Abstract

This review synthesizes insights from the literature and incorporates computational and experimental analyses to explore various types of safety valves and their applications across industries such as oil and gas, chemical manufacturing, and power generation. Key areas of focus include global regulatory standards from organizations like the American Society of Mechanical Engineers (ASME), International Organization for Standardization (ISO), Deutsches Institut für Normung (DIN), and American Petroleum Institute (API), which ensure stringent design and testing requirements. This paper examines the historical development of safety valves, recent technological advancements such as smart valves with integrated sensors, and predictive maintenance capabilities, along with ongoing challenges in high-pressure and corrosive environments. Additionally, it highlights the role of computational tools like CFD and FEA in optimizing valve designs and ensuring reliability under demanding conditions. By presenting a streamlined analysis of standards, innovations, and future directions, this review underscores the indispensable importance of safety valve technology in ensuring operational safety across various industrial applications.

1. Introduction

Safety valves are vital components in industrial systems, designed to prevent overpressure situations that could otherwise lead to catastrophic failures, equipment damage, and safety hazards [1,2,3,4,5]. Their role is very important in maintaining the integrity of processes across industries such as oil and gas, chemical manufacturing, power generation, and transportation [6,7]. According to the American Society of Mechanical Engineers (ASME), a safety valve is defined as a device that automatically releases a substance from a boiler, pressure vessel, or other systems when the pressure exceeds preset limits, ensuring operational safety and reliability (ASME BPVC, Section VIII). By acting as a pressure relief mechanism, these valves serve as the last line of defense in systems under pressure, protecting not only the equipment but also personnel and the environment from potentially dangerous failures.

