Research on Erosion Damage Laws and Structural Optimization of Bypass Valve for Positive Displacement Motors

Abstract

:1. Introduction

2. Bypass Valve Working Principle

3. Valve Core Flow Field Simulation Model

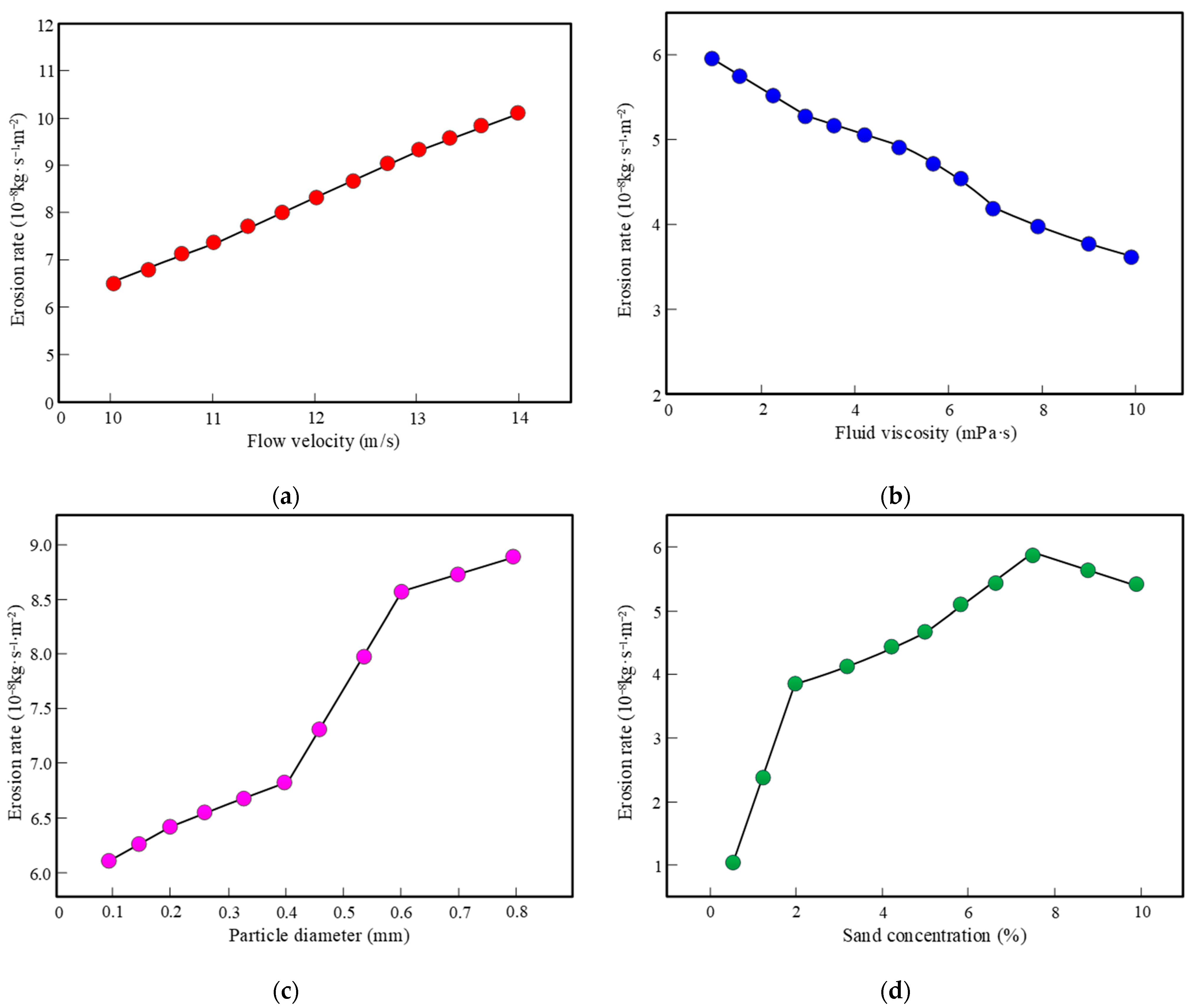

