Efficient Use of Secondary Raw Material from the Production of Polyamide Construction Products

Abstract

1. Introduction

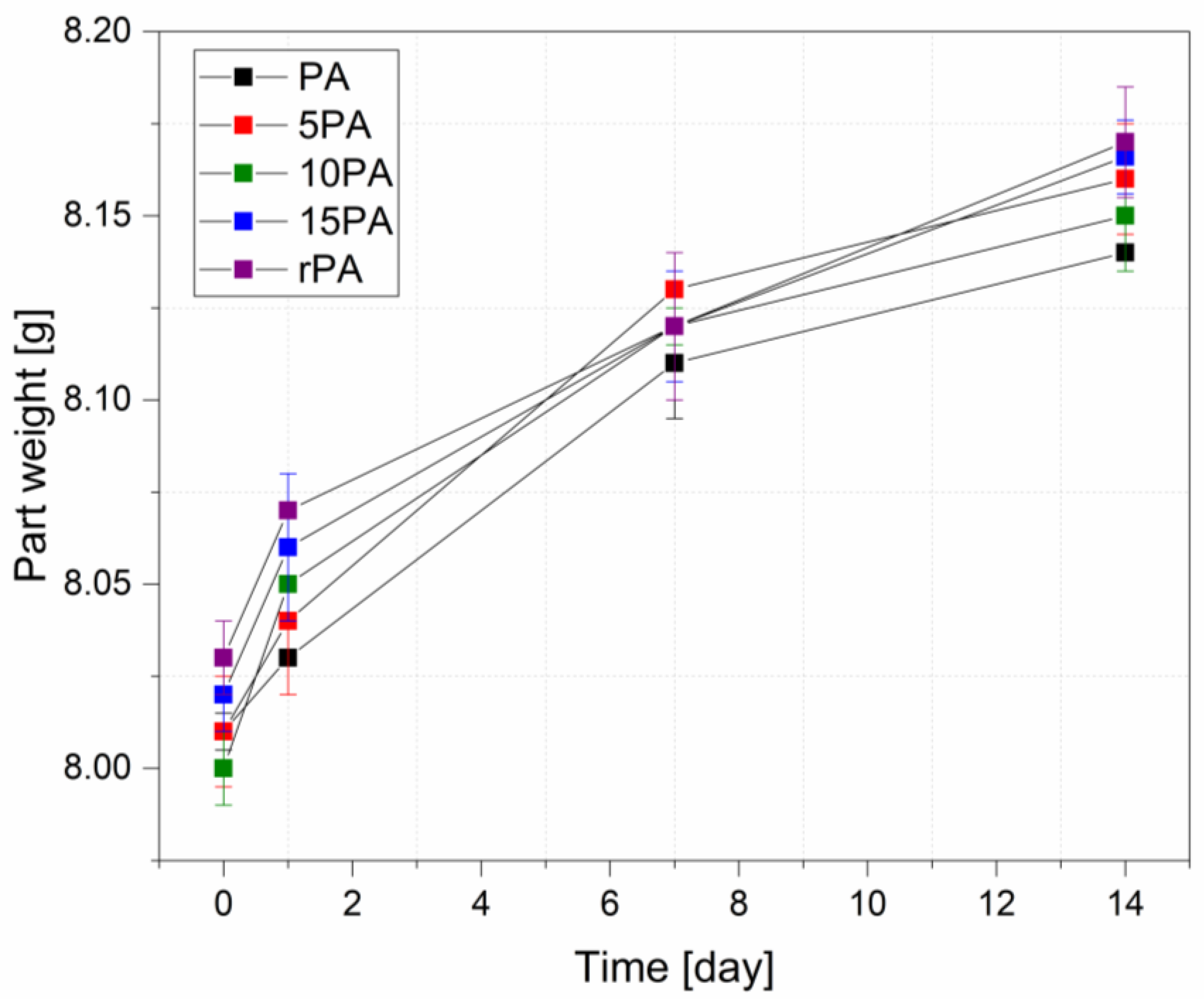

2. Materials and Methods

