IoT-Based Data Mining Framework for Stability Assessment of the Laser-Directed Energy Deposition Process

Abstract

1. Introduction

2. Materials and Methods

2.1. Hardware Systems

2.1.1. Pre-Process Machines for Feedstock Assessment

2.1.2. Industrial Grade DED-L System

2.1.3. Post-Processing Machines for Heat Treatment and Quality Assessment

2.2. Sensors

2.2.1. Integrated OCT-System

2.2.2. Integrated Near-Infrared Camera

2.2.3. Integrated Environment Sensors

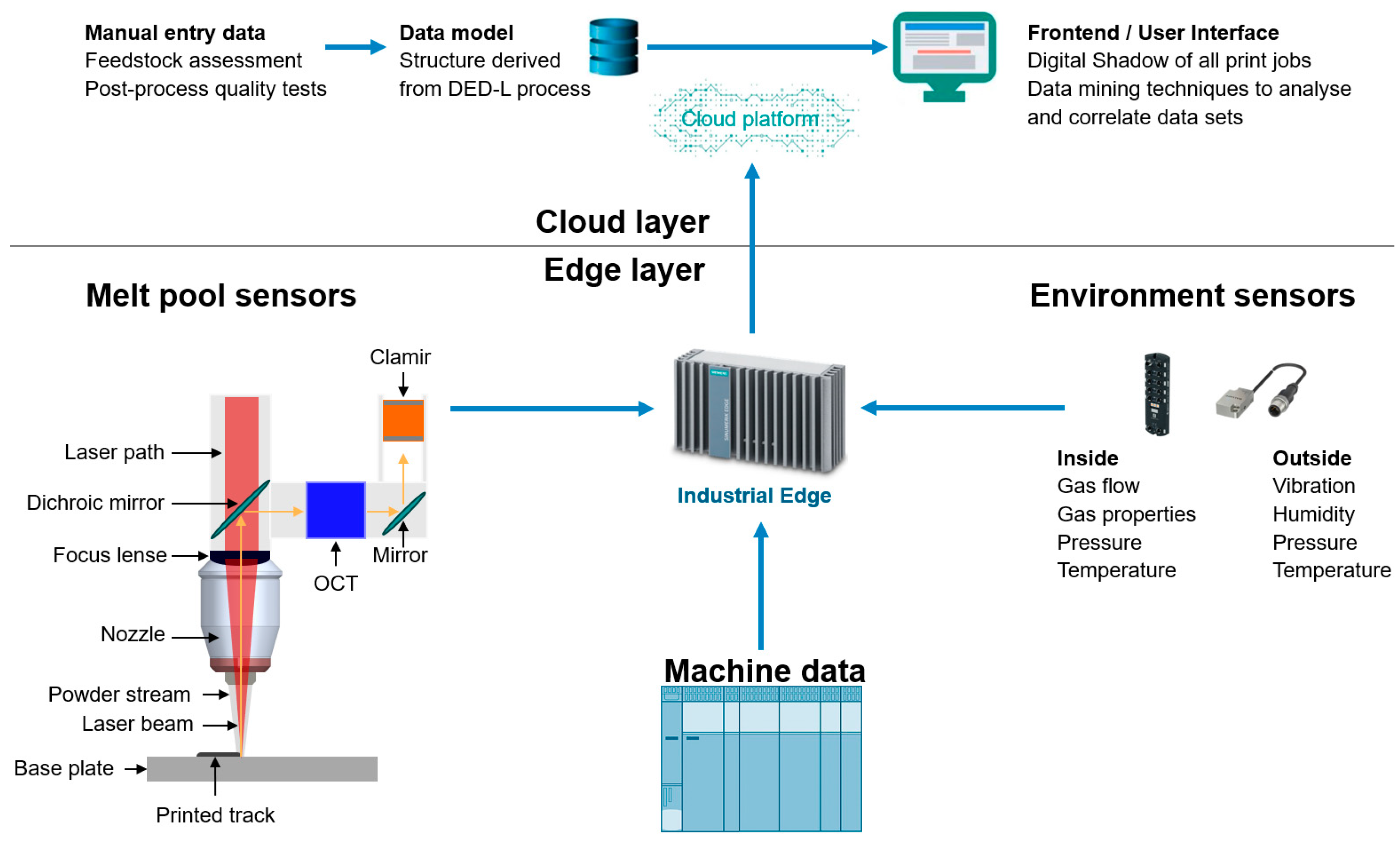

2.3. Digital Architecture

2.4. Front End with Digital Shadow

2.5. Methodology

3. Results

3.1. Feedstock Assessment

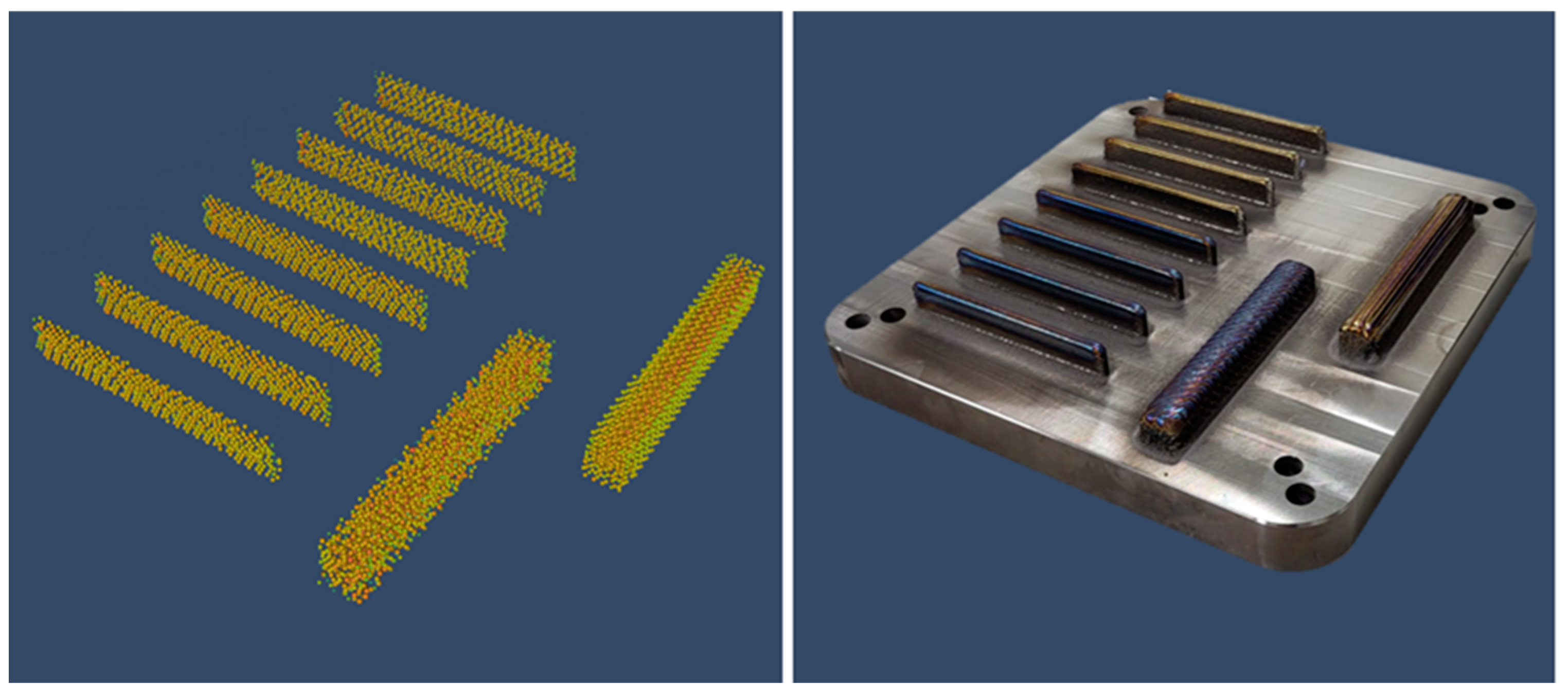

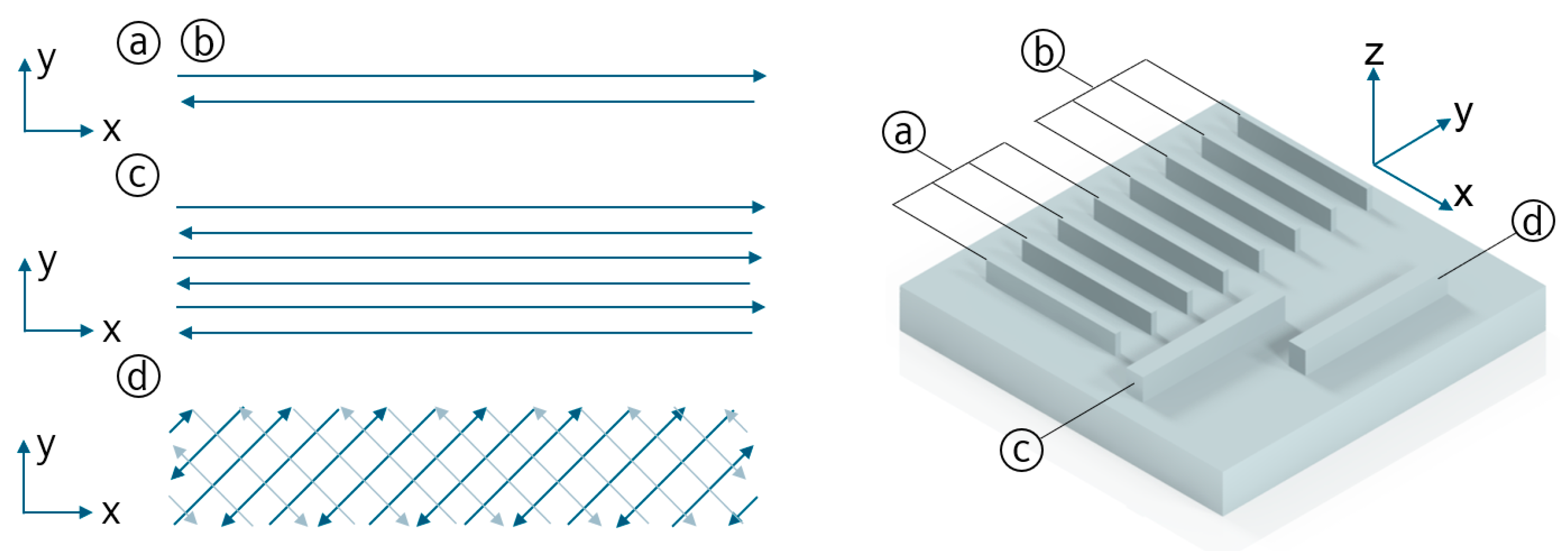

3.2. Process Planning

