A Novel Exact and Heuristic Solution for the Periodic Location-Routing Problem Applied to Waste Collection

Abstract

1. Introduction

2. Literature Review

3. Problem Description

- Each route must start and end at the same depot.

- Plastic waste, paper and wood, glass, metal, and electronic waste can all be transported in the same non-compartmentalized vehicle, since these wastes can be mixed.

- Organic-type waste must be transported by a single vehicle without being mixed with other types of waste due to the potential harm it may cause to others.

- A customer may be visited more than once a day depending on the type of waste to collect.

- A customer cannot be visited two days in a row (there must be at least one intermediate day so bins may re-fill).

- There is a set of depots that can be opened to receive customer waste.

- The Euclidean distance was considered for cost estimation.

4. Proposed Mathematical Model

4.1. Sets

- , set of all customers, where N is the maximum number of customers.

- , set of days, where H is the maximum number of days in planning horizon.

- , set of waste type (1: organic, 2: non-organic).

- , set of depots, where is the maximum number of depots.

- , set of vehicles.

- , set of available sequences (Table 3).

- , set of customer type (Table 2).

- , set of sequences for customer type and its waste .

- , set of feasible arcs between all nodes.

- , set of feasible routes between customers.

- , set of feasible routes between depots and customers or between customers.

4.2. Parameters

- : capacity of depots [md3].

- : capacity of each vehicle [md3].

- : proportion of capacity of each depot to store waste type .

- : customer demand for collection of each type of waste [md3].

- : distances for each arc [km].

- : customer type to the customer . The possible results are stored in the set .

- : number of days for waste collection required by customer .

- : binary matrix relating the feasibility of sequence to day .

- : auxiliary binary matrix that defines if customer has waste type .

- : cost per traveled kilometer [USD/km].

- : fixed cost of opening a depot .

4.3. Decision Variables

- : order of the sequence in which customer with waste type is attended by vehicle .

4.4. Proposed MILP Model

5. Proposed Variable Neighborhood Search

5.1. Encoding Phase

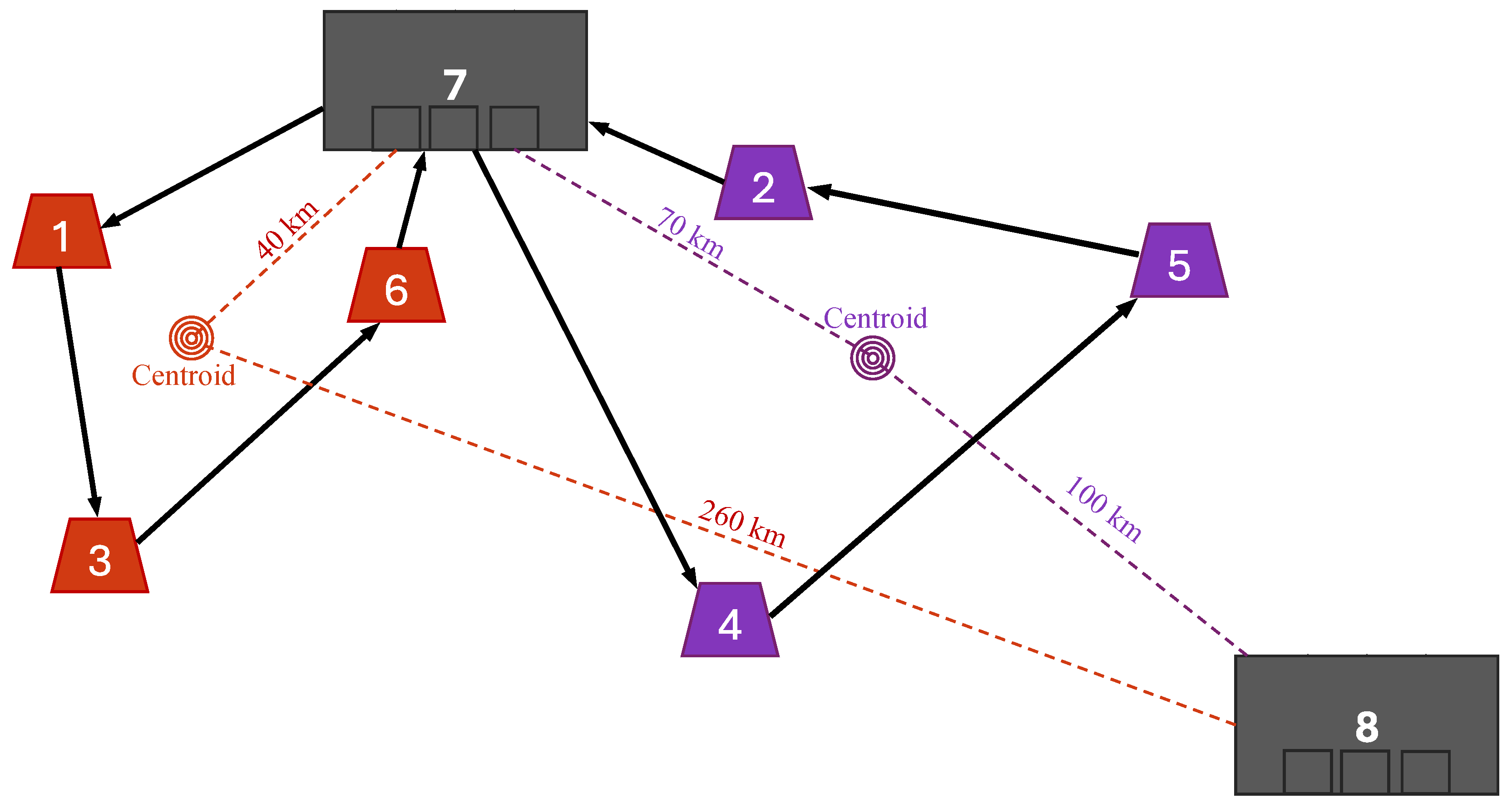

5.2. Decoding Phase

| Algorithm 1 Decoding Phase. |

|

Input: feasible solution coding Output: routes’ vehicles and cost 1: function decode(input solution, input data) 2: sort Nodes by RandomKey ← List of nodes() 3: for each day in Days Planned do 4: assign node to the day ← list of nodes() 5: end for 6: for each route in Route do 7: if vehicle capacity available > demand of node then 8: assign node to the route ← list of nodes() 9: else 10: create New Route() 11: assign node to the route ← list of nodes() 12: end if 13: end for 14: for each route in Route do 15: generate Centroid(coordinates of nodes) ← list of nodes() 16: if depot = near depot then 17: assign depot to the route ← list of routes() 18: end if 19: end for 20: for each route in Route do 21: calculate Distance ← list of routes() 22: end for 23: calculate Total Cost ← Solution(Distances, Depots) 24: end function |

