Application of Principal Component Analysis for the Elucidation of Operational Features for Pervaporation Desalination Performance of PVA-Based TFC Membrane

Abstract

:1. Introduction

2. PVA-Based TFC Membranes: With and without Selective Layers

| Separative Layer | Crosslinking Agent | Porous Substrate | Thickness of Separative Layer (δ; μm) | NaCl Concentrations of the Feeding Solution (NaCl; wt%) | Operation Temperature (T; °C) | Water Permeation Flux (P; kg m−2 h−1) | Normalized P with Selective Layer Thickness (Pnorm; kg μm m−2 h−1) | Salt Rejection (%) | Reference |

|---|---|---|---|---|---|---|---|---|---|

| PVA | Glutaraldehyde | Electrospun PAN nanofiber mat on polyester nonwoven | 0.62 | 3.5 | 25 | 7.36 | 4.56 | 99.5 | [20] |

| PVA | Maleic acid | Polysulfone hollow fiber | 0.1 | 3.0 | 70 | 7.4 | 0.74 | 99.9 | [21] |

| PVA | Sulfo-succinic acid | PAN ultrafiltration membrane | 4.9 | 3.5 | 70 | 27.9 | 136.7 | 99.8 | [22] |

| PVA | SPTA | PAN ultrafiltration membrane | 0.8 | 3.5 | 70 | 46.3 | 37.0 | 99.5 | [8] |

| PVA | Pyromellitic dianhydride | PAN ultrafiltration membrane | 2 | 3.5 | 70 | 32.3 | 64.6 | 99.98 | [23] |

| PVA | Poly acrylic acid co-2-acrylamido-2-methyl propane sulfonic acid | Electrospun PAN nanofiber mat | 0.73 | 3.5 | 75 | 234.9 | 171.5 | 99.7 | [18] |

| PVA/GO | Glutaraldehyde | Electrospun PAN nanofiber mat | 0.12 | 3.5 | 70 | 69.1 | 8.3 | 99.9 | [24] |

| PVA/CNT | Maleic anhydride | PAN ultrafiltration membrane | 1.0 | 3.5 | 45 | 14.5 | 14.5 | 99.96 | [25] |

| PVA/UIO 66 MOF a | P (AA-AMPS) b | Porous polysulfone membrane | 0.95 | 3.5 | 70 | 120 | 114 | 99.9 | [26] |

| PVA/Ws-OL | Maleic anhydride | PAN ultrafiltration membrane | 0.53 | 3.5 | 65 | 56.4 | 29.9 | 99.97 | [5] |

| PVA/Ws-OL | SPTA | PAN ultrafiltration membrane | 0.53 | 3.5 | 65 | 78.6 | 41.6 | 99.91 | [5] |

