Development of the Design of Plate with Variable Diameters of Holes and Its Impact on Meat-Grinding Quality and Efficiency

Abstract

1. Introduction

2. Materials and Methods

2.1. Meat Samples

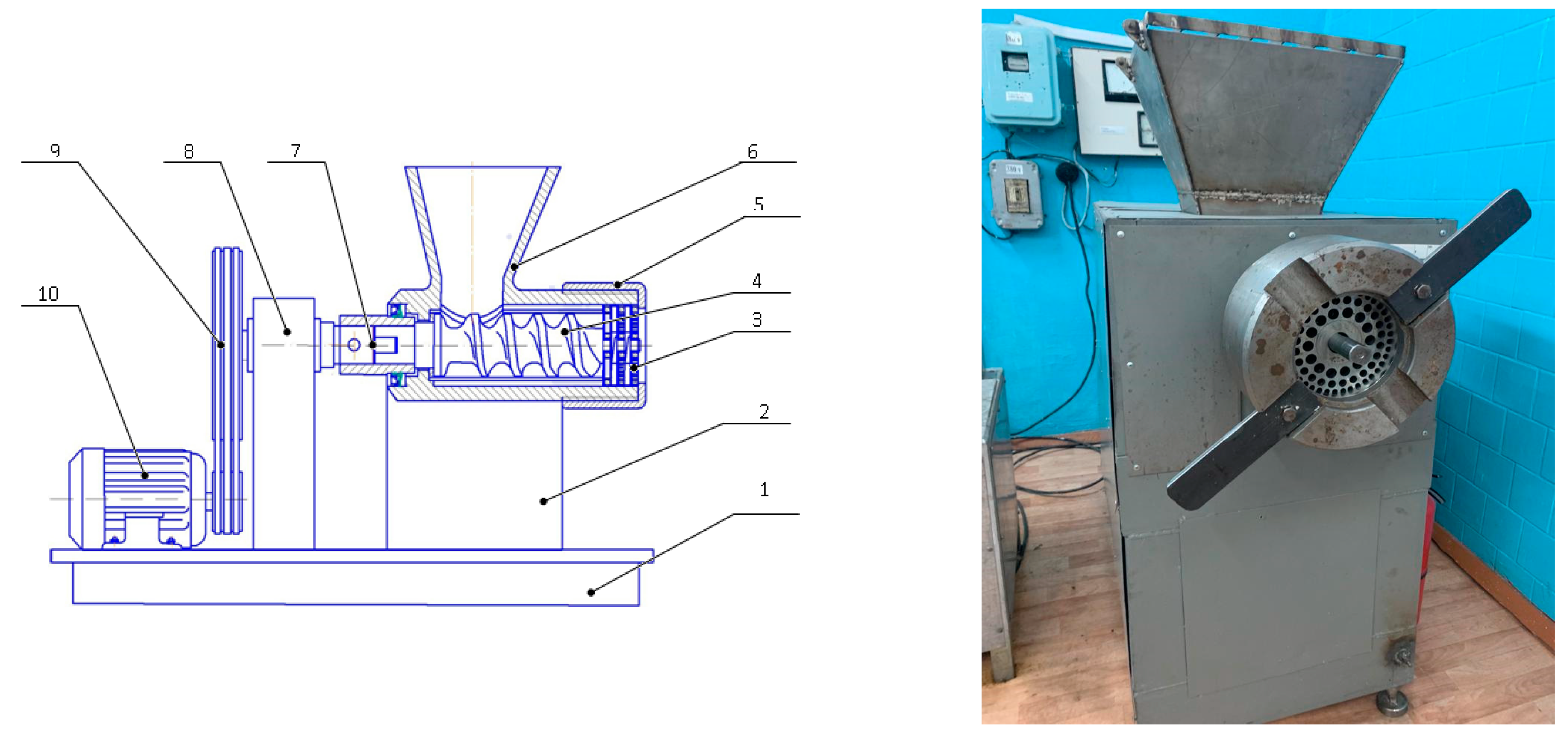

2.2. Description of the Experimental Meat Grinder

2.3. Scheme of Experiments

- Determination of Chemical Composition

- Determination of Water-Binding Capacity

- Determination of Yield Stress

- Determination of Meat-Grinder Energy Characteristics

- Determination of Particle Size Distribution

- Calculation of the Flow Capacity of a Meat-Grinder Plate Based on the Hagen–Poiseuille Equation

