Effect of A Moringa Oil–Beeswax Edible Coating on the Shelf-Life and Quality of Fresh Cucumber

Abstract

:1. Introduction

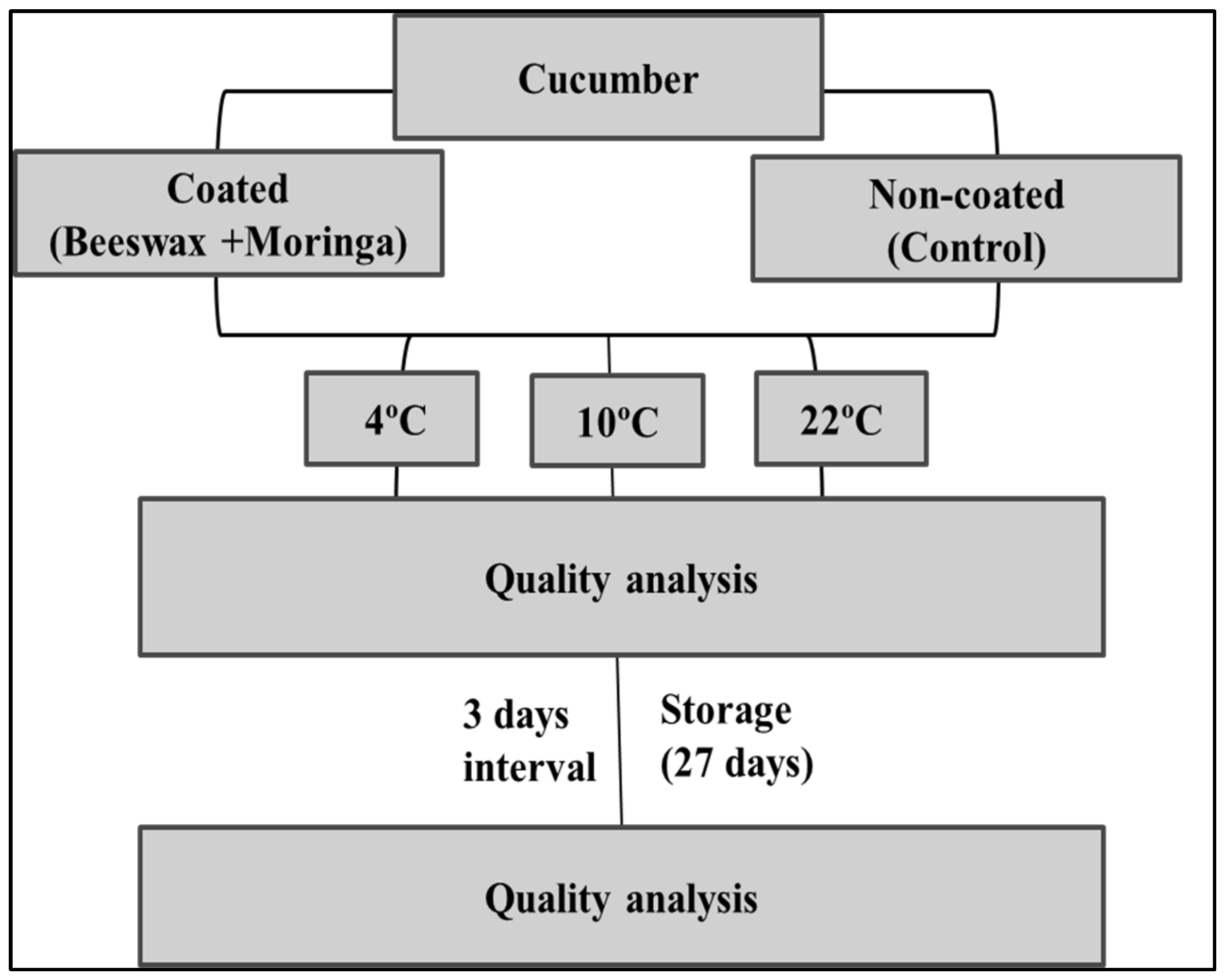

2. Materials and Method

2.1. Experimental Material Collection

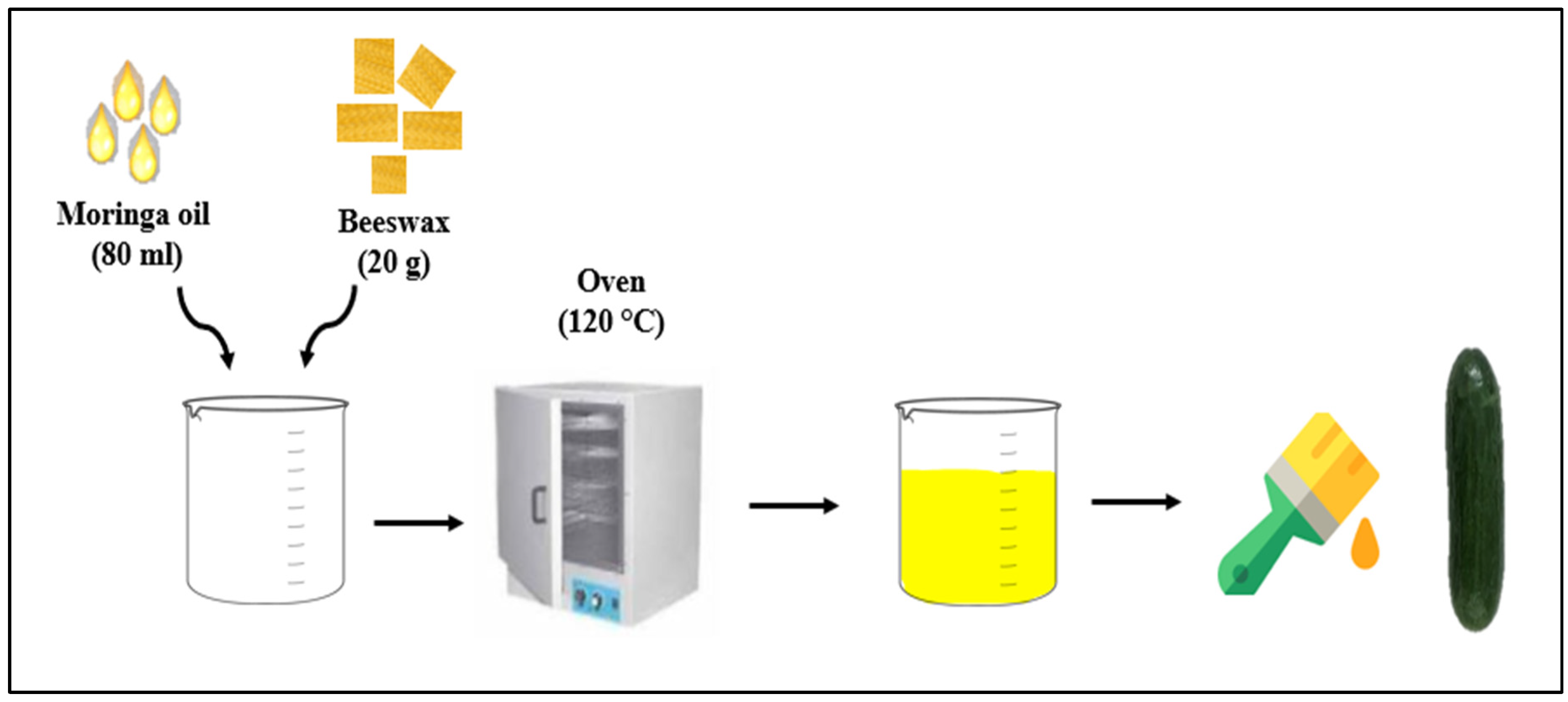