4. Simulation of Influencing Factors on Valve Core Erosion

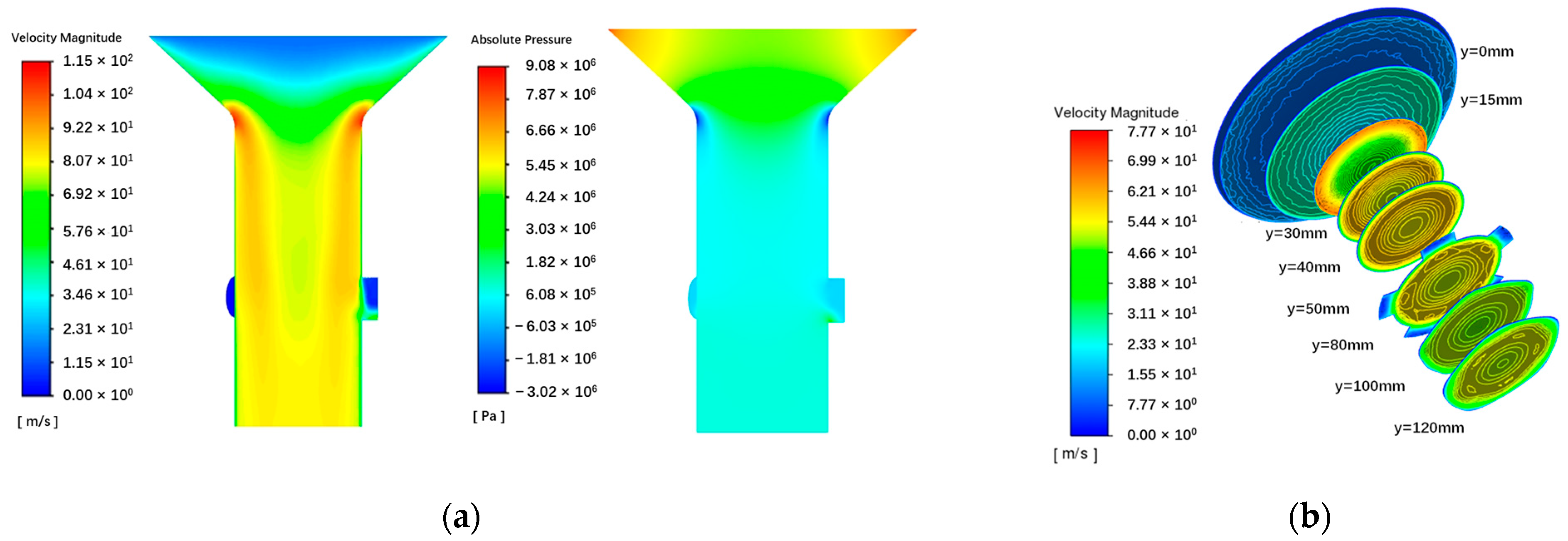

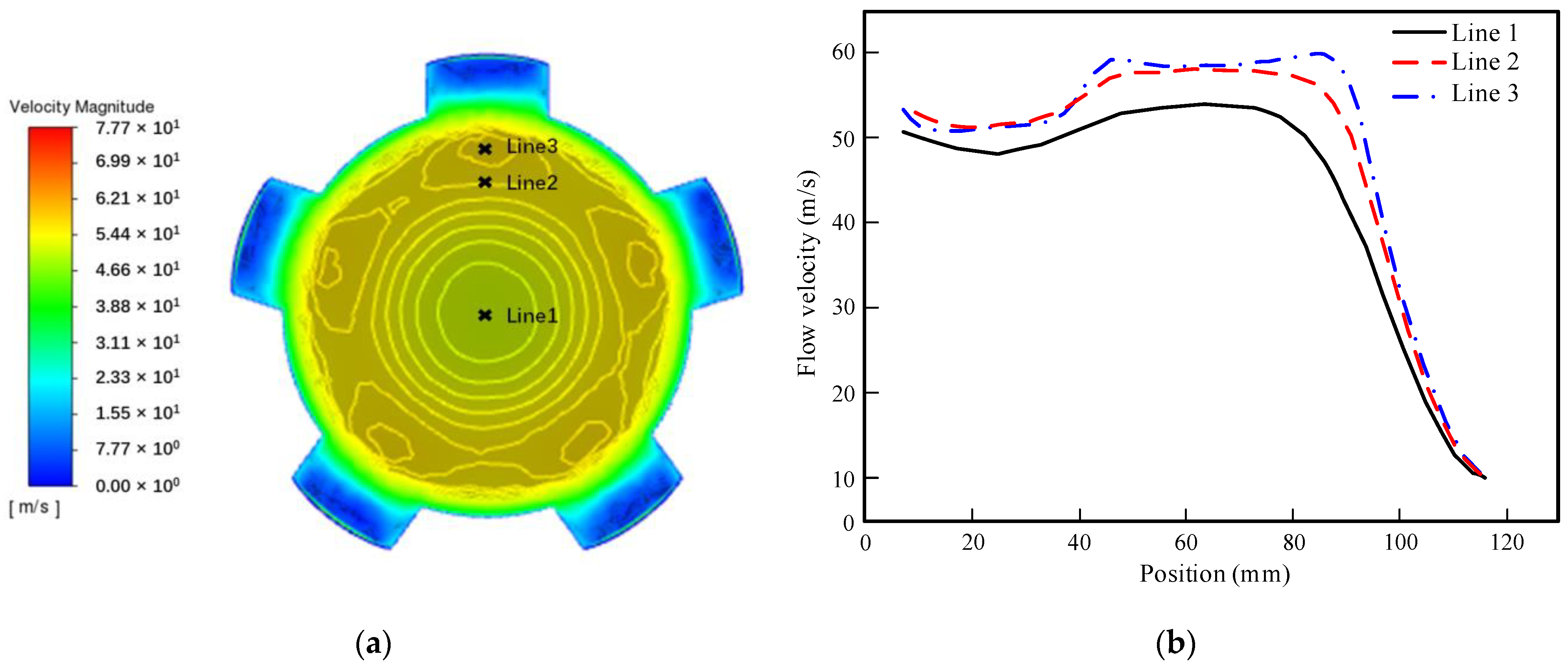

4.1. Flow Field Simulation and Analysis

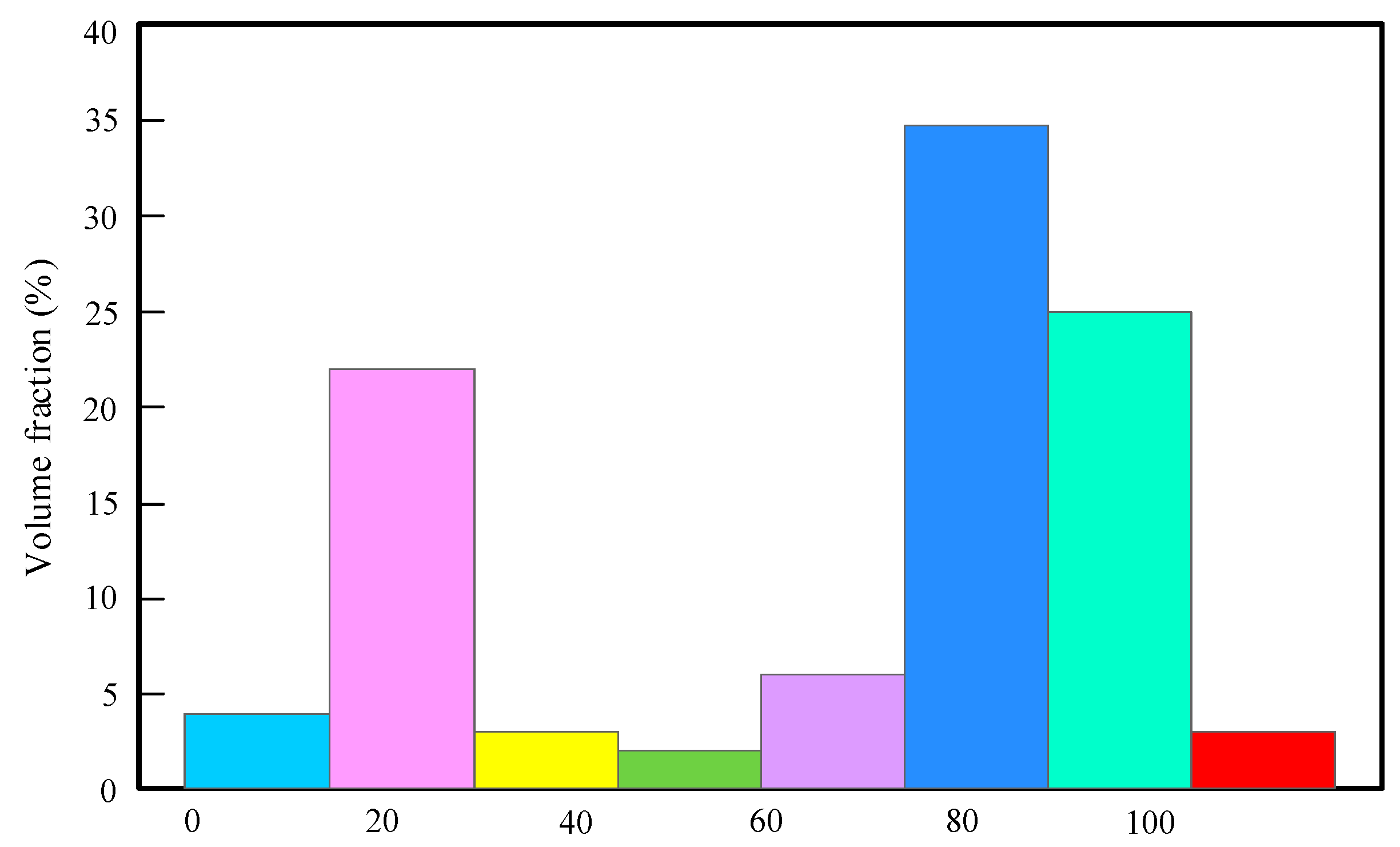