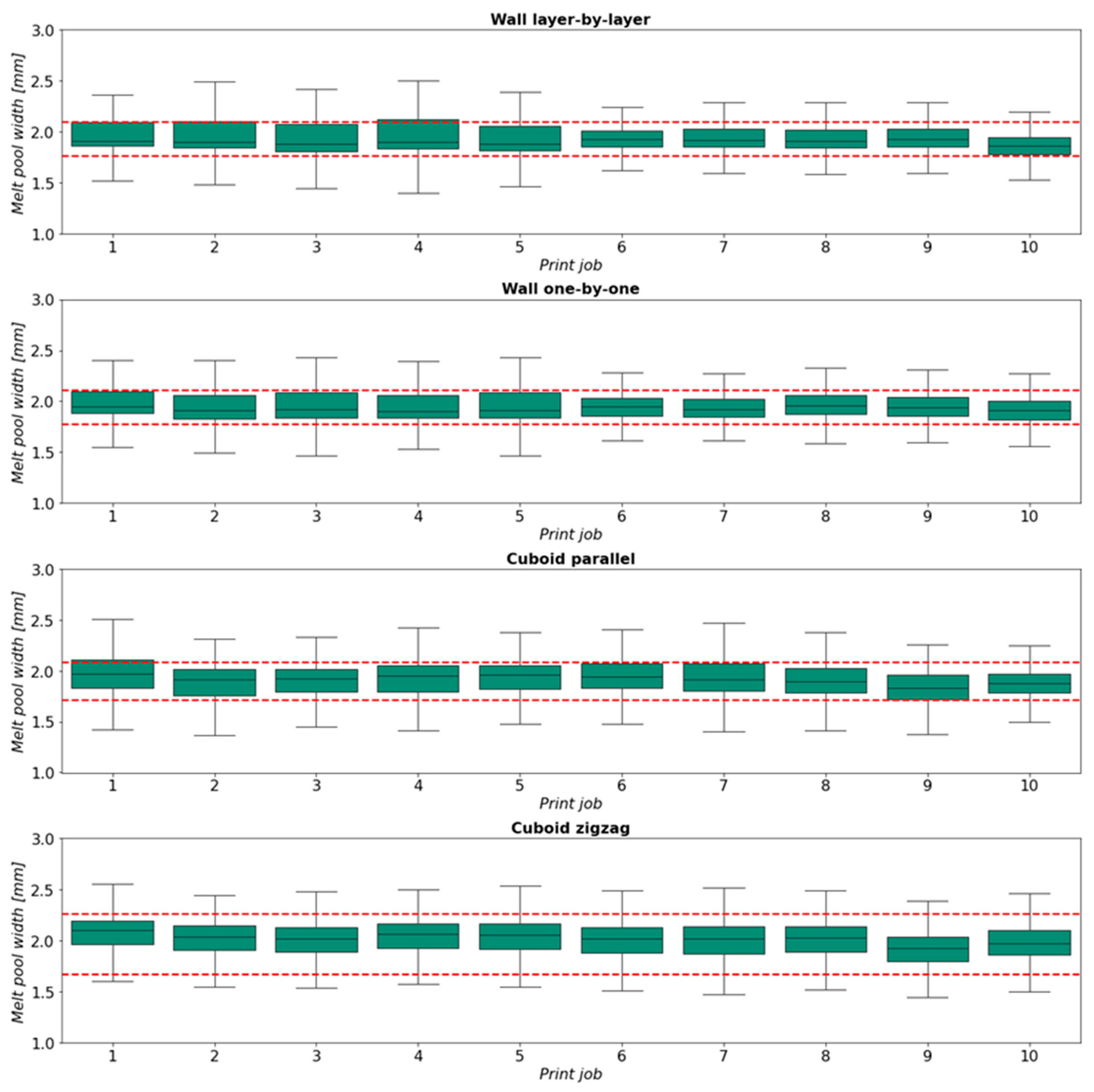

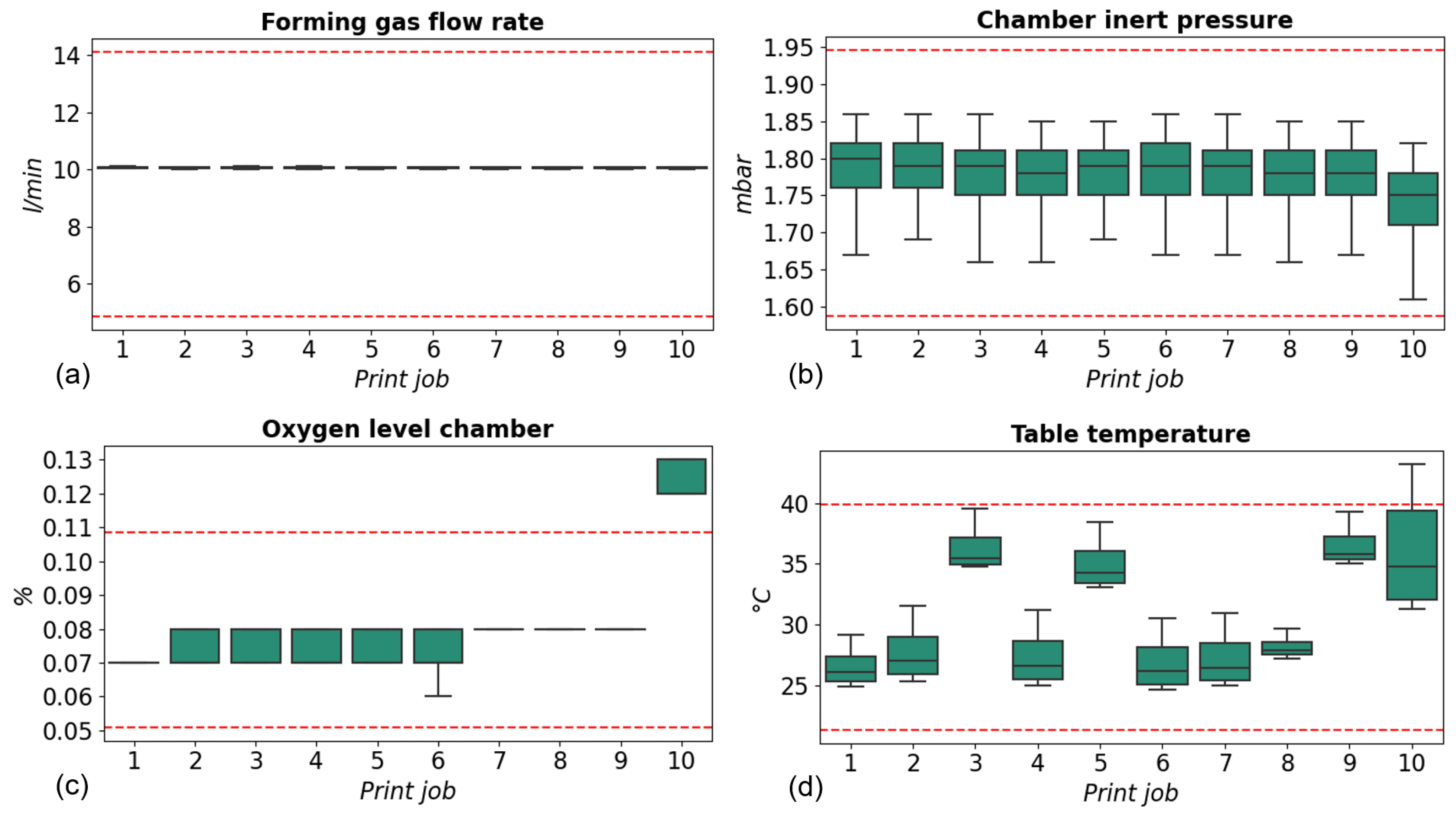

3.3. In Situ Process Data

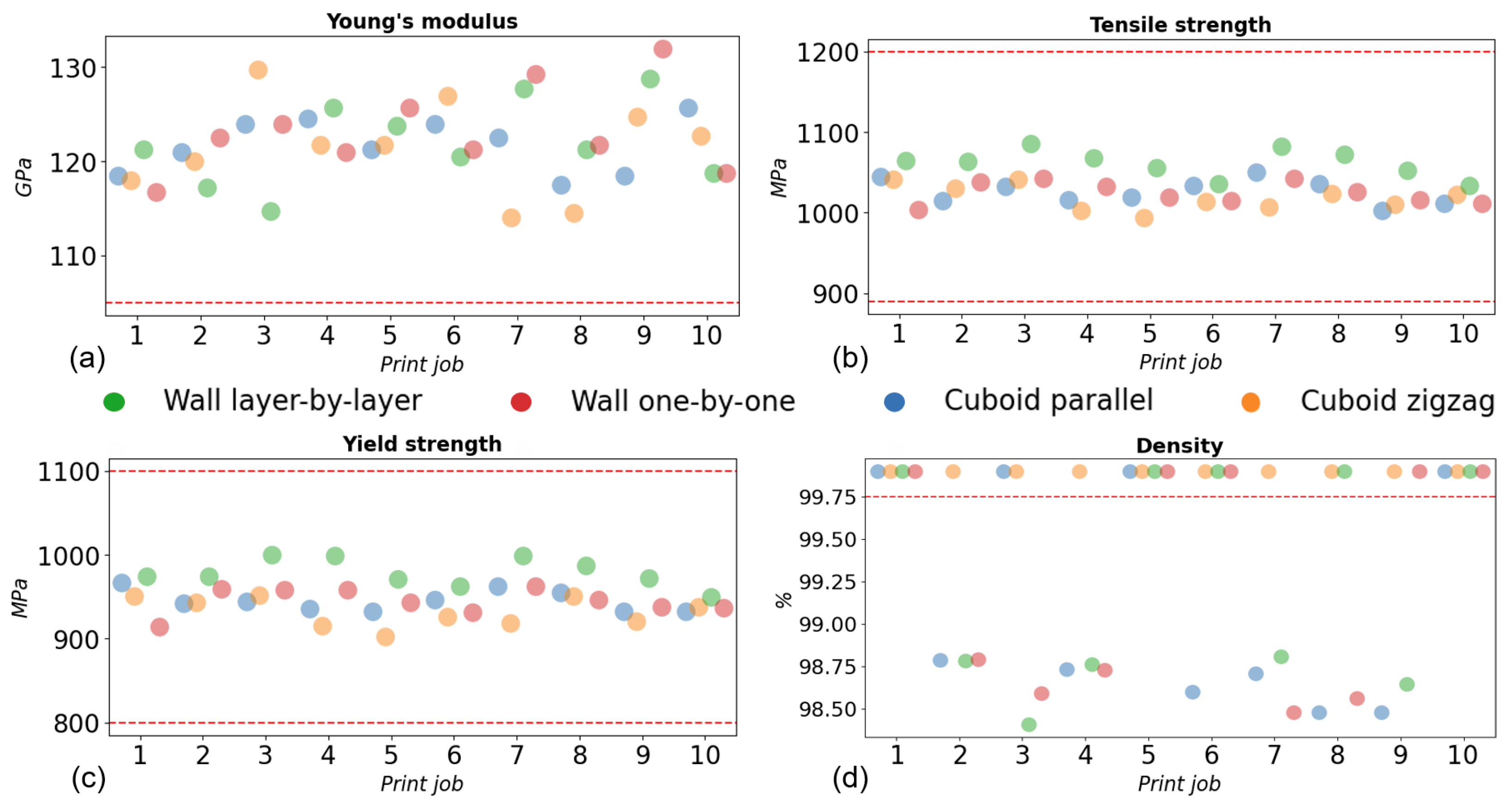

3.4. Post-Process Data

4. Discussion

5. Conclusions

- A total of 18 sensors were integrated into an industrial-grade DED-L system to collect data from the melt pool and machine environment during multiple printing processes.

- An edge IPC was employed to pre-process and fuse the data streams from the sensors with the data coming from the DED-L machine to create a digital shadow of each print job.

- All in situ data points were transferred into the cloud and subsequently stored in a database alongside the corresponding data sets from all other lifecycle steps.

