Effect of Far-Infrared Drying on Broccoli Rhizomes: Drying Kinetics and Quality Evaluation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Methods

2.2.1. Far-Infrared Drying

2.2.2. Drying Kinetics

Moisture Ratio

Drying Rate

Effective Moisture Diffusivity

Drying Activation Energy

Thermodynamic Parameter

Drying Mathematical Model

2.2.3. Physicochemical Properties Index

Determination of Color

Determination of Rehydration Ratio

2.2.4. Nutritional Quality Indicators

Determination of Total Flavonoids

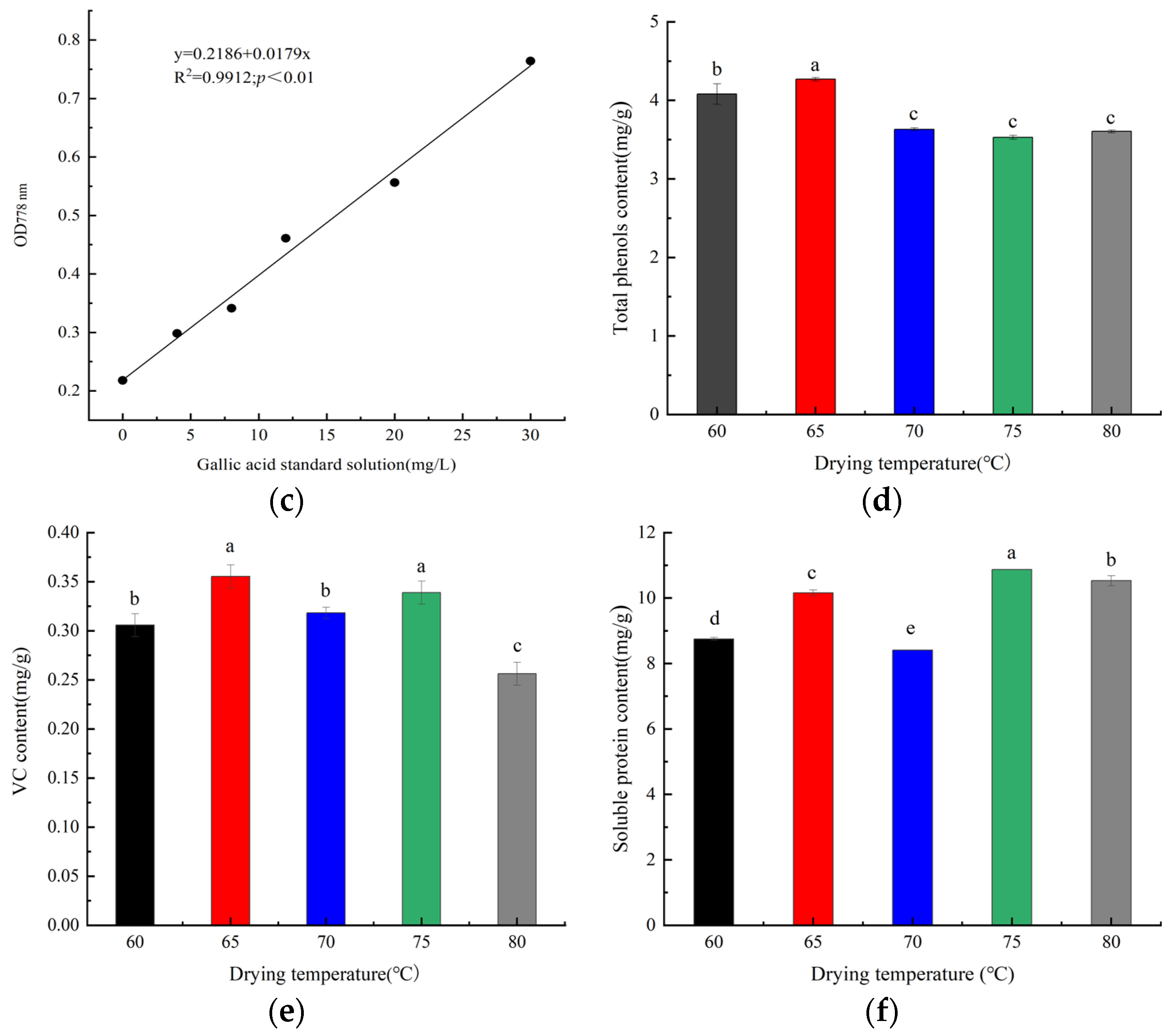

Determination of Total Polyphenols

Determination of Soluble Protein and Ascorbic Acid (VC) Content

Determination of Chlorophyll and Carotenoids

2.3. Data Processing and Analysis

3. Results and Analysis

3.1. Effects of Different Temperatures on the Drying Characteristics of Broccoli Rhizomes Using Far-Infrared Drying

3.2. Moisture Effective Diffusion Coefficient, Activation Energy, and Thermodynamic Parameters of the Broccoli Rhizomes

3.3. Fitting and Analysis of the Drying Mathematical Model

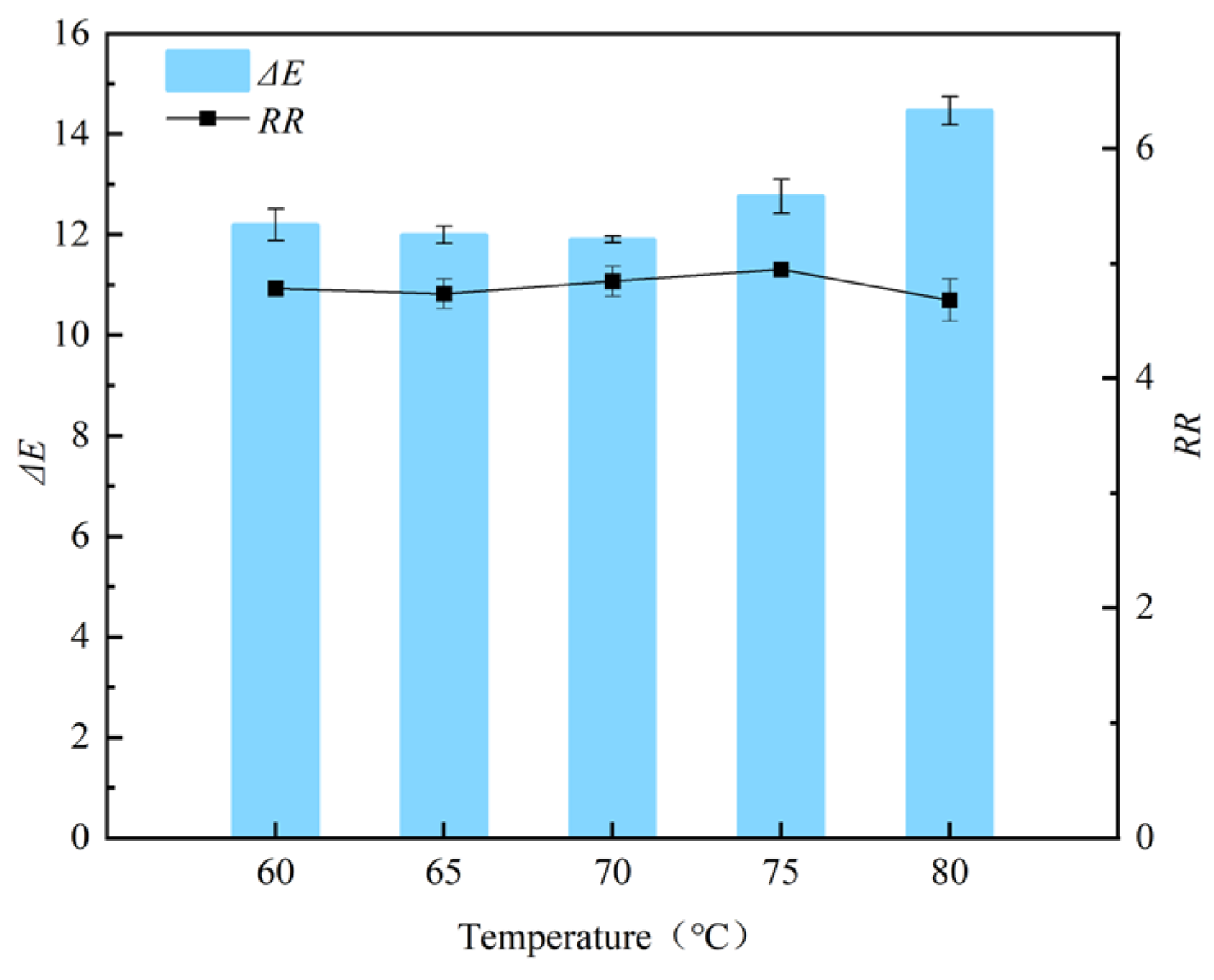

3.4. Effects of Different Temperatures on the Color of the Broccoli Rhizomes during Far-Infrared Drying

3.5. Effects of Different Temperatures of Far-Infrared Drying on the Rehydration Ratio of the Broccoli Rhizomes