4.2. Particle Motion Simulation and Analysis

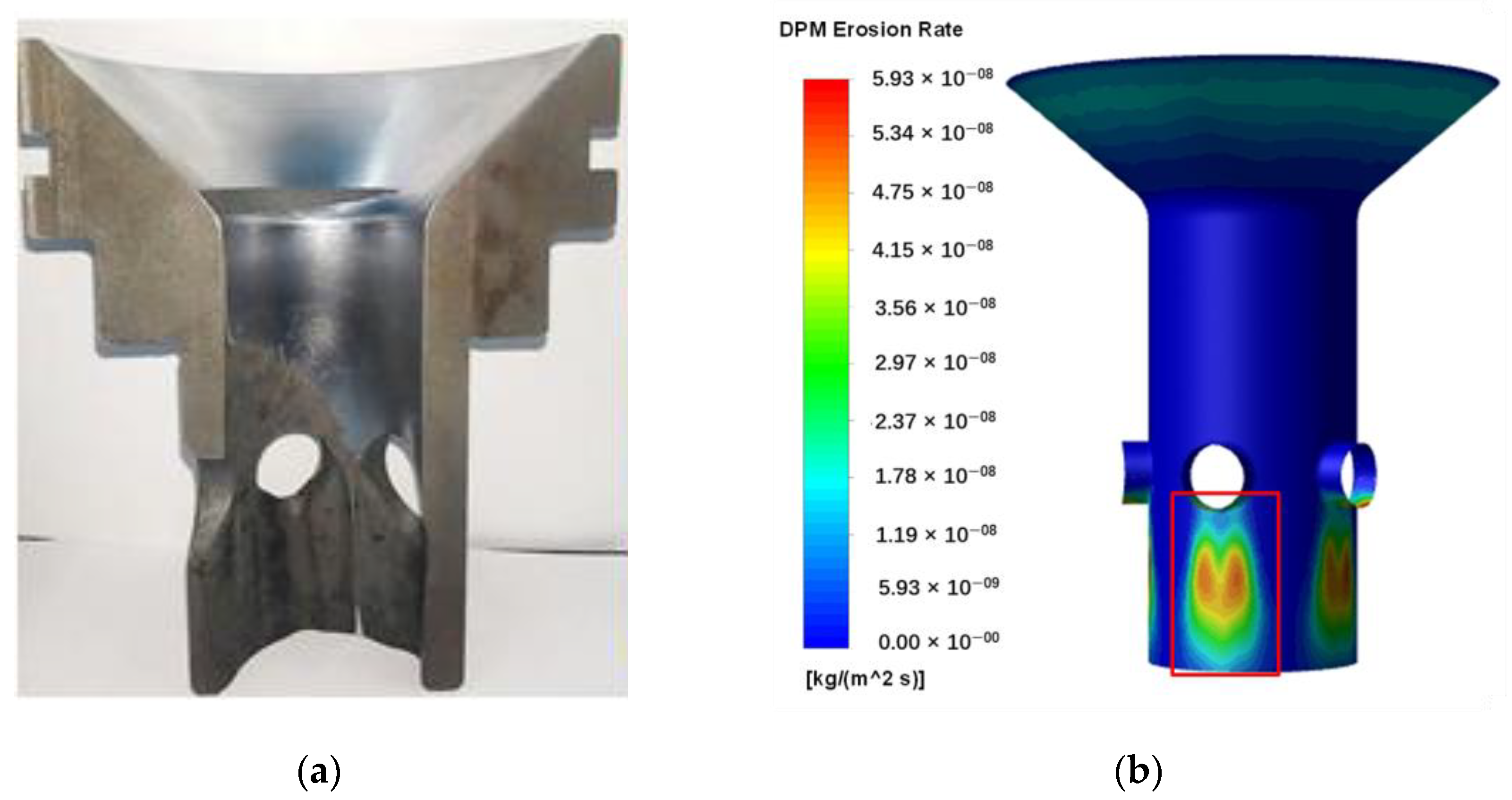

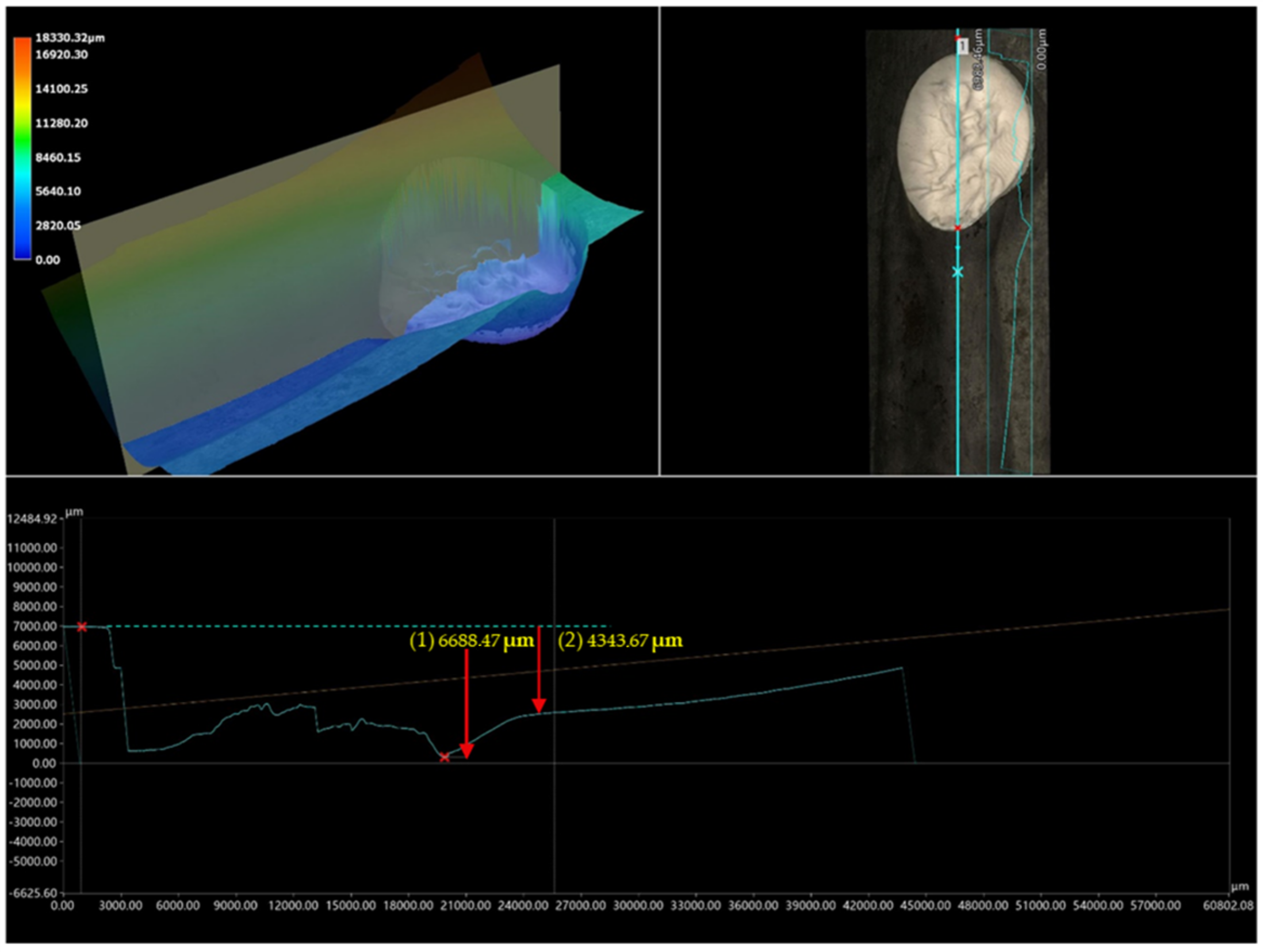

4.3. Experimental and Simulation Verification

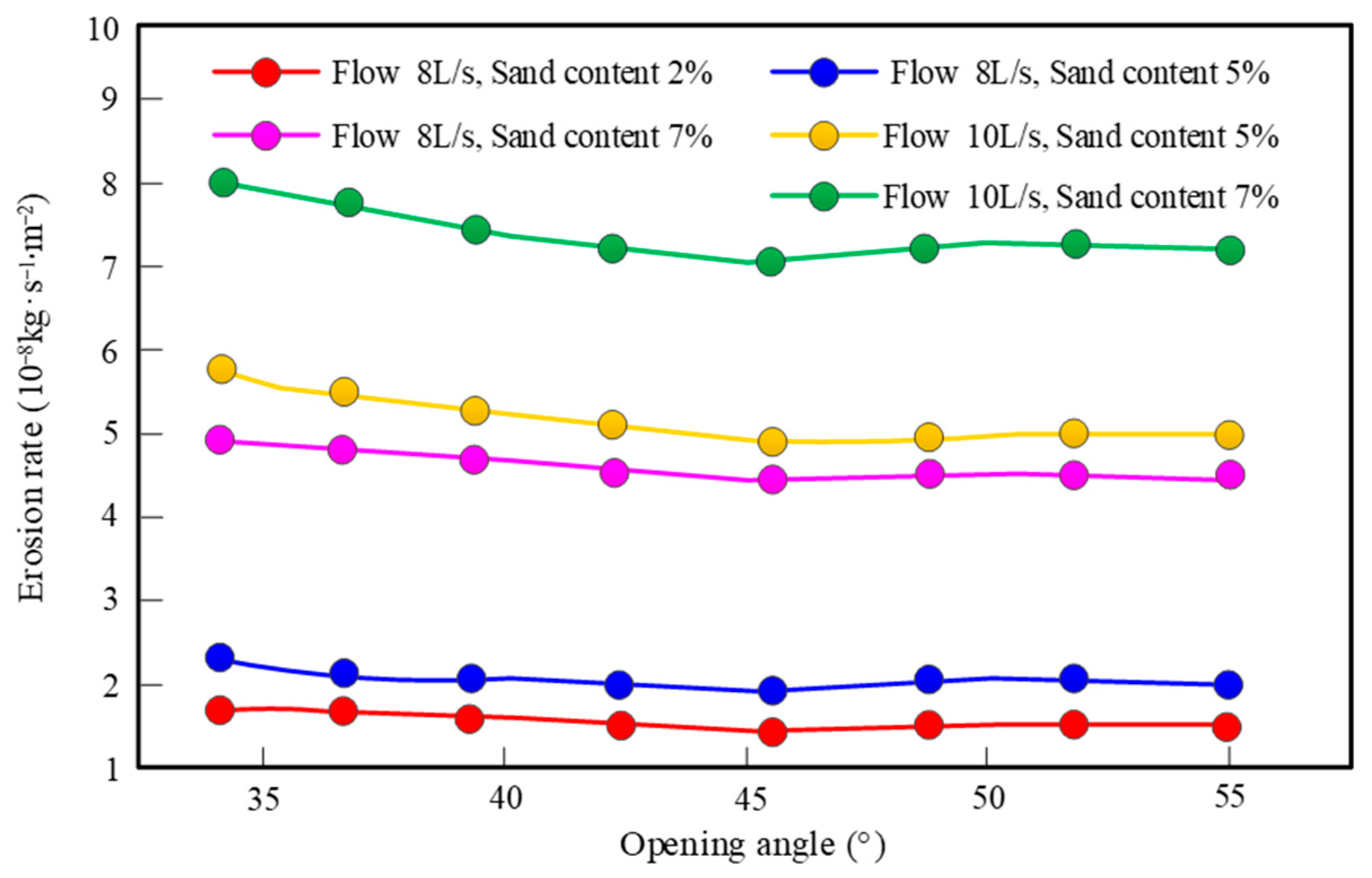

5. Valve Core Structure Optimization