2.1. Materials and Sample Preparation

2.2. Methods

3. Results

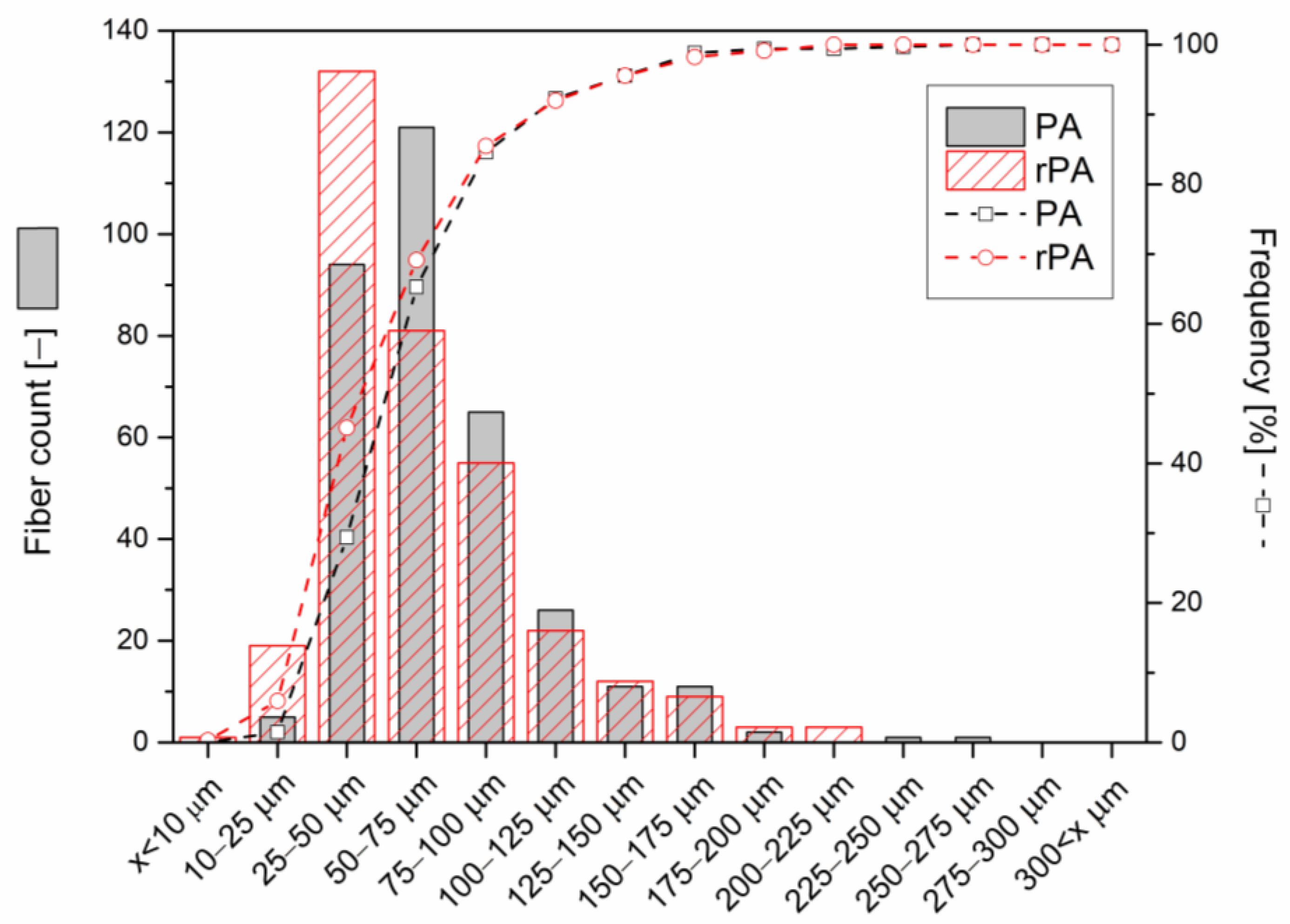

3.1. Fiber Length Distribution

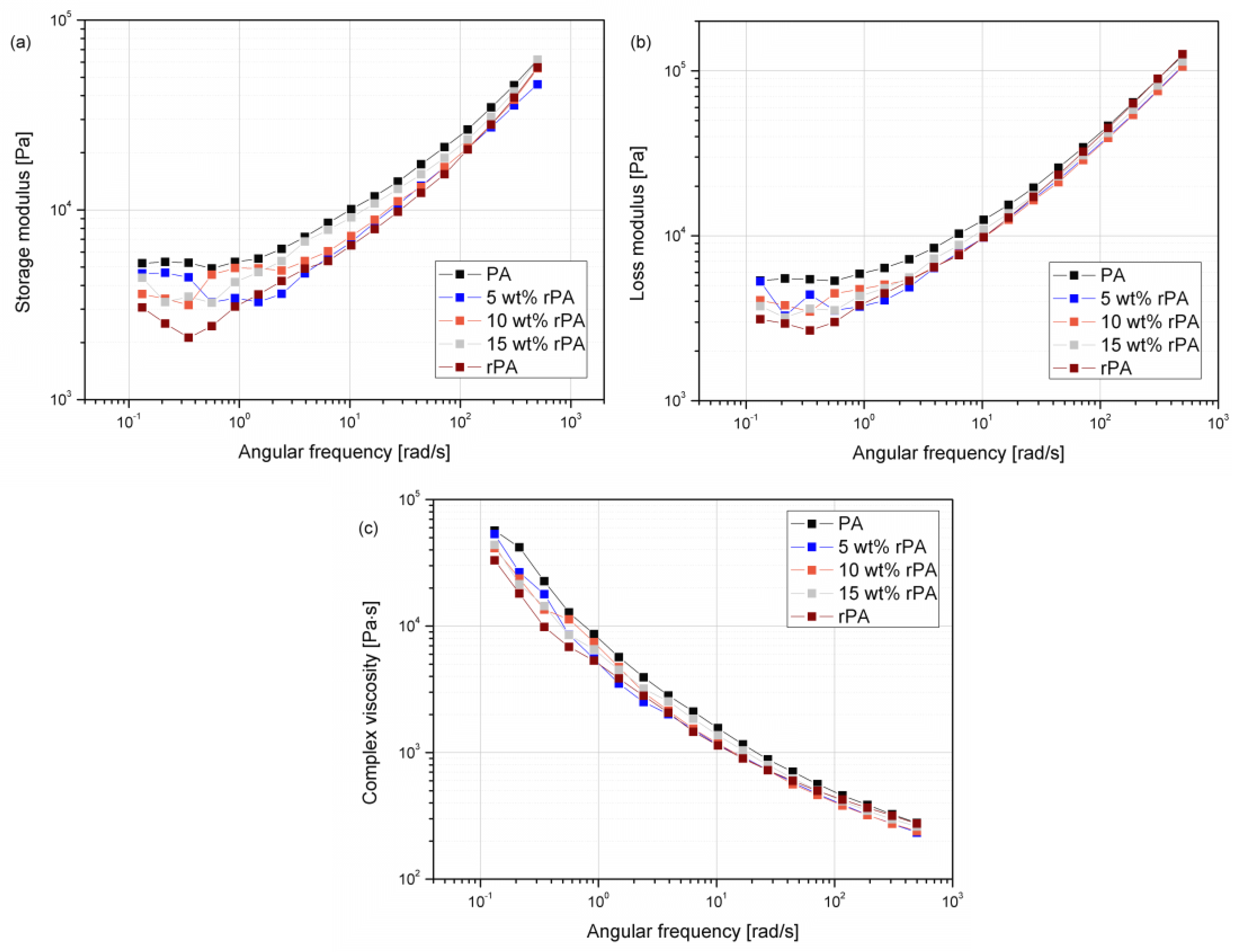

3.2. Rheological Behavior

