Development and Evaluation of a Universal Seed Discharger for Precision Planting in Corn-Soybean Cropping System

Abstract

1. Introduction

2. Materials and Methods

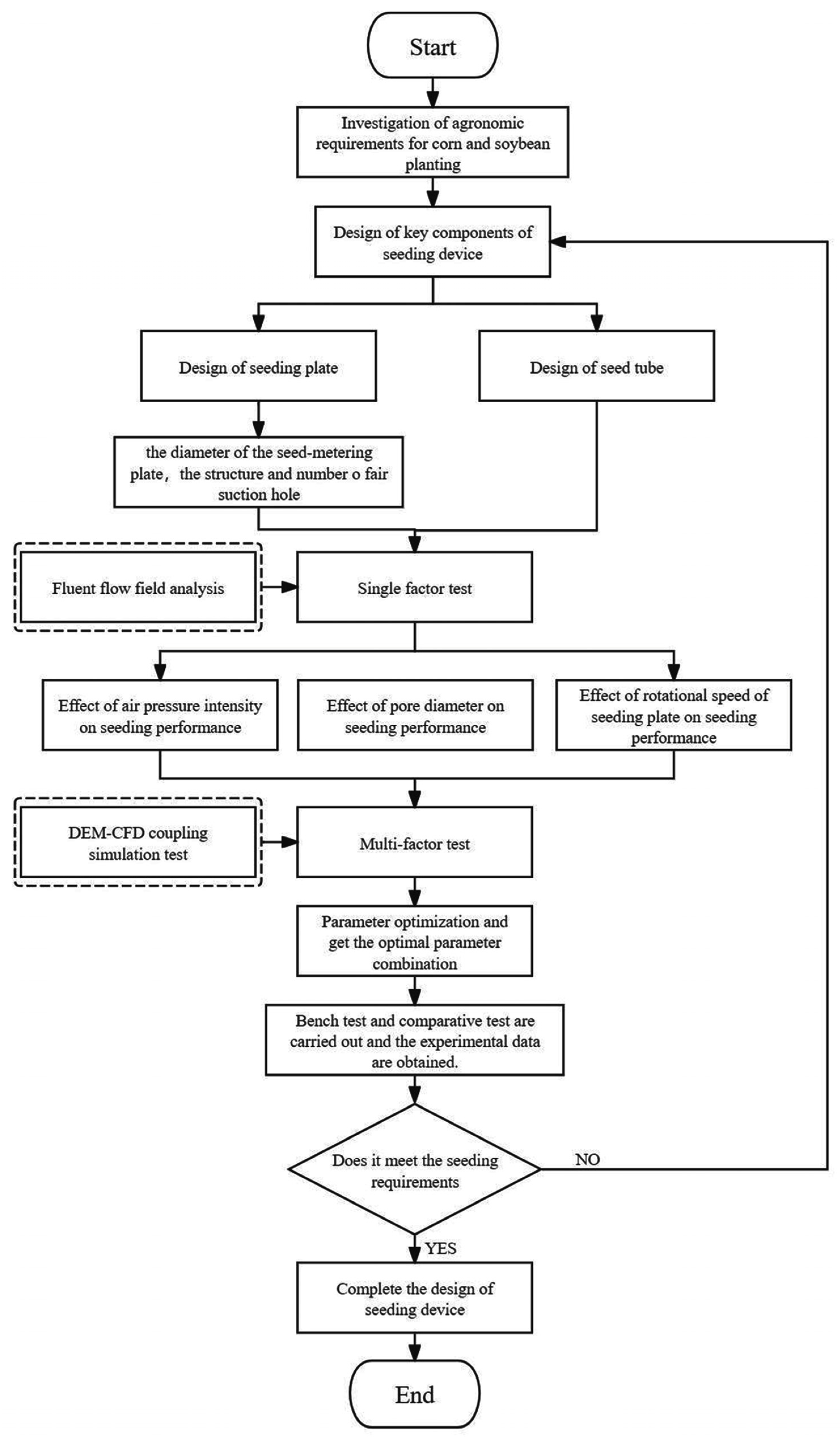

2.1. Flow Chart of the Development and Evaluation Process of the Seed-Metering Device

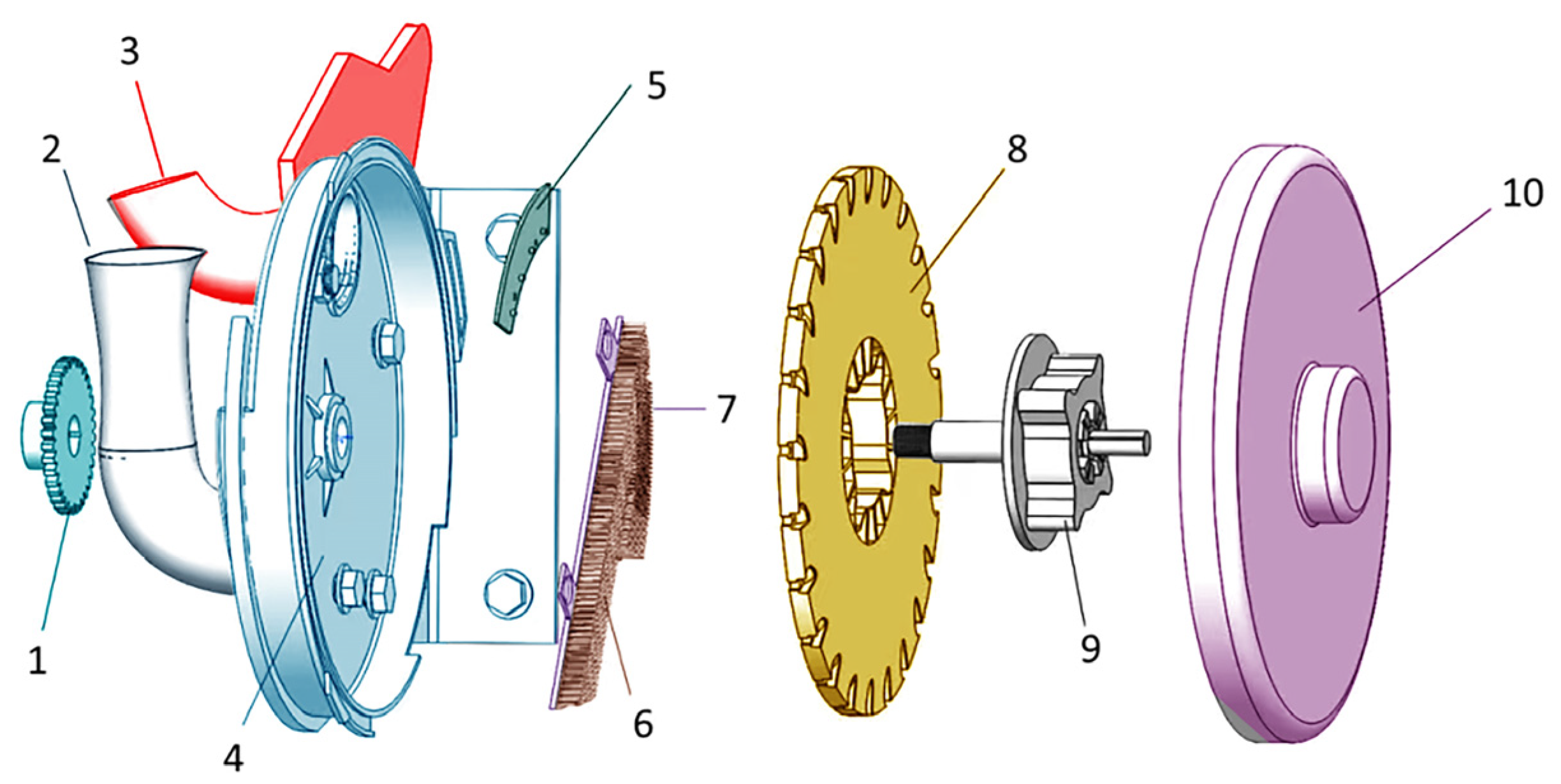

2.2. The Structure and the Working Principle of the Seeding-Metering Device

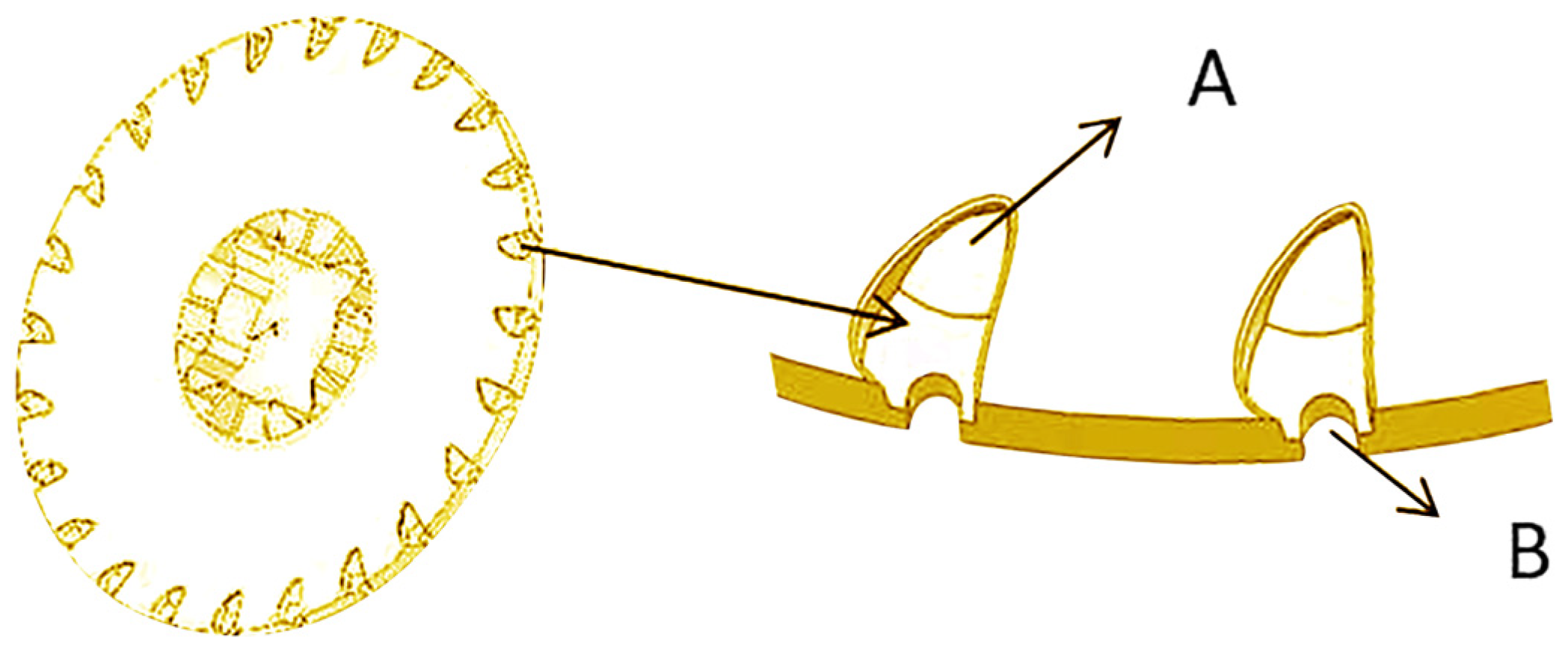

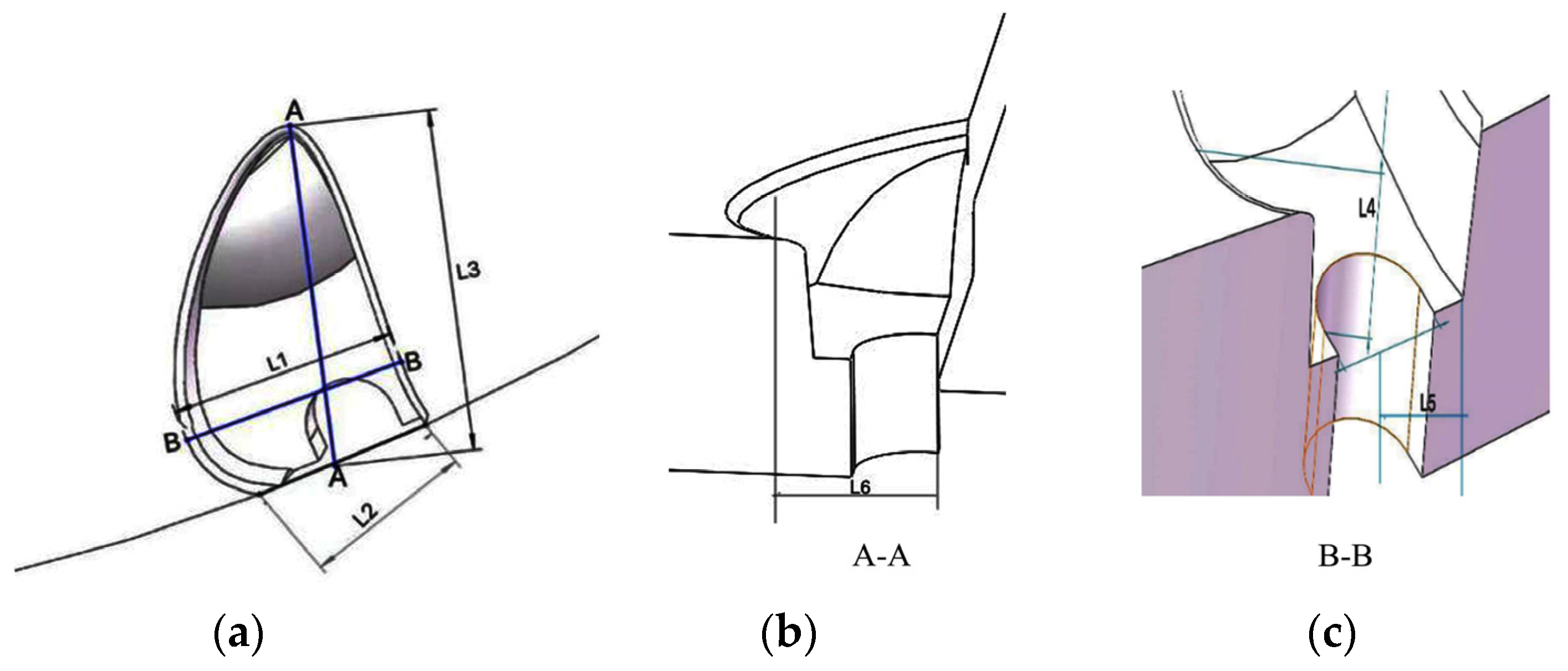

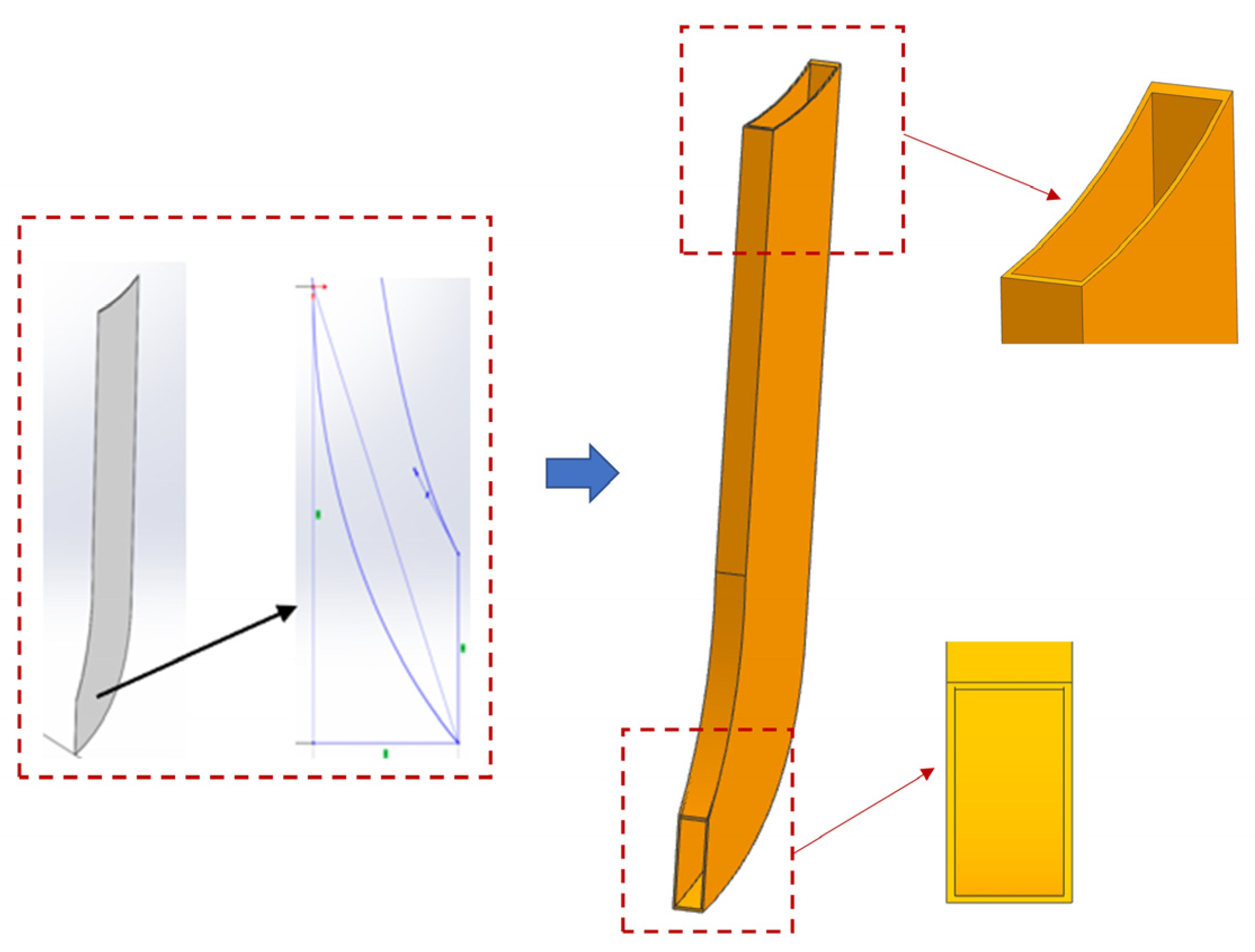

2.3. Design of the Seeding Plate

2.4. Design of the Seed Tube

3. Coupled Simulation Test

3.1. Single-Factor Test

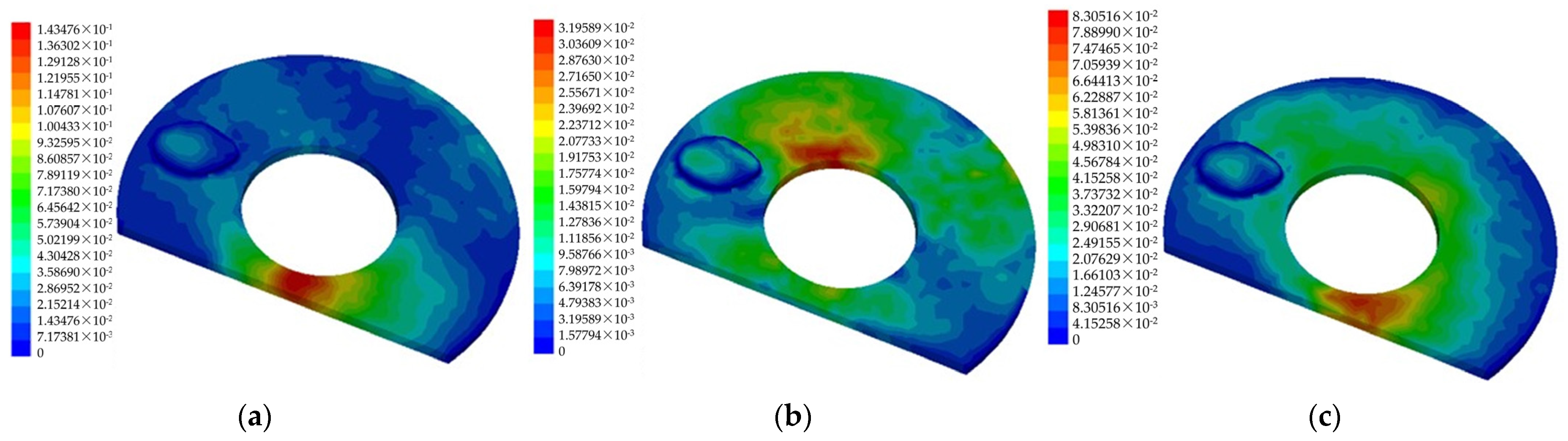

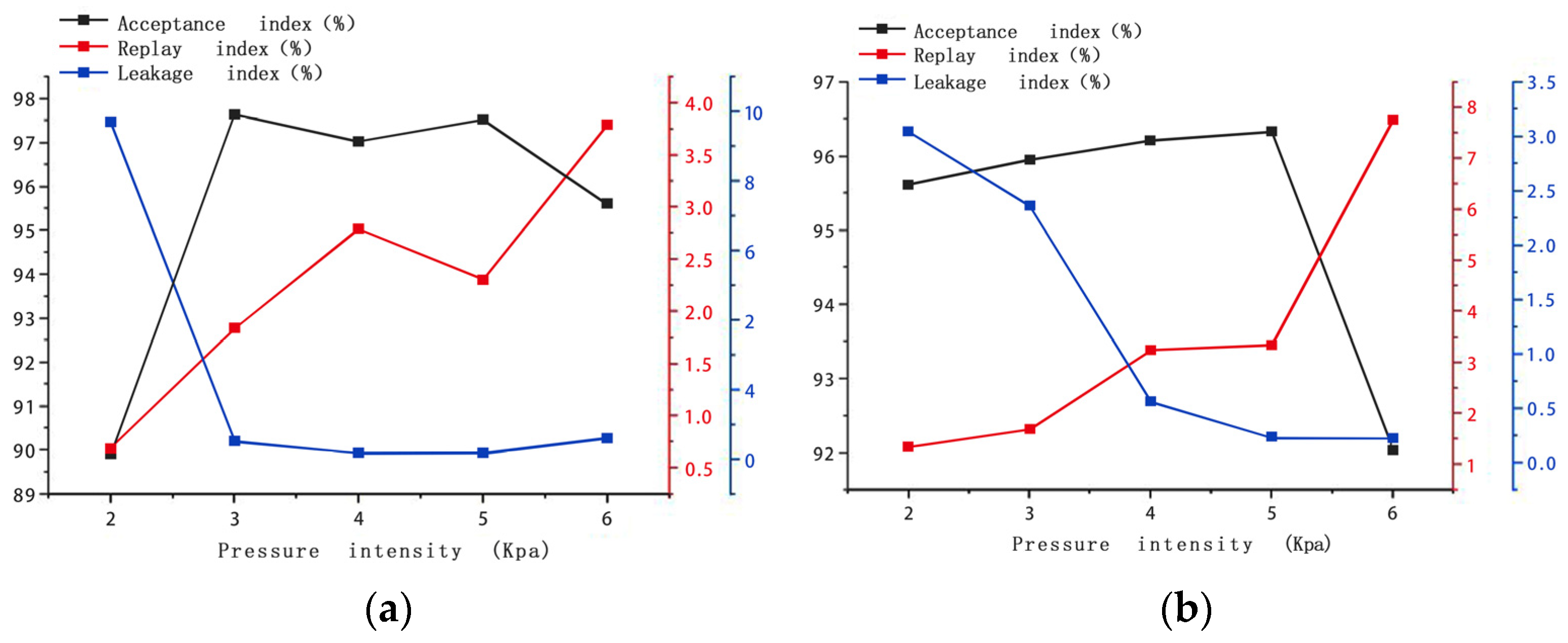

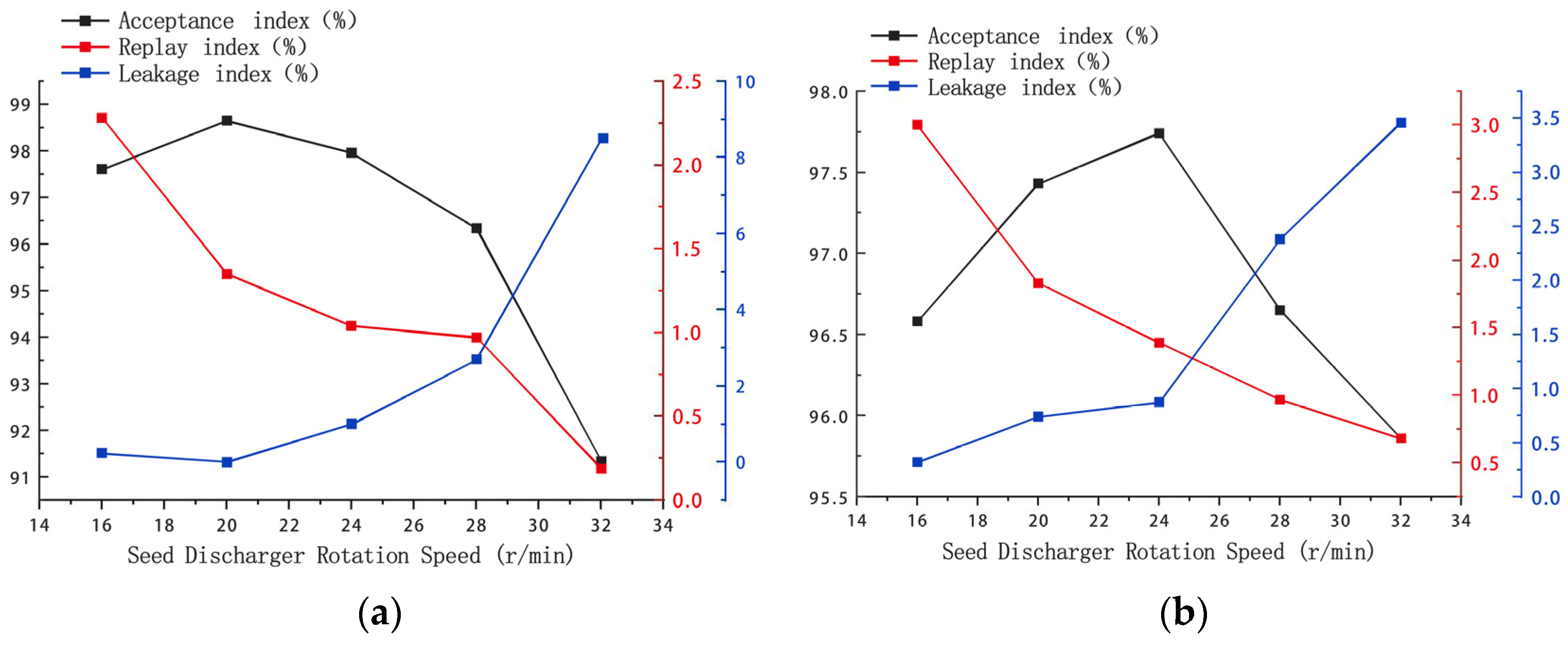

3.1.1. Effect of the Air Pressure Intensity on the Seeding Performance

