An Optimization Study of 3D Printing Technology Utilizing a Hybrid Gel System Based on Astragalus Polysaccharide and Wheat Starch

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.2. Instruments and Equipment

- Lab-made pneumatic-extrusion condensing 3D food printer;

- JA3003 electronic analytical balance, Shanghai Zanwei Weighing Apparatus Co., Ltd., Shanghai, China;

- TL-PRO texture analyzer, Beijing Ying Sheng Heng Tai Technology Co., Ltd., Beijing, China;

- DF-101S constant-temperature oil bath magnetic stirrer, Shanghai Qiu Zuo Scientific Instruments Co., Ltd., Shanghai, China;

- MC-7K centrifuge, Zhejiang Ou Mai Ke Testing Instruments Co., Ltd., Huzhou, Zhejiang, China.

Pneumatic-Extrusion Condensing 3D Food Printer

2.3. Experimental Methods

2.3.1. Preparation of Printing Materials

2.3.2. The 3D Printer Extrusion Layer Height Setting

2.3.3. Single-Factor 3D Printing Parameter Setting

2.3.4. Evaluation of 3D Printing Sample Molding Effect

2.3.5. Measurement of Texture Characteristics

2.3.6. Determination of Gel Deposition Rate

2.3.7. Optimization of the Test Design of the Printing Process Response Surface

2.3.8. Printing Process Response Surface Optimization Test Design

3. Results and Analysis

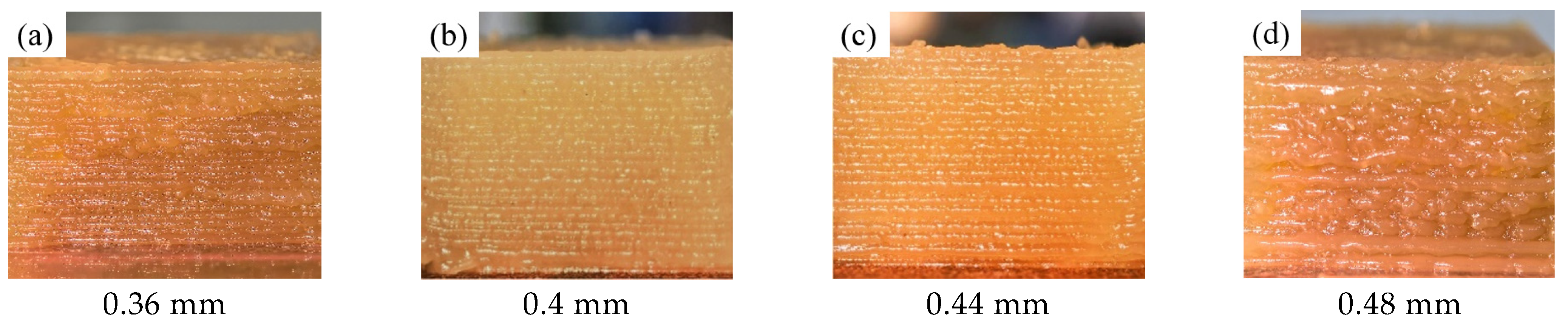

3.1. Determination of Printing Layer Height

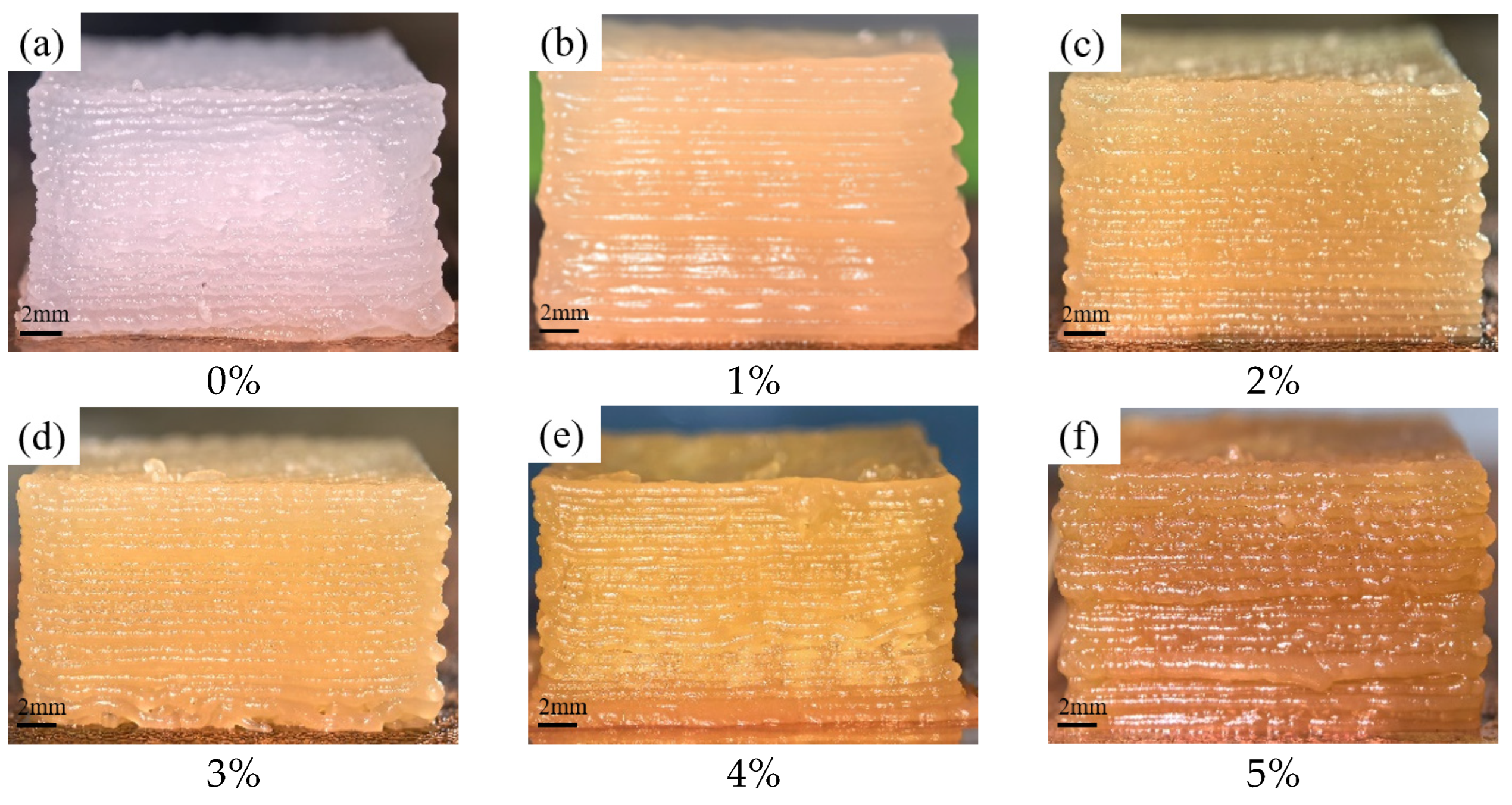

3.2. The Influence of Polysaccharide Content on the 3D Printing Performance of Astragalus–Starch Mixed Gels

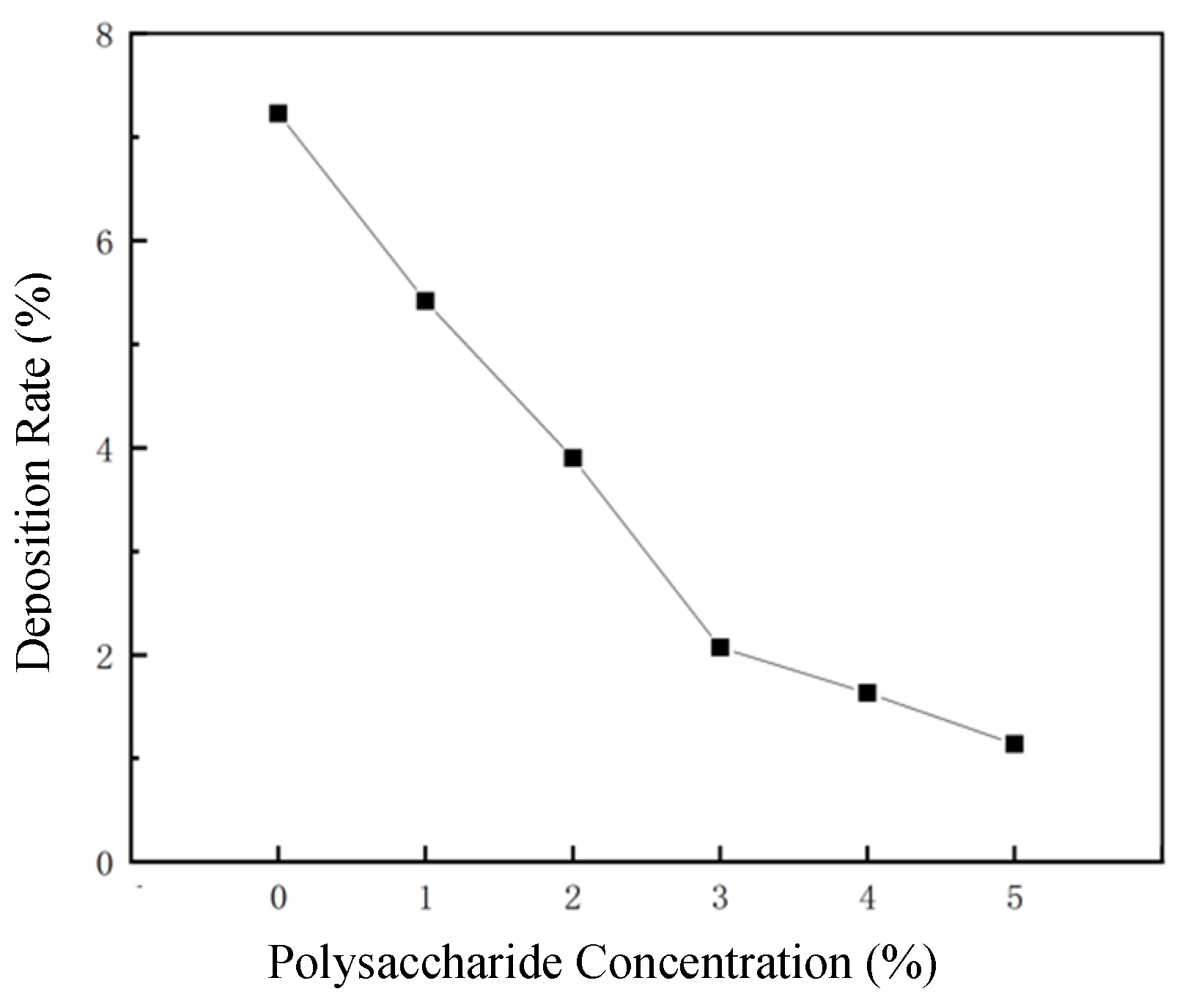

3.3. The Impact of Polysaccharide Content on the Deposition Rate of Astragalus–Starch Mixed Gels

3.4. The Influence of Polysaccharide Content on the Textural Properties of Astragalus–Starch Mixed-Gel 3D Printing Samples