5.3. Initial Solution

5.4. Movement Rules: Three Generations of Neighborhoods

- Route Sequence Level: The exchange operator is used in this level. It consists of choosing two nodes (they must have the same type of waste between organic and not organic), and then their random key values are re-assigned. In Figure 2, nodes one and four were chosen and their values were exchanged. This allows changes to be made to the routes.

- Visit Sequence Level: The Relocate and Shift operators were adapted. First, they select one customer node and, depending on the type of customer, switch the visit sequence of it (within the available sequences). This change can generate a different visit route for the days where the customer was previously.

- Depot Opening Level: Depending on the number of depots, all possible combinations are established, considering openings from one depot up to the corresponding number. Subsequently, the cost of each combination is evaluated, and the opening scheme (number and location) with the lowest cost is selected.

5.5. Stopping Criterion

6. Results

6.1. Adaptation of the Instances

- Each depot will have a maximum capacity of 180,000 dm3.

- The number of depots available to open corresponds to of the number of customers.

- Using technical data sheets, it was determined that the capacity of the vehicles should be 18,000 dm3. In relation to the weight capacity, in a variety of Volvo truck brands with this volume, it was found that the standard load capacity is 28,000 kg.

- It was determined that there are 10 vehicles available for each depot that is opened.

- The combination of waste demanded will be assigned to each customer randomly, where each customer will recycle a maximum of three different types of waste out of the five available.

- The amount of waste produced by customers depends on the type of waste they recycle. Likewise, the frequency at which the customer will be visited per week is also assigned (also depending on the type of waste). See Table 5.

- In relation to the combination of days available for waste collection, depending on the frequency of each customer, the maximum frequency obtained by type of waste will be chosen [58]. The combination of available days for waste collection will depend on the size of its frequency.

- The demand to be collected from each customer will be the consolidated demand divided by the maximum frequency of visits depending on the types of waste each particular customer has, based on the proposal by [58]. For example, if a customer has organic, paper and cardboard, and glass waste, the maximum frequency that predominates over the others is that of organic waste, with 3 days a week (paper and cardboard have 2 and glass has 1). Thus, the demand is divided by 3 days and the need for collection per visit day is generated. Since metal and WEEE were considered to include electronic waste from appliances and electronic products, it is known that these products contain a small amount of different metals (such as nickel, lead, tin, and mercury) that do not represent a large weight when discarded. In fact, the densest components, which are usually circuit boards, have a density of 1600 kg/m3, but they represent a considerable volume of WEEE. If a vehicle were filled only with WEEE, it should have an average density less than or equal to 1555 kg/m3.

