Numerical Study on the Fracturing of Deep Rock Masses by Blasting Based on the Material Point Method

Abstract

:1. Introduction

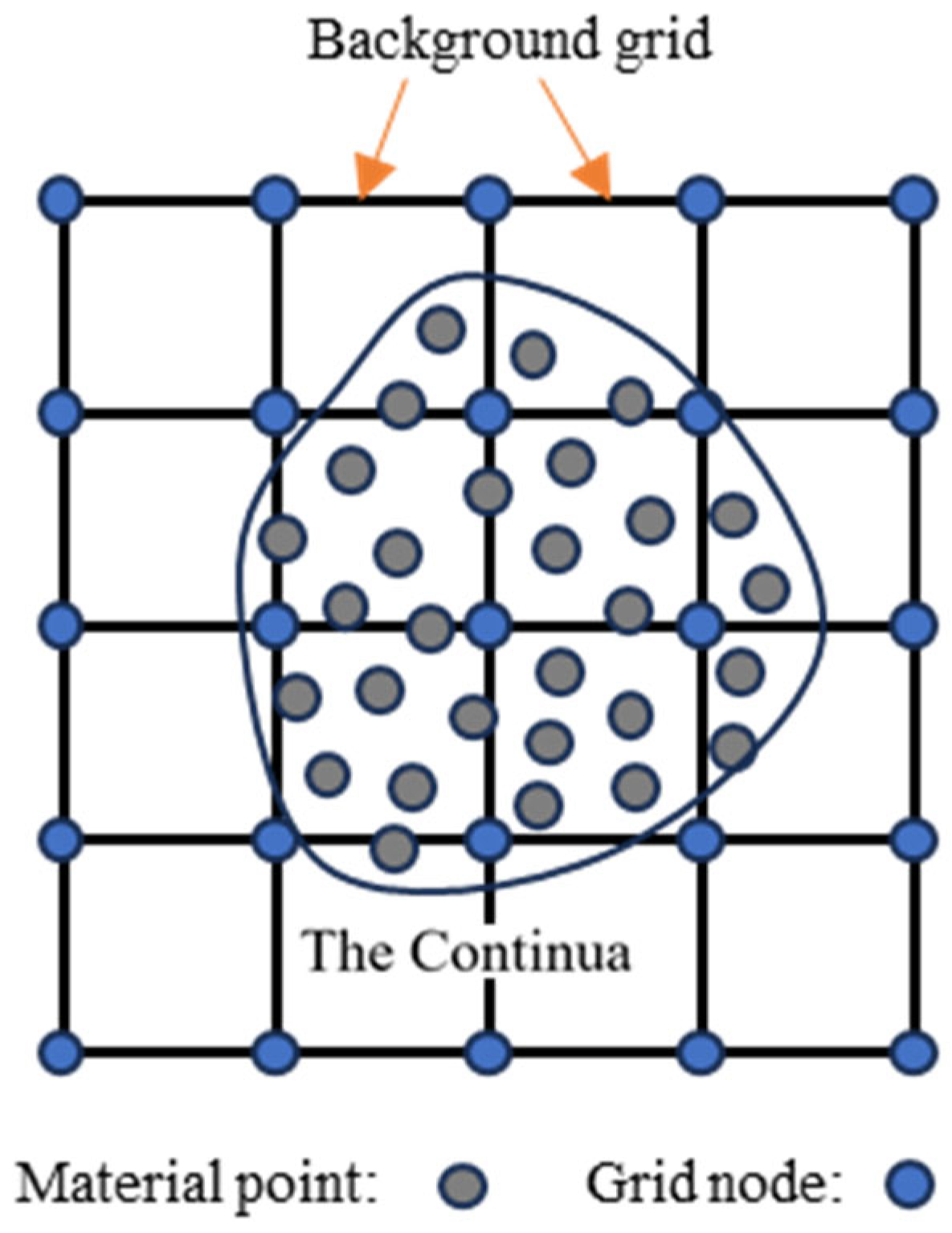

2. Material Point Method

2.1. Governing Equations

2.2. MPM Solution Scheme

2.3. Base Function of GIMP and CPDI

2.4. Time Step Control

3. Theoretical Analysis and Numerical Model

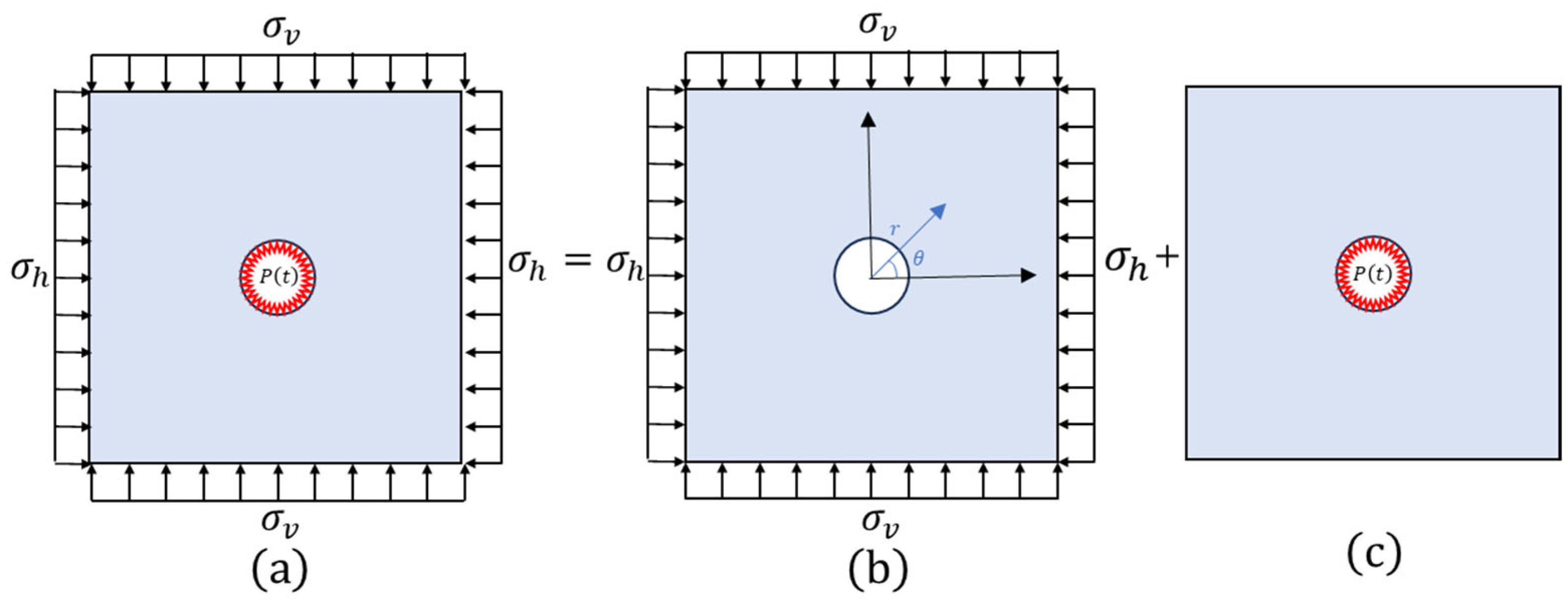

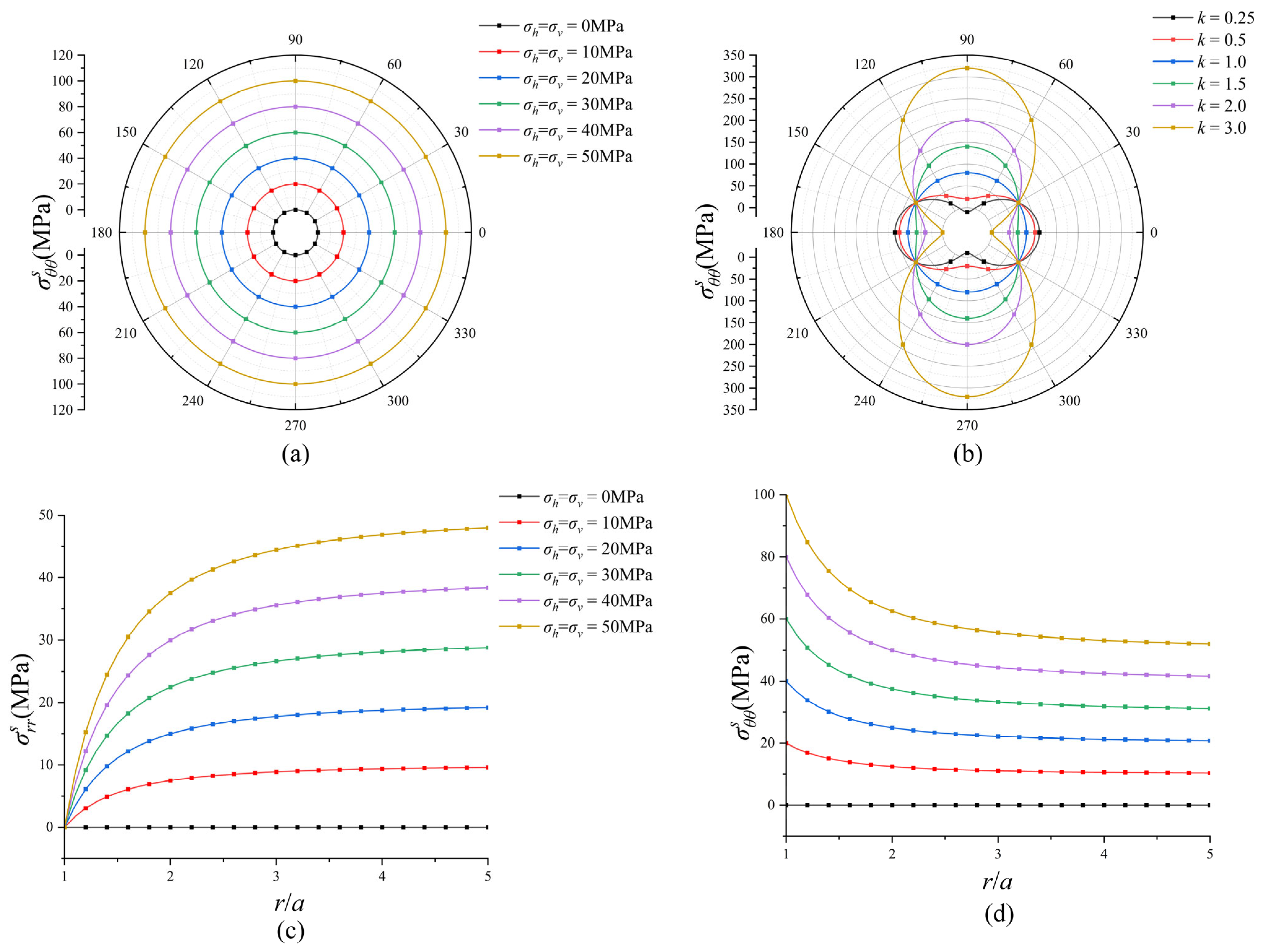

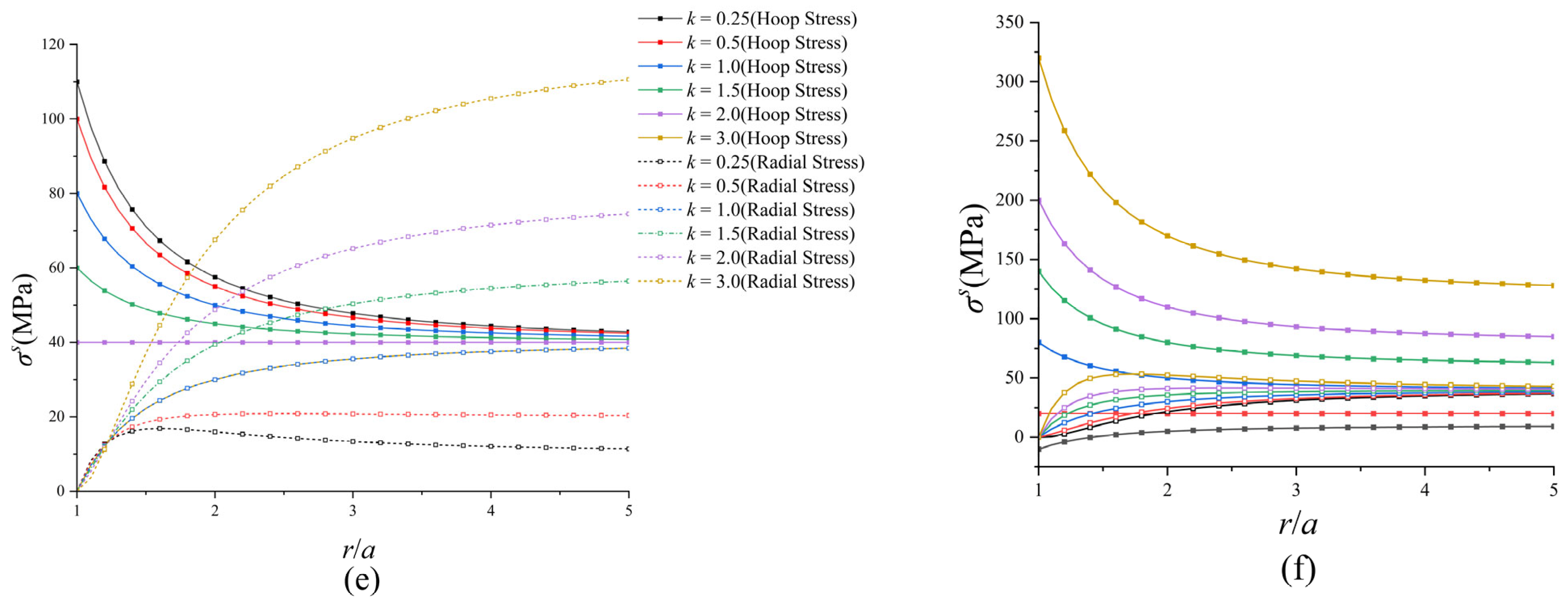

3.1. Stress Distributions under Static Loads

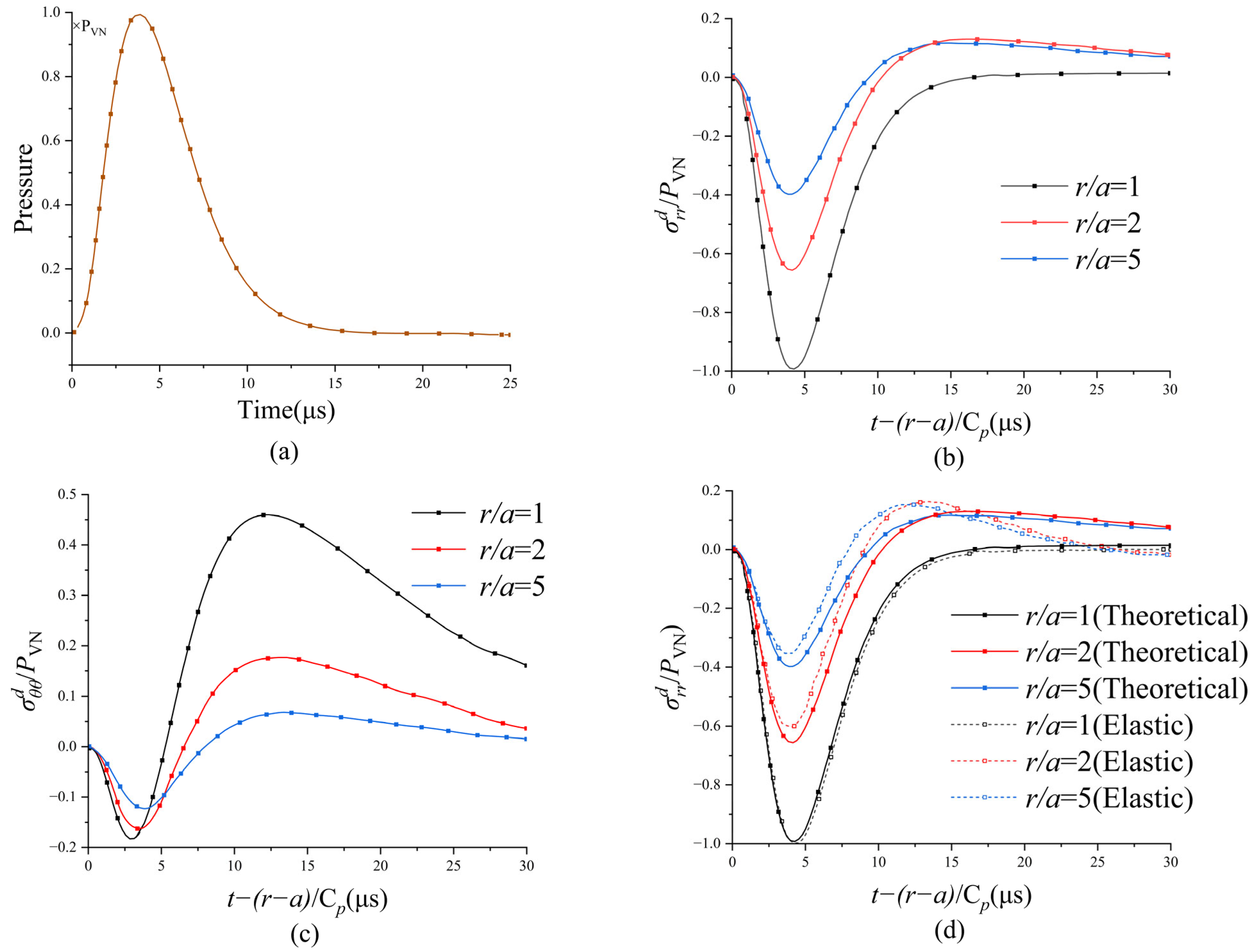

3.2. Stress Distributions under Dynamic Loads

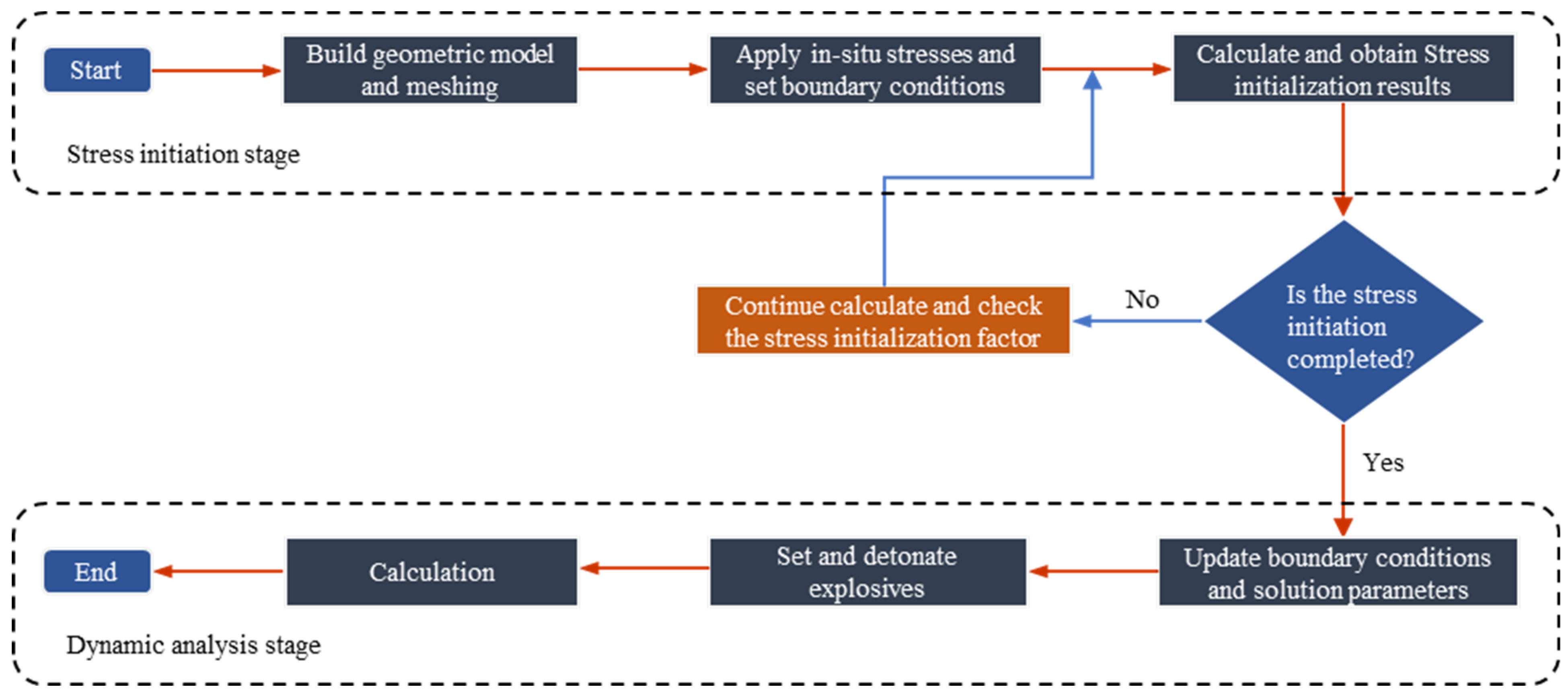

3.3. Numerical Simulation Model

3.4. Parameters of the Model

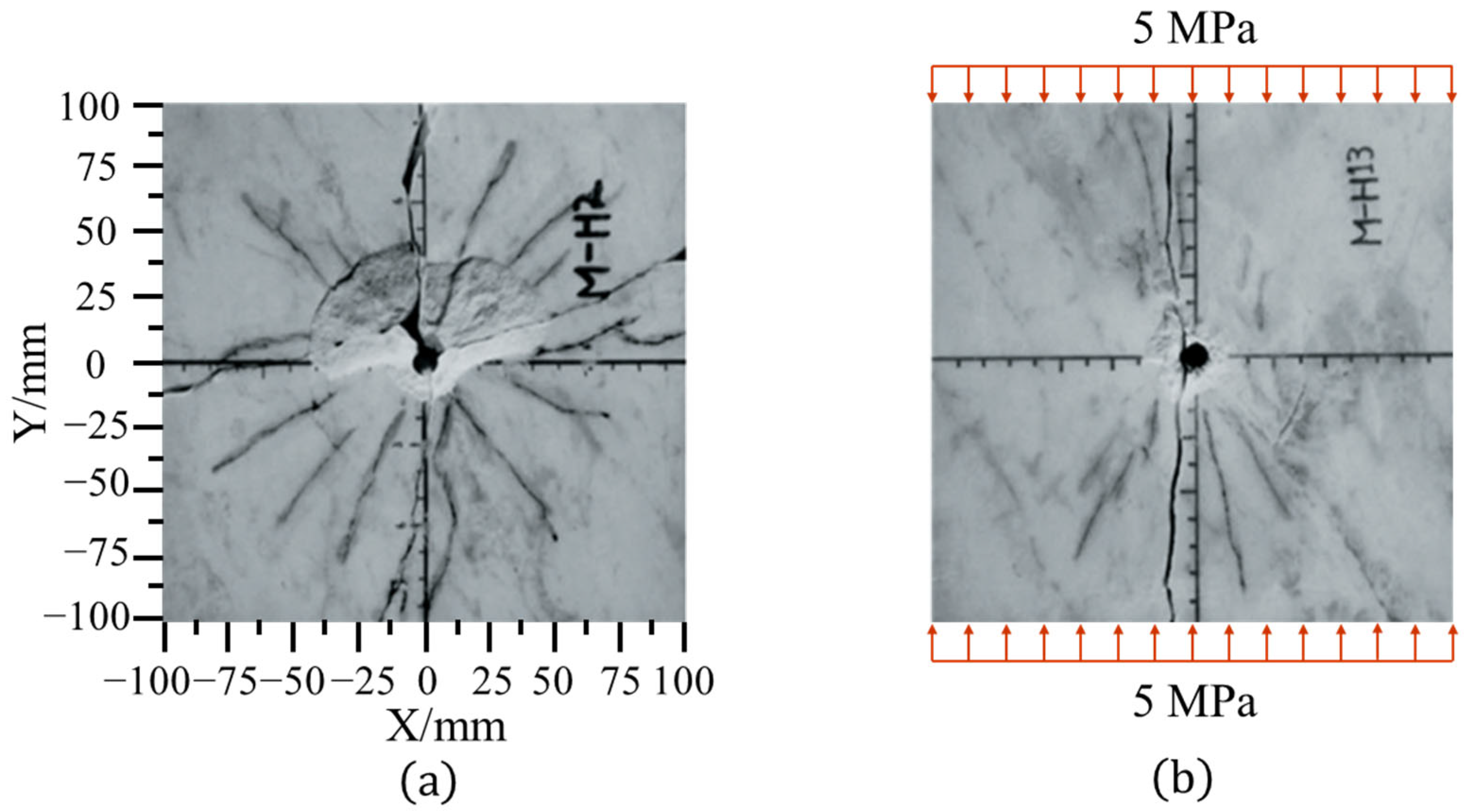

3.5. Verification of the Numerical Method and Model

4. Numerical Simulation Results

4.1. Stress Initialization

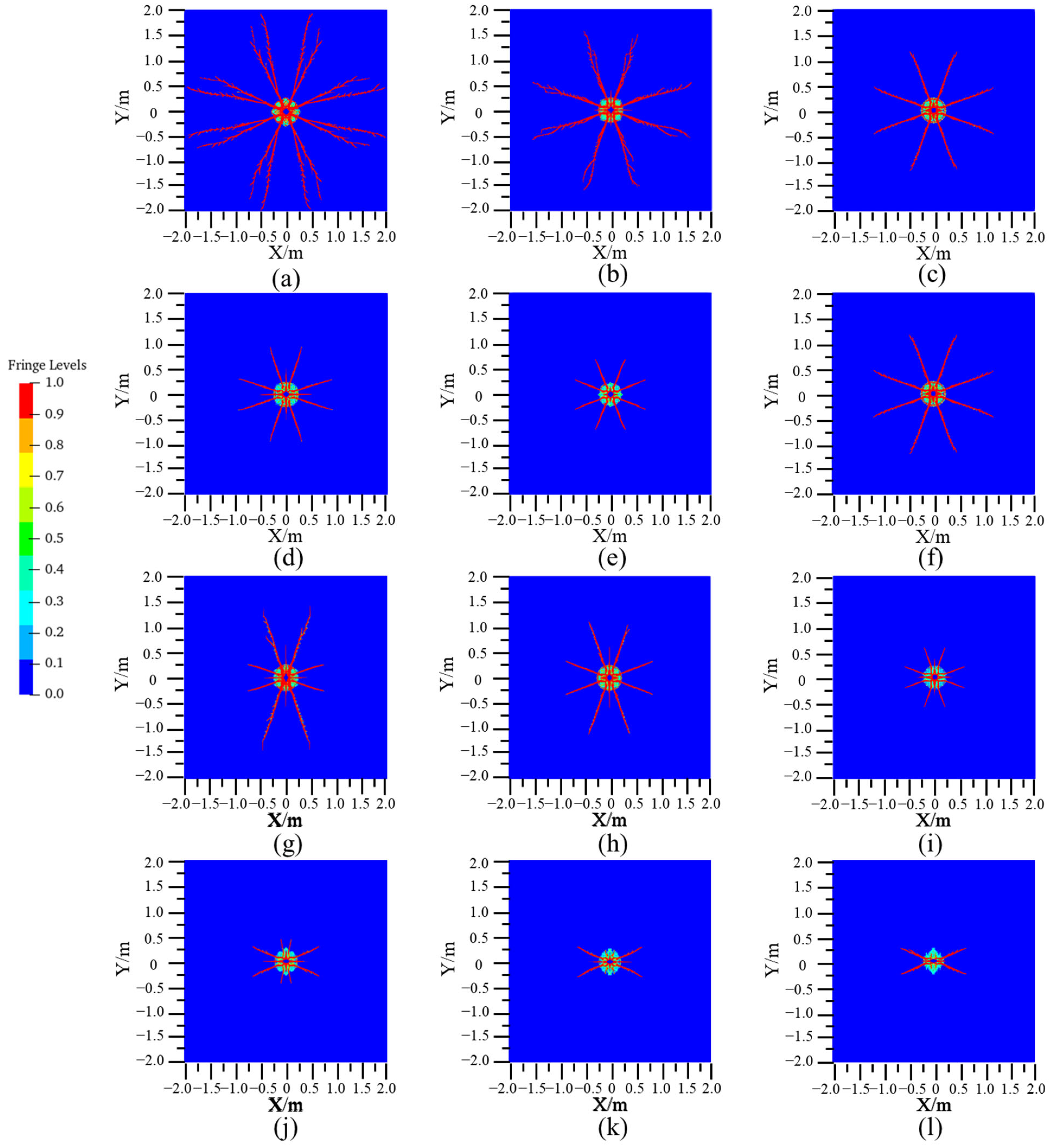