3.6. Effects of Far-Infrared Drying at Different Temperatures on the Content of Total Flavonoids, Total Phenols, VC, and Soluble Protein in Broccoli Rhizomes

3.7. Effects of Different Temperatures on Chlorophyll and Carotenoid in Broccoli Rhizomes Using Far-Infrared Drying

3.8. Comprehensive Evaluation of the Effects of Different Temperatures on the Quality of Broccoli Rhizomes Using Far-Infrared Drying

3.8.1. Correlation Analysis

3.8.2. Principal Component Analysis

3.8.3. Membership Function Values and Comprehensive Ranking of Quality Indexes of Broccoli Rhizomes Treated with Far-Infrared Drying at Different Temperatures

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, M.; Ma, C.; Ge, B.G.; Wang, C.D.; Yang, L.F.; Meng, X.F. Effect of drying temperature on hot air drying process of broccoli. Hortic. North China 2020, 19, 102–106. [Google Scholar]

- Zhang, M.; Wu, M.Y.; Yang, L.F.; Wang, C.D.; Fan, Q.; Meng, X.F.; Ma, C. Effects of different drying methods on physical properties and nutritional quality of old stem powder of broccoli. Food Sci. Technol. 2018, 43, 60–66. [Google Scholar]

- Tian, M. Effects of Selenium Treatment on Synthesis and Metabolism of Glucosinolates in Broccoli. Ph.D. Thesis, Huazhong Agricultural University, Wuhan, China, 2018. [Google Scholar]

- Zhang, J.H.; Guo, N.; Yang, Y.; Li, Q.P.; Guo, Q.; Duan, Y.Q.; Ha, Y.M. Extraction, purification, and identification of sulforaphane from by-products of broccoli. Food Sci. 2019, 40, 248–255. [Google Scholar]