2.2. Coating Formulation and Application

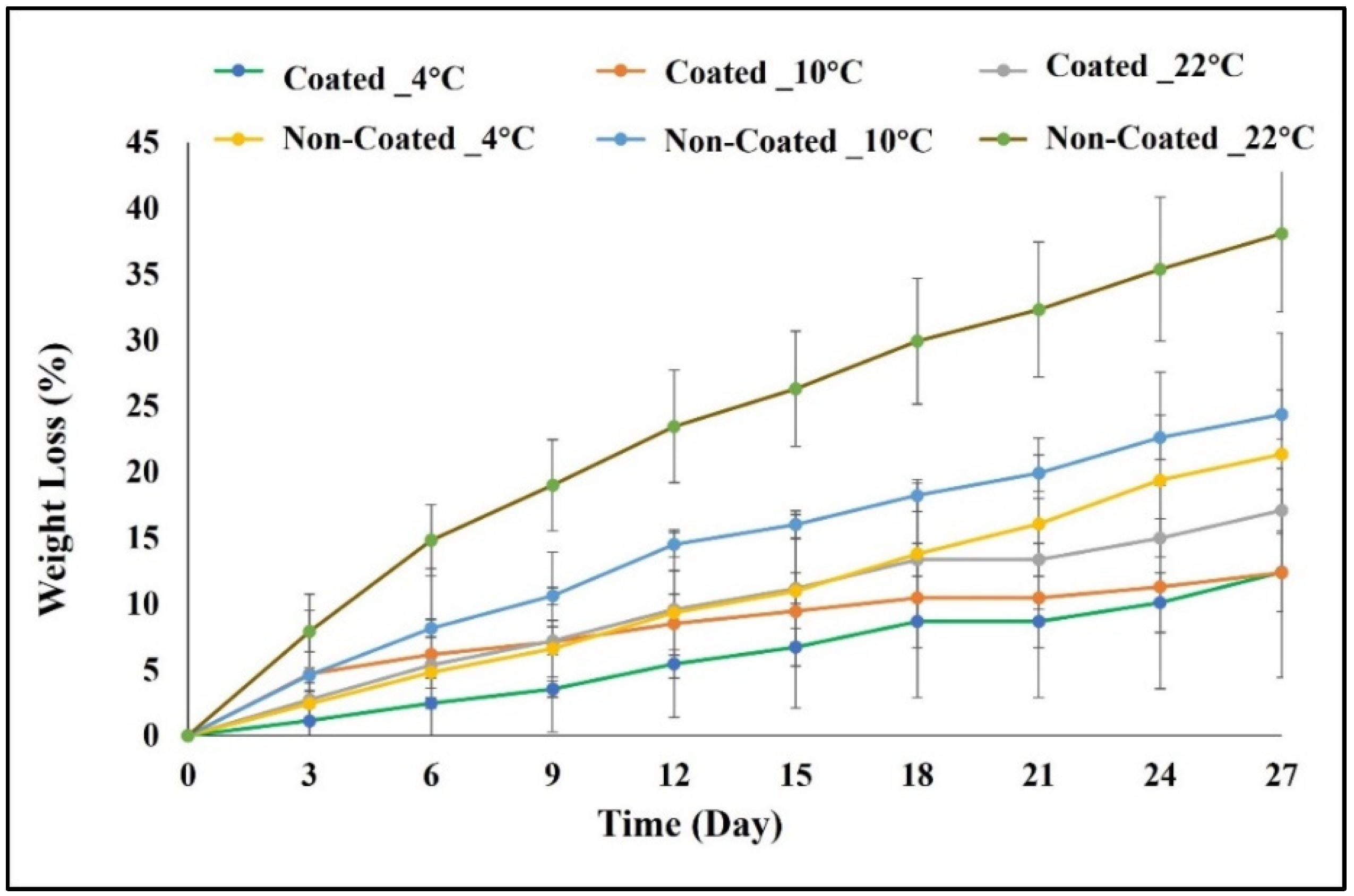

2.3. Weight Loss (%)

- = the initial mass of banana fruit (g) before storage.

- = the banana fruit mass measured every 3 days.

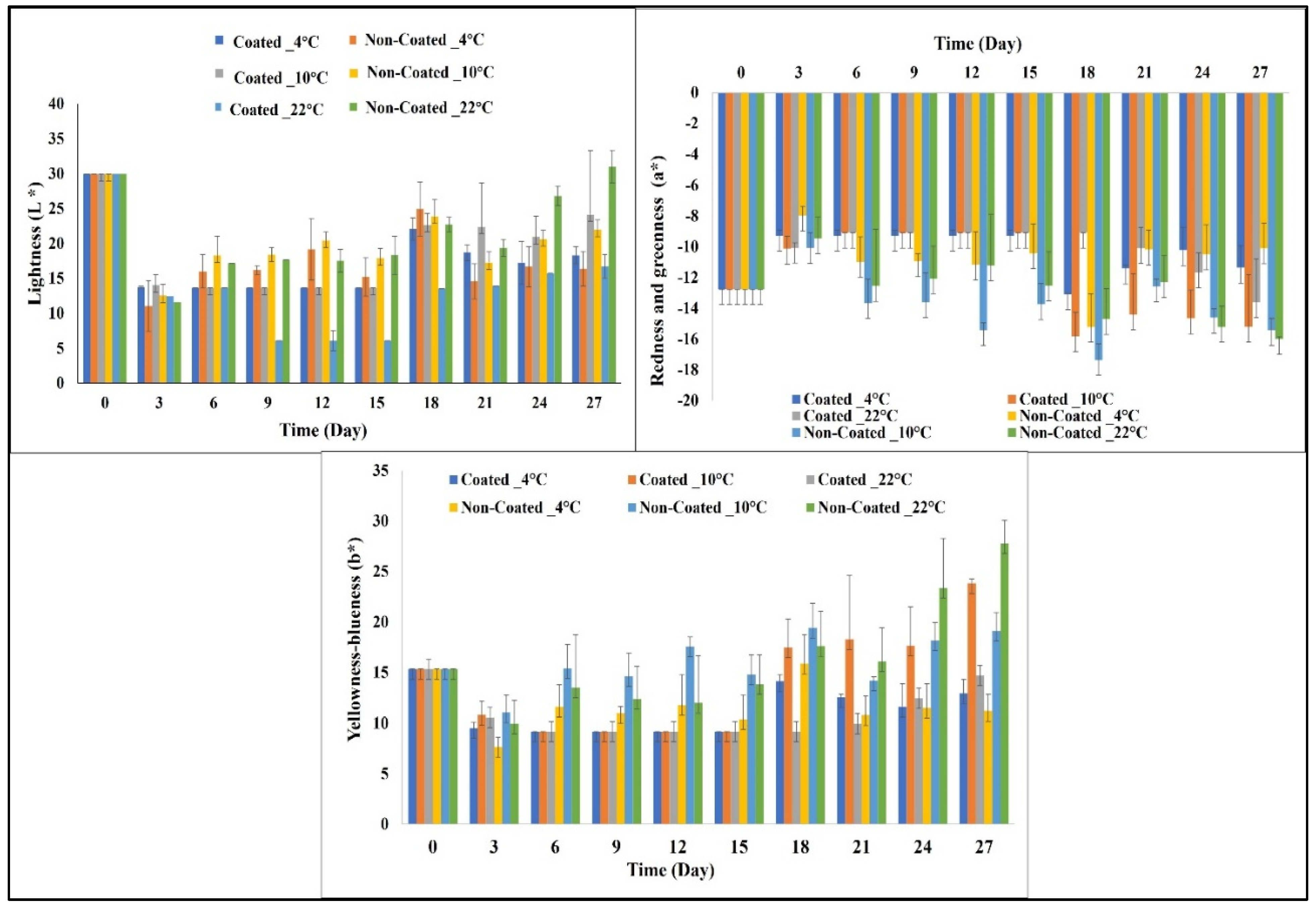

2.4. Color

2.5. pH

2.6. Titratable Acidity (TA)

2.7. Ascorbic Acid

- A: Content of L-Ascorbic acid in the sample (mg L−1);

- S: The amount of iodine solution consumed (0.05 M) at the end point of titration (mL);

- N: Normality of iodine solution in mol L−1 (0.01);

- F: Consumed iodine solution factor (0.885).