- Statistics

3. Results

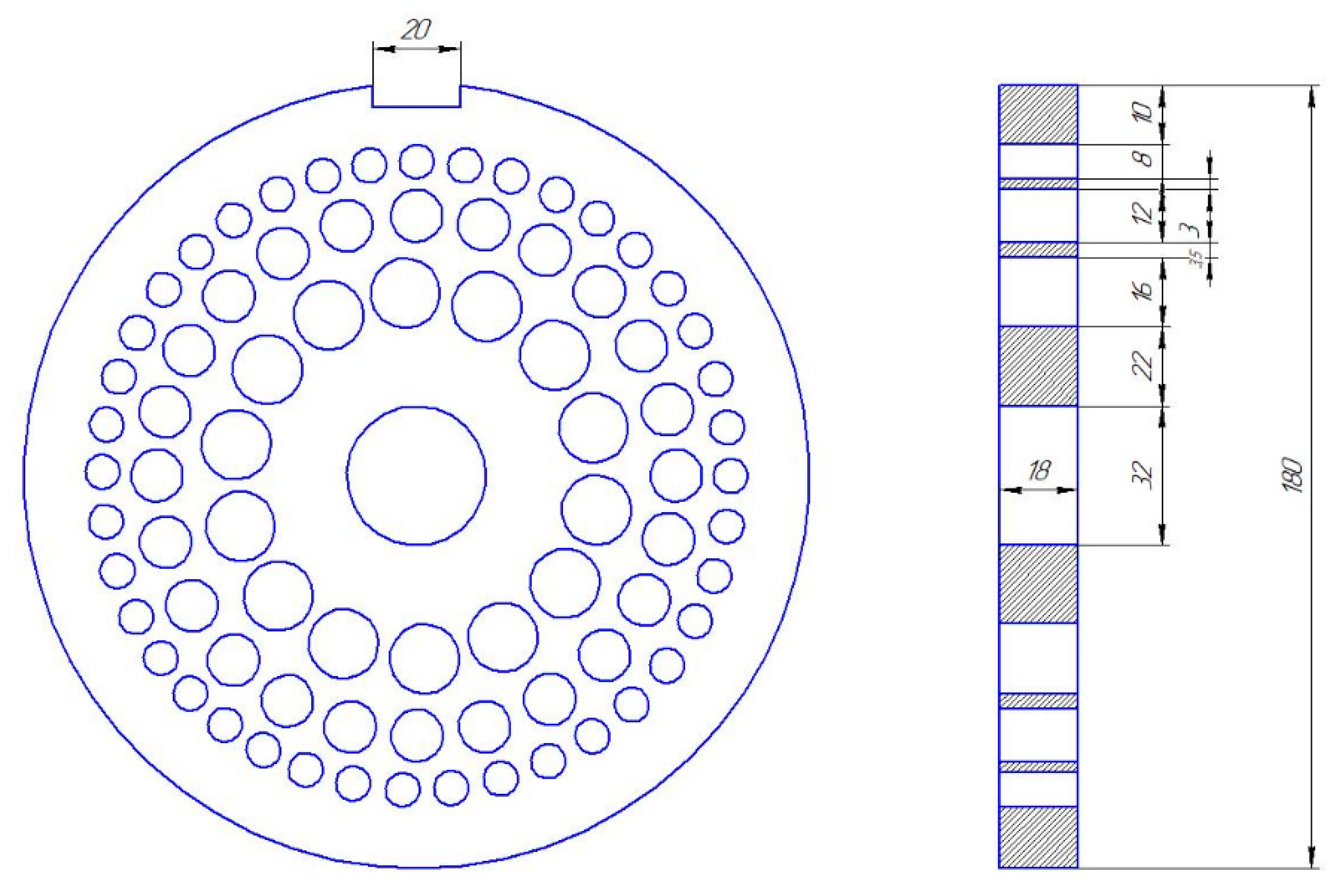

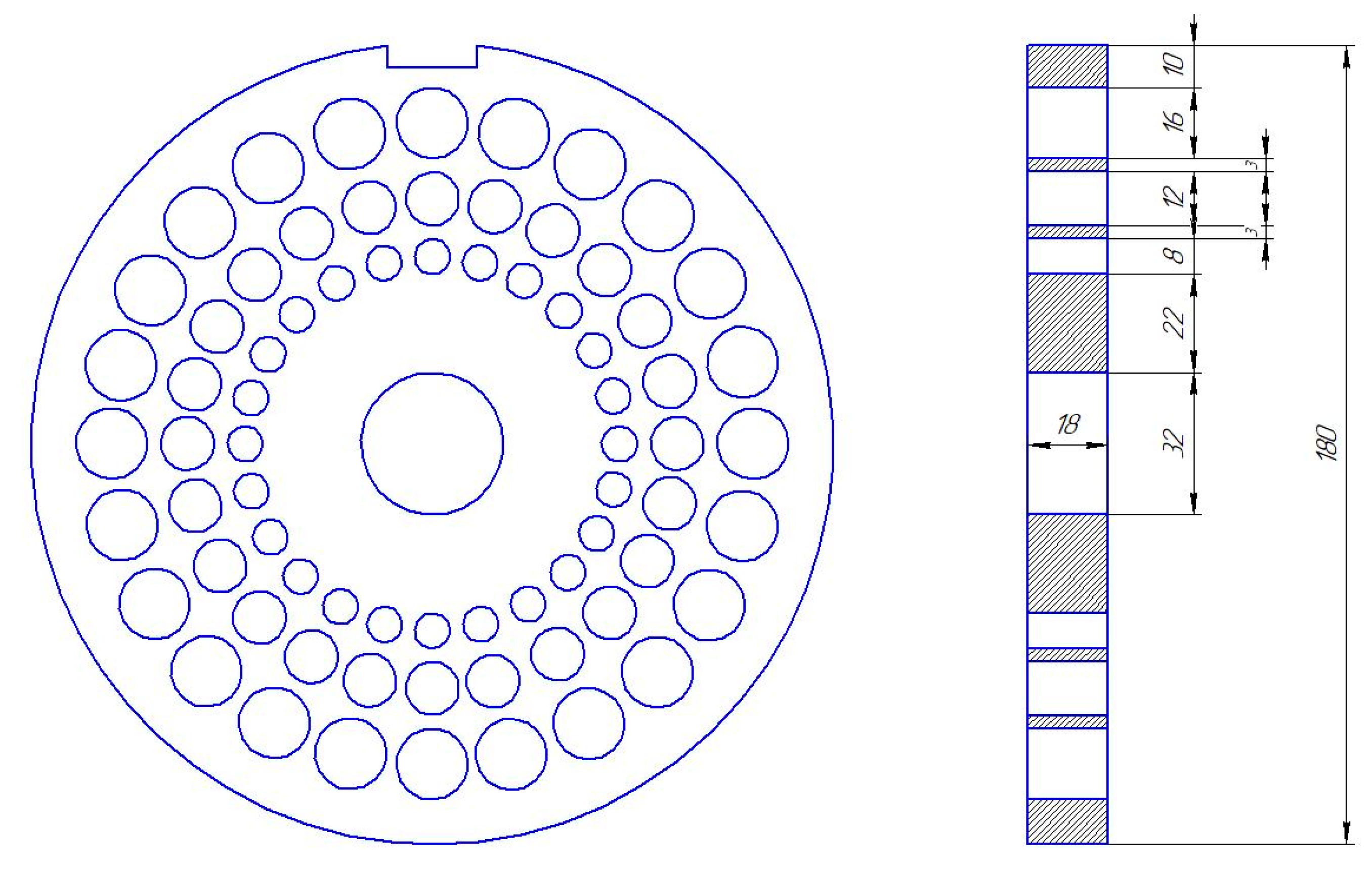

3.1. Design and Calculation of the Throughput Capacity of a Meat-Grinder Plate

3.2. Studying the Chemical Composition of Meat

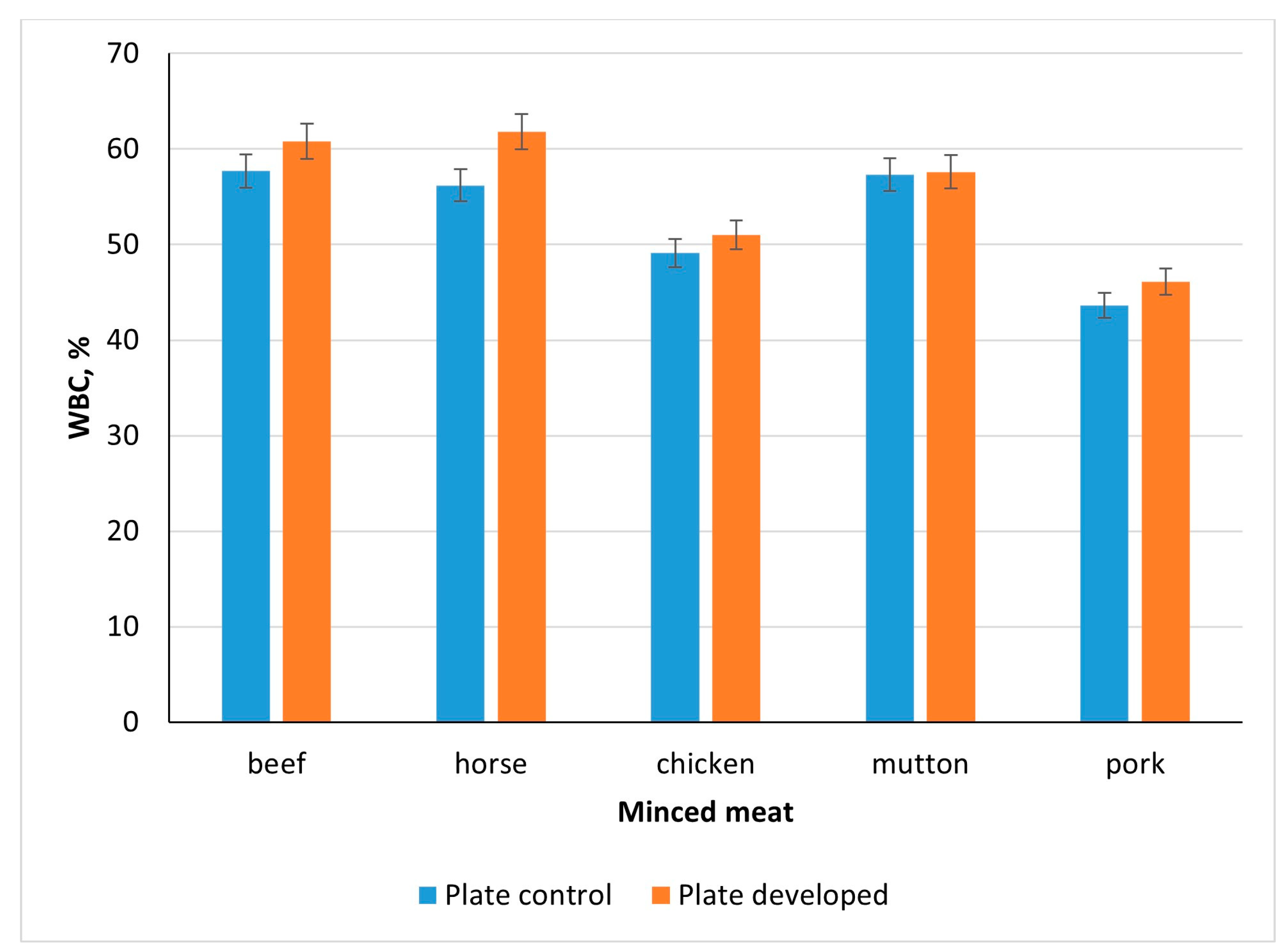

3.3. Investigation of the Effect of the Developed Plate on the Change of Water-Binding Capacity of Minced Meat

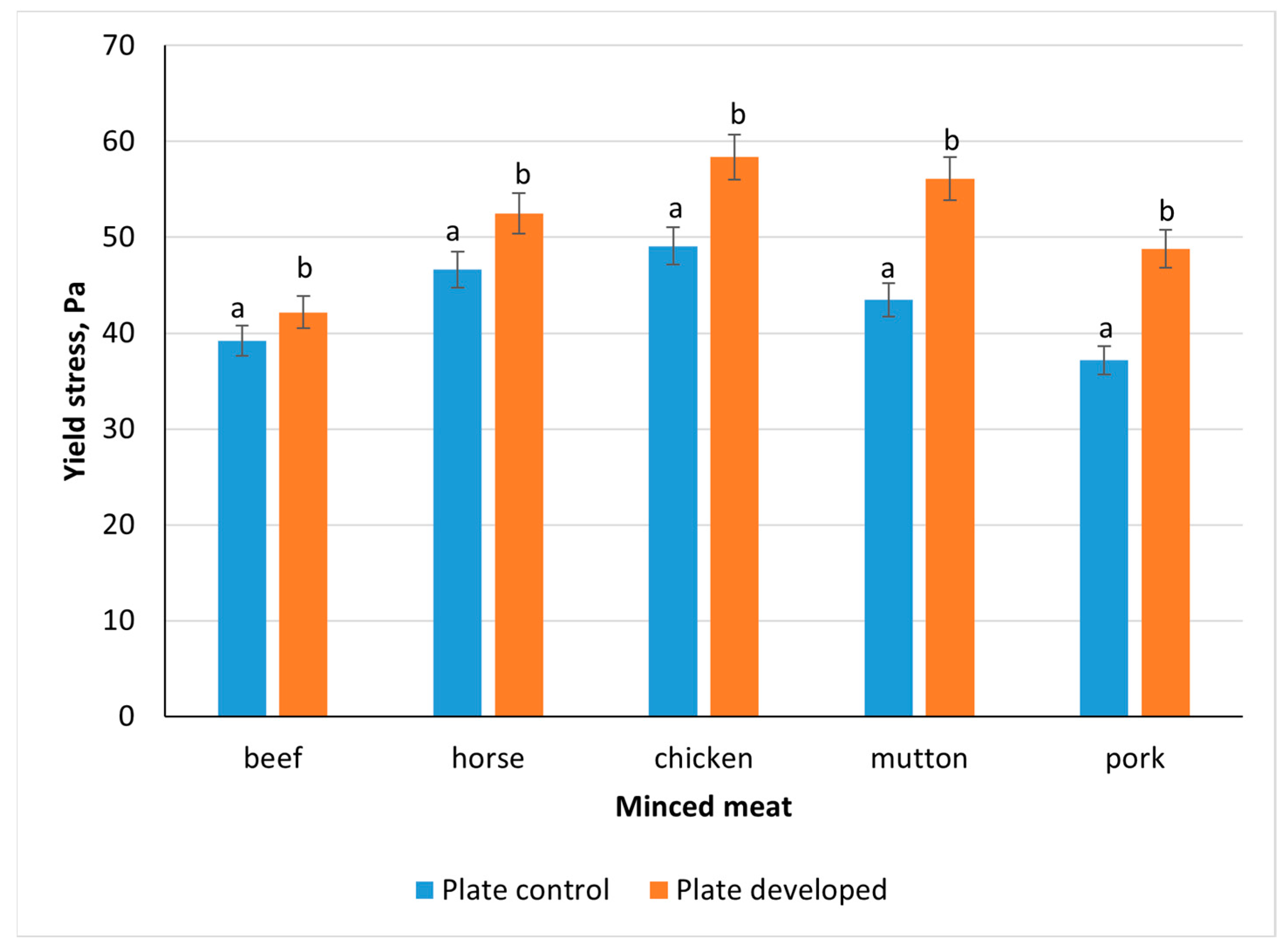

3.4. The Impact of Grinder Plate Design on Changes in the Yield Stress of Minced Meat

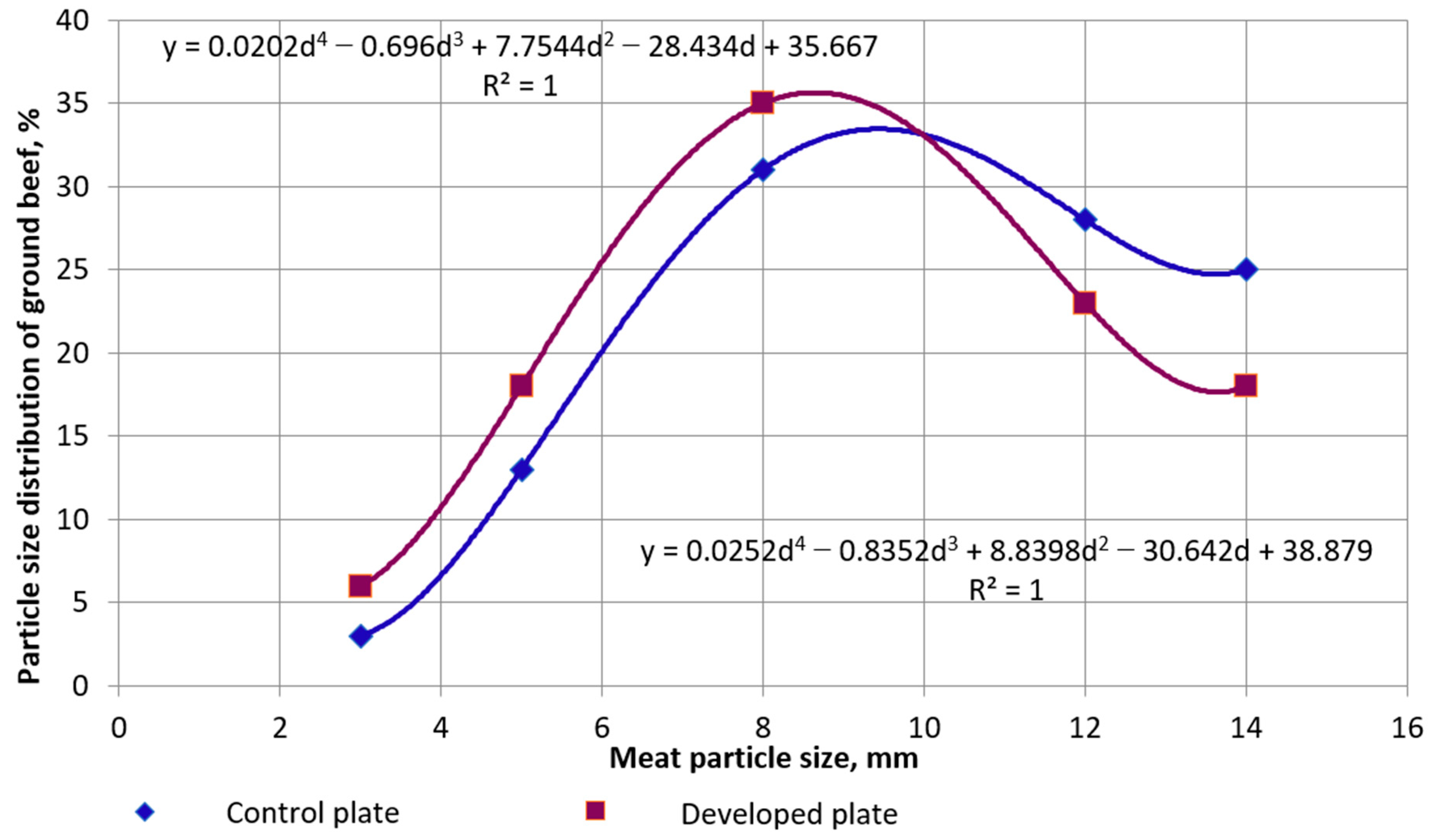

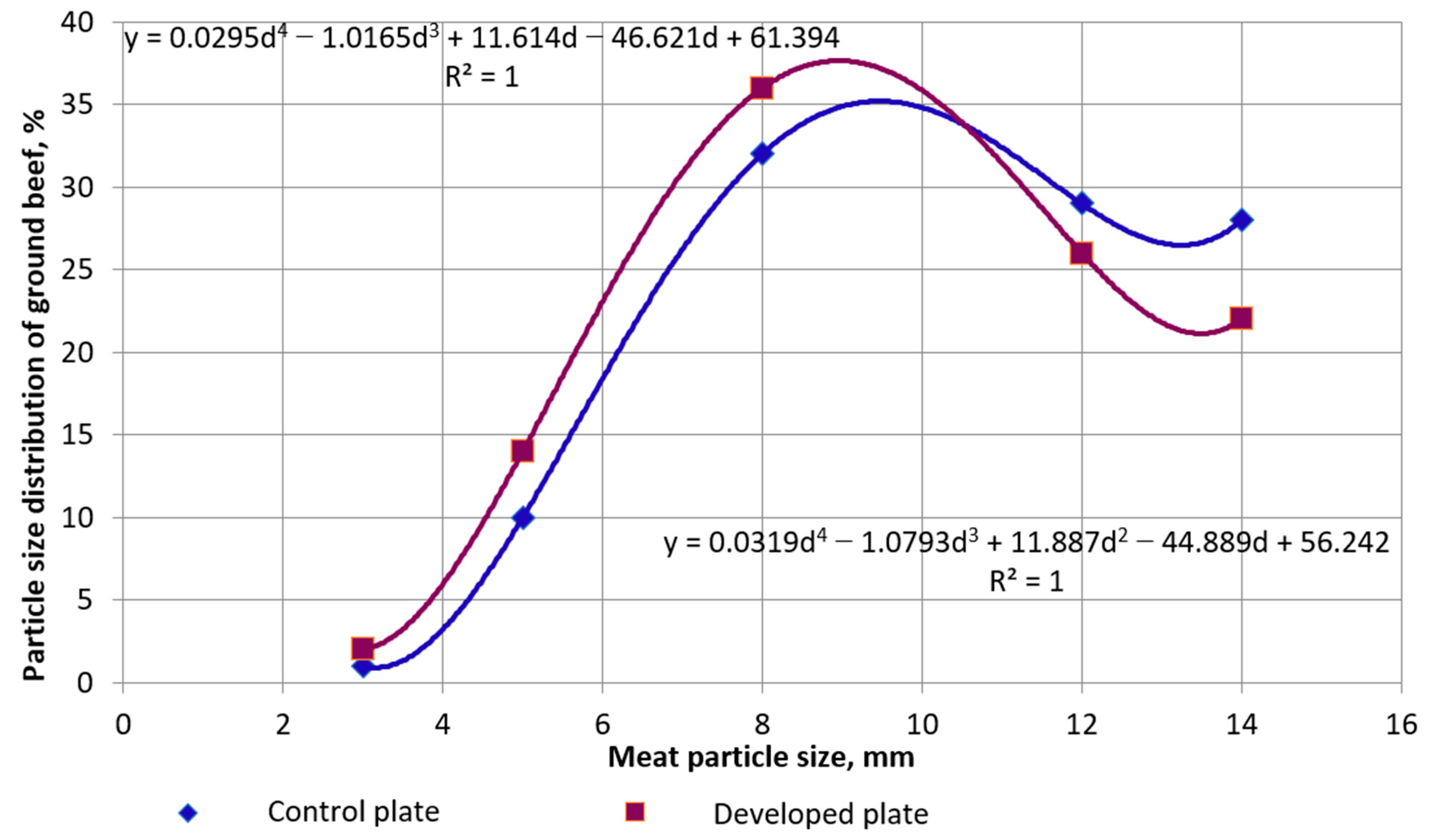

3.5. Effect of Cutting Mechanism Design on Changes in the Particle Size Distribution of Minced Meat