- Du, X.M.; Wu, H.Z.; Zhao, Y.S.; Su, X.H.; Gao, G.Q. Effect of microwave drying on sulforaphane content in different parts of broccoli. Fresh-Keep. Process. 2018, 18, 95–99. [Google Scholar]

- Rang, F.J.; Wang, J.L.; Liu, W.; Ren, J.X.; Ou, Y.Y. Study on extraction and physicochemical properties of pectin from the stem of broccoli. Food Res. Dev. 2022, 43, 104–110. [Google Scholar]

- Sun, Y.D.; Chen, Y.; Guo, Y.Y.; Zhang, Y.X.; Ma, Y.L.; Yang, M.; Fu, R.Q.; Wang, Y.J. Effect of stem extract of broccoli on storage quality of broccoli. Food Ind. Sci. Technol. 2022, 43, 355–362. [Google Scholar]

- Li, W.F.; Zhang, X.Y.; Wang, C.; Lin, L.T.; Chen, X.P.; Qu, Y.; Zhang, X.M.; Lin, Y.; Tan, W.; Zheng, Q.R.; et al. Characteristics of gas jet impact drying kinetics and polyphenol degradation kinetics of stem mustard. Food Sci. 2021, 42, 106–114. [Google Scholar]

- Wu, M.J. Effects of Different Drying Methods, Packaging Materials, and Temperature on the Storage Quality of Jujube Slices. Ph.D. Thesis, Nanjing Agricultural University, Nanjing, China, 2021. [Google Scholar]

- Chen, K.J.; Wang, S.; Yan, J.C.; Nuhu Jibrril, A.; Yu, H.M.; Sun, J. Study on drying characteristics and quality of rice under different far infrared drying conditions of graphene at low temperature. J. Agric. Mach. 2021, 3, 1–18. [Google Scholar]

