A Comprehensive Review on Enhancing Seasonal Energy Storage Systems through Energy Efficiency Perspectives

Abstract

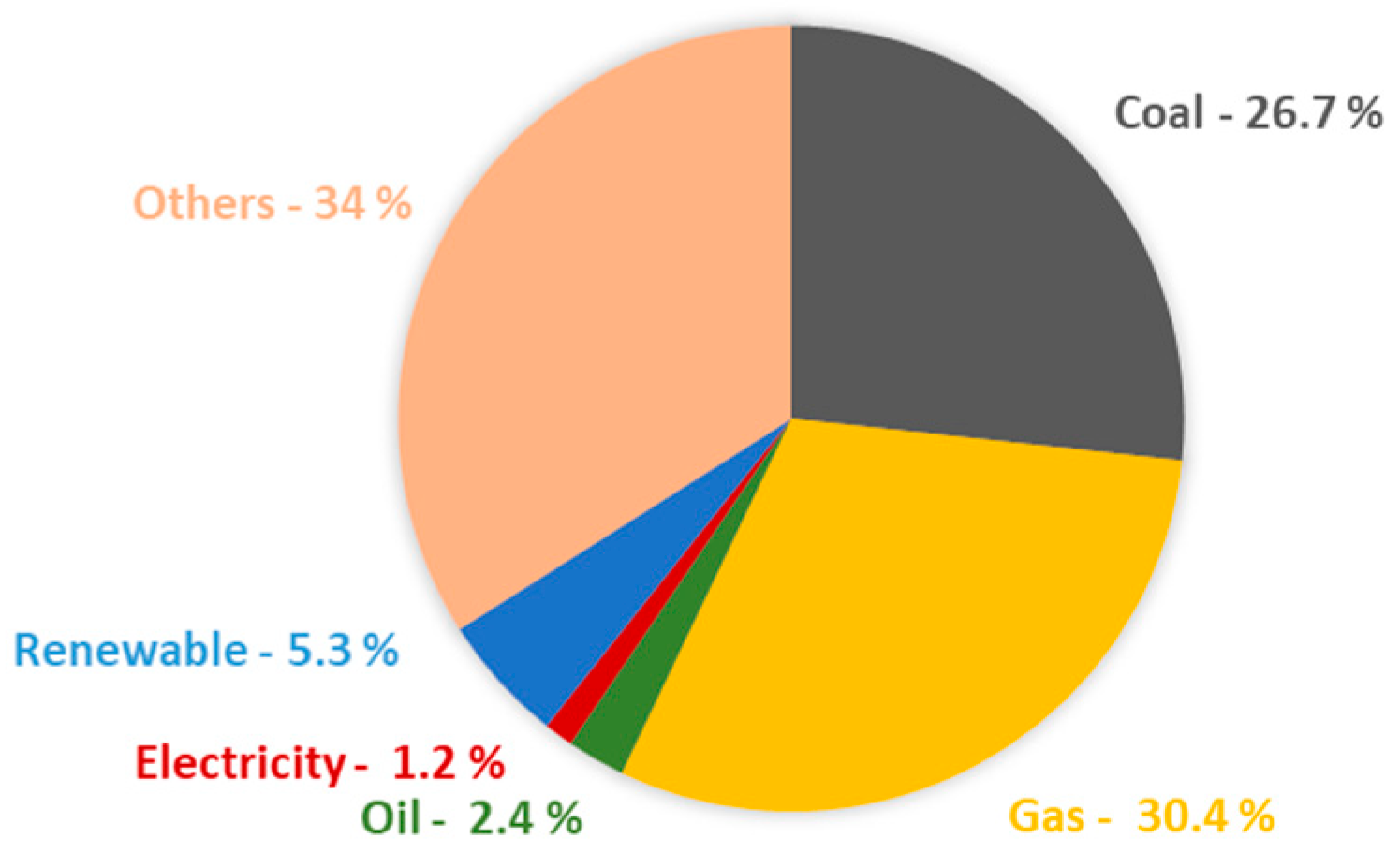

:1. Introduction

2. State of the Art

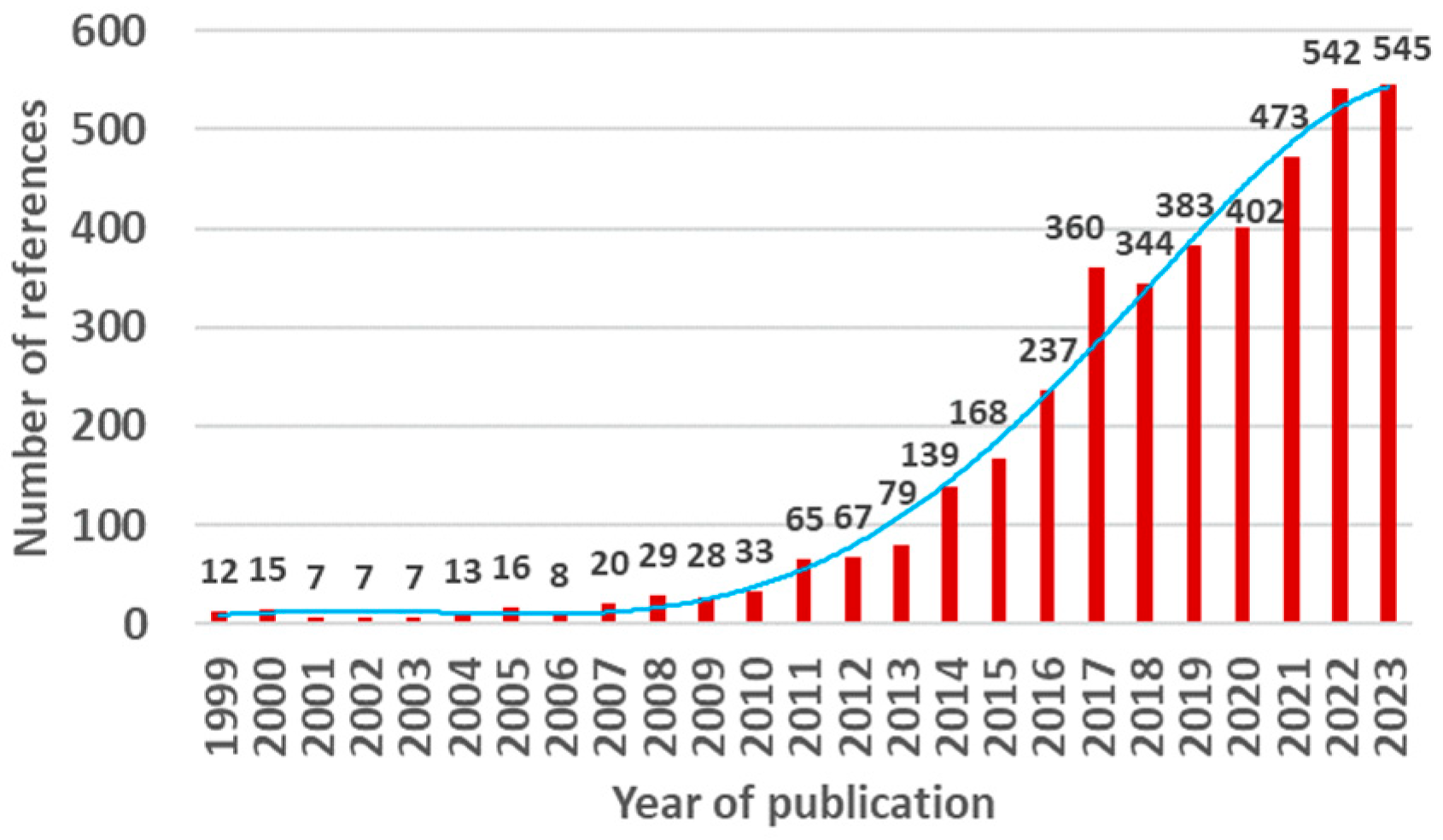

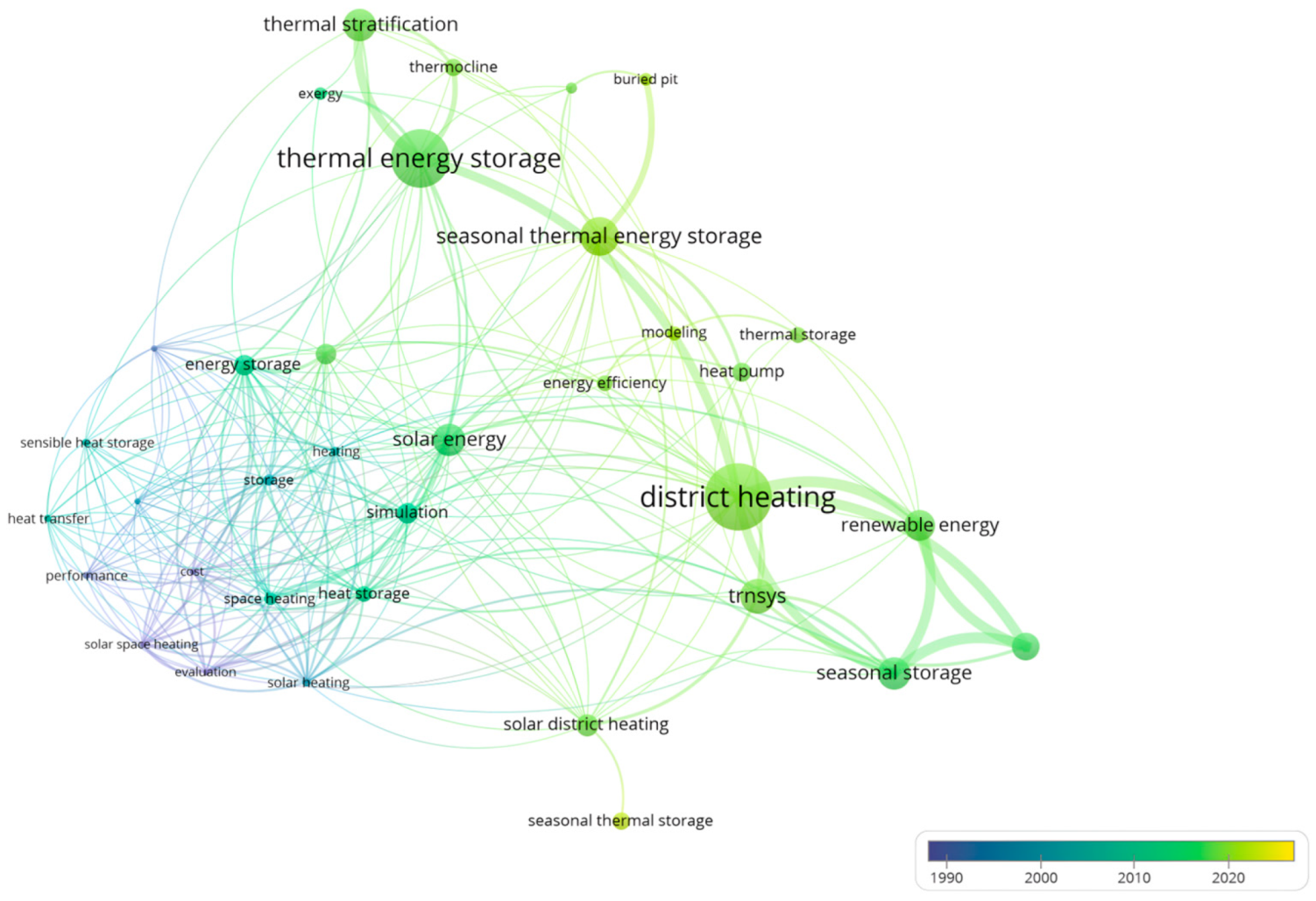

2.1. Bibliometric Analysis

2.2. Seasonal Storage Methods Based on Sensible Heat

2.3. Seasonal Heat Storage Tanks

2.3.1. Constructive Parameters

2.3.2. Parameters Related to Efficiency

3. Seasonal Energy Storage through an Efficiency Lens

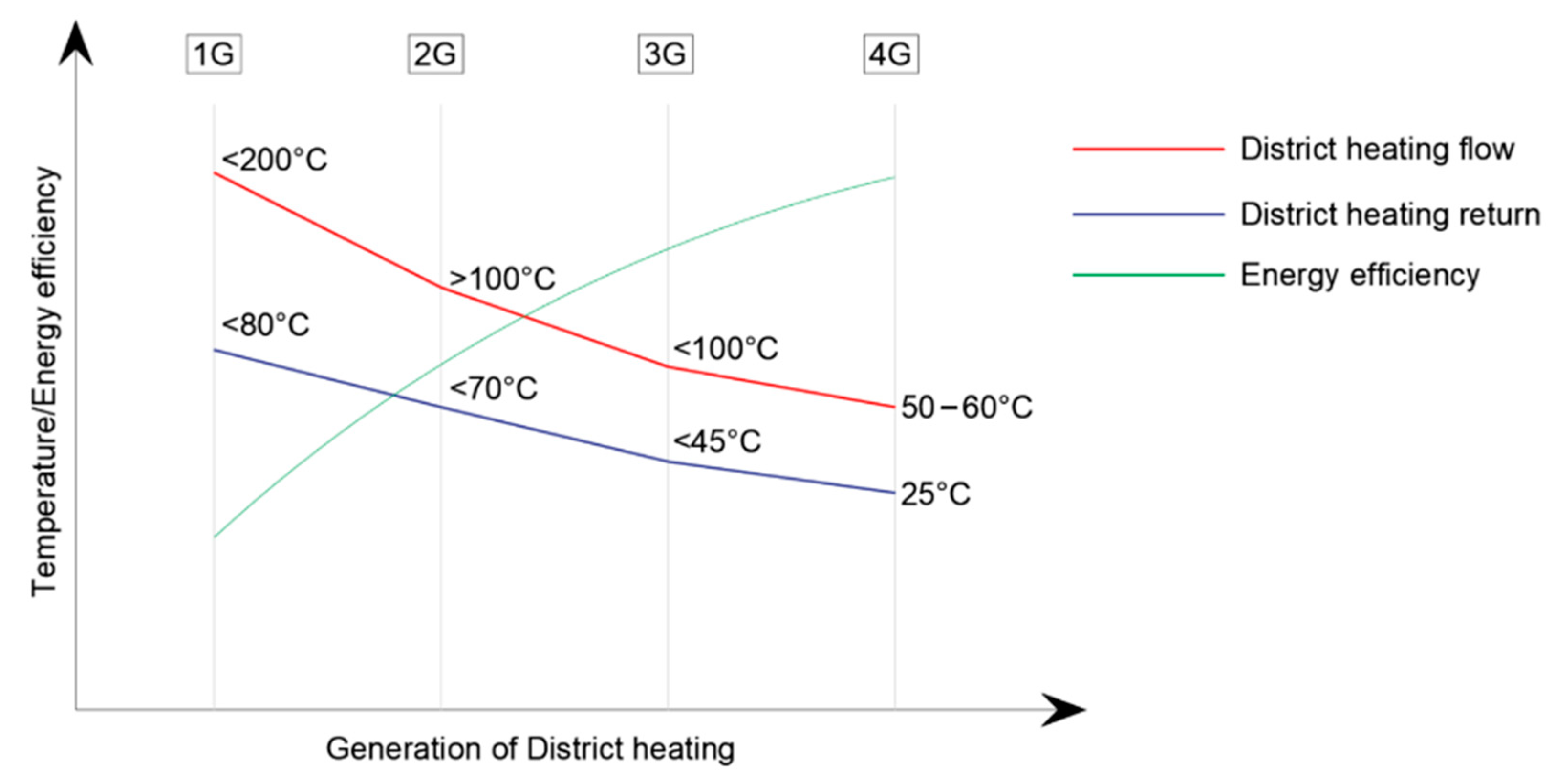

3.1. The Evolution of District Heating toward Synergy with Seasonal Heat Storage

3.2. Parameters Related to Performance Metrics

4. Case Studies

4.1. Case Silkeborg, Denmark

4.2. Case Vojens, Denmark

4.3. Case Dronninglund Fjernvarme, Denmark

