1. Introduction

This article focuses on the abnormal operation of a pumping station, which represents a complete hydraulic system equipped with several pumps, connecting piping and the suction and discharge objects. The analysis is based on the numerical simulation of multiphase flow with the free water level.

Ordinarily, the suction objects are equipped with the draft tubes, to which the pumps are connected, or in the case of the application of vertical pumps, the open sump intake design is applied, in which the pumps are equipped with some form of suction bells. In this study, the vertical mixed-flow pumps with the suction bells are mounted inside the intake objects with a free level and separated with the concrete walls. There are many experimental and numerical studies concerning the free-surface flows close to the pump sump with such an arrangement during the pumping regime. First of all, the operation of pumps is very sensitive to the vortical structures entering the impeller. In the case of vertical pumps with the suction bells, both the free surface vortices and the submerged vortices can be often observed as a result of the pressure drop and the pre-rotation flow in the vicinity of the pump suction. They cause many unwanted effects as the unsteady nonuniform flow resulting in the impeller vibrations or the cavitation effects in the vortex core. The free surface vortices are particularly undesirable, as they can cause the danger of air entrainment from the free surface. Increasing the submergence value is a typical way to avoid these vortices because they are directly related to the submergence value. Anti-Vortex Devices (AVDs) are frequently used to suppress both the free surface vortices and the submerged vortices [

1,

2]; they can significantly decrease the angular momentum of flow. It is very important to predict the operation conditions when the above-mentioned phenomena take place and then to prevent their formation. That is why these phenomena are widely examined both numerically and experimentally [

3,

4,

5,

6,

7,

8,

9,

10,

11]. Due to the time and financial costs, Computational Fluid Dynamics (CFD) methods prevail. Most of the available studies are devoted to the pumping regime, but there are practically no studies linked to the turbine or abnormal regimes, especially in the case of the vertical pumps with suction bells and the presence of AVD.

Though the discharge objects are less important in this study, they are included in the case description. Two hydraulic designs of the discharge are considered, as they are favored for safety reasons and can be easily installed and operated, with minimum mechanical and electronic equipment. The first solution is based on the overflow walls, and the second one is based on the siphon outlets. According to the authors’ knowledge, there are few works dealing with the numerical simulations of the supercritical and especially near-critical flows over the overflow walls. Interesting results can be found, e.g., in [

12,

13,

14,

15], considering the broad-crested and sharp-crested weirs with a 2D geometry, or [

13] considering the side weir. The modeling of a complete pump station with a V-shaped broad-crested weir can be found in [

16]. Compared to the overflow walls, siphons offer a possibly higher hydraulic efficiency, but a siphon-breaking valve is required to prevent back-flow and allow for venting at start-up. Numerical simulations of a complete pumping system with the siphon outlet, modeling the flow as the single-phase one, are presented in [

17]. The complex models, also considering the free water level, can be found in [

18], where the transient phenomena during the stopping process in the axial-flow pump system with the siphon outlet are simulated, or in [

15], which models the transient phenomena during the start-up phase of the complete pumping station with the welded siphon. A combined experimental and numerical research of the siphon flow applying both the CFD tools and the lattice-Boltzmann method is described in [

19,

20]. The numerical simulations considering the multiphase flow with the free water level commonly use the VOF (Volume of Fluid) model [

21]. This multiphase flow model solves the equation for the volume fraction of the liquid component and does not take into account the formation of individual water particles or air and water vapor bubbles and their interactions.

After the pump is accidentally switched off or the electric power is lost due to the failure and the (possibly existing) valve fails, both in the case of overflow walls and the siphon discharge, the water gradually stops to flow up and due to the gravity forces starts to flow back to empty the discharge piping. This may not be a serious problem when a short discharge piping contains a small, limited amount of water. But in the case of the discharge piping with the diameter in meters and length in kilometers, a large amount of water returns back to the suction basin with the serious water waves and flooding capacity. Also, the time necessary to empty the discharge piping can be very long. During this process, the pump gradually changes its operation regime from the pump one (when the pumped water flows inside the pump from its suction side to the discharge piping while the pump shaft rotates in the pump direction) to the no-load turbine conditions when the water flows from the discharge piping to the pump suction while the pump shaft rotates close to the turbine runaway speed. During this time span, the brake regime has to be considered when the pumped water flows inside the pump from its discharge piping to the suction side while the pump shaft rotates in the pump direction. The achieved shaft speed is very important for the pump, the gear box and the motor and its cooling. Also, the achieved flow rates are important to design the suction basin and its surroundings.