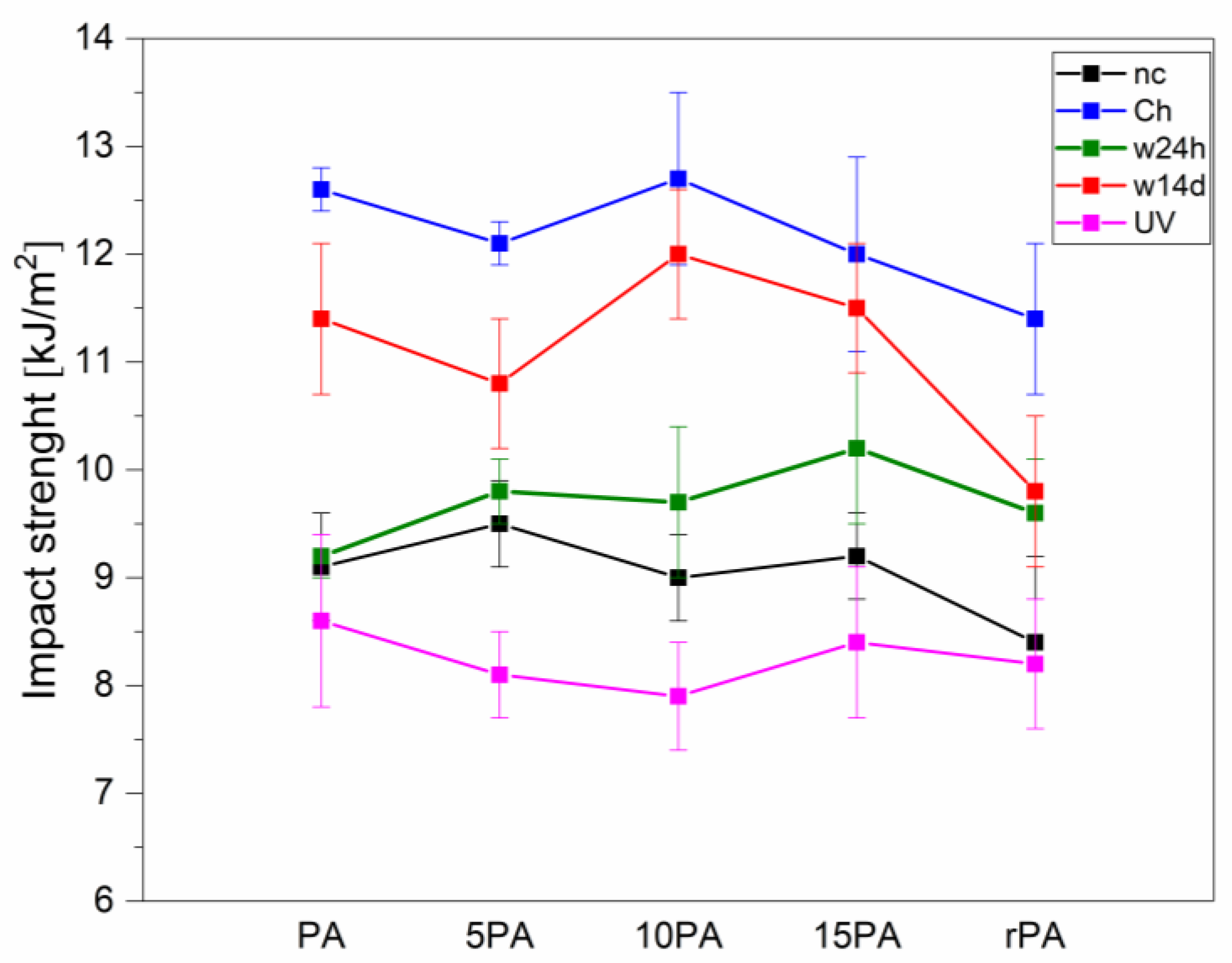

3.3. Impact Strength

3.4. Tensile Strength

3.5. Heat Deflection Temperature (HDT)

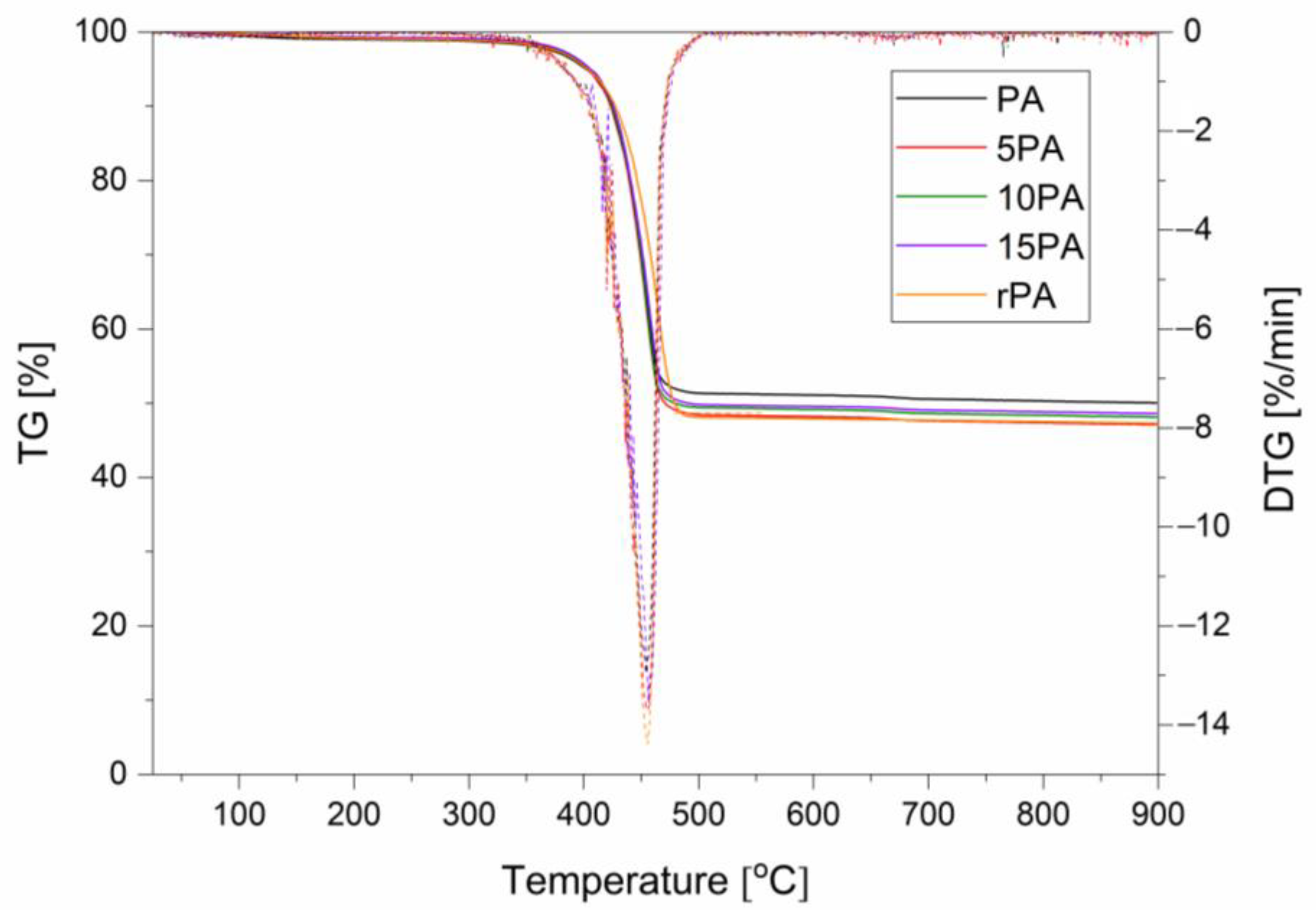

3.6. Thermogravimetry

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Okan, M.; Aydin, H.M.; Barsbay, M. Current approaches to waste polymer utilization and minimization: A review. J. Chem. Technol. Biotechnol. 2019, 94, 8–21. [Google Scholar] [CrossRef]

