Novel Efficiency Calculation Model Based on Fine Particle Tracking Behavior

Abstract

1. Introduction

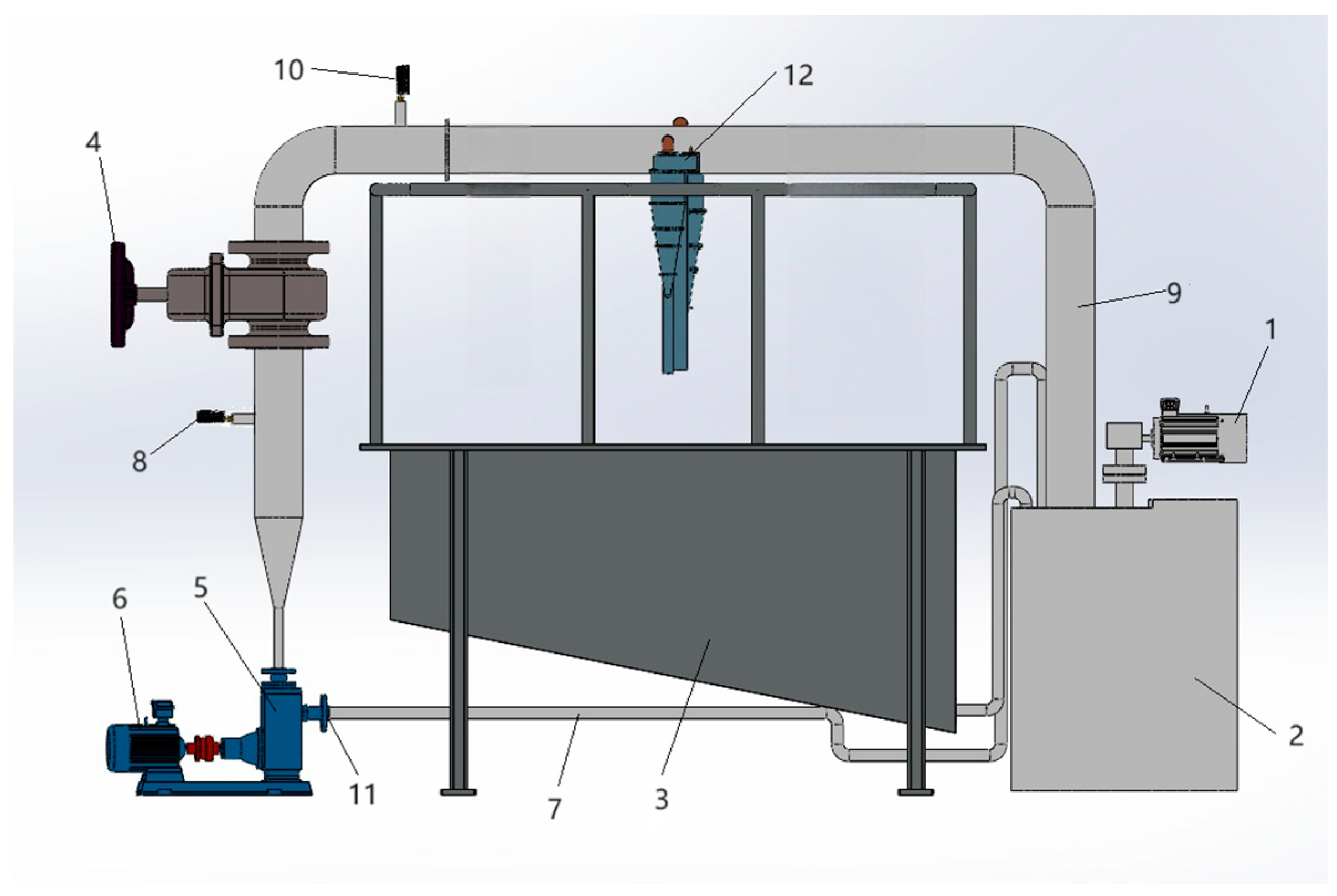

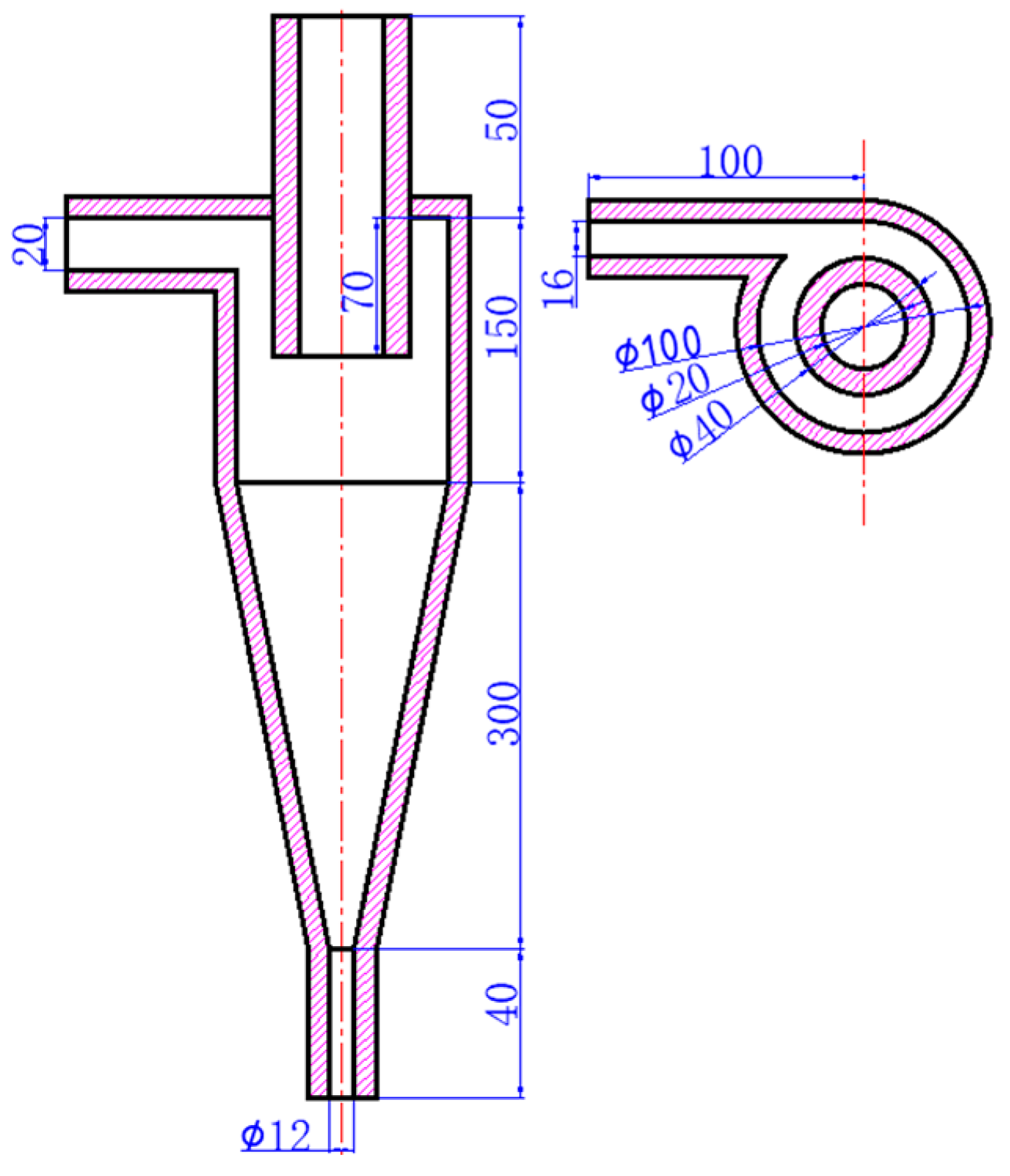

2. Materials and Methods

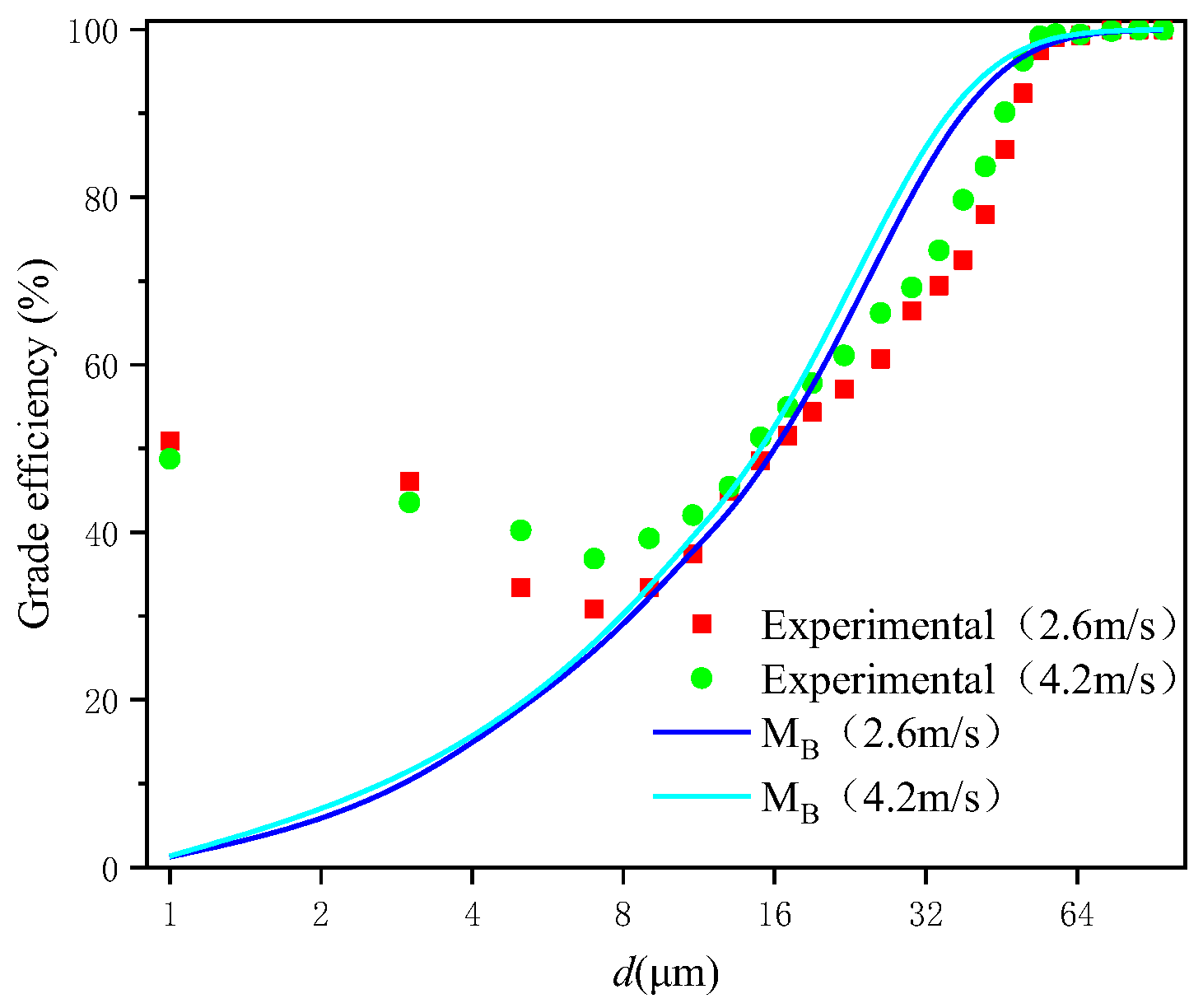

3. Experimental Results

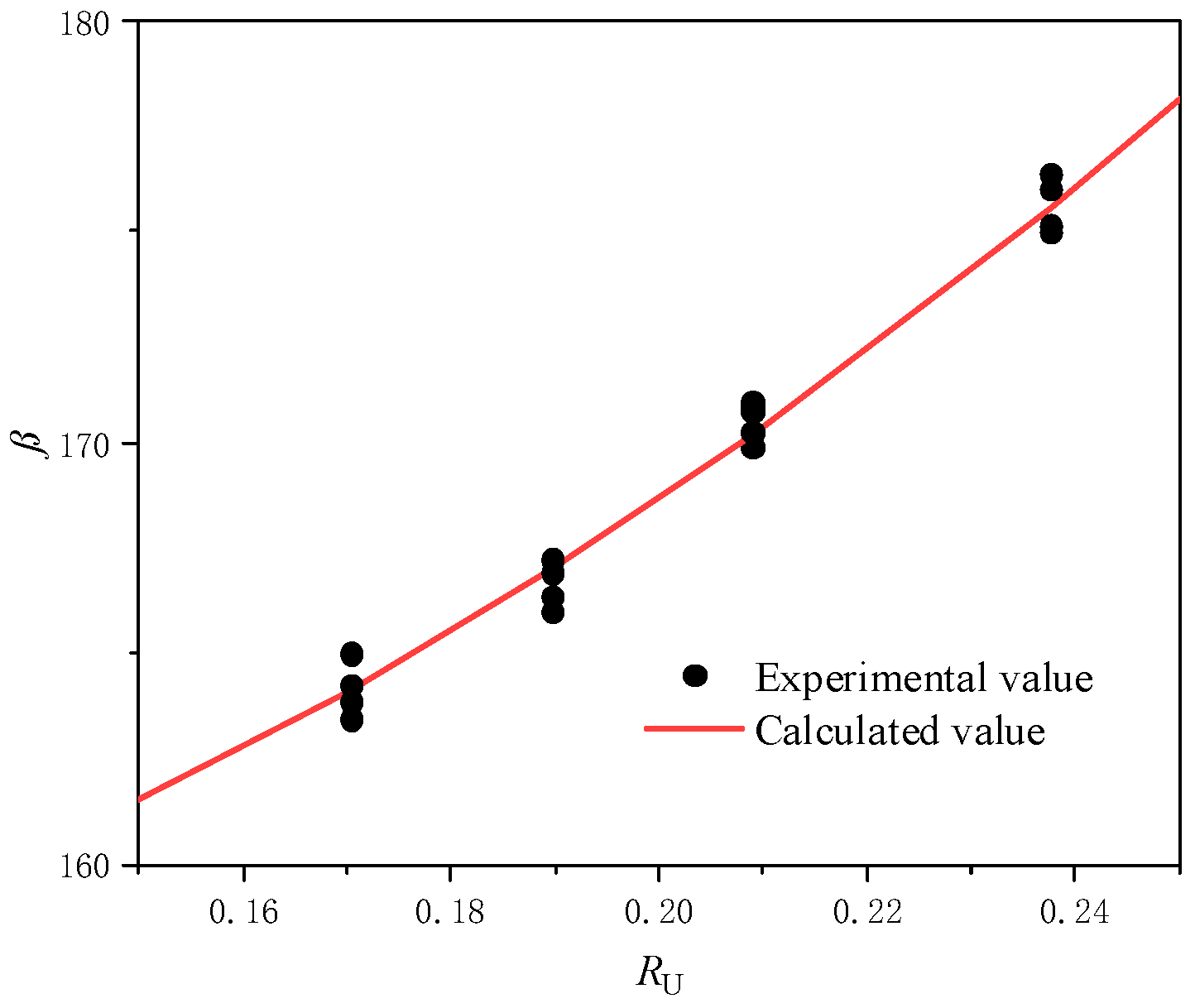

4. Model Analysis and Correction Methods

4.1. Tracking Coefficient

4.2. Entrainment Coefficient

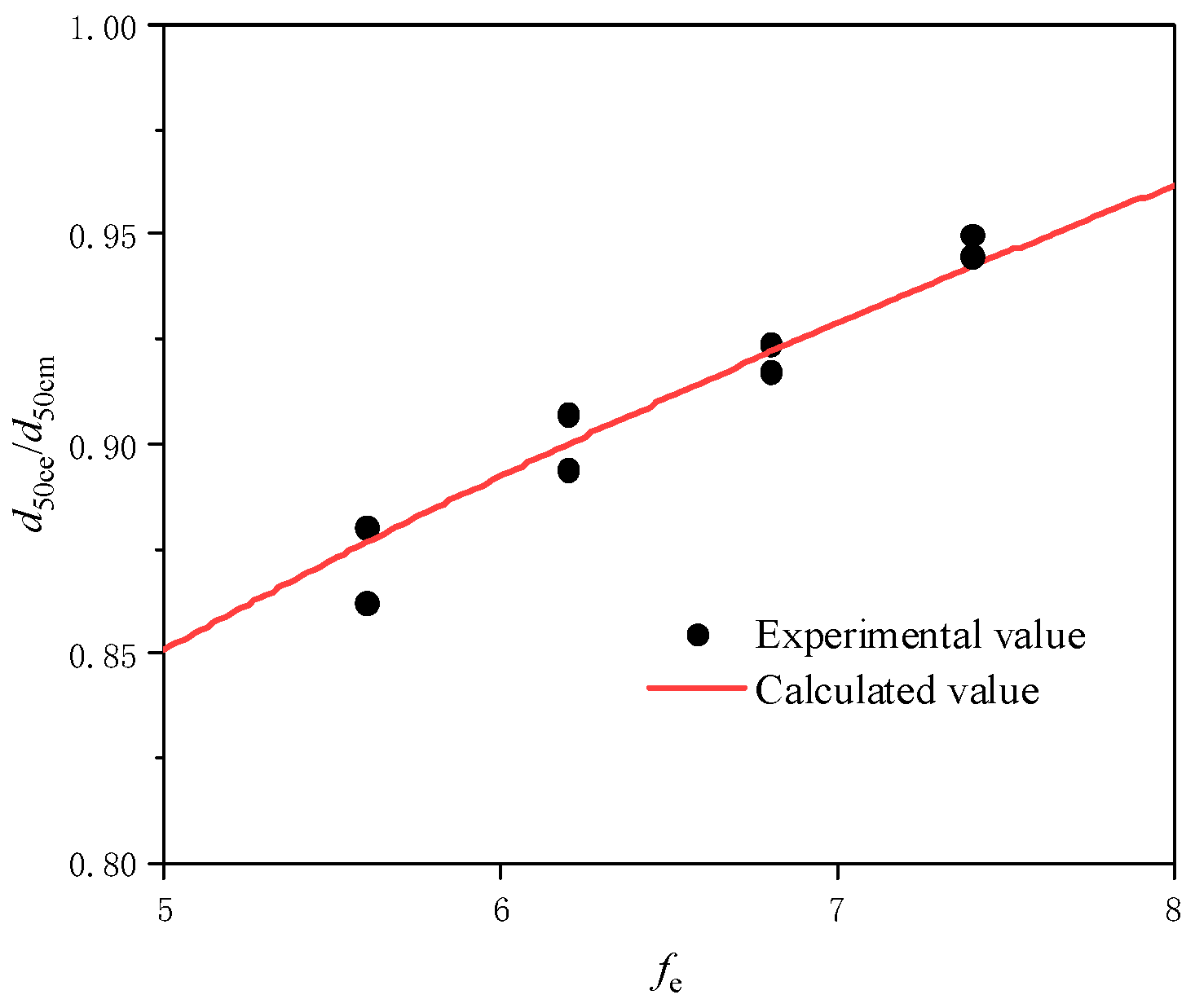

4.3. Cut Size d50c

4.4. Model Formulation

5. Validation of Proposed Model

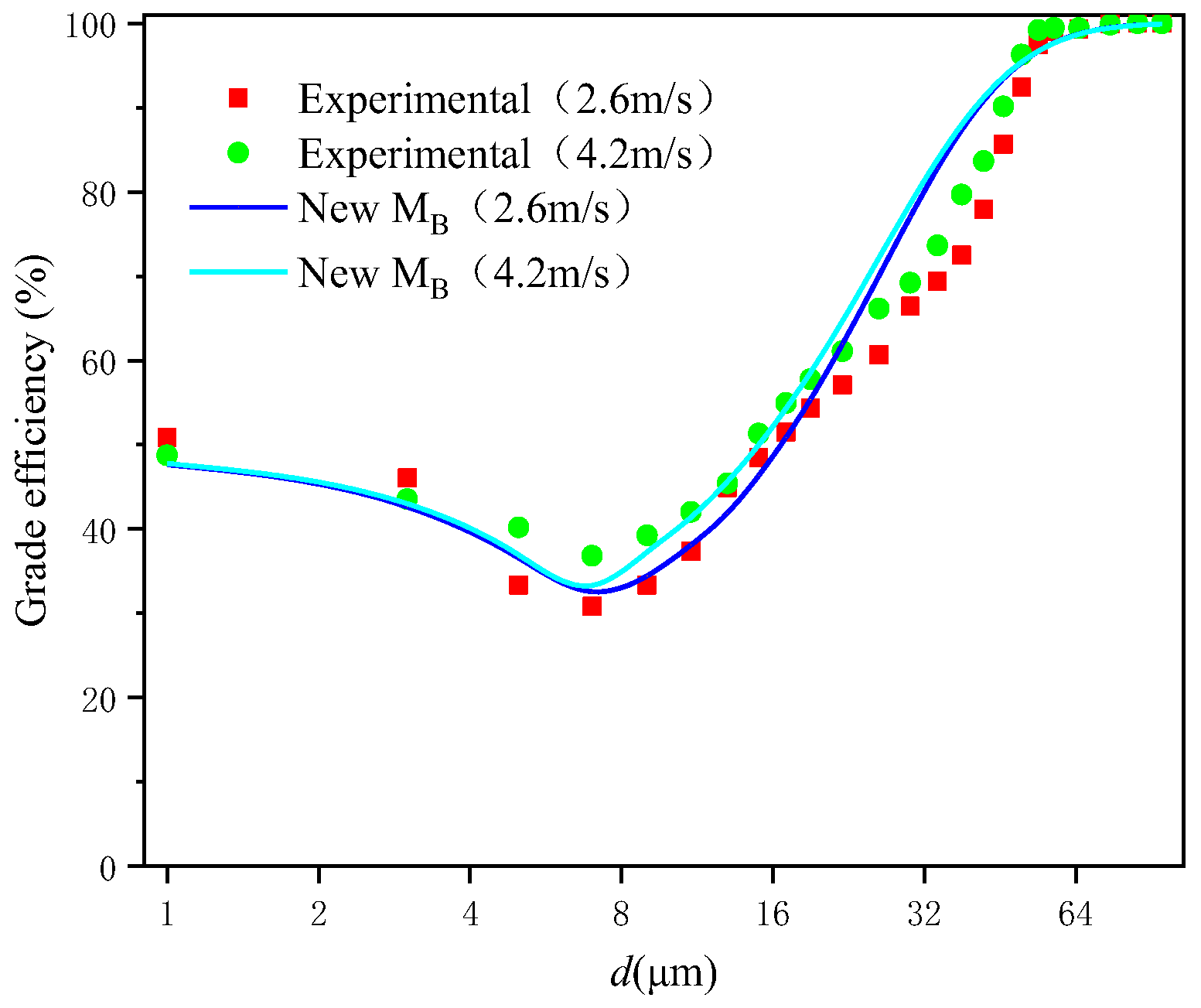

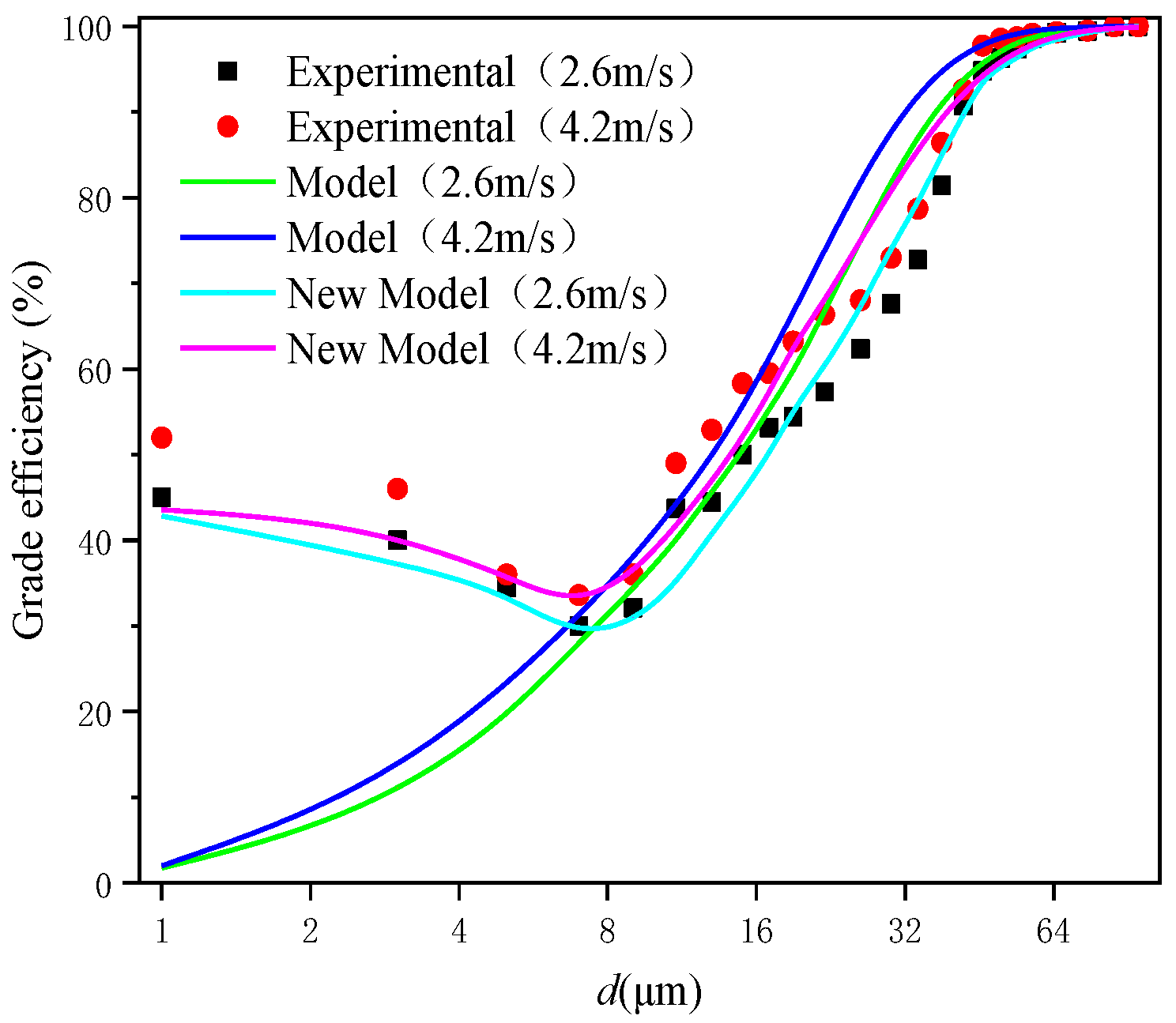

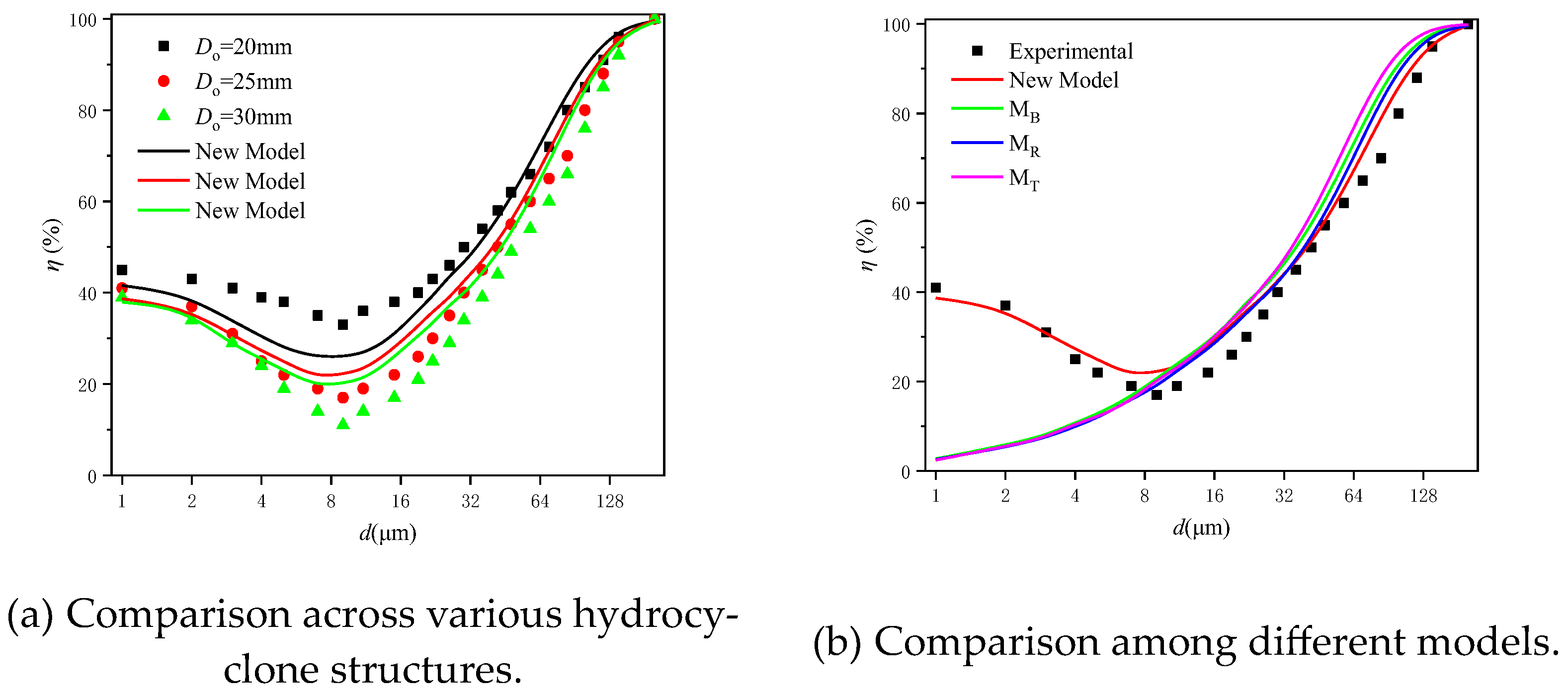

5.1. Comparison and Verification with Experimental Results