To be able to analyze the pump performance during the accidental shutdown, a large part of the full 4-quadrant behavior must be known, typically in the form of the dimensionless variables. The advantage of the creation of a dimensionless representation of the 4-quadrant characteristics is a possibility of repeated calculations for different cases and initial states, without the necessity of repeated CFD simulations, which are very expensive and CPU-time-consuming. On the other hand, using the 4-quadrant characteristics, one must rely on the validity of the hydraulic affinity laws and should be careful of their range. There are many references related to the 4-quadrant characteristics, with the classical form of the dimensionless variables [

22,

23,

24,

25] or with different modifications, e.g., in the form of the Suter curves [

26]. Also, the range of utilization of the 4-quadrant characteristics is very broad in PAT (Pump as Turbine) applications, from the PAT turbine startup [

27,

28,

29], through the pump–turbine transition [

30,

31], up to the “S” zone close to the turbine runaway conditions, where the so-called S-instability occurs [

32,

33,

34,

35,

36,

37]. The simulation of pump performance during the accidental shutdown can be found, e.g., in [

38], where a large vertical mixed-flow pump with a draft tube is modeled inside the commercial CFD software ANSYS Fluent with the angular momentum acting on the impeller updated in each time step by a User-Defined Function (UDF), or in [

39], where the runaway and runaway shutdown processes of the tubular turbine inside the circulating cooling water system are simulated based on the combination of CFD and the method of characteristics (MOC) and also using the Fluent UDF. The process of power failure in the case of the submersible tubular pump is also solved in [

40] using the direct combination of the Fluent code and the 6DOF model based on the fourth-order multi-point Adams–Moulton formula. Numerical simulations of the bidirectional transition from the pump to turbine modes and back can be found in [

41], where, in the process of a transient simulation, the torque balance equation is applied for calculating the rotational speed of the impeller through the Fluent UDF.

References dealing with the S-instability mentioned above indicate a close relation of this instability to the complex pattern of vortical structures appearing especially inside the runner. A detailed analysis of the vortex evolution in the runner of a PAT under the runaway conditions combined with an experimental verification can be found in [

42], while in [

43], an advanced experimental research on flow fields inside the pump–turbine by means of the Particle Imaging Velocimetry (PIV) is presented in combination with the full-flow numerical simulation. The Delayed Detached-Eddy Simulation (DDES) is applied in [

44] to the analysis of the transient vortices in the runner and the draft tube of a PAT during the S-instability. All these studies confirm very unfavorable flow conditions linked with the S-shaped curve. The complexity of the flow conditions can even be increased by the presence of the free water level. A detailed view of complex vortical structures interacting with the free water level inside a very low head (VLH) turbine in an open channel under no-load conditions can be found in [

45].

As it has been already mentioned at the beginning of this section, the aim of this paper is to describe the abnormal situation of when the pump trip appears, but the paper also aims to present a methodology which can be successfully applied to monitor various critical regimes in the pumping station in real time. Against the above background, the paper is composed as follows.

Section 2 presents, in detail, the study case and the methods used within the CFD analysis and the 1D dynamic model.

Section 3 shows key differences in the flow fields during the most important operating modes of the pumps, equipped with the suction bells and AVD, derived complete 4-quadrant characteristics and the results of the simulation of the station power cut event. The obtained data and the applicability of the presented methodology are discussed in the Discussion and Conclusions sections.