- McKeen, L.W. Polyamides (Nylons). In The Effect of UV Light and Weather on Plastics and Elastomers; Elsevier: Amsterdam, The Netherlands, 2019; pp. 185–222. [Google Scholar]

- Kondo, M.Y.; Montagna, L.S.; de Melo Morgado, G.F.; de Castilho, A.L.G.; dos Santos Batista, L.A.P.; Botelho, E.C.; Costa, M.L.; Passador, F.R.; Rezende, M.C.; Ribeiro, M.V. Recent advances in the use of Polyamide-based materials for the automotive industry. Polímeros 2022, 32, e2022023. [Google Scholar] [CrossRef]

- SLATER, K. Environmental impact of polyester and polyamide textiles. In Polyesters and Polyamides; Elsevier: Amsterdam, The Netherlands, 2008; pp. 171–199. [Google Scholar]

- Datta, J.; Błażek, K.; Włoch, M.; Bukowski, R. A New Approach to Chemical Recycling of Polyamide 6.6 and Synthesis of Polyurethanes with Recovered Intermediates. J. Polym. Environ. 2018, 26, 4415–4429. [Google Scholar] [CrossRef]

- Manker, L.P.; Hedou, M.A.; Broggi, C.; Jones, M.J.; Kortsen, K.; Puvanenthiran, K.; Kupper, Y.; Frauenrath, H.; Marechal, F.; Michaud, V.; et al. Performance polyamides built on a sustainable carbohydrate core. Nat. Sustain. 2024, 7, 640–651. [Google Scholar] [CrossRef]

- Plastics Europe. Plastics—The Fast Facts 2023; Plastics Europe: Brussels, Belgium, 2023. [Google Scholar]

- Žagar, E.; Češarek, U.; Drinčić, A.; Sitar, S.; Shlyapnikov, I.M.; Pahovnik, D. Quantitative Determination of PA6 and/or PA66 Content in Polyamide-Containing Wastes. ACS Sustain. Chem. Eng. 2020, 8, 11818–11826. [Google Scholar] [CrossRef]

- Shershneva, E.G. Plastic Waste: Global Impact and Ways to Reduce Environmental Harm. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1079, 062047. [Google Scholar] [CrossRef]

- Lebreton, L.; Andrady, A. Future scenarios of global plastic waste generation and disposal. Palgrave Commun. 2019, 5, 6. [Google Scholar] [CrossRef]

- Hirschberg, V.; Rodrigue, D. Recycling of polyamides: Processes and conditions. J. Polym. Sci. 2023, 61, 1937–1958. [Google Scholar] [CrossRef]

- Fernandez, E.; Edeleva, M.; Fiorio, R.; Cardon, L.; D’hooge, D.R. Increasing the Sustainability of the Hybrid Mold Technique through Combined Insert Polymeric Material and Additive Manufacturing Method Design. Sustainability 2022, 14, 877. [Google Scholar] [CrossRef]

- Shao, Y.; Dong, Y.; Yang, Y. Effect of Low-Cycle Fatigue and Hydrothermal Aging on Tensile Properties of Open-Hole Glass Fiber/Polycarbonate and Glass Fiber/Polyamide 6 Composites. Fibers Polym. 2021, 22, 2527–2534. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Tzounis, L.; Maniadi, A.; Velidakis, E.; Mountakis, N.; Kechagias, J.D. Sustainable Additive Manufacturing: Mechanical Response of Polyamide 12 over Multiple Recycling Processes. Materials 2021, 14, 466. [Google Scholar] [CrossRef] [PubMed]

- Mondragon, G.; Kortaberria, G.; Mendiburu, E.; González, N.; Arbelaiz, A.; Peña-Rodriguez, C. Thermomechanical recycling of polyamide 6 from fishing nets waste. J. Appl. Polym. Sci. 2020, 137, 48442. [Google Scholar] [CrossRef]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef]

- Kassab, A.; Al Nabhani, D.; Mohanty, P.; Pannier, C.; Ayoub, G.Y. Advancing Plastic Recycling: Challenges and Opportunities in the Integration of 3D Printing and Distributed Recycling for a Circular Economy. Polymers 2023, 15, 3881. [Google Scholar] [CrossRef] [PubMed]

- Matykiewicz, D.; Olszewski, T.; Andrzejewski, J. Waste Management after the Injection Process by Manufacturing Polyamide Products Based on Regranulate. ChemEngineering 2023, 7, 51. [Google Scholar] [CrossRef]

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef] [PubMed]

- Czarnecka-Komorowska, D.; Tomasik, M.; Thakur, V.K.; Kostecka, E.; Rydzkowski, T.; Jursa-Kulesza, J.; Bryll, K.; Mysłowski, J.; Gawdzińska, K. Biocomposite composting based on the sugar-protein condensation theory. Ind. Crops Prod. 2022, 183, 114974. [Google Scholar] [CrossRef]

- Gijsman, P.; Meijers, G.; Vitarelli, G. Comparison of the UV-degradation chemistry of polypropylene, polyethylene, polyamide 6 and polybutylene terephthalate. Polym. Degrad. Stab. 1999, 65, 433–441. [Google Scholar] [CrossRef]

- ISO 1133-1:2022; Plastics: Determination of the Melt Mass-Flow Rate (MFR) and Melt Volume-Flow Rate (MVR) of Thermoplastics, Part 1: Standard Method. International Organization for Standardization: Geneva, Switzerland, 2022.