3. Materials and Methods

3.1. Data Normalization

3.2. PCA

4. Results and Discussion

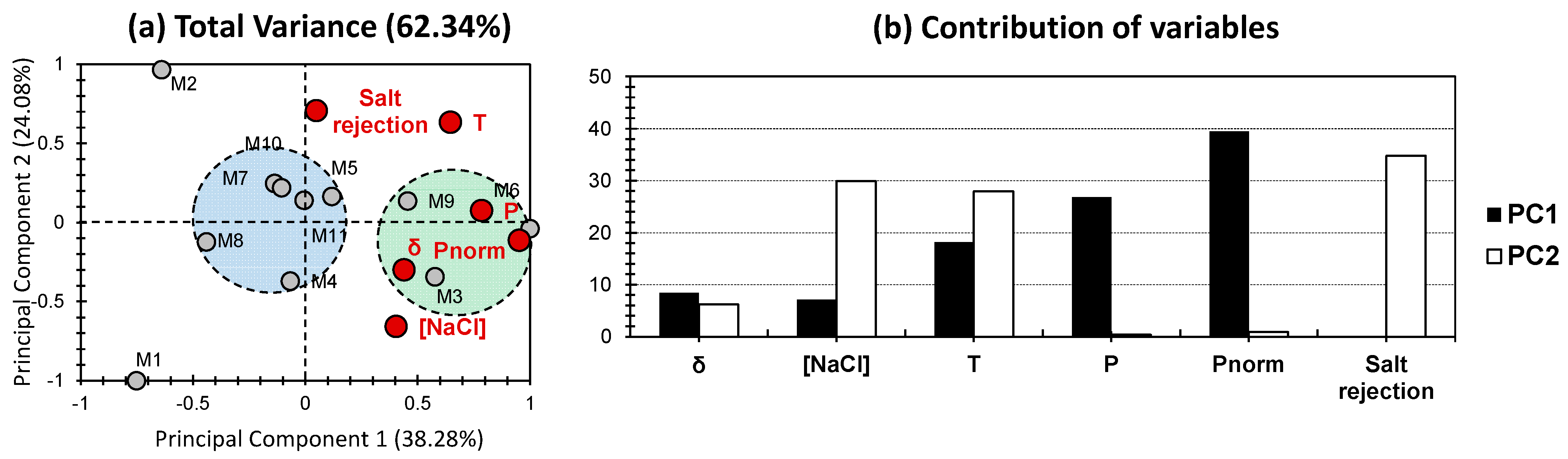

4.1. PCA All-in-One Dataset

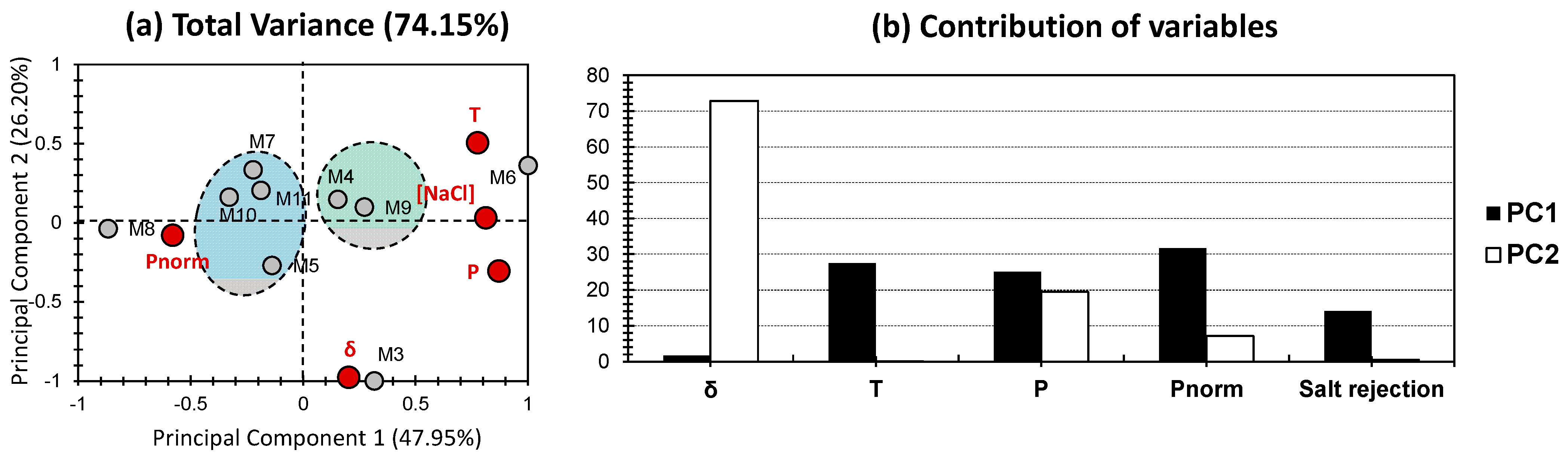

4.2. PCA of PVA-Based TFC with and without Specific Layers

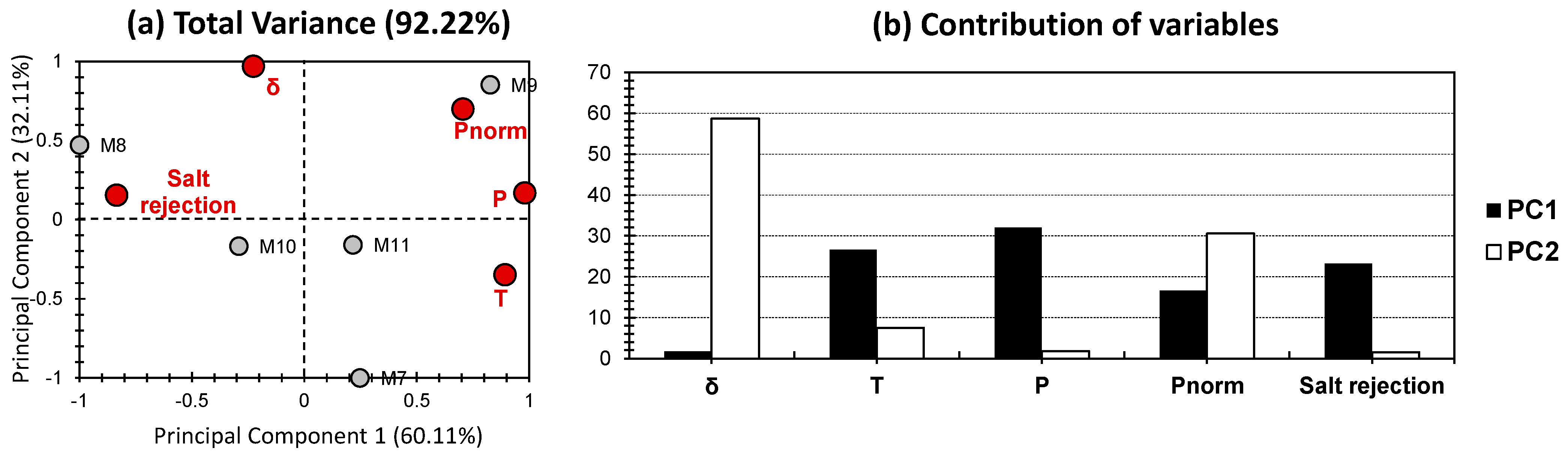

4.3. Permeation: Between Intrinsic Properties and Operational Features

4.4. Layer Thickness: Influence of Selective Layer

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, S.; Zhou, G.; Cheng, G.; Wang, X.; Liu, G.; Jin, W. Emerging Membranes for Separation of Organic Solvent Mixtures by Pervaporation or Vapor Permeation. Sep. Purif. Technol. 2022, 299, 121729. [Google Scholar] [CrossRef]