2. Materials and Methods

2.1. Case Description

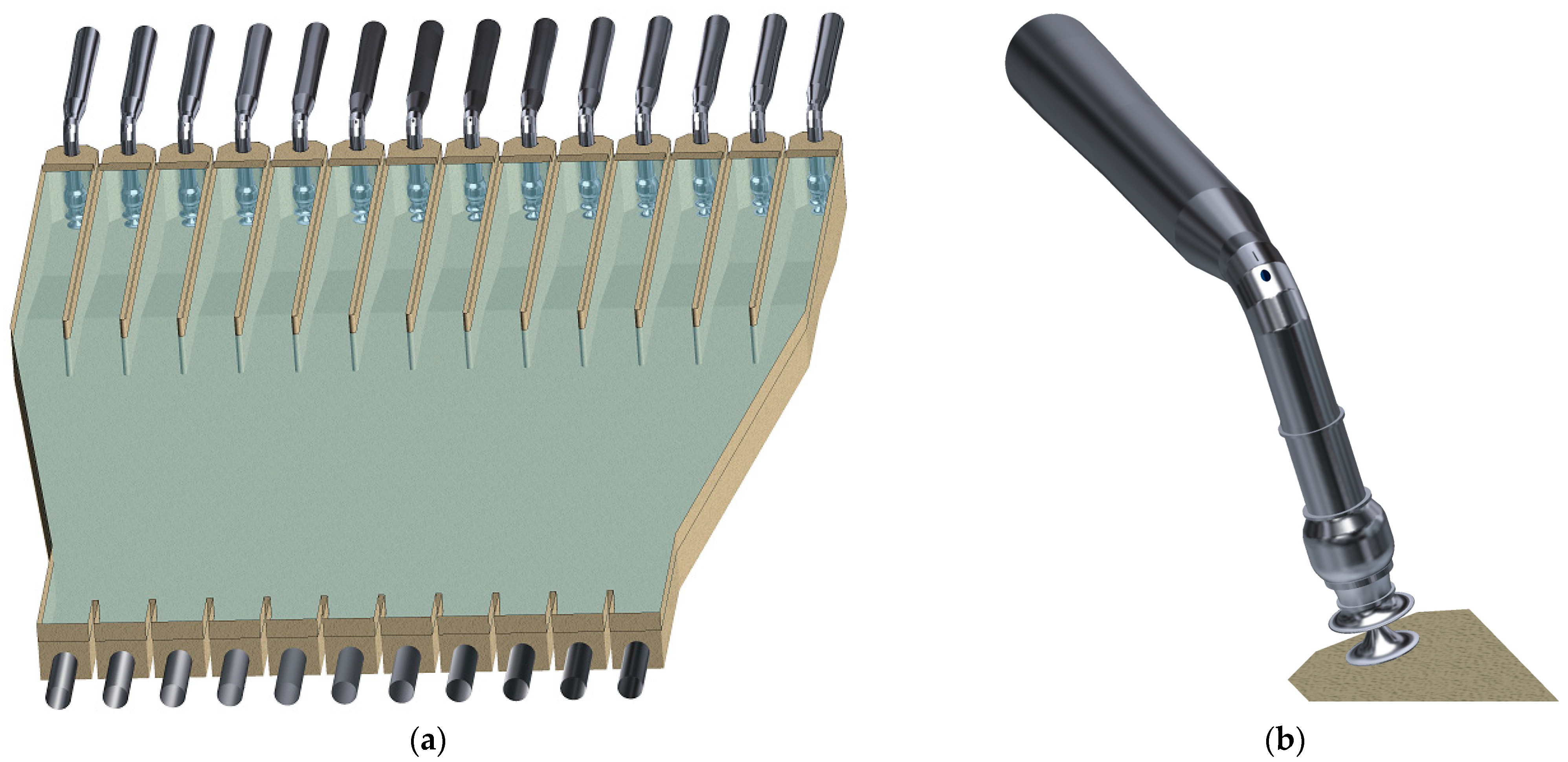

This study deals with a virtual pumping station operating a set of 14 mixed-flow pumps with a nominal flow rate

Q = 10.29 m

3/s and speed of 400 rpm. These pumps are installed in the suction/intake object, each in its own basin bounded by the concrete pillars (