4.4. Case Salaspils, Letonia

4.5. Case Friesach, Austria

4.6. Zhangjiakou, China

4.7. Drake Landing Solar Community, Canada

4.8. Langkazi, Tibet

5. Challenges, Barriers and Opportunities

5.1. Challenges of Implementing Solar Heating Systems with Seasonal Heat Storage

5.2. Barriers to Constructing Seasonal Heat Storage Systems

5.3. Improving the Insulation of the Water Tank

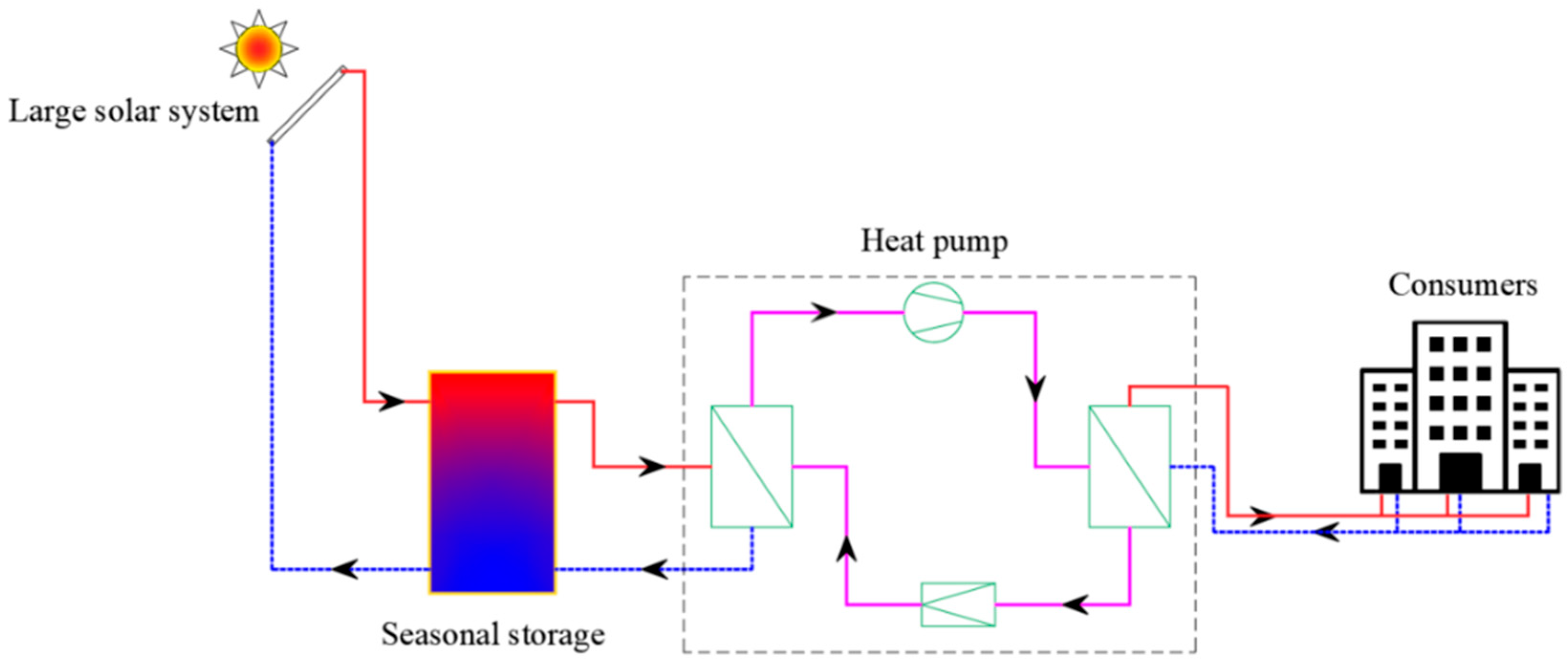

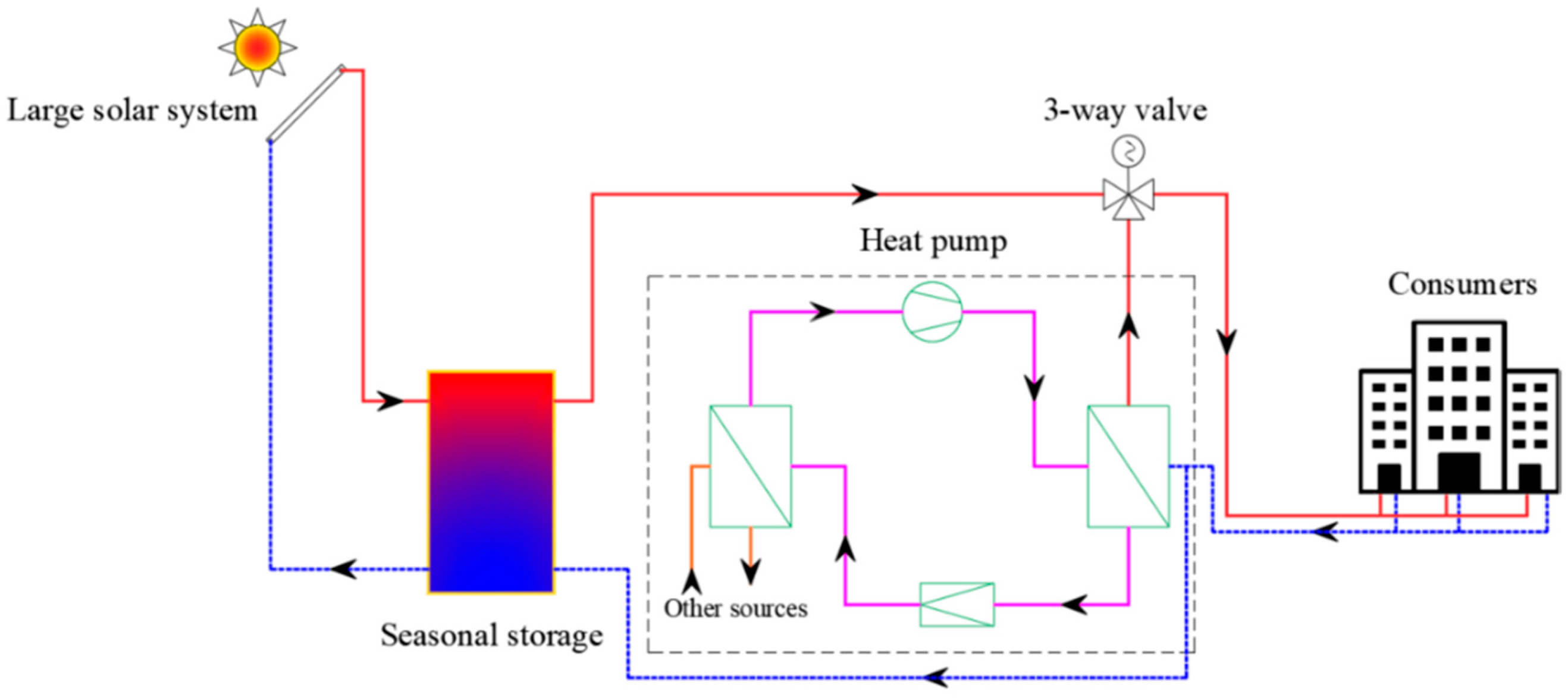

5.4. Coupling Solar Heating Systems and Seasonal Water-Based Storage with Heat Pumps

- The heat pump represents the heat source, and the produced heat will be stored in the tank;

- The cold source of the heat pump is constituted by the storage tank.

6. Policy Recommendations and Future Directions

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gong, X.; Shi, R.; Xu, J.; Lin, B. Analyzing Spillover Effects between Carbon and Fossil Energy Markets from a Time-Varying Perspective. Appl. Energy 2021, 285, 116384. [Google Scholar] [CrossRef]

- Wu, Q.; Wang, M.; Tian, L. The Market-Linkage of the Volatility Spillover between Traditional Energy Price and Carbon Price on the Realization of Carbon Value of Emission Reduction Behavior. J. Clean. Prod. 2020, 245, 118682. [Google Scholar] [CrossRef]

- Hussain, S.A.; Razi, F.; Hewage, K.; Sadiq, R. The Perspective of Energy Poverty and 1st Energy Crisis of Green Transition. Energy 2023, 275, 127487. [Google Scholar] [CrossRef]

- European Green Deal—Consilium. Available online: https://www.consilium.europa.eu/en/policies/green-deal/ (accessed on 7 April 2024).