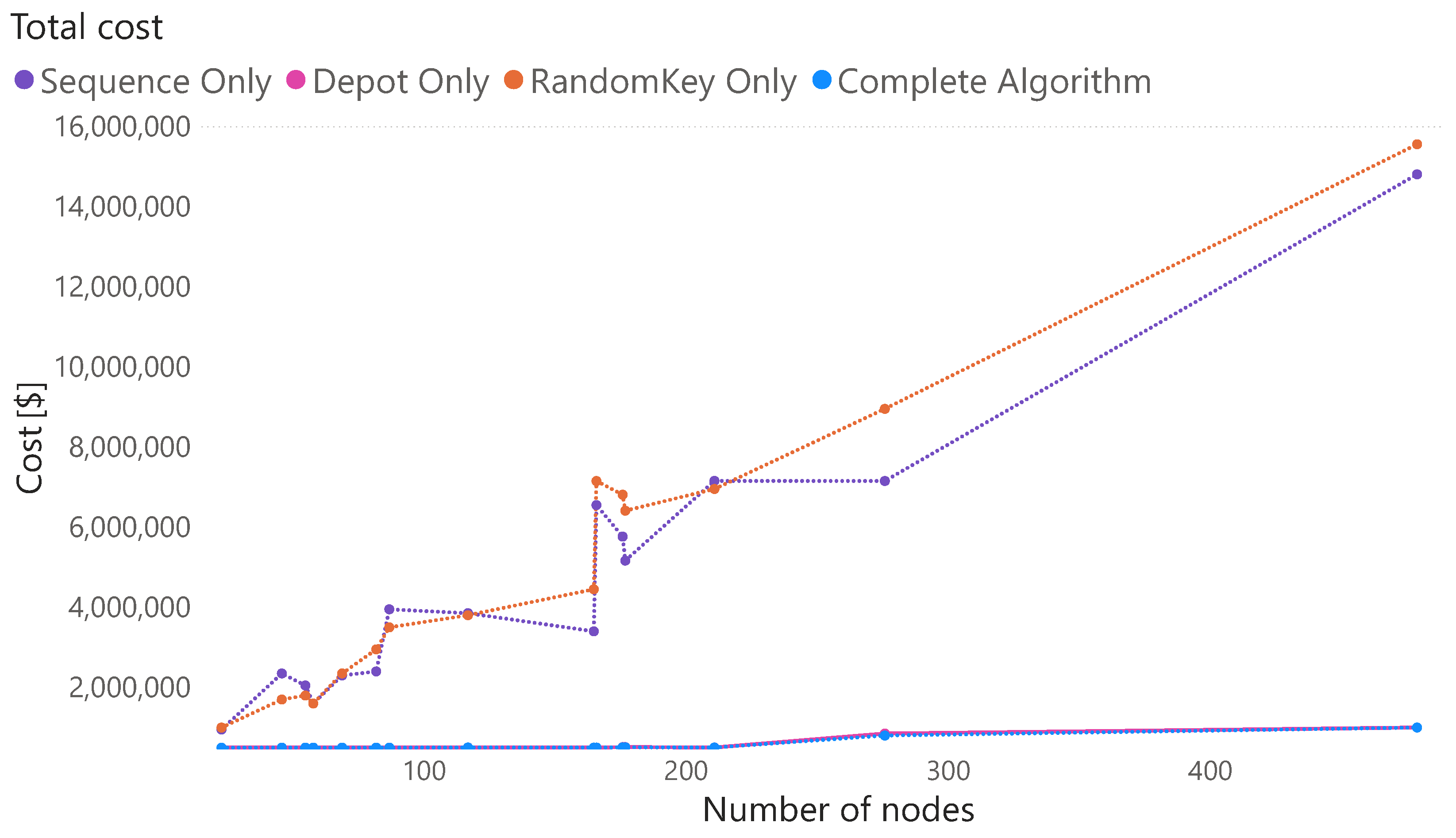

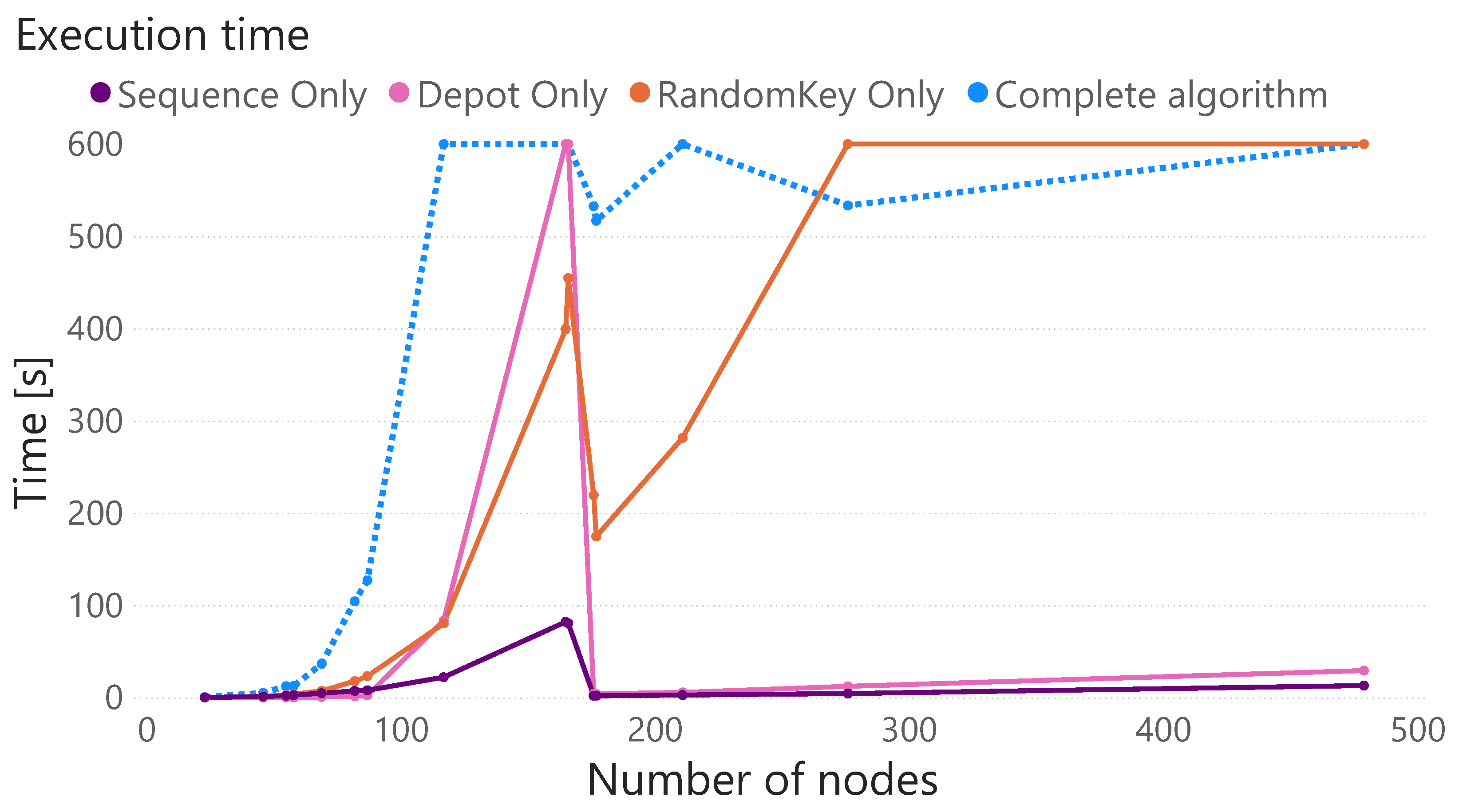

6.2. Validate Neighborhood Structures

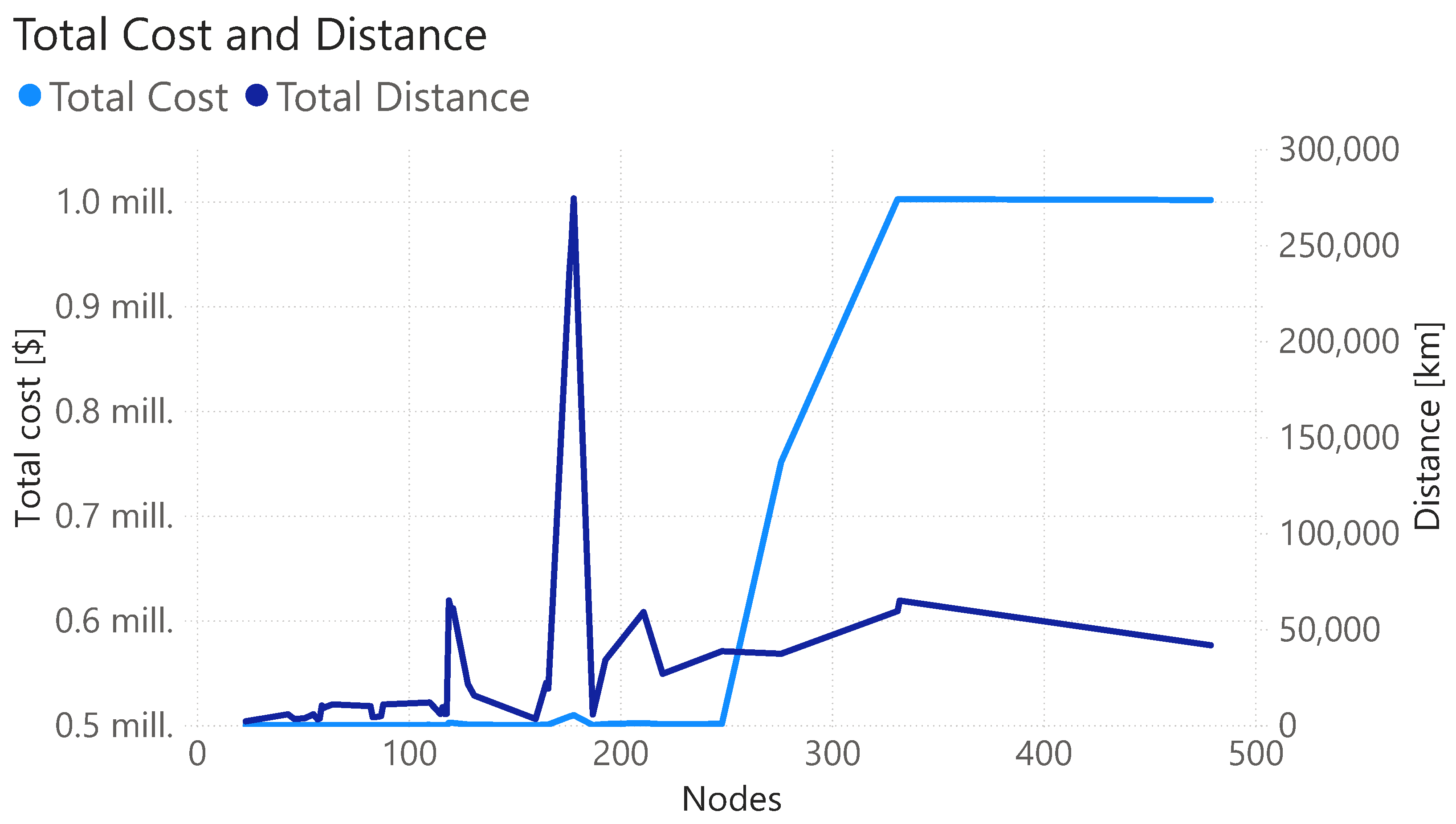

6.3. Computational Results

7. Limitations and Future Work

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- OECD. Plastic Pollution Is Growing Relentlessly as Waste Management and Recycling Fall Short, Says OECD; OECD: Paris, France, 2022. [Google Scholar]

- Ramos, T.R.P.; Gomes, M.I.; Barbosa-Póvoa, A.P. Economic and environmental concerns in planning recyclable waste collection systems. Transp. Res. Part E Logist. Transp. Rev. 2014, 62, 34–54. [Google Scholar] [CrossRef]

- Gruler, A.; Juan, A.A.; Contreras-Bolton, C.; Gatica, G. A Biased-Randomized Heuristic for the Waste Collection Problem in Smart Cities. Adv. Intell. Syst. Comput. 2018, 730, 255–263. [Google Scholar] [CrossRef]

- Senior, K.; Mazza, A. Italian “Triangle of death” linked to waste crisis. Lancet Oncol. 2004, 5, 525–527. [Google Scholar] [CrossRef] [PubMed]

- United Nations. Sustainable Development Goals—Goal 12: Ensure Sustainable Consumption and Production Patterns; United Nations: New York, NY, USA, 2023. [Google Scholar]

- Boskovic, G.; Jovicic, N.; Jovanovic, S.; Simovic, V. Calculating the costs of waste collection: A methodological proposal. Waste Manag. Res. J. Sustain. Circ. Econ. 2016, 34, 775–783. [Google Scholar] [CrossRef] [PubMed]