Figure 1a). The width of the basin between the pillars is 5 m and the thickness of the pillars is 0.6 m (

Figure 1a). The Low Water Level (LWL) is 6.65 m above the floor at the position of pump. Details of the pump design are shown in

Figure 1b and

Figure 2a. The pump with a specific speed

nq = 94 has an impeller with five blades and a stator with nine vanes. The pump is equipped with a suction bell and an anti-rotating device, represented by a cone with one vane mounted on the downstream side of the cone. Behind the pump casing, a welded 90° elbow is installed. Each pump is connected with the discharge object by the piping 2970 m long, with a diameter of DN 2500, ending with a welded siphon (

Figure 3) equipped with two siphon-breaking valves. The piping has a complicated altitudinal scheme with the maximum difference of the static head of 27.83 m. The shape of the considered terrain is not flat or simply inclined, and the piping must copy the ground. For this reason, the altitudinal scheme in

Figure 4 is divided into several intervals with significant slant changes. Three intervals are ascending (corresponding to the pump convention) while the other three are descending. At about 42% of the horizontal distance, the piping reaches nearly the same relative spot height (26 m) as the discharge object.

The volume of water inside one piping is approximately 14,580 m3, which makes the overall volume of water in the discharge piping system about 204,120 m3, which would return to the suction object in the case of an accidental shutdown.

In this study, the following definition of the dimensionless speed

nED, the dimensionless flow rate

QED and the dimensionless torque

TED is used [

46], as described in equation system (1):

where

n is the rotor speed [rpm],

D is the impeller diameter [m],

H is the head [m],

Q is the flow rate [m

3/s] and

T is the torque [Nm].

2.2. Computational Domain and CFD Analysis Settings

Calculations are based on the unsteady Reynolds-Averaged Navier–Stokes equations (URANS):

where

Ui are the Reynolds-averaged velocity components in the 3D Cartesian coordinate system,

ρ is the fluid density,

P is the Reynolds-averaged static pressure,

μ is the dynamic viscosity,

μt is the turbulent viscosity obtained from the turbulence model and

SM is the general momentum source term (here, representing the gravity forces).

The SST turbulence model has been applied. It blends the standard

k-ε and

k-ω models using two blending functions (

F1 and

F2) which are dependent on the dimensionless wall distance. The turbulence model can be described by the following governing equations:

where

is the turbulence production term,

k is the turbulent kinetic energy and

ω is the turbulent frequency. The turbulent viscosity is described in the following formula:

where

S is the strain rate. During the last two decades, the SST model became a highly valued turbulence model for a wide range of industrial applications. It is very robust and enables us to solve problems with high adverse pressure gradients and separated and swirling flows. More details of the Menter’s SST model, including a definition and discussion of the blending functions and all used constants (

a,

β,

σ,

γ), can be found in [

47,

48].

There are two computational domains for the CFD analysis: the suction object including all pumps (

Figure 1 and

Figure 2) and the discharge object with all siphons (

Figure 3). These two domains are linked with the 1D dynamic model representing the pipeline shown in

Figure 4. In reality, the discharge domain is necessary only for the simulations of flow in the pump and reverse pump modes when the pressure losses inside the siphon and in the water jet behind the siphon outlet influence the pump performance curves. With the reversed water flow during the brake/dissipation I mode, the turbine mode, the runaway mode and the break II mode, only the link between the CFD analysis of the suction object and the 1D dynamic model representing the pipeline is considered. There are also the remaining modes of the full 4-quadrant behavior: the brake III mode, the reverse turbine mode and the brake IV mode; these are the artificial modes, which could be reached only inside a special test rig. This is why these modes were simulated in this study in the configuration which corresponds to the closed experimental test rig, as shown in

Figure 5. Of course, in this case, the computational domain does not include the complete test rig, and the main tank and fittings are replaced by the straight pipes in front of the pump and behind the elbow so as to set the boundary conditions correctly.

Figure 6 shows the computational scheme for the determination of the full 4-quadrant representation. A total of 128 operating points were used to cover all the eight modes and identify the runaway operation regime.