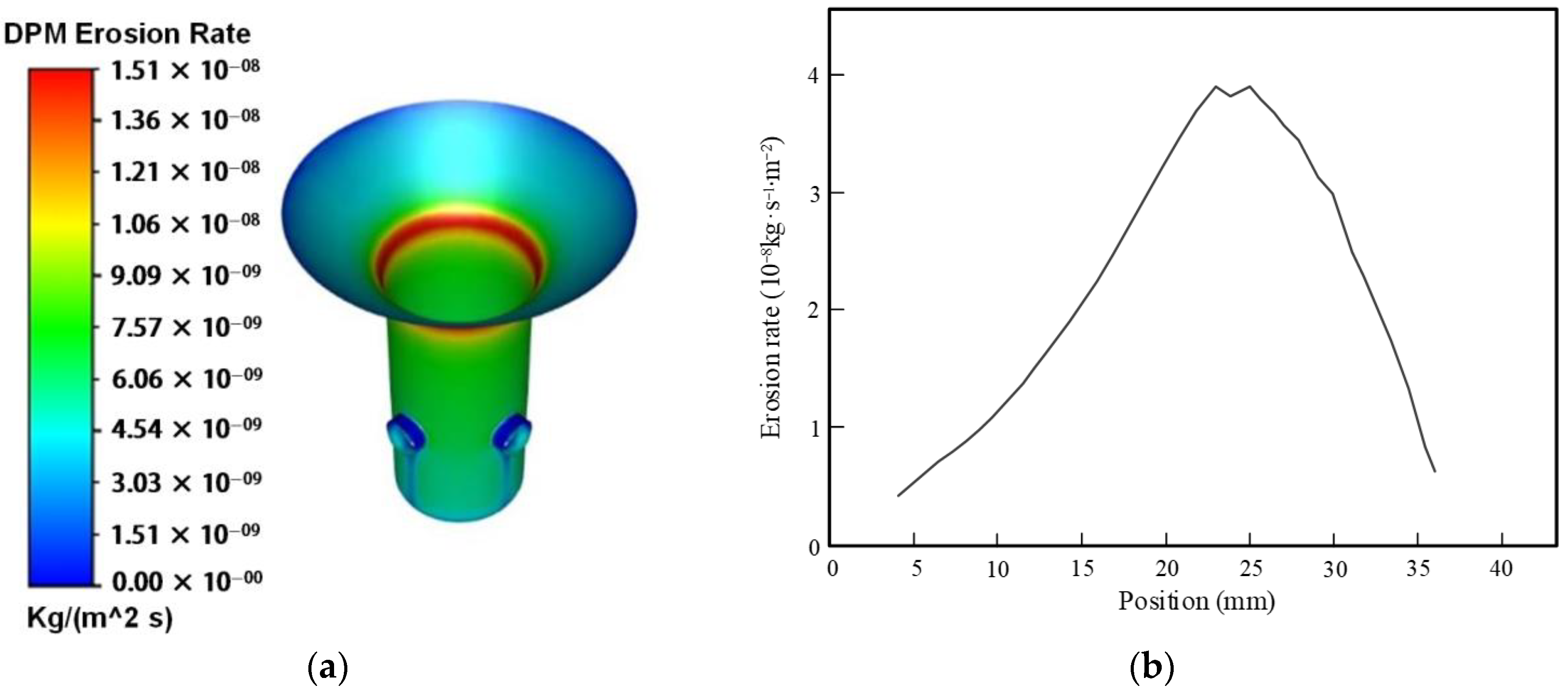

5.1. Reduce the Number of Holes

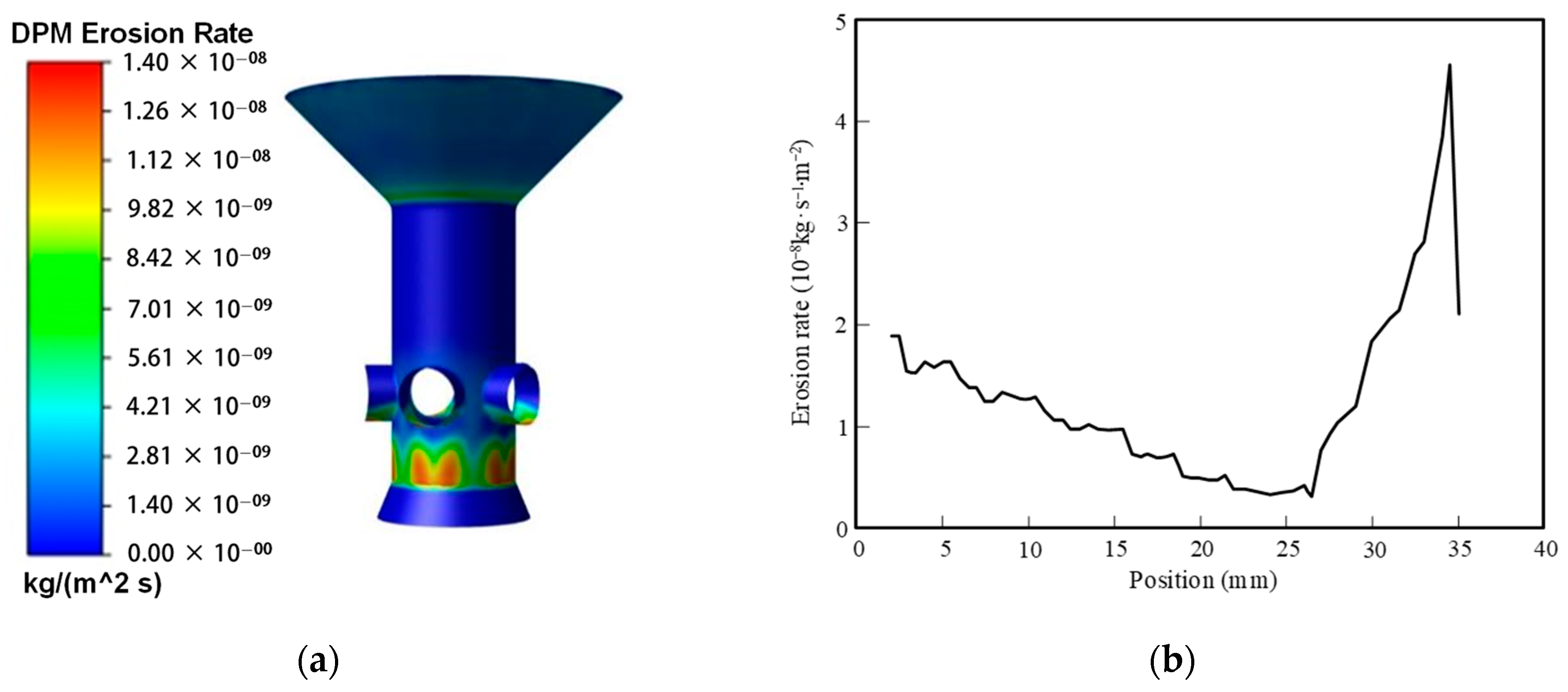

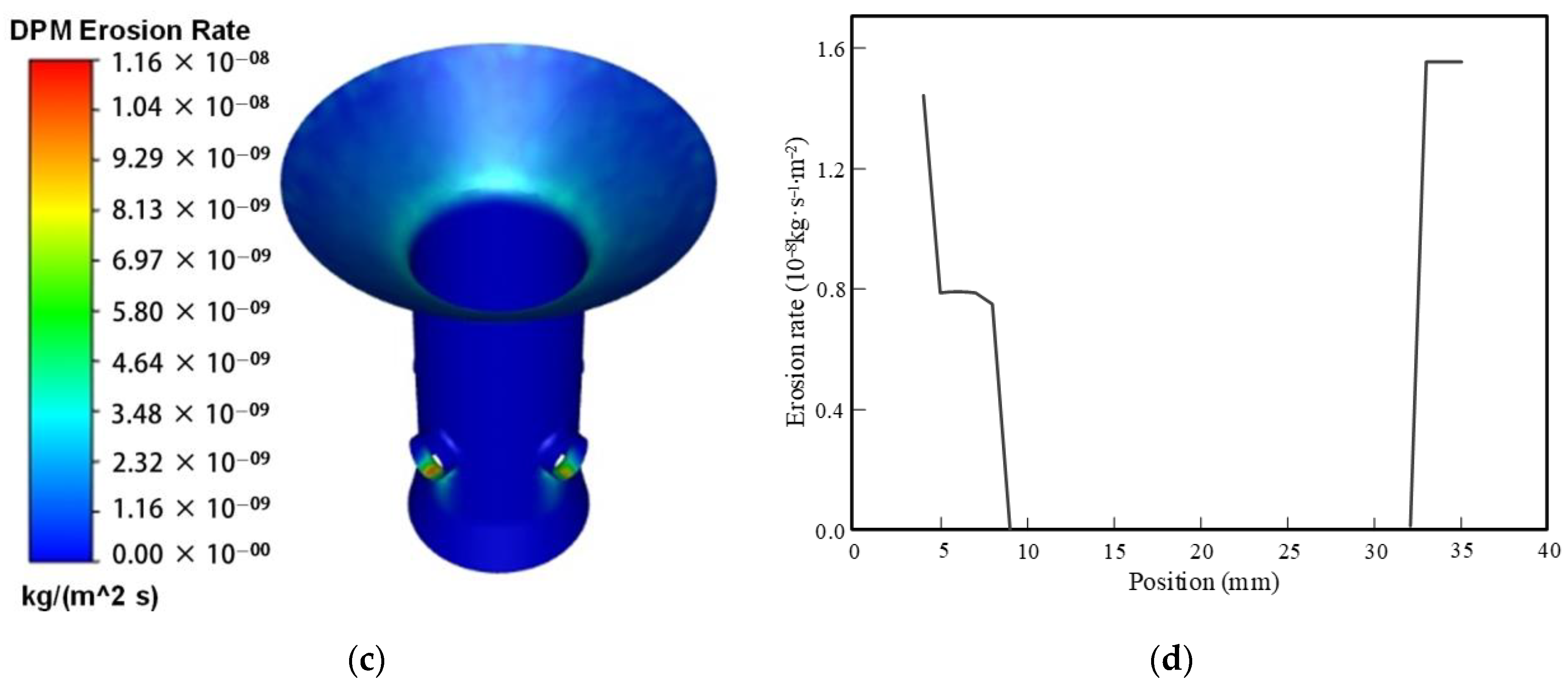

5.2. Valve Core Flow Channel Optimization

6. Optimization Effect Evaluation

6.1. Factors Affecting Erosion Impact Selection

6.2. Valve Core Life Prediction Model

7. Conclusions and Discussion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mazurek, M.; Gimmi, T.; Zwahlen, C.; Aschwanden, L.; Gaucher, E.; Kiczka, M.; Rufer, D.; Wersin, P.; Fernandes, M.M.; Glaus, M.; et al. Swiss deep drilling campaign 2019–2022: Geological overview and rock properties with focus on porosity and pore-space architecture. Appl. Geochem. 2023, 159, 105839. [Google Scholar] [CrossRef]