- Liu, Z.B.; Zhang, Z.Y.; Li, D.J.; Li, D.H.; Jiang, N.; Liu, C.Q. Variation of internal moisture during far-infrared drying of Pleurotus ostreatus. Food Sci. 2016, 37, 82–86. [Google Scholar]

- Li, K.X.; Zhang, Y.; Song, C.; Meng, X.; Wang, J.; Yang, L.Q.; Wang, P.Y. Effect of hot air drying and far infrared drying on the quality characteristics of strawberry powder. Food Res. Dev. 2023, 44, 47–54. [Google Scholar]

- Chen, S.M.; Zhang, N. Effects of different drying methods on four common components of Euonymus ulmoides leaves. Anhui Chem. Ind. 2023, 49, 94–97. [Google Scholar]

- GB 5009.3-2016; National Food Safety Standard Determination of Moisture in Food. Standardization Administration of China: Beijing, China, 2016.

- Ma, T.T.; Ou, Y.J.; Xiao, Z.F.; Shen, J. Hot air drying characteristics and drying model of Antarctic krill. Fish. Mod. 2023, 50, 93–102. [Google Scholar]

- Zhong, C.J.; Zhu, W.X.; Liu, Y.H.; Wu, J.Y.; Fan, J.L.; Luo, L. Study on a kinetic model of thin-layer drying of carrot. Food Sci. 2014, 35, 24–29. [Google Scholar]

- Ma, J.S.; Ou, Y.J.; Ma, T.T.; Huang, T.; Shen, J. Heating and drying characteristics and drying kinetics model of Antarctic krill spiral sleeves. Fish. Mod. 2024, 51, 102–112. [Google Scholar]

- Li, Y.; Zhu, W.U.; Chen, P.X.; Wang, Y.K.; Jiang, M.M.; Wang, D.X.; Chen, L.; Zhang, Y.Q.; Hu, X.Y.; Wang, J. Study on hot air drying characteristics and thermodynamic properties of different varieties of high-oleic peanuts. Food Ind. Technol. 2024, 14, 42–49. [Google Scholar]

- Han, W.N.; Yan, J.H.; Wu, F.J.; Liu, Y.; Li, S.Q.; Li, S.M.; Gao, L. Effect of heat pump-low temperature regeneration runner dehumidification combined drying on drying characteristics of white radish slices. Food Ferment. Ind. 2024, 1–12. [Google Scholar] [CrossRef]

- Li, Y.; Zhu, W.; Chen, P.X.; Wang, Y.K.; Jiang, M.M.; Wang, D.X.; Chen, L.; Zhang, Y.Q.; Hu, X.Y.; Wang, J.; et al. Study on Hot Air drying and Thermodynamic Properties of different varieties of Peanut with High oleic Acid. Food Ind. Sci. Technol. 2024, 1–16. [Google Scholar]

- Yin, X.F.; Yang, L. Characteristics and mathematical model of thin layer infrared drying of rice. Chin. J. Cereals Oils 2024, 4, 1–12. [Google Scholar]

- Wang, K.H.; Li, J.M.; Peng, F.; Liu, Y.D.; Ma, Q.; Li, M.; Xu, H.D. Effect of radio frequency treatment on medium and short wave infrared drying kinetics and quality characteristics of red jujube. Food Sci. 2020, 41, 117–123. [Google Scholar]

- Deng, Q.L.; Liu, M.W.; Shen, J.; Tuerxun, A.D.; Chen, X.S.; Xu, W.S.; Xiao, H. Study on total polyphenols content and antioxidant activity of total flavonoids in mulberry leaves from different producing areas. China Food Addit. 2024, 35, 130–137. [Google Scholar]

- DB43/T476-2009; Determination of Flavone in Vegetal Food. Hunan Quality and Technology Supervise Bureau of the People’s Republic of China: Changsha, China, 2009.