3.1.2. Effect of the Pore Diameter on the Seeding Performance

3.1.3. Effect of the Rotational Speed of the Seeding Plate on the Seeding Performance

3.2. Multi-Factor Test

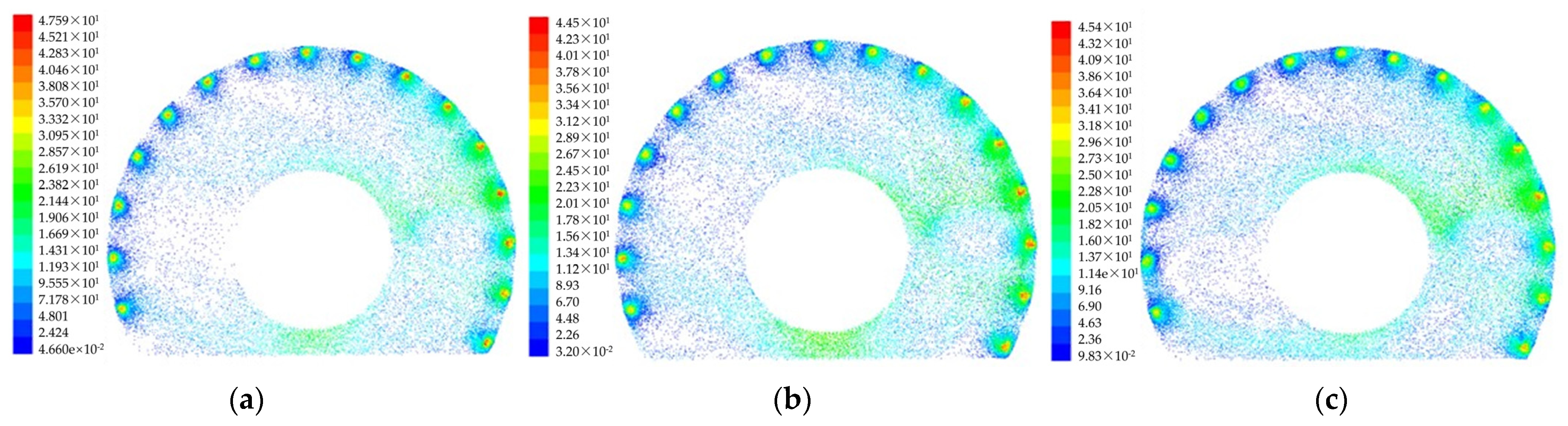

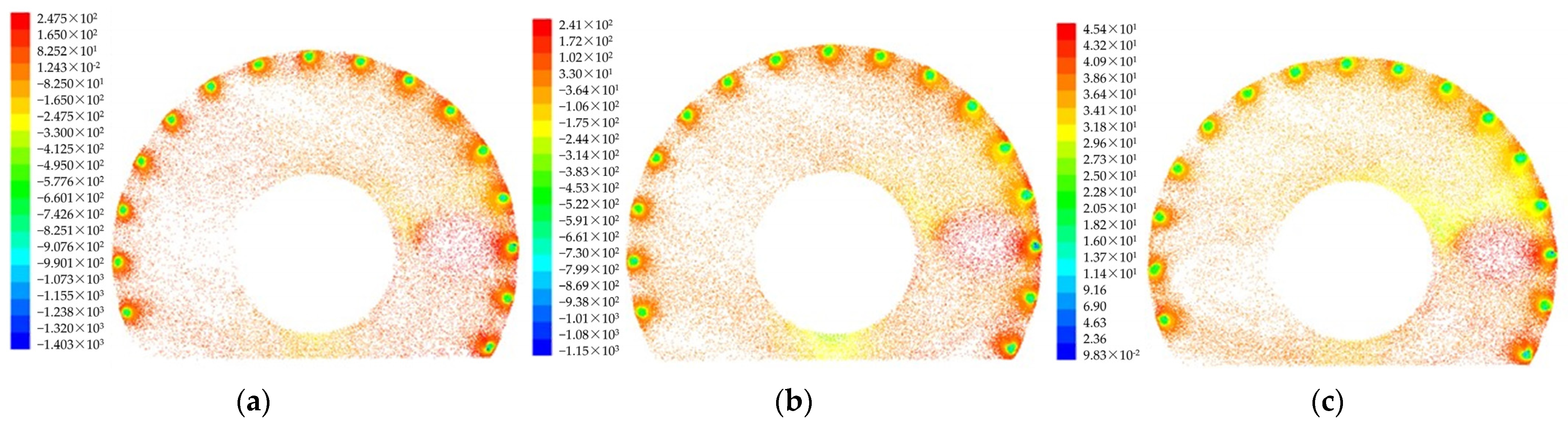

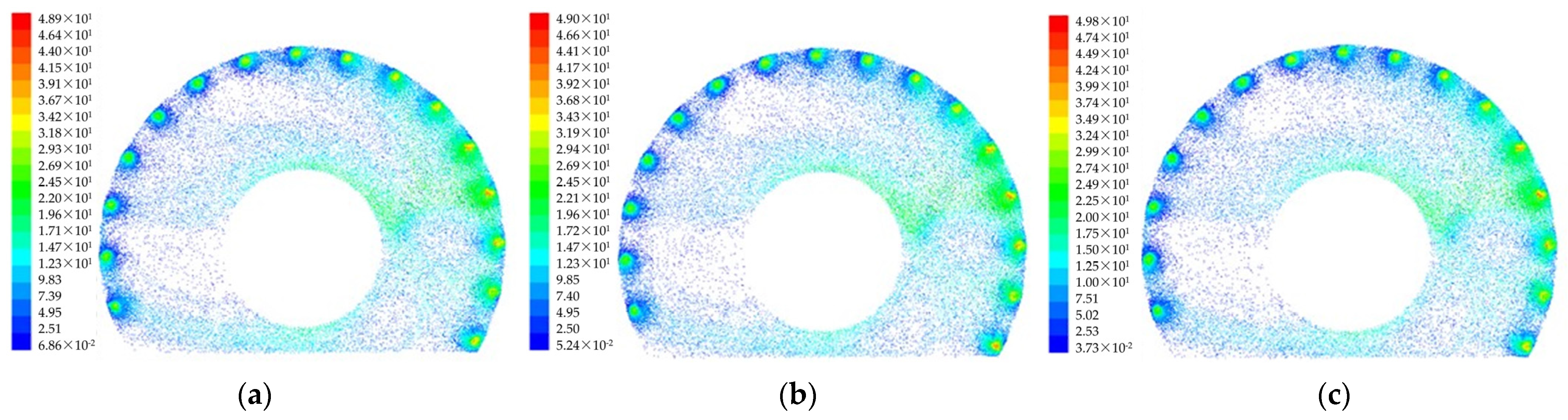

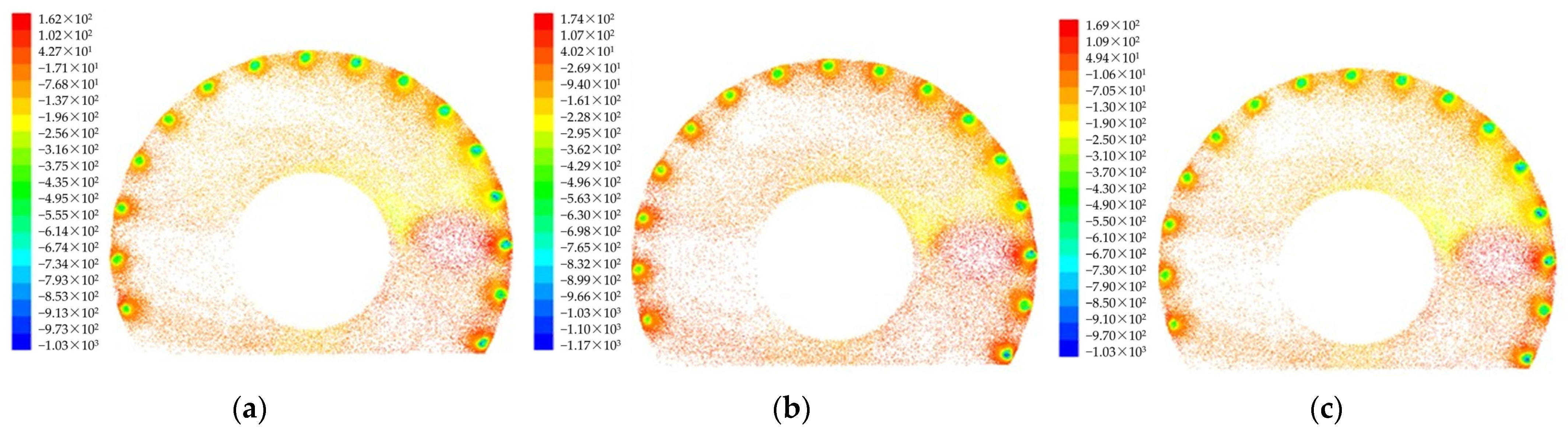

3.2.1. Establishment of the Seed Model

3.2.2. Simulation Process

3.2.3. Test Results

4. Results and Discussion

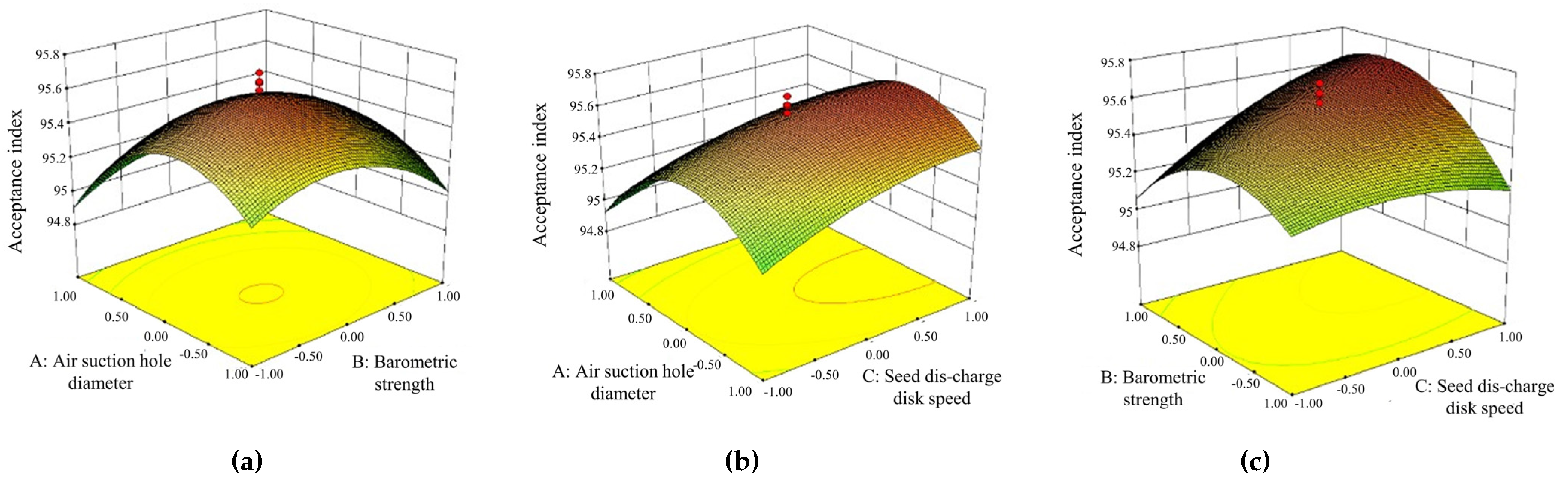

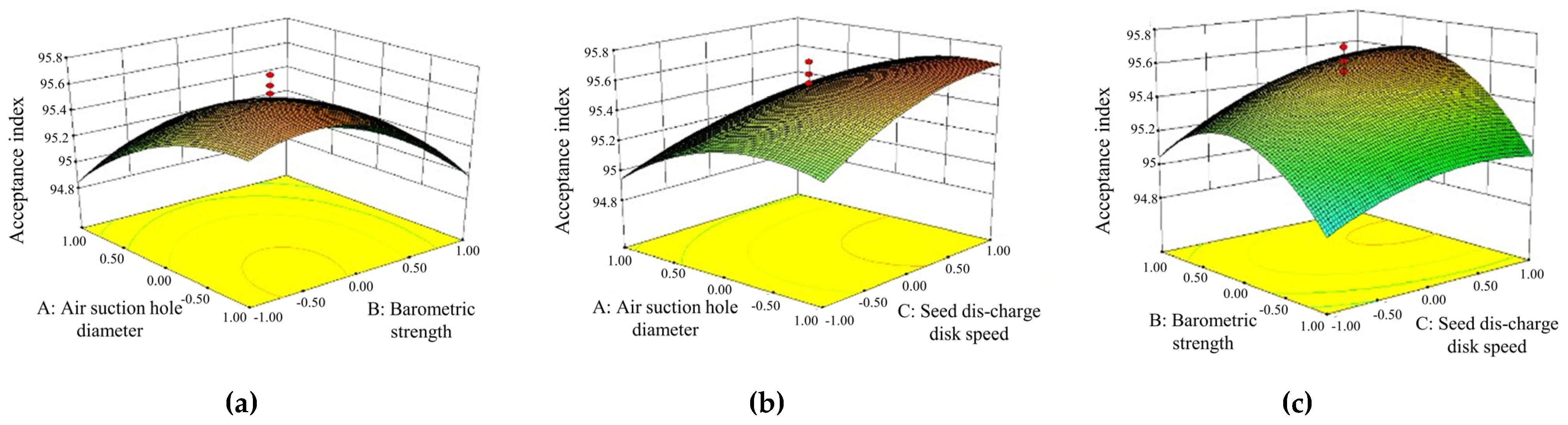

4.1. Test Results and the Establishment of the Regression Model

4.2. Parameter Optimization

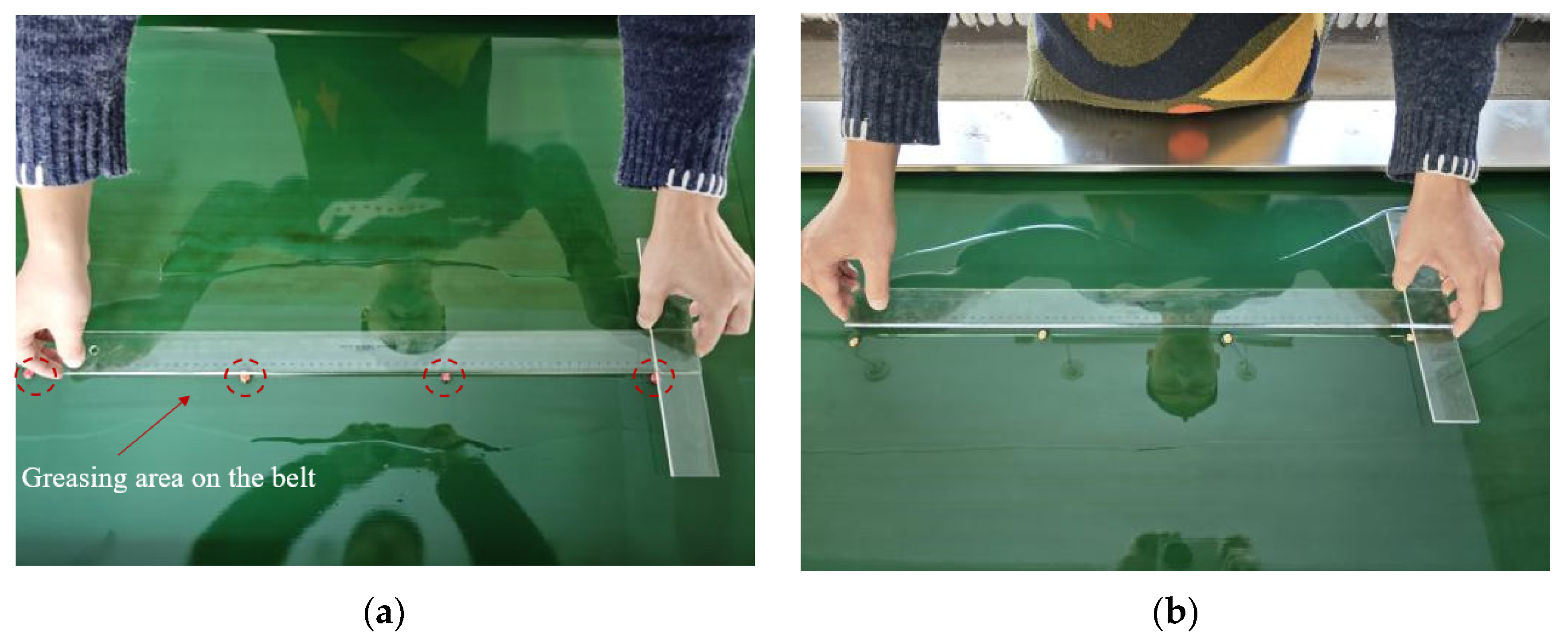

4.3. Bench Test and Comparative Test

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Food and Agriculture Organization. World Food and Agriculture Statistical Yearbook; FAO: Roma, Italy, 2023. [Google Scholar]