- Dong, G.; Zhang, Y.; Pang, X.; Guo, M.; Moriyama, N.; Nagasawa, H.; Kanezashi, M.; Tsuru, T. Sub-Nanometer Scale Tailoring of the Microstructures of Composite Organosilica Membranes for Efficient Pervaporation of Toluene/n-Heptane Mixtures. J. Membr. Sci. 2023, 672, 121469. [Google Scholar] [CrossRef]

- Liu, G.; Jin, W. Pervaporation Membrane Materials: Recent Trends and Perspectives. J. Membr. Sci. 2021, 636, 119557. [Google Scholar] [CrossRef]

- Yang, G.; Xie, Z.; Cran, M.; Ng, D.; Gray, S. Enhanced Desalination Performance of Poly (Vinyl Alcohol)/Carbon Nanotube Composite Pervaporation Membranes via Interfacial Engineering. J. Membr. Sci. 2019, 579, 40–51. [Google Scholar] [CrossRef]

- Lai, C.-Y.; Sun, Y.-M.; Liu, Y.-L. Water-Soluble Ozonated Lignin as a Hydrophilic Modifier for Poly (Vinyl Alcohol) Membranes for Pervaporation Desalination. J. Membr. Sci. 2023, 685, 121959. [Google Scholar] [CrossRef]