- Hou, S.; Zhang, X.J.; Zhou, D.D.; Ma, F.Y.; Wang, D.P.; Zhao, S.Q.; Ding, C.; Liu, Q. Analysis of phenolic metabolism of stored rice under high-temperature stress based on dielectric barrier discharge low-temperature plasma. Chin. Agric. Sci. 2024, 57, 1180–1190. [Google Scholar]

- H/AHIA 005-2018; Contratada: Nogueira Santos Advogados Associados. Department of Administration and Finance: Teofilândia, Brazil, 2018.

- Han, Y. Effect of Slightly Acidic Electrolyzed Water on Circulation Quality of Postharvest Broccoli. Ph.D. Thesis, Shenyang Agricultural University, Shenyang, China, 2023. [Google Scholar]

- An, R.H.; Zhou, H.S.; Luo, S.F.; Zhang, Y.T.; Zhang, L.G.; Hu, H.L.; Li, P.X. Effects of vacuum precooling and different circulation modes on the quality of green shelves in Shanghai. Food Sci. 2021, 42, 241–248. [Google Scholar]

- Zhu, K.Y.; Ren, G.Y.; Duan, X.; Li, L.L.; Zhao, L.J.; Liu, P.P. Characterization of texture, nutrient composition, and energy consumption of shelled flowers under different drying methods. Chin. J. Food 2022, 22, 177–188. [Google Scholar]

- Yuan, D.; Li, Y.; Chen, F.; Zhang, X.S.; Huang, J.W. Analysis of characteristics and quality of blueberry by microwave freeze drying. Chin. J. Food 2024, 4, 1–17. [Google Scholar]

- Zhang, Q. Study on Microwave Vacuum Drying of Sea Cucumber and Its Effect on Quality. Ph.D. Thesis, Huazhong Agricultural University, Wuhan, China, 2023. [Google Scholar]

- Wang, R.Y.; Zhao, Y.; Shi, Q.L. Effects of drying methods on thermodynamic properties and storage stability of mulberry powder. Food Ferment. Ind. 2018, 2, 247–255. [Google Scholar]

- Zhang, G.; Niu, P.; Lai, Y.S. Effects of drying conditions on drying characteristics and physicochemical properties of broccoli. Food Ferment. Ind. 2024, 1–10. [Google Scholar] [CrossRef]

- Wang, Q. Low Temperature Drying Characteristics of Sludge and Analysis of Heat Pump Drying System. Ph.D. Thesis, Southwest University of Science and Technology, Mianyang, China, 2024. [Google Scholar]

- Gan, T.; Yi, P.; Huang, M.; Sheng, J.F.; Zheng, L.J.; Lin, D.; Zhang, L.; Li, L. Study on microwave drying characteristics and mathematical model of mango. Food Sci. Technol. 2024, 49, 19–26. [Google Scholar]

- Wang, D.; Cao, Z.; Gao, Y.; Yang, L.; Zhao, L. Impact of the Pre-Dehydration and Drying Methods on the Mass Transfer and Quality Attributes of Yak Milk Casein. Foods 2024, 13, 1062. [Google Scholar] [CrossRef] [PubMed]

- Nie, M.M.; Yang, H.Z.; Li, D.J.; Xiao, Y.D.; Yang, Y.W.; Yu, R.; Liu, C.J.; Niu, L.Y.; Jin, P. Optimization of vacuum freeze drying process and its effect on the quality of blueberry pretreated by ultrasonic. J. Nanjing Agric. Univ. 2024, 4, 1–17. [Google Scholar]

- Zheng, X. Study on Drying Characteristics and Quality of Red Jujube Mud Slices Based on Different Drying Techniques. Ph.D. Thesis, China Agricultural University, Beijing, China, 2016. [Google Scholar]

- Yu, Y.Y.; Tang, D.B.; Wen, J.; Wu, J.J.; Yu, Y.S.; An, K.J.; Zou, Y. Effect of heat pump temperature on drying rate and quality of white radish. Food Mach. 2020, 36, 211–214. [Google Scholar]

- Wang, H.D.; Sun, P.; Li, X.D.; Xiao, J.X.; Guo, L.P. Study on hot air drying characteristics and quality of broccoli. J. Food Saf. Qual. Insp. 2022, 13, 182–189. [Google Scholar]

- Tang, X.D.; Wang, L.; Cui, J.Y. Optimization of the extraction process and comparative study on the content of total flavonoids in different kinds of tea. Int. J. Pharm. Res. 2019, 46, 862–866. [Google Scholar]