2.8. Total Soluble Solid (TSS)

2.9. Firmness

2.10. Statistical Analysis

3. Results and Discussion

3.1. Weight Loss (%)

3.2. Color

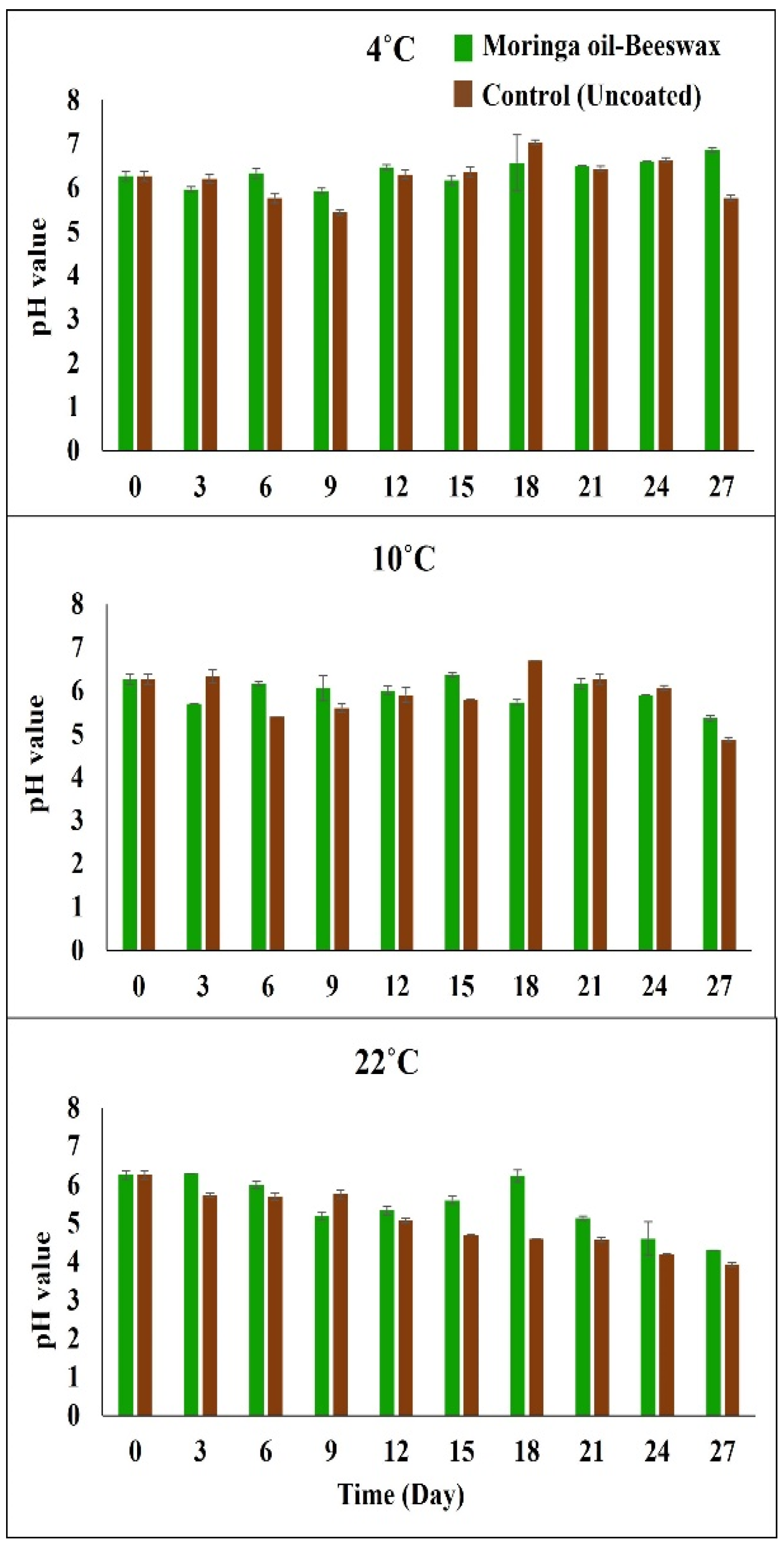

3.3. pH

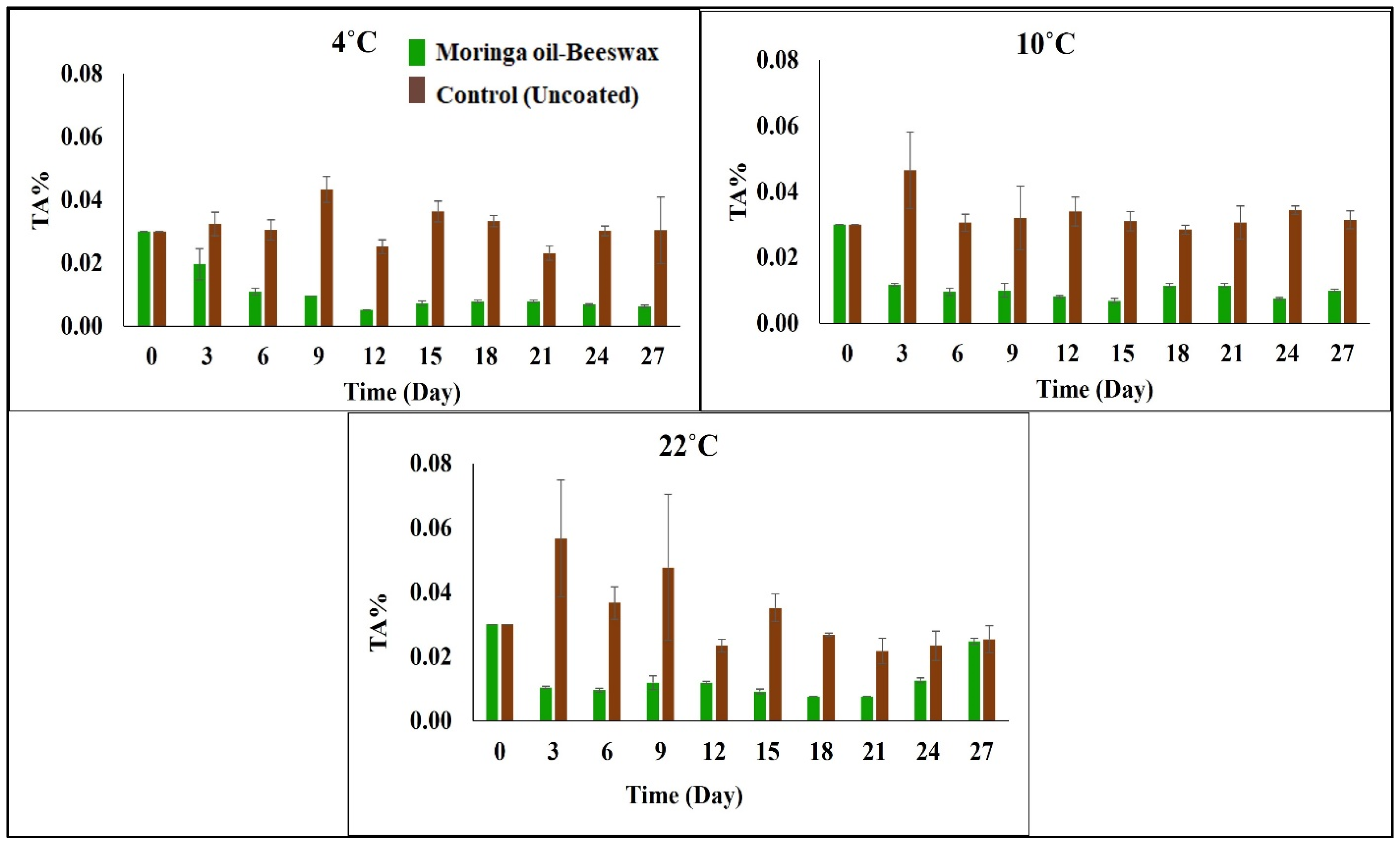

3.4. Titratable Acidity (TA)

3.5. Vitamin C

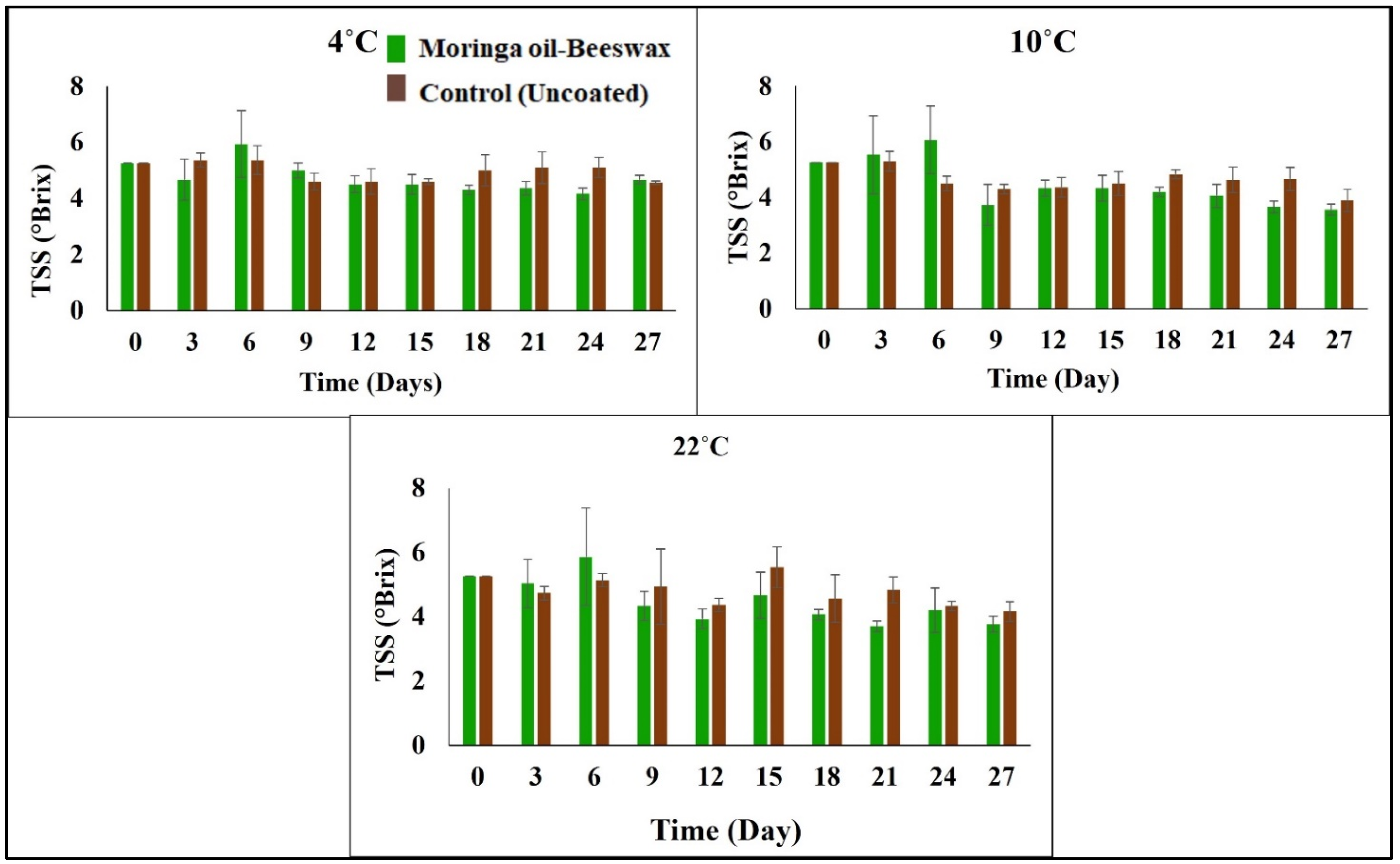

3.6. Total Soluble Solids (TSSs)

3.7. Firmness

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Al-Hadrami, A.; Pathare, P.B.; Al-Dairi, M.; Al-Mahdouri, A. Investigation of Bruise Damage and Storage on Cucumber Quality. AgriEngineering 2023, 5, 855–875. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, R.; Kumar, D.; Gautam, N.; Singh, N.; Parkash, C.; Dhiman, M.R.; Shukla, Y.R. Heterotic potential, potence ratio, combining ability and genetic control of yield and its contributing traits in cucumber (Cucumis sativus L.). N. Z. J. Crop Hortic. Sci. 2017, 45, 175–190. [Google Scholar] [CrossRef]

- FAOSTAT Food and Agriculture Organization Corporate Statistical Database; FAO: Rome, Italy, 2021.

- Al-Rawahi, M.; Al-Said, F.; Khan, I.; Al-Khanjary, S. Diversity of Cucumber Accessions in Oman. Int. J. Agric. Biol. 2011, 13, 505–510. [Google Scholar]

- Bahnasawy, A.H.; Khater, E.-S.G. Effect of wax coating on the quality of cucumber fruits during storage. J. Food Process. Technol. 2014, 5, 339. [Google Scholar] [CrossRef]

- Cortbaoui, P.E.; Ngadi, M.O. New method to quantify postharvest quality loss of cucumber using the Taguchi approach. Food Sci. Qual. Manag. 2015, 44, 13–22. [Google Scholar]

- Kader, A. Postharvest Technology of Horticultural Crops; University of California Agriculture and Natural Resources: Davis, CA, USA, 2002. [Google Scholar]

- Kaur, P.; Devgan, K.; Kumar, N.; Kaur, A.; Kumar, M.; Sandhu, K. Quality retention and shelf-life prolongation of cucumbers (Cucumis sativus L.) under different cool storage systems with passive modified atmosphere bulk packaging. Packag. Technol. Sci. 2021, 34, 567–578. [Google Scholar] [CrossRef]

- Helal, M.; Sami, R.; Algarni, E.; Alshehry, G.; Aljumayi, H.; Al-Mushhin, A.A.M.; Benajiba, N.; Chavali, M.; Kumar, N.; Iqbal, A.; et al. Active bionanocomposite coating quality assessments of some cucumber properties with some diverse applications during storage condition by chitosan, nano titanium oxide crystals, and sodium tripolyphosphate. Crystals 2022, 12, 131. [Google Scholar] [CrossRef]

- Manjunatha, M.; Anurag, R.K. Effect of modified atmosphere packaging and storage conditions on quality characteristics of cucumber. J. Food Sci. Technol. 2014, 51, 3470–3475. [Google Scholar] [CrossRef]

- Andriani, V.; Handayani, N.A. Recent technology of edible coating production: A review. Mater. Today Proc. 2023, 87, 200–206. [Google Scholar] [CrossRef]

- Mahajan, P.V.; Caleb, O.J.; Singh, Z.; Watkins, C.B.; Geyer, M. Postharvest treatments of fresh produce. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2014, 372, 20130309. [Google Scholar] [CrossRef]

- Dhall, R. Advances in edible coatings for fresh fruits and vegetables: A review. Crit. Rev. Food Sci. Nutr. 2013, 53, 435–450. [Google Scholar] [CrossRef] [PubMed]

- Eshetu, A.; Ibrahim, A.M.; Forsido, S.F.; Kuyu, C.G. Effect of beeswax and chitosan treatments on quality and shelf-life of selected mango (Mangifera indica L.) cultivars. Heliyon 2019, 5, e01116. [Google Scholar] [CrossRef] [PubMed]

- Abugoch, L.; Tapia, C.; Plasencia, D.; Pastor, A.; Castro-Mandujano, O.; López, L.; Escalona, V.H. Shelf-life of fresh blueberries coated with quinoa protein/chitosan/sunflower oil edible film. J. Sci. Food Agric. 2016, 96, 619–626. [Google Scholar] [CrossRef] [PubMed]

- Chouhan, N.K.; Singh, V. Effect of postharvest edible coatings on quality and shelf-life of pear fruit cv. Punjab Beauty. Res. Sq. 2023. [Google Scholar] [CrossRef]

- Sharma, H.P.; Chaudhary, V.; Kumar, M. Importance of edible coating on fruits and vegetables: A review. J. Pharmacogn. Phytochem. 2019, 8, 4104–4110. [Google Scholar]

- Sari, P.; Darmawati, E.; Ahmad, U. Aloe vera and beeswax-based coating to maintain shelf-life of salak cv. Madu. IOP Conf. Ser. Earth Environ. Sci. 2020, 542, 012014. [Google Scholar] [CrossRef]

- Aly, A.; Ali, H.; Abdeldaiem, M. Improvement of the sunflower oil stability by blending with moringa or sesame oils. Slovak J. Food Sci. 2021, 15, 111–120. [Google Scholar] [CrossRef]

- Afedzi, A.; Ahadjie, V.; Quansah, L. Gum Arabic and beeswax as edible coatings for extending the postharvest shelf-life of tomato (Lycopersicon esculentum L.) fruit. Ghana J. Sci. 2022, 63, 31–42. [Google Scholar] [CrossRef]

- Ngcobo, B.; Shinga, M.; Mwelase, S.; Bertling, I. The potential use of moringa seed oil in agriculture. Acta Hortic. 2024, 1394, 125–130. [Google Scholar] [CrossRef]

- Silva, S.; Sousa, A.P.; Gomes, J.; Andrade, R.; Lima, G.; Siqueira, E.; Silva, W.; e Silva, C.S.; Filho, F.; Campos, A.R. Postharvest conservation of Tommy atkins mango fruits during storage using Moringa oleifera oil-based coating. Aust. J. Crop Sci. 2021, 15, 278–283. [Google Scholar] [CrossRef]

- Liamngee, K.; Terna, A.; Ussuh, M. Effect of Moringa oleifera leaf extract on the postharvest quality of tomato fruits during storage. J. Postharvest Technol. 2019, 7, 45–55. [Google Scholar]

- Nasrin, T.A.A.; Rahman, M.A.; Arfin, M.S.; Islam, M.N.; Ullah, M.A. Effect of novel coconut oil and beeswax edible coating on postharvest quality of lemon at ambient storage. J. Agric. Food Res. 2020, 2, 100019. [Google Scholar] [CrossRef]

- Dadzie, R.G.; Ampofo-Asiama, J.; Quaye, B.; Kizzie-Hayford, N.; Amoako-Andoh, F.; Abano, E.E.; Amoah, R.S. Effect of Beeswax Coating on the Quality of Eggplant Fruit During Cold Storage and Optimization of Coating Conditions. J. Food Qual. 2023, 2023, 5879085. [Google Scholar] [CrossRef]

- Al Lawati, R.; Al Shukaili, Z.; Al-Dairi, M.; Pathare, P.B. Effect of aloe-vera coating on the quality of mechanically damaged zucchini during long-term storage. Sustain. Chem. Pharm. 2024, 39, 101603. [Google Scholar] [CrossRef]

- Al-Dairi, M.; Pathare, P.B.; Al-Yahyai, R.; Al-Mahdouri, A. Effect on physiological properties of banana fruit based on pendulum impact test and storage. Curr. Res. Food Sci. 2023, 7, 100640. [Google Scholar] [CrossRef] [PubMed]

- Al-Dairi, M.; Pathare, P.B.; Al-Mahdouri, A. Effect of storage conditions on postharvest quality of tomatoes: A case study at market-level. J. Agric. Mar. Sci. 2021, 26, 13–20. [Google Scholar]

- Al-Dairi, M.; Pathare, P.B.; Al-Yahyai, R. Chemical and nutritional quality changes of tomato during postharvest transportation and storage. J. Saudi Soc. Agric. Sci. 2021, 20, 401–408. [Google Scholar] [CrossRef]

- Mohkami, Z.; Sanikhani, M.; Tavakolizadeh, M. Health Promoting Compounds Synthesis Affected by Stimulants in Bitter Squash (Jounpouri Cultivar). 2022. Available online: https://ssrn.com/abstract=4167472 (accessed on 26 February 2024).

- Amin, U.; Khan, M.K.I.; Khan, M.U.; Ehtasham Akram, M.; Pateiro, M.; Lorenzo, J.M.; Maan, A.A. Improvement of the performance of chitosan—Aloe vera coatings by adding beeswax on postharvest quality of mango fruit. Foods 2021, 10, 2240. [Google Scholar] [CrossRef] [PubMed]

- Pathare, P.B.; Al-Dairi, M. Bruise susceptibility and impact on quality parameters of pears during storage. Front. Sustain. Food Syst. 2021, 5, 658132. [Google Scholar] [CrossRef]

- Forato, L.A.; de Britto, D.; de Rizzo, J.S.; Gastaldi, T.A.; Assis, O.B. Effect of cashew gum-carboxymethylcellulose edible coatings in extending the shelf-life of fresh and cut guavas. Food Packag. Shelf-Life 2015, 5, 68–74. [Google Scholar] [CrossRef]

- Wani, A.A.; Singh, P.; Gul, K.; Wani, M.H.; Langowski, H.-C. Sweet cherry (Prunus avium): Critical factors affecting the composition and shelf-life. Food Packag. Shelf-Life 2014, 1, 86–99. [Google Scholar] [CrossRef]

- Doreyappa Gowda, I.; Huddar, A. Studies on ripening changes in mango (Mangifera indica L.) fruits. J. Food Sci. Technol. 2001, 38, 135–137. [Google Scholar]

- Flores-López, M.L.; Vieira, J.M.; Rocha, C.M.R.; Lagarón, J.M.; Cerqueira, M.A.; Jasso de Rodríguez, D.; Vicente, A.A. Postharvest Quality Improvement of Tomato (Solanum lycopersicum L.) Fruit Using a Nanomultilayer Coating Containing Aloe vera. Foods 2023, 13, 83. [Google Scholar] [CrossRef] [PubMed]

- Jahan, S.E.; Hassan, M.K.; Roy, S.; Ahmed, Q.M.; Hasan, G.N.; Muna, A.Y.; Sarkar, M.N. Effects of different postharvest treatments on nutritional quality and shelf life of cucumber. Asian J. Crop Soil Sci. Plant Nutr. 2020, 2, 51–61. [Google Scholar] [CrossRef]

- Al-Dairi, M.; Pathare, P.B.; Al-Yahyai, R.; Jayasuriya, H.; Al-Attabi, Z. Evaluation of chemical quality attributes in bruised bananas during storage. LWT 2024, 197, 115904. [Google Scholar] [CrossRef]

- Muddather, A.E.; Abu-Goukh, A.-B.A. Effect of Maleic Hydrazide and Waxing on Quality and Shelf-life of Mango (Mangifera indica L.) Fruits. Univ. Khartoum J. Agric. Sci. 2019, 24, 42–59. [Google Scholar] [CrossRef]

- El-Gioushy, S.F.; Abdelkader, M.F.M.; Mahmoud, M.H.; Abou El Ghit, H.M.; Fikry, M.; Bahloul, A.M.E.; Morsy, A.R.; A., L.A.; Abdelaziz, A.M.R.A.; Alhaithloul, H.A.S.; et al. The effects of a gum arabic-based edible coating on guava fruit characteristics during storage. Coatings 2022, 12, 90. [Google Scholar] [CrossRef]

- Klangmuang, P.; Sothornvit, R. Active hydroxypropyl methylcellulose-based composite coating powder to maintain the quality of fresh mango. LWT 2018, 91, 541–548. [Google Scholar] [CrossRef]

- Baswal, A.; Dhaliwal, H.; Singh, Z.; Mahajan, B.; Kalia, A.; Gill, K. Influence of carboxy methylcellulose, chitosan and beeswax coatings on cold storage life and quality of Kinnow mandarin fruit. Sci. Hortic. 2020, 260, 108887. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Rashdi, S.; Al-Subhi, N.; Al-Dairi, M.; Pathare, P.B. Effect of A Moringa Oil–Beeswax Edible Coating on the Shelf-Life and Quality of Fresh Cucumber. Processes 2024, 12, 1148. https://doi.org/10.3390/pr12061148

Al-Rashdi S, Al-Subhi N, Al-Dairi M, Pathare PB. Effect of A Moringa Oil–Beeswax Edible Coating on the Shelf-Life and Quality of Fresh Cucumber. Processes. 2024; 12(6):1148. https://doi.org/10.3390/pr12061148

Chicago/Turabian StyleAl-Rashdi, Shekha, Nusaiba Al-Subhi, Mai Al-Dairi, and Pankaj B. Pathare. 2024. "Effect of A Moringa Oil–Beeswax Edible Coating on the Shelf-Life and Quality of Fresh Cucumber" Processes 12, no. 6: 1148. https://doi.org/10.3390/pr12061148