4.2. Single-Hole Blasting with In-Situ Stress

4.3. Discussion

5. Conclusions

- In the stress initialization stage, the dynamic relaxation method is adopted in the material point method to simulate the in-situ stress field and in-situ stress field results obtained by numerical simulation, consistent with theoretical results. The dynamic relaxation method is straightforward and cost-effective in the display dynamics software and only requires the introduction of a damping coefficient in the velocity update equation.

- The in-situ stress significantly inhibits the crack extension produced by rock blasting, and the maximum crack length decreases considerably with the increase in in-situ stress due to the significant difference in the level of in-situ stress between the deep and shallow rock mass. Adjusting borehole spacing is advised to ensure complete crack extension to optimize rock fragmentation and excavation profile quality in deep-rock masses under high in-situ stress.

- Under unequal horizontal and vertical stress, the orientation of the most extended cracks produced by blasting aligns with the direction of the maximum in-situ stress. Consequently, the arrangement of boreholes along the direction of the maximum in-situ stress is more conducive to promoting the connection of cracks produced between adjacent boreholes after blasting.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Feng, X.; Yao, Z.; Li, S.; Wu, S.; Yang, C.; Guo, H.; Zhong, S. In Situ Observation of Hard Surrounding Rock Displacement at 2400-m-Deep Tunnels. Rock Mech. Rock Eng. 2018, 51, 873–892. [Google Scholar] [CrossRef]

- Wagner, H. Deep Mining: A Rock Engineering Challenge. Rock Mech. Rock Eng. 2019, 52, 1417–1446. [Google Scholar] [CrossRef]