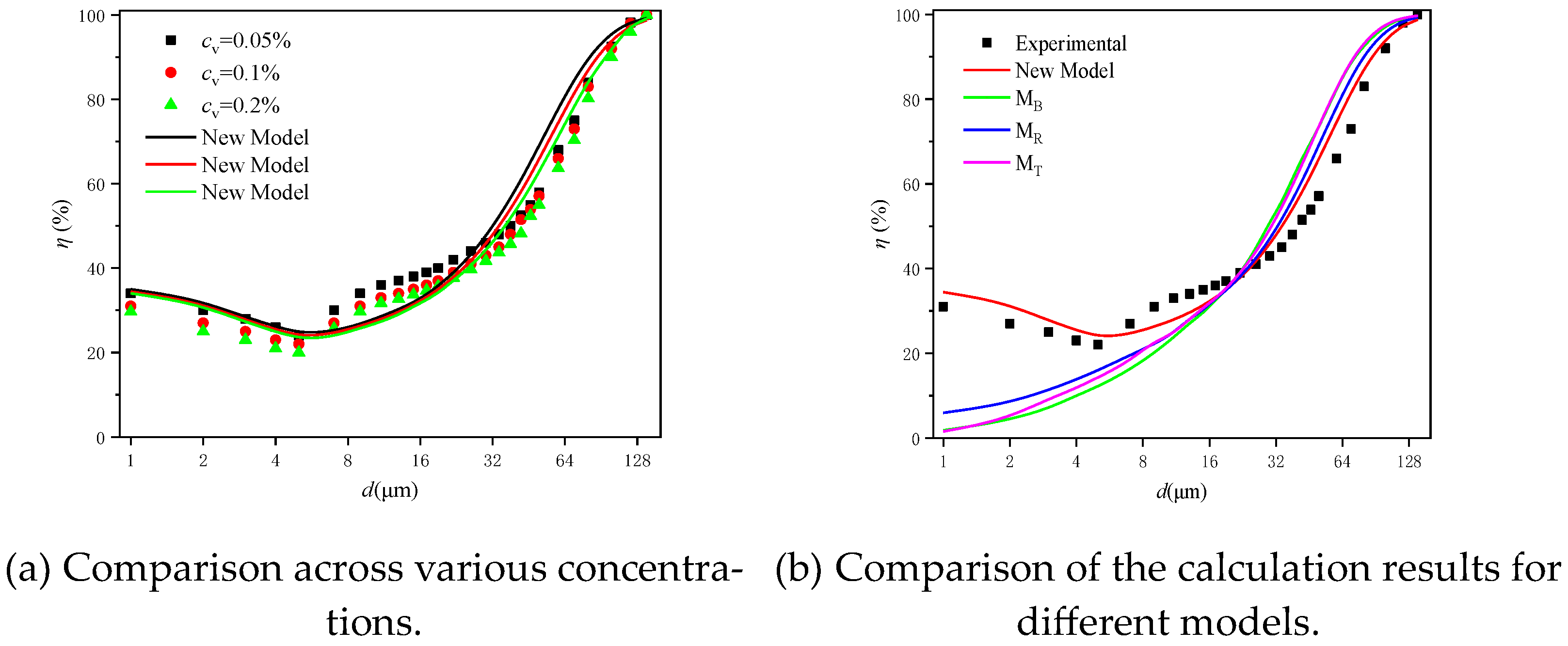

5.2. Verification of Proposed Model

6. Conclusions

- (1)

- The proposed model leverages changes in centrifugal settling velocity to describe how underflow entrainment affects the separation performance of particles. Specifically, large particles experience a decrease in velocity due to the entrainment effect while small particles increase in velocity due to the tracking effect. These effects on particle velocity can be quantified using tracking and entrainment coefficients. The relationship between these coefficients and factors such as the structure of the hydrocyclone, operating conditions, and particle properties was successfully expressed through theoretical analysis and mathematical fitting.