- Selim, A.; Toth, A.J.; Haaz, E.; Fozer, D.; Szanyi, A.; Hegyesi, N.; Mizsey, P. Preparation and Characterization of PVA/GA/Laponite Membranes to Enhance Pervaporation Desalination Performance. Sep. Purif. Technol. 2019, 221, 201–210. [Google Scholar] [CrossRef]

- Song, Y.; Li, R.; Pan, F.; He, Z.; Yang, H.; Li, Y.; Yang, L.; Wang, M.; Wang, H.; Jiang, Z. Ultrapermeable Graphene Oxide Membranes with Tunable Interlayer Distances via Vein-like Supramolecular Dendrimers. J. Mater. Chem. A 2019, 7, 18642–18652. [Google Scholar] [CrossRef]

- Liang, B.; Li, Q.; Cao, B.; Li, P. Water Permeance, Permeability and Desalination Properties of the Sulfonic Acid Functionalized Composite Pervaporation Membranes. Desalination 2018, 433, 132–140. [Google Scholar] [CrossRef]

- Kim, M.; Chang, J.W.; Park, K.; Yang, D.R. Comprehensive Assessment of the Effects of Operating Conditions on Membrane Intrinsic Parameters of Forward Osmosis (FO) Based on Principal Component Analysis (PCA). J. Membr. Sci. 2022, 641, 119909. [Google Scholar] [CrossRef]

- Jalaei Salmani, H.; Hardian, R.; Kalani, H.; Moradi, M.R.; Karkhanechi, H.; Szekely, G.; Matsuyama, H. Predicting the Performance of Organic Solvent Reverse Osmosis Membranes Using Artificial Neural Network and Principal Component Analysis by Considering Solvent–Solvent and Solvent–Membrane Affinities. J. Membr. Sci. 2023, 687, 122025. [Google Scholar] [CrossRef]

- Younes, K.; Mouhtady, O.; Chaouk, H.; Obeid, E.; Roufayel, R.; Moghrabi, A.; Murshid, N. The Application of Principal Component Analysis (PCA) for the Optimization of the Conditions of Fabrication of Electrospun Nanofibrous Membrane for Desalination and Ion Removal. Membranes 2021, 11, 979. [Google Scholar] [CrossRef]

- Joliffe, I.; Morgan, B. Principal Component Analysis and Exploratory Factor Analysis. Stat. Methods Med. Res. 1992, 1, 69–95. [Google Scholar] [CrossRef]

- Younes, K.; Abdallah, M.; Hanna, E.G. The Application of Principal Components Analysis for the Comparison of Chemical and Physical Properties among Activated Carbon Models. Mater. Lett. 2022, 325, 132864. [Google Scholar] [CrossRef]

- Peiris, R.H.; Budman, H.; Moresoli, C.; Legge, R.L. Understanding Fouling Behaviour of Ultrafiltration Membrane Processes and Natural Water Using Principal Component Analysis of Fluorescence Excitation-Emission Matrices. J. Membr. Sci. 2010, 357, 62–72. [Google Scholar] [CrossRef]

- Peiris, R.H.; Budman, H.; Moresoli, C.; Legge, R.L. Development of a Species Specific Fouling Index Using Principal Component Analysis of Fluorescence Excitation–Emission Matrices for the Ultrafiltration of Natural Water and Drinking Water Production. J. Membr. Sci. 2011, 378, 257–264. [Google Scholar] [CrossRef]

- Younes, K.; Kharboutly, Y.; Antar, M.; Chaouk, H.; Obeid, E.; Mouhtady, O.; Abu-samha, M.; Halwani, J.; Murshid, N. Application of Unsupervised Learning for the Evaluation of Aerogels’ Efficiency towards Dye Removal—A Principal Component Analysis (PCA) Approach. Gels 2023, 9, 327. [Google Scholar] [CrossRef]