- Zhou, J.; Li, X.; Mitri, H.S. Evaluation method of rockburst: State-of-the-art literature review. Tunn. Undergr. Space Technol. 2018, 81, 632–659. [Google Scholar] [CrossRef]

- Sousa, L.M. The influence of the characteristics of quartz and mineral deterioration on the strength of granitic dimensional stones. Environ. Earth Sci. 2013, 69, 1333–1346. [Google Scholar] [CrossRef]

- Barton, N. Shear strength criteria for rock, rock joints, rockfill and rock masses: Problems and some solutions. J. Rock Mech. Geotech. Eng. 2013, 5, 249–261. [Google Scholar] [CrossRef]

- Barton, N. Review of a new shear-strength criterion for rock joints. Eng. Geol. 1973, 7, 287–332. [Google Scholar] [CrossRef]

- Koca, T.K.; Köken, E. A combined application of two soft computing algorithms for weathering degree quantification of andesitic rocks. Appl. Comput. Geosci. 2022, 16, 100101. [Google Scholar] [CrossRef]

- Bhatawdekar, R.M.; Edy, M.T.; Danial, J.A. Building information model for drilling and blasting for tropically weathered rock. J. Mines Met. Fuels 2022, 67, 494–500. [Google Scholar]

- Thuro, K.; Plinninger, R. Hard rock tunnel boring, cutting, drilling and blasting: Rock parameters for excavatability. In Proceedings of the ISRM Congress, Sandton, South Africa, 8–12 September 2003; p. ISRM–10CONGRESS-2003-2212. [Google Scholar]

- Xie, H.; Peng, S.; He, M. Basic Theory and Engineering Practice in Deep Mining; Science Press: Beijing, China, 2006. [Google Scholar]

- Zhu, Z. Evaluation of the range of horizontal stresses in the earth’s upper crust by using a collinear crack model. J. Appl. Geophys. 2013, 88, 114–121. [Google Scholar] [CrossRef]

- Lucier, A.M.; Zoback, M.D.; Heesakkers, V.; Reches, Z.E.; Murphy, S.K. Constraining the far-field in situ stress state near a deep South African gold mine. Int. J. Rock Mech. Min. Sci. 2009, 46, 555–567. [Google Scholar] [CrossRef]

- Pesch, R.; Robertson, A. Drilling and blasting for underground space. In Proceedings of the EXPLO Conference, Wollongong, Australia, 3–4 September 2007; pp. 189–193. [Google Scholar]

- Zuo, J.; Yang, R.; Gong, M.; Ma, X.; Wang, Y. Fracture characteristics of iron ore under uncoupled blast loading. Int. J. Min. Sci. Technol. 2022, 32, 657–667. [Google Scholar] [CrossRef]

- AyalaCarcedo, F. Drilling and Blasting of Rocks; Routledge: London, UK, 2017. [Google Scholar]

- Kaiser, P.K.; Kim, B.-H. Characterization of Strength of Intact Brittle Rock Considering Confinement-Dependent Failure Processes. Rock Mech. Rock Eng. 2015, 48, 107–119. [Google Scholar] [CrossRef]

- Lu, W.; Chen, M.; Geng, X.; Shu, D.; Zhou, C. A study of excavation sequence and contour blasting method for underground powerhouses of hydropower stations. Tunn. Undergr. Space Technol. 2012, 29, 31–39. [Google Scholar] [CrossRef]