- Zhao, H.; Wu, H.; Shen, L.; Zhu, Z.; Shan, Y. Research on slim-hole drilling technology for shale gas geological survey in China. Pet. Res. 2024, in press. [Google Scholar] [CrossRef]

- Adumene, S.; Khan, F.; Adedigba, S.; Mamudu, A.; Rosli, M.I. Offshore oil and gas development in remote harsh environments: Engineering challenges and research opportunities. Saf. Extrem. Environ. 2023, 5, 17–33. [Google Scholar] [CrossRef]

- Du, K.; Xi, W.; Huang, S.; Zhou, J. Deep-sea Mineral Resource Mining: A Historical Review, Developmental Progress, and Insights. Min. Metall. Explor. 2024, 41, 173–192. [Google Scholar] [CrossRef]

- Fernando IP, S.; Jayawardena, T.U.; Wu, J. Marine proteins and peptides: Production, biological activities, and potential applications. Food Innov. Adv. 2023, 2, 69–84. [Google Scholar] [CrossRef]

- Wubben, E.; Veenstra, T.; Witkowski, J.; Raffi, I.; Hilgen, F.; Bos, R.; van Dijk, J.; Lathouwers, Y.; Spiering, B.; Vennema, L.; et al. Astrochronology of the Miocene Climatic Optimum record from Ocean Drilling Program Site 959 in the eastern equatorial Atlantic. Newsl. Stratigr. 2023, 56, 457–484. [Google Scholar] [CrossRef]

- Li, X.; Xiong, L.; Xie, W.; Gao, K.; Shao, Y.; Chen, Y.; Yu, Y.; Kou, B.; Lu, Q.; Zeng, J.; et al. Design and experimental study of core bit for hard rock drilling in deep-sea. J. Mar. Sci. Eng. 2023, 11, 306. [Google Scholar] [CrossRef]

- Johnston, N.; Dumnov, D.; Melling, J. Modelling of Pumps and Motors As Source Flow Ripple and Source Impedance. In Fluid Power Systems Technology; American Society of Mechanical Engineers: New York, NY, USA, 2023; Volume 87431, p. V001T01A008. [Google Scholar]

- Lu, J.X.; Kong, L.R.; Wang, Y.; Feng, C.; Gao, Y.L. Optimized parameters of downhole all-metal PDM based on genetic algorithm. Pet. Sci. 2024, 21, 2663–2676. [Google Scholar] [CrossRef]

- Ba, S.; Pushkarev, M.; Kolyshkin, A.; Song, L.; Yin, L.L. Positive displacement motor modeling: Skyrocketing the way we design, select, and operate mud motors. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 7–10 November 2016; SPE: Kuala Lumpur, Malaysia, 2016; p. D021S053R005. [Google Scholar]

- Nguyen, T.C.; Al-Safran, E.; Nguyen, V. Theoretical modeling of positive displacement motors performance. J. Pet. Sci. Eng. 2018, 166, 188–197. [Google Scholar] [CrossRef]

- Cui, G.; Xu, J.; Zhang, L.; Jin, N.; Zhao, J.; Wang, Y. Increasing Drilling Speed in Hard-to-Drill Formations with Various Types of Tools. Chem. Technol. Fuels Oils 2023, 59, 841–849. [Google Scholar] [CrossRef]

- Soares, M.M.; dos Passos, A.G.L.G.; De Lima, F.M.; De Souza, M.F.A.; de Souza Moreira, J.; Martins, A.F.V.; Pioli, R.M.; Spredemann, R.; Buzza, J.E.H.; Fernandes, F.B. ROP Optimization and Improved Wellbore Quality with New BHA and Drill Bits Modeling in Soft Shallow Formations. In Proceedings of the Offshore Technology Conference Brasil, Rio de Janeiro, Brazil, 24–26 October 2023; OTC: Tucson, AZ, USA, 2023; p. D011S006R001. [Google Scholar]

- Alattar, A.; Mustafa, M.M.; Nobre, D.; Applegate, R.; Pushkarev, M.; Dashti, S.; Saleh, K.; Saffar, A.H.; Harbi, A.A.; Anas, M. New Positive Displacement Motor Technology Significantly Improves the Drilling Performance through Challenging and Abrasive Strata in Northern Kuwait. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 13–16 November 2017; SPE: Kuala Lumpur, Malaysia, 2017; p. D011S008R003. [Google Scholar]

- Tikhonov, V.S.; Baldenko, F.D.; Bukashkina, O.S.; Liapidevskii, V.Y. Effect of hydrodynamics on axial and torsional oscillations of a drillstring with using a positive displacement motor. J. Pet. Sci. Eng. 2019, 183, 106423. [Google Scholar] [CrossRef]

- Liu, H.; Ma, T.; Chen, P.; Wang, X.; Wang, X. Mechanical behaviors of bottom hole assembly with bent-housing positive displacement motor under rotary drilling. Arab. J. Sci. Eng. 2019, 44, 6029–6043. [Google Scholar] [CrossRef]

- Shi, X.; Jiao, Y.; Yang, X.; Liu, J.; Zhuo, Y. Establishment of Drill-String System Dynamic Model with PDM and Influence of PDM Parameters on Stick–Slip Vibration. Arab. J. Sci. Eng. 2024, 49, 8727–8739. [Google Scholar] [CrossRef]

- Liagov, I.; Liagov, A.; Liagova, A. Optimization of the Configuration of the Power Sections of Special Small-Sized Positive Displacement Motors for Deep-Penetrating Perforation Using the Technical System “Perfobore”. Appl. Sci. 2021, 11, 4977. [Google Scholar] [CrossRef]

- Guanghui, Z.; Guipeng, L. Elastic-plastic Fracture Analysis of External Thread of Drive Shaft Shell of a Positive Displacement Motor. Mechanics 2020, 26, 375–382. [Google Scholar]