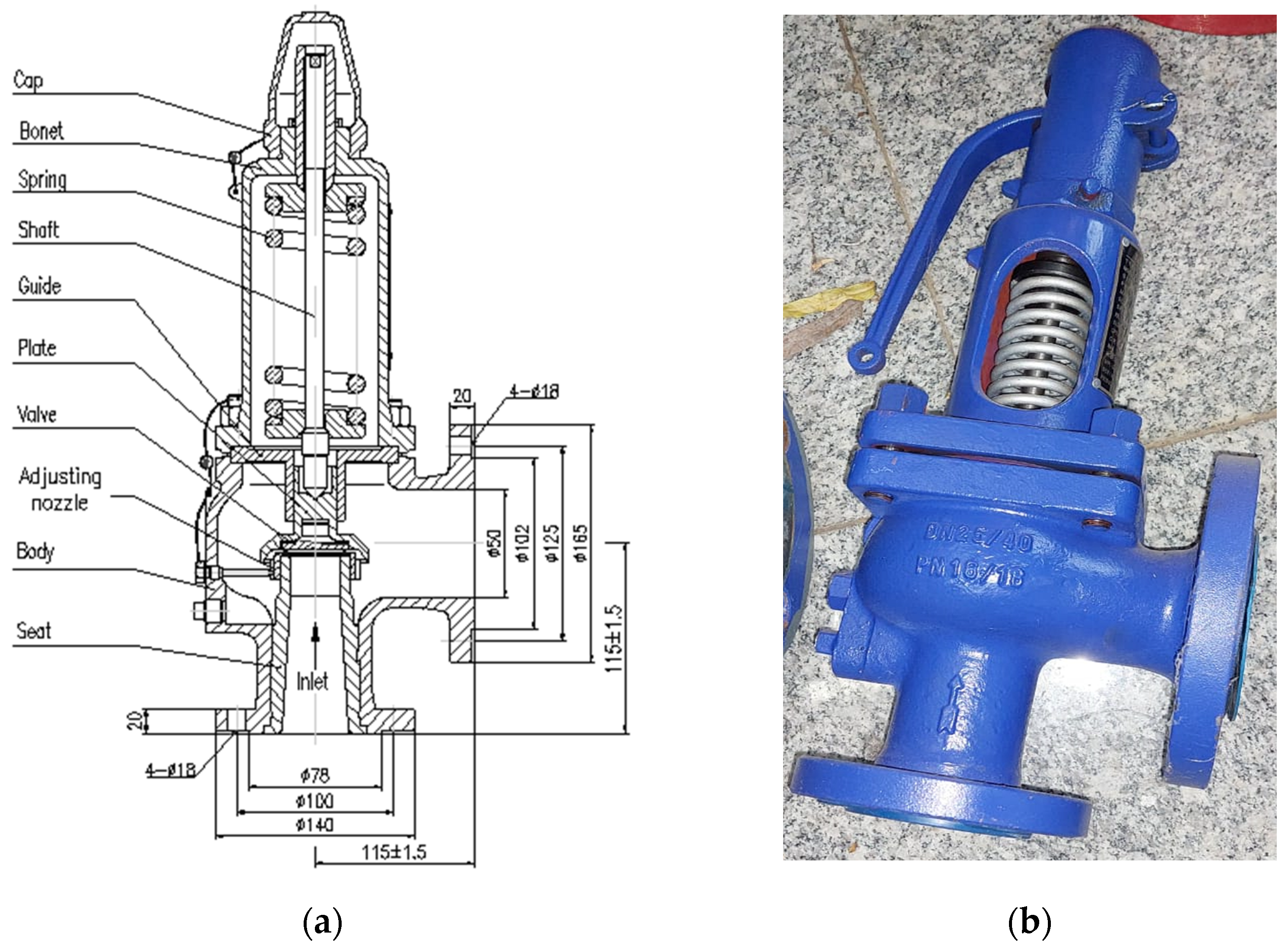

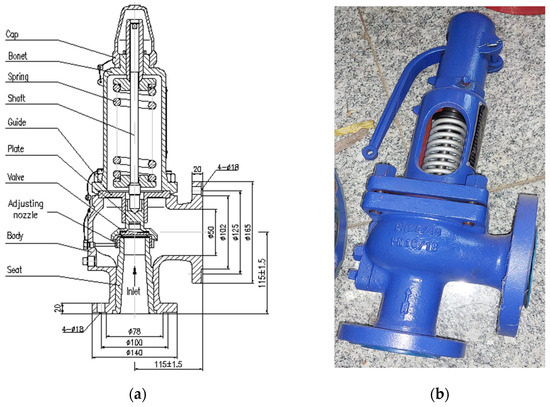

In Figure 1 an example is presented of a pressure valve commonly used in the oil and gas industry and its main components.

Figure 1.

Example of pressure relief valve: (a) 2D drawing; (b) real shape [8].

Since both the sealing surface of the valve and the seat surface are coated with hard materials, the valve includes the valve body and plate, while the seat assembly comprises the seat body and adjusting nozzle. Figure 2 illustrates the assembly of these two components, which is typical for discharge valves.

Figure 2.

Components of the pressure valve: (a) plate assembly and (b) seat assembly [8].

An extensive range of the scientific literature [3,5,9,10,11,12,13,14,15,16,17,18,19,20] has been dedicated to the description and analysis of valve systems.

This review provides a comprehensive analysis of the different types of safety valves, including spring-loaded, pilot-operated, and other specialty valves and their application across various industries. This paper explores the major global standards that regulate safety valves, such as those developed by ASME, the American Petroleum Institute (API), and the International Organization for Standardization (ISO). Each of these standards imposes stringent requirements on the design, testing, and maintenance of safety valves to ensure they perform reliably under operational conditions. Additionally, this review discusses the core principles of valve design, pressure settings, the materials used, and operating environments.

Technological advancements in safety valve design and operation present both opportunities and challenges. For instance, while traditional safety valves have evolved to handle high pressures and corrosive environments, modern industry demands even greater performance, particularly in terms of automation and predictive monitoring. Smart safety valves, equipped with sensors and integrated with artificial intelligence (AI), are becoming an essential part of Industry 4.0, allowing real-time monitoring and predictive maintenance capabilities [21,22]. Furthermore, advancements in materials, such as corrosion-resistant coatings and high-performance alloys, have significantly improved the longevity and reliability of safety valves under extreme conditions [15,23,24,25,26,27,28,29]. Despite these improvements, the ongoing challenge remains to balance operational reliability with the need for innovation, especially in industries requiring higher performance under demanding conditions such as high temperatures and corrosive or hazardous fluids.

