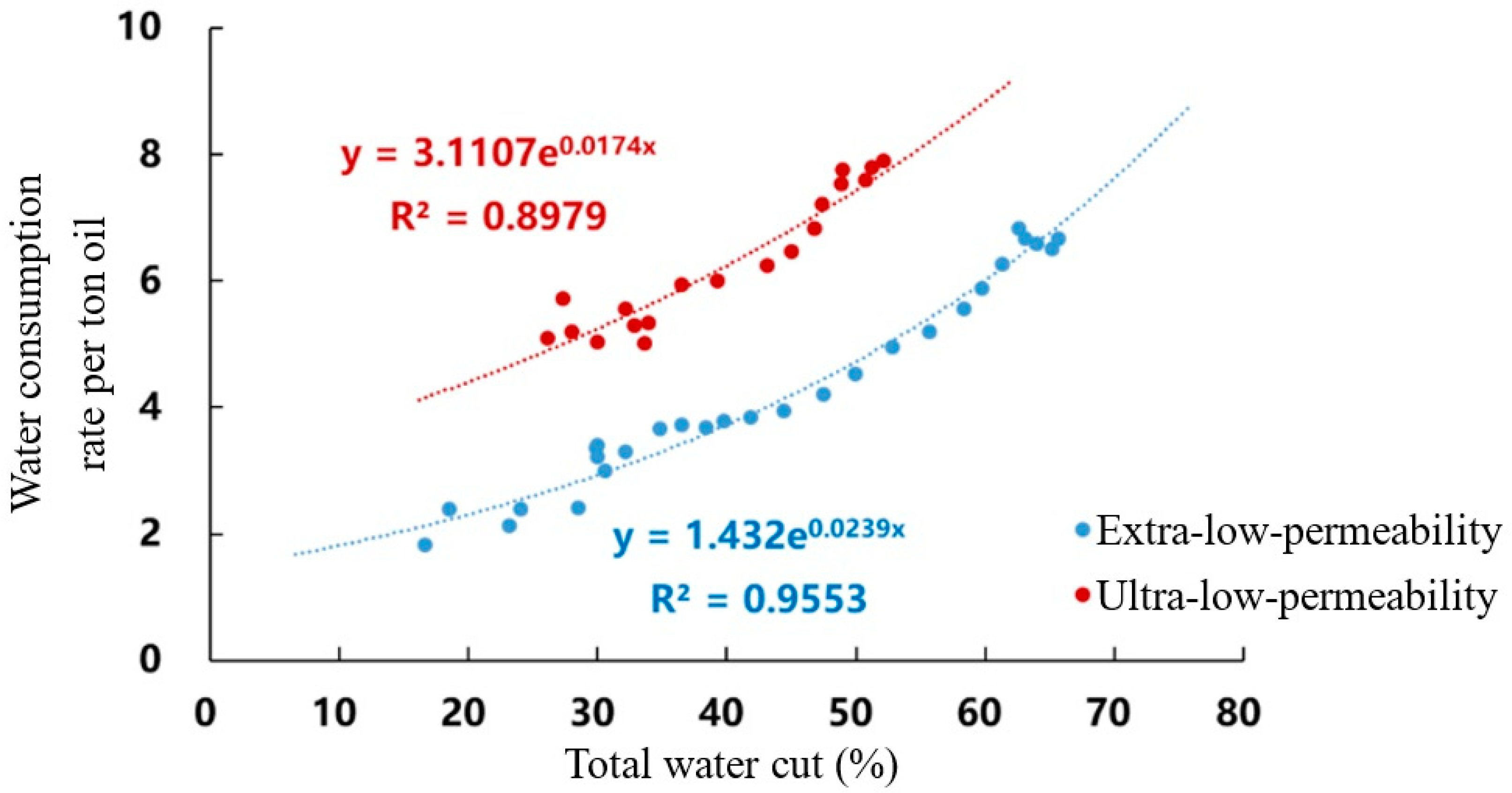

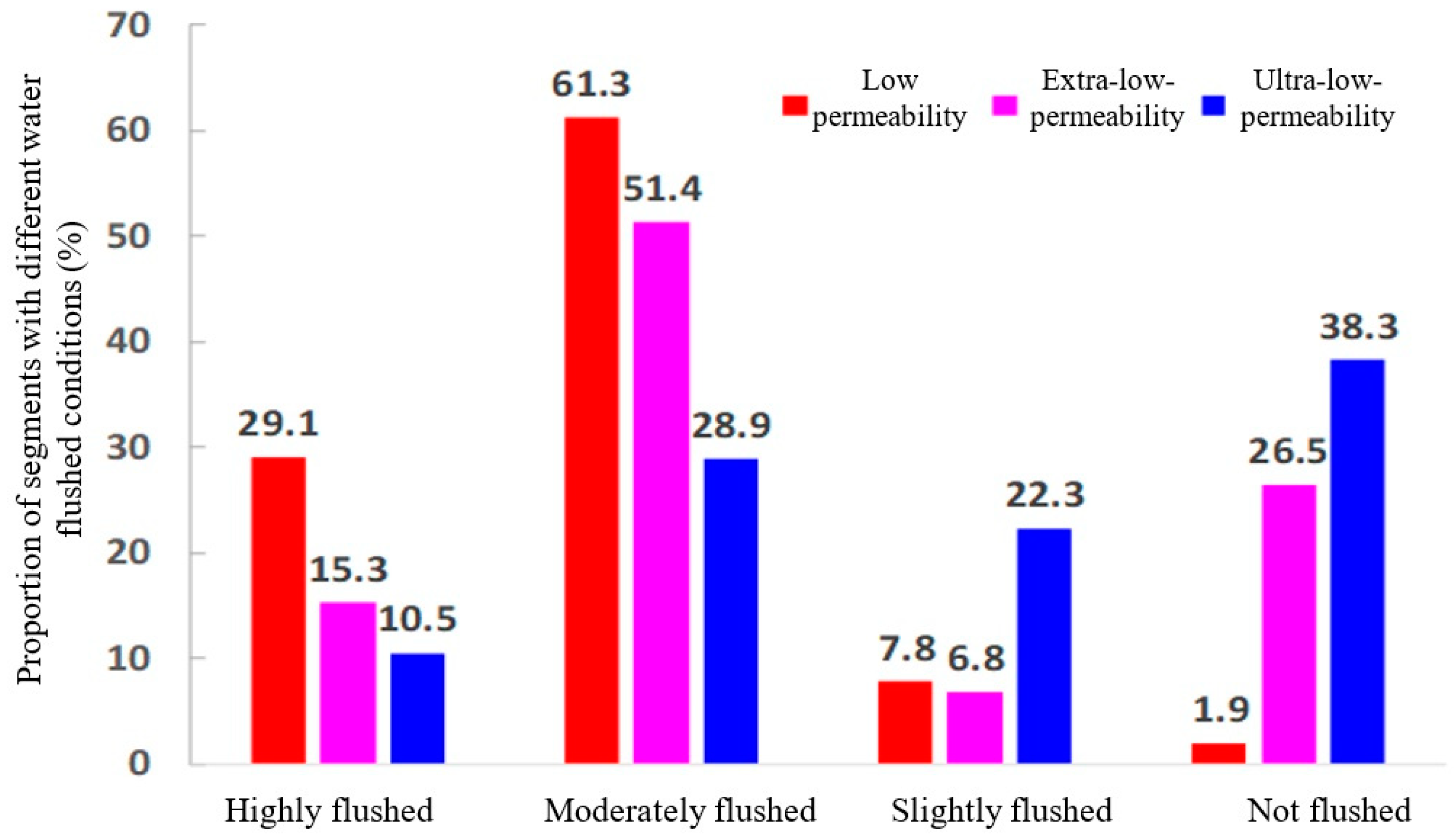

2.3.2. Aging of Oil Field

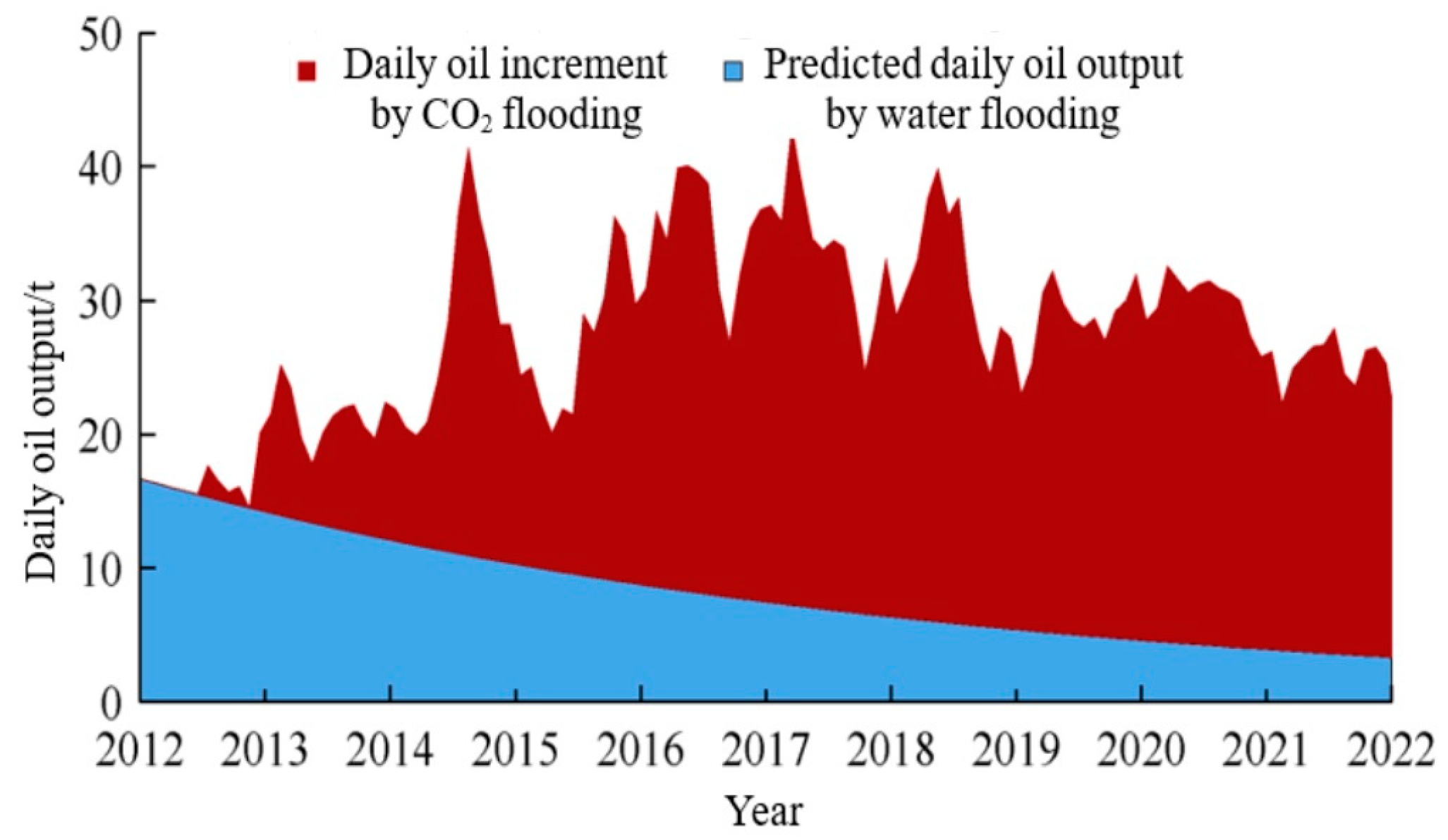

2.3.3. Tertiary Recovery Has Not Yet Been Applied in a Large-Scale and Profitable Manner

3. Major Development Technologies and Development Potential

3.1. Solid Resource Base

3.2. Increasingly Improved Fine Water Flooding Technology

3.3. Increasingly Abundant EOR Means

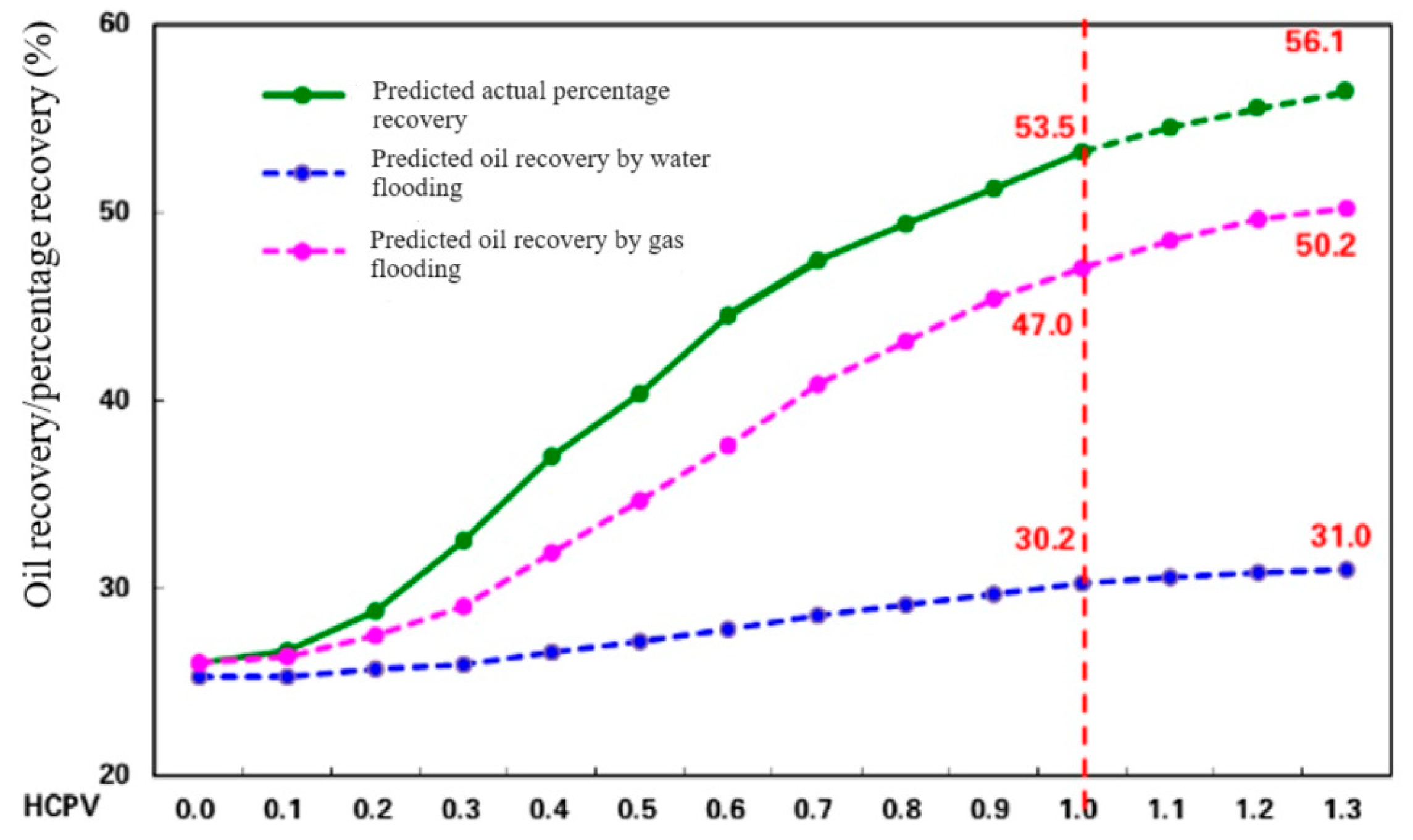

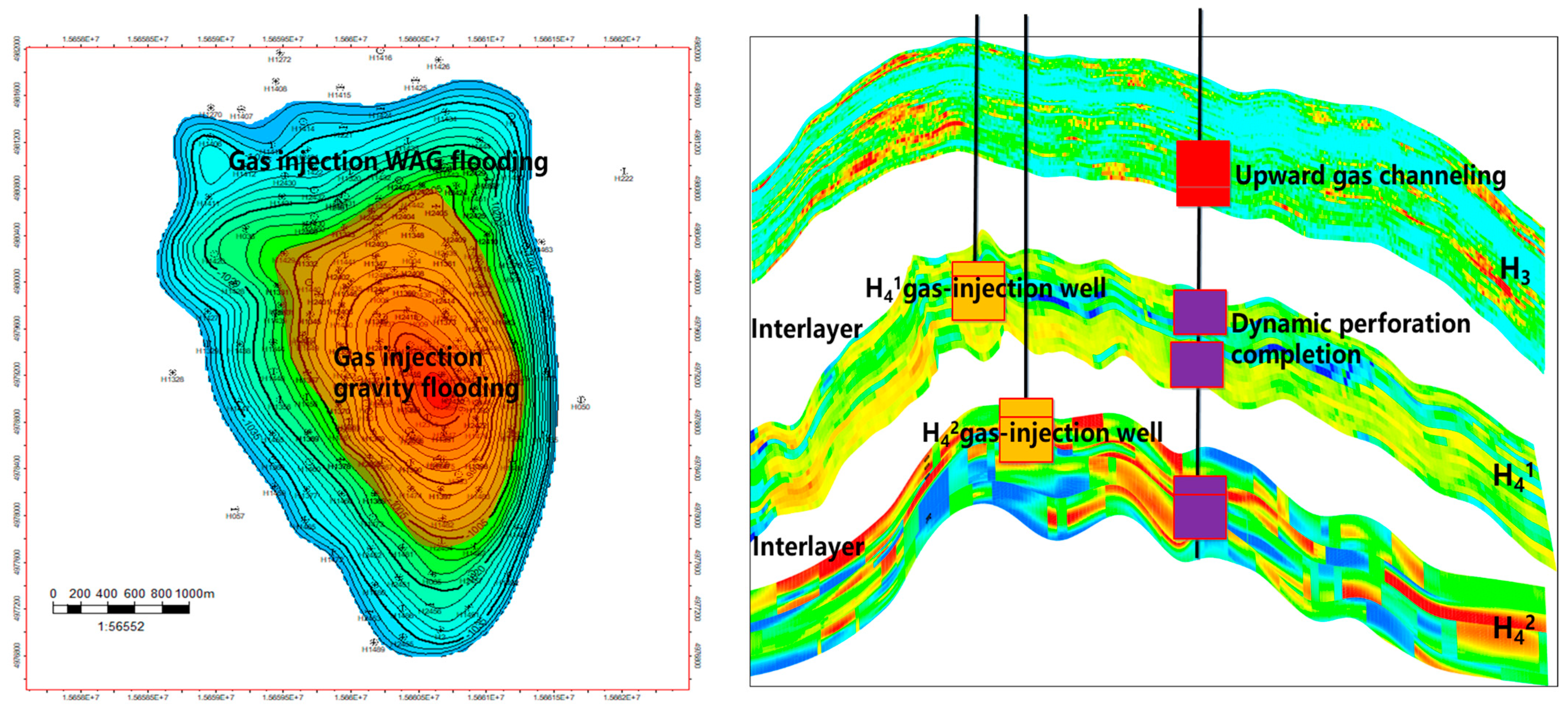

3.3.1. CCUS-EOR Technologies

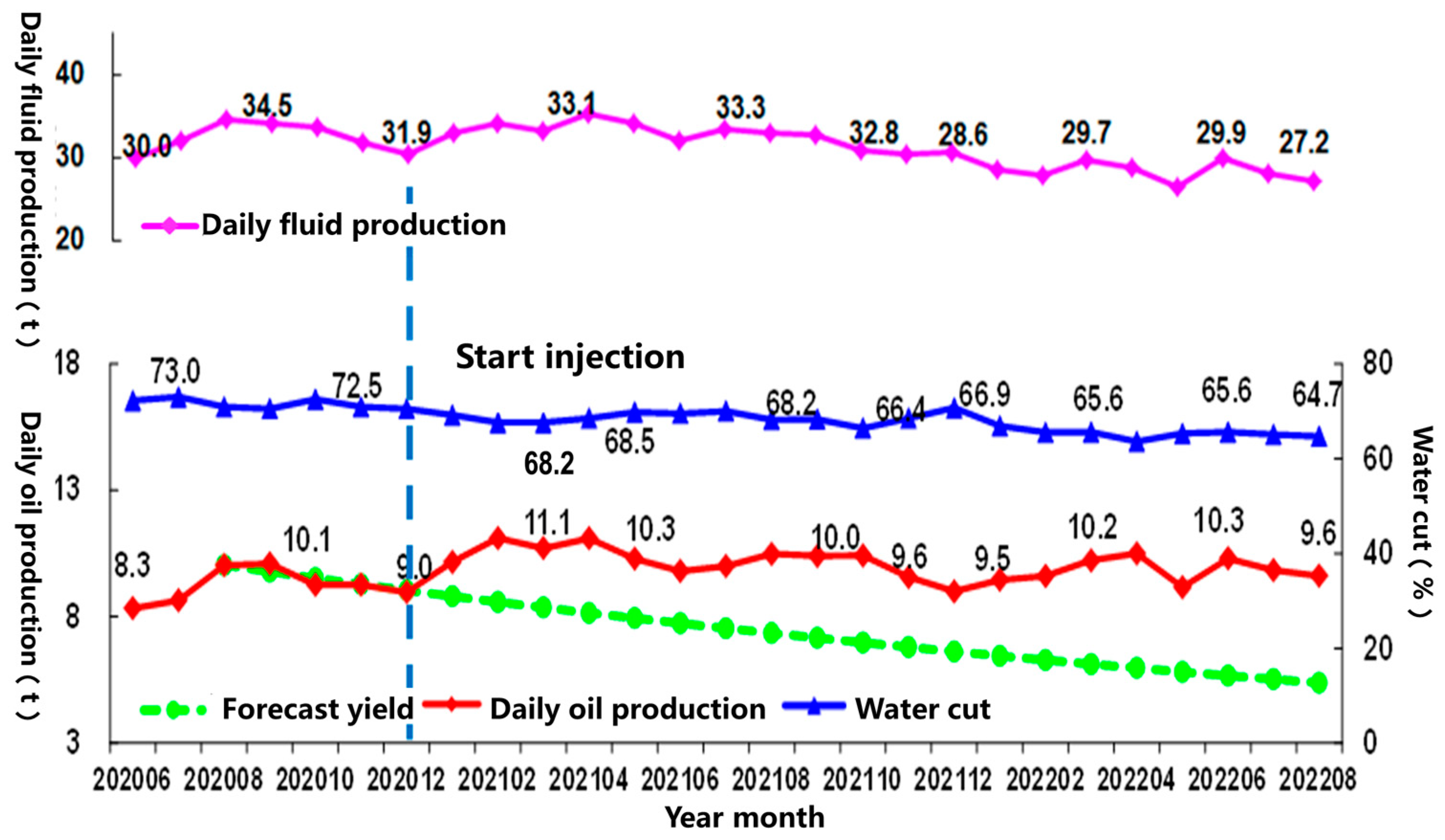

3.3.2. Technologies for Changing Water Flooding Mode in Ultra-Low-Permeability Reservoirs

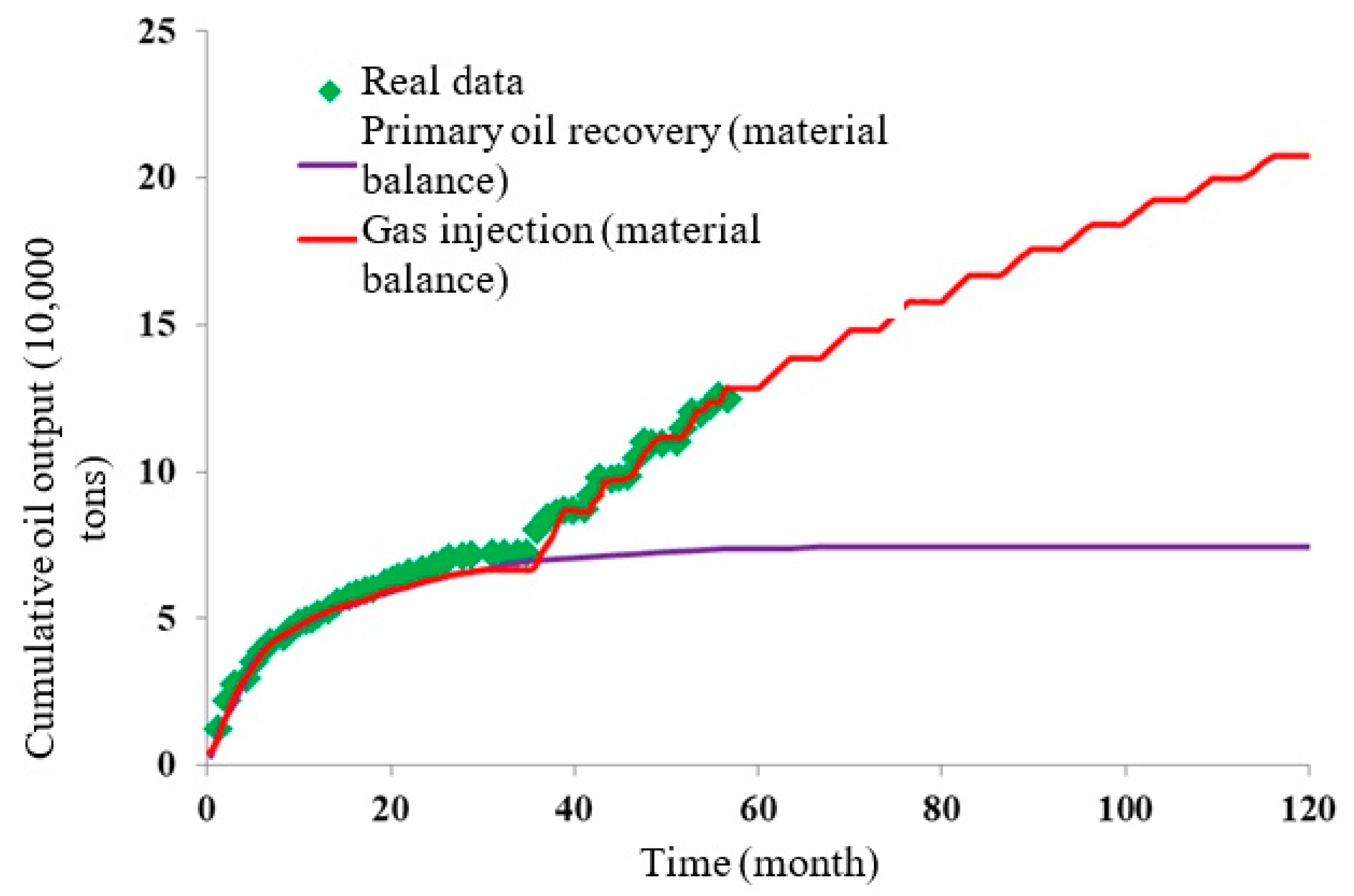