- Yang, W.; Nigonb, T.; Hao, Z.; Paiao, G.D.; Fernández, F.G.; Mulla, D.; Yang, C. Estimation of corn yield based on hyperspectral imagery and convolutional neural network. Comput. Electron. Agric. 2021, 184, 106092. [Google Scholar] [CrossRef]

- Di Salvo, J.; Lee, C.; Salmerón, M. Regional multi-environment analysis of corn productivity and yield stability as impacted by hybrid maturity. Field Crop. Res. 2021, 262, 108025. [Google Scholar] [CrossRef]

- Yang, L.; He, X.T.; Cui, T.; Zhang, D.X. Development of mechatronic driving system for seed meters equipped on conventional precision corn planter. Int. J. Agric. Biol. Eng. 2015, 8, 1–9. [Google Scholar]

- Santa Ormond, A.T.; Angeli Furlani, C.E.; De Oliveira, M.F.; De Freitas Noronha, R.H.; de Oliveira Tavares, T.; De Menezes, P.C. Maize Sowing Speeds and Seed-Metering Mechanisms. J. Agric. Sci. 2018, 10, 468. [Google Scholar]

- Jia, H.L.; Chen, Y.L.; Zhao, J.L.; Guo, M.Z.; Huang, D.Y.; Zhuang, J. Design and key parameter optimization of an agitated soybean seed metering device with horizontal seed filling. Int. J. Agric. Biol. Eng. 2018, 11, 76–87. [Google Scholar] [CrossRef]

- Liao, Y.T.; Wang, L.; Liao, Q.X. Design and test of an inside-filling pneumatic precision centralized seed-metering device for rapeseed. Int. J. Agric. Biol. Eng. 2017, 10, 56–62. [Google Scholar]

- Liu, H.; Liu, J.; Tang, S.; Xu, X. Design on opposed inclined-plate high-speed precision seed-metering device and its working mechanism analysis. Trans. Chin. Soc. Agric. Eng. 2016, 32, 24–31. [Google Scholar]

- Kamgar, S.; Noei-Khodabadi, F.; Shafaei, S.M. Design, development and field assessment of a controlled seed metering unit to be used in grain drills for direct seeding of wheat. Inf. Process. Agric. 2015, 2, 169–176. [Google Scholar] [CrossRef]