- Sun, P.; Wang, H.D.; Wang, F.W.; Xiao, J.X.; Geng, X.; Guo, L.P. Study on hot air drying kinetics and quality of purple cabbage powder. Food Sci. Technol. 2020, 45, 61–67. [Google Scholar]

- Sun, Q.Y.; Zhang, Z.C.; Jia, Z.C.; Han, M.L.; Zhao, F. Effects of pretreatment methods and drying temperature on hot air drying characteristics and quality of Chinese cabbage. Food Ind. Sci. Technol. 2021, 42, 210–215. [Google Scholar]

- Long, Y.Y.; Lei, Y.J.; Ma, X.Y.; Min, T.T.; Zhao, J.; Yue, J. Research Progress on Degradation and Color Protection Technology of Vegetable Chlorophyll in Thermal Processing. Food Sci. 2024, 1–18. Available online: http://kns.cnki.net/kcms/detail/11.2206.TS.20240529.1331.004.html (accessed on 7 July 2024).

- Yuan, D.S. Study on Nutritional Quality and Antioxidant Properties of Broccoli during Processing. Ph.D. Thesis, Henan University of Technology, Luoyang, China, 2018. [Google Scholar]

- Liao, Z.J.; Liao, M.; Li, Q.M.; Wang, F.; Li, W.J.; Zhou, Y.; Su, X.J. Effect of drying methods on the quality of perilla leaves. Chin. Condiment 2024, 49, 116–121. [Google Scholar]

- Lu, J.Y.; Tian, H.; Xiong, J.B.; Wu, X.J.; Liu, Y.; Zhang, H.S. A comprehensive evaluation of cold tolerance of 14 native Pennisetum seedlings. J. Grass Ind. 2024, 8, 98–111. [Google Scholar]

- Li, Y.N. Study on the Correlation between the Drying Process and Quality of Salvia Miltiorrhiza Extract. Ph.D. Thesis, Chengdu University of Traditional Chinese Medicine, Chengdu, China, 2018. [Google Scholar]

- Ge, Q.L.; Liu, Y.; Fan, Y.F.; Ma, L.N.; Chen, D.W.; Gao, Y.S.; Zhou, Y.M.; Tang, X.J. Study on meat quality evaluation of Ningdu yellow chicken based on correlation analysis and principal component analysis. J. Food Saf. Qual. Insp. 2024, 10, 49–55. [Google Scholar]

- Su, X.Y.; Gao, T.M.; Zhang, P.Y.; Li, F.; Wu, Y.; Wang, D.Y.; Tian, Y.; Wei, S.L. A comprehensive evaluation of heat tolerance of sesame at seedling stage based on principal component analysis and membership function method. Crop J. 2023, 4, 52–59. [Google Scholar]

- Lu, K.; Zhu, G.X.; Shi, J.G.; Chai, G.H.; Dillon; Zhang, G.R.; Qin, Y.Y.; Duan, Y.Z. Evaluation of adaptability of different sea buckthorn varieties in the Yulin area. China Agric. Bull. 2021, 34, 52–58. [Google Scholar]

| Model | Model Name | Model Equations |

|---|---|---|

| Theoretical model | Page | |

| Henderson and Pabis | ||

| Lewis | ||

| Modified Page | ||

| Asymptotic | ||

| Empirical model | Wang and Singh | |

| Weibull | ||

| Geometric |

| Temp/°C | Deff/(10−6 m2/min) | Ea/kJ/mol | ∆H/kJ/mol | ∆G/kJ/mol | ∆S/kJ/(mol·K) |