- ISO 179-1:2023; Determination of Charpy Impact Properties, Part 1: Non-Instrumented Impact Test. International Organization for Standardization: Geneva, Switzerland, 2023.

- ISO 527-1:2019; Plastics—Determination of Tensile Properties. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 75-2:2013; Plastics—Determination of Temperature of Deflection under Load Part 2: Plastics and Ebonite. International Organization for Standardization: Geneva, Switzerland, 2013.

- Pötschke, P.; Fornes, T.D.; Paul, D.R. Rheological behavior of multiwalled carbon nanotube/polycarbonate composites. Polymer 2002, 43, 3247–3255. [Google Scholar] [CrossRef]

- Arabeche, K.; Abdelmalek, F.; Delbreilh, L.; Zair, L.; Berrayah, A. Physical and rheological properties of biodegradable poly(butylene succinate)/Alfa fiber composites. J. Thermoplast. Compos. Mater. 2022, 35, 1709–1727. [Google Scholar] [CrossRef]

- Gültürk, C.; Berber, H. Effects of mechanical recycling on the properties of glass fiber–reinforced polyamide 66 composites in automotive components. e-Polymers 2023, 23, 20230129. [Google Scholar] [CrossRef]

- Nikiforov, A.A.; Vol’fson, S.I.; Okhotina, N.A.; Rinberg, R.; Kroll, L. The Influence of Processing Additives on the Properties of Glass-fibre-reinforced Composites Based on Biobased Polyamide 1010. Int. Polym. Sci. Technol. 2017, 44, 43–48. [Google Scholar] [CrossRef]

- Thomason, J.L. The influence of fibre length, diameter and concentration on the impact performance of long glass-fibre reinforced polyamide 6,6. Compos. Part. A Appl. Sci. Manuf. 2009, 40, 114–124. [Google Scholar] [CrossRef]

- Thomason, J.L.; Vlug, M.A. Influence of fibre length and concentration on the properties of glass fibre-reinforced polypropylene: 1. Tensile and flexural modulus. Compos. Part. A Appl. Sci. Manuf. 1996, 27, 477–484. [Google Scholar] [CrossRef]

- Hassan, A.; Yahya, R.; Yahaya, A.H.; Tahir, A.R.M.; Hornsby, P.R. Tensile, Impact and Fiber Length Properties of Injection-Molded Short and Long Glass Fiber-Reinforced Polyamide 6,6 Composites. J. Reinf. Plast. Compos. 2004, 23, 969–986. [Google Scholar] [CrossRef]

- Venoor, V.; Park, J.H.; Kazmer, D.O.; Sobkowicz, M.J. Understanding the Effect of Water in Polyamides: A Review. Polym. Rev. 2021, 61, 598–645. [Google Scholar] [CrossRef]

- Thomason, J.L. Structure–property relationships in glass reinforced polyamide, part 2: The effects of average fiber diameter and diameter distribution. Polym. Compos. 2007, 28, 331–343. [Google Scholar] [CrossRef]

- Kouparitsas, C.E.; Kartalis, C.N.; Varelidis, P.C.; Tsenoglou, C.J.; Papaspyrides, C.D. Recycling of the fibrous fraction of reinforced thermoset composites. Polym. Compos. 2002, 23, 682–689. [Google Scholar] [CrossRef]

- Sahu, A.K.; Sudhakar, K.; Sarviya, R.M. Influence of U.V light on the thermal properties of HDPE/Carbon black composites. Case Stud. Therm. Eng. 2019, 15, 100534. [Google Scholar] [CrossRef]

- Eftekhari, M.; Fatemi, A. Tensile behavior of thermoplastic composites including temperature, moisture, and hygrothermal effects. Polym. Test. 2016, 51, 151–164. [Google Scholar] [CrossRef]

- Touris, A.; Turcios, A.; Mintz, E.; Pulugurtha, S.R.; Thor, P.; Jolly, M.; Jalgaonkar, U. Effect of molecular weight and hydration on the tensile properties of polyamide 12. Results Mater. 2020, 8, 100149. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, P.; Tan, L.; Huang, H.; Jiang, G. Relationship between screw structure and properties of recycled glass fiber reinforced flame retardant nylon 46. RSC Adv. 2015, 5, 13296–13306. [Google Scholar] [CrossRef]