3.3.3. “Secondary-Tertiary Combination” Technologies

4. Technical Countermeasures and Development Directions

4.1. Tackling of Problems in Benefit-Driven Development Technologies for Difficult-to-Produce Reserves

4.1.1. Design of All-Factor Life-Cycle Development Schemes

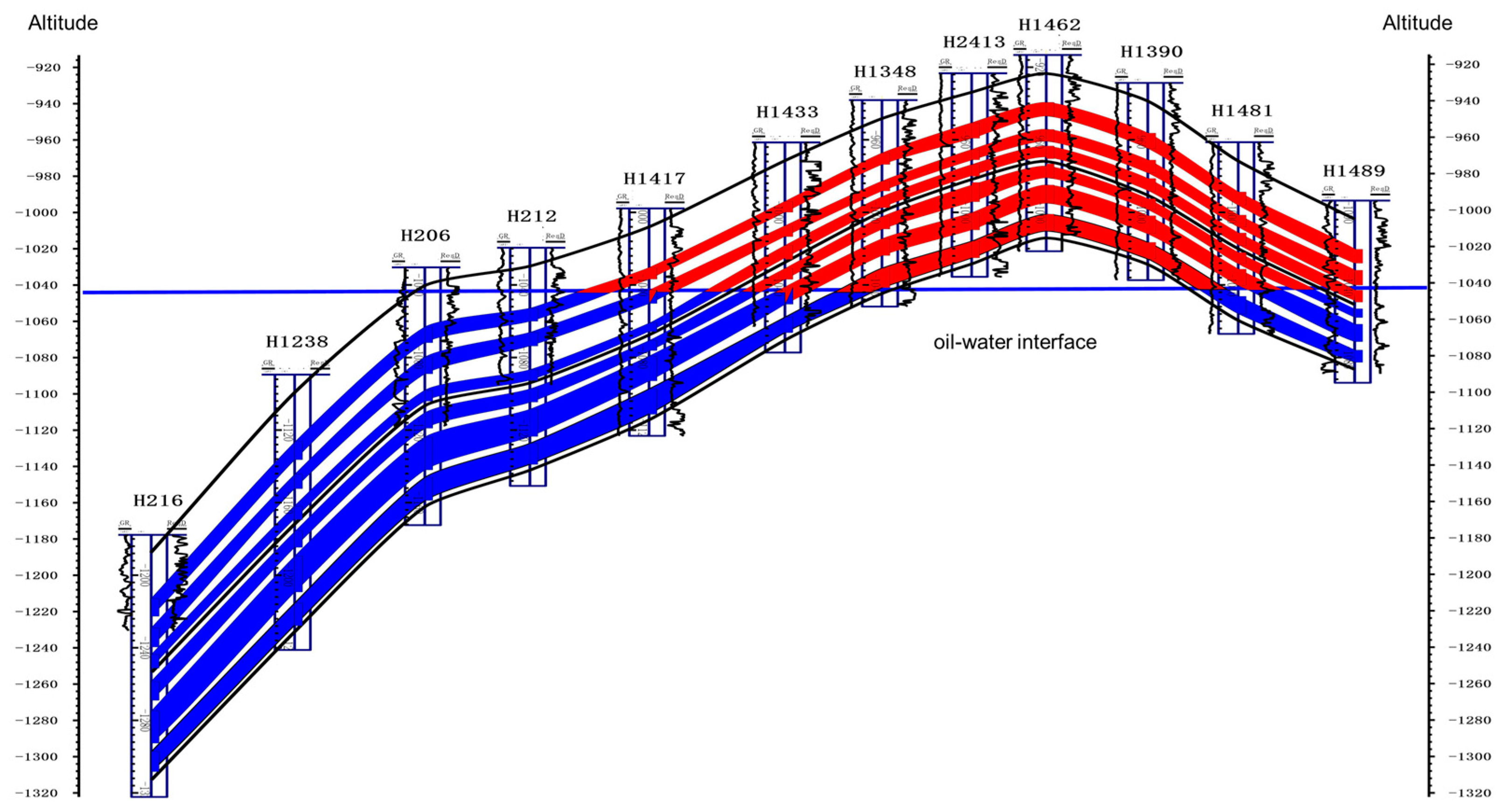

4.1.2. Gas Injection and Energy Supplement Development Technologies in New Fields

4.1.3. Technologies Greatly Increasing Single-Well Output

4.2. Development and Improvement of Water Flooding Technologies

4.2.1. Fine Reservoir Description Technologies

4.2.2. Functional Water Flooding Technology

4.2.3. Nano Intelligent Water Flooding Technology

4.3. Reserve Technologies Greatly Enhancing Oil Recovery