- Eksioglu, B.; Vural, A.V.; Reisman, A. The vehicle routing problem: A taxonomic review. Comput. Ind. Eng. 2009, 57, 1472–1483. [Google Scholar] [CrossRef]

- Ouertani, N.; Ben-Romdhane, H.; Nouaouri, I.; Allaoui, H.; Krichen, S. A multi-compartment VRP model for the health care waste transportation problem. J. Comput. Sci. 2023, 72, 102104. [Google Scholar] [CrossRef]

- Mojtahedi, M.; Fathollahi-Fard, A.M.; Tavakkoli-Moghaddam, R.; Newton, S. Sustainable vehicle routing problem for coordinated solid waste management. J. Ind. Inf. Integr. 2021, 23, 100220. [Google Scholar] [CrossRef]

- Mohammadi, M.; Rahmanifar, G.; Hajiaghaei-Keshteli, M.; Fusco, G.; Colombaroni, C.; Sherafat, A. A dynamic approach for the multi-compartment vehicle routing problem in waste management. Renew. Sustain. Energy Rev. 2023, 184, 113526. [Google Scholar] [CrossRef]

- Eren, E.; Rıfat Tuzkaya, U. Safe distance-based vehicle routing problem: Medical waste collection case study in COVID-19 pandemic. Comput. Ind. Eng. 2021, 157, 107328. [Google Scholar] [CrossRef]

- Prodhon, C. A Metaheuristic for the Periodic Location-Routing Problem. Oper. Res. Proc. 2008, 2007, 159–164. [Google Scholar] [CrossRef]

- Rabbani, M.; Amirhossein Sadati, S.; Farrokhi-Asl, H. Incorporating location routing model and decision making techniques in industrial waste management: Application in the automotive industry. Comput. Ind. Eng. 2020, 148, 106692. [Google Scholar] [CrossRef]