- Liu, Y.; Lian, Z.; Xia, C.; Qian, L.; Liu, S. Fracture failure analysis and research on drive shaft of positive displacement motor. Eng. Fail. Anal. 2019, 106, 104145. [Google Scholar] [CrossRef]

- Liu, Y.; Lian, Z.; Zou, J.; Deng, C.; He, Y. Fracture failure analysis and research on thread joint of drive shaft shell of positive displacement motor. Eng. Fail. Anal. 2020, 118, 104805. [Google Scholar] [CrossRef]

- Zhu, X.; Lin, D.; Li, J. Failure analysis and structure optimization of the connecting thread of driving shaft in positive displacement motor. Adv. Mech. Eng. 2016, 8, 1687814016652313. [Google Scholar] [CrossRef]

- Zhang, H.L.; Zang, Y.H.; Mi, K.F.; Guo, T.M.; Guo, C.; Gao, Y. Study on the Coupling Law of the Stator and Rotor of Positive Displacement Motor with the Application of Highly Filled Rubber. In Proceedings of the International Field Exploration and Development Conference, Xi’an, China, 16–18 November 2022; Springer Nature: Singapore, 2022; pp. 2434–2450. [Google Scholar]

- Alvarez, A.A.; Boscan, J. Predicting rotor-stator fit in positive displacement motors PDMs. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, The Hague, The Netherlands, 14–16 March 2017; SPE: Kuala Lumpur, Malaysia, 2017; p. D031S015R005. [Google Scholar]

- Yang, S. A New Design of Vibration Damping Structure for Positive Displacement Motor. Acad. J. Sci. Technol. 2024, 9, 146–152. [Google Scholar] [CrossRef]

- Li, Y.F.; Lin, Z.L.; Li, M.; Zou, Y.; Huang, P.P.; Hao, W.W.; Wang, H. Discussion on Mechanical and Drilling Performance of the Positive Displacement Motors of Wall Thickness Rubber. In Proceedings of the International Field Exploration and Development Conference, Wuhan, China, 20–22 September 2023; Springer Nature: Singapore, 2023; pp. 958–971. [Google Scholar]

- Zhang, J.; Liu, Y.; Zhang, H. Design and Mechanics Analysis of the Deep Cavity Tapered Roller Thrust Bearing Used in a Positive Displacement Motor. Trans. FAMENA 2019, 43, 53–64. [Google Scholar] [CrossRef]

- Huang, X.; Chen, Y.; Zhuo, H.; He, X. Research on the wear failur mechanism of high speed positive displacement motor bearings. Int. J. Mechatron. Appl. Mech. 2024, 127. [Google Scholar] [CrossRef]

- Zhang, J.; Han, C.; Liang, Z. Physics of failure analysis of power section assembly for positive displacement motor. J. Loss Prev. Process Ind. 2016, 44, 414–423. [Google Scholar] [CrossRef]

- Chen, X.; Gao, D.; Guo, B.; Feng, Y. Real-time optimization of drilling parameters based on mechanical specific energy for rotating drilling with positive displacement motor in the hard formation. J. Nat. Gas Sci. Eng. 2016, 35, 686–694. [Google Scholar] [CrossRef]

- El-Sayed, I.; Hopkins, Z.; Dupriest, F.; Noynaert, S.F. Theoretical Vs. Actual Mud Motor Performance in Unconventional Formations and Strategies to Extend Motor Life. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, Galveston, TX, USA, 3–5 March 2020; SPE: Kuala Lumpur, Malaysia, 2020; p. D091S010R002. [Google Scholar]

- Kong, L.; Wang, Y.; Wu, C.; Yang, S. Self-Powered Multifunctional Sensor of Positive Displacement Motor Based on Triboelectric Nanogenerator. IEEE Sens. J. 2021, 21, 18593–18600. [Google Scholar] [CrossRef]

- Koulidis, A.; Ahmed, S. Positive Displacement Motor Condition and Performance Prediction Using Surface and Downhole Sensor Data; IntechOpen: London, UK, 2024. [Google Scholar]

- Galo Fernandes, R.A.; Silva Rocha Rizol, P.M.; Nascimento, A.; Matelli, J.A. A Fuzzy Inference System for Detection of Positive Displacement Motor (PDM) Stalls during Coiled Tubing Operations. Appl. Sci. 2022, 12, 9883. [Google Scholar] [CrossRef]

- Hou, L.; Wu, J. Mechanism analysis and preventive measures of drill string leakage caused by corrosion. Oil Drill. Technol. 2006, 26–28. [Google Scholar] [CrossRef]

| Hidden Layer Function | Output Layer Function | Error Percentage (%) | Mean Squared Error |

|---|---|---|---|

| Logsig | Tansig | 40.63 | 0.9025 |

| Logsig | Purelin | 0.08 | 0.0001 |

| Logsig | Logsig | 352.65 | 181.2511 |

| Tansig | Tansig | 31.9 | 1.1733 |

| Tansig | Logsig | 340.9 | 162.9598 |

| Tansig | Purelin | 1.7 | 0.0107 |

| Purelin | Logsig | 343.36 | 143.7633 |

| Purelin | Tansig | 120.08 | 113.0281 |

| Purelin | Purelin | 196.49 | 99.0121 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Zhang, L.; Gao, Y.; Shi, P.; Wang, Y.; Kong, L. Research on Erosion Damage Laws and Structural Optimization of Bypass Valve for Positive Displacement Motors. Processes 2024, 12, 1953. https://doi.org/10.3390/pr12091953

Zhang Y, Zhang L, Gao Y, Shi P, Wang Y, Kong L. Research on Erosion Damage Laws and Structural Optimization of Bypass Valve for Positive Displacement Motors. Processes. 2024; 12(9):1953. https://doi.org/10.3390/pr12091953

Chicago/Turabian StyleZhang, Yanbo, Lei Zhang, Yulin Gao, Ping Shi, Yu Wang, and Lingrong Kong. 2024. "Research on Erosion Damage Laws and Structural Optimization of Bypass Valve for Positive Displacement Motors" Processes 12, no. 9: 1953. https://doi.org/10.3390/pr12091953