- Pelin, C.-E.; Ficai, A.; Andronescu, E.; Stefan, A.; Pelin, G. Recycling and Reusing Polyamide 6 Extruded Waste Products to Manufacture Carbon Fiber Based Composites. Ann. Acad. Rom. Sci. Online Ser. Phys. Chem. Sci. 2017, 2, 91–103. [Google Scholar]

- Chen, C.-W.; Ranganathan, P.; Mutharani, B.; Shiu, J.-W.; Rwei, S.-P.; Chang, Y.-H.; Chiu, F.-C. Synthesis of High-Value Bio-Based Polyamide 12,36 Microcellular Foams with Excellent Dimensional Stability and Shape Recovery Properties. Polymers 2024, 16, 159. [Google Scholar] [CrossRef] [PubMed]

- Ranganathan, P.; Chen, C.-W.; Tasi, M.-C.; Rwei, S.-P.; Lee, Y.-H. Biomass Thermoplastic (Co)polyamide Elastomers Synthesized from a Fatty Dimer Acid: A Sustainable Route toward a New Era of Uniform and Bimodal Foams. Ind. Eng. Chem. Res. 2021, 60, 12139–12154. [Google Scholar] [CrossRef]

- Staikos, T.; Rahimifard, S. Post-Consumer Waste Management Issues in the Footwear Industry. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2007, 221, 363–368. [Google Scholar] [CrossRef]

| Name | MFR (g/10 min) |

|---|---|

| PA | 47.8 ± 1.0 |

| 5PA | 53.6 ± 0.4 |

| 10PA | 65.4 ± 0.5 |

| 15PA | 66.2 ± 1.0 |

| rPA | 91.7 ± 3.5 |

| Name | nc | w24h | w14d | Ch | UV |

|---|---|---|---|---|---|

| ak [kJ/m2] | ak [kJ/m2] | ak [kJ/m2] | ak [kJ/m2] | ak [kJ/m2] | |

| PA | 9.1 ± 0.5 | 9.2 ± 0.2 | 11.4 ± 0.2 | 12.6 ± 0.7 | 8.6 ± 0.8 |

| 5PA | 9.5 ± 0.4 | 9.8 ± 0.2 | 10.8 ± 0.3 | 12.1 ± 0.6 | 8.1 ± 0.4 |

| 10PA | 9.0 ± 0.4 | 9.7 ± 0.8 | 12.0 ± 0.7 | 12.7 ± 0.6 | 7.9 ± 0.5 |

| 15PA | 9.2 ± 0.4 | 10.2 ± 0.9 | 11.5 ± 0.7 | 12.0 ± 0.6 | 8.4 ± 0.7 |

| rPA | 8.4 ± 0.8 | 9.6 ± 0.7 | 9.8 ± 0.5 | 11.4 ± 0.7 | 8.2 ± 0.6 |

| Name | nc | w24h | w14d | Ch | UV |

|---|---|---|---|---|---|

| Fmax [N] | Fmax [N] | Fmax [N] | Fmax [N] | Fmax [N] | |

| PA | 562.5 ± 23.5 | 637.5 ± 60.1 | 475.3 ± 15.8 | 470.9 ± 14.2 | 515.3 ± 24.6 |

| 5PA | 560.9 ± 12.1 | 622.5 ± 34.2 | 474.1 ± 15.2 | 484.6 ± 14.5 | 477.8 ± 15.2 |

| 10PA | 529.4 ± 27.5 | 500.6 ± 25.1 | 496.2 ± 10.1 | 524.1 ± 12.5 | 468.6 ± 26.1 |

| 15PA | 507.9 ± 33.5 | 522.9± 11.9 | 537.2 ± 21.8 | 480.8 ± 15.5 | 503.3 ± 40.2 |

| rPA | 525.1 ± 55.7 | 465.61 ± 13.8 | 535.6 ± 51.8 | 448.6± 9.2 | 427.7 ± 14.3 |