- European Parliament Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the Energy Performance of Buildings. Available online: https://eur-lex.europa.eu/legal-content/en/TXT/?uri=celex%3A32010L0031 (accessed on 30 June 2024).

- Report from the Commission to the European Parliament, The Council, The European Economic and Social Committee and the Committee of the Regions State of the Energy Union 2022 (Pursuant to Regulation (EU) 2018/1999 of the Governance of the Energy Union and Climate Action). Available online: https://eur-lex.europa.eu/legal-content/en/TXT/?uri=CELEX%3A52022DC0547&qid=1666595113558 (accessed on 30 June 2024).

- Clean Energy—Consilium. Available online: https://www.consilium.europa.eu/en/policies/clean-energy/ (accessed on 7 April 2024).

- District Heating: Policies for Cutting Emissions Need Work Says IEA—Energy Post. Available online: https://energypost.eu/district-heating-policies-for-cutting-emissions-need-work-says-iea/ (accessed on 9 April 2024).

- Bacquet District Heating and Cooling in the European Union: Overview of Markets and Regulatory Frameworks under the Revised Renewable Energy Directive; Publications Office of the European Union: Copenhagen, Denmark, 2022.

- IEA District Heating. Available online: https://www.iea.org/reports/district-heating (accessed on 14 June 2023).

- Directive 2012/27/EU of the European Parliament and of the Council of 25 October 2012 on Energy Efficiency, Amending Directives 2009/125/EC and 2010/30/EU and Repealing Directives 2004/8/EC and 2006/32/EC Text with EEA Relevance. 2012. Available online: http://data.europa.eu/eli/dir/2012/27/oj (accessed on 1 April 2024).

- Lyden, A.; Brown, C.S.; Kolo, I.; Falcone, G.; Friedrich, D. Seasonal Thermal Energy Storage in Smart Energy Systems: District-Level Applications and Modelling Approaches. Renew. Sustain. Energy Rev. 2022, 167, 112760. [Google Scholar] [CrossRef]

- Duffie, J.; Beckman, W. Solar Engineering of Thermal Processes. J. Sol. Energy Eng. 1980, 116, 67–68. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Martorell, I.; Miró, L.; Fernández, A.I.; Barreneche, C. Introduction to Thermal Energy Storage (TES) Systems. In Advances in Thermal Energy Storage Systems Methods and Applications; Woodhead Publishing: Cambridge, UK, 2015; pp. 1–28. [Google Scholar] [CrossRef]

- Mangold, D.; Deschaintre, L. Seasonal Thermal Energy Storage; IEA SHC Task: Berne, Germany, 2015. [Google Scholar]

- Pavlov, G.K.; Olesen, B.W. Thermal Energy Storage—A Review of Concepts and Systems for Heating and Cooling Applications in Buildings: Part 1-Seasonal Storage in the Ground. HVAC R Res. 2012, 18, 515–538. [Google Scholar] [CrossRef]

- Dahash, A.; Ochs, F.; Janetti, M.B.; Streicher, W. Advances in Seasonal Thermal Energy Storage for Solar District Heating Applications: A Critical Review on Large-Scale Hot-Water Tank and Pit Thermal Energy Storage Systems. Appl. Energy 2019, 239, 296–315. [Google Scholar] [CrossRef]

- Din, I.; Rosen, M.A. Thermal Energy Storage: Systems and Applications, 2nd ed.; John Wiley & Sons: Chichester, UK, 2011. [Google Scholar]

- Li, G. Sensible Heat Thermal Storage Energy and Exergy Performance Evaluations. Renew. Sustain. Energy Rev. 2016, 53, 897–923. [Google Scholar] [CrossRef]

- Perez-Mora, N.; Bava, F.; Andersen, M.; Bales, C.; Lennermo, G.; Nielsen, C.; Furbo, S.; Martínez-Moll, V. Solar District Heating and Cooling: A Review. Int. J. Energy Res. 2018, 42, 1419–1441. [Google Scholar] [CrossRef]

- Alva, G.; Lin, Y.; Fang, G. An Overview of Thermal Energy Storage Systems. Energy 2018, 144, 341–378. [Google Scholar] [CrossRef]

- Novo, A.V.; Bayon, J.R.; Castro-Fresno, D.; Rodriguez-Hernandez, J. Review of Seasonal Heat Storage in Large Basins: Water Tanks and Gravel–Water Pits. Appl. Energy 2010, 87, 390–397. [Google Scholar] [CrossRef]

- Guelpa, E.; Verda, V. Thermal Energy Storage in District Heating and Cooling Systems: A Review. Appl. Energy 2019, 252, 113474. [Google Scholar] [CrossRef]

- Xu, J.; Wang, R.Z.; Li, Y. A Review of Available Technologies for Seasonal Thermal Energy Storage. Sol. Energy 2014, 103, 610–638. [Google Scholar] [CrossRef]

- Bott, C.; Dressel, I.; Bayer, P. State-of-Technology Review of Water-Based Closed Seasonal Thermal Energy Storage Systems. Renew. Sustain. Energy Rev. 2019, 113, 109241. [Google Scholar] [CrossRef]

- Villasmil, W.; Troxler, M.; Hendry, R.; Schuetz, P.; Worlitschek, J. Control Strategies of Solar Heating Systems Coupled with Seasonal Thermal Energy Storage in Self-Sufficient Buildings. J. Energy Storage 2021, 42, 103069. [Google Scholar] [CrossRef]

- Dahash, A.; Ochs, F.; Tosatto, A.; Streicher, W. Toward Efficient Numerical Modeling and Analysis of Large-Scale Thermal Energy Storage for Renewable District Heating. Appl. Energy 2020, 279, 115840. [Google Scholar] [CrossRef]

- Gonzalez-Ayala, J.; Blázquez, C.S.; Lagüela, S.; Nieto, I.M. Assesment for Optimal Underground Seasonal Thermal Energy Storage. Energy Convers. Manag. 2024, 308, 118394. [Google Scholar] [CrossRef]

- Dolgun, G.K.; Keçebaş, A.; Ertürk, M.; Daşdemir, A. Optimal Insulation of Underground Spherical Tanks for Seasonal Thermal Energy Storage Applications. J. Energy Storage 2023, 69, 107865. [Google Scholar] [CrossRef]

- Bauer, D.; Marx, R.; Nußbicker-Lux, J.; Ochs, F.; Heidemann, W.; Müller-Steinhagen, H. German Central Solar Heating Plants with Seasonal Heat Storage. Sol. Energy 2010, 84, 612–623. [Google Scholar] [CrossRef]

- Yang, T.; Liu, W.; Kramer, G.J.; Sun, Q. Seasonal Thermal Energy Storage: A Techno-Economic Literature Review. Renew. Sustain. Energy Rev. 2021, 139, 110732. [Google Scholar] [CrossRef]

- Guadalfajara, M.; Lozano, M.A.; Serra, L.M. Simple Calculation Tool for Central Solar Heating Plants with Seasonal Storage. Sol. Energy 2015, 120, 72–86. [Google Scholar] [CrossRef]

- Hesaraki, A.; Holmberg, S.; Haghighat, F. Seasonal Thermal Energy Storage with Heat Pumps and Low Temperatures in Building Projects—A Comparative Review. Renew. Sustain. Energy Rev. 2015, 43, 1199–1213. [Google Scholar] [CrossRef]

- Ochs, F.; Heidemann, W.; Müller-Steinhagen, H. Effective Thermal Conductivity of Moistened Insulation Materials as a Function of Temperature. Int. J. Heat. Mass. Transf. 2008, 51, 539–552. [Google Scholar] [CrossRef]

- Kocijel, L.; Mrzljak, V.; Glažar, V. Numerical Analysis of Geometrical and Process Parameters Influence on Temperature Stratification in a Large Volumetric Heat Storage Tank. Energy 2020, 194, 116878. [Google Scholar] [CrossRef]

- Arslan, M.; Igci, A.A. Thermal Performance of a Vertical Solar Hot Water Storage Tank with a Mantle Heat Exchanger Depending on the Discharging Operation Parameters. Sol. Energy 2015, 116, 184–204. [Google Scholar] [CrossRef]

