Investigation of Cavitation Flow and Entropy Production Characteristics in a Dual-Rotor Turbine Flowmeter

Abstract

:1. Introduction

2. Numeric Simulation Scheme

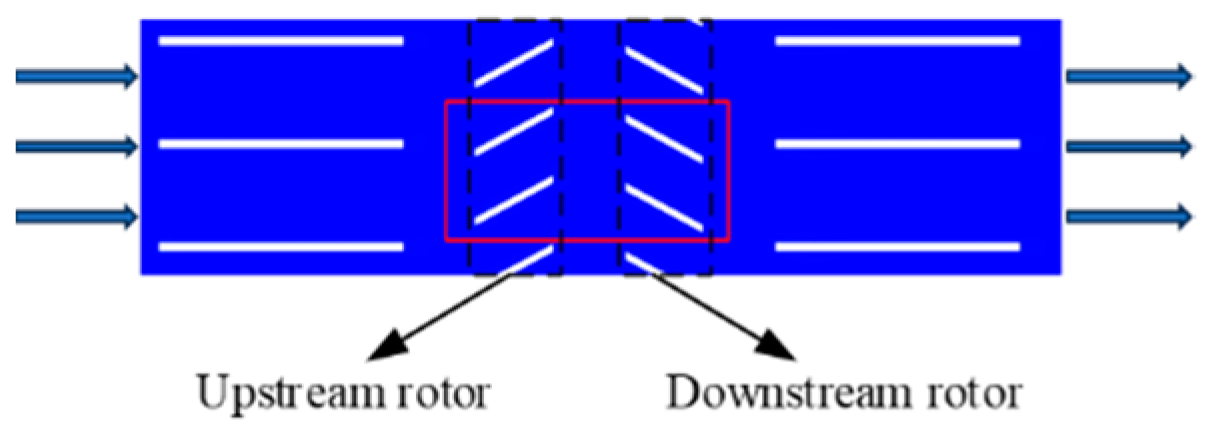

2.1. Geometry Description

2.2. Governing Equations

2.2.1. Fundamental Governing Equation

2.2.2. Cavitation Model

2.2.3. Entropy Production Theory

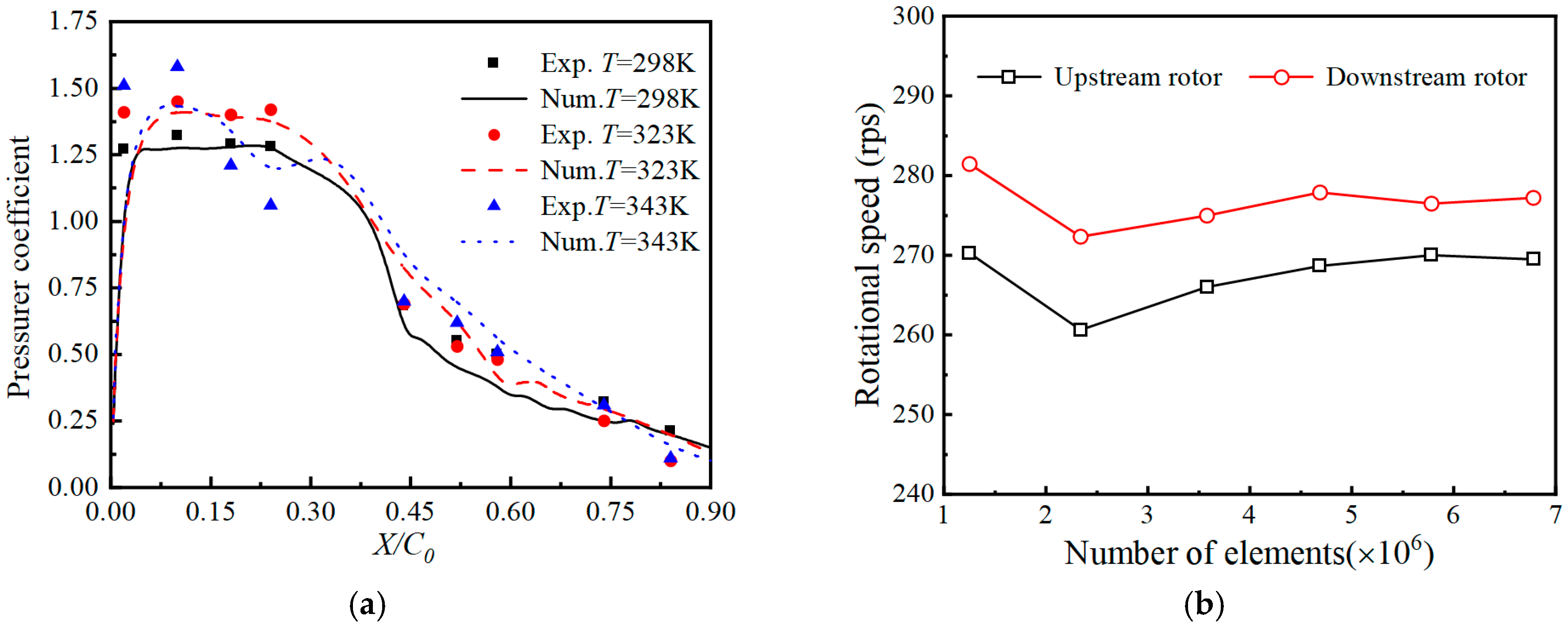

2.3. Model Validation

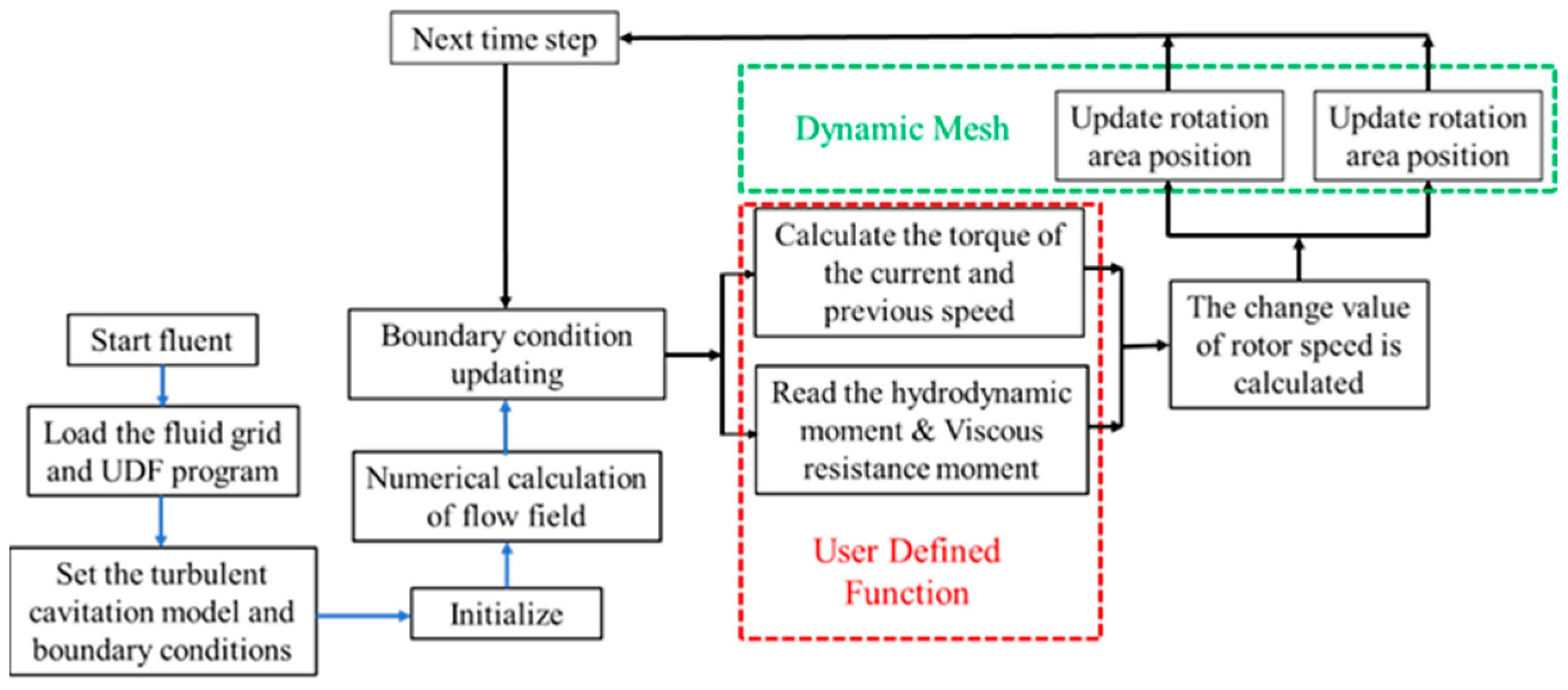

2.4. CFD Simulation Method

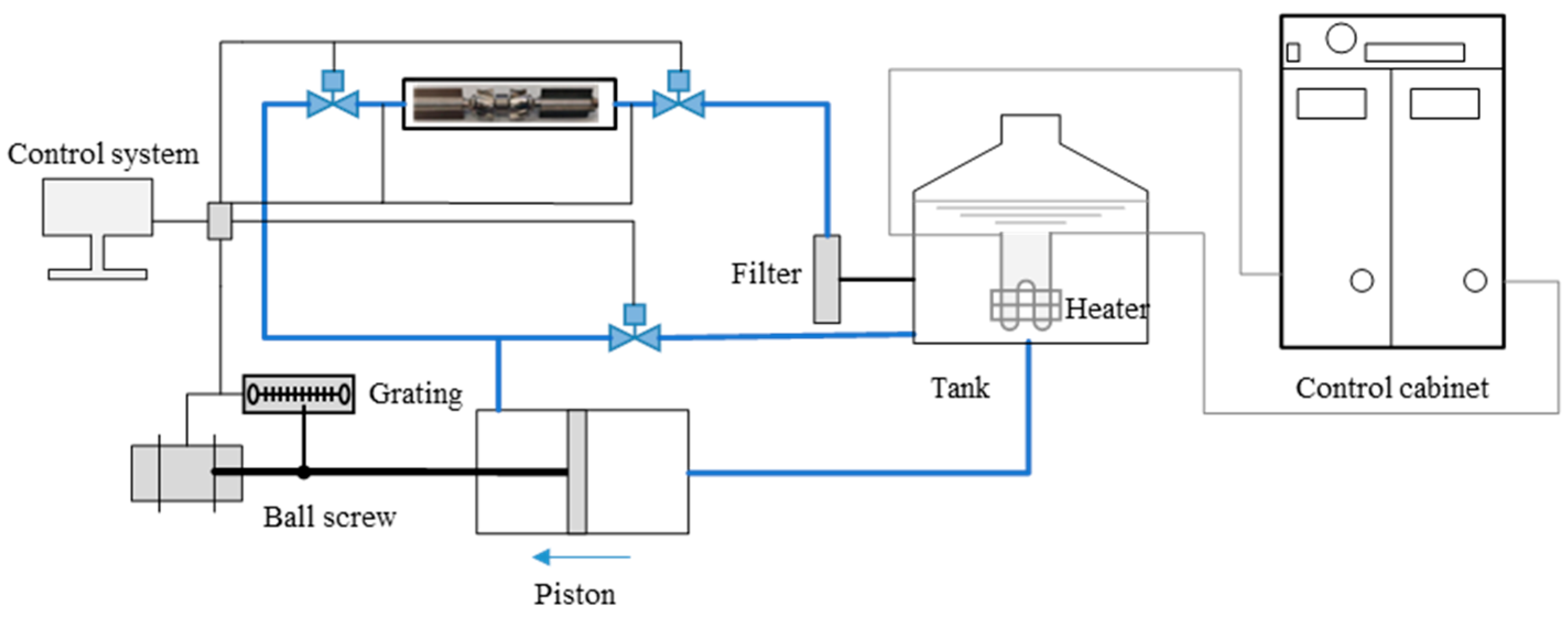

3. Experimental Apparatus and Procedures

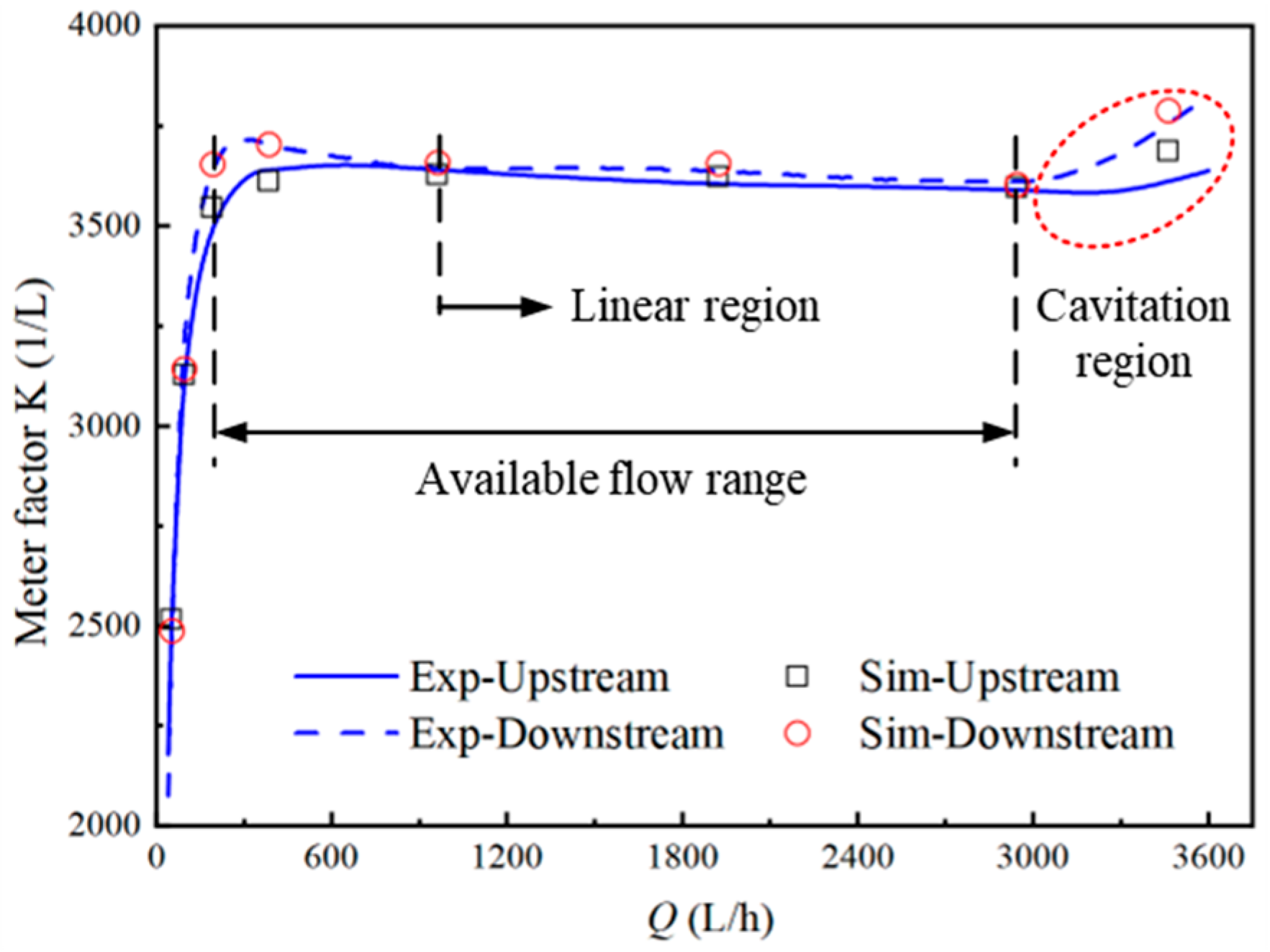

4. Result and Discussion

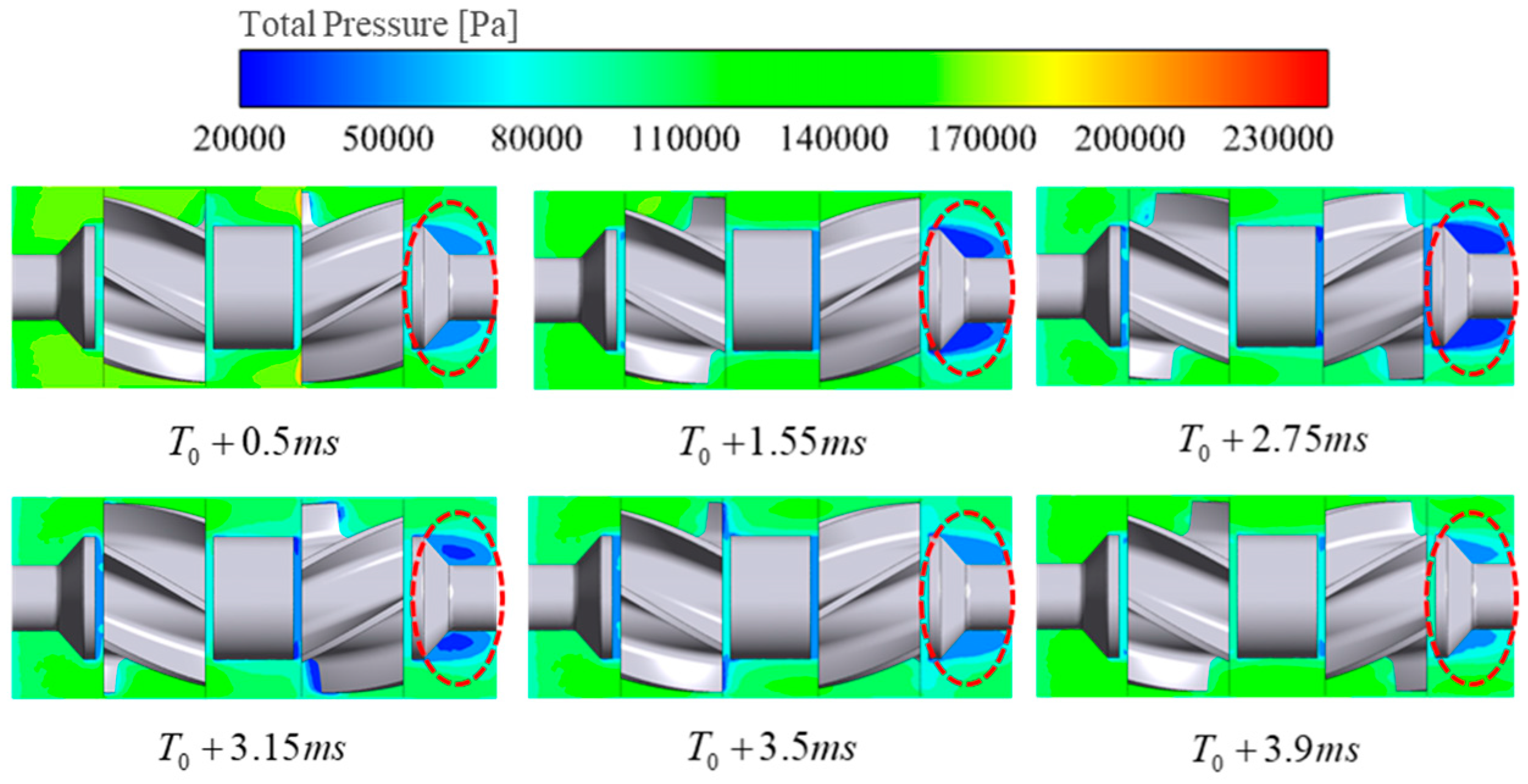