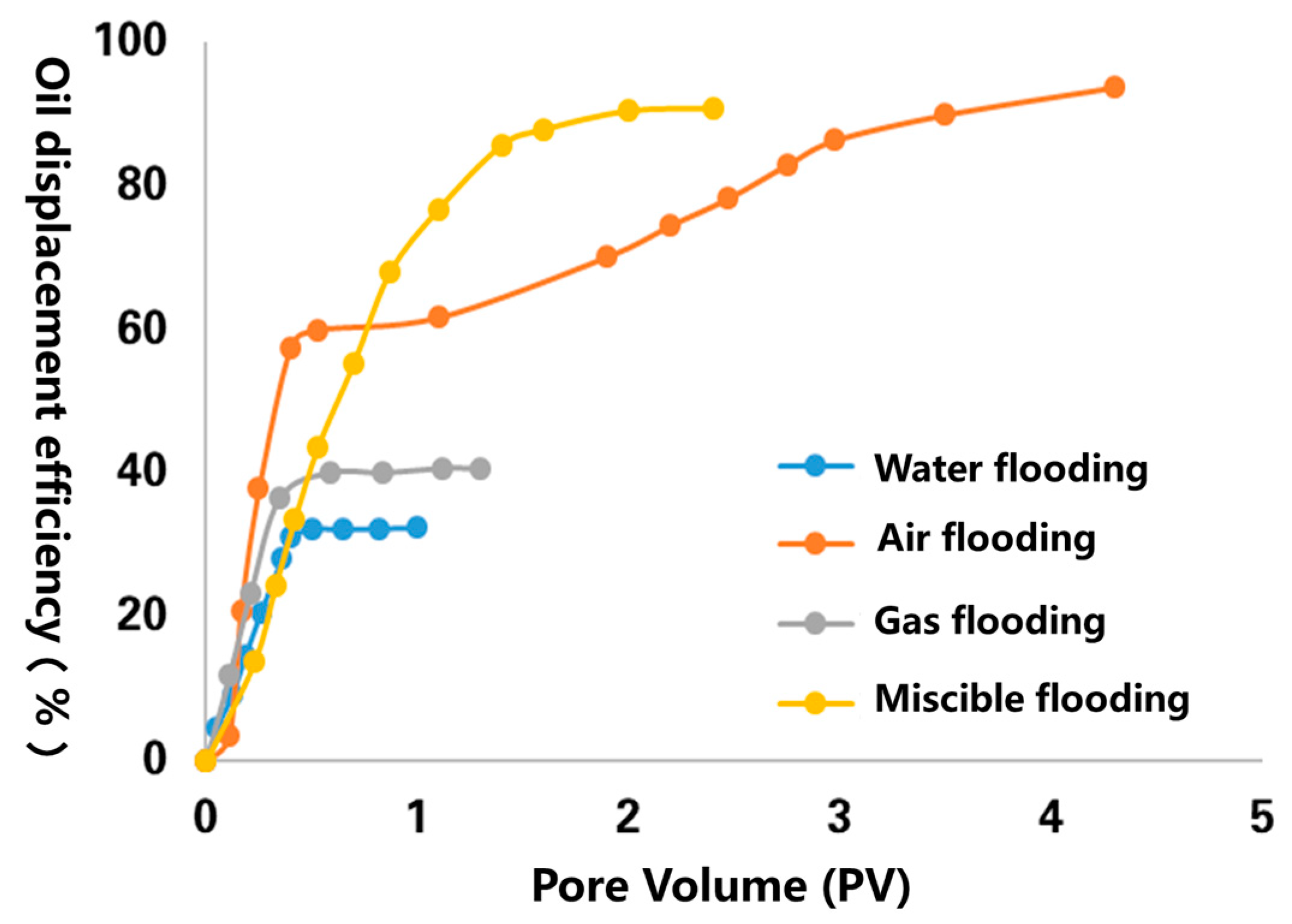

4.3.1. Gas Flooding EOR Technologies

4.3.2. Middle-Phase Microemulsion Flooding Technology

4.3.3. Air Injection Thermal Miscible Flooding Technology

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yuan, S.; Wang, Q. New progress and prospect of oilfields development technologies in China. Pet. Explor. Dev. 2018, 45, 657–668. [Google Scholar] [CrossRef]

- Jia, C.; Pang, X.; Jiang, F. Research status and development directions of hydrocarbon resources in China. Pet. Sci. Bull. 2016, 1, 2–23. [Google Scholar]

- Li, D. The Development of the Low Permeability Sandstone Oil Field; Petroleum Industry Press: Beijing, China, 1997. [Google Scholar]