- Prodhon, C. A hybrid evolutionary algorithm for the periodic location-routing problem. Eur. J. Oper. Res. 2011, 210, 204–212. [Google Scholar] [CrossRef]

- Ahmadi Basir, S.; Şahin, G.; Özbaygın, G. A comparative study of alternative formulations for the periodic vehicle routing problem. Comput. Oper. Res. 2024, 165, 106583. [Google Scholar] [CrossRef]

- Hemmelmayr, V.; Smilowitz, K.; de la Torre, L. A periodic location routing problem for collaborative recycling. IISE Trans. 2017, 49, 414–428. [Google Scholar] [CrossRef]

- Dantzig, G.B.; Ramser, J.H. The Truck Dispatching Problem. Manag. Sci. 1959, 6, 80–91. [Google Scholar] [CrossRef]

- Campbell, A.M.; Wilson, J.H. Forty years of periodic vehicle routing. Networks 2014, 63, 2–15. [Google Scholar] [CrossRef]

- Beltrami, E.J.; Bodin, L.D. Networks and vehicle routing for municipal waste collection. Networks 1974, 4, 65–94. [Google Scholar] [CrossRef]

- Christofides, N.; Beasley, J.E. The period routing problem. Networks 1984, 14, 237–256. [Google Scholar] [CrossRef]

- Cordeau, J.F.; Gendreau, M.; Laporte, G. A tabu search heuristic for periodic and multi-depot vehicle routing problems. Networks 1997, 30, 105–119. [Google Scholar] [CrossRef]

- Salhi, S.; Thangiah, S.R.; Rahman, F. A Genetic Clustering Method for the Multi-Depot Vehicle Routing Problem. In Artificial Neural Nets and Genetic Algorithms; Springer: Vienna, Austria, 1998; pp. 234–237. [Google Scholar] [CrossRef]

- Drummond, L.M.; Ochi, L.S.; Vianna, D.S. An asynchronous parallel metaheuristic for the period vehicle routing problem. Future Gener. Comput. Syst. 2001, 17, 379–386. [Google Scholar] [CrossRef]

- Teixeira, J.; Antunes, A.P.; de Sousa, J.P. Recyclable waste collection planning—A case study. Eur. J. Oper. Res. 2004, 158, 543–554. [Google Scholar] [CrossRef]

- Irnich, S.; Toth, P.; Vigo, D. Chapter 1: The Family of Vehicle Routing Problems. In Vehicle Routing; Society for Industrial and Applied Mathematics: Philadelphia, PA, USA, 2014; pp. 1–33. [Google Scholar] [CrossRef]

- Prodhon, C. An ELSxPath Relinking Hybrid for the Periodic Location-Routing Problem. Hybrid Metaheuristics 2009, 5818, 15–29. [Google Scholar] [CrossRef]

- Pirkwieser, S.; Raidl, G.R. Variable Neighborhood Search Coupled with ILP-Based Very Large Neighborhood Searches for the (Periodic) Location-Routing Problem. Hybrid Metaheuristics 2010, 6373, 174–189. [Google Scholar] [CrossRef]

- Vidal, T.; Crainic, T.G.; Gendreau, M.; Lahrichi, N.; Rei, W. A Hybrid Genetic Algorithm for Multidepot and Periodic Vehicle Routing Problems. Oper. Res. 2012, 60, 611–624. [Google Scholar] [CrossRef]

- Hemmelmayr, V.C. Sequential and parallel large neighborhood search algorithms for the periodic location routing problem. Eur. J. Oper. Res. 2015, 243, 52–60. [Google Scholar] [CrossRef]

- Koç, Ç. A unified-adaptive large neighborhood search metaheuristic for periodic location-routing problems. Transp. Res. Part C Emerg. Technol. 2016, 68, 265–284. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, S.; Wang, J.; Huang, M. A branch-and-price algorithm for the heterogeneous fleet green vehicle routing problem with time windows. Transp. Res. Part B Methodol. 2019, 122, 511–527. [Google Scholar] [CrossRef]

- Aringhieri, R.; Bruglieri, M.; Malucelli, F.; Nonato, M. A Special Vehicle Routing Problem Arising in the Optimization of Waste Disposal: A Real Case. Transp. Sci. 2018, 52, 277–299. [Google Scholar] [CrossRef]

- Franca, L.S.; Ribeiro, G.M.; Chaves, G.d.L.D. The planning of selective collection in a real-life vehicle routing problem: A case in Rio de Janeiro. Sustain. Cities Soc. 2019, 47, 101488. [Google Scholar] [CrossRef]

- Flores-Carrasco, J.; Morillo-Torres, D.; Escobar, J.; Linfati, R.; Gatica, G. The Periodic Location-Routing with Selective Recycling Problem: Two Solution Approaches. IFAC-PapersOnLine 2021, 54, 787–792. [Google Scholar] [CrossRef]

- Vidović, M.; Ratković, B.; Bjelić, N.; Popović, D. A two-echelon location-routing model for designing recycling logistics networks with profit: MILP and heuristic approach. Expert Syst. Appl. 2016, 51, 34–48. [Google Scholar] [CrossRef]

- Wang, L.; Zhao, X.; Wu, P. Resource-Constrained Emergency Scheduling for Forest Fires via Artificial Bee Colony and Variable Neighborhood Search Combined Algorithm. IEEE Trans. Intell. Transp. Syst. 2024, 25, 5791–5806. [Google Scholar] [CrossRef]

- Meng, L.; Cheng, W.; Zhang, B.; Zou, W.; Duan, P. A novel hybrid algorithm of genetic algorithm, variable neighborhood search and constraint programming for distributed flexible job shop scheduling problem. Int. J. Ind. Eng. Comput. 2024, 15, 813–832. [Google Scholar] [CrossRef]

- García-Vasquez, K.; Linfati, R.; Escobar, J.W. A three-phase algorithm for the pollution traveling Salesman problem. Heliyon 2024, 10. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, K.; de Queiroz, T.; Munari, P.; Toledo, F. A variable neighborhood search for the green vehicle routing problem with two-dimensional loading constraints and split delivery. Eur. J. Oper. Res. 2024, 316, 597–616. [Google Scholar] [CrossRef]