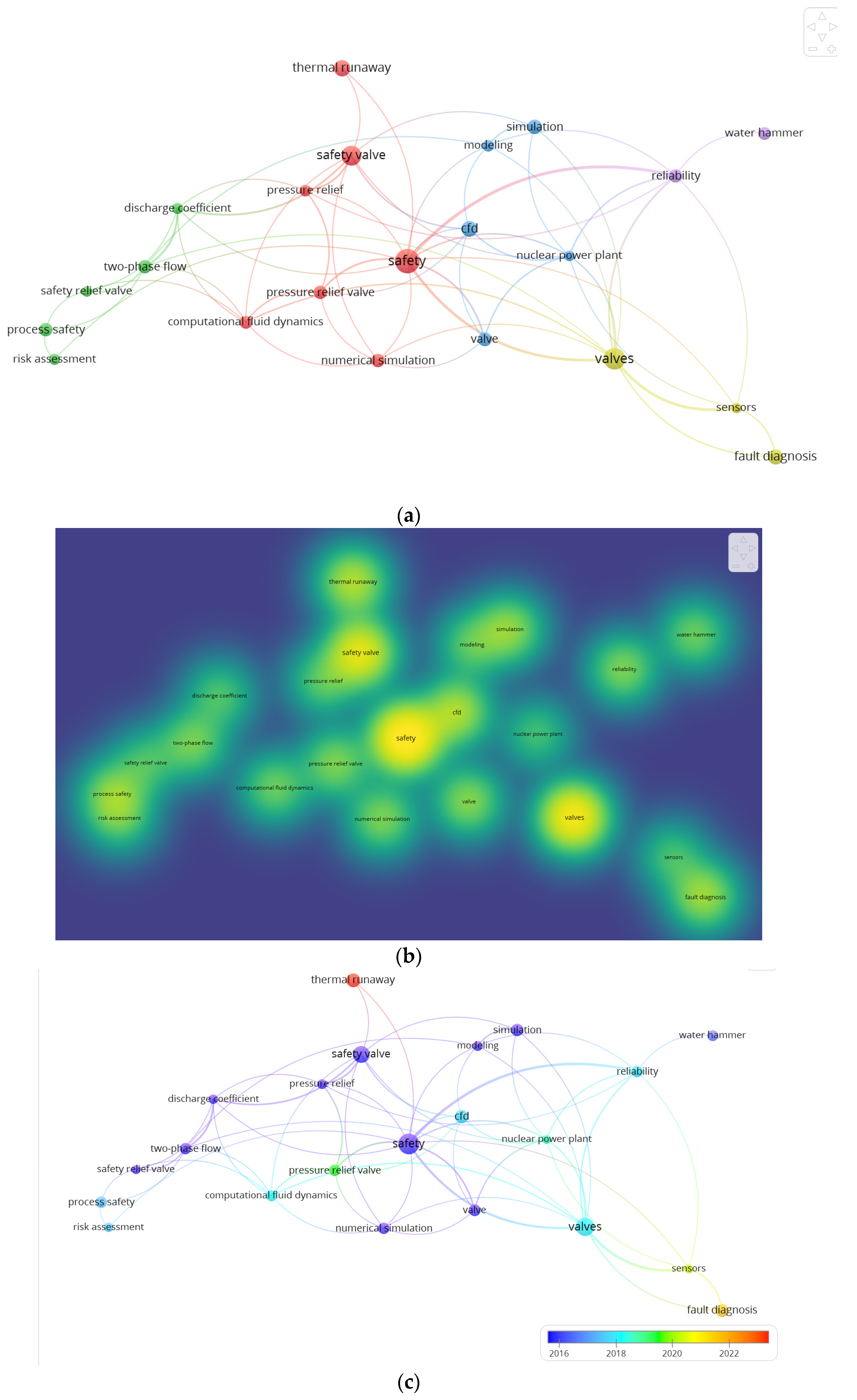

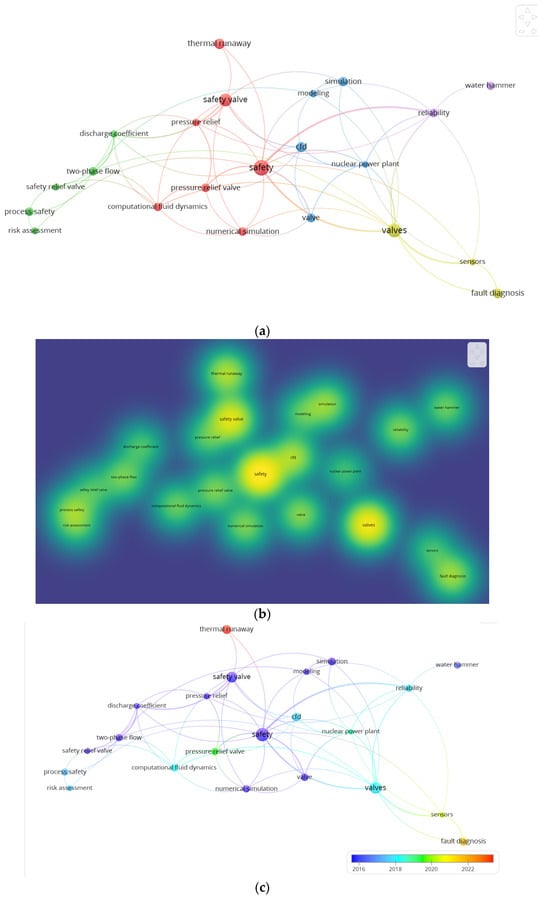

For this review, an extensive search was conducted using the Web of Science (WOS) database, focusing on the keywords “safety valves” within the research area of engineering. The selection process involved filtering relevant studies published in English, covering key aspects such as safety valve design, materials, standards, and technological advancements. Studies were evaluated based on their methodological rigor, experimental or computational analysis, and relevance to industrial safety. The identified studies were then synthesized to address the gap in the literature regarding recent innovations and their practical applications in various industries. After finding the relevant papers (920 article types and 22 review articles), we performed a cluster analysis with VOSviewer version 1.6.20, as seen in Figure 3.

Figure 3.

VOS viewer analysis results: (a) keywords co-occurrence network; (b) density visualization; (c) overlay visualization.

Figure 3a depicts the network of keywords associated with safety valves and related topics. The interconnected terms like “safety valve”, “pressure valve”, and “fluid dynamics” highlight the primary areas of focus, demonstrating the emphasis on valve performance and fluid safety. Figure 3b, with its heatmap visualization, reveals areas of higher research activity, such as “safety” and “valves”, indicating well-explored domains. However, emerging topics like “fault diagnosis” and “smart technologies” appear underrepresented, suggesting critical gaps in addressing modern industrial challenges. Lastly, Figure 3c illustrates the temporal trends of these research themes, showing an increasing interest in areas like “simulation” and “reliability” but limited progress in adopting predictive maintenance and prevention techniques. These figures collectively highlight the need for more focused research on integrating advanced technologies and addressing operational limitations, which this review aims to explore comprehensively.

The evolution of safety valve technology has been instrumental in addressing industrial safety challenges. Early designs, such as weight-loaded valves, laid the groundwork for more sophisticated spring-loaded mechanisms developed in the 19th century, which resolved critical issues like tampering and operational reliability. These advancements enabled the widespread adoption of safety valves in steam engines, chemical plants, and other industrial applications. In recent decades, the transition toward smart safety valves equipped with sensors and predictive maintenance capabilities has further enhanced operational safety and reliability, aligning with the principles of Industry 4.0.

Although significant progress has been made, challenges persist in ensuring valve reliability under extreme conditions such as high pressures and corrosive environments. Furthermore, the potential of computational tools like CFD and FEA to optimize valve design and predict performance under complex operating conditions remains underexplored.