3.5. The Impact of Single-Factor Parameters on the Precision of Printed Samples

3.5.1. The Influence of Fill Rate on the Precision of Printed Samples

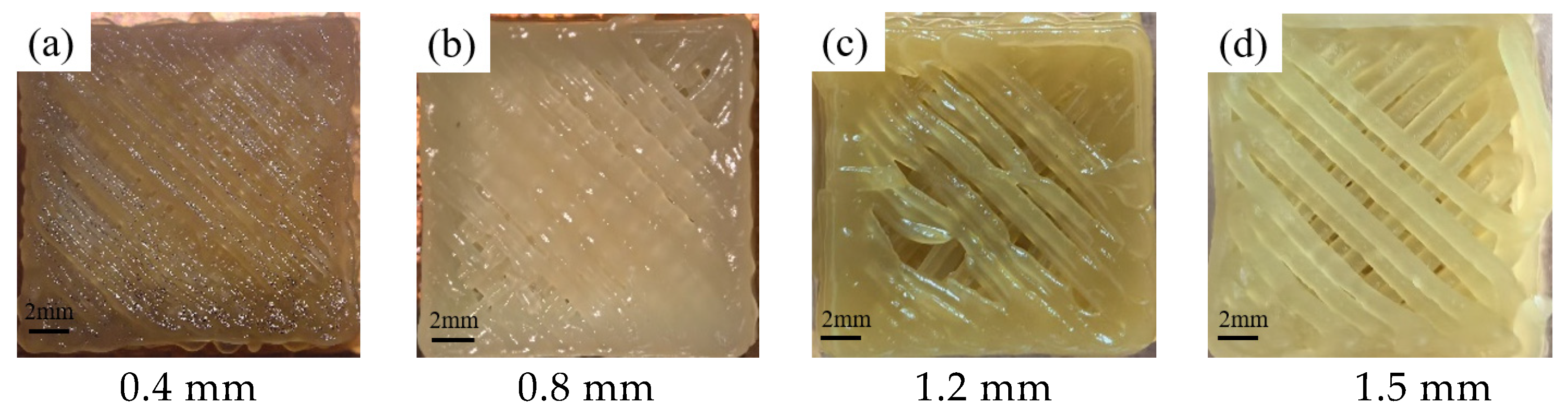

3.5.2. The Influence of Nozzle Diameter on the Precision of Printed Samples

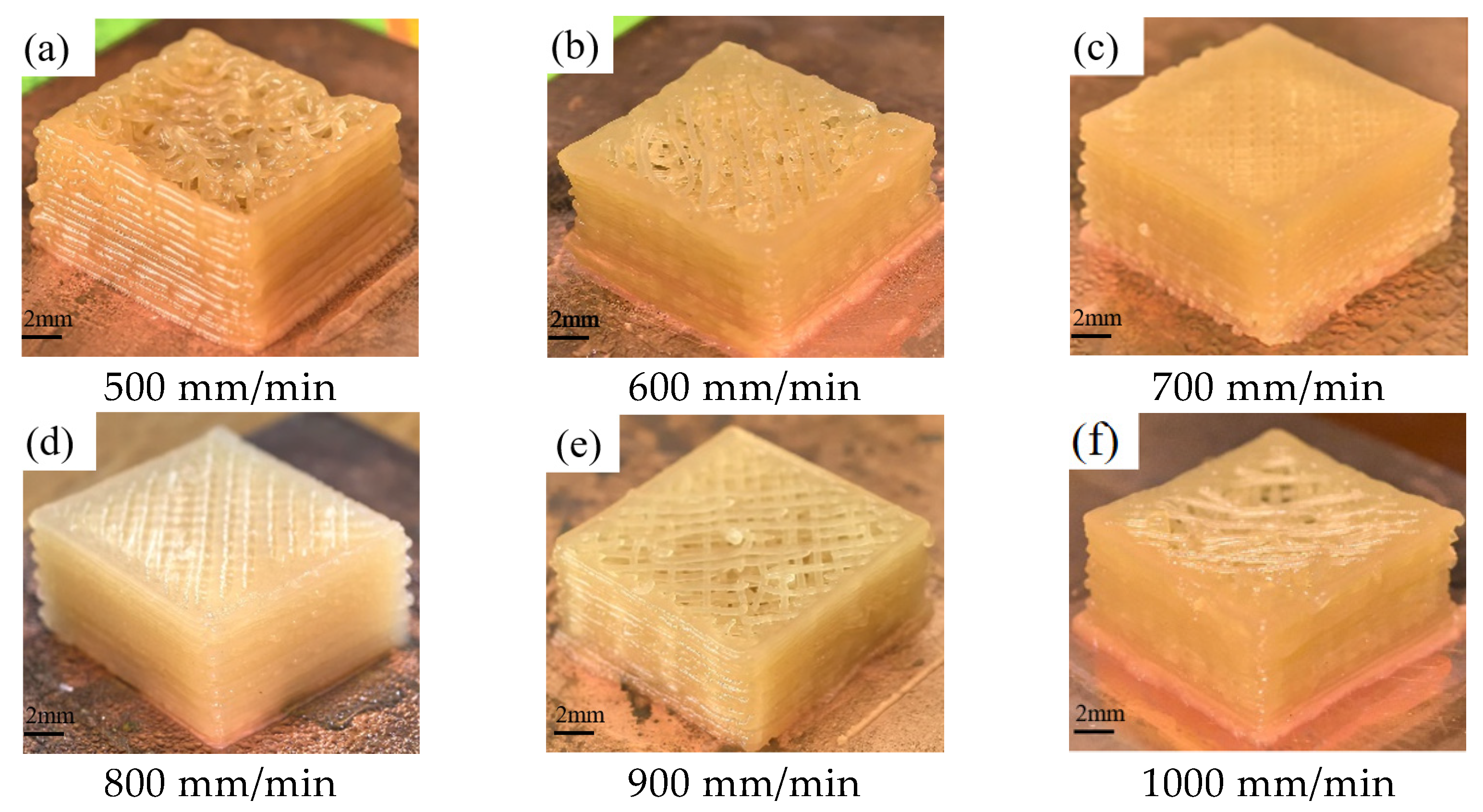

3.5.3. The Influence of Printing Speed on the Precision of Printed Samples

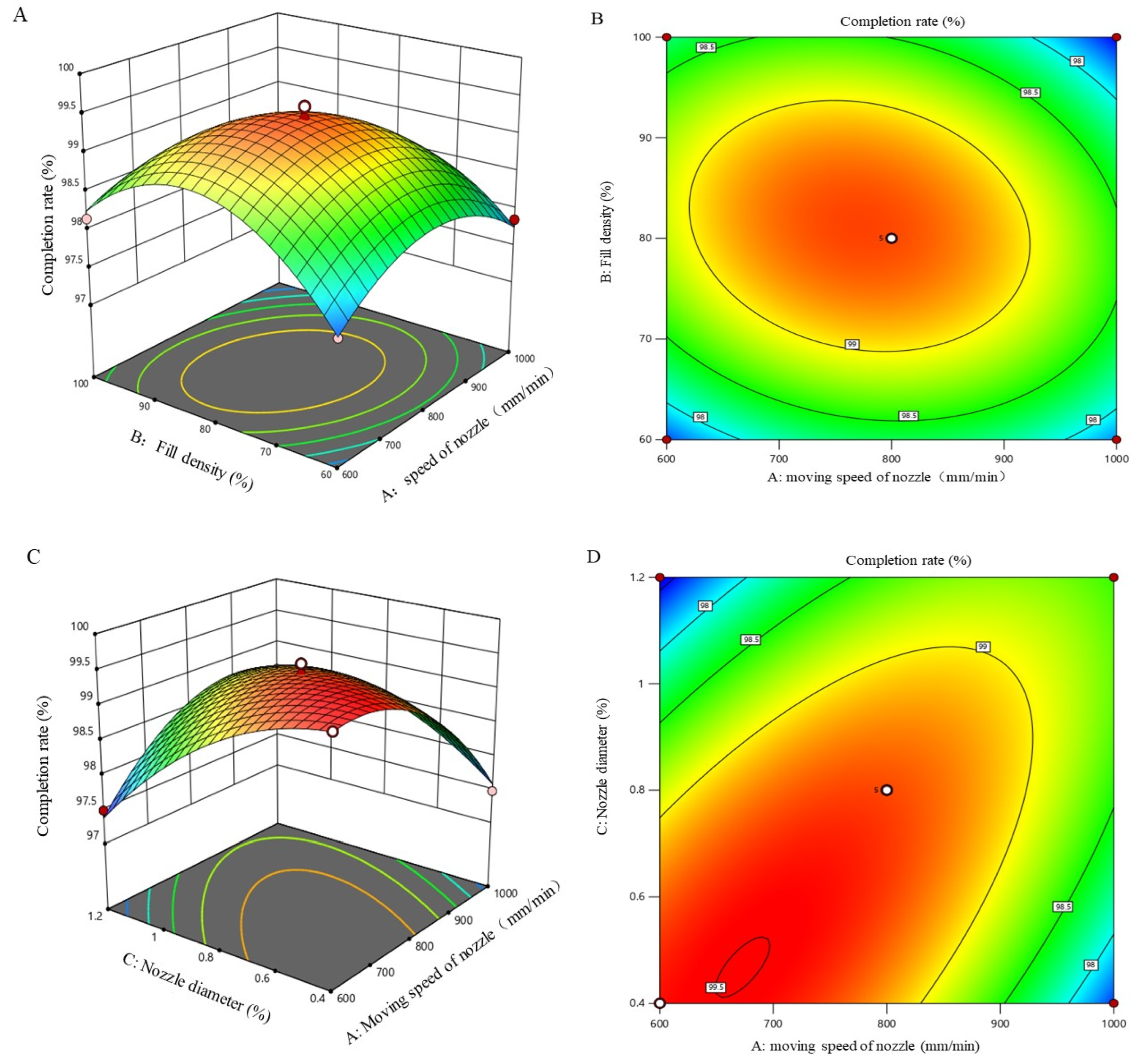