- Zhai, J.B.; Xiao, J.F.; Zhou, Y.; Zhang, S. Design and experimental study of the control system for precision seed-metering device. Int. J. Agric. Biol. Eng. 2014, 7, 13–18. [Google Scholar]

- Tang, H.; Xu, F.D.; Xu, C.S.; Zhao, J.L.; Wang, Y.J. The influence of a seed drop tube of the inside-filling air-blowing precision seed-metering device on seeding quality. Comput. Electron. Agric. 2023, 204, 107555. [Google Scholar] [CrossRef]

- Zhong, W.D.; Zhao, X.; Liu, F.; Bai, H.B.; Dong, W.X.; Hu, H.T.; Kong, X. Design and Experiment of Precision Seed Metering Device for Flow Adsorption of Quinoa Seeds. Agriculture 2024, 14, 434. [Google Scholar] [CrossRef]

- Hu, M.J.; Xia, J.F.; Zhou, M.K.; Liu, Z.Y.; Xie, D.Y. Design and Experiment of Seed-Cleaning Mechanism for Inside-Filling Pneumatic Cotton Precision Seed-Metering Device. Agriculture 2022, 12, 1217. [Google Scholar] [CrossRef]

- Tang, H.; Xu, F.D.; Guan, T.Y.; Xu, C.S.; Wang, J.W. Design and test of a pneumatic type of high-speed maize precision seed metering device. Comput. Electron. Agric. 2023, 211, 107997. [Google Scholar] [CrossRef]

- Wang, J.; Tang, H.; Wang, J.; Xin, L.; Huang, H. Optimization design and experiment on ripple surface type pickup finger of precision maize seed metering device. Int. J. Agric. Biol. Eng. 2017, 10, 61–71. [Google Scholar]

- Liu, J.; Cui, T.; Zhang, D.; Huang, S.; Shi, S. Experimental study on pressure of air blowing precision seed-metering device. Trans. Chin. Soc. Agric. Eng. 2011, 27, 18–22. [Google Scholar]

- Liao, Q.; Yang, B.; Li, X.; Liao, Y.; Zhang, N. Simulation and experiment of insidefilling air-blow precision metering device for rapeseed. Trans. Chin. Soc. Agric. Mach. 2012, 43, 51–54. [Google Scholar]