To address the gap in existing research, this review provides a distinctive contribution by synthesizing and analyzing key advancements and challenges in safety valve technology, with a focus on their evolving role in industrial applications. While previous studies have primarily focused on specific aspects such as design optimization, material selection, or compliance with regulatory standards, this paper adopts a comprehensive approach. It integrates discussions on global standards, historical developments, and emerging innovations such as smart safety valves and Industry 4.0 technologies. Furthermore, this review identifies critical challenges faced by safety valves in demanding environments, including high-pressure and corrosive conditions, and proposes directions for future research to address these limitations. By bridging the gap between traditional design principles and modern technological advancements, this study aims to provide a comprehensive perspective that informs both academic research and industrial practices.

The comparative and qualitative analysis of the information regarding the use of safety valves pursued the achievement of the following objectives. This set of objectives underscores the critical aspects that need to be addressed in a safety valve analysis review, leveraging insights from the contemporary literature and industry standards.

- Performance evaluation: assess the performance of safety valves across a range of operating conditions to identify potential failure points and prevent incidents;

- Operating condition assessment: analyze historical accidents and operational data to define the expected conditions under which the safety valves must function;

- Proper selection criteria: develop guidelines for selecting safety relief valves by considering critical factors such as equipment type, fluid properties, operating temperature, set pressure, and required discharge capacity;

- Accessibility analysis: ensure that all safety-critical valves are easily accessible for maintenance and inspection during the analysis phase;

- Design variable influence: investigate how design variables affect the operational characteristics of pressure safety valves, particularly their opening and reclosing behaviors;

- Optimal structural identification: identify the most effective structural designs for safety valves that deliver the best performance and reliability based on analysis results and industry benchmarks;

- Test result review: conduct a thorough review of existing test results and empirical data to evaluate and compare the performance metrics of various safety valves;

- Prototype applicability: assess the relevance and effectiveness of prototypical valve designs within specific systems to ensure they meet operational demands;

- Reliability and efficiency assessment: determine the reliability and efficiency of safety valves in mitigating overpressure situations and protecting system integrity;

- Improvement recommendations: formulate actionable recommendations for design modifications or operational changes aimed at enhancing the overall performance, reliability, and safety of safety valves.

This study focuses on evaluating the performance of safety valves under varying conditions, optimizing material selection for durability, and integrating IoT-based predictive maintenance systems to address current industry challenges.

2. Historical Background

The development of safety valves has a long and rich history, dating back to the early days of industrialization when the need to control pressure in steam engines and boilers became critical for safe operations. The first recorded use of safety valves can be traced to the 17th century, when Denis Papin, a French physicist and inventor, introduced a rudimentary form of the safety valve to control steam pressure in his pressure cooker invention in 1679 [30]. This early innovation laid the groundwork for the industrial applications that followed during the Industrial Revolution.

Around 1830, Timothy Hackworth developed an open-ended safety valve for the emerging steam trains and boilers of the time, marking the beginning of modern safety valve design. However, despite this innovation, steam installations did not significantly improve in safety with the early safety devices available [31].

In 1848, Charles Retchie invented the accumulation chamber, which increases the compression surface within the safety valve allowing it to open rapidly within a narrow overpressure margin [32].

Early safety valves were rudimentary, relying on weights to maintain steam pressure. However, these designs were prone to tampering or accidental release. In 1856, John Ramsbottom introduced a tamper-proof, spring-loaded safety valve, which quickly became the standard for railway applications and later for stationary installations [33].

The 19th century saw significant advancements in safety valve design, particularly with the rise of steam engines in locomotives and factories. Safety valves became essential for protecting boilers from dangerous overpressure, which could cause catastrophic explosions. By the late 19th century, safety valves were not only in widespread use in steam-powered machinery but were also being integrated into chemical and petrochemical industries, where managing volatile and pressurized fluids became essential.