- Braun, J.E.; Klein, S.A.; Mitchell, J.W. Seasonal Storage of Energy in Solar Heating. Sol. Energy 1981, 26, 403–411. [Google Scholar] [CrossRef]

- Drew, M.S.; Selvage, R.B.G. Sizing Procedure and Economic Optimization Methodology for Seasonal Storage Solar Systems. Sol. Energy 1980, 25, 79–83. [Google Scholar] [CrossRef]

- Fisch, M.N.; Guigas, M.; Dalenback, J.O. A Review of Large-Scale Solar Heating Systems in Europe. Sol. Energy 1998, 63, 355–366. [Google Scholar] [CrossRef]

- Haller, M.Y.; Cruickshank, C.A.; Streicher, W.; Harrison, S.J.; Andersen, E.; Furbo, S. Methods to Determine Stratification Efficiency of Thermal Energy Storage Processes—Review and Theoretical Comparison. Sol. Energy 2009, 83, 1847–1860. [Google Scholar] [CrossRef]

- Huang, H.; Xiao, Y.; Lin, J.; Zhou, T.; Liu, Y.; Zhao, Q. Thermal Characteristics of a Seasonal Solar Assisted Heat Pump Heating System with an Underground Tank. Sustain. Cities Soc. 2020, 53, 101910. [Google Scholar] [CrossRef]

- Lago, J.; De Ridder, F.; Mazairac, W.; De Schutter, B. A 1-Dimensional Continuous and Smooth Model for Thermally Stratified Storage Tanks Including Mixing and Buoyancy. Appl. Energy 2019, 248, 640–655. [Google Scholar] [CrossRef]

- Lottner, V.; Schulz, M.E.; Hahne, E. Solar-Assisted District Heating Plants: Status of the German Programme Solarthermie-2000. Sol. Energy 2000, 69, 449–459. [Google Scholar] [CrossRef]

- Lund, P.D. A General Design Methodology for Seasonal Storage Solar Systems. Sol. Energy 1989, 42, 235–251. [Google Scholar] [CrossRef]

- Narula, K.; de Oliveira Filho, F.; Villasmil, W.; Patel, M.K. Simulation Method for Assessing Hourly Energy Flows in District Heating System with Seasonal Thermal Energy Storage. Renew. Energy 2020, 151, 1250–1268. [Google Scholar] [CrossRef]

- Nicotra, M.; Caldera, M.; Leone, P.; Zanghirella, F. Model-Based Analysis of Thermal Energy Storage for Multiple Temperature Level Heat Supply. Appl. Therm. Eng. 2018, 141, 288–297. [Google Scholar] [CrossRef]

- Ochs, F.; Dahash, A.; Tosatto, A.; Bianchi Janetti, M. Techno-Economic Planning and Construction of Cost-Effective Large-Scale Hot Water Thermal Energy Storage for Renewable District Heating Systems. Renew. Energy 2020, 150, 1165–1177. [Google Scholar] [CrossRef]

- Raab, S.; Mangold, D.; Müller-Steinhagen, H. Validation of a Computer Model for Solar Assisted District Heating Systems with Seasonal Hot Water Heat Store. Sol. Energy 2005, 79, 531–543. [Google Scholar] [CrossRef]

- Raccanello, J.; Rech, S.; Lazzaretto, A. Simplified Dynamic Modeling of Single-Tank Thermal Energy Storage Systems. Energy 2019, 182, 1154–1172. [Google Scholar] [CrossRef]

- Rezaie, B.; Reddy, B.V.; Rosen, M.A. Thermodynamic Analysis and the Design of Sensible Thermal Energy Storages. Int. J. Energy Res. 2017, 41, 39–48. [Google Scholar] [CrossRef]

- Schmidt, T.; Mangold, D.; Müller-Steinhagen, H. Central Solar Heating Plants with Seasonal Storage in Germany. Sol. Energy 2004, 76, 165–174. [Google Scholar] [CrossRef]

- Tanaka, H.; Tomita, T.; Okumiya, M. Feasibility Study of a District Energy System with Seasonal Water Thermal Storage. Sol. Energy 2000, 69, 535–547. [Google Scholar] [CrossRef]

- Soloha, R.; Pakere, I.; Blumberga, D. Solar Energy Use in District Heating Systems. A Case Study in Latvia. Energy 2017, 137, 586–594. [Google Scholar] [CrossRef]

- Williams, G.T.; Attwater, C.R.; Hooper, F.C. A Design Method to Determine the Optimal Distribution and Amount of Insulation for In-Ground Heat Storage Tanks. Sol. Energy 1980, 24, 471–475. [Google Scholar] [CrossRef]

- Rezaie, B.; Reddy, B.V.; Rosen, M.A. Exergy Analysis of Thermal Energy Storage in a District Energy Application. Renew. Energy 2015, 74, 848–854. [Google Scholar] [CrossRef]

- Dincer, I. Thermal Energy Storage Systems as a Key Technology in Energy Conservation. Int. J. Energy Res. 2002, 26, 567–588. [Google Scholar] [CrossRef]

- Dincer, I. On Thermal Energy Storage Systems and Applications in Buildings. Energy Build. 2002, 34, 377–388. [Google Scholar] [CrossRef]

- Dincer, I.; Dost, S.; Li, X. Performance Analyses of Sensible Heat Storage Systems for Thermal Applications. Int. J. Energy Res. 1997, 21, 1157–1171. [Google Scholar] [CrossRef]

- Lund, P.D.; Peltola, S.S. SOLCHIPS—A Fast Predesign and Optimization Tool for Solar Heating with Seasonal Storage. Sol. Energy 1992, 48, 291–300. [Google Scholar] [CrossRef]

- Campos Celador, A.; Odriozola, M.; Sala, J.M. Implications of the Modelling of Stratified Hot Water Storage Tanks in the Simulation of CHP Plants. Energy Convers. Manag. 2011, 52, 3018–3026. [Google Scholar] [CrossRef]

- Wiltshire, R. (Ed.) Advanced District Heating and Cooling (DHC) Systems; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Gong, Y.; Ma, G.; Jiang, Y.; Wang, L. Research Progress on the Fifth-Generation District Heating System Based on Heat Pump Technology. J. Build. Eng. 2023, 71, 106533. [Google Scholar] [CrossRef]

- Lund, H.; Werner, S.; Wiltshire, R.; Svendsen, S.; Thorsen, J.E.; Hvelplund, F.; Mathiesen, B.V. 4th Generation District Heating (4GDH): Integrating Smart Thermal Grids into Future Sustainable Energy Systems. Energy 2014, 68, 1–11. [Google Scholar] [CrossRef]

- Maccarini, A.; Sotnikov, A.; Sommer, T.; Wetter, M.; Sulzer, M.; Afshari, A. Influence of Building Heat Distribution Temperatures on the Energy Performance and Sizing of 5th Generation District Heating and Cooling Networks. Energy 2023, 275, 127457. [Google Scholar] [CrossRef]

- Werner, S. International Review of District Heating and Cooling. Energy 2017, 137, 617–631. [Google Scholar] [CrossRef]

- Pans, M.A.; Claudio, G.; Eames, P.C. Modelling of 4th Generation District Heating Systems Integrated with Different Thermal Energy Storage Technologies—Methodology. Energy Convers. Manag. 2023, 276, 116545. [Google Scholar] [CrossRef]

- Lund, H.; Østergaard, P.A.; Chang, M.; Werner, S.; Svendsen, S.; Sorknæs, P.; Thorsen, J.E.; Hvelplund, F.; Mortensen, B.O.G.; Mathiesen, B.V.; et al. The Status of 4th Generation District Heating: Research and Results. Energy 2018, 164, 147–159. [Google Scholar] [CrossRef]

- Pompei, L.; Mannhardt, J.; Nardecchia, F.; Pastore, L.M.; de Santoli, L. A Different Approach to Develop a District Heating Grid Based on the Optimization of Building Clusters. Processes 2022, 10, 1575. [Google Scholar] [CrossRef]