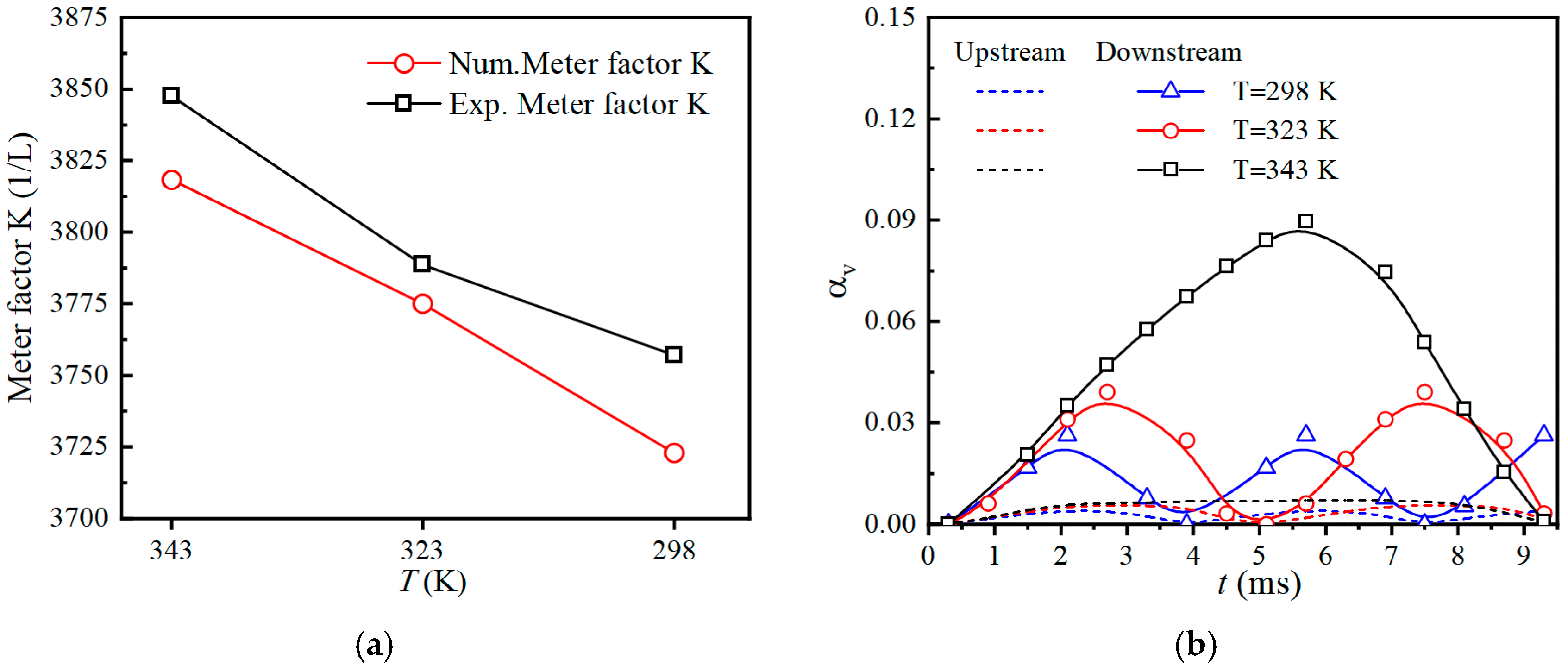

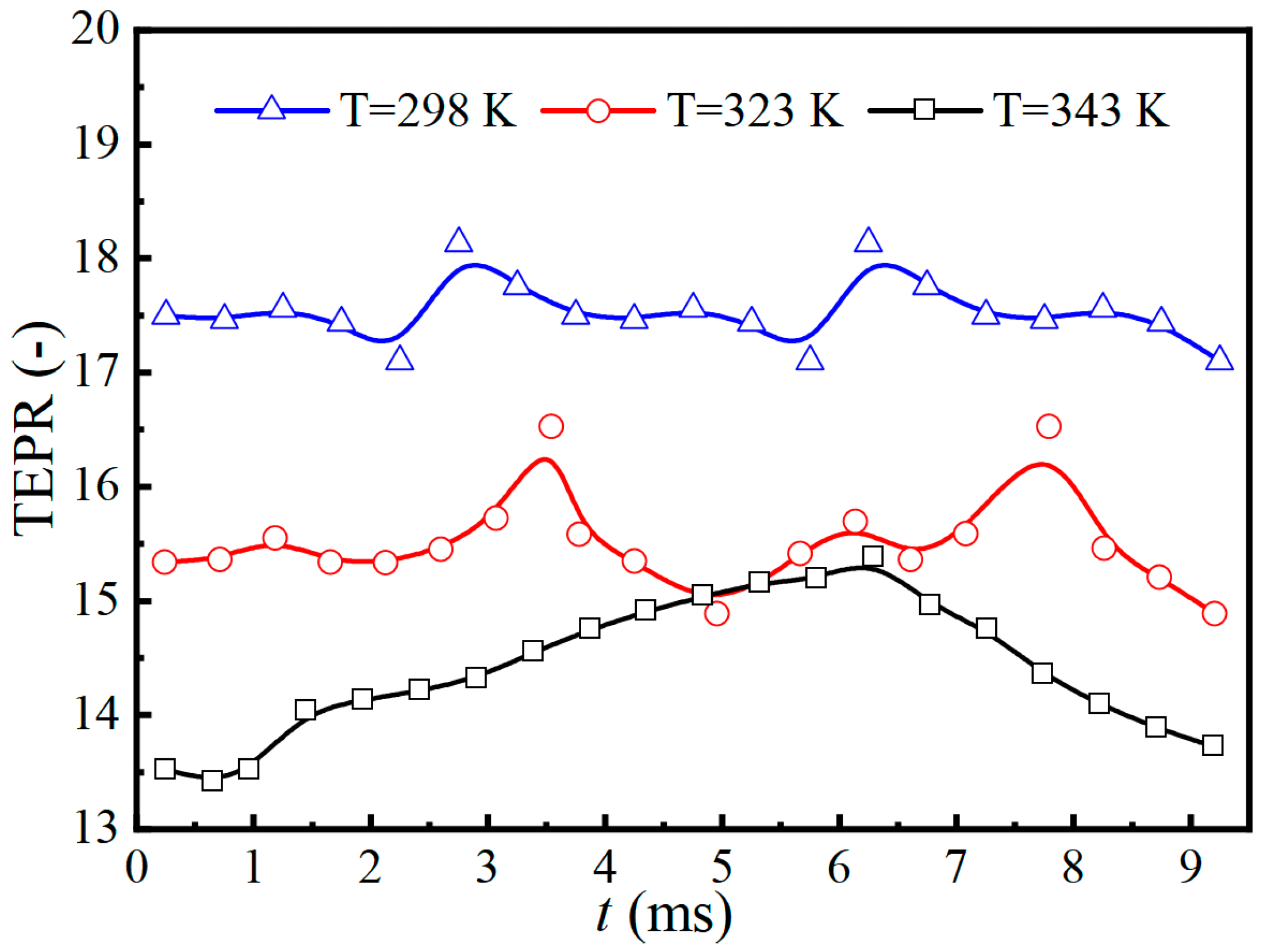

4.1. Cavitation Flow Anslysis

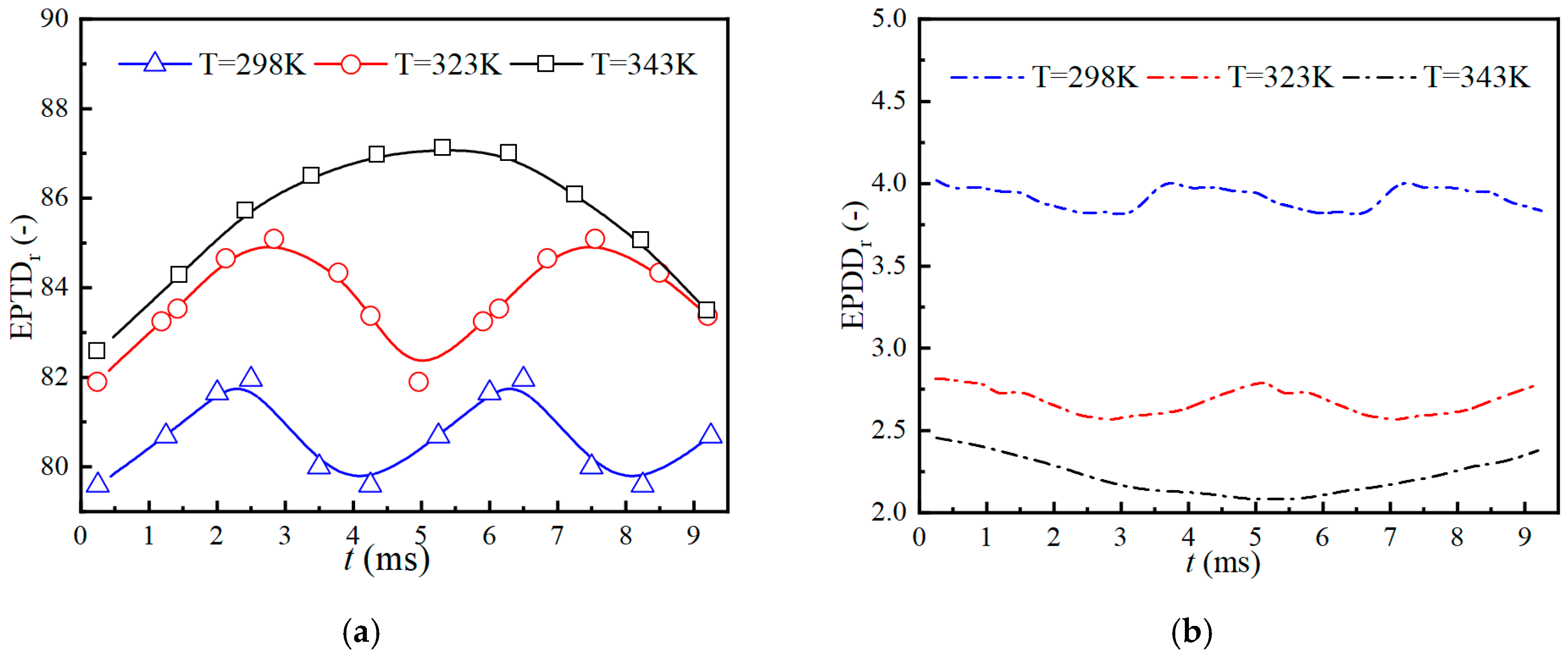

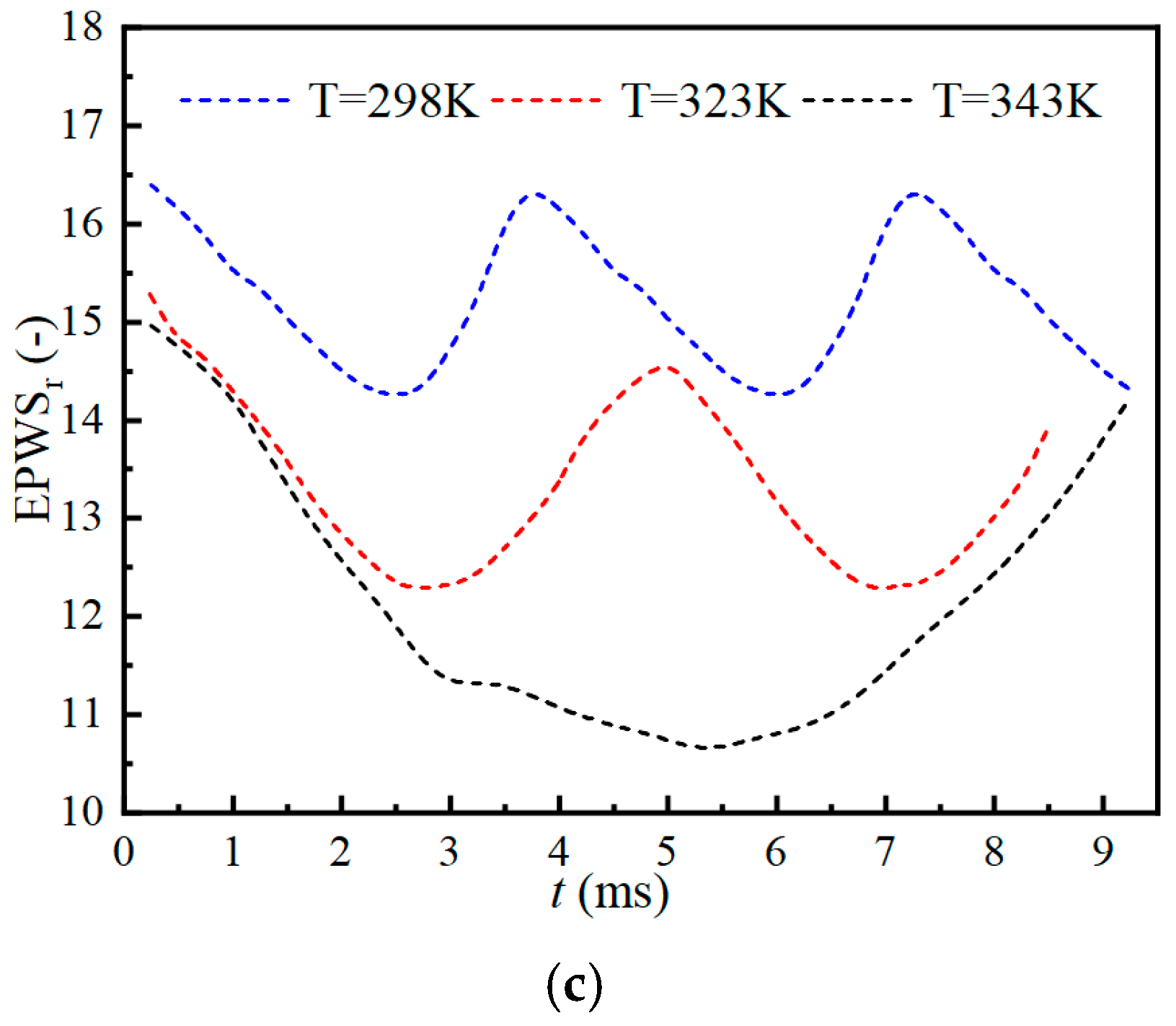

4.2. Entropy Production Analysis

5. Conclusions

- The meter factor of the dual-rotor turbine flowmeter increases at high flow points, which corresponds with the onset of cavitation. At maximum flow rates, the volume of attached cavities on both the upstream and downstream rotor blades increases with temperature, extending the cavitation cycle duration. However, the meter coefficient decreases with rising temperature, underscoring the influence of cavitation on the accuracy