- Kutter, H.; Fairhurst, C. On the fracture process in blasting. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1971, 8, 181–202. [Google Scholar] [CrossRef]

- Nicholls, H.R.; Duvall, W.I. Presplitting Rock in the Presence of a Static Stress Field; US Department of the Interior, Bureau of Mines: Pittsburgh, PA, USA, 1966; Volume 6843. [Google Scholar]

- Jung, W.J.; Utagawa, M.; Ogata, Y.; Seto, M.; Katsuyama, K.; Miyake, A.; Ogawa, T. Effects of rock pressure on crack generation during tunnel blasting. J. Jpn. Explos. Soc. 2001, 62, 138–146. [Google Scholar]

- Yang, L.; Yang, R.; Hu, P.; Song, Y. Experimental study on the effect of initial compression-stress field on blast-induced crack behaviors. J. China Coal Soc. 2013, 38, 404–410. [Google Scholar]

- Shu, Y.; Zhu, Z.; Wang, M.; Ying, P.; Wang, F.; Wan, D.; Li, X.; Gao, W. A plastic damage constitutive model for rock-like material focusing on the hydrostatic pressure induced damage and the interaction of tensile and shear damages under impact and blast loads. Comput. Geotech. 2022, 150, 104921. [Google Scholar] [CrossRef]

- Tao, J.; Yang, X.; Li, H.; Zhou, J.; Qi, S.; Lu, G. Numerical investigation of blast-induced rock fragmentation. Comput. Geotech. 2020, 128, 103846. [Google Scholar] [CrossRef]

- Dai, J.; Yang, J.; Yao, C.; Hu, Y.; Zhang, X.; Jiang, Q.; Zhou, C. Study on the mechanism of displacement mutation for jointed rock slopes during blasting excavation. Int. J. Rock Mech. Min. Sci. 2022, 150, 105032. [Google Scholar] [CrossRef]

- Zhang, Z.; Gao, W.; Li, K.; Li, B. Numerical simulation of rock mass blasting using particle flow code and particle expansion loading algorithm. Simul. Model. Pract. Theory 2020, 104, 102119. [Google Scholar] [CrossRef]

- Zhu, F.; Zhao, J. Peridynamic modelling of blasting induced rock fractures. J. Mech. Phys. Solids 2021, 153, 104469. [Google Scholar] [CrossRef]

- Bendezu, M.A.L.; Romanel, C.; Roehl, D. Finite element analysis of blast-induced fracture propagation in hard rocks. Comput. Struct. 2017, 182, 1–13. [Google Scholar] [CrossRef]

- Fakhimi, A.; Lanari, M. DEM-SPH simulation of rock blasting. Comput. Geotech. 2014, 55, 158–164. [Google Scholar] [CrossRef]

- Koneshwaran, S.; Thambiratnam, D.P.; Gallage, C. Blast Response of Segmented Bored Tunnel using Coupled SPH–FE Method. Structures 2015, 2, 58–71. [Google Scholar] [CrossRef]

- Sulsky, D.; Chen, Z.; Schreyer, H.L. A particle method for history-dependent materials. Comput. Methods Appl. Mech. Eng. 1994, 118, 179–196. [Google Scholar] [CrossRef]

- Sulsky, D.; Zhou, S.-J.; Schreyer, H.L. Application of a particle-in-cell method to solid mechanics. Comput. Phys. Commun. 1995, 87, 236–252. [Google Scholar] [CrossRef]

- Bardenhagen, S.G.; Kober, E.M. The generalized interpolation material point method. CMES-Comput. Model. Eng. Sci. 2004, 5, 477–495. [Google Scholar]

- Sadeghirad, A.; Brannon, R.M.; Burghardt, J. A convected particle domain interpolation technique to extend applicability of the material point method for problems involving massive deformations. Int. J. Numer. Methods Eng. 2011, 86, 1435–1456. [Google Scholar] [CrossRef]

- Sadeghirad, A.; Brannon, R.M.; Guilkey, J.E. Second-order convected particle domain interpolation (CPDI2) with enrichment for weak discontinuities at material interfaces. Int. J. Numer. Methods Eng. 2013, 95, 928–952. [Google Scholar] [CrossRef]

- Wan, D.; Wang, M.; Zhu, Z.; Wang, F.; Zhou, L.; Liu, R.; Gao, W.; Shu, Y.; Xiao, H. Coupled GIMP and CPDI material point method in modelling blast-induced three-dimensional rock fracture. Int. J. Min. Sci. Technol. 2022, 32, 1097–1114. [Google Scholar] [CrossRef]

- An, H.M.; Liu, H.Y.; Han, H.; Zheng, X.; Wang, X.G. Hybrid finite-discrete element modelling of dynamic fracture and resultant fragment casting and muck-piling by rock blast. Comput. Geotech. 2017, 81, 322–345. [Google Scholar] [CrossRef]

- Johnson, G.R.; Holmquist, T.J. An improved computational constitutive model for brittle materials. In Proceedings of the AIP Conference Proceedings, Colorado Springs, CO, USA, 2–28 July 1994; pp. 981–984. [Google Scholar]

- Brackbill, J.U.; Ruppel, H.M. FLIP: A method for adaptively zoned, particle-in-cell calculations of fluid flows in two dimensions. J. Comput. Phys. 1986, 65, 314–343. [Google Scholar] [CrossRef]

- Kirsch, E.G. Die Theorie der Elastizit t und die Bed rfnisse der Festigkeitslehre. Zeitshrift Vereines Dtsch. Ingenieure 1898, 42, 797–807. [Google Scholar]

- Blair, D.P. A comparison of Heelan and exact solutions for seismic radiation from a short cylindrical charge. Geophysics 2007, 72, E33–E41. [Google Scholar] [CrossRef]

- Hustrulid, W.A. Blasting Principles for Open Pit Mining; A.A. Balkema Publisher: Brookfiled, VT, USA, 1999. [Google Scholar]