- Mozumder, I.; Kumar Thapa, R.; Sevda, S.; Aryal, N.; Prebilič, V.; Može, M.; Golobič, I. Waste-to-Energy Processes as a Municipality-Level Waste Management Strategy: A Case Study of Kočevje, Slovenia. Processes 2024, 12, 1010. [Google Scholar] [CrossRef]

- Buffa, S.; Cozzini, M.; D’Antoni, M.; Baratieri, M.; Fedrizzi, R. 5th Generation District Heating and Cooling Systems: A Review of Existing Cases in Europe. Renew. Sustain. Energy Rev. 2019, 104, 504–522. [Google Scholar] [CrossRef]

- Volkova, A.; Pakere, I.; Murauskaite, L.; Huang, P.; Lepiksaar, K.; Zhang, X. 5th Generation District Heating and Cooling (5GDHC) Implementation Potential in Urban Areas with Existing District Heating Systems. Energy Rep. 2022, 8, 10037–10047. [Google Scholar] [CrossRef]

- Weiss, W.; Spörk-Dür, M. Solar Heat Worldwide. Global Market Development and Trends 2021. Detailed Market Figures 2020; Federal Ministry Republic of Austria, Climate Actions, Environment, Energy, Mobility, Innovation and Technology: Vienna, Austria, 2022. [Google Scholar]

- Salvestroni, M.; Pierucci, G.; Pourreza, A.; Fagioli, F.; Taddei, F.; Messeri, M.; De Lucia, M. Design of a Solar District Heating System with Seasonal Storage in Italy. Appl. Therm. Eng. 2021, 197, 117438. [Google Scholar] [CrossRef]

- Maximov, S.A.; Mehmood, S.; Friedrich, D. Multi-Objective Optimisation of a Solar District Heating Network with Seasonal Storage for Conditions in Cities of Southern Chile. Sustain. Cities Soc. 2021, 73, 103087. [Google Scholar] [CrossRef]

- Tulus, V.; Boer, D.; Cabeza, L.F.; Jiménez, L.; Guillén-Gosálbez, G. Enhanced Thermal Energy Supply via Central Solar Heating Plants with Seasonal Storage: A Multi-Objective Optimization Approach. Appl. Energy 2016, 181, 549–561. [Google Scholar] [CrossRef]

- European Commission. Case Study on Solar-Heating Plant in Silkeborg, Denmark; European Commission: Ispra, Italy, 2019.

- Vojens District Heating—Solar Heat Europe. Available online: https://solarheateurope.eu/2020/05/19/vojens-district-heating/ (accessed on 9 May 2024).

- Solar District Heating—Solar Heat Europe. Available online: https://solarheateurope.eu/about-solar-heat/solar-district-heating/ (accessed on 9 May 2024).

- State of Green District Energy. Energy Efficiency for Urban Areas. 2016. Available online: https://ens.dk/sites/ens.dk/files/Globalcooperation/district_energy.pdf/ (accessed on 19 July 2024).

- Dronninglund Solar District Heating in Denmark—Copenhagen Centre on Energy Efficiency. Available online: https://c2e2.unepccc.org/kms_object/dronninglund-solar-district-heating-in-denmark/ (accessed on 9 May 2024).

- Tschopp, D.; Tian, Z.; Berberich, M.; Fan, J.; Perers, B.; Furbo, S. Large-Scale Solar Thermal Systems in Leading Countries: A Review and Comparative Study of Denmark, China, Germany and Austria. Appl. Energy 2020, 270, 114997. [Google Scholar] [CrossRef]

- 15 MW SDH Plant Inaugurated in Latvia—Solar District Heating. Available online: https://www.solar-district-heating.eu/15-mw-sdh-plant-inaugurated-in-latvia/ (accessed on 9 May 2024).

- Summary. Available online: https://www.districtenergyaward.org/wp-content/uploads/2021/06/64a576aaa511448999e06bdcbc217e52tmp1.pdf (accessed on 9 May 2024).

- 25-Year Heat Supply Contract for 4 MW SDH Plant|Solarthermalworld. Available online: https://solarthermalworld.org/news/25-year-heat-supply-contract-4-mw-sdh-plant/ (accessed on 9 May 2024).

- Zhou, X.; Xu, Y.; Zhang, X.; Xu, D.; Linghu, Y.; Guo, H.; Wang, Z.; Chen, H. Large Scale Underground Seasonal Thermal Energy Storage in China. J. Energy Storage 2021, 33, 102026. [Google Scholar] [CrossRef]

- Li, X.; Wang, Z.; Li, J.; Yang, M.; Yuan, G.; Bai, Y.; Chen, L.; Xu, T.; Gilmanova, A. Comparison of Control Strategies for a Solar Heating System with Underground Pit Seasonal Storage in the Non-Heating Season. J. Energy Storage 2019, 26, 100963. [Google Scholar] [CrossRef]

- Karasu, H.; Dincer, I. Life Cycle Assessment of Integrated Thermal Energy Storage Systems in Buildings: A Case Study in Canada. Energy Build. 2020, 217, 109940. [Google Scholar] [CrossRef]

- Epp, B.; Oropeza, M. Solar Heat for Cities. 2019. Available online: http://files.iea-shc.org/public/mrj/d-d2-investor-brochure.pdf (accessed on 14 June 2024).

- Hiris, D.P.; Pop, O.G.; Balan, M.C. Preliminary Sizing of Solar District Heating Systems with Seasonal Water Thermal Storage. Heliyon 2022, 8, e08932. [Google Scholar] [CrossRef] [PubMed]

- Midttømme, K.; Kocbach, J.; Ramstad, R.K.; Henne, I. Aquifer Thermal Energy Storage (ATES). Tech. Poszuk. Geol. Geoterm. Zrównoważony Rozw. 2017, 2, 203–213. [Google Scholar]

- Narula, K.; Filho, F.D.O.; Chambers, J.; Patel, M.K. Simulation and Comparative Assessment of Heating Systems with Tank Thermal Energy Storage—A Swiss Case Study. J. Energy Storage 2020, 32, 101810. [Google Scholar] [CrossRef]

- Chang, C.; Leng, G.; Li, C.; Nie, B.; She, X.; Peng, X.; Deng, J. Investigation on Transient Cooling Process in a Water Heat Storage Tank with Inclined Sidewalls. Energy Procedia 2017, 142, 142–147. [Google Scholar] [CrossRef]

- Sifnaios, I.; Jensen, A.R.; Furbo, S.; Fan, J. Heat Losses in Water Pit Thermal Energy Storage Systems in the Presence of Groundwater. Appl. Therm. Eng. 2023, 235, 121382. [Google Scholar] [CrossRef]

- Mahon, H.; O’Connor, D.; Friedrich, D.; Hughes, B. A Review of Thermal Energy Storage Technologies for Seasonal Loops. Energy 2022, 239, 122207. [Google Scholar] [CrossRef]

- Li, X.; Yilmaz, S.; Patel, M.K.; Chambers, J. Techno-Economic Analysis of Fifth-Generation District Heating and Cooling Combined with Seasonal Borehole Thermal Energy Storage. Energy 2023, 285, 129382. [Google Scholar] [CrossRef]

- Lu, H.; Tian, P.; He, L. Evaluating the Global Potential of Aquifer Thermal Energy Storage and Determining the Potential Worldwide Hotspots Driven by Socio-Economic, Geo-Hydrologic and Climatic Conditions. Renew. Sustain. Energy Rev. 2019, 112, 788–796. [Google Scholar] [CrossRef]

- Kurşun, B. Thermal Stratification Enhancement in Cylindrical and Rectangular Hot Water Tanks with Truncated Cone and Pyramid Shaped Insulation Geometry. Sol. Energy 2018, 169, 512–525. [Google Scholar] [CrossRef]

- Hermans, L.; Haesen, R.; Uytterhoeven, A.; Peere, W.; Boydens, W.; Helsen, L. Pre-Design of Collective Residential Solar Districts with Seasonal Thermal Energy Storage: Importance of Level of Detail. Appl. Therm. Eng. 2023, 226, 120203. [Google Scholar] [CrossRef]

- Kim, M.H.; Kim, D.W.; Lee, D.W.; Heo, J. Energy Conservation Performance of a Solar Thermal and Seasonal Thermal Energy Storage-Based Renewable Energy Convergence System for Glass Greenhouses. Case Stud. Therm. Eng. 2023, 44, 102895. [Google Scholar] [CrossRef]