of the flowmeter. This phenomenon suggests that the displayed flow rate in cavitating conditions will be slightly higher than in non-cavitating conditions, with the cavitation region setting the maximum operational range of the flowmeter.

- The transient evolution of cavitation flow is categorized into three stages: cavity production, development, and collapse. As the inlet water temperature increases, the proportion of energy losses attributed to turbulent dissipation entropy production rate (EPTD) induced by fluctuating velocity gradients also increases, while the proportions of other types of losses decrease. Specifically, EPTD accounts for a maximum proportion of 81.95% at 298 K, 85.1% at 323 K, and 87.11% at 343 K. Losses induced by fluctuating velocity gradients are predominant, followed by wall losses, with losses induced by mean velocity gradients being minimal.

- Comparative analysis of cavitation motion, vortex development, turbulent kinetic energy evolution, and entropy evolution processes revealed that vortices, turbulent kinetic energy, and entropy primarily appear at the interfaces and rear parts of the attached cavities. This indicates that the instability of cavities leads to increased vorticity, turbulent kinetic energy, and entropy.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ren, Z.; Zhou, W.; Li, D. Response and flow characteristics of a dual-rotor turbine flowmeter. Flow Meas. Instrum. 2022, 83, 102120. [Google Scholar] [CrossRef]

- Ren, Z.; Zhou, W.; Li, D. Investigation on pressure fluctuations of dual-and analogical single-rotor turbine flowmeters. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 7166–7178. [Google Scholar] [CrossRef]

- Huang, B.; Qiu, S.-C.; Li, X.-B.; Wu, Q.; Wang, G. A review of transient flow structure and unsteady mechanism of cavitating flow. J. Hydrodyn. 2019, 31, 429–444. [Google Scholar] [CrossRef]

- Guo, X.; Zhu, L.; Zhu, Z.; Cui, B.; Li, Y. Numerical and experimental investigations on the cavitation characteristics of a high-speed centrifugal pump with a splitter-blade inducer. J. Mech. Sci. Technol. 