| Name | nc | w24h | w14d | Ch | UV |

|---|---|---|---|---|---|

| δm [MPa] | δm [MPa] | δm [MPa] | δm [MPa] | δm [MPa] | |

| PA | 193.3 ± 2.9 | 177.4 ± 2.2 | 135.6 ± 2.6 | 133.2 ± 5.5 | 189.7 ± 0.9 |

| 5PA | 189.0 ± 1.0 | 178.4 ± 1.1 | 137.4 ± 1.5 | 132.0 ± 2.6 | 173.7 ± 6.7 |

| 10PA | 190.5 ± 0.6 | 176.8 ± 1.3 | 136.4 ± 1.5 | 129.6 ± 4.9 | 183.2 ± 1.7 |

| 15PA | 187.6 ± 2.1 | 173.6 ± 1.1 | 136.2 ± 0.8 | 130.6 ± 1.7 | 181.2 ± 1.7 |

| rPA | 171.0 ± 1.0 | 161.0 ± 2.0 | 124.3 ± 0.6 | 120.7 ± 1.0 | 166.2 ± 1.5 |

| Name | nc | w24h | w14d | Ch | UV |

|---|---|---|---|---|---|

| Et [Mpa] | Et [Mpa] | Et [Mpa] | Et [Mpa] | Et [Mpa] | |

| PA | 9447 ± 355 | 5662 ± 68 | 4576 ± 289 | 7500 ± 248 | 10,225 ± 126 |

| 5PA | 7540 ± 270 | 5514 ± 256 | 3488 ± 506 | 7467 ± 152 | 9463 ± 226 |

| 10PA | 5535 ± 129 | 5404 ± 98 | 3157 ± 496 | 7060 ± 107 | 7823 ± 240 |

| 15PA | 4363 ± 121 | 5412 ± 153 | 3654 ± 985 | 6728 ± 208 | 3970 ± 204 |

| rPA | 3285 ± 120 | 5260 ± 236 | 3157 ± 372 | 6048 ± 369 | 2225 ± 757 |

| Name | nc | w24h | w14d | Ch | UV |

|---|---|---|---|---|---|

| εm [%] | εm [%] | εm [%] | εm [%] | εm [%] | |

| PA | 6.2 ± 0.1 | 9.1 ± 0.3 | 5.7 ± 0.3 | 6.4 ± 0.9 | 5.8 ± 0.1 |

| 5PA | 6.1 ± 0.1 | 9.4 ± 0.3 | 5.9 ± 0.3 | 6.9 ± 0.1 | 5.1 ± 0.4 |

| 10PA | 6.1 ± 0.1 | 9.1 ± 0.3 | 5.8 ± 0.3 | 6.8 ± 0.4 | 5.2 ± 0.1 |

| 15PA | 6.0 ± 0.4 | 9.3 ± 0.2 | 6.2 ± 0.2 | 7.1 ± 0.3 | 5.2 ± 0.1 |

| rPA | 6.1 ± 0.1 | 9.1 ± 0.2 | 6.1 ± 0.3 | 7.3 ± 0.3 | 5.6 ± 0.1 |

| Heat Deflection Temperature [°C] | |||||

|---|---|---|---|---|---|

| Name | Not Conditioned | Conditioned in the Chamber | Conditioned in the Water 24 h | Conditioned in the Water 14 d | UV Aging Chamber |

| PA | 209.1 ± 0.2 | 199.7 ± 0.4 | 202.9 ± 0.8 | 201.9 ± 0.8 | 204.3 ± 0.5 |

| 5PA | 207.0 ± 0.3 | 200.8 ± 0.3 | 204.3 ± 0.6 | 202.3 ± 0.6 | 203.0 ± 0.3 |

| 10PA | 209.6 ± 0.3 | 202.4 ± 0.7 | 205.3 ± 0.7 | 202.3 ± 0.7 | 205.7 ± 0.2 |

| 15PA | 211.5 ± 0.7 | 196.7 ± 0.3 | 208.9 ± 0.3 | 207.9 ± 0.3 | 208.9 ± 0.2 |

| rPA | 202.9 ± 0.7 | 193.7 ± 0.3 | 199.9 ± 0.8 | 197.9 ± 0.8 | 201.1 ± 0.5 |

| Name | T5% [°C] | T10% [°C] | Residual Mass [%] | DTG |

|---|---|---|---|---|

| PA | 402.2 | 423.5 | 50.0 | 454.2 °C; −12.9%/min |

| 5PA | 403.0 | 423.3 | 47.1 | 456.7 °C; −13.7%/min |

| 10PA | 404.3 | 424.1 | 48.1 | 456.6 °C; −14.4%/min |

| 15PA | 405.6 | 425.5 | 48.6 | 456.1 °C; −13.6%/min |

| rPA | 403.3 | 427.3 | 47.2 | 464.2 °C; −13.6%/min |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olszewski, T.; Matykiewicz, D.; Barczewski, M.; Andrzejewski, J. Efficient Use of Secondary Raw Material from the Production of Polyamide Construction Products. Processes 2024, 12, 1304. https://doi.org/10.3390/pr12071304

Olszewski T, Matykiewicz D, Barczewski M, Andrzejewski J. Efficient Use of Secondary Raw Material from the Production of Polyamide Construction Products. Processes. 2024; 12(7):1304. https://doi.org/10.3390/pr12071304

Chicago/Turabian StyleOlszewski, Tomasz, Danuta Matykiewicz, Mateusz Barczewski, and Jacek Andrzejewski. 2024. "Efficient Use of Secondary Raw Material from the Production of Polyamide Construction Products" Processes 12, no. 7: 1304. https://doi.org/10.3390/pr12071304

APA StyleOlszewski, T., Matykiewicz, D., Barczewski, M., & Andrzejewski, J. (2024). Efficient Use of Secondary Raw Material from the Production of Polyamide Construction Products. Processes, 12(7), 1304. https://doi.org/10.3390/pr12071304