- Yu, J.; Wang, G.; Xin, N.; Fu, H. Simulation analysis of working process and performance of cell wheel metering device. Trans. Chin. Soc. Agric. Mach. 2011, 42, 83–87, 101. [Google Scholar]

- Wu, Z.; Li, M.; Lei, X.; Wu, Z.; Jiang, C.; Zhou, L.; Ma, R.; Chen, Y. Simulation and parameter optimisation of a centrifugal rice seeding spreader for a UAV. Biosyst. Eng. 2020, 192, 275–293. [Google Scholar] [CrossRef]

- Xi, X.; Gao, W.; Gu, C.; Shi, Y.; Han, L.; Zhang, Y.; Zhang, B.; Zhang, R. Optimisation of no-tube seeding and its application in rice planting. Biosyst. Eng. 2021, 210, 115–128. [Google Scholar] [CrossRef]

- Hu, M.J.; Xia, J.F.; Zhou, M.K.; Liu, Z.Y.; Xie, D.Y. Design and Experiment of Inside-filling Pneumatic High Speed Precision Seed-metering Device for Cotton. Trans. Chin. Soc. Agric. Mach. 2021, 52, 73–85. [Google Scholar]

- Shah, K.; Alam, M.S.; Nasir, F.E.; Qadir, M.U.; Haq, I.U. Design and Performance Evaluation of a Novel Variable Rate Multi-Crop Seed Metering Unit for Precision Agriculture. IEEE Access 2022, 10, 133152–133163. [Google Scholar] [CrossRef]

- Wang, D.W.; Ji, R.Q.; He, X.N. Study of a high-speed precision seed discharger for peanuts with drive-guide combination slot-assisted seed attachment and air suction. J. Agric. Mech. 2023, 54, 59–70+149. [Google Scholar]

- Shi, S.B.; Zheng, Y.N.; Yang, N. Simulation analysis of seed guiding process of air-absorbing duckbill type corn precision seed discharger. Agric. Mech. Res. 2023, 45, 24–29. [Google Scholar]

- Liu, R.; Liu, Z.J.; Liu, L.J. Design and testing of a high-speed air-aspirated seed discharger for disturbance-assisted seed filling of corn. J. Agric. Mech. 2022, 53, 50–59. [Google Scholar]

- Ding, L.; Yang, L.; Zhang, D.X. Parametric design and test of seed cleaning mechanism of air-absorbing corn seed discharger. Trans. Chin. Soc. Agric. Mach. 2019, 50, 47–56. [Google Scholar]

- Jia, H.L.; Chen, Y.L.; Zhao, J.L. Design and test of pneumatic-absorption-mechanical compound soybean precision seeder. J. Agric. Mech. 2018, 49, 75–86+139. [Google Scholar]

- Karayel, Z.D.; Barut, B.; Özmerzi, A. Mathematical Modelling of Vacuum Pressure on a Precision Seeder. Biosyst. Eng. 2004, 87, 437–444. [Google Scholar] [CrossRef]

- He, S.Y.; Zang, Y.; Huang, Z.S.; Tao, W.Y.; Xing, H.; Qin, W.; Jiang, Y.C.; Wang, Z.M. Design of and Experiment on a Cleaning Mechanism of the Pneumatic Single Seed Metering Device for Coated Hybrid Rice. Agriculture 2022, 12, 1239. [Google Scholar] [CrossRef]

- Gaikwad, B.B.; Sirohi, N.P.S. Design of a low-cost pneumatic seeder for nursery plug trays. Biosyst. Eng. 2008, 99, 322–329. [Google Scholar] [CrossRef]

- Zhao, Z.; Li, Y.; Chen, J.; Xu, L. Numerical analysis and laboratory testing of seed spacing uniformity performance for vacuum-cylinder precision seeder. Biosyst. Eng. 2010, 106, 344–351. [Google Scholar]

- Onal, I.; Degirmencioglu, A.; Yazgi, A. An evaluation of seed spacing accuracy of a vacuum type precision metering unit based on theoretical considerations and experiments. Turk. J. Agric. For. 2012, 36, 133–144. [Google Scholar]

- Yasir, S.H.; Liao, Q.; Yu, J.; He, D. Design and test of a pneumatic precision metering device for wheat. Agric. Eng. 2012, 14, 16–25. [Google Scholar]

- Ding, Y.; Liao, Q.; Huang, H. The seeding migration trajectory extraction and analysis of pneumatic precision metering device for rapeseed. J. Food. Agric. Environ. 2013, 11, 477–482. [Google Scholar]

- JB/T 51017-1999; Product Quality Grading of Precision Seeder for Intertillage Crops. MIIT: Beijing, China, 1999.

- JB/T 10293-2013; Technical Conditions of Single Grain (Precision) Seeder. MIIT: Beijing, China, 2013.

| Number | Factor | Index | ||||

|---|---|---|---|---|---|---|

| Air Suction Hole Diameter (mm) | Barometric Strength (kPa) | Seed Discharge Disk Speed (r/min) | Acceptance Index (%) | Replay Index (%) | Leakage Index (%) | |

| 1 | 5.5 | 3 | 20 | 95.12 | 1.37 | 3.51 |

| 2 | 5.8 | 6 | 22 | 95.19 | 3.55 | 1.26 |

| 3 | 5.5 | 5 | 24 | 94.75 | 3.34 | 1.91 |

| 4 | 5.8 | 4 | 22 | 95.65 | 2.27 | 2.08 |

| 5 | 5.8 | 4 | 22 | 95.32 | 1.98 | 2.7 |

| 6 | 5.8 | 4 | 22 | 95.66 | 2.21 | 2.13 |

| 7 | 5.8 | 2 | 22 | 94.74 | 1.47 | 3.79 |

| 8 | 6.1 | 5 | 20 | 95.03 | 3.4 | 1.57 |

| 9 | 6.4 | 4 | 22 | 94.52 | 1.75 | 3.73 |

| 10 | 5.8 | 4 | 22 | 95.71 | 2.32 | 1.97 |

| 11 | 5.8 | 4 | 22 | 95.59 | 1.48 | 2.93 |

| 12 | 5.8 | 4 | 26 | 95.35 | 2.71 | 1.94 |

| 13 | 6.1 | 5 | 24 | 94.38 | 3.15 | 2.47 |

| 14 | 5.5 | 3 | 24 | 94.97 | 1.47 | 3.56 |

| 15 | 6.1 | 3 | 24 | 94.72 | 2.05 | 2.23 |

| 16 | 5.8 | 4 | 18 | 95.42 | 2.17 | 2.41 |

| 17 | 5.8 | 4 | 22 | 95.61 | 1.92 | 2.47 |

| 18 | 6.1 | 3 | 20 | 94.77 | 2.77 | 2.46 |

| 19 | 5.2 | 4 | 22 | 94.68 | 1.46 | 3.86 |

| 20 | 5.5 | 5 | 20 | 95.55 | 2.74 | 1.71 |

| Number | Factor | Index | ||||

|---|---|---|---|---|---|---|

| Air Suction Hole Diameter (mm) | Barometric Strength (kPa) | Seed Discharge Disk Speed (r/min) | Acceptance Index (%) | Replay Index (%) | Leakage Index (%) | |

| 1 | 5.2 | 4 | 22 | 95.31 | 3.47 | 1.22 |

| 2 | 5.8 | 4 | 22 | 95.52 | 3.26 | 1.22 |

| 3 | 5.5 | 5 | 20 | 95.77 | 3.47 | 0.76 |

| 4 | 5.8 | 4 | 18 | 95.62 | 3.51 | 0.87 |

| 5 | 5.5 | 5 | 24 | 95.27 | 3.13 | 1.6 |

| 6 | 5.8 | 6 | 22 | 94.72 | 3.53 | 1.75 |

| 7 | 6.1 | 5 | 20 | 94.87 | 3.64 | 1.49 |

| 8 | 5.8 | 4 | 22 | 95.45 | 3.11 | 1.44 |

| 9 | 6.1 | 5 | 24 | 94.67 | 3.47 | 1.86 |

| 10 | 5.5 | 3 | 24 | 94.72 | 3.13 | 2.15 |

| 11 | 5.8 | 4 | 22 | 95.71 | 3.39 | 0.9 |

| 12 | 6.1 | 3 | 20 | 94.64 | 3.14 | 2.22 |

| 13 | 5.8 | 4 | 22 | 95.63 | 3.12 | 1.25 |

| 14 | 5.8 | 2 | 22 | 94.63 | 2.95 | 2.42 |

| 15 | 6.4 | 4 | 22 | 94.79 | 3.43 | 1.78 |

| 16 | 5.8 | 4 | 22 | 95.57 | 3.35 | 1.08 |

| 17 | 5.8 | 4 | 22 | 95.37 | 3.17 | 1.46 |

| 18 | 5.5 | 3 | 20 | 94.93 | 3.45 | 1.62 |

| 19 | 6.1 | 3 | 24 | 94.57 | 2.77 | 2.66 |

| 20 | 5.8 | 4 | 26 | 94.91 | 3.11 | 1.98 |

| Source | Qualified Index A/% | Replay Index D/% | Missing Index M/% | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SS | df | F | p-Value * | SS | df | F | p-Value * | SS | df | F | p-Value * | |