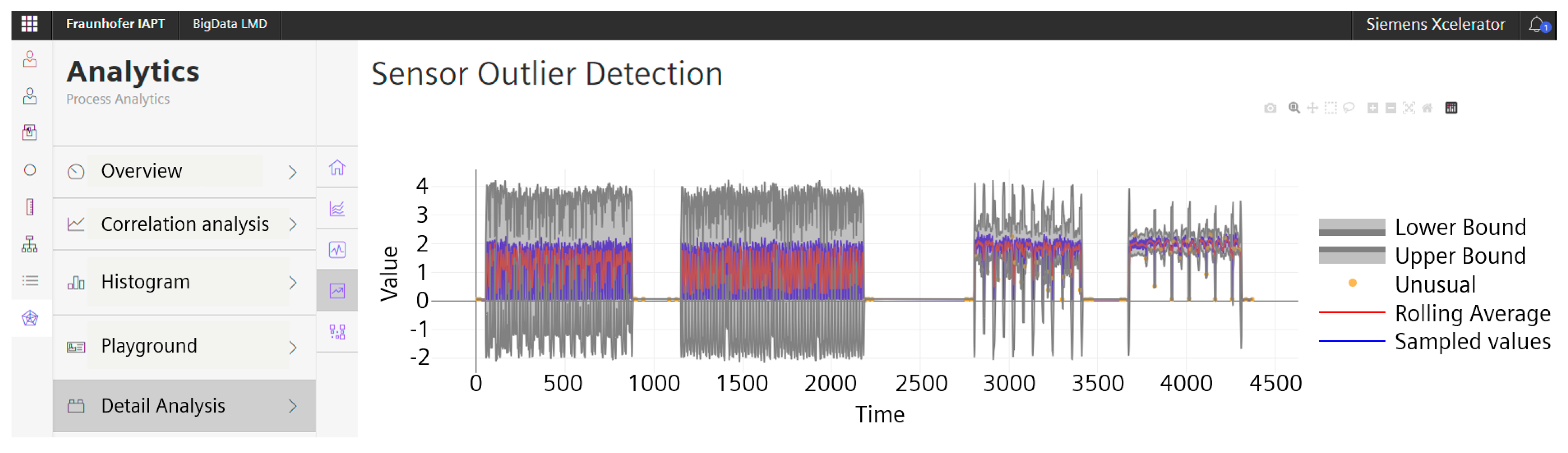

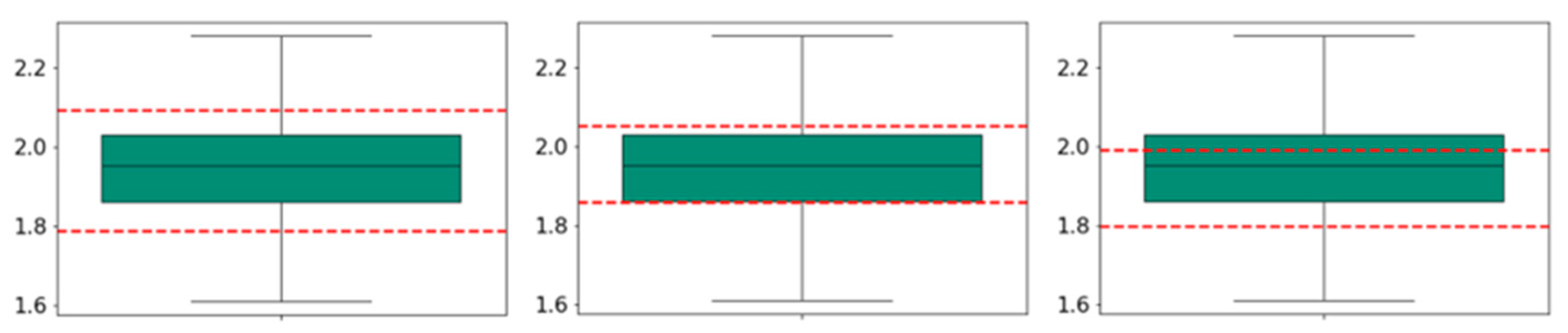

- To identify anomalies in the sensor data, thresholds were defined based on the standard deviation from the mean and the interquartile range of the respective data sets.

- Ten print jobs consisting of four sub-print jobs, each representing a different build strategy, were manufactured to test the capabilities of the proposed framework.

- For the feedstock assessment as well as the process planning stage, no anomalies were detected in the data.

- Considering the in situ sensor data, the proposed boundaries indicated multiple sub-print jobs as potentially anomalous.

- The post-process data for the Young’s modulus, tensile, and yield strength exhibited no outliers, while the density tests identified anomalies in a total of 16 sub-print jobs.

- As these 16 sub-print jobs can only be partially traced back to anomalies in the in situ sensor data, a clear need for a more sophisticated sensor setup and calibration can be derived from this study.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Machine Name | Process | Used for | Characteristics |

|---|---|---|---|

| Pre-process feedstock assessment | |||

| Hall flowmeter | Flowmeter | Characterization of bulk and tap density, powder flowrate, and Hausner ratio | Density-based on 25 cm3 of volume; powder flow–based on 50 g of powder passing defined funnel |

| Camsizer X2 | Dynamic image analysis | Particle size distribution | Measures powder from 0.8 mm to 8 mm in a dispersion |

| Granudrum | Optical based rheometer | Avalanche angle of response | Recording of images with a 2 Hz frequency |

| DED-L system | |||

| Beam Modulo 400 | DED-L | Specimen near-net-shape manufacturing | 2 kW IPG laser source, inert gas chamber, vibration powder feeder |

| Post-process machining | |||

| Nabertherm N41/h | Furnace | Stress release of specimens | Up to 1280 °C, no controlled atmosphere |