The grids of the computational domains were created using the ANSYS ICEM CFD software (Release 2020 R1) as the multi-block ones and represent about 84 mil. grid nodes for the suction object (including pumps) and about 36 mil. grid nodes for the discharge object (

Figure 7). When optimizing the grids, it should be taken into account that very complex flow phenomena appear in the computational domain, changing their character and location based on different performance modes. In fact, it was not possible to carry out a typical grid-dependence study relating simply to the number of grid points for all the performance modes. Because the topology and overall quality of the grid are the most important in these simulations, the parameters like the aspect ratio and skewness as well as the near-wall grid resolution were preferred during the optimization, and the meshes were limited in their size just by the requirement to be able to work within the computer operating memory of 1 TB.

The presented CFD analysis was performed with the ANSYS CFX software (Release 2020 R1) [

49]. The high-resolution scheme was used for the momentum equations, while the turbulence numerics was based on the first-order scheme. The time discretization was of the second order and used the backward Euler scheme. The multiphase capability was used to model the flow inside the compound, including the free water level. The numerical solution of the free-surface flow was carried out by means of the VOF method. Pumps were modeled with all hydraulic surfaces (

Figure 2a) and with the impeller tip clearance. The SST model was applied with an automatic wall treatment. The Multiple Frame of Reference (MFR) capability in which different domains are rotating relative to one another and the fully-unsteady model of flow (known usually as the Transient Rotor–Stator or the Sliding Mesh) inside the entire pump were used to capture the interactions between the stationary parts inside the pump set and the rotating components. The time steps for the rotation speeds above 300 rpm corresponded to the rotor revolution by 2°; consequently, one rotor revolution represented 180 time steps. For lower rotational speeds, time steps were proportionally decreased to capture the flow dynamics sufficiently. The residuals of the primary variables were set to 10

−4, and the integral values (like head, power input/output, mass flow rate, axial and radial forces) were also evaluated during the time steps in order to monitor the convergence and periodicity of the unsteady solution.

The boundary conditions in the suction object were specified as follows: for the pump and the reverse pump modes, the same velocity and turbulent kinetic energy and its dissipation rate were prescribed at the suction tubes (eleven located at the basin inlet) according to the flow rate and the estimated turbulence intensity and eddy length scale. At the outlets (ends of fourteen pipes behind pumps), the same pressure outlet boundary condition was set for all running pumps. Two transient rotor–stator interfaces were located between the suction object and the impeller and between the impeller and the diffuser of each pump. In the rotating domain, the impeller shroud was treated as the counter-rotating wall. The pump and piping metal walls are supposed to be smooth but all concrete walls of the suction and discharge objects were treated as rough ones, with an equivalent sand roughness of 2 mm. For the brake I, brake II and turbine modes, at each pump discharge piping (behind the elbow), the total pressure, the velocity direction normal to the boundary and the turbulence intensity and its dissipation rate were prescribed. At the suction tubes entry, the same static pressure was set as the outlet condition. For the brake III, brake IV and reverse turbine modes, at the pump discharge piping, the total pressure, the velocity direction normal to the boundary and the turbulence intensity and its dissipation rate were prescribed. At the pump inlet piping entry (

Figure 5a), the mass flow rate was set as the outlet condition.

The boundary conditions in the discharge object were specified as follows: at the tubes (fourteen located in front of the siphons), the same velocity and turbulent kinetic energy and its dissipation rate were prescribed according to the flow rate and the estimated turbulence intensity and eddy length scale. At the outlet of the basin, the pressure outlet boundary condition was set with respect to the buoyancy and gravity forces.