2015, 29, 259–267. [Google Scholar] [CrossRef]

- Guo, Z.; Pan, J.; Qian, Z.; Ji, B. Experimental and numerical analysis of the unsteady influence of the inlet guide vanes on cavitation performance of an axial pump. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 3816–3826. [Google Scholar] [CrossRef]

- Peng, X.; Ji, B.; Cao, Y.; Xu, L.; Zhang, G.; Luo, X.; Long, X. Combined experimental observation and numerical simulation of the cloud cavitation with U-type flow structures on hydrofoils. Int. J. Multiph. Flow 2016, 79, 10–22. [Google Scholar] [CrossRef]

- Long, Y.; Long, X.; Ji, B.; Huang, H. Numerical simulations of cavitating turbulent flow around a marine propeller behind the hull with analyses of the vorticity distribution and particle tracks. Ocean Eng. 2019, 189, 106310. [Google Scholar] [CrossRef]

- Han, C.; Long, Y.; Bai, X.; Ji, B.J. Numerical investigation of unsteady cavitation flow around E779A propeller in a nonuniform wake with an insight on how cavitation influences vortex. Shock Vib. 2021, 2021, 5577517. [Google Scholar] [CrossRef]

- Ji, B.; Luo, X.; Arndt, R.E.; Wu, Y. Numerical simulation of three dimensional cavitation shedding dynamics with special emphasis on cavitation–vortex interaction. Ocean Eng. 2014, 87, 64–77. [Google Scholar] [CrossRef]