| DMU 50 ecoline | Milling machine | Specimen form milling | 5-axis milling, up to 8000 revolutions per minute |

| ROBOCUT α-C600iB | Wire EDM | Final specimen form cutting | Minimum step size of the drives: 0.0001 mm |

| Post-process quality testing | |||

| ZwickRoell Z100 | Tensile tests | Measuring of E-Module the Elongation at Break Tensile Strength , Yield Strength | Max. testing force 100 kN. Rapid, static, oscillating, or alternating force application possible. |

| Keyence VHX-5000 | Digital microscope | Determining the porosity and density of specimens | 4 K imaging with a zoom up to 6000× |

| Sensor Name | Frequency | Process Parameters | Source |

|---|---|---|---|

| Machine data | 500 Hz | X, Y, Z, B, C, speed, laser power | Numerical control unit |

| Environmental data inside of the machine | 2 Hz | Gas flow: Hopper speed, Forming gas flow rate, Central gas flow rate, Inert gas flow rate Pressure: Chamber pressure, Forming gas pressure, Central gas pressure Inert chamber gas properties: Chamber oxygen level, Chamber oxygen percentage, Chamber humidity Temperature: Chamber temperature, Table temperature | PLC |

| Environmental data outside of the machine | 0.3 Hz | Vibration Temperature Humidity Pressure | OPC UA |

| OCT sensor | 500 Hz read out | Stand-off distance | Edge IPC |

| Clamir camera | 500 Hz read out | Melt pool width | Edge IPC |

References

- Lemu, H.G. On Opportunities and Limitations of Additive Manufacturing Technology for Industry 4.0 Era. In Advanced Manufacturing and Automation VIII; Wang, K., Wang, Y., Strandhagen, J.O., Yu, T., Eds.; Lecture Notes in Electrical Engineering; Springer: Singapore, 2019; pp. 106–113. [Google Scholar] [CrossRef]

- Ahn, D.-G. Directed Energy Deposition (DED) Process: State of the Art. Int. J. Precis. Eng. Manuf. Technol. 2021, 8, 703–742. [Google Scholar] [CrossRef]

- Zhong, C.; Kittel, J.; Gasser, A.; Schleifenbaum, J.H. Study of nickel-based super-alloys Inconel 718 and Inconel 625 in high-deposition-rate laser metal deposition. Opt. Laser Technol. 2019, 109, 352–360. [Google Scholar] [CrossRef]

- Svetlizky, D.; Das, M.; Zheng, B.; Vyatskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed energy deposition (DED) additive manufacturing: Physical characteristics, defects, challenges and applications. Mater. Today 2021, 49, 271–295. [Google Scholar] [CrossRef]

- Mukherjee, T.; DebRoy, T. A digital twin for rapid qualification of 3D printed metallic components. Appl. Mater. Today 2019, 14, 59–65. [Google Scholar] [CrossRef]

- Ertay, D.S.; Naiel, M.A.; Vlasea, M.; Fieguth, P. Process performance evaluation and classification via in-situ melt pool monitoring in directed energy deposition. CIRP J. Manuf. Sci. Technol. 2021, 35, 298–314. [Google Scholar] [CrossRef]

- Jardon, Z.; Ertveldt, J.; Hinderdael, M.; Guillaume, P. Process parameter study for enhancement of directed energy deposition powder efficiency based on single-track geometry evaluation. J. Laser Appl. 2021, 33, 042023. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components–Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Chen, Z.; Han, C.; Gao, M.; Kandukuri, S.Y.; Zhou, K. A review on qualification and certification for metal additive manufacturing. Virtual Phys. Prototyp. 2022, 17, 382–405. [Google Scholar] [CrossRef]

- Everton, S.K.; Hirsch, M.; Stravroulakis, P.; Leach, R.K.; Clare, A.T. Review of in-situ process monitoring and in-situ metrology for metal additive manufacturing. Mater. Des. 2016, 95, 431–445. [Google Scholar] [CrossRef]

- Tang, Z.-J.; Liu, W.-W.; Wang, Y.-W.; Saleheen, K.M.; Liu, Z.-C.; Peng, S.-T.; Zhang, Z.; Zhang, H.-C. A review on in situ monitoring technology for directed energy deposition of metals. Int. J. Adv. Manuf. Technol. 2020, 108, 3437–3463. [Google Scholar] [CrossRef]

- Liu, W.-W.; Tang, Z.-J.; Liu, X.-Y.; Wang, H.-J.; Zhang, H.-C. A Review on In-situ Monitoring and Adaptive Control Technology for Laser Cladding Remanufacturing. Procedia CIRP 2017, 61, 235–240. [Google Scholar] [CrossRef]

- He, W.; Shi, W.; Li, J.; Xie, H. In-situ monitoring and deformation characterization by optical techniques; part I: Laser-aided direct metal deposition for additive manufacturing. Opt. Lasers Eng. 2019, 122, 74–88. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Brandt, M. An accurate and real-time melt pool dimension measurement method for laser direct metal deposition. Int. J. Adv. Manuf. Technol. 2021, 114, 2421–2432. [Google Scholar] [CrossRef]

- Borovkov, H.; de la Yedra, A.G.; Zurutuza, X.; Angulo, X.; Alvarez, P.; Pereira, J.C.; Cortes, F. In-Line Height Measurement Technique for Directed Energy Deposition Processes. J. Manuf. Mater. Process. 2021, 5, 85. [Google Scholar] [CrossRef]

- Bartsch, K.; Pettke, A.; Hübert, A.; Lakämper, J.; Lange, F. On the digital twin application and the role of artificial intelligence in additive manufacturing: A systematic review. J. Physics Mater. 2021, 4, 032005. [Google Scholar] [CrossRef]