2.3. 1D Dynamic Model

The 1D dynamic model, based on MOC, links the suction object with pumps (

Figure 1 and

Figure 2) and the discharge object (

Figure 3). As it was already mentioned, for the pump trip event, the discharge domain is necessary only during the simulations of flow in the pump mode because during the time necessary to empty the discharge piping (the brake I and the turbine modes, or in the vicinity of runaway regime), water from the discharge object does not influence the 1D transient analysis. Still, all the piping with the content of water is considered, including the hydraulic losses caused by the friction on the piping walls. The dynamic model also takes into account the inertia of the pump, the electric motor and the gear box given by their manufacturers. The MOC basic scheme is expressed as follows:

where

n is the speed,

T is the total rotor torque and

J is the total moment of inertia. The calculation starts with the steady flow rate corresponding to the pumping station design point. After the accidental shutdown, the following computational scheme is adopted (

Figure 8) using the precalculated 4-quadrant characteristics:

There are some important sections of the flow analysis due to time. The first section starts with the pump operating in the pump mode (at the design point) and ends with the shut-off point, in which the pump flow rate reaches zero and the delivery head is the same as the station static delivery head. In this section, the inertia of the water mass and rotating inertia of the pump, the electric engine and the gearbox play the most important role.

The second section represents the break regime. The gravitational forces acting on the water as well as the machine’s mechanical losses decrease the shaft’s rotational speed. At the end of this section, the rotation of the impeller stops to prepare the PAT regime. The inertia of the pump, the electric engine and the gearbox play the most important role at this stage, but still, the inclination of the discharge piping just in front of the discharge object is very important, as well.

The third section represents the turbine regime. The water flowing in the opposite direction generates a torque, which is not efficiently utilized, and the shaft speed is typical for the water turbine. The turbine characteristics of the machine play the most important role at this stage. At the end of this section, the torque of the impeller reaches zero, and the runaway speed is reached.

In the fourth, the longest section, the pump works close to the turbine runaway operating regime. Of course, there are also the mass inertia and mechanical losses, which influence the real operating points, but the time scales are quite large and the changes in the shaft speed are less significant. The mechanical losses inside the pump, the electric engine and the gearbox play the most important role at this stage.

4. Discussion

After a pump is accidentally switched off or electric power is lost due to failure and the (possibly existing) valve fails, a large amount of water returns back to the suction basin with serious water waves and a flooding capacity. In the presented case, a set of 14 mixed-flow pumps is installed in the suction/intake object, and the volume of water inside one piping is approximately 14,580 m

3, which makes the overall volume of water in the discharge piping system about 204,120 m

3, which would return to the suction object in the case of an accidental shutdown. As it can be seen in

Figure 30b, a tsunami with a flow rate of more than 140 m

3/s appears some 15 min after the power failure. Also, the achieved shaft speed is very important for the pump, the gear box as well as for the motor and its cooling. There are two time intervals when the speed of PAT exceeds 500 rpm (which is assessed as the limit for the long-term operation). The first one starts about 19 s after the power failure and takes about 48 s. The second one is much longer. Due to a complicated altitudinal scheme of the discharge piping, it starts about 23 min after the power failure and takes about 4.3 min. These time intervals can be very important for the selection of the gear box as well as for the electric motor.

The key issue in the link between the CFD and 1D dynamic models is the interpolation process and a smooth transition between different pump performance modes (or points, in which the performance curve stops to act as a function). Both piecewise representations of the 4-quadrant characteristics (e.g., QED(nED) and nED(QED), the same for torque) are necessary for an appropriate evaluation; or a piecewise representation QED(s), TED(s) and nED(s) can be used with an artificial parameter s. Both methods were tested; the second one is slightly faster, nevertheless MOC is much faster than the CFD part of the simulations, and the speed of interpolation plays a minor role. Very important is the algorithm selecting the correct branch of the S-shaped curve because when the pump works close to the turbine runaway operating regime, due to the mass inertia and mechanical losses, the real operating points oscillate between the Turbine and Brake2 modes. In this algorithm, some more factors (e.g., the change in the piping inclination) should be considered.