- İslim, R.B.; Çatay, B. An effective matheuristic approach for solving the electric traveling salesperson problem with time windows and battery degradation. Eng. Appl. Artif. Intell. 2024, 132, 107943. [Google Scholar] [CrossRef]

- Su, Y.; Zhang, S.; Zhang, C. A lightweight genetic algorithm with variable neighborhood search for multi-depot vehicle routing problem with time windows. Appl. Soft Comput. 2024, 161, 111789. [Google Scholar] [CrossRef]

- Lou, P.; Zhou, Z.; Zeng, Y.; Fan, C. Vehicle routing problem with time windows and carbon emissions: A case study in logistics distribution. Environ. Sci. Pollut. Res. 2024, 31, 41600–41620. [Google Scholar] [CrossRef] [PubMed]

- Prakash, R.; Pushkar, S. Green vehicle routing problem: Metaheuristic solution with time window. Expert Syst. 2024, 41, e13007. [Google Scholar] [CrossRef]

- Chagas, G.O.; Lorena, L.A.; dos Santos, R.D.; Renaud, J.; Coelho, L.C. A parallel variable neighborhood search for α-neighbor facility location problems. Comput. Oper. Res. 2024, 165, 106589. [Google Scholar] [CrossRef]

- Wei, C.; Wøhlk, S.; Che, A. A multi-level capacitated arc routing problem with intermediate facilities in waste collection. Comput. Oper. Res. 2024, 167, 106671. [Google Scholar] [CrossRef]

- Peng, Z.; Li, Y.; Zhang, J. Joint optimization of train timetable and passing facility: A capacity allocation strategy. Expert Syst. Appl. 2024, 252, 124173. [Google Scholar] [CrossRef]

- Souza, V.A.; Melo, R.A.; Mateus, G.R. The Vehicle Routing Problem with Cross-Docking and Scheduling at the Docking Station: Compact formulation and a General Variable Neighborhood Search metaheuristic. Appl. Soft Comput. 2024, 161, 111744. [Google Scholar] [CrossRef]

- Sugianto, W.C.; Kim, B.S. Iterated variable neighborhood search for integrated scheduling of additive manufacturing and multi-trip vehicle routing problem. Comput. Oper. Res. 2024, 167, 106659. [Google Scholar] [CrossRef]

- Hemmelmayr, V.C.; Doerner, K.F.; Hartl, R.F. A variable neighborhood search heuristic for periodic routing problems. Eur. J. Oper. Res. 2009, 195, 791–802. [Google Scholar] [CrossRef]

- Voigt, S.; Frank, M.; Fontaine, P.; Kuhn, H. Hybrid adaptive large neighborhood search for vehicle routing problems with depot location decisions. Comput. Oper. Res. 2022, 146, 105856. [Google Scholar] [CrossRef]

- Sluijk, N.; Florio, A.M.; Kinable, J.; Dellaert, N.; Van Woensel, T. Two-echelon vehicle routing problems: A literature review. Eur. J. Oper. Res. 2023, 304, 865–886. [Google Scholar] [CrossRef]

- Wang, K.; Shao, Y.; Zhou, W. Matheuristic for a two-echelon capacitated vehicle routing problem with environmental considerations in city logistics service. Transp. Res. Part D Transp. Environ. 2017, 57, 262–276. [Google Scholar] [CrossRef]

- de Melo, V.A.; Boaventura-Netto, P.O. Metaheuristics Evaluation: A Proposal for A Multicriteria Methodology. Pesqui. Oper. 2015, 35, 539–554. [Google Scholar] [CrossRef]

- Mladenović, N.; Hansen, P. Variable neighborhood search. Comput. Oper. Res. 1997, 24, 1097–1100. [Google Scholar] [CrossRef]

- Matsumoto, M.; Nishimura, T. Mersenne twister: A 623-dimensionally equidistributed uniform pseudo-random number generator. ACM Trans. Model. Comput. Simul. 1998, 8, 3–30. [Google Scholar] [CrossRef]

- Sarasola, B.; Doerner, K.F. Adaptive large neighborhood search for the vehicle routing problem with synchronization constraints at the delivery location. Networks 2020, 75, 64–85. [Google Scholar] [CrossRef]

- Alvarez, A.; Munari, P. An exact hybrid method for the vehicle routing problem with time windows and multiple deliverymen. Comput. Oper. Res. 2017, 83, 1–12. [Google Scholar] [CrossRef]

- Prodhon, C.; Prins, C. A Memetic Algorithm with Population Management (MA|PM) for the Periodic Location-Routing Problem. Hybrid Metaheuristics 2008, 5296, 43–57. [Google Scholar] [CrossRef]

| Paper | Problem | Solution Approach | MD | WC | HC | HD | P | LRP |

|---|---|---|---|---|---|---|---|---|

| [29] | PLRP | LNS | ✓ | ✓ | ✓ | ✓ | ||

| [16] | PLRP | ALNS | ✓ | ✓ | ✓ | ✓ | ✓ | |

| [30] | PLRP | ALNS | ✓ | ✓ | ✓ | |||

| [31] | GVRPTW | B&P | ✓ | |||||

| [32] | VRP | NS | ✓ | ✓ | ||||

| [33] | VRP | MILP | ✓ | ✓ | ||||

| [34] | PLRP | MILP & H | ✓ | ✓ | ✓ | ✓ | ✓ | |

| [35] | RLN * | MILP & H | ✓ | ✓ | ||||

| This paper | PLRP | MILP & VNS | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Type | Organic | Plastic | Paper and Cardboard | Glass | Metal and WEEE |