- (2)

- Experimental results showed that, compared to the original model, the proposed model’s efficiency calculations aligned more closely with experimental values and could accurately compute grade efficiency curves, including their fishhook segments. The model was validated based on experimental data from previous studies, demonstrating that despite variations in hydrocyclone structures, particle types, and particle concentrations, the proposed model captured the influence of various parameters and delivered consistently accurate calculation results.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cilliers, J.; Diaz-Anadon, L.; Wee, F. Temperature, classification and dewatering in 10 mm hydrocyclones. Miner. Eng. 2004, 17, 591–597. [Google Scholar] [CrossRef]

- Tang, X. Influence of feed rate on the performance of hydrocyclone flow field. Separations 2022, 9, 349. [Google Scholar] [CrossRef]

- Zhao, Q.; Cui, B.; Zou, G.; Song, T.; Yang, T.; Zhou, J.; Shen, Y. Evaluation and improvement of mathematical models for hydrocyclone classifiers part I: Laboratory scale. Powder Technol. 2023, 427, 118718. [Google Scholar] [CrossRef]

- Xia, Y.; Deng, S.; Gu, M.; Jiao, G.; Zhang, F. Field simulation of liquid-liquid hydrocyclone based on large eddy theory. DBLP 2009, 62, 901. [Google Scholar] [CrossRef]

- Padhi, M.; Kumar, M.; Mangadoddy, N. Understanding the bicomponent particle separation mechanism in a hydrocyclone using a