A very important part of the numerical simulation is the possibility to verify the results with the experimental data. In the presented study, there was an intention to verify the possibility of the CFD simulation to capture the instabilities in the 4-quadrant characteristics. Of course, it is very difficult to realize the complete measurements of all eight modes of the characteristics. This is why the comparison of the experimental and numerical results was performed for the pump regime, which experiences instability in the suboptimal flow rates. The experiment was realized in the hydraulic laboratory of the SIGMA Research and Development Institute with a model pump (impeller diameter of 306 mm). The test rig enabled us to measure model pumps with a power input of up to 400 kW, but at the moment, only the pump regime was supported by the test rig equipment. The magnetic-inductive flowmeter of the accuracy class of 0.2% was applied to measure the volume flow rate. For all measurements of the pressure differences, the pressure transducers were used. They worked in the accuracy class of 0.04%. The temperature of the water was measured with the platinum thermometer in the accuracy class of 0.5%. The evaluation of the power input was based on measurements of the torque and shaft speed by means of the torque transducer in the accuracy class of 0.1.

Figure 30 shows the comparison of numerically and experimentally obtained characteristics

nED(

QED) and

TED(

QED) with the signum of the dimensionless variables corresponding to the pump convention. It can be seen that there are differences in the dimensionless speed of less than 1% in the stable part of the curve and up to 3% in the unstable region. The dimensionless torque shows differences of about 3.5% in the stable part of the curve and up to 9% in the unstable region. These differences can be acceptable considering the fact that in the unstable region, the uncertainty of both the experimental and CFD data highly increases, and in the evaluation of the torque in

Figure 30b, the mechanical losses are not included.

As expected, the simulations show very convenient flow conditions at the nominal flow rate, which is utilized under the normal pump station operation. At this flow rate and even at the low water level, no air enters the pump suction, and the flow is free of the unsteady water-level and bottom vortices. Also, no global separation can be found on the floor, and the flow close to the anti-rotating cone is very uniform. On the other hand, the flow inside and outside the pump significantly deteriorates during the turbine runaway regime, which is typical for most of the time necessary to empty the discharge piping after an accidental shutdown. The rotating stall and the S-shape instability revealed by the simulations can result in an overstrain and increased vibrations which are very dangerous for PAT as well as the other mechanical components. All these factors should be taken into account when estimating the MTBR (Mean Time Between Replacements) values and the life cycle cost of the station.

This study does not consider the cavitation analysis of the PAT performance. Highly unsteady cavitation phenomena can be another problem, which can influence all the situations of when the pump trip appears. The cavitation performance of PAT is usually well known for the pump and turbine regimes. But to study, in detail, the cavitation performance of PAT in all the 4-quadrant characteristics, this represents a challenge, which can be the target of future simulations and experimental research.

5. Conclusions

This study describes the abnormal situation when a pump trip appears. To be able to analyze the pump performance during an accidental shutdown, the full 4-quadrant characteristics of the pump was applied in the form of dimensionless variables. The application of the 4-quadrant characteristics relies on the validity of the hydraulic affinity laws, and users should be careful of their range. On the other hand, the creation of the dimensionless representation of the 4-quadrant characteristics gives the possibility to repeat calculations for different scenarios and initial states in real time without the necessity of repeated CFD simulations, which are very time-consuming. This is fully in line with the concept of the “digital product passport”, enabling us to solve all critical events in real time based on the necessary data provided by the supplier.

There is one more aspect of the applications of the 4-quadrant characteristics: they are usually derived through experimental configurations with respect to the closed hydraulic test rig. There are also some results obtained for the pumps with the suction elbow/draft tube; however, there are practically no available data related to the pumps with suction bells. This study, therefore, aimed (at least for the most important performance modes) to simulate a real vertical position of the pump in the suction basin with the anti-rotating cone and the free water level.

This paper shows a detailed insight into the two most important operating modes that appear during the pump trip event: pump regime and turbine runaway. The aim is to show completely different flow phenomena inside and in the vicinity of the pump as well as the completely different behaviors of the water level in the suction object. These differences should be taken into account during the design of the pump suction bell, the AVD device as well as the shape of the pump sump. It must be also stressed that the highly unsteady complex phenomena appearing inside and in the vicinity of a pump during some operating modes cannot be modeled in real time in a two-way CFD-1D dynamic model, even with the support of supercomputer facilities. There are also the stability and convergence difficulties, which do not allow us to use a fully automatic generation of CFD data and require full control over the computational processes.