- Hu, W. The present and future of low permeability oil and gas in China. Eng. Sci. 2009, 11, 29–37. [Google Scholar]

- Hu, W.; Wei, Y.; Bao, J. Development of the theory and technology for low permeability reservoirs in China. Pet. Explor. Dev. 2018, 45, 646–656. [Google Scholar] [CrossRef]

- Zhao, L.; Zou, C.; Guo, Y.; Han, J.; Wang, H. Fine Water Flooding Efficiency Improvement. Technology for Lowpermeability Reservoirs and Its Application. Pet. Sci. Technol. Forum 2023, 42, 67–76. [Google Scholar]

- Liao, G.; He, D.; Wang, G. Discussion on the limit recovery factor of carbon dioxide flooding in a permanent sequestration scenario. Pet. Explor. Dev. 2022, 49, 1262–1268. [Google Scholar] [CrossRef]

- Wilberforce, T.; Olabi, A.G.; Sayed, E.T.; Elsaid, K.; Abdelkareem, M.A. Progress in carbon capture technologies. Sci. Total Environ. 2021, 761, 143–203. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Li, Y.; Ma, Q. Development of carbon capture, utilization and storage technology in China. Strat. Study CAE 2021, 23, 70–80. [Google Scholar] [CrossRef]

- Hu, Y.; Hao, M.; Chen, G. Technologies and practice of CO2 flooding and sequestration in China. Pet. Explor. Dev. 2019, 46, 716–727. [Google Scholar] [CrossRef]

- Chen, X.; Li, Y.; Liao, G. Experimental investigation on stable displacement mechanism and oil recovery enhancement of oxygen-reduced air assisted gravity drainage. Pet. Explor. Dev. 2020, 47, 780–788. [Google Scholar] [CrossRef]