- Younes, K.; Kharboutly, Y.; Antar, M.; Chaouk, H.; Obeid, E.; Mouhtady, O.; Abu-samha, M.; Halwani, J.; Murshid, N. Application of Unsupervised Machine Learning for the Evaluation of Aerogels’ Efficiency towards Ion Removal—A Principal Component Analysis (PCA) Approach. Gels 2023, 9, 304. [Google Scholar] [CrossRef]

- Xue, Y.L.; Huang, J.; Lau, C.H.; Cao, B.; Li, P. Tailoring the Molecular Structure of Crosslinked Polymers for Pervaporation Desalination. Nat. Commun. 2020, 11, 1461. [Google Scholar] [CrossRef]

- Ashtekar, S.; McLeod, A.S.; Mantle, M.D.; Barrie, P.J.; Gladden, L.F.; Hastings, J.J. Determining the Adsorption Sites for Binary Mixtures of -Xylene and n-Heptane in Silicalite Using FT-Raman Spectroscopy and Temperature-Programmed Desorption. J. Phys. Chem. B 2000, 104, 5281–5287. [Google Scholar] [CrossRef]

- Liang, B.; Pan, K.; Li, L.; Giannelis, E.P.; Cao, B. High Performance Hydrophilic Pervaporation Composite Membranes for Water Desalination. Desalination 2014, 347, 199–206. [Google Scholar] [CrossRef]

- Chaudhri, S.G.; Rajai, B.H.; Singh, P.S. Preparation of Ultra-Thin Poly(Vinyl Alcohol) Membranes Supported on Polysulfone Hollow Fiber and Their Application for Production of Pure Water from Seawater. Desalination 2015, 367, 272–284. [Google Scholar] [CrossRef]

- Zhang, R.; Liang, B.; Qu, T.; Cao, B.; Li, P. High-Performance Sulfosuccinic Acid Cross-Linked PVA Composite Pervaporation Membrane for Desalination. Environ. Technol. 2019, 40, 312–320. Available online: https://www.tandfonline.com/doi/full/10.1080/09593330.2017.1388852 (accessed on 23 May 2024). [CrossRef]

- Zhang, R.; Xu, X.; Cao, B.; Li, P. Fabrication of High-Performance PVA/PAN Composite Pervaporation Membranes Crosslinked by PMDA for Wastewater Desalination. Pet. Sci. 2018, 15, 146–156. [Google Scholar] [CrossRef]

- Cheng, C.; Shen, L.; Yu, X.; Yang, Y.; Li, X.; Wang, X. Robust Construction of a Graphene Oxide Barrier Layer on a Nanofibrous Substrate Assisted by the Flexible Poly(Vinylalcohol) for Efficient Pervaporation Desalination. J. Mater. Chem. A 2017, 5, 3558–3568. [Google Scholar] [CrossRef]

- Tseng, C.; Liu, Y.-L. Creation of Water-Permeation Pathways with Matrix-Polymer Functionalized Carbon Nanotubes in Polymeric Membranes for Pervaporation Desalination. J. Membr. Sci. Lett. 2022, 2, 100027. [Google Scholar] [CrossRef]

- Xing, Y.; Xue, Y.; Qin, D.; Zhao, P.; Li, P. Microwave-Induced Ultrafast Crosslinking of Poly (Vinyl Alcohol) Blended with Nanoparticles as Wave Absorber for Pervaporation Desalination. J. Membr. Sci. Lett. 2022, 2, 100021. [Google Scholar] [CrossRef]

- Saleh, T.A.; Gupta, V.K. Nanomaterial and Polymer Membranes: Synthesis, Characterization, and Applications; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Yan, D. Membrane Desalination Technologies. In A Multidisciplinary Introduction to Desalination; River Publishers: Aalborg, Denmark, 2022; pp. 155–199. [Google Scholar]