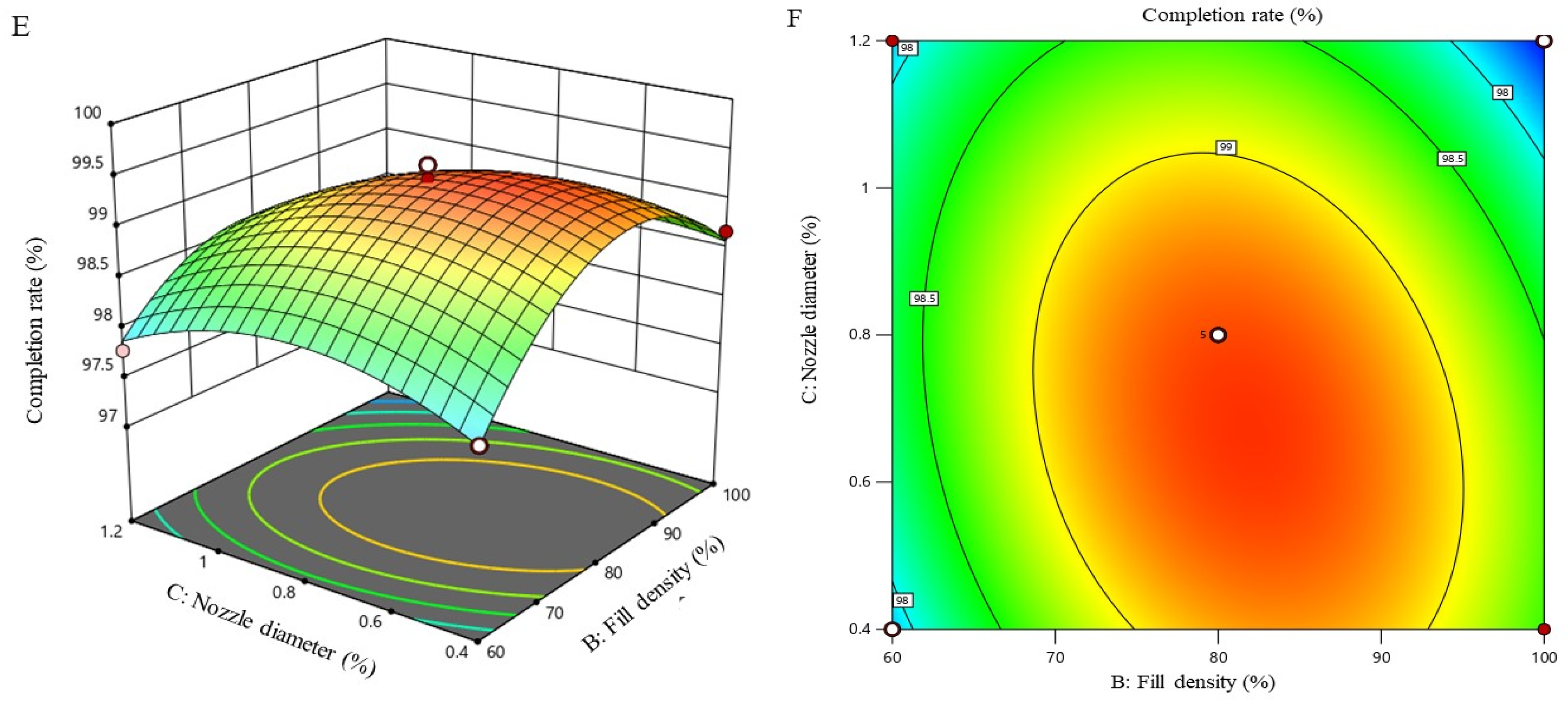

3.6. Response Surface Optimization Test Design and Results and Response Surface Model

3.6.1. Response Surface Test Design and Result Analysis

3.6.2. Response Surface Analysis and Determination of Optimal Printing Parameters

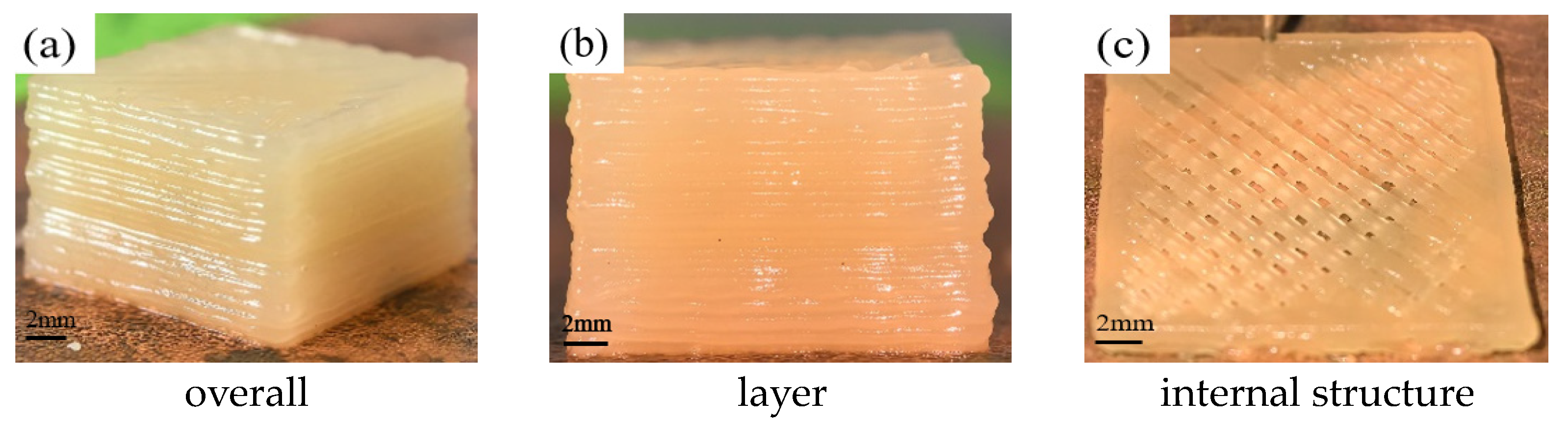

3.6.3. Verification of Optimal Printing Parameters

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fan, C.; Cheng, L.; Hong, Y.; Li, Z.; Li, C.; Ban, X.; Gu, Z. Study on the gelatinization and digestive characteristics of wheat starch and potato starch under low moisture conditions. Int. J. Biol. Macromol. 2024, 269, 132192. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Wu, H.; Zhu, J.; Shi, Z.; Zou, L.; Shen, R.; Yao, Y. Research progress on food 3D printing based on starch. Food Sci. 2024, 45, 257–265. [Google Scholar]