computational fluid dynamics model. Ind. Eng. Chem. Res. 2020, 59, 11621–11644. [Google Scholar] [CrossRef]

- Alper, N.; Okay, A. Considering hydrocyclone operation for tailings dewatering purpose and its effects on product specifications of paste backfill operations. Miner. Eng. 2021, 173, 107176. [Google Scholar] [CrossRef]

- Liu, P.; Fu, W.; Jiang, L. The separation performance of a parabolic hydrocyclone in separating iron from red mud. Powder Technol. 2023, 416, 118205. [Google Scholar] [CrossRef]

- Nageswararao, K.; Karri, B. Fish hook in classifier efficiency curves: An update. Sep. Purif. Technol. 2015, 158, 31–38. [Google Scholar] [CrossRef][Green Version]

- Izquierdo, J.; Sukunza, X.; Espinazo, P.; Vicente, J.; Aguado, R.; Olazar, M. Quantitative assessment of the prominence of fish hooks in hydrocyclones over different operation and geometrical parameters. Powder Technol. 2024, 431, 119079. [Google Scholar] [CrossRef]

- Zhang, Y.; Cai, P.; Jiang, F.; Dong, K.; Jiang, Y.; Wang, B. Understanding the separation of particles in a hydrocyclone by force analysis. Powder Technol. 2017, 322, 471–489. [Google Scholar] [CrossRef]

- Zhu, G.; Liow, J. Experimental study of particle separation and the fishhook effect in a mini-hydrocyclone. Chem. Eng. Sci. 2014, 111, 94–105. [Google Scholar] [CrossRef]

- Chen, Q.; Zhuang, Y.; Zhao, J.; Li, B.; Fan, W. Study on the impedance dynamics and control of the active suspensions based on the equilibrium trajectory error. J. Vib. Control. 2023, 29, 479–491. [Google Scholar] [CrossRef]

- Bram, M.; Hansen, L.; Hansen, D.; Yang, Z. Hydrocyclone separation efficiency modeled by flow resistances and droplet trajectories. IFAC-Pap. Line 2018, 51, 132–137. [Google Scholar] [CrossRef]

- Zeng, X.; Fan, G.; Wang, M.; Zhao, L.; Yan, C. Experimental and numerical study on the length of LZVV in the bubble separator for molten salt reactor. Nucl. Eng. Des. 2023, 401, 112100. [Google Scholar] [CrossRef]

- Zhao, Q.; Cui, B.; Ji, A.; Song, T.; Shen, Y. Experimental and numerical study of the effect of particle size distribution on hydrocyclone classification. Adv. Powder Technol. 2024, 35, 104398. [Google Scholar] [CrossRef]