- Xu, B.; Zhang, T.; Wang, S.; Chen, Z. Dynamic Characteristics and Energy Efficiency Evaluation of a Novel Solar Seasonal Thermal Storage—Heating System. Appl. Therm. Eng. 2023, 234, 121223. [Google Scholar] [CrossRef]

- Zhou, Y.; Min, C.; Wang, K.; Xie, L.; Fan, Y. Optimization of Integrated Energy Systems Considering Seasonal Thermal Energy Storage. J. Energy Storage 2023, 71, 108094. [Google Scholar] [CrossRef]

- Hosseini, S.M.; Carli, R.; Dotoli, M. Robust Optimal Demand Response of Energy-Efficient Commercial Buildings. In Proceedings of the 2022 European Control Conference, ECC 2022, London, UK, 12–15 July 2022; pp. 1606–1609. [Google Scholar] [CrossRef]

- Bahlawan, H.; Losi, E.; Manservigi, L.; Morini, M.; Pinelli, M.; Spina, P.R.; Venturini, M. Optimization of a Renewable Energy Plant with Seasonal Energy Storage for the Transition towards 100% Renewable Energy Supply. Renew. Energy 2022, 198, 1296–1306. [Google Scholar] [CrossRef]

- Gabrielli, P.; Gazzani, M.; Martelli, E.; Mazzotti, M. Optimal Design of Multi-Energy Systems with Seasonal Storage. Appl. Energy 2018, 219, 408–424. [Google Scholar] [CrossRef]

- Danish Energy Agency, Regulation and Planning of District Heating in Denmark. 2015. Available online: https://ens.dk/sites/ens.dk/files/contents/material/file/regulation_and_planning_of_district_heating_in_denmark.pdf (accessed on 28 June 2024).

- Haslinger, E.; Turewicz, V.; Hammer, A.; Götzl, G. Assessment of Deep and Shallow Geothermal Resources and Measurement of Waste Heat Potentials from Industrial Processes for Supplying Renewable Heat for Industry and Urban Quarters. Processes 2022, 10, 1125. [Google Scholar] [CrossRef]

- Johansen, K.; Werner, S. Something Is Sustainable in the State of Denmark: A Review of the Danish District Heating Sector. Renew. Sustain. Energy Rev. 2022, 158, 112117. [Google Scholar] [CrossRef]

- Bolton, R.; Cameron, L.; Kerr, N.; Winskel, M.; Desguers, T. Seasonal Thermal Energy Storage as a Complementary Technology: Case Study Insights from Denmark and The Netherlands. J. Energy Storage 2023, 73, 109249. [Google Scholar] [CrossRef]

- Persson, J.; Westermark, M. Low-Energy Buildings and Seasonal Thermal Energy Storages from a Behavioral Economics Perspective. Appl. Energy 2013, 112, 975–980. [Google Scholar] [CrossRef]

- Connolly, D.; Lund, H.; Mathiesen, B.V.; Werner, S.; Möller, B.; Persson, U.; Boermans, T.; Trier, D.; Østergaard, P.A.; Nielsen, S. Heat Roadmap Europe: Combining District Heating with Heat Savings to Decarbonise the EU Energy System. Energy Policy 2014, 65, 475–489. [Google Scholar] [CrossRef]

| Parameter | U.M. | Tanks | Pits | Boreholes | Aquifers |

|---|---|---|---|---|---|

| The storage medium | [-] | water | gravel–water | soil | sand–water |

| Energy density | [kWh/m3] | 60–80 | 30–50 | 15–30 | 30–40 |

| Equivalent storage water volume | [m3 water] | 1 | 1.3–2 | 3–5 | 2–3 |

| Specific costs | [EUR/m3] | 30–500 | 30–500 | 50–150 | 40–100 |

| Depth/height | [m] | 5–15 m | 5–15 m | 20–50 m | 30–200 m |

| Geological conditions | [-] | stable soil | stable soil | drillable land | aquifer layer |

| Features | Tanks | Pits | Boreholes | Aquifers |

|---|---|---|---|---|

| Structure | pre-stressed reinforced concrete or stainless steel | a load-bearing frame is not required for construction | deep vertical U-type drills made in the ground or rocks | geological structures containing groundwater |

| Insulation | thick layer of insulation | pits are covering | necessary at the top of the well. | complete thermal insulation is not possible |

| Place | any place | limited choice of locations | limited choice of locations | limited choice of location placement. |

| Maintenance and repair | possible with conventional technologies | difficult/impossible | difficult/impossible | difficult/impossible |

| Special requirement | designed regardless of the necessary geometry | the excavations covered with polymer material sheets welded on the lateral sides and the bottom of the pit | drilling is carried out at depths of 30–200 m | permission from the responsible authorities for groundwater |

| City | Country | V [m3] | A [m2] | d [m] | h [m] | A/V [1/m] | h/d [-] | Ref. |

|---|---|---|---|---|---|---|---|---|

| Hamburg | DEU | 4500 | 1650 | 25.7 | 10.7 | 0.37 | 0.42 | [17] |

| Friedrichshafen | DEU | 12,000 | 2796 | 32.4 | 19.4 | 0.23 | 0.60 | [17] |

| Ilmenau | DEU | 300 | 262 | 7.2 | 8 | 0.87 | 1.11 | [17] |

| Hanover | DEU | 2750 | 1135 | 19 | 11.1 | 0.41 | 0.58 | [17] |

| Attenkirchen | DEU | 500 | 350 | 8.9 | 8 | 0.70 | 0.90 | [17] |

| Crailsheim | DEU | 480 | 362 | 6.3 | 14.5 | 0.75 | 2.30 | [17] |

| Munich | DEU | 6000 | 1800 | 24.6 | 16.1 | 0.30 | 0.65 | [17] |

| Studsvik | SWE | 1200 | 450 | - | - | 0.38 | - | [34] |

| Lombohov | SWE | 10,000 | 1750 | - | - | 0.18 | - | [34] |

| Rottweil | DEU | 597 | 470 | 13 | 5 | 0.79 | 0.38 | [25] |

| Cosenza | ITA | 500 | - | 10 | 7.3 | - | 0.73 | [25] |

| Neuchatel | CHE | 1000 | 1075 | 14.6 | 16.15 | 0.45 | 1.1 | [25] |

| Rise | DNK | 4000 | 1445 | 20 | 13 | 0.36 | 0.65 | [25] |

| Mühldorf | DEU | 16.4 | 42.7 | 1.8 | 7 | 2.6 | 3.8 | [25] |

| Vaulruz | CHE | 3517 | 6331 | 30.5 | 6.2 | 1.8 | 0.22 | [25] |

| City | Country | Placement | Geometric Shape |

|---|---|---|---|

| Rottweil | DEU | partially buried | cylinder |

| Cosenza | ITA | buried | cylinder |

| Friedrichshafen | DEU | partially buried | cylinder |

| Neuchatel | CHE | - | cylinder |

| Ilmenau | DEU | above ground | cylinder |

| Hannover | DEU | buried | cylinder |

| Rise | DNK | above ground | cylinder |

| Munich | DEU | partially buried | cylinder |

| Hamburg | DEU | buried | cylinder |

| Mühldorf | DEU | above ground | cylinder |

| Vaulruz | CHE | buried | truncated cone |

| City | Country | The Material of the Structural Element | The Thickness of the Structural Material [m] |

|---|---|---|---|

| Rottweil | DEU | concrete | 0.25 |

| Cosenza | ITA | concrete | 0.2–0.5 |

| Friedrichshafen | DEU | concrete | 0.3 |

| Neuchatel | CHE | concrete | - |

| Ilmenau | DEU | glass fiber reinforced plastic | 0.02 (0.17) |

| Hannover | DEU | concrete | 0.3 |

| Rise | DNK | steel | - |

| Munich | DEU | concrete | 0.16 |

| Hamburg | DEU | concrete | 0.3 |

| Mühldorf | DEU | stainless steel | 0.2 |

| Vaulruz | CHE | - | - |

| Hoerby | DNK | concrete | - |

| Herlev | DNK | concrete and sheet steel | - |

| Ingelstad | SWE | concrete | - |

| City | Country | The Insulating Material of the Base | The Insulating Material of the Walls | The Insulating Material of the Upper Part | Insulation Thickness [m] |