- Shi, S.; Wen, J.; Geng, H.; Zhan, X.; Liu, Y. Physicochemical properties, structural properties and gels 3D printing properties of wheat starch. Int. J. Biol. Macromol. 2024, 261, 129885. [Google Scholar] [CrossRef]

- Abedini, A.; Sohrabvandi, S.; Sadighara, P.; Hosseini, H.; Farhoodi, M.; Assadpour, E.; Sani, M.A.; Zhang, F.; Seyyedi-Mansour, S.; Jafari, S.M. Personalized nutrition with 3D-printed foods: A systematic review on the impact of different additives. Adv. Colloid Interface Sci. 2024, 328, 103181. [Google Scholar] [CrossRef]

- Warsi, S.B.F.; Panda, B.; Biswas, P. Exploring fiber addition methods and mechanical properties of fibre-reinforced 3D printed concrete: A review. Dev. Built Environ. 2023, 16, 100295. [Google Scholar] [CrossRef]

- KS, J.H.; Subramaniam, M.P.; KT, M.K.; Sreeram, P.; Parvathi, S.; Sari, P.S.; Pullanchiyodan, A.; Mulhivill, D.M.; Raghavan, P. Fabrication and challenges of 3D printed sensors for biomedical applications-Comprehensive review. Results Eng. 2024, 21, 101867. [Google Scholar]

- Agunbiade, A.O.; Song, L.; Agunbiade, O.J.; Ofoedu, C.E.; Chacha, J.S.; Duguma, H.T.; Hossaini, S.M.; Rasaq, W.A.; Shorstkii, I.; Osuji, C.M.; et al. Potentials of 3D extrusion-based printing in resolving food processing challenges: A perspective review. J. Food Process Eng. 2022, 45, e13996. [Google Scholar] [CrossRef]

- Chen, L.; Hao, X.; Li, X.; Wang, L.; Song, J.; Zhang, H.; Zhang, N. Research Progress on the Effect of Non-starch Polysaccharides on Starch Properties. Sci. Technol. Food Ind. 2024, 45, 386–394. [Google Scholar]

- Su, H.; Hou, J.; Liu, Q.; Hou, L. Research Progress on Antiviral Substance Basis and Mechanism of Astragalus Membranaceus. Chin. Arch. Tradit. Chin. Med. 2024, 1–16. Available online: http://kns.cnki.net/kcms/detail/21.1546.R.20240419.1351.024.html (accessed on 6 August 2024).

- Wang, D.; Cui, Q.; Yang, Y.J.; Liu, A.Q.; Zhang, G.; Yu, J.C. Application of dendritic cells in tumor immunotherapy and progress in the mechanism of anti-tumor effect of Astragalus polysaccharide (APS) modulating dendritic cells: A review. Biomed. Pharmacother. 2022, 155, 113541. [Google Scholar] [CrossRef]

- Mushtaq, R.T.; Wang, Y.; Bao, C.; Rehman, M.; Sharma, S.; Khan, A.M.; Elsayed, M.; Eldin, T.; Abbas, M. Maximizing performance and efficiency in 3D printing of polylactic acid biomaterials: Unveiling of microstructural morphology, and implications of process parameters and modeling of the mechanical strength, surface roughness, print time, and print energy for fused filament fabricated (FFF) bioparts. Int. J. Biol. Macromol. 2024, 259, 129201. [Google Scholar]

- Wang, X.; Fang, J.; Cheng, L.; Gu, Z.; Hong, Y. Interaction of starch and non-starch polysaccharides in raw potato flour and their effects on thickening stability. Int. J. Biol. Macromol. 2023, 242, 124702. [Google Scholar] [CrossRef] [PubMed]

- Shi, X.; Yu, M.; Yin, H.; Peng, L.; Cao, Y.; Wang, S. Multiscale structures, physicochemical properties, and in vitro digestibility of oat starch complexes co-gelatinized with jicama non-starch polysaccharides. Food Hydrocoll. 2023, 144, 108983. [Google Scholar] [CrossRef]

- Xiao, Y.; Liu, S.; Shen, M.; Jiang, L.; Ren, Y.; Luo, Y.; Xie, J. Effect of different Mesona chinensis polysaccharides on pasting, gelation, structural properties and in vitro digestibility of tapioca starch-Mesona chinensis polysaccharides gels. Food Hydrocoll. 2020, 99, 105327. [Google Scholar] [CrossRef]

- Gedrovica, I.; Karklina, D.; Fras, A.; Jablonka, O.; Boros, D. The non–starch polysaccharides quantity changes in pastry products where Jerusalem artichoke (Helianthus tuberosus L.) added. Procedia Food Sci. 2011, 1, 1638–1644. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, Q.; Zhang, J.; Zhang, B.; Wu, X.; Yan, X. Effect of Cyperus esculentus polysaccharide on Cyperus esculentus starch: Pasting, rheology and in vitro digestibility. Food Chem. X 2024, 22, 101511. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, B.; Zhou, S.; Han, X.; Jiang, Y.; Zhou, X.; Yang, X.; Zhao, J. Pasting, rheology, structural properties and in vitro digestibility of potato starch complexes co-gelatinized with squash polysaccharides. Food Biosci. 2024, 61, 104932. [Google Scholar] [CrossRef]

- Xu, W.; Jiang, D.; Zhao, Q.; Wang, L. Study on printability of 3D printing carbon fiber reinforced eco-friendly concrete: Characterized by fluidity and consistency. Case Stud. Constr. Mater. 2024, 21, e03589. [Google Scholar] [CrossRef]

- Song, Z.; Dai, H.; Bo, L.; Song, C.; Liu, X.; Ren, J. Set yogurt incorporated with insoluble dietary fiber maintains non-sedimentation: Combined alkaline hydrogen peroxide modification and high-pressure homogenization process. LWT 2024, 206, 116617. [Google Scholar] [CrossRef]

- GB/T 8883-2017; Edible wheat starch. Chinese Standardization Technical Committee for Edible Starches and Starches Derivatives: Wuxi, China, 2017.