- Cohen-Tanugi, D.; McGovern, R.K.; Dave, S.H.; Lienhard, J.H.; Grossman, J.C. Quantifying the Potential of Ultra-Permeable Membranes for Water Desalination. Energy Environ. Sci. 2014, 7, 1134–1141. [Google Scholar] [CrossRef]

- Mouhtady, O.; Obeid, E.; Abu-samha, M.; Younes, K.; Murshid, N. Evaluation of the Adsorption Efficiency of Graphene Oxide Hydrogels in Wastewater Dye Removal: Application of Principal Component Analysis. Gels 2022, 8, 447. [Google Scholar] [CrossRef]

- Younes, K.; Moghrabi, A.; Moghnie, S.; Mouhtady, O.; Murshid, N.; Grasset, L. Assessment of the Efficiency of Chemical and Thermochemical Depolymerization Methods for Lignin Valorization: Principal Component Analysis (PCA) Approach. Polymers 2022, 14, 194. [Google Scholar] [CrossRef]

- Dmitrenko, M.; Kuzminova, A.; Zolotarev, A.; Ermakov, S.; Roizard, D.; Penkova, A. Enhanced Pervaporation Properties of PVA-Based Membranes Modified with Polyelectrolytes. Application to IPA Dehydration. Polymers 2020, 12, 14. [Google Scholar] [CrossRef]

- Selima, A.; Totha, A.; Fozera, D.; Haaza, E.; Nagya, T.; Mizseya, P. Laponite/PVA Pervaporation Membrane for Desalinating Simulated RO High-Salinity by-Product. Alcohol 2019, 12, 18. [Google Scholar] [CrossRef]

- Galiano, F.; Castro-Muñoz, R.; Figoli, A. Pervaporation, Vapour Permeation and Membrane Distillation: From Membrane Fabrication to Application. Membranes 2021, 11, 162. [Google Scholar] [CrossRef] [PubMed]

- Unlu, D. Water Desalination by Pervaporation Using MIL-101(Cr) and MIL-101(Cr)@GODoped PVA Hybrid Membranes. Water. Air. Soil Pollut. 2023, 234, 96. [Google Scholar] [CrossRef]

- Praptowidodo, V.S. Influence of Swelling on Water Transport through PVA-Based Membrane. J. Mol. Struct. 2005, 739, 207–212. [Google Scholar] [CrossRef]

- Zhang, J.; Li, S.; Ren, D.; Li, H.; Lv, X.; Han, L.; Su, B. Fabrication of Ultra-Smooth Thin-Film Composite Nanofiltration Membrane with Enhanced Selectivity and Permeability on Interlayer of Hybrid Polyvinyl Alcohol and Graphene Oxide. Sep. Purif. Technol. 2021, 268, 118649. [Google Scholar] [CrossRef]

- Sun, Z.; Zhu, X.; Tan, F.; Zhou, W.; Zhang, Y.; Luo, X.; Xu, J.; Wu, D.; Liang, H.; Cheng, X. Poly(Vinyl Alcohol)-Based Highly Permeable TFC Nanofiltration Membranes for Selective Dye/Salt Separation. Desalination 2023, 553, 116479. [Google Scholar] [CrossRef]

- Qian, X.; Li, N.; Wang, Q.; Ji, S. Chitosan/Graphene Oxide Mixed Matrix Membrane with Enhanced Water Permeability for High-Salinity Water Desalination by Pervaporation. Desalination 2018, 438, 83–96. [Google Scholar] [CrossRef]

- Zhan, Z.-M.; Tang, Y.-J.; Zhu, K.-K.; Xue, S.-M.; Ji, C.-H.; Tang, C.Y.; Xu, Z.-L. Coupling Heat Curing and Surface Modification for the Fabrication of High Permselectivity Polyamide Nanofiltration Membranes. J. Membr. Sci. 2021, 623, 119073. [Google Scholar] [CrossRef]