|---|---|---|---|---|---|

| 60 | 1.22 | 12.26 | 9.49 | 119.62 | −0.33058 |

| 65 | 1.25 | 9.45 | 121.37 | −0.33099 | |

| 70 | 1.34 | 9.41 | 123.02 | −0.33109 | |

| 75 | 1.46 | 9.37 | 124.62 | −0.33104 | |

| 80 | 1.55 | 9.33 | 126.27 | −0.33116 |

| Model Name | Temp/°C | Model Indexes | Evaluating Indicator | |||||

|---|---|---|---|---|---|---|---|---|

| k | n | a | b | R2 | χ2 | RMSE | ||

| Page | 80 | 0.0027 | 1.2113 | 0.9929 | 9.5431 × 10−4 | 0.0095 | ||

| 75 | 0.0016 | 1.2864 | 0.9953 | 6.8295 × 10−4 | 0.0075 | |||

| 70 | 7.976 × 10−4 | 1.3566 | 0.9962 | 5.601 × 10−4 | 0.0067 | |||

| 65 | 6.327 × 10−4 | 1.3579 | 0.9977 | 3.4872 × 10−4 | 0.0049 | |||

| 60 | 5.652 × 10−4 | 1.3588 | 0.9983 | 2.5856 × 10−4 | 0.0039 | |||

| Henderson and Pabis | 80 | 0.0078 | 1.0265 | 0.9826 | 0.0023 | 0.0231 | ||

| 75 | 0.0069 | 1.0509 | 0.9826 | 0.0025 | 0.0276 | |||

| 70 | 0.0056 | 1.0612 | 0.9795 | 0.003 | 0.0358 | |||

| 65 | 0.0048 | 1.0601 | 0.985 | 0.0022 | 0.0307 | |||

| 60 | 0.0045 | 1.0633 | 0.9854 | 0.0022 | 0.0336 | |||

| Lewis | 80 | 0.0075 | 0.9827 | 0.0023 | 0.0252 | |||

| 75 | 0.0065 | 0.9791 | 0.003 | 0.0361 | ||||

| 70 | 0.0051 | 0.9737 | 0.0038 | 0.0499 | ||||

| 65 | 0.0045 | 0.9798 | 0.003 | 0.0455 | ||||

| 60 | 0.0041 | 0.9792 | 0.0032 | 0.0508 | ||||

| Modified Page | 80 | −1.981 × 10−8 | 1.464 × 10−8 | 0.9936 | 9.5408 × 10−4 | 0.0095 | ||

| 75 | −1.98 × 10−8 | 1.462 × 10−8 | 0.9953 | 6.8264 × 10−4 | 0.0075 | |||

| 70 | −1.874 × 10−8 | 1.461 × 10−8 | 0.9962 | 5.5875 × 10−4 | 0.0067 | |||

| 65 | −2.007 × 10−8 | 1.456 × 10−8 | 0.9988 | 3.4787 × 10−4 | 0.0049 | |||

| 60 | −1.998 × 10−8 | 1.454 × 10−8 | 0.9983 | 2.5728 × 10−4 | 0.0039 | |||

| Wang and Singh | 80 | −0.0057 | 8.0396 × 10−6 | 0.9983 | 2.22899 × 10−4 | 0.0022 | ||

| 75 | −0.0049 | 5.8496 × 10−6 | 0.9996 | 5.88887 × 10−5 | 6.478 × 10−4 | |||

| 70 | −0.0038 | 3.5024 × 10−6 | 0.9987 | 1.90102 × 10−4 | 0.0023 | |||

| 65 | −0.0033 | 2.7193 × 10−6 | 0.9992 | 1.14041 × 10−4 | 0.0016 | |||

| 60 | −0.0030 | 2.2874 × 10−6 | 0.999 | 1.67368 × 10−4 | 0.0025 | |||

| Geometric | 80 | 0.4346 | 3.0187 | 0.0308 | 0.1283 | 1.2833 | ||

| 75 | 0.4324 | 3.1706 | 0.1523 | 0.1224 | 1.3469 | |||

| 70 | 0.3986 | 3.0237 | 0.1862 | 0.1185 | 1.4215 | |||

| 65 | 0.3992 | 3.1018 | 0.291 | 0.1067 | 1.494 | |||

| 60 | 0.3973 | 3.1405 | 0.3296 | 0.1025 | 0.3973 | |||

| Temp/°C | Chlorophyll a | Chlorophyll b | Carotenoid |

|---|---|---|---|

| 60 | 2.02 ± 0.03 a | 1.66 ± 0.06 a | 0.89 ± 0.01 a |

| 65 | 1.66 ± 0.02 b | 0.86 ± 0.05 b | 0.73 ± 0.01 b |

| 70 | 1.03 ± 0.73 c | 0.45 ± 0.34 bc | 0.44 ± 0.31 c |

| 75 | 1.01 ± 0.06 c | 0.43 ± 0.08 c | 0.42 ± 0.01 c |

| 80 | 0.99 ± 0.07 c | 0.34 ± 0.24 c | 0.42 ± 0.3 c |

| Number | Eigenvalue | Percentage Variance of Initial Eigenvalue | Cumulative Variance Contribution |