- ElShebiny, T.; Matthaios, S.; Menezes, L.M.; Tsolakis, I.A.; Palomo, J.M. Effect of printing technology, layer height, and orientation on assessment of 3D-printed models. J. World Fed. Orthod. 2024, 13, 169–174. [Google Scholar]

- Lan, G.; Xie, S.; Duan, Q.; Huang, W.; Huang, W.; Zhou, J.; Chen, P.; Xie, F. Effect of soybean polysaccharide and soybean oil on gelatinization and retrogradation properties of corn starch. Int. J. Biol. Macromol. 2024, 264, 130772. [Google Scholar] [CrossRef]

- Jia, R.; Cui, C.; Gao, L.; Qin, Y.; Ji, N.; Dai, L.; Wang, Y.; Xiong, L.; Shi, R.; Sun, Q. A review of starch swelling behavior: Its mechanism, determination methods, influencing factors, and influence on food quality. Carbohydr. Polym. 2023, 321, 121260. [Google Scholar] [CrossRef]

- Min, C.; Zhang, C.; Cao, Y.; Li, H.; Pu, H.; Huang, J.; Xiong, Y.L. Rheological, textural, and water-immobilizing properties of mung bean starch and flaxseed protein composite gels as potential dysphagia food: The effect of Astragalus polysaccharide. Int. J. Biol. Macromol. 2023, 239, 124236. [Google Scholar] [CrossRef] [PubMed]

- Zheng, L.; Liu, J.; Liu, R.; Xing, Y.; Jiang, H. 3D printing performance of gels from wheat starch, flour and whole meal. Food Chem. 2021, 356, 129546. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Qiu, J.; Wu, Y.; Ouyang, J. Impact of soluble soybean polysaccharide on the gelatinization and retrogradation of corn starches with different amylose content. Food Res. Int. 2024, 184, 114254. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Guan, L.; Seib, P.A.; Shi, Y.C. Settling volume and morphology changes in cross-linked and unmodified starches from wheat, waxy wheat, and waxy maize in relation to their pasting properties. Carbohydr. Polym. 2018, 196, 18–26. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, J.; Wu, J.; Luo, S.; Chen, R.; Liu, C.; Gilbert, R.G. Modification of retrogradation property of rice starch by improved extrusion cooking technology. Carbohydr. Polym. 2019, 213, 192–198. [Google Scholar] [CrossRef]

- Ai, Z.; Zhang, M.; Li, H.; Ji, S.; Zhang, J.; Yang, Y. Effects of different heat treatments on the quality of wheat flour and its steamed cakes. Trans. Chin. Soc. Agric. Eng. 2024, 40, 317–324. [Google Scholar]

- Zhou, R.; Wang, Y.; Wang, Z.; Liu, K.; Wang, Q.; Bao, H. Effects of Auricularia auricula-judae polysaccharide on pasting, gelatinization, rheology, structural properties and in vitro digestibility of kidney bean starch. Int. J. Biol. Macromol. 2021, 191, 1105–1113. [Google Scholar] [CrossRef]

- Ren, Y.; Rong, L.; Shen, M.; Liu, W.; Xiao, W.; Luo, Y.; Xie, J. Interaction between rice starch and Mesona chinensis Benth polysaccharide gels: Pasting and gelling properties. Carbohydr. Polym. 2020, 240, 116316. [Google Scholar] [CrossRef]

- Li, Y.; Wu, T.; Wu, Y.; Zhao, C.; Xu, X.; Liu, J. Effect of Auricularia cornea Ehrenb. Polysaccharide on the Retrogradation and Digestion of Corn Starch. J. Chin. Inst. Food Sci. Technol. 2021, 21, 78–90. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, H.; Chen, R.; Chen, J.; Liu, X.; Luo, S.; Chen, T. Effects of creeping fig seed polysaccharide on pasting, rheological, textural properties and in vitro digestibility of potato starch. Food Hydrocoll. 2021, 118, 106810. [Google Scholar] [CrossRef]

- Pan, X.; Chen, X.; Niu, H.; Shen, M.; Ye, X.; Mo, S.; Xie, J. large and small amplitude oscillatory shear techniques evaluate the nonlinear rheological properties of Ficus pumila polysaccharide-wheat starch gel. Int. J. Biol. Macromol. 2024, 270, 132352. [Google Scholar] [CrossRef] [PubMed]

- Yi, H.; Li, J.; Li, J.; Wang, P.; Wang, S.; Liu, H. Effect of Fermented Soybean Whey W/O Slow-Release Coagulants on Gel Properties of Soybean Whole Powder Emulsion. Food Sci. 2024, 1–12. Available online: http://kns.cnki.net/kcms/detail/11.2206.TS.20240821.1147.006.html (accessed on 6 August 2024).