As industrial processes grew in scale and complexity throughout the 20th century, the demand for more reliable and standardized safety valves intensified. This led to the establishment of various international standards, such as the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code (BPVC) in 1914 [31]. ASME played an essential role in shaping the modern standards for the design, testing, and use of safety valves, ensuring consistency and safety across industries (ASME BPVC, 1914). The ASME Boiler and Pressure Vessel Code, Section I, became a mandatory requirement in all states that acknowledged the necessity for legislation [31]. Additionally, the American Petroleum Institute (API) and the International Organization for Standardization (ISO) further developed specific regulations to address the needs of the oil, gas, and chemical industries, where extreme pressures and hazardous environments are common.

Throughout the 20th century, safety valve technology continued to evolve. Innovations in materials science, particularly the development of alloys and composites that can withstand high pressures and corrosive environments, significantly improved valve performance. These materials were essential for meeting the growing demands of industries operating under more extreme conditions, such as oil refineries, chemical plants, and power generation facilities. In parallel, advances in engineering design, such as pilot-operated and balanced-bellows safety valves, allowed for greater precision and reliability in valve operation [30].

In recent decades, the emergence of smart technologies and automation has further transformed the landscape of safety valve design. The introduction of digital monitoring systems, sensors, and artificial intelligence (AI) has enabled real-time tracking of valve performance and predictive maintenance, significantly reducing the risk of failures and improving operational efficiency [21,22]. This evolution reflects the broader trend toward Industry 4.0, where interconnected systems and data-driven technologies are reshaping industrial safety and maintenance practices.

3. Overview of Global Standards Governing Safety Valves

Safety and relief valves are strictly regulated by codes and regulations, with the two primary frameworks being ASME in the USA and PED in Europe. The main applicable standards for safety valves are shown in Table 1 [34].

Table 1.

Safety valves applicable standards.

Table 2 provides a concise summary of the key operational code requirements based on the current global standards [44].

Table 2.

Main operational code requirements according to the current worldwide codes.

Using the bibliography list, the following analysis was defined regarding the comparison between findings and recommendations in standards and the existing literature in the safety valve industry:

- ✓

- Sizing methodologies: ASME outlines specific procedures for valve sizing, yet the literature indicates that dynamic effects, such as fluctuating flow rates, can lead to under-sizing in practical applications [10,14];

- ✓

- Material specifications: standards specify acceptable materials for corrosion resistance, whereas the literature highlights new composites that may surpass traditional materials in corrosive environments [15,24];

- ✓

- Operational testing: while standards mainly prescribe static pressure tests, research advocates for dynamic testing to better simulate real-life scenarios, leading to more accurate performance assessments [4,19];

- ✓

- Failure analysis: standards may not adequately address the fatigue mechanisms that can lead to safety valve failures; studies emphasize the need to integrate these findings into quality assurance protocols [5,12];

- ✓

- Installation requirements: installation standards suggest basic configuration guidelines, but the literature emphasizes the importance of system integration factors such as pipe layout and fluid dynamics [11,25];

- ✓

- Performance under transient conditions: standards often focus on steady-state operation, while the literature discusses the significant impact of transient conditions on safety valve performance, advising for adaptive approaches [19,45];

- ✓

- User training protocols: drawing from standards which focus on valve operation, the literature calls for enhanced training programs targeting user awareness to improve valve reliability and maintenance procedures [11,46];

- ✓

- Emergency procedures: standards outline basic emergency response steps; however, the literature stresses comprehensive drills and scenarios for better preparedness in real incidents [26,47];

- ✓

- Monitoring technologies: while standards describe basic monitoring techniques, the literature encourages the use of advanced data analytics and IoT technologies for predictive maintenance [21,48];

- ✓

- Environmental compliance: standards include basic guidelines for emissions; the literature suggests comprehensive environmental impact assessments for safety valves, especially in chemical industries [6,49];

- ✓

- Impact of backpressure: standards acknowledge backpressure considerations, but the literature suggests deeper analytical methods to quantify its effect on valve performance [50,51];

- ✓

- Smart valve integration: standards may lack specifics for smart technologies, while the emerging literature proposes frameworks for integrating smart algorithms to enhance valve responsiveness [22,48];

- ✓

- Validation of sizing methods: standards mention traditional sizing methodologies, but studies evaluate their adequacy and propose advanced metrics tailored to specific industry scenