Study on the Application of Finite Difference in Geological Mine Fault Groups: A Case Study

Abstract

:1. Introduction

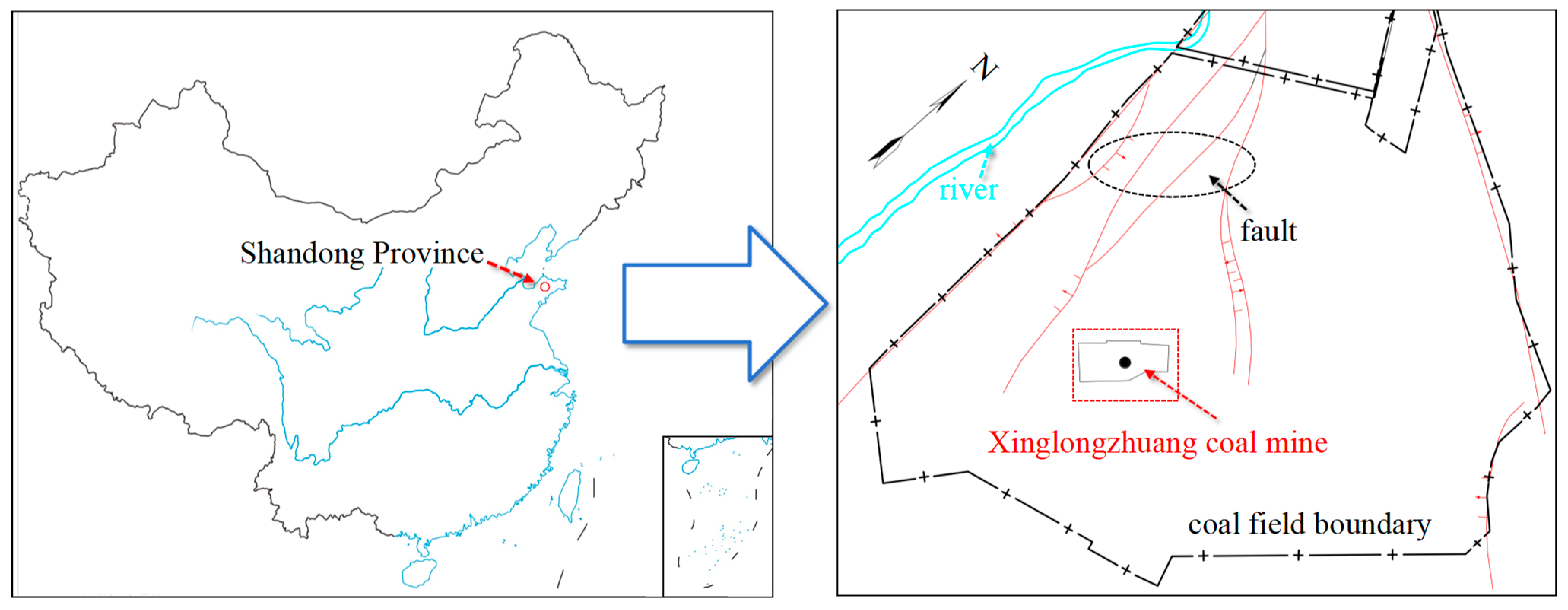

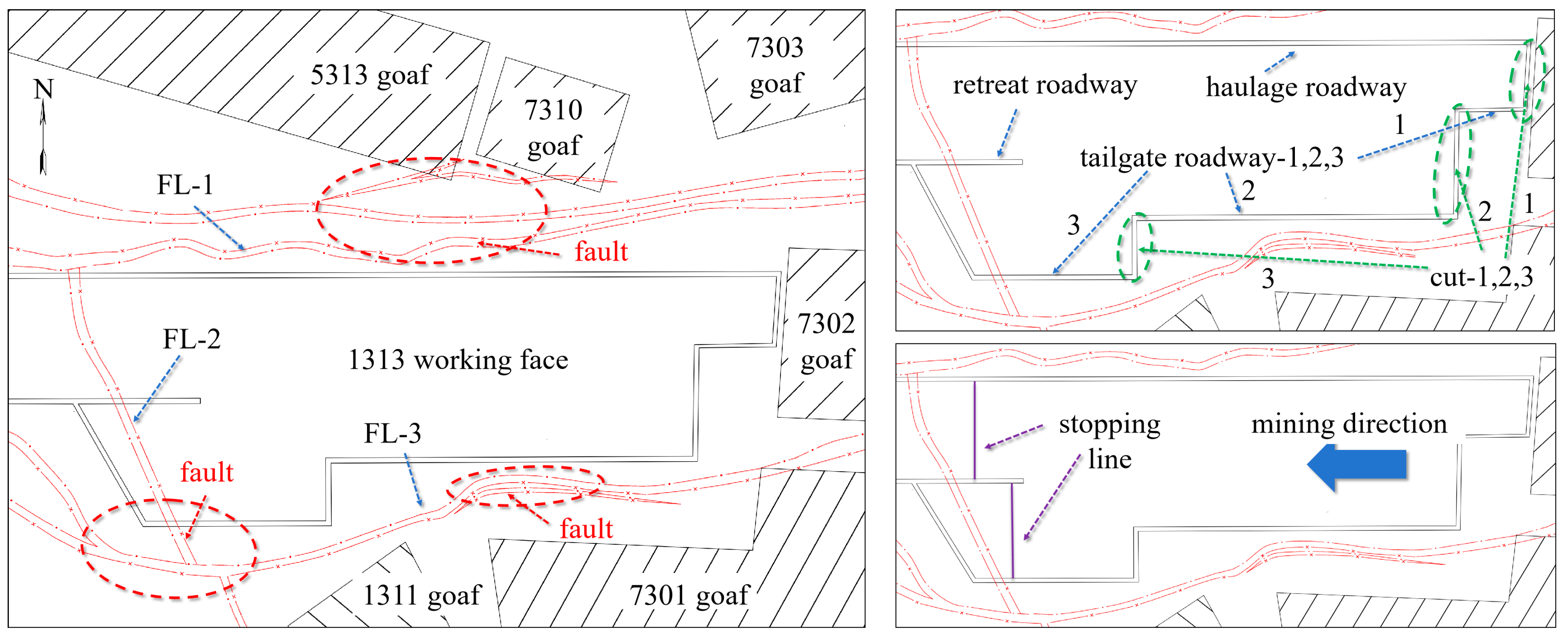

2. Engineering Background

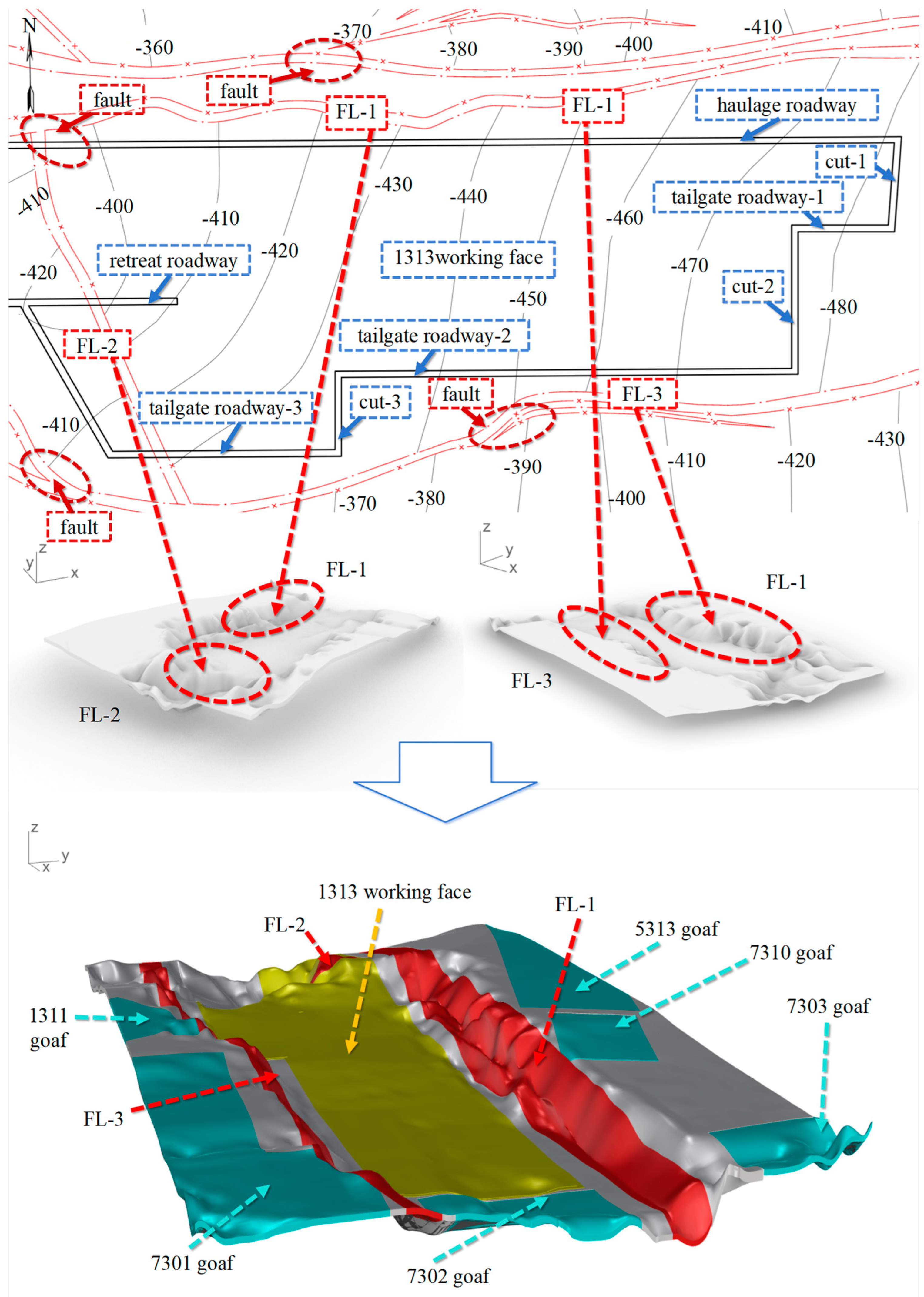

3. Research on 3D Modeling Technology

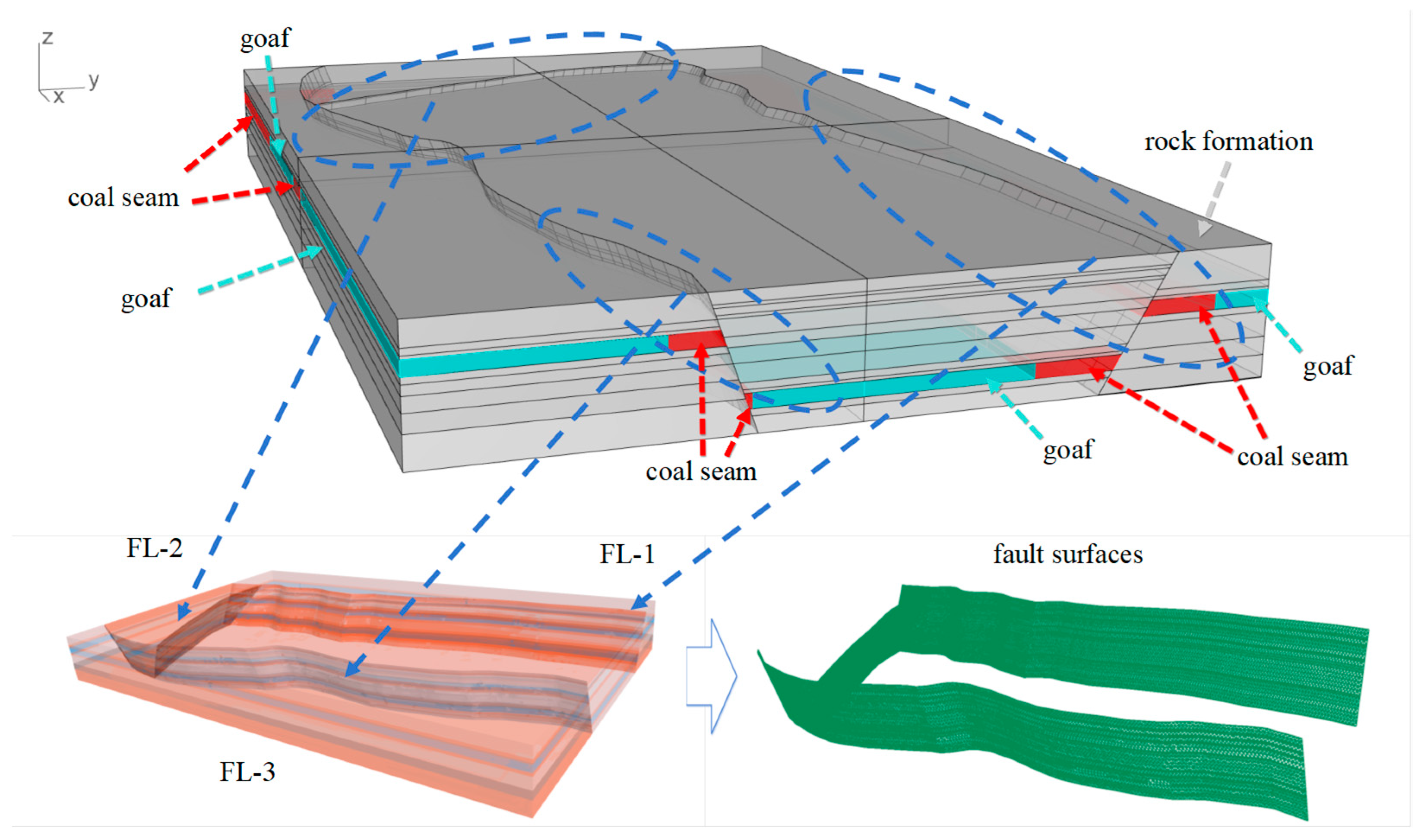

3.1. Transparent Geological Model

3.2. Three-Dimensional Model Construction

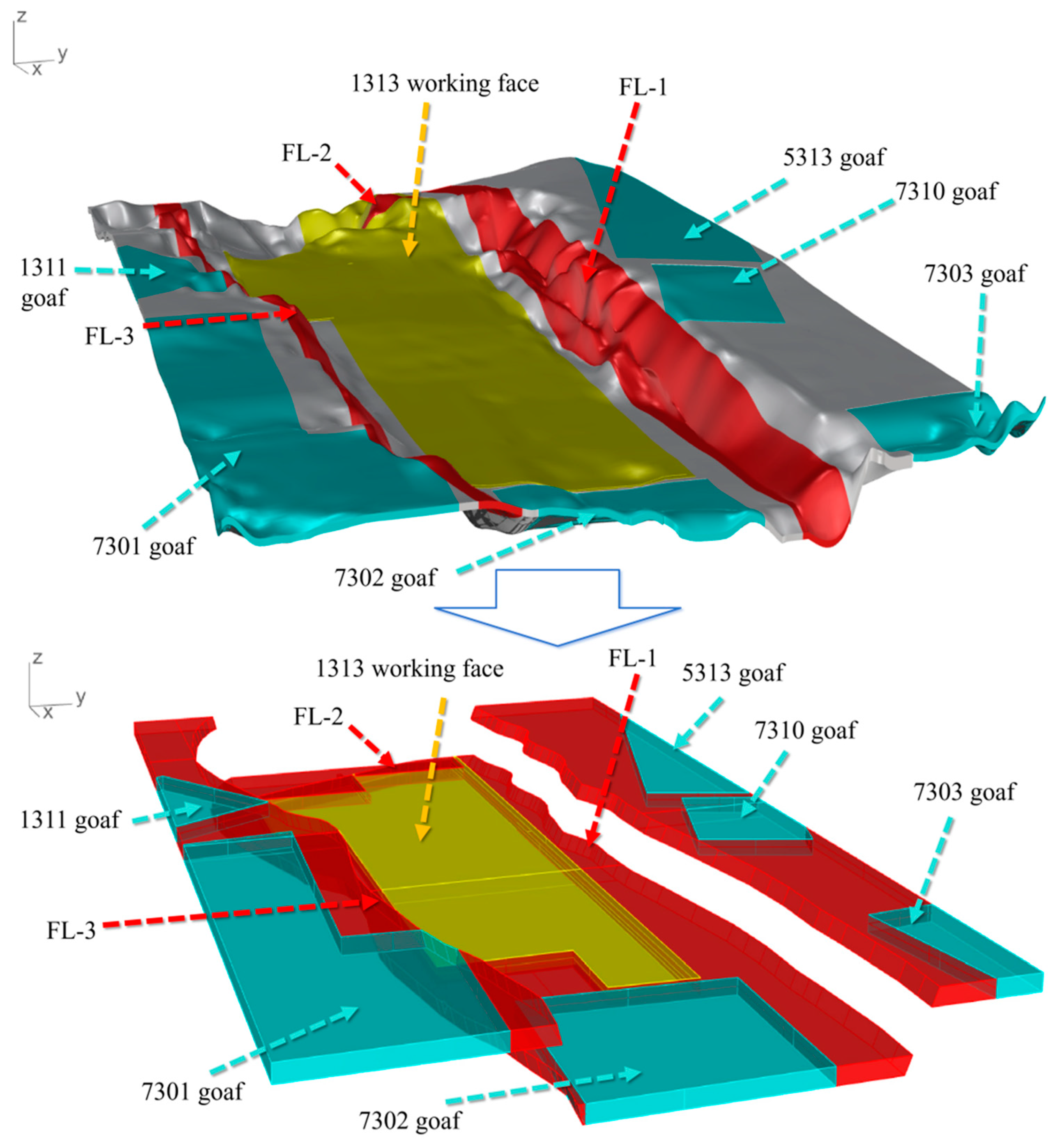

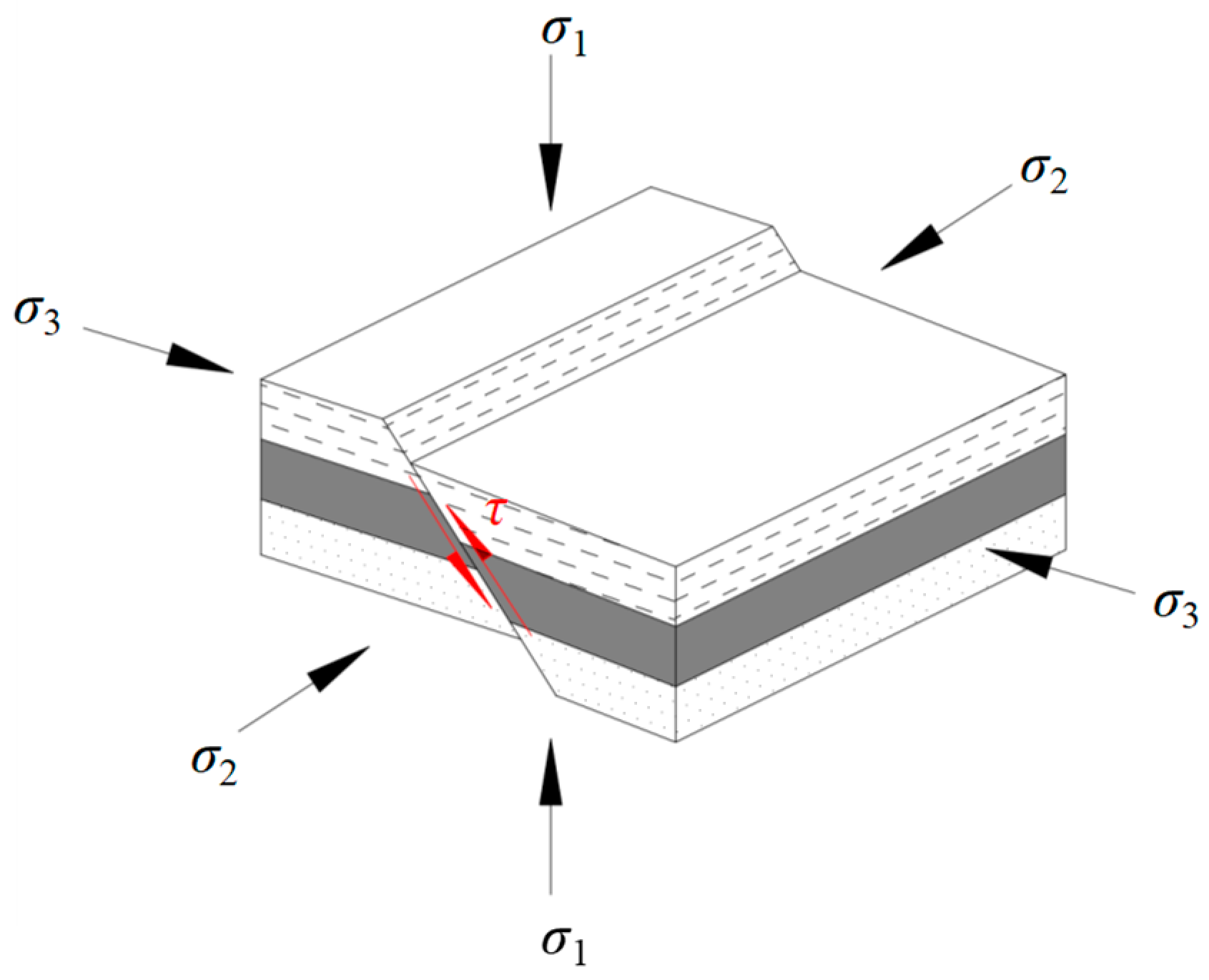

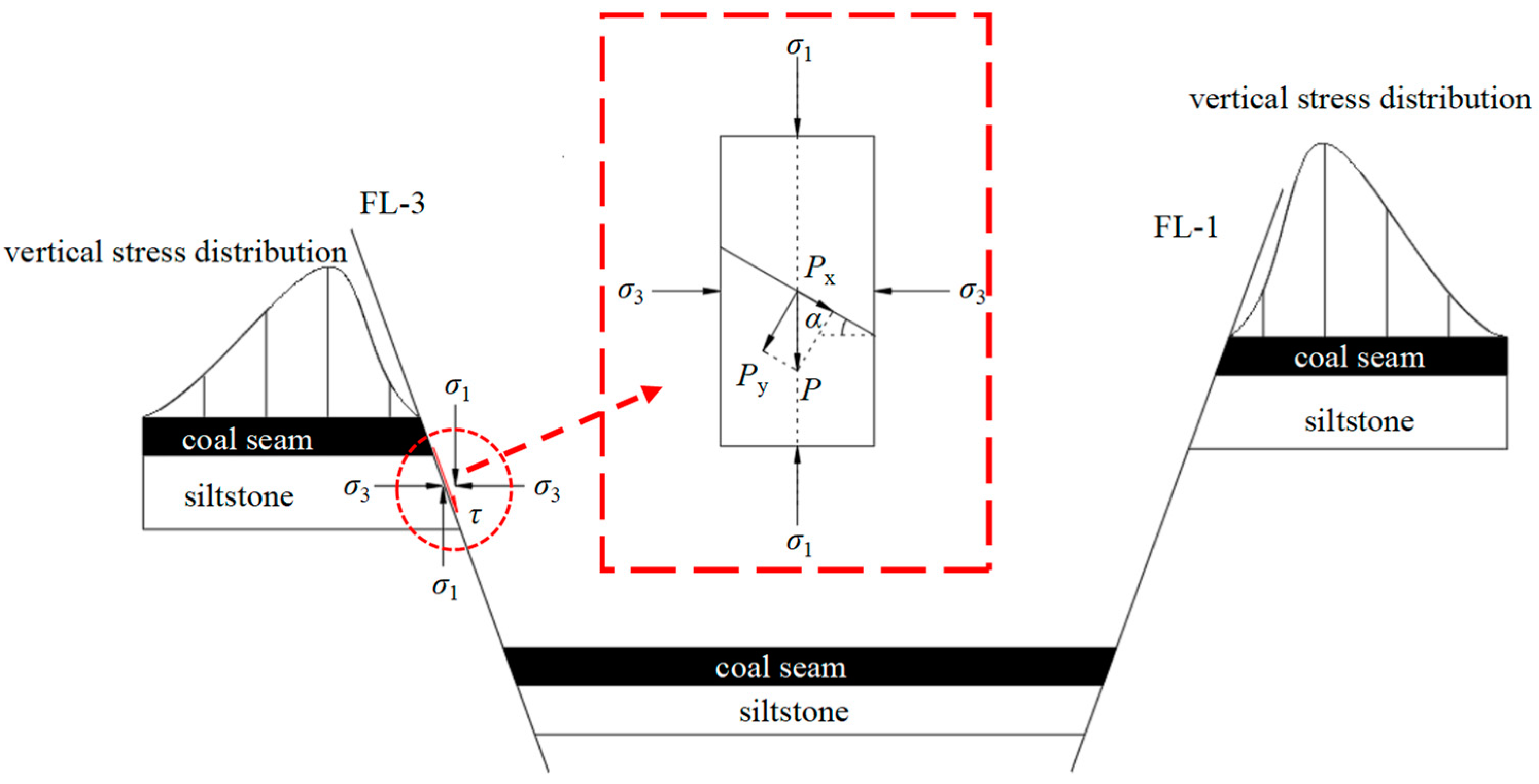

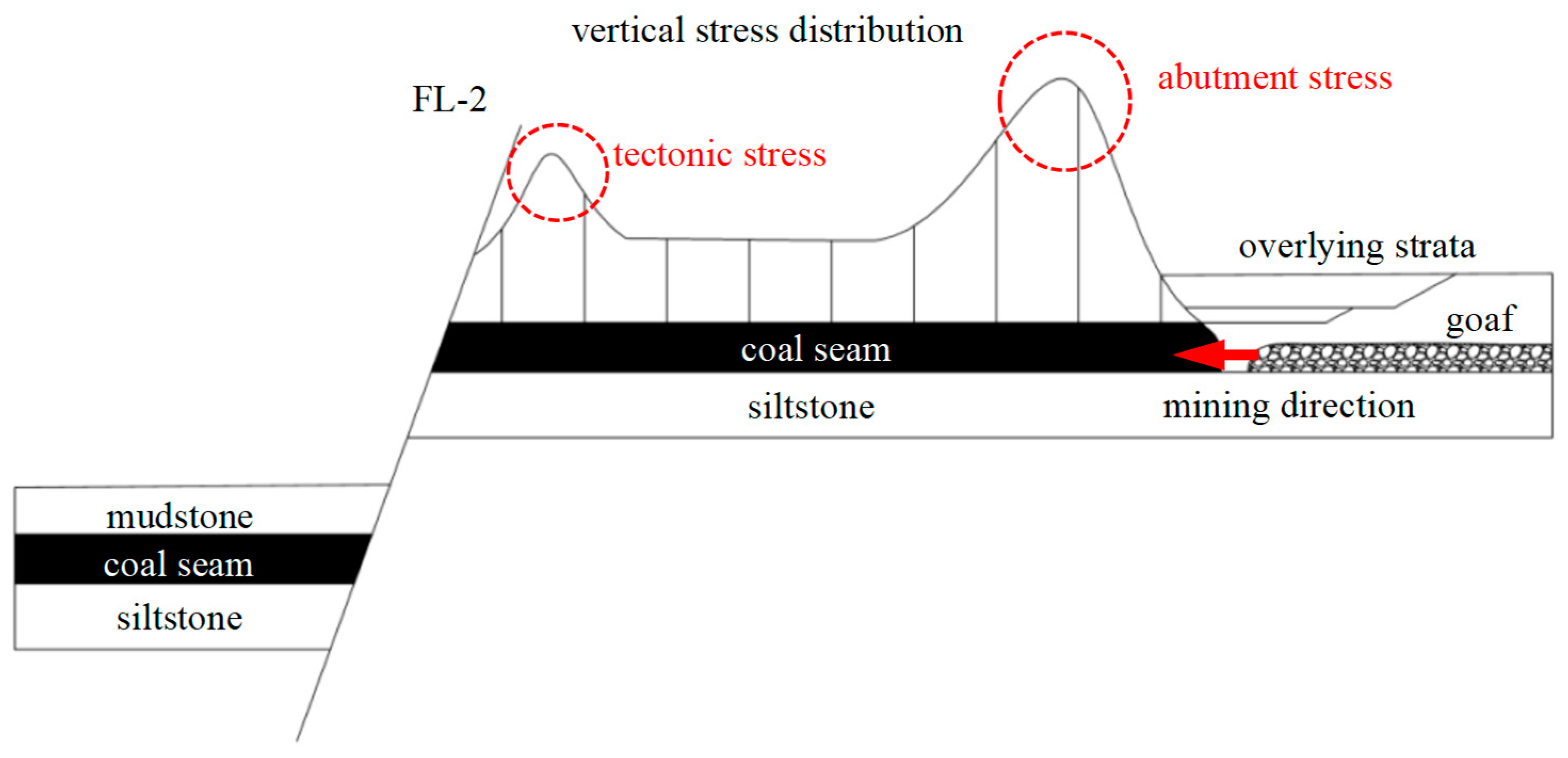

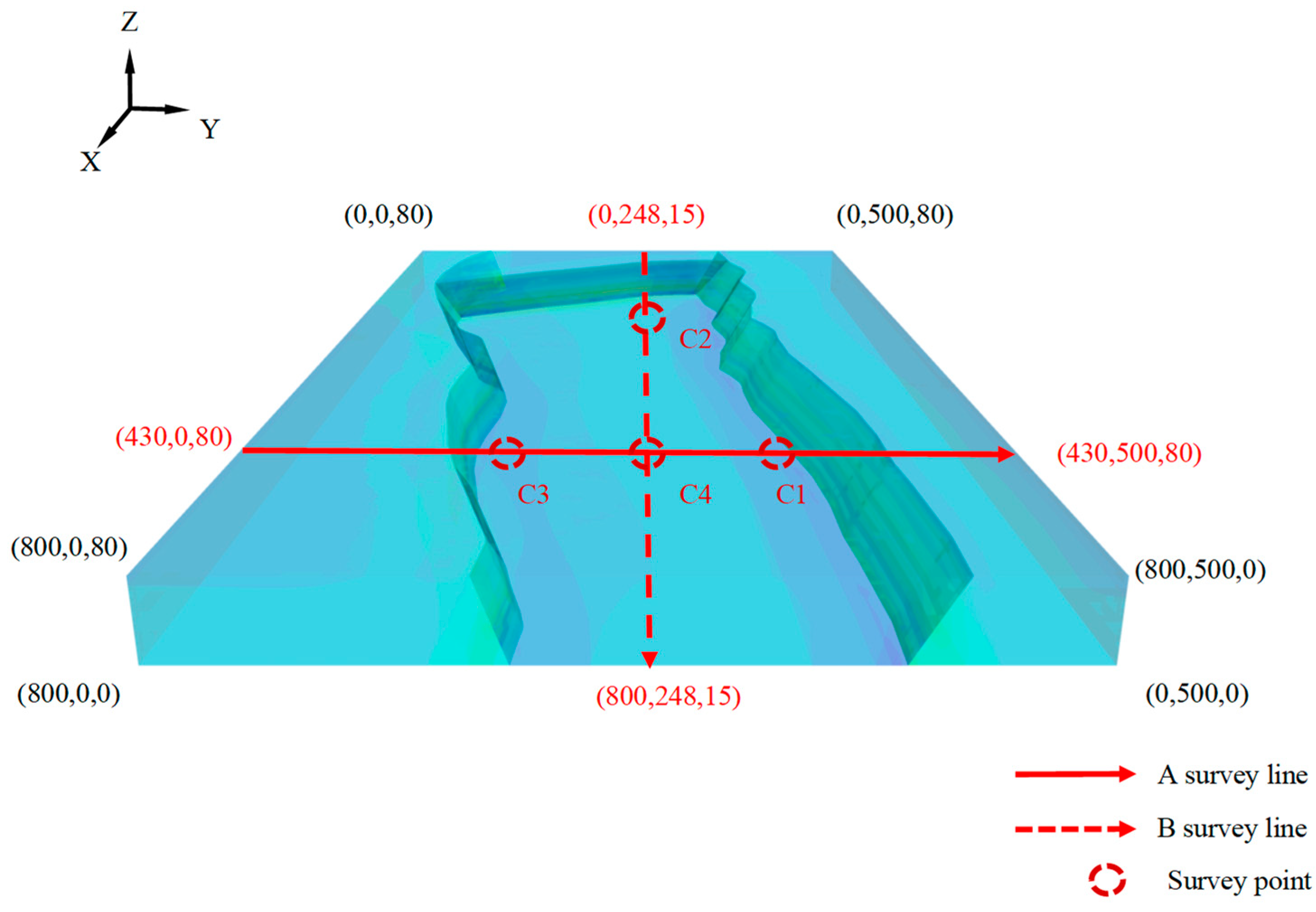

3.3. Numerical Model Construction

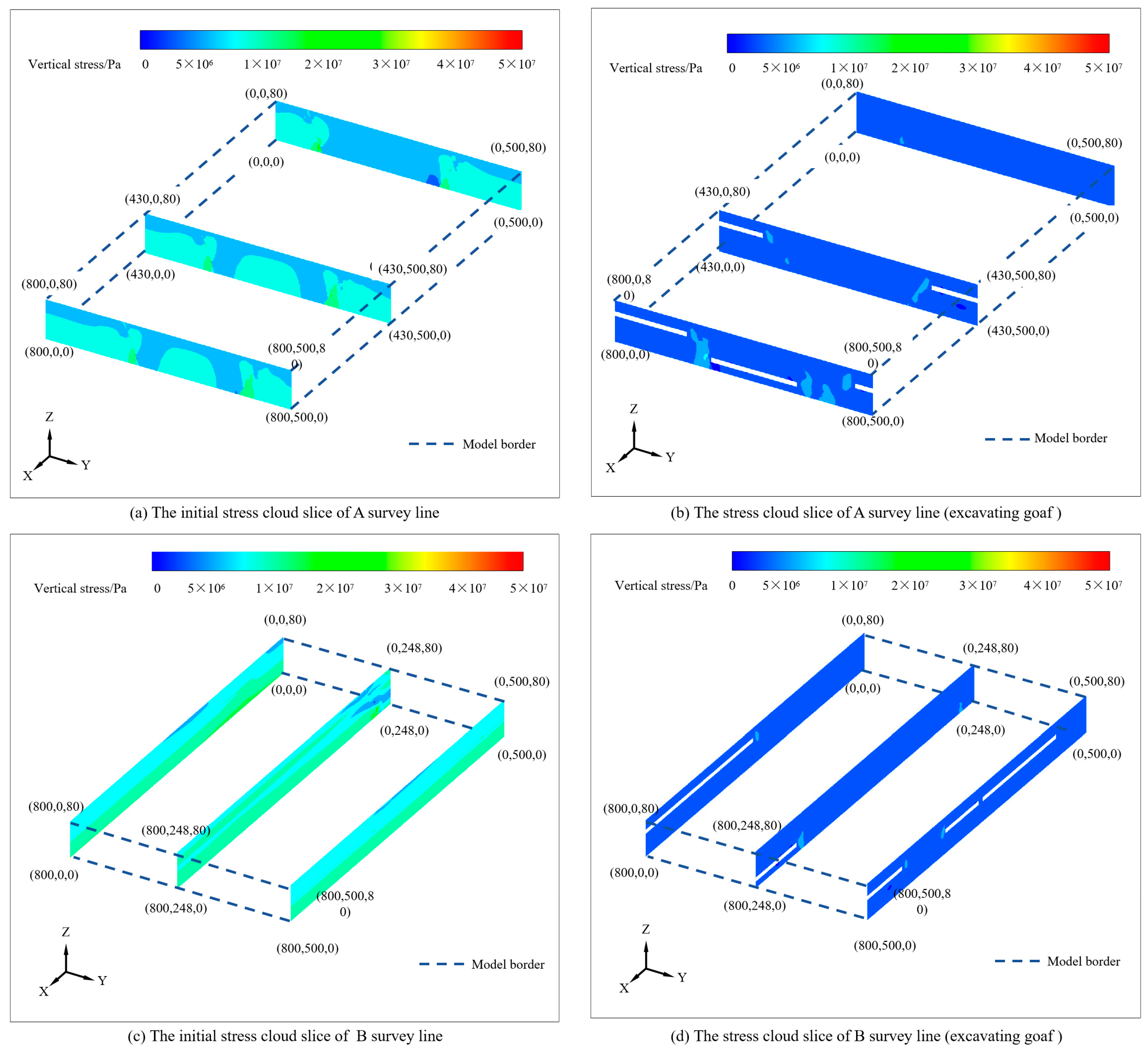

4. Results and Discussion

5. Conclusions

- (1)

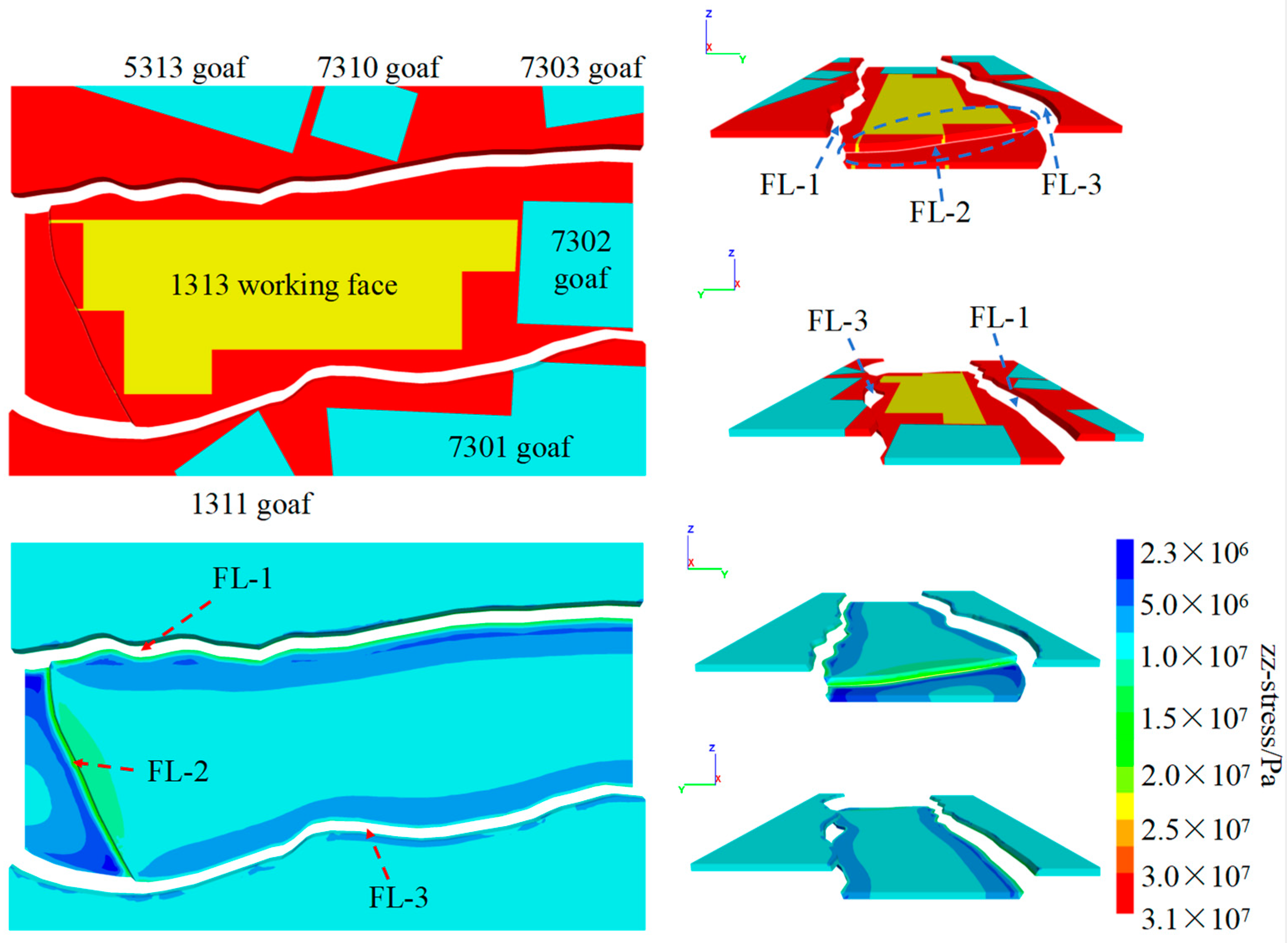

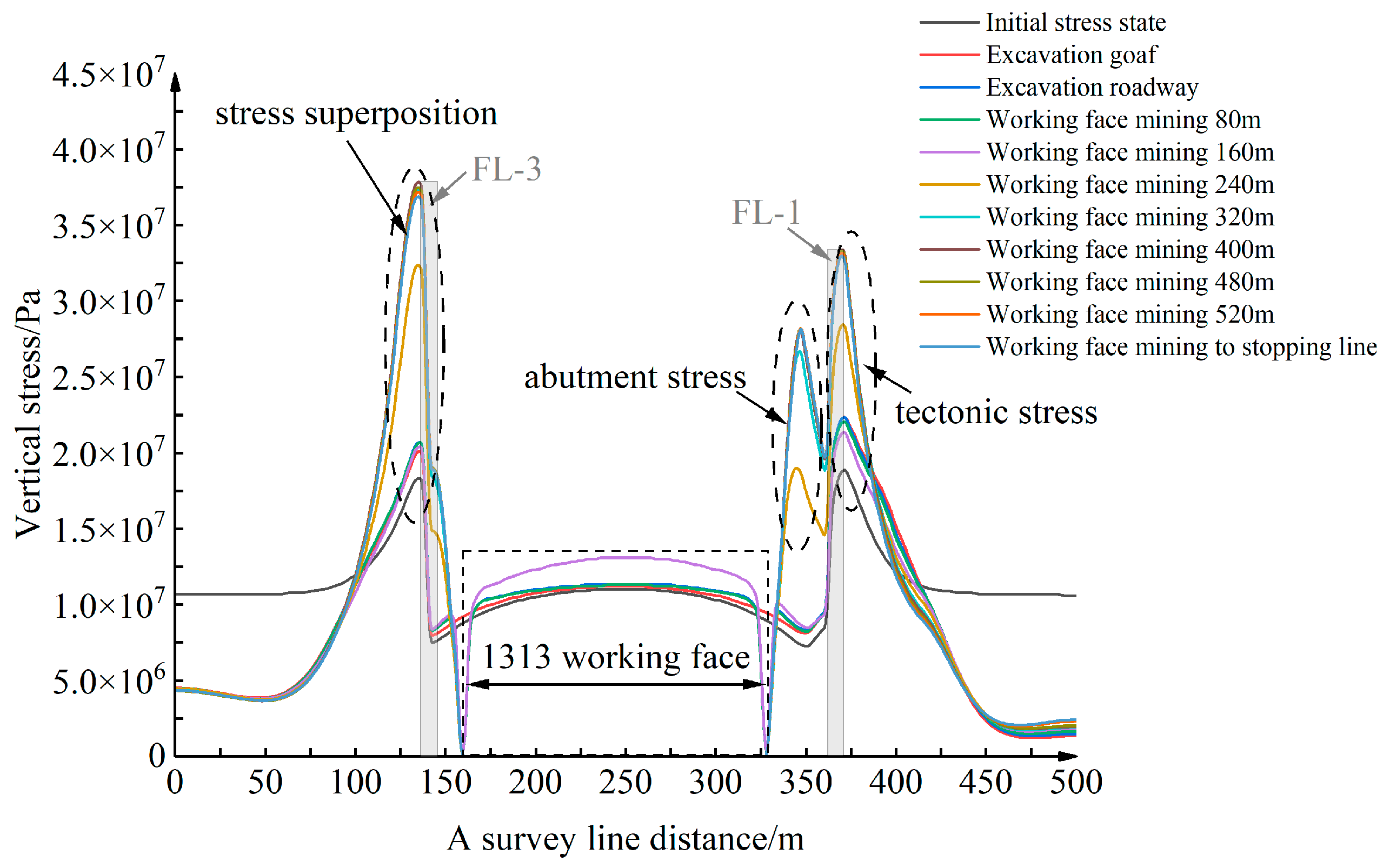

- The fault structure groups are composed of FL-1, FL-2 and FL-3, under the influence of no mining disturbance. Under the initial stress balance state, a reduced stress area in the 35 m range appears on the hanging wall of the fault, which is reduced by 3.9 MPa, and an increased stress area of about 30 m appears on the footwall of the fault, which is increased by 1.3 MPa.

- (2)

- During the excavation of the surrounding goaf, due to the stress barrier effect of the fault structure groups, the coal pillar faults near FL-1 and FL-3 are mainly affected by the goaf. The stress near the measuring points C1 and C3 is relatively increased, and the stress increases are 1.2 MPa and 0.4 MPa, respectively. FL-2 is less affected by the goaf as a whole.

- (3)

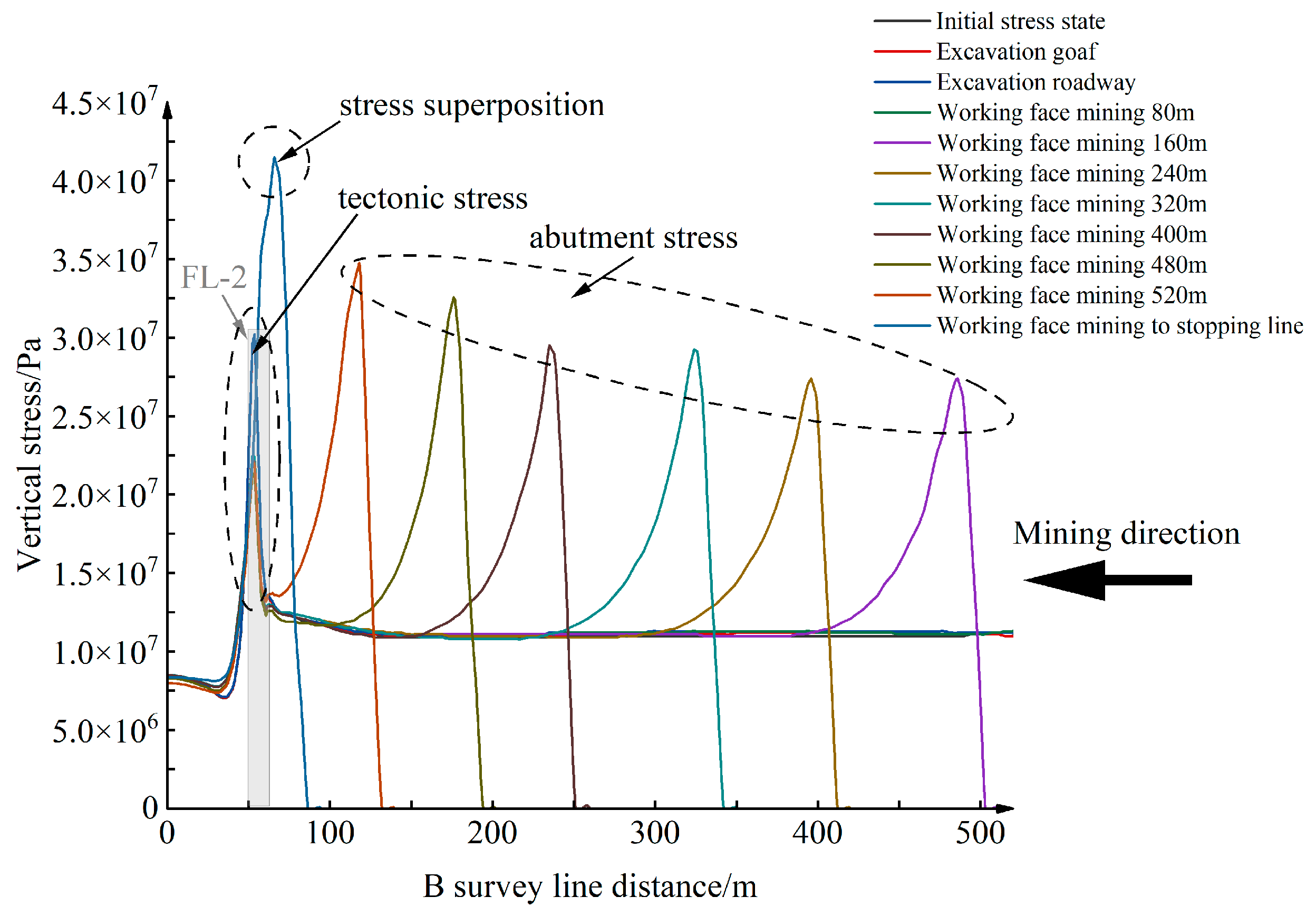

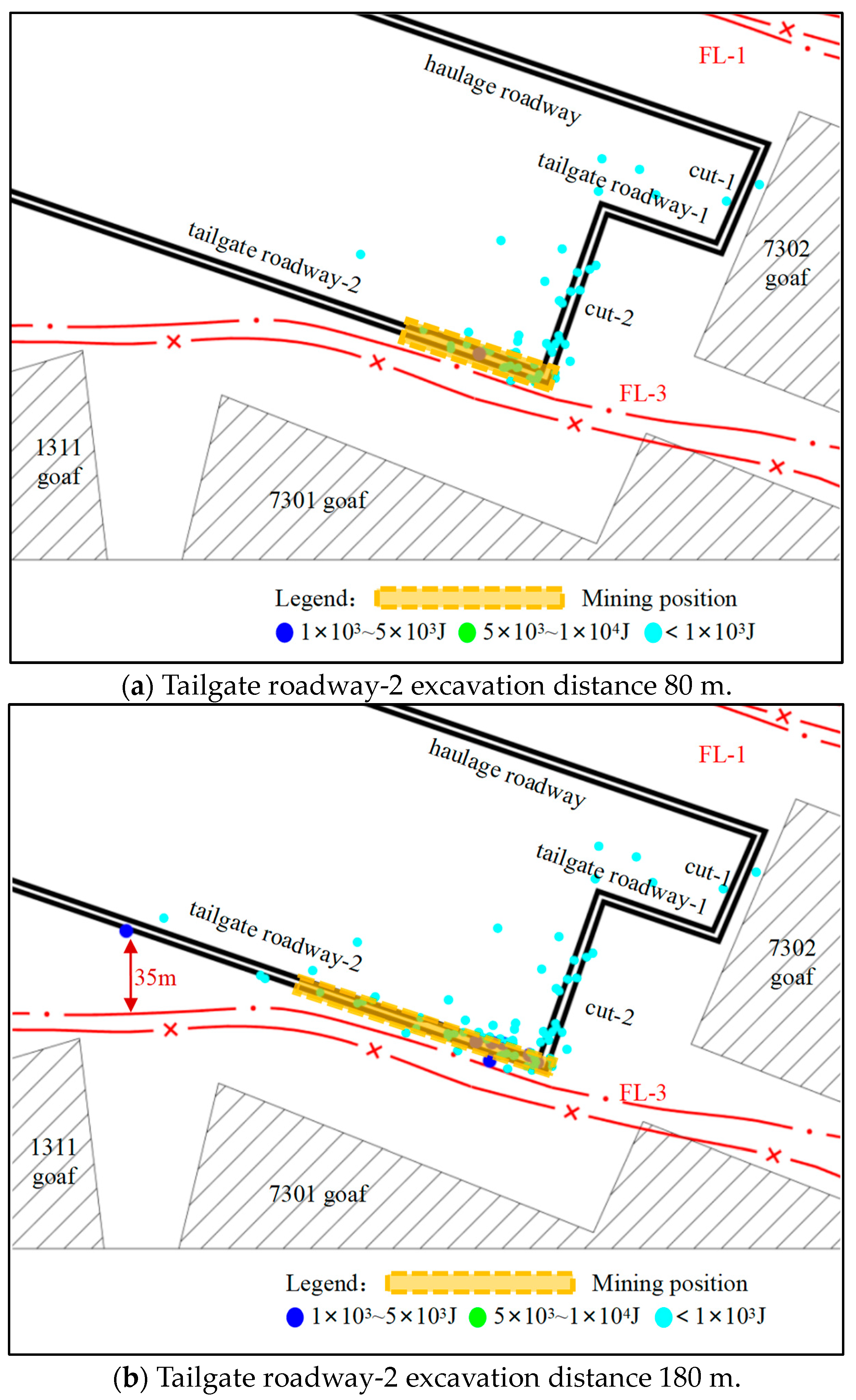

- During the mining period of the 1313 working face, the fault structure groups as a whole have a barrier effect on the propagation of coal seam stress. On the A line, the peak stress of the FL-3 coal pillar fault is 37.7 MPa, and the peak stress of the FL-1 coal pillar fault is 33.5 MPa. Both FL-1 and FL-3 have stress peaks in the footwall of the fault, which are in the range of 11 m and 6 m, respectively, and a stress barrier effect occurs in the hanging wall of the fault. At the end of the FL-2 fault mining, the superposition of the advanced support stress and the tectonic stress is more obvious, and the peak stress is up to 41.5 MPa.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Han, H.; Hu, Z.; Liu, Y.; Zuo, W.; Wang, X.; Shi, C.; He, Y.; Qi, Y. Mining stress formation and distribution: Predictive model based on overburden key strata structure. Energy Sci. Eng. 2024, 12, 1551–1568. [Google Scholar] [CrossRef]

- Wang, C.; Si, G.; Zhang, C.; Cao, A.; Canbulat, I. Ground motion characteristics and their cumulative impacts to burst risks in underground coal mines. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 39. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, K.; Reniers, G.; You, G. Statistical analysis the characteristics of extraordinarily severe coal mine accidents (ESCMAs) in China from 1950 to 2018. Process Saf. Environ. Prot. 2020, 133, 332–340. [Google Scholar] [CrossRef]

- Keneti, A.; Sainsbury, B.-A. Review of published rockburst events and their contributing factors. Eng. Geol. 2018, 246, 361–373. [Google Scholar] [CrossRef]

- Zhang, C.; Canbulat, I.; Hebblewhite, B.; Ward, C.R. Assessing coal burst phenomena in mining and insights into directions for future research. Int. J. Coal Geol. 2017, 179, 28–44. [Google Scholar] [CrossRef]

- Wei, C.; Zhang, C.; Canbulat, I.; Huang, W. Numerical investigation into impacts of major fault on coal burst in longwall mining—A case study. Int. J. Rock Mech. Min. Sci. 2021, 147, 104907. [Google Scholar] [CrossRef]

- Gao, F.; Kang, H.; Li, J. Numerical simulation of fault-slip rockbursts using the distinct element method. Tunn. Undergr. Space Technol. 2021, 110, 103805. [Google Scholar] [CrossRef]

- Li, Z.; Dou, L.; Cai, W.; Wang, G.; He, J.; Gong, S.; Ding, Y. Investigation and analysis of the rock burst mechanism induced within fault–pillars. Int. J. Rock Mech. Min. Sci. 2014, 70, 192–200. [Google Scholar] [CrossRef]

- Liu, Z.; Cao, A.; Liu, G.; Li, J. Experimental Research on Stress Relief of High-Stress Coal Based on Noncoupling Blasting. Arab. J. Sci. Eng. 2018, 43, 3717–3724. [Google Scholar] [CrossRef]

- Hofmann, G.F.; Scheepers, L.J. Simulating fault slip areas of mining induced seismic tremors using static boundary element numerical modelling. Min. Technol. 2011, 120, 53–64. [Google Scholar] [CrossRef]

- Jiao, Z.; Yuan, Q.; Zou, P.; Shi, B. Case Study of the Characteristics and Mechanism of Rock Burst near Fault in Yima Coalfield, China. Shock Vib. 2021, 2021, 9950273. [Google Scholar] [CrossRef]

- Guo, Y.; Luo, L.; Wang, C. Research on Fault Activation and Its Influencing Factors on the Barrier Effect of Rock Mass Movement Induced by Mining. Appl. Sci. 2023, 13, 651. [Google Scholar] [CrossRef]

- Kong, P.; Liu, R.; Xing, L.; Li, Z.; Xu, C.; Zhang, Z. Study on the dynamic response and the hazard of rock burst under the influence of fault slip. Front. Earth Sci. 2023, 10, 1034332. [Google Scholar] [CrossRef]

- Tong, J. Application of Grey System Optimal Theory Model in Forecasting Rockburst. J. North China Inst. Water Conserv. Hydroelectr. Power 2003, 24, 37–40. [Google Scholar]

- Skrzypkowski, K.; Zagórski, K.; Zagórska, A.; Apel, D.B.; Wang, J.; Xu, H.; Guo, L. Choice of the Arch Yielding Support for the Preparatory Roadway Located near the Fault. Energies 2022, 15, 3774. [Google Scholar] [CrossRef]

- Mark, C. Coal bursts that occur during development: A rock mechanics enigma. Int. J. Min. Sci. Technol. 2018, 28, 35–42. [Google Scholar] [CrossRef]

- Maleki, H.; Lawson, H. Analysis of geomechanical factors affecting rock bursts insedimentary rock formations. Procedia Eng. 2017, 191, 82–88. [Google Scholar] [CrossRef]

- Li, Z.; Dou, L.; Lu, C.; Mu, Z.; Cao, A. Study on fault induced rock bursts. J. China Univ. Min. Technol. 2008, 18, 321–326. [Google Scholar] [CrossRef]

- Afraei, S.; Shahriar, K.; Madani, S.H. Statistical assessment of rock burst potential and contributions of considered predictor variables in the task. Tunn. Undergr. Space Technol. 2018, 72, 250–271. [Google Scholar] [CrossRef]

- Frith, R.; Reed, G.; Jones, A. A causation mechanism for coal bursts during roadway development based on the major horizontal stress in coal: Very specific structural geology causing a localised loss of effective coal confinement and Newton’s second law. Int. J. Min. Sci. Technol. 2020, 30, 39–47. [Google Scholar] [CrossRef]

- Shen, B.; Duan, Y.; Luo, X.; van de Werken, M.; Dlamini, B.; Chen, L.; Vardar, O.; Canbulat, I. Monitoring and modelling stress state near major geological structures in an underground coal mine for coal burst assessment. Int. J. Rock Mech. Min. Sci. 2020, 129, 104294. [Google Scholar] [CrossRef]

- Deng, S.; Li, J.; Jiang, H.; Wang, M. Experimental and theoretical study of the fault slip events of rock masses around underground tunnels induced by external disturbances. Eng. Geol. 2018, 233, 191–199. [Google Scholar] [CrossRef]

- Li, G.; Ma, F.; Guo, J.; Zhao, H.; Liu, G. Study on deformation failure mechanism and support technology of deep soft rock roadway. Eng. Geol. 2020, 264, 105262. [Google Scholar] [CrossRef]

- Zhang, J.; Li, X.; Qin, Q.; Wang, Y.; Gao, X. Study on overlying strata movement patterns and mechanisms in super-large mining height stopes. Bull. Eng. Geol. Environ. 2023, 82, 142. [Google Scholar] [CrossRef]

- Li, M.; Li, K.; Liu, Y.; Wu, S.; Qin, Q.; Yue, R. Goaf risk prediction based on IAOA–SVM and numerical simulation: A case study. Undergr. Space 2024, 15, 153–175. [Google Scholar] [CrossRef]

- Dong, M.; Gao, Z.; Liu, L. Model Optimization Method Based on Rhino. Adv. Manuf. Autom. IX 2020, 634, 267–274. [Google Scholar] [CrossRef]

- Suchowerska, A.M.; Carter, J.P.; Merifield, R.S. Horizontal stress under supercritical longwall panels. Int. J. Rock Mech. Min. Sci. 2014, 70, 240–251. [Google Scholar] [CrossRef]

- Zhang, L.; Shen, W.; Li, X.; Wang, Y.; Qin, Q.; Lu, X.; Xue, T. Abutment Pressure Distribution Law and Support Analysis of Super Large Mining Height Face. Int. J. Environ. Res. Public Health 2023, 20, 227. [Google Scholar] [CrossRef]

- Zhang, W.; Li, C.; Jin, J.; Qu, X.; Fan, S.; Xin, C. A new monitoring-while-drilling method of large diameter drilling in underground coal mine and their application. Measurement 2021, 173, 108840. [Google Scholar] [CrossRef]

- Sainoki, A.; Mitri, H.S. Dynamic Modelling of Fault Slip Induced by Stress Waves due to Stope Production Blasts. Rock Mech. Rock Eng. 2016, 49, 165–181. [Google Scholar] [CrossRef]

- Wu, K.; Zou, J.; Jiao, Y.-Y.; He, S.; Wang, G. Insight and Effectiveness of Working-Face Deep-Hole Blasting for Prevention of Strong Seismicity Induced by Deep Coal Mining. Rock Mech. Rock Eng. 2023, 56, 8693–8709. [Google Scholar] [CrossRef]

- Zou, J.; Wu, K.; Zhang, X.; Zhu, J.; Zhou, Z.; Zheng, F.; Xie, H.; Jiao, Y.-Y. Effective evaluation of deep-hole blasting for controlling strong tremors induced by deep coal mining—A case study. Int. J. Rock Mech. Min. Sci. 2022, 159, 105211. [Google Scholar] [CrossRef]

| Type of the Strata | Rock Category | Average Thickness (/m) | Lithological Characteristics |

|---|---|---|---|

| Main roof | Interbedding of siltstone-sandstone | 20.54 | Gray-white, massive oblique bedding with a diameter of 5 mm in the upper part, locally sandwiched with thin layers of fine sandstone |

| Immediate roof | Siltstone | 3.66 | Grey-black, block contains plant fossil fragments, cracks are developed |

| Immediate floor | Siltstone | 3.12 | Dark gray, a small amount of charcoal, horizontal thin layer; the top root-bearing fossils contain fine sheep teeth and khoda tree fossils |

| Main floor | Medium sandstone | 15.52 | Gray-white, quartz feldspar, muscovite sheet and black carbon debris; the siliceous cementation is hard with black siltstone and developed cracks |

| Fault Name | Strike/° | Tendency/° | Dip/° | Drop/m |

|---|---|---|---|---|

| FL-1 | 104.7~131.4 | 194.7~221.4 | 60 | 0~30 |

| FL-2 | 171~181 | 261~271 | 55 | 0~15 |

| FL-3 | 161~169 | 71~79 | 70~80 | 0~36 |

| Lithology | Bulk Modulus/GPa | Shear Modulus/GPa | Cohesion/MPa | Internal Friction Angel/ ° | Tensile Strength/ MPa | Density/ kg/m3 |

|---|---|---|---|---|---|---|

| Medium sandstone | 6.5 | 3.5 | 8.3 | 39 | 4.2 | 2650 |

| 3# Coal | 1.5 | 0.6 | 1.5 | 23 | 0.2 | 1300 |

| Mudstone | 4.1 | 2.9 | 4.8 | 28 | 2.3 | 2340 |

| Fine sandstone | 5.5 | 2.5 | 4.9 | 30 | 4.2 | 2650 |

| Siltstone | 6.5 | 3.5 | 8.3 | 35 | 3.4 | 2750 |

| Fault Name | Stiffness—Shear /GPa | Stiffness—Normal/GPa | Cohesion /MPa | Internal Friction Angel /° |

|---|---|---|---|---|

| FL-1 | 20.0 | 20.0 | 2.0 | 30 |

| FL-2 | 20.0 | 20.0 | 2.0 | 30 |

| FL-3 | 20.0 | 20.0 | 2.0 | 30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, J.; Wang, C.; Liu, Z.; Lyu, J.; Lu, Y.; You, W.; Yan, J. Study on the Application of Finite Difference in Geological Mine Fault Groups: A Case Study. Processes 2024, 12, 1162. https://doi.org/10.3390/pr12061162

Yuan J, Wang C, Liu Z, Lyu J, Lu Y, You W, Yan J. Study on the Application of Finite Difference in Geological Mine Fault Groups: A Case Study. Processes. 2024; 12(6):1162. https://doi.org/10.3390/pr12061162

Chicago/Turabian StyleYuan, Jianbo, Chao Wang, Zhigang Liu, Jingchao Lyu, Yajun Lu, Wuchao You, and Jiazheng Yan. 2024. "Study on the Application of Finite Difference in Geological Mine Fault Groups: A Case Study" Processes 12, no. 6: 1162. https://doi.org/10.3390/pr12061162