- Zárybnická, L.; Machotová, J.; Pagáč, M.; Rychlý, J.; Vykydalová, A. The effect of filling density on flammability and mechanical properties of 3D-printed carbon fiber-reinforced nylon. Polym. Test. 2023, 120, 107944. [Google Scholar] [CrossRef]

- Vaneker, T.H.J.; Kuiper, S.; Willemstein, N.; Baran, I. Effects of nozzle design on CFRP print quality using Commingled Yarn. Procedia CIRP 2023, 120, 1492–1497. [Google Scholar] [CrossRef]

- Tian, H.; Geng, M.; Wo, X.; Shi, L.; Zhai, Y.; Ji, P. Development and conceptual design of a sewage Sludge-to-Fuel hybrid Process: Prediction and optimization under analysis of variance and response surface model. Energy Convers. Manag. 2024, 306, 118143. [Google Scholar] [CrossRef]

- Youssef, M.; Ei-Shatoury, E.H.; Ali, S.S.; El-Taweel, G.E. Enhancement of Phenol Degradation by Free and Immobilized Mixed Culture of Providencia stuartii PL4 and Pseudomonas aeruginosa PDM Isolated from Activated Sludge. Bioremediat. J. 2019, 23, 53–71. [Google Scholar] [CrossRef]

- Lee, C.P.; Hashimoto, M. Prediction of textural properties of 3D-printed food using response surface methodology. Heliyon 2024, 10, e27658. [Google Scholar] [CrossRef] [PubMed]

| Level | Factors | ||

|---|---|---|---|

| Print Speed (mm/min) | Filling Rates (%) | Nozzle Diameter (mm) | |

| −1 | 600 | 60 | 0.4 |

| 0 | 800 | 80 | 0.8 |

| 1 | 1000 | 100 | 1.2 |

| NO. | Factors | Comprehensive Completion Rate (%) | ||

|---|---|---|---|---|

| Print Speed (mm/min) | Filling Rates (%) | Nozzle Diameter (mm) | ||

| 1 | 600 | 60 | 0.8 | 97.62 |

| 2 | 1000 | 60 | 0.8 | 97.86 |

| 3 | 600 | 100 | 0.8 | 98.15 |

| 4 | 1000 | 100 | 0.8 | 97.48 |

| 5 | 600 | 80 | 0.4 | 99.46 |

| 6 | 1000 | 80 | 0.4 | 97.48 |

| 7 | 600 | 80 | 1.2 | 97.49 |

| 8 | 1000 | 80 | 1.2 | 98.58 |

| 9 | 800 | 60 | 0.4 | 97.87 |

| 10 | 800 | 100 | 0.4 | 98.68 |

| 11 | 800 | 60 | 1.2 | 97.78 |

| 12 | 800 | 100 | 1.2 | 97.48 |

| 13 | 800 | 80 | 0.8 | 99.48 |

| 14 | 800 | 80 | 0.8 | 99.34 |

| 15 | 800 | 80 | 0.8 | 99.28 |

| 16 | 800 | 80 | 0.8 | 99.31 |

| 17 | 800 | 80 | 0.8 | 99.29 |

| Source of Variance | Sum of Squares | Degree of Freedom | Mean Square | F Value | p Value |

|---|---|---|---|---|---|

| Model | 10.58 | 9 | 1.18 | 90.14 | <0.0001 ** |

| A | 0.2178 | 1 | 0.2178 | 16.70 | 0.0047 * |

| B | 0.0545 | 1 | 0.0545 | 4.17 | 0.0803 |

| C | 0.5832 | 1 | 0.5832 | 44.71 | 0.0003 * |

| AB | 0.2070 | 1 | 0.2070 | 15.87 | 0.0053 |

| AC | 2.36 | 1 | 2.36 | 180.65 | <0.0001 ** |

| BC | 0.3080 | 1 | 0.3080 | 23.62 | 0.0018 * |

| A2 | 1.68 | 1 | 1.68 | 128.64 | <0.0001 ** |

| B2 | 3.65 | 1 | 3.65 | 279.96 | <0.0001 ** |

| C2 | 0.8765 | 1 | 0.8765 | 67.20 | <0.0001 ** |

| Residual | 0.0913 | 7 | 0.0130 | ||

| Lack of Fit | 0.0647 | 3 | 0.0216 | 3.24 | 0.1427 |

| Pure Error | 0.0266 | 4 | 0.0066 | ||

| Cor Total | 10.67 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, G.; Tao, L.; Zhang, S.; Hao, X.; Ou, S. An Optimization Study of 3D Printing Technology Utilizing a Hybrid Gel System Based on Astragalus Polysaccharide and Wheat Starch. Processes 2024, 12, 1898. https://doi.org/10.3390/pr12091898

Xia G, Tao L, Zhang S, Hao X, Ou S. An Optimization Study of 3D Printing Technology Utilizing a Hybrid Gel System Based on Astragalus Polysaccharide and Wheat Starch. Processes. 2024; 12(9):1898. https://doi.org/10.3390/pr12091898

Chicago/Turabian StyleXia, Guofeng, Lilulu Tao, Shiying Zhang, Xiangyang Hao, and Shengyang Ou. 2024. "An Optimization Study of 3D Printing Technology Utilizing a Hybrid Gel System Based on Astragalus Polysaccharide and Wheat Starch" Processes 12, no. 9: 1898. https://doi.org/10.3390/pr12091898

APA StyleXia, G., Tao, L., Zhang, S., Hao, X., & Ou, S. (2024). An Optimization Study of 3D Printing Technology Utilizing a Hybrid Gel System Based on Astragalus Polysaccharide and Wheat Starch. Processes, 12(9), 1898. https://doi.org/10.3390/pr12091898