|---|---|---|---|---|---|

| 1 | 1 | ||||

| 2 | 1 | ||||

| 3 | 1 | ||||

| 4 | 1 | ||||

| 5 | 1 | ||||

| 6 | 1 | 1 | |||

| 7 | 1 | 1 | |||

| 8 | 1 | 1 | |||

| 9 | 1 | 1 | |||

| 10 | 1 | 1 | |||

| 11 | 1 | 1 | |||

| 12 | 1 | 1 | |||

| 13 | 1 | 1 | |||

| 14 | 1 | 1 | |||

| 15 | 1 | 1 | |||

| 16 | 1 | 1 | 1 | ||

| 17 | 1 | 1 | 1 | ||

| 18 | 1 | 1 | 1 | ||

| 19 | 1 | 1 | 1 | ||

| 20 | 1 | 1 | 1 | ||

| 21 | 1 | 1 | 1 | ||

| 22 | 1 | 1 | 1 | ||

| 23 | 1 | 1 | 1 | ||

| 24 | 1 | 1 | 1 | ||

| 25 | 1 | 1 | 1 |

| Combinations | Monday | Tuesday | Wednesday | Thursday | Friday | Saturday | Sunday |

|---|---|---|---|---|---|---|---|

| 1 | 1 | ||||||

| 2 | 1 | ||||||

| 3 | 1 | ||||||

| 4 | 1 | ||||||

| 5 | 1 | ||||||

| 6 | 1 | ||||||

| 7 | 1 | ||||||

| 8 | 1 | 1 | |||||

| 9 | 1 | 1 | |||||

| 10 | 1 | 1 | |||||

| 11 | 1 | 1 | |||||

| 12 | 1 | 1 | |||||

| 13 | 1 | 1 | |||||

| 14 | 1 | 1 | |||||

| 15 | 1 | 1 | |||||

| 16 | 1 | 1 | |||||

| 17 | 1 | 1 | |||||

| 18 | 1 | 1 | |||||

| 19 | 1 | 1 | |||||

| 20 | 1 | 1 | |||||

| 21 | 1 | 1 | |||||

| 22 | 1 | 1 | 1 | ||||

| 23 | 1 | 1 | 1 | ||||

| 24 | 1 | 1 | 1 | ||||

| 25 | 1 | 1 | 1 | ||||

| 26 | 1 | 1 | 1 | ||||

| 27 | 1 | 1 | 1 | ||||

| 28 | 1 | 1 | 1 |

| Customer | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| RKOrg | 0.78 | 0 | 0.42 | 0.57 | 0 |

| RKNoOrg | 0 | 0.61 | 0.8 | 0.12 | 0.3 |

| SecOrg | 27 | 15 | 8 | 2 | 27 |

| SecNoOrg | 18 | 10 | 2 | 2 | 27 |

| Depot | 0 | 1 | 2 | 3 | 4 |

| Status | 1 | 0 | 0 | 0 | 0 |

| Type of Waste | Demand (dm3) | Frequency (Days) |

|---|---|---|

| Organic | 200 | 3 |

| Plastic | 4500 | 3 |

| Paper and Cardboard | 4500 | 2 |

| Glass | 400 | 1 |

| Metal and WEEE | 120 | 1 |

| Inst. | C | D | V | Mathematical Model | Proposed VNS | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Z [USD] | St | t [s] | d [km] | Z [USD] | St | t [s] | d [km] | ||||

| p14 | 20 | 3 | 30 | - | 411 | 600 | - | 500,072.2 | 1 | 0.9 | 2051.2 |

| p15 | 38 | 5 | 50 | - | 411 | 600 | - | 500,201.8 | 1 | 17.9 | 5713 |

| p17 | 40 | 6 | 60 | - | 411 | 600 | - | 500,114.6 | 1 | 20 | 3245.4 |

| pr01 | 48 | 7 | 70 | - | 411 | 600 | - | 500,202.8 | 1 | 38.5 | 5742.4 |

| p02 | 50 | 7 | 70 | - | 411 | 600 | - | 500,109.4 | 1 | 42.4 | 3098 |

| p03 | 50 | 7 | 70 | - | 411 | 600 | - | 500,124.2 | 1 | 39.6 | 3517 |

| p01 | 51 | 7 | 70 | - | 411 | 600 | - | 500,128.4 | 1 | 42.1 | 3638.4 |

| p24 | 51 | 7 | 70 | - | 411 | 600 | - | 500,363.0 | 1 | 49.8 | 10,286.4 |

| p25 | 51 | 7 | 70 | - | 411 | 600 | - | 500,321.6 | 1 | 41.2 | 9115 |

| p26 | 51 | 7 | 70 | - | 411 | 600 | - | 500,338.6 | 1 | 51.7 | 9596.4 |

| p16 | 56 | 8 | 80 | - | 411 | 600 | - | 500,383.6 | 1 | 82.2 | 10,866.4 |

| p21 | 60 | 9 | 90 | - | 411 | 600 | - | 500,187.2 | 1 | 111.8 | 5296.8 |

| Inst. | C | D | V | Mathematical Model | Proposed VNS | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Z [USD] | St | t [s] | d [km] | Z [USD] | St | t [s] | d [km] | ||||