- Schubert, H. On the Origin of “Anomalous” Shapes of the Separation Curve in Hydrocyclone Separation of Fine Particles. Part. Sci. Technol. 2004, 22, 219–234. [Google Scholar] [CrossRef]

- Patra, G.; Chakraborty, S.; Meikap, B. Role of vortex finder depth on pressure drop and performance efficiency in a ribbed hydrocyclone. South Afr. J. Chem. Eng. 2018, 25, 103–109. [Google Scholar] [CrossRef]

- Kashiwaya, K.; Noumachi, T.; Hiroyoshi, N.; Ito, M.; Tsunekawa, M. Effect of particle shape on hydrocyclone classification. Powder Technol. 2012, 226, 147–156. [Google Scholar] [CrossRef]

- Dueck, G.; Minkov, L.; Pikushchak, V. Modeling of the fish-hook-effect in a classifier. J. Eng. Phys. Thermophys. 2007, 80, 64–73. [Google Scholar] [CrossRef]

- Majumder, A.; Shah, H.; Shukla, P. Effect of operating variables on shape of “fish-hook” curves in cyclones. Miner. Eng. 2007, 20, 204–206. [Google Scholar] [CrossRef]

- Eswaraiah, C.; Angadi, S.; Mishra, B. Mechanism of particle separation and analysis of fish-hook phenomenon in a circulating air classifier. Powder Technol. 2012, 218, 57–63. [Google Scholar] [CrossRef]

- Padhi, M.; Mangadoddy, N.; Sreenivas, T.; Vakamalla, T.R.; Mainza, A.N. Study on multi-component particle behaviour in a hydrocyclone classifier using experimental and computational fluid dynamics techniques. Sep. Purif. Technol. 2019, 229, 115698. [Google Scholar] [CrossRef]

- Wan, Z.; Zhou, K.; Yang, W.; You, Z.; Sun, K. Effect of rotational diffusion of anisotropic particles on the stability of a suspension shear flow. Fluid Dyn. Res. 2019, 51, 035507. [Google Scholar] [CrossRef]

- Tian, J.; Wang, H.; Lv, W.; Huang, Y.; Fu, P.; Li, J.; Liu, Y. Enhancement of pollutants hydrocyclone separation by adjusting back pressure ratio and pressure drop ratio. Sep. Purif. Technol. 2020, 240, 116604. [Google Scholar] [CrossRef]

- Spelay, B.; Hashemi, A.; Gillies, G.; Sanders, R.S. A multispecies 1D concentration distribution model for coarse-particle slurries. Can. J. Chem. Eng. 2022, 100, 2245–2258. [Google Scholar] [CrossRef]

- Qin, F.; Ping, Z.; Gang, J. Modeling on Hydrocyclone Separation Performance by Neural Network. Appl. Mech. Mater. 2011, 105–107, 185–188. [Google Scholar] [CrossRef]

- Muthukrishnan, R.; Kalaivani, S. Data depth approach in fitting linear regression models. Mater. Today Proc. 2022, 57, 2212–2215. [Google Scholar] [CrossRef]

- Cao, M.; Chen, J.; Hu, B.; Fan, X.; Cui, H.; Wei, Y. Measurements of particle velocity and solid concentration near the wall of a cyclone using high-speed particle shadow velocimetry. Powder Technol. 2023, 426, 226–237. [Google Scholar] [CrossRef]

- Rahimi, M.; Abdollahzadeh, A.; Rezai, B. The Effect of Particle Size, pH, and Flocculant Dosage on the Gel Point, Effective Solid Stress, and Thickener Performance of a Coal-Washing Plant. Int. J. Coal Prep. Util. 2015, 35, 125–142. [Google Scholar] [CrossRef]

- Jiang, L.; Liu, P.; Yang, X.; Zhang, Y.; Li, X.; Zhang, Y.; Wang, H. Effect of Overflow Pipe on the Internal Flow Fields and Separation Performance of W-Shaped Hydrocyclones. Minerals 2020, 10, 329. [Google Scholar] [CrossRef]

| Particles | D50 | Density | Sphericity |

|---|---|---|---|

| Quartz | 35.76 μm | 2.7 g/cm3 | 0.74 |

| Glass frit | 40.52 μm | 2.56 g/cm3 | 0.98 |

| Structure Parameters | Abdollahzadeh (mm) | Jiang (mm) |

|---|---|---|

| D | 15 | 75 |

| Din | 4.2 | 18 |

| Do | 5.1 | 25 |

| H1 | 5 | 120 |

| H2 | 79 | 97 |

| Du | 3 | 15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Chen, J.; Cui, H.; Ma, X.; Zhang, H.; Shan, Y. Novel Efficiency Calculation Model Based on Fine Particle Tracking Behavior. Processes 2024, 12, 1710. https://doi.org/10.3390/pr12081710

Liu X, Chen J, Cui H, Ma X, Zhang H, Shan Y. Novel Efficiency Calculation Model Based on Fine Particle Tracking Behavior. Processes. 2024; 12(8):1710. https://doi.org/10.3390/pr12081710

Chicago/Turabian StyleLiu, Xiulin, Jianyi Chen, Hao Cui, Xiao Ma, Hongbin Zhang, and Yongrui Shan. 2024. "Novel Efficiency Calculation Model Based on Fine Particle Tracking Behavior" Processes 12, no. 8: 1710. https://doi.org/10.3390/pr12081710

APA StyleLiu, X., Chen, J., Cui, H., Ma, X., Zhang, H., & Shan, Y. (2024). Novel Efficiency Calculation Model Based on Fine Particle Tracking Behavior. Processes, 12(8), 1710. https://doi.org/10.3390/pr12081710