|---|---|---|---|---|---|

| Rottweil | DEU | non-insulated | mineral fibers | mineral fibers | - |

| Cosenza | ITA | expanded glass foam gravel | expanded glass foam gravel | expanded glass foam gravel | 0.2 |

| Friedrichshafen | DEU | non-insulated | mineral fibers | mineral fibers | 0.3 |

| Neuchatel | CHE | non-insulated | mineral fibers + XPS | mineral fibers + XPS | - |

| Ilmenau | DEU | non-insulated | polyurethane foam | polyurethane foam | - |

| Hannover | DEU | non-insulated | expanded glass granules | expanded glass granules | - |

| Rise | DNK | non-insulated | mineral fibers | mineral fibers | - |

| Munich | DEU | expanded glass foam gravel | expanded glass granules | expanded glass granules | - |

| Hamburg | DEU | non-insulated | mineral fibers | mineral fibers | 0.3 |

| Mühldorf | DEU | perlite | perlite | perlite | - |

| Vaulruz | CHE | non-insulated | EPS | EPS | - |

| Ref. | V | A/V | Geometry | h/d | Location Type | Structure | Insulation |

|---|---|---|---|---|---|---|---|

| [21] | ✓ | ✓ | |||||

| [36] | ✓ | ✓ | |||||

| [25] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| [37] | ✓ | ✓ | |||||

| [17] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| [27] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| [38] | ✓ | ✓ | |||||

| [39] | ✓ | ✓ | ✓ | ✓ | |||

| [32] | ✓ | ✓ | ✓ | ||||

| [23] | ✓ | ✓ | ✓ | ||||

| [40] | ✓ | ||||||

| [41] | ✓ | ✓ | ✓ | ||||

| [35] | ✓ | ✓ | ✓ | ✓ | |||

| [42] | ✓ | ✓ | ✓ | ||||

| [19] | ✓ | ✓ | |||||

| [43] | ✓ | ✓ | |||||

| [44] | ✓ | ✓ | |||||

| [45] | ✓ | ✓ | |||||

| [46] | ✓ | ✓ | |||||

| [22] | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| [34] | ✓ | ✓ | |||||

| [47] | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| [16] | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| [48] | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| [49] | ✓ | ✓ | ✓ | ||||

| [50] | ✓ | ||||||

| [51] | ✓ | ✓ | |||||

| [52] | ✓ | ✓ | |||||

| [24] | ✓ | ✓ | ✓ | ✓ | |||

| [33] | ✓ | ✓ | ✓ | ||||

| [39] | ✓ | ✓ | |||||

| [53] | ✓ | ||||||

| [54] | ✓ | ✓ |

| Ref. | Energetic Efficiency [%] | Evaluation Method |

|---|---|---|

| [56] | 90 | simulation |

| [57] | 90 | simulation |

| [58] | 90 | simulation |

| [32] | 88 | simulation |

| [23] | 70 | - |

| [45] | 66.4 | measurement |

| [45] | 65.7 | simulation |

| [47] | (72–88) | simulation |

| [48] | 71.2 | measurement |

| [55] | 60 | measurement |

| [52] | 90 | simulation |

| [59] | (85–90) | simulation |

| Ref. | ηst | ηdes | ηchr | ψst | Str | MIX | Aspects Studied | Main Finding |

|---|---|---|---|---|---|---|---|---|

| [36] | (0–1) | energy efficiency | measures to improve efficiency | |||||

| [25] | ✓ | state of the art | increasing efficiency with multi-store combines | |||||

| [60] | ✓ | exergy efficiency | exergy destruction influences the economic feasibility | |||||

| [17] | ✓ | ✓ | ✓ | ✓ | ✓ | (0–1) | state of the art | higher stratification for tanks than pits |

| [27] | ✓ | ✓ | (0.14–0.55) | energy efficiency | higher stratification for tank than pit in Dronninglund | |||

| [56] | ✓ | ✓ | ✓ | ✓ | energy and exergy efficiency | exergetic analyses are more relevant than energetic ones | ||

| [57] | ✓ | ✓ | ✓ | ✓ | energy and exergy efficiency | exergetic analyses are more relevant than energetic ones | ||

| [58] | ✓ | ✓ | ✓ | ✓ | energy and exergy efficiency | exergetic analyses are more relevant than energetic ones | ||

| [32] | ✓ | evaluation of solar heating systems | larger storage tanks are more efficient | |||||

| [23] | ✓ | ✓ | ✓ | ✓ | state of the art | thermal energy storage has more advantages than batteries | ||

| [40] | ✓ | ✓ | ✓ | ✓ | ✓ | (0–1) | state of the art | separating the effects due to heat losses from those of the mixture |

| [19] | ✓ | ✓ | ✓ | ✓ | state of the art | sensible thermal energy storage is cheap and easy to control | ||

| [45] | ✓ | feasibility of solar heating systems | making a modelling tool for multi-energy heating system | |||||

| [48] | ✓ | model validation for district heating | model was validated, the deviations are less than 5% | |||||

| [49] | ✓ | thermal behavior of storage tanks | efficiency is higher in open systems (one-dimensional models) | |||||

| [55] | ✓ | ✓ | ✓ | ✓ | Friedrichshafen district heating | overall energy efficiencies (60%) and exergy efficiencies (19%) | ||

| [51] | ✓ | district heating technologies | new concepts for seasonal heat storage | |||||

| [53] | ✓ | district solar heating in Latvia | the specific costs for solar district heating are close to natural gas | |||||

| [52] | ✓ | feasibility of solar heating systems | seasonal heat storage indicates energy savings of 26% | |||||

| [59] | ✓ | predesign and optimization tool | optimizations can reduce the annual energy price by 50% |

| Country | Collector Surface | Number of Systems | Thermal Power |

|---|---|---|---|

| [-] | [m2] | [-] | [MW] |

| DNK | 1,608,401 | 125 | 1126 |

| CHN | 390,000 | 41 | 279 |

| DEU | 117,000 | 45 | 81.5 |

| AUT | 49,000 | 22 | 34 |

| OTH European | 45,000 | 7 | 28.1 |

| SAU | 41,000 | 1 | 25.4 |

| SWE | 39,000 | 24 | 23.9 |

| POL | 20,000 | 8 | 12.5 |

| FRA | 16,000 | 8 | 11.4 |

| NLD | 12,000 | 3 | 7.5 |

| CHE | 11,000 | 7 | 7.3 |

| Asia w/o China | 7000 | 3 | 4.5 |

| USA/CAN | 6000 | 2 | 2.8 |

| ZAF | 4000 | 2 | 0.8 |

| ITA | 2000 | 1 | 0.7 |

| Case Study | Ref. | Evaluation Method |

|---|---|---|

| Silkeborg, Denmark | [76] | desk search, field visits, and interviews with project owners |

| Vojens, Denmark | [77,78,79] | desk search |

| Dronninglund Fjernvarme, Denmark | [80,81] | design and operation |

| Salaspils, Letonia | [82,83] | interviews with project owners, design and operation |

| Friesach, Austria | [84] | interviews with project owners, design and operation |

| Zhangjiakou, China | [85,86] | design and simulation |

| Drake Landing Solar Community, Canada | [87] | design and simulation |

| Langkazi, Tibet | [81,88] | design and operation |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hiris, D.; Balan, M.C.; Bode, F.I. A Comprehensive Review on Enhancing Seasonal Energy Storage Systems through Energy Efficiency Perspectives. Processes 2024, 12, 1623. https://doi.org/10.3390/pr12081623

Hiris D, Balan MC, Bode FI. A Comprehensive Review on Enhancing Seasonal Energy Storage Systems through Energy Efficiency Perspectives. Processes. 2024; 12(8):1623. https://doi.org/10.3390/pr12081623

Chicago/Turabian StyleHiris, Daniel, Mugur Ciprian Balan, and Florin Ioan Bode. 2024. "A Comprehensive Review on Enhancing Seasonal Energy Storage Systems through Energy Efficiency Perspectives" Processes 12, no. 8: 1623. https://doi.org/10.3390/pr12081623