- Zhao, X.; Chen, Z.; Wang, B.; Liao, X.; Li, D.; Zhou, B. A Multi-medium and Multi-mechanism model for CO2 injection and storage in fractured shale gas reservoirs. Fuel 2023, 345, 128167. [Google Scholar] [CrossRef]

- Wang, Z.; Cao, G.; Bai, Y.; Wang, P.; Wang, X. Development Status and Prospect of EOR Technology in Low-Permeability Reservoirs. Spec. Oil Gas Reserv. 2023, 30, 1–13. [Google Scholar]

- Wang, G. Carbon dioxide capture, enhanced-oil recovery and storage technology and engineering practice in Jilin Oilfield, NE China. Pet. Explor. Dev. 2023, 50, 219–226. [Google Scholar] [CrossRef]

- Li, H.; Hu, Y.; Zou, C. Research progress on optimization technologies of secondary-tertiary combination in high water cut reservoir. Sci. Technol. Eng. 2018, 18, 210–220. [Google Scholar]

- Daniel, O.; Roberto, A.; Karthik, S. Material Balance Forecast of Huff-and-Puff Gas Injection in Multiporosity Shale Oil Reservoirs. In Proceedings of the SPE Canada Unconventional Resources Conference, Calgary, AB, Canada, 13 March 2018. SPE-189783-MS. [Google Scholar]

- Bhatti, A.A.; Raza, A.; Mahmood, S.M.; Gholami, R. Assessing the application of miscible CO2 flooding in oil reservoirs: A case study from Pakistan. J. Petrol. Explor. Product. Technol. 2019, 9, 685–701. [Google Scholar] [CrossRef]

- Wang, G.; Qin, J.; Sun, W. CCUS Cases Analysis and Industrial Development Suggestions; Chemical Industry Press: Beijing, China, 2020; pp. 16–18. [Google Scholar]