- Ertveldt, J.; Guillaume, P.; Helsen, J. MiCLAD as a platform for real-time monitoring and machine learning in laser metal deposition. Procedia CIRP 2020, 94, 456–461. [Google Scholar] [CrossRef]

- Hartmann, S.; Murua, O.; Arrizubieta, J.I.; Lamikiz, A.; Mayr, P. Digital Twin of the laser-DED process based on a multiscale approach. Simul. Model. Pract. Theory 2024, 132, 102881. [Google Scholar] [CrossRef]

- Reisch, R.T.; Hauser, T.; Lutz, B.; Tsakpinis, A.; Winter, D.; Kamps, T.; Knoll, A. Context awareness in process monitoring of additive manufacturing using a digital twin. Int. J. Adv. Manuf. Technol. 2022, 119, 3483–3500. [Google Scholar] [CrossRef]

- Chen, L.; Bi, G.; Yao, X.; Tan, C.; Su, J.; Ng, N.P.H.; Chew, Y.; Liu, K.; Moon, S.K. Multisensor fusion-based digital twin for localized quality prediction in robotic laser-directed energy deposition. Robot. Comput. Manuf. 2023, 84, 102581. [Google Scholar] [CrossRef]

- Yang, T.; Mazumder, S.; Jin, Y.; Squires, B.; Sofield, M.; Pantawane, M.V.; Dahotre, N.B.; Neogi, A. A Review of Diagnostics Methodologies for Metal Additive Manufacturing Processes and Products. Materials 2021, 14, 4929. [Google Scholar] [CrossRef]

- Khorasani, M.; Loy, J.; Ghasemi, A.H.; Sharabian, E.; Leary, M.; Mirafzal, H.; Cochrane, P.; Rolfe, B.; Gibson, I. A review of Industry 4.0 and additive manufacturing synergy. Rapid Prototyp. J. 2022, 28, 1462–1475. [Google Scholar] [CrossRef]

- Ashima, R.; Haleem, A.; Bahl, S.; Javaid, M.; Mahla, S.K.; Singh, S. Automation and manufacturing of smart materials in additive manufacturing technologies using Internet of Things towards the adoption of industry 4.0. Mater. Today Proc. 2021, 45, 5081–5088. [Google Scholar] [CrossRef]

- Židek, K.; Piteľ, J.; Adámek, M.; Lazorík, P.; Hošovský, A. Digital Twin of Experimental Smart Manufacturing Assembly System for Industry 4.0 Concept. Sustainability 2020, 12, 3658. [Google Scholar] [CrossRef]

- Luściński, S. Digital Twinning for Smart Industry. In Proceedings of the 3rd EAI International Conference on Management of Manufacturing Systems, Dubrovnik, Croatia, 6–8 November 2018. [Google Scholar] [CrossRef]

- Chen, B.; Wan, J.; Shu, L.; Li, P.; Mukherjee, M.; Yin, B. Smart Factory of Industry 4.0: Key Technologies, Application Case, and Challenges. IEEE Access 2018, 6, 6505–6519. [Google Scholar] [CrossRef]

- Nain, G.; Pattanaik, K.; Sharma, G. Towards edge computing in intelligent manufacturing: Past, present and future. J. Manuf. Syst. 2022, 62, 588–611. [Google Scholar] [CrossRef]

- Kubiak, K.; Dec, G.; Stadnicka, D. Possible Applications of Edge Computing in the Manufacturing Industry—Systematic Literature Review. Sensors 2022, 22, 2445. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zheng, P.; Peng, T.; Yang, H.; Zou, J. Smart additive manufacturing: Current artificial intelligence-enabled methods and future perspectives. Sci. China Technol. Sci. 2020, 63, 1600–1611. [Google Scholar] [CrossRef]

- Guo, L.; Cheng, Y.; Zhang, Y.; Liu, Y.; Wan, C.; Liang, J. Development of Cloud-Edge Collaborative Digital Twin System for FDM Additive Manufacturing. In Proceedings of the 2021 IEEE 19th International Conference on Industrial Informatics (INDIN), Palma de Mallorca, Spain, 21–23 July 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Demčák, J.; Lishchenko, N.; Pavlenko, I.; Pitel’, J.; Židek, K. The Experimental SMART Manufacturing System in SmartTechLab. In Advances in Manufacturing II; Trojanowska, J., Kujawińska, A., Machado, J., Pavlenko, I., Eds.; Lecture Notes in Mechanical Engineering; Springer International Publishing: Cham, Switzerland, 2022; pp. 228–238. [Google Scholar] [CrossRef]

- Wang, Y.; Lin, Y.; Zhong, R.Y.; Xu, X. IoT-enabled cloud-based additive manufacturing platform to support rapid product development. Int. J. Prod. Res. 2019, 57, 3975–3991. [Google Scholar] [CrossRef]

- Majeed, A.; Zhang, Y.; Ren, S.; Lv, J.; Peng, T.; Waqar, S.; Yin, E. A big data-driven framework for sustainable and smart additive manufacturing. Robot. Comput. Manuf. 2021, 67, 102026. [Google Scholar] [CrossRef]

- Jia, P.; Wang, X.; Shen, X. Digital-Twin-Enabled Intelligent Distributed Clock Synchronization in Industrial IoT Systems. IEEE Internet Things J. 2021, 8, 4548–4559. [Google Scholar] [CrossRef]

- Haghnegahdar, L.; Joshi, S.S.; Dahotre, N.B. From IoT-based cloud manufacturing approach to intelligent additive manufacturing: Industrial Internet of Things—An overview. Int. J. Adv. Manuf. Technol. 2022, 119, 1461–1478. [Google Scholar] [CrossRef]

- Liu, C.; Le Roux, L.; Körner, C.; Tabaste, O.; Lacan, F.; Bigot, S. Digital Twin-enabled Collaborative Data Management for Metal Additive Manufacturing Systems. J. Manuf. Syst. 2020, 62, 857–874. [Google Scholar] [CrossRef]

- Martikkala, A.; Wiikinkoski, O.; Asadi, R.; Queguineur, A.; Ylä-Autio, A.; Ituarte, I.F. Industrial IoT system for laser-wire direct energy deposition: Data collection and visualization of manufacturing process signals. IOP Conf. Series Mater. Sci. Eng. 2023, 1296, 012006. [Google Scholar] [CrossRef]

- DIN 13322-2:2021-12; Particle Size Analysis—Image Analysis Methods—Part 2: Dynamic Image Analysis Method. Beuth Verlag GmbH: Berlin, Germany, 2021.