3.6. Effect of Plate Design on the Variation of Meat-Grinder Performance

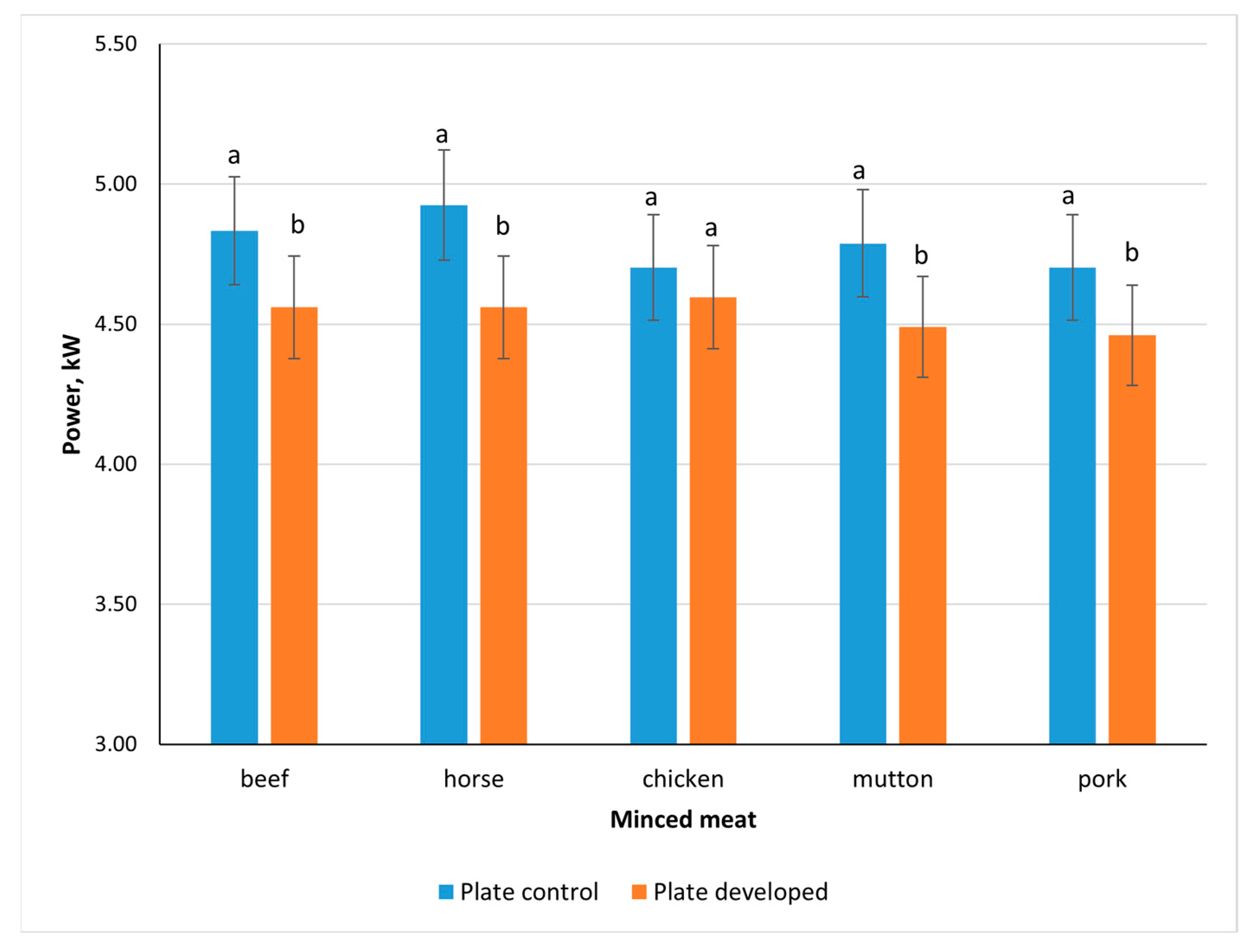

3.7. Effect of Plate Design on the Variation of Power Consumption of a Meat Grinder

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Soladoye, O.P. Meat and meat products processing. In Food Science and Technology; Durban University of Technology, Ed.; De Gruyter: Berlin, Germany, 2021. [Google Scholar]

- Kapovsky, B.; Zakharov, A.; Nikitina, M. Intelligent control system for minced meat production. Potravin. Slovak J. Food Sci. 2020, 14, 750–758. [Google Scholar] [CrossRef]