|---|---|---|---|

| 1 | 6.205 | 51.709 | 51.709 |

| 2 | 2.000 | 16.664 | 68.374 |

| 3 | 1.711 | 14.257 | 82.631 |

| 4 | 1.213 | 10.110 | 92.741 |

| Temp/°C | L | a | b | ΔE | RR | Total Flavonoids | Total Phenols |

| 60 | 80.88 ± 0.42 | 0.33 ± 0.02 | 24.57 ± 0.07 | 12.19 ± 0.31 | 4.78 ± 0.05 | 2.93 ± 0.03 | 4.08 ± 0.13 |

| 65 | 80.62 ± 0.34 | 0.33 ± 0.02 | 24.57 ± 0.06 | 12.00 ± 0.17 | 4.73 ± 0.12 | 4.13 ± 0.02 | 4.27 ± 0.02 |

| 70 | 81.11 ± 0.16 | −0.36 ± 0.04 | 24.19 ± 0.15 | 11.90 ± 0.06 | 4.85 ± 0.13 | 3.94 ± 0.02 | 3.64 ± 0.02 |

| 75 | 82.15 ± 0.24 | 0.15 ± 0.01 | 24.47 ± 0.35 | 13.03 ± 0.34 | 4.95 ± 0.16 | 5.28 ± 0.05 | 3.53 ± 0.02 |

| 80 | 83.55 ± 0.34 | 1.27 ± 0.13 | 23.8 ± 0.11 | 14.28 ± 0.29 | 4.68 ± 0.18 | 6.17 ± 0.05 | 3.60 ± 0.02 |

| Temp/°C | VC | Soluble protein | Chlorophyll a | Chlorophyll b | Carotenoid | The mean value of the membership function | Integrated ranking |

| 60 | 0.31 ± 0.01 | 8.75 ± 0.04 | 2.02 ± 0.03 | 1.66 ± 0.06 | 0.89 ± 0.01 | 0.82 | 1 |

| 65 | 0.36 ± 0.01 | 10.16 ± 0.08 | 1.66 ± 0.02 | 0.86 ± 0.05 | 0.73 ± 0.01 | 0.70 | 2 |

| 70 | 0.32 ± 0.01 | 8.41 ± 0.12 | 1.03 ± 0.73 | 0.45 ± 0.34 | 0.44 ± 0.31 | 0.44 | 4 |

| 75 | 0.34 ± 0.01 | 10.87 ± 0.07 | 1.01 ± 0.06 | 0.43 ± 0.08 | 0.42 ± 0.01 | 0.57 | 3 |

| 80 | 0.26 ± 0.01 | 10.53 ± 0.04 | 0.99 ± 0.07 | 0.34 ± 0.24 | 0.42 ± 0.30 | 0.26 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.; Yu, Y.; Yao, C.; Zhou, L.; Zhu, G.; Lai, Y.; Niu, P. Effect of Far-Infrared Drying on Broccoli Rhizomes: Drying Kinetics and Quality Evaluation. Processes 2024, 12, 1674. https://doi.org/10.3390/pr12081674

Zhang G, Yu Y, Yao C, Zhou L, Zhu G, Lai Y, Niu P. Effect of Far-Infrared Drying on Broccoli Rhizomes: Drying Kinetics and Quality Evaluation. Processes. 2024; 12(8):1674. https://doi.org/10.3390/pr12081674

Chicago/Turabian StyleZhang, Gen, Yun Yu, Chunyu Yao, Lang Zhou, Guangyao Zhu, Yushu Lai, and Po Niu. 2024. "Effect of Far-Infrared Drying on Broccoli Rhizomes: Drying Kinetics and Quality Evaluation" Processes 12, no. 8: 1674. https://doi.org/10.3390/pr12081674