- Saboori, A.; Gallo, D.; Biamino, S.; Fino, P.; Lombardi, M. An Overview of Additive Manufacturing of Titanium Components by Directed Energy Deposition: Microstructure and Mechanical Properties. Appl. Sci. 2017, 7, 883. [Google Scholar] [CrossRef]

- Addup Solutions. Modulo 400: Directed Energy Deposition. Available online: https://addupsolutions.com/wp-content/uploads/2023/09/Modulo-400-Tech-Specs-22-EN.pdf (accessed on 3 June 2024).

- Nabertherm GmbH. Furnaces for Fiber Optics and Glass. Available online: https://nabertherm.com/sites/default/files/2023-02/fiber_optics_glass_english_0.pdf (accessed on 3 June 2024).

- DIN 50125:2022-08; Testing of Metallic Materials—Tensile Test Pieces. Beuth Verlag GmbH: Berlin, Germany, 2022.

- ZwickRoell. Produktinformation: Material-Prüfmaschinen AllroundLine Z005 bis Z100. Available online: https://www.zwickroell.com/fileadmin/content/Files/SharePoint/user_upload/PI_DE/02_284_Material_Pruefmaschine_AllroundLine_Z005_bis_Z100_PI_DE.pdf (accessed on 3 June 2024).

- Möller, M.L.B. Prozessmanagement für das Laser-Pulver-Auftragschweißen, 1st ed.; Imprint: Springer Vieweg; Springer: Berlin/Heidelberg, Germany, 2021; ISBN 9783662622247. [Google Scholar]

- Prakash, V.J.; Möller, M.; Weber, J.; Emmelmann, C. Laser Metal Deposition of Titanium Parts with Increased Productivity. In 3D Printing and Additive Manufacturing Technologies; Kumar, L.J., Pandey, P.M., Wimpenny, D.I., Eds.; Springer: Singapore, 2019; pp. 297–311. [Google Scholar] [CrossRef]

- Reutzel, E.W.; Nassar, A.R. A survey of sensing and control systems for machine and process monitoring of directed-energy, metal-based additive manufacturing. Rapid Prototyp. J. 2015, 21, 159–167. [Google Scholar] [CrossRef]

- Precitec GmbH & Co. KG. Precitec IDM: Laser Welding—Process Monitoring. Available online: https://www.precitec.com/laser-welding/products/process-monitoring/precitec-idm/ (accessed on 3 June 2024).

- New Infrared Technologies, S.L. Clamir. Available online: https://www.niteurope.com/wp-content/uploads/2024/04/24-04-26_CLAMIR.pdf (accessed on 3 June 2024).

- Balluff Inc. Condition Monitoring Sensors. Available online: https://www.balluff.com/en-us/focus-topics/condition-monitoring (accessed on 3 June 2024).

- Siemens AG. Industrial Edge for Machine Tools. Available online: https://www.siemens.com/global/en/products/automation/topic-areas/industrial-edge/machine-tools.html (accessed on 3 June 2024).

- Liu, M.; Fang, S.; Dong, H.; Xu, C. Review of digital twin about concepts, technologies, and industrial applications. J. Manuf. Syst. 2021, 58, 346–361. [Google Scholar] [CrossRef]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. IFAC-PapersOnLine 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Huber, F. A Logical Introduction to Probability and Induction; Oxford University Press: New York, NY, USA, 2019; ISBN 9780190845384. [Google Scholar]

- NumFOCUS, Inc. pandas.DataFrame.std. Available online: https://pandas.pydata.org/docs/reference/api/pandas.DataFrame.std.html (accessed on 3 June 2024).

- Ruiz, J.E.; I Arrizubieta, J.; Vega, J.M.; Ostolaza, M.; Lamikiz, A. Study of corrosion resistance in Ti 6Al 4V additive manufactured parts. IOP Conf. Series Mater. Sci. Eng. 2021, 1193, 012039. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hartmann, S.; Vykhtar, B.; Möbs, N.; Kelbassa, I.; Mayr, P. IoT-Based Data Mining Framework for Stability Assessment of the Laser-Directed Energy Deposition Process. Processes 2024, 12, 1180. https://doi.org/10.3390/pr12061180

Hartmann S, Vykhtar B, Möbs N, Kelbassa I, Mayr P. IoT-Based Data Mining Framework for Stability Assessment of the Laser-Directed Energy Deposition Process. Processes. 2024; 12(6):1180. https://doi.org/10.3390/pr12061180

Chicago/Turabian StyleHartmann, Sebastian, Bohdan Vykhtar, Nele Möbs, Ingomar Kelbassa, and Peter Mayr. 2024. "IoT-Based Data Mining Framework for Stability Assessment of the Laser-Directed Energy Deposition Process" Processes 12, no. 6: 1180. https://doi.org/10.3390/pr12061180

APA StyleHartmann, S., Vykhtar, B., Möbs, N., Kelbassa, I., & Mayr, P. (2024). IoT-Based Data Mining Framework for Stability Assessment of the Laser-Directed Energy Deposition Process. Processes, 12(6), 1180. https://doi.org/10.3390/pr12061180