- Peng, C.; Tian, S.; Li, G.; Sukop, M.C. Simulation of multiple cavitation bubbles interaction with single-component multiphase Lattice Boltzmann method. Int. J. Heat Mass Transf. 2019, 137, 301–317. [Google Scholar] [CrossRef]

- Yin, T.-Y.; Pavesi, G.; Pei, J.; Yuan, S.-Q.; Gan, X.-C. Large eddy simulation of cloud cavitation and wake vortex cavitation around a trailing-truncated hydrofoil. J. Hydrodyn. 2022, 34, 893–903. [Google Scholar] [CrossRef]

- Tian, B.; Chen, J.; Zhao, X.; Zhang, M.; Huang, B. Numerical analysis of interaction between turbulent structures and transient sheet/cloud cavitation. Phys. Fluids 2022, 34, 047116. [Google Scholar] [CrossRef]

- Movahedian, A.; Pasandidehfard, M.; Roohi, E. LES investigation of sheet-cloud cavitation around a 3-D twisted wing with a NACA 16012 hydrofoil. Ocean Eng. 2019, 192, 106547. [Google Scholar] [CrossRef]

- Ren, Z.; Li, D.; Wang, C.; Wang, H.; Liu, J.; Li, Y. Hump and mass-transfer characteristics of dissolved oxygen induced by gaseous cavitation in a space micropump. Int. Commun. Heat Mass Transf. 2023, 145, 106830. [Google Scholar] [CrossRef]

- Ren, Z.; Li, D.; Hao, H.; Wang, H.; Liu, J.; Li, Y. Gas–liquid transport behaviors and mass transfer mechanism during oxygen dissolution and evolution processes in a micropump. J. Fluids Eng. 2023, 145, 071401. [Google Scholar] [CrossRef]

- Zhang, Y.; Peng, J.; Li, S. Flow characteristic investigation on Laval-type flow rate regulating valves by fluid-thermal-structure interaction. Int. Commun. Heat Mass Transf. 2023, 144, 106771. [Google Scholar] [CrossRef]

- Feng, G.; Zhang, J.; Chen, M.; Gao, J.; Bao, W. Mathematical representation of liquid jet diffusion characteristics effected with evaporation process in supersonic crossflow. Fuel 2023, 353, 129110. [Google Scholar] [CrossRef]

- Feng, G.; Zhang, J.; Chen, M.; Qiu, H.; Bao, W. Diffusion characteristics of liquid kerosene with heat transfer in a strut-equipped supersonic combustor. Acta Astronaut. 2023, 203, 246–251. [Google Scholar] [CrossRef]

- Bejan, A. Entropy Production Minimization: The Method of Thermodynamic Optimization of Finite-Size Systems and Finite-Time Processes; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Ren, Z.; Li, D.; Fu, X.; Wang, H.; Liu, J.; Li, Y. Synergistic effects of vapor and gaseous cavitation and mass-transfer mechanism in a mechanical pump. Phys. Fluids 2023, 35, 053335. [Google Scholar]

- An, Y.; Qinghong, T.; Daqing, Z. Entropy production analysis in thermodynamic cavitating flow with the consideration of local compressibility. Int. J. Heat Mass Transf. 2020, 153, 119604. [Google Scholar]

- Yu, A.; Tang, Q.; Zhou, D.; Liu, J. Entropy production analysis in two-phase cavitation flows with thermodynamic cavitation model. Appl. Therm. Eng. 2020, 171, 115099. [Google Scholar] [CrossRef]

- Li, D.; Wang, H.; Qin, Y.; Han, L.; Wei, X.; Qin, D. Entropy production analysis of hysteresis characteristic of a pump-turbine model. Energy Convers. Manag. 2017, 149, 175–191. [Google Scholar] [CrossRef]

- Long, Y.; Long, X.; Ji, B.; Xing, T. Verification and validation of Large Eddy Simulation of attached cavitating flow around a Clark-Y hydrofoil. Int. J. Multiph. Flow 2019, 115, 93–107. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, B. Numerical simulation of the three-dimensional unsteady cavitating flow around a twisted hydrofoil. Ocean Eng. 2019, 188, 106313. [Google Scholar] [CrossRef]

- Cervone, A.; Bramanti, C.; Rapposelli, E.; d’Agostino, L. Thermal cavitation experiments on a NACA 0015 hydrofoil. ASME J. Fluids Eng. 2006, 128, 326–331. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Zhang, Z.; Wang, B.; Han, Y.; Huang, F.; Chen, M.; Zan, H. Investigation of Cavitation Flow and Entropy Production Characteristics in a Dual-Rotor Turbine Flowmeter. Processes 2024, 12, 1329. https://doi.org/10.3390/pr12071329

Liu J, Zhang Z, Wang B, Han Y, Huang F, Chen M, Zan H. Investigation of Cavitation Flow and Entropy Production Characteristics in a Dual-Rotor Turbine Flowmeter. Processes. 2024; 12(7):1329. https://doi.org/10.3390/pr12071329

Chicago/Turabian StyleLiu, Jiabao, Zhibin Zhang, Bing Wang, Yuxiang Han, Fuji Huang, Mantang Chen, and Hao Zan. 2024. "Investigation of Cavitation Flow and Entropy Production Characteristics in a Dual-Rotor Turbine Flowmeter" Processes 12, no. 7: 1329. https://doi.org/10.3390/pr12071329