- Li, Z.; Li, S.; Liao, G.; Tian, C. Practice from Significant Experiment on Effective Development of Changqing Ultra-low Permeability Reservoirs. Pet. Sci. Technol. Forum 2021, 40, 1–11. [Google Scholar]

- Hui, G.; Chen, S.; He, Y.; Wang, H.; Gu, F. Production forecast for shale gas in unconventional reservoirs via machine learning approach: Case study in Fox Creek, Alberta. J. Nat. Gas Sci. Eng. 2021, 94, 104045. [Google Scholar] [CrossRef]

- Hui, G.; Chen, Z.; Wang, Y.; Zhang, D.; Gu, F. An integrated machine learning-based approach to identifying controlling factors of unconventional shale productivity. Energy 2023, 266, 126512. [Google Scholar] [CrossRef]

- Xu, J.; Wu, K.; Yang, S.; Cao, J.; Chen, Z.; Pan, Y.; Yan, B. Real gas transport in tapered noncircular nanopores of shale rocks. AIChE J. 2017, 63, 3224–3242. [Google Scholar] [CrossRef]

- Ding, Y.; Li, B.; Li, J.; Chen, S.; Song, H.; Duan, S.; Zeng, X. Study of Changes in Apparent Permeability in Shale’s Complex Microfracture Networks. Ind. Eng. Chem. Res. 2023, 62, 13687–13700. [Google Scholar] [CrossRef]

- Xu, J.; Wu, K.; Li, R.; Li, Z.; Li, J.; Xu, Q.; Li, L.; Chen, Z. Nanoscale pore size distribution effects on gas production from fractal shale rocks. Fractals 2019, 27, 1950142. [Google Scholar] [CrossRef]

- Chen, H.; Li, S.; Deng, X. Advances in the study of fine reservoir description in low permeability oilfield. Sci. Technol. Eng. 2018, 18, 129–142. [Google Scholar]

- Luo, J.; Ding, B.; Yan, Y. Molecular dynamics simulation of adsorption behavior of alkyl-modified SiO2 nanoparticles at oil/water interface. J. China Univ. Pet. (Ed. Nat. Sci.) 2015, 39, 130–136. [Google Scholar]

- Wu, J.; Han, H.; Wang, B. Interaction of reservoir oil/water/rock and EOR method of ion matching in low permeability reservoir. J. China Univ. Pet. (Ed. Nat. Sci.) 2023, 47, 116–124. [Google Scholar]

- Xi, C.; Wang, B.; Zhao, F. Oxidization characteristics and thermal miscible flooding of high pressure air injection in light oil reservoirs. Pet. Explor. Dev. 2022, 49, 760–769. [Google Scholar] [CrossRef]

| Development Classification | Number of Oil Reservoirs Evaluated | Developed Geological Reserves (10,000 Tons) | Developed Recoverable Reserves (10,000 Tons) | Annual Oil Output (10,000 Tons) | Proportion of Geological Reserves (%) | Proportion of Output (%) | Comprehensive Water Cut (%) | Percentage Recovery of Recoverable Reserves (%) | Dynamic Recovery (%) |

|---|---|---|---|---|---|---|---|---|---|

| Class I | 21 | 18,773 | 5061 | 83 | 2.5 | 2.4 | 51.1 | 57.6 | 27.0 |

| Class II | 29 | 47,853 | 11,694 | 337 | 6.5 | 9.9 | 71.0 | 66.6 | 24.4 |

| Class III | 114 | 244,708 | 50,504 | 1232 | 33.2 | 36.1 | 66.1 | 55.1 | 20.6 |

| Class IV | 189 | 426,706 | 73,873 | 1764 | 57.8 | 51.6 | 72.4 | 51.7 | 17.3 |

| Total | 353 | 738,039 | 141,132 | 3415 | 100.0 | 100.0 | 69.9 | 54.4 | 19.1 |

| Item | High-Level Development Scheme of First-Class Companies in Foreign Countries | Present Situation of Development Schemes in China |

|---|---|---|

| Basic research time in the early stage | 3–5 years | 1–3 years |

| Basic data situation | Comprehensive, detailed and complete | Relatively detailed, but sometimes incomplete due to short time. |

| Scheme design mode | Whole life cycle schemes, with a designed development period of as long as 50–80 years, and a stable production period of 20–30 years. | Focus on production in the first 3–5 years, with little attention to the countermeasures for the uncertain situations that will occur after 15 years. |

| Parameter optimization demonstration process | Comparison of each parameter under more than 5 situations, and repeated argumentation with iterative correction. | Comparison of each parameter under three situations mostly, and one-way circulation workflow mode without continuous correction |

| Scheme review and implementation | Rigorous process review and rigid implementation | Focus on result review, with frequent adjustments during implementation |

| Implementation effect | The ratio of targeting is greater than 90% | The ratio of targeting is 65–85%, and the contribution rate is 35–45% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, J.; Hao, M.; Chen, Y.; Li, B.; Liu, Z.; Liu, Y.; Xu, J. Advancing PetroChina’s Development Strategies for Low-Permeability Oil Reservoirs. Processes 2024, 12, 351. https://doi.org/10.3390/pr12020351

Cao J, Hao M, Chen Y, Li B, Liu Z, Liu Y, Xu J. Advancing PetroChina’s Development Strategies for Low-Permeability Oil Reservoirs. Processes. 2024; 12(2):351. https://doi.org/10.3390/pr12020351

Chicago/Turabian StyleCao, Jun, Mingqiang Hao, Yujia Chen, Baozhu Li, Zhuo Liu, Yang Liu, and Jinze Xu. 2024. "Advancing PetroChina’s Development Strategies for Low-Permeability Oil Reservoirs" Processes 12, no. 2: 351. https://doi.org/10.3390/pr12020351