- Abilmazhinov, Y.; Abdilova, G.; Rebezov, M.; Zalilov, R.; Nesterenko, A.; Khayrullin, M.; Morozova, R.; Mikolaychik, I.; Ponomarev, E.; Kulikov, D. Technical characteristics and construction features of meat grinders. J. Exp. Biol. Agric. Sci. 2020, 8, S361–S367. [Google Scholar] [CrossRef]

- Ataev, P.L.; Islamova, O.V.; Tokov, A.Z.; Zhilayev, A.A. Development of Lattice Design for Increasing the Energy Efficiency of the Grinding Process of Food Products. In Proceedings of the 2018 IEEE International Conference “Quality Management, Transport and Information Security, Information Technologies” (IT&QM&IS), St. Petersburg, Russia, 24–28 September 2018; pp. 415–416. [Google Scholar] [CrossRef]

- Berger, L.M.; Witte, F.; Tomasevic, I.; Heinz, V.; Weiss, J.; Gibis, M.; Terjung, N. A review on the relation between grinding process and quality of ground meat. Meat Sci. 2023, 205, 109320. [Google Scholar] [CrossRef] [PubMed]

- Berger, L.M.; Witte, F.; Terjung, N.; Weiss, J.; Gibis, M. Influence of Processing Steps on Structural, Functional, and Quality Properties of Beef Hamburgers. Appl. Sci. 2022, 12, 7377. [Google Scholar] [CrossRef]

- Dovbush, T.; Khomyk, N.; Dovbush, A. Study of the work of the grinder in different types of meat cropping. Sci. J. Ternopil Natl. Tech. Univ. 2023, 3, 76–83. [Google Scholar] [CrossRef]

- Peleev, A.I. Technological Equipment of the Enterprises of Meat Industry; Publishing House “Food Industry”: Moscow, Russia, 1971; 519p. [Google Scholar]

- Awdallah, Y.; Wasfy, K. Engineering parameters affecting the performance of meat grinder. Misr J. Agric. Eng. 2017, 34, 347–368. [Google Scholar] [CrossRef]

- Litovchenko, D.V.; Levchenko, E.A. Investigation of the Influence of Operational Characteristics of the Grinding Process on the Quality Indicators of the Obtained Minced Meat. Mod. Technol. Probl. Prospect. 2020, 1, 241–247. Available online: https://www.elibrary.ru/item.asp?id=43125028 (accessed on 2 July 2024).