| pr07 | 72 | 10 | 100 | - | 411 | 600 | - | 500,345 | 1 | 90.3 | 9777 |

| p04 | 75 | 7 | 70 | - | 411 | 600 | - | 500,147 | 1 | 94.6 | 4179 |

| p05 | 75 | 11 | 110 | - | 411 | 600 | - | 500,158 | 1 | 96.8 | 4483.5 |

| p06 | 75 | 11 | 110 | - | 411 | 600 | - | 500,171 | 1 | 101.3 | 4844.5 |

| p18 | 76 | 11 | 110 | - | 411 | 600 | - | 500,382 | 1 | 116.6 | 10,824.5 |

| pr02 | 96 | 14 | 140 | - | 411 | 600 | - | 500,419 | 1 | 252.8 | 11,860 |

| p07 | 100 | 15 | 150 | - | 411 | 600 | - | 500,208 | 1 | 250.6 | 5908 |

| p08 | 100 | 15 | 150 | - | 411 | 600 | - | 500,330 | 1 | 600 | 9355 |

| p09 | 100 | 15 | 150 | - | 411 | 600 | - | 500,207 | 1 | 269.2 | 5865 |

| p10 | 100 | 15 | 150 | - | 411 | 600 | - | 500,209 | 1 | 324.9 | 5943.5 |

| p27 | 102 | 15 | 150 | - | 411 | 600 | - | 502,294 | 1 | 324.5 | 64,977.5 |

| p28 | 102 | 15 | 150 | - | 411 | 600 | - | 502,145 | 1 | 316.7 | 60,781 |

| p29 | 102 | 15 | 150 | - | 411 | 600 | - | 502,148 | 1 | 293.6 | 60,846 |

| p19 | 112 | 16 | 160 | - | 411 | 600 | - | 500,757 | 1 | 473.3 | 21,439.5 |

| p22 | 114 | 17 | 170 | - | 411 | 600 | - | 500,546 | 1 | 502.3 | 15,475 |

| p11 | 139 | 21 | 210 | - | 411 | 600 | - | 500,115 | 1 | 600 | 3266.5 |

| pr03 | 144 | 21 | 210 | - | 411 | 600 | - | 500,778 | 1 | 600 | 22,052 |

| pr08 | 144 | 21 | 210 | - | 411 | 600 | - | 500,675 | 1 | 600 | 19,125 |

| Inst. | C | D | V | Mathematical Model | Algorithm | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Z [USD] | St | t [s] | d [km] | Z [USD] | St | t [s] | d [km] | ||||

| p30 | 153 | 23 | 230 | - | 411 | 600 | - | 508,364 | 1 | 600 | 236,954 |

| p31 | 153 | 23 | 230 | - | 411 | 600 | - | 508,917 | 1 | 600 | 252,632 |

| p32 | 153 | 23 | 230 | - | 411 | 600 | - | 509,685 | 1 | 600 | 274,363 |

| p12 | 163 | 24 | 240 | - | 411 | 600 | - | 500,197 | 1 | 505.5 | 5595 |

| p23 | 168 | 25 | 250 | - | 411 | 600 | - | 501,201 | 1 | 541.7 | 34,020 |

| p20 | 184 | 27 | 270 | - | 411 | 600 | - | 502,081 | 1 | 600 | 58,947 |

| pr04 | 192 | 28 | 280 | - | 411 | 600 | - | 500,945 | 1 | 600 | 26,786 |

| pr09 | 216 | 32 | 320 | - | 411 | 600 | - | 501,361 | 1 | 600 | 38,561 |

| pr05 | 240 | 36 | 360 | - | 411 | 600 | - | 751,313 | 1 | 600 | 37,231 |

| pr06 | 288 | 43 | 430 | - | 411 | 600 | - | 1,002,100 | 1 | 600 | 59,455 |

| pr10 | 288 | 43 | 430 | - | 411 | 600 | - | 1,002,290 | 1 | 600 | 64,906 |

| p13 | 417 | 62 | 620 | - | 411 | 600 | - | 1,001,475 | 1 | 600 | 41,660 |

| Inst. | AMPL CPLEX | AMPL Gurobi | Proposed VNS | ||||||

|---|---|---|---|---|---|---|---|---|---|

| t [s] | Z [USD] | d [km] | t [s] | Z [USD] | d [km] | t [s] | Z [USD] | d [km] | |

| p01a | 600 | 500,265 | 7513 | 600 | 500,202 | 5722 | 0.12 | 500,030 | 850 |

| p02a | 600 | 500,214 | 6068 | 600 | 500,188 | 5326 | 0.06 | 500,030 | 841 |

| p04a | 600 | 500,243 | 6881 | 600 | 500,187 | 5297 | 0.11 | 500,029 | 822 |

| p07a | 600 | 500,173 | 4901 | 600 | 500,175 | 4958 | 0.03 | 500,025 | 697 |

| p14a | 600 | 500,323 | 9150 | 600 | 500,321 | 9093 | 0.05 | 500,044 | 1244 |

| p15a | 600 | 500,561 | 15,895 | 600 | 500,538 | 15,241 | 0.08 | 500,080 | 2266 |

| p16a | 600 | 500,598 | 16,952 | 600 | 500,644 | 18,244 | 0.09 | 500,090 | 2555 |

| p17a | 600 | 500,332 | 9414 | 600 | 500,315 | 8924 | 0.20 | 500,047 | 1340 |

| p21a | 600 | 500,337 | 9538 | 600 | 500,333 | 9433 | 0.20 | 500,047 | 1326 |

| pr01a | 600 | 500,491 | 13,909 | 600 | 500,470 | 13,314 | 0.15 | 500,072 | 2040 |

| pr02a | 600 | 500,591 | 16,734 | 600 | 500,573 | 16,232 | 0.26 | 500,085 | 2399 |

| pr07a | 600 | 500,598 | 16,929 | 600 | 500,597 | 16,912 | 0.17 | 500,091 | 2564 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Noreña-Zapata, D.; Restrepo-Vallejo, J.C.; Morillo-Torres, D.; Gatica, G. A Novel Exact and Heuristic Solution for the Periodic Location-Routing Problem Applied to Waste Collection. Processes 2024, 12, 1557. https://doi.org/10.3390/pr12081557

Noreña-Zapata D, Restrepo-Vallejo JC, Morillo-Torres D, Gatica G. A Novel Exact and Heuristic Solution for the Periodic Location-Routing Problem Applied to Waste Collection. Processes. 2024; 12(8):1557. https://doi.org/10.3390/pr12081557

Chicago/Turabian StyleNoreña-Zapata, Daniel, Julián Camilo Restrepo-Vallejo, Daniel Morillo-Torres, and Gustavo Gatica. 2024. "A Novel Exact and Heuristic Solution for the Periodic Location-Routing Problem Applied to Waste Collection" Processes 12, no. 8: 1557. https://doi.org/10.3390/pr12081557

APA StyleNoreña-Zapata, D., Restrepo-Vallejo, J. C., Morillo-Torres, D., & Gatica, G. (2024). A Novel Exact and Heuristic Solution for the Periodic Location-Routing Problem Applied to Waste Collection. Processes, 12(8), 1557. https://doi.org/10.3390/pr12081557