- Miklowitz, J.; Kaul, R.K. The Theory of Elastic Waves and Waveguides. J. Appl. Mech. 1979, 46, 969. [Google Scholar] [CrossRef]

- Durbin, F. Numerical inversion of Laplace transforms: An efficient improvement to Dubner and Abate’s method. Comput. J. 1974, 17, 371–376. [Google Scholar] [CrossRef]

- Yue, Z.; Zhou, J.; Feng, C.; Wang, X.; Peng, L.; Cong, J. Coupling of material point and continuum discontinuum element methods for simulating blast-induced fractures in rock. Comput. Geotech. 2022, 144, 104629. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Z.; Liu, Y. The Material Point Method: A Continuum-Based Particle Method for Extreme Loading Cases; Academic Press: New York, NY, USA, 2016. [Google Scholar]

- Kury, J.; Hornig, H.; Lee, E.; McDonnel, J.; Ornellas, D.; Finger, M.; Strange, F.; Wilkins, M. Metal acceleration by chemical explosives. In Proceedings of the Fourth Symposium (International) on Detonation, White Oak, MD, USA, 12–15 October 1965; pp. 3–13. [Google Scholar]

- Banadaki, M.M.D.; Mohanty, B. Numerical simulation of stress wave induced fractures in rock. Int. J. Impact Eng. 2012, 40–41, 16–25. [Google Scholar] [CrossRef]

- Zhang, X.; Hao, H.; Ma, G. Dynamic material model of annealed soda-lime glass. Int. J. Impact Eng. 2015, 77, 108–119. [Google Scholar] [CrossRef]

- Wang, J.; Yin, Y.; Esmaieli, K. Numerical simulations of rock blasting damage based on laboratory-scale experiments. J. Geophys. Eng. 2018, 15, 2399–2417. [Google Scholar] [CrossRef]

- Xie, L.; Zhang, Q.; Gu, J.; Lu, W.; Yang, S.; Jing, H.; Wang, Z. Damage evolution mechanism in production blasting excavation under different stress fields. Simul. Model. Pract. Theory 2019, 97, 101969. [Google Scholar] [CrossRef]

- Yang, J.; Wu, Z.; Sun, W.; Yao, C.; Wang, Q. Numerical simulation on radiation and energy of blast-induced seismic waves in deep rock masses. J. Cent. South Univ. 2022, 29, 645–662. [Google Scholar] [CrossRef]

- Ai, H.A.; Ahrens, T.J. Simulation of dynamic response of granite: A numerical approach of shock-induced damage beneath impact craters. Int. J. Impact Eng. 2006, 33, 1–10. [Google Scholar] [CrossRef]

- Wan, D.; Wang, M.; Zhu, Z.; Wang, Y.; Xiao, H.; Gao, W. A coupled model of asymmetric GIMP and tetrahedron CPDI based on the penalty contact algorithm for simulating dynamic rock splitting. Int. J. Rock Mech. Min. Sci. 2023, 170, 105483. [Google Scholar] [CrossRef]

- Yang, J.-C.; Liu, K.-W.; Li, X.-D.; Liu, Z.-X. Stress initialization methods for dynamic numerical simulation of rock mass with high in-situ stress. J. Cent. South Univ. 2020, 27, 3149–3162. [Google Scholar] [CrossRef]

- Kilic, B.; Madenci, E. An adaptive dynamic relaxation method for quasi-static simulations using the peridynamic theory. Theor. Appl. Fract. Mech. 2010, 53, 194–204. [Google Scholar] [CrossRef]

- Shan, Z.; Liao, Z.; Dong, Y.; Wang, D.; Cui, L. Implementation of absorbing boundary conditions in dynamic simulation of the material point method. J. Zhejiang Univ.-Sci. A 2021, 22, 870–881. [Google Scholar] [CrossRef]

| Material | A (kPa) | B (kPa) | R1 | R2 | ω | E0 (kJ/m3) |

|---|---|---|---|---|---|---|

| PETN | 573,100,000 | 20,160,000 | 6 | 1.8 | 0.28 | 7,190,001 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| ρ (g/cm3) E (MPa) | 2.66 51,188.28 | (MPa) | 0.25 4500 |

| υ | 0.16818 | (MPa) | 3700 |

| A | 0.76 | Beta | 0.5 |

| B | 0.25 | 0.4 | |

| C | 0.005 | 0.9 | |

| M | 0.62 | (GPa) | 25.7 |

| (s−1) | 1 | (GPa) | −4500 |

| T (MPa) | 54 | (GPa) | 300,000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, H.; Wang, M.; Gao, W.; Zou, M.; Wang, Y.; Sun, J. Numerical Study on the Fracturing of Deep Rock Masses by Blasting Based on the Material Point Method. Processes 2024, 12, 1048. https://doi.org/10.3390/pr12061048

Xiao H, Wang M, Gao W, Zou M, Wang Y, Sun J. Numerical Study on the Fracturing of Deep Rock Masses by Blasting Based on the Material Point Method. Processes. 2024; 12(6):1048. https://doi.org/10.3390/pr12061048

Chicago/Turabian StyleXiao, Hu, Meng Wang, Weiting Gao, Ming Zou, Yuntao Wang, and Jinshan Sun. 2024. "Numerical Study on the Fracturing of Deep Rock Masses by Blasting Based on the Material Point Method" Processes 12, no. 6: 1048. https://doi.org/10.3390/pr12061048

APA StyleXiao, H., Wang, M., Gao, W., Zou, M., Wang, Y., & Sun, J. (2024). Numerical Study on the Fracturing of Deep Rock Masses by Blasting Based on the Material Point Method. Processes, 12(6), 1048. https://doi.org/10.3390/pr12061048