- Colmenero, F.J.; Carrascosa, A.V.; Barreto, G.; Fernandez, P.; Carballo, J. Chopping temperature effects on the characteristics and chilled storage of low-and high-fat pork bologna sausages. Meat Sci. 1996, 44, 1–9. [Google Scholar] [CrossRef]

- Bakieva, A.; Akimov, M.; Abdilova, G.; Ibragimov, N.; Bekeshova, G. Developing new type of disk plate for meat chopper and its effect to water-binding capacity and yield stress of minced meat. Int. J. Mech. Prod. Eng. Res. Dev. 2019, 9, 377–390. [Google Scholar]

- Antipova, L.V.; Glotova, I.A.; Rogov, I.A. Meat and Meat Products Research Methods; “KoloS” Publishing House: Moscow, Russia, 2001. [Google Scholar]

- GOST 23042-86; Interstate Standard. Meat and Meat Products. Methods of Determination of Fat. Standartinfrom: Moscow, Russia, 2010.

- GOST 25011-81; Interstate Standard. Meat and Meat Products. Methods of Determination of Protein. Standartinfrom: Moscow, Russia, 2010.

- Okuskhanova, E.; Rebezov, M.; Yessimbekov, Z.; Suychinov, A.; Semenova, N.; Rebezov, Y.; Gorelik, O.; Zinina, O. Study of water binding capacity, pH, chemical composition and microstructure of livestock meat and poultry. Annu. Res. Rev. Biol. 2017, 14, 1–7. [Google Scholar] [CrossRef]

- GOST R 50814-95; Meat Products. Methods of Determination of Penetration by Cone and Needle Indenter. FSUE Standardinform: Moscow, Russia, 1995; 8p.

- Abdilova, G.; Sergibayeva, Z.; Orynbekov, D.; Shamenov, M.; Zhumadilova, G.; Bakiyeva, A.; Mukashev, N.; Bayadilova, A.; Dukenbayev, D. Influence of Grinding Degree and Screw Rotation Speed on Sunflower Oil Pressing Process. Appl. Sci. 2023, 13, 9958. [Google Scholar] [CrossRef]

- Ivashov, V.I. Technological Equipment of Meat Industry Enterprises; GIORD Publishing House: Saint-Petersburg, Russia, 2010; 736p. [Google Scholar]

- Bacelar, M.D.; Ferreira, H.C.M.G.; Alassar, R.S.; Lopes, A.B. Hagen-Poiseuille Flow in a Quarter-Elliptic Tube. Fluids 2023, 8, 247. [Google Scholar] [CrossRef]

- Suchenko, Y.; Suchenko, V.; Mushtruk, M.; Vasyliv, V.; Boyko, Y. Changing the quality of ground meat for sausage products in the process of grinding. East.-Eur. J. Enterp. Technol. 2017, 4, 56–63. [Google Scholar] [CrossRef]

- Suman, S.; Sharma, B. Effect of grind size and fat levels on the physico-chemical and sensory characteristics of low-fat ground buffalo meat patties. Meat Sci. 2003, 65, 973–976. [Google Scholar] [CrossRef]

- Kajiama, F.; Aji, M.; Shuwa, M.; Taktak, E. Design, Construction and Performance Evaluation of a Manually Operated Meat Mincing Machine. Arid Zone J. Eng. Technol. Environ. 2020, 16, 579–586. [Google Scholar]

- Murashev, S.V.; Kodirov, U.O. Influence of grinding depth on the properties of ground beef. Sci. J. Natl. Res. Univ. ITMO Ser. “Process. Appar. Food Prod.” 2014, 1, 17. [Google Scholar]

- Dreeling, N.; Allen, P.; Butler, F. Effect of the Degree of Comminution on Sensory and Texture Attributes of Low-fat Beefburgers. LWT-Food Sci. Technol. 2000, 33, 290–294. [Google Scholar] [CrossRef]

- Kudryashov, L.S.; Kudryashova, O.A. Water-holding and water-holding capacity of meat and methods of its determination. Theory Pract. Meat Process. 2023, 8, 62–70. [Google Scholar] [CrossRef]

- Yessimbekov, Z.; Kakimov, A.; Kabdylzhar, B.; Suychinov, A.; Baikadamova, A.; Akimova, D.; Abdilova, G. Chemical, physical properties, microstructure and granulometric composition of ultra-finely ground chicken bone paste. Appl. Food Res. 2023, 3, 100318. [Google Scholar] [CrossRef]

- Puolanne, E.J.; Ruusunen, M.H.; Vainionpää, J.I. Combined effects of NaCl and raw meat pH on water-holding in cooked sausage with and without added phosphate. Meat Sci. 2001, 58, 1–7. [Google Scholar] [CrossRef]

- Tsaregorodtseva, E.V. An effect of the recipe composition on minced meat properties. Theory Pract. Meat Process. 2021, 6, 174–182. [Google Scholar] [CrossRef]

- Shestakov, S.D. Energy state of water and its binding by biopolymers of food raw materials: New possibilities. Storage Process. Agric. Raw Mater. 2003, 4, 35–37. [Google Scholar]

- Yang, H.; Zhang, W.; Li, T.; Zheng, H.; Khan, M.A.; Xu, X.; Sun, J.; Zhou, G. Effect of protein structure on water and fat distribution during meat gelling. Food Chem. 2016, 204, 239–245. [Google Scholar] [CrossRef] [PubMed]