- Mahto, A.; Halakarni, M.A.; Maraddi, A.; D’Souza, G.; Samage, A.A.; Thummar, U.G.; Mondal, D.; Nataraj, S.K. Upcycling Cellulose Acetate from Discarded Cigarette Butts: Conversion of Contaminated Microfibers into Loose-Nanofiltration Membranes for Selective Separation. Desalination 2022, 535, 115807. [Google Scholar] [CrossRef]

- Shi, C.; Zhang, S.; Wang, W.; Linhardt, R.J.; Ragauskas, A.J. Preparation of Highly Reactive Lignin by Ozone Oxidation: Application as Surfactants with Antioxidant and Anti-UV Properties. ACS Sustain. Chem. Eng. 2020, 8, 22–28. [Google Scholar] [CrossRef]

- Stafie, N. Poly (Dimethyl Siloxane)—Based Composite Nanofiltration Membranes for Non-Aqueous Applications. Ph.D. Thesis, University of Twente, Enschede, The Netherlands, 2004. [Google Scholar]

- Cuperus, F.P.; Smolders, C.A. Characterization of UF Membranes: Membrane Characteristics and Characterization Techniques. Adv. Colloid Interface Sci. 1991, 34, 135–173. [Google Scholar] [CrossRef]

- Scott, K. Handbook of Industrial Membranes; Elsevier: Amsterdam, The Netherlands, 1995. [Google Scholar]

- Ng, L.Y.; Mohammad, A.W.; Ng, C.Y. A Review on Nanofiltration Membrane Fabrication and Modification Using Polyelectrolytes: Effective Ways to Develop Membrane Selective Barriers and Rejection Capability. Adv. Colloid Interface Sci. 2013, 197, 85–107. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Cao, T.; Dykstra, J.E.; Porada, S.; Biesheuvel, P.M.; Elimelech, M. Salt and Water Transport in Reverse Osmosis Membranes: Beyond the Solution-Diffusion Model. Environ. Sci. Technol. 2021, 55, 16665–16675. [Google Scholar] [CrossRef]

- Khoo, Y.S.; Lau, W.J.; Liang, Y.Y.; Yusof, N.; Ismail, A.F. Surface Modification of PA Layer of TFC Membranes: Does It Effective for Performance Improvement? J. Ind. Eng. Chem. 2021, 102, 271–292. [Google Scholar] [CrossRef]

- Li, L.; Hou, J.; Ye, Y.; Mansouri, J.; Chen, V. Composite PVA/PVDF Pervaporation Membrane for Concentrated Brine Desalination: Salt Rejection, Membrane Fouling and Defect Control. Desalination 2017, 422, 49–58. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chaouk, H.; Obeid, E.; Halwani, J.; Arayro, J.; Mezher, R.; Amine, S.; Gazo Hanna, E.; Mouhtady, O.; Younes, K. Application of Principal Component Analysis for the Elucidation of Operational Features for Pervaporation Desalination Performance of PVA-Based TFC Membrane. Processes 2024, 12, 1502. https://doi.org/10.3390/pr12071502

Chaouk H, Obeid E, Halwani J, Arayro J, Mezher R, Amine S, Gazo Hanna E, Mouhtady O, Younes K. Application of Principal Component Analysis for the Elucidation of Operational Features for Pervaporation Desalination Performance of PVA-Based TFC Membrane. Processes. 2024; 12(7):1502. https://doi.org/10.3390/pr12071502

Chicago/Turabian StyleChaouk, Hamdi, Emil Obeid, Jalal Halwani, Jack Arayro, Rabih Mezher, Semaan Amine, Eddie Gazo Hanna, Omar Mouhtady, and Khaled Younes. 2024. "Application of Principal Component Analysis for the Elucidation of Operational Features for Pervaporation Desalination Performance of PVA-Based TFC Membrane" Processes 12, no. 7: 1502. https://doi.org/10.3390/pr12071502