| Model | 3.12 | 9 | 10.70 | 0.0005 ** | 8.26 | 9 | 7.98 | 0.0016 ** | 9.74 | 9 | 5.43 | 0.0071 ** |

| 0.2266 | 1 | 6.99 | 0.0245 * | 0.6319 | 1 | 5.49 | 0.0411 * | 0.3476 | 1 | 1.74 | 0.2163 | |

| 0.0576 | 1 | 1.78 | 0.2120 | 5.25 | 1 | 45.66 | 0.0001 ** | 5.11 | 1 | 25.62 | 0.0005 ** | |

| 0.2288 | 1 | 7.06 | 0.0240 * | 0.0298 | 1 | 0.2593 | 0.6217 | 0.0012 | 1 | 0.0062 | 0.9390 | |

| 0.0105 | 1 | 0.3245 | 0.5815 | 0.2850 | 1 | 2.48 | 0.1465 | 0.9800 | 1 | 4.91 | 0.0510 | |

| 0.0078 | 1 | 0.2412 | 0.6340 | 0.3486 | 1 | 3.03 | 0.1123 | 0.0221 | 1 | 0.1105 | 0.7464 | |

| 0.1953 | 1 | 6.03 | 0.0339 * | 0.1176 | 1 | 1.02 | 0.3357 | 0.2048 | 1 | 1.03 | 0.3348 | |

| 1.84 | 1 | 56.84 | 0.0001 ** | 0.0880 | 1 | 0.7648 | 0.4024 | 2.41 | 1 | 12.10 | 0.0059 ** | |

| 0.7519 | 1 | 23.21 | 0.0007 ** | 0.8429 | 1 | 7.33 | 0.0220 * | 0.0228 | 1 | 0.1145 | 0.7421 | |

| 0.0921 | 1 | 2.84 | 0.1227 | 0.6792 | 1 | 5.91 | 0.0354 * | 0.3855 | 1 | 1.93 | 0.1947 | |

| Residual | 0.3239 | 10 | 1.15 | 10 | 1.99 | 10 | ||||||

| Lack of fit | 0.2277 | 5 | 2.37 | 0.1830 | 0.6589 | 5 | 1.34 | 0.3776 | 1.26 | 5 | 1.72 | 0.2832 |

| Error | 0.0962 | 5 | 0.4912 | 5 | 0.7336 | 5 | ||||||

| Total | 3.44 | 19 | 9.41 | 19 | 11.74 | 19 | ||||||

| Source | Qualified Index A/% | Replay Index D/% | Missing Index M/% | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SS | df | F | p-Value * | SS | df | F | p-Value * | SS | df | F | p-Value * | |

| Model | 3.17 | 9 | 14.01 | 0.0001 ** | 0.8562 | 9 | 10.02 | 0.0006 ** | 4.80 | 9 | 12.92 | 0.0002 ** |

| 0.5800 | 1 | 23.10 | 0.0007 ** | 0.0038 | 1 | 0.3983 | 0.5421 | 0.6775 | 1 | 16.41 | 0.0023 ** | |

| 0.2564 | 1 | 10.21 | 0.0096 ** | 0.3529 | 1 | 37.16 | 0.0001 ** | 1.21 | 1 | 29.33 | 0.0003 ** | |

| 0.3461 | 1 | 13.78 | 0.0040 ** | 0.2568 | 1 | 27.04 | 0.0004 ** | 1.20 | 1 | 29.05 | 0.0003 ** | |

| 0.1404 | 1 | 5.59 | 0.0396 * | 0.1740 | 1 | 19.33 | 0.0016 ** | 0.0018 | 1 | 0.0436 | 0.8388 | |

| 0.0242 | 1 | 0.9637 | 0.3494 | 0.0018 | 1 | 0.1895 | 0.6725 | 0.0392 | 1 | 0.9495 | 0.3528 | |

| 0.0220 | 1 | 0.8781 | 0.3708 | 0.0040 | 1 | 0.4265 | 0.5285 | 0.0072 | 1 | 0.1744 | 0.6851 | |

| 0.4717 | 1 | 18.78 | 0.0015 ** | 0.0572 | 1 | 6.03 | 0.0340 * | 0.2004 | 1 | 4.85 | 0.0522 | |

| 1.42 | 1 | 56.40 | 0.0001 ** | 0.0018 | 1 | 0.1915 | 0.6710 | 1.52 | 1 | 36.81 | 0.0001 ** | |

| 0.1586 | 1 | 6.32 | 0.0307 * | 0.0026 | 1 | 0.2772 | 0.6100 | 0.1204 | 1 | 2.92 | 0.1185 | |

| Residual | 0.2511 | 10 | 0.0950 | 10 | 0.4128 | 10 | ||||||

| Lack of fit | 0.1758 | 5 | 2.34 | 0.1867 | 0.0240 | 5 | 0.3388 | 0.8700 | 0.1841 | 5 | 0.8048 | 0.5913 |

| Error | 0.0753 | 5 | 0.0709 | 5 | 0.2288 | 5 | ||||||

| Total | 3.42 | 19 | 0.9512 | 19 | 5.21 | 19 | ||||||

| Level | Corn | Soybean | Corn (Trad) | Soybean (Trad) | ||||

|---|---|---|---|---|---|---|---|---|

| Acceptance Index (%) | Replay Index (%) | Leakage Index (%) | Acceptance Index (%) | Replay Index (%) | Leakage Index (%) | Acceptance Index (%) | Acceptance Index(%) | |

| 1 | 96.12 | 1.76 | 2.12 | 95.56 | 3.33 | 1.11 | 97.63 | 98.21 |

| 2 | 95.45 | 1.45 | 3.1 | 95.68 | 3.26 | 1.06 | 98.85 | 98.36 |

| 3 | 95.77 | 1.32 | 2.91 | 95.78 | 3.25 | 0.97 | 97.48 | 97.89 |

| 4 | 95.21 | 1.26 | 3.53 | 95.64 | 3.21 | 1.15 | 98.53 | 97.75 |

| 5 | 95.35 | 1.34 | 3.31 | 96.13 | 2.92 | 0.95 | 98.44 | 98.13 |

| Average | 95.58 | 1.43 | 2.99 | 95.74 | 3.21 | 1.05 | 98.2 | 98.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, X.; Zhang, J.; Liu, S.; Fu, L.; Huang, D. Development and Evaluation of a Universal Seed Discharger for Precision Planting in Corn-Soybean Cropping System. Processes 2024, 12, 1595. https://doi.org/10.3390/pr12081595

Jiang X, Zhang J, Liu S, Fu L, Huang D. Development and Evaluation of a Universal Seed Discharger for Precision Planting in Corn-Soybean Cropping System. Processes. 2024; 12(8):1595. https://doi.org/10.3390/pr12081595

Chicago/Turabian StyleJiang, Xinming, Jie Zhang, Shuyan Liu, Lili Fu, and Dongyan Huang. 2024. "Development and Evaluation of a Universal Seed Discharger for Precision Planting in Corn-Soybean Cropping System" Processes 12, no. 8: 1595. https://doi.org/10.3390/pr12081595

APA StyleJiang, X., Zhang, J., Liu, S., Fu, L., & Huang, D. (2024). Development and Evaluation of a Universal Seed Discharger for Precision Planting in Corn-Soybean Cropping System. Processes, 12(8), 1595. https://doi.org/10.3390/pr12081595