- McDonnell, C.K.; Allen, P.; Morin, C.; Lyng, J.G. The effect of ultrasonic salting on protein and water–protein interactions in meat. Food Chem. 2014, 147, 245–251. [Google Scholar] [CrossRef]

- Thompson, R.L.; Sica, L.U.; de Souza Mendes, P.R. The yield stress tensor. J. Non-Newton. Fluid Mech. 2018, 261, 211–219. [Google Scholar] [CrossRef]

- Kakimov, A.; Yessimbekov, Z.; Bepeyeva, A.; Kabulov, B.; Kakimova, Z. Consistency cone penetrometry for food products. Pak. J. Nutr. 2015, 14, 837–840. [Google Scholar] [CrossRef]

- Coussot, P.; Navier, L. Yield stress fluid flows: A review of experimental data. J. Non-Newton. Fluid Mech. 2014, 211, 31–49. [Google Scholar] [CrossRef]

- Sun, A.; Gunasekaran, S. Yield Stress in Foods: Measurements and Applications. Int. J. Food Prop. 2009, 12, 101–170. [Google Scholar] [CrossRef]

- Bonn, D.; Denn, M. Yield Stress Fluids Slowly Yield to Analysis. Science 2009, 324, 1401–1402. [Google Scholar] [CrossRef]

- Mustafaeva, A.K.; Kabulov, B.B.; Bakieva, A.B.; Tashybayeva, M.M.; Japparov, P.A. Analysis of equipment for grinding meat and bone raw materials. In Proceedings of the 20th International Scientific and Practical Conference “Modern Problems of Engineering and Technology of Food Production”; Altai State Technical University: Barnaul, Russia, 2019; pp. 244–246. [Google Scholar]

- Kapovsky, B.; Kuznetsova, T.; Lazarev, A.; Plyasheshnik, P. Energy-saving technology for fine grinding of food raw materials frozen in blocks. E3S Web Conf. 2021, 279, 03009. [Google Scholar] [CrossRef]

- Pelenko, V.; Ivanenko, V.; Verboloz, E.; Demchenko, V.; Usmanov, I. Formation of the Correct Mathematical Model of Grinding Raw Meat in Meat Mincer. KnE Life Sci. 2020, 5, 12–26. [Google Scholar] [CrossRef]

- Bekeshova, G.; Ibragimov, N.; Kakimov, A.; Suychinov, A.; Yessimbekov, Z.; Kabdylzhar, B.; Tokhtarov, Z.; Zhumadilova, G.; Abdilova, G. Effect of Rotational Speed and Gap between Rotating Knives of the Grinder on the Yield Stress and Water-Binding Capacity of Fine Ground Chicken Bone. Appl. Sci. 2022, 12, 3533. [Google Scholar] [CrossRef]

| Indicator | Plate | ||||

|---|---|---|---|---|---|

| d—8 mm | d—12 mm | d—16 mm | d—16, 12, and 8 mm | d—8, 12, and 16 mm | |

| z—the number of holes in the plate | 132 | 72 | 46 | 78 (14; 24; 40) | 72 (24; 24; 24) |

| ϕ—cutting capacity utilization factor | 0.33 | 0.37 | 0.46 | 0.40 | 0.38 |

| M—production capacity (kg/s) | 0.24 | 0.67 | 1.4 | 0.80 | 0.76 |

| Meat Type | Mass Fraction Content, % | |||

|---|---|---|---|---|

| Water | Fat | Ash | Protein | |

| Beef | 63.9 ± 1.02 | 16.0 ± 0.24 | 1.3 ± 0.02 | 18.8 ± 0.31 |

| Horse | 71.0 ± 1.06 | 8.7 ± 0.16 | 2.2 ± 0.03 | 18.1 ± 0.30 |

| Chicken | 71.4 ± 1.63 | 6.1 ± 0.10 | 1.0 ± 0.02 | 21.5 ± 0.41 |

| Mutton | 61.5 ± 0.77 | 20.5 ± 0.22 | 1.6 ± 0.03 | 16.4 ± 0.18 |

| Pork | 53.7 ± 0.59 | 21.7 ± 0.17 | 1.4 ± 0.03 | 23.2 ± 0.32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bakiyeva, A.; Yerengaliyev, A.; Kakimov, A.; Zhumadilova, G.; Abdilova, G.; Serikov, E.; Suychinov, A.; Turagulov, R.; Yessimbekov, Z. Development of the Design of Plate with Variable Diameters of Holes and Its Impact on Meat-Grinding Quality and Efficiency. Processes 2024, 12, 1808. https://doi.org/10.3390/pr12091808

Bakiyeva A, Yerengaliyev A, Kakimov A, Zhumadilova G, Abdilova G, Serikov E, Suychinov A, Turagulov R, Yessimbekov Z. Development of the Design of Plate with Variable Diameters of Holes and Its Impact on Meat-Grinding Quality and Efficiency. Processes. 2024; 12(9):1808. https://doi.org/10.3390/pr12091808

Chicago/Turabian StyleBakiyeva, Anara, Aman Yerengaliyev, Aitbek Kakimov, Gulmira Zhumadilova, Galiya Abdilova, Erzat Serikov, Anuarbek Suychinov, Rasul Turagulov, and Zhanibek Yessimbekov. 2024. "Development of the Design of Plate with Variable Diameters of Holes and Its Impact on Meat-Grinding Quality and Efficiency" Processes 12, no. 9: 1808. https://doi.org/10.3390/pr12091808

APA StyleBakiyeva, A., Yerengaliyev, A., Kakimov, A., Zhumadilova, G., Abdilova, G., Serikov, E., Suychinov, A., Turagulov, R., & Yessimbekov, Z. (2024). Development of the Design of Plate with Variable Diameters of Holes and Its Impact on Meat-Grinding Quality and Efficiency. Processes, 12(9), 1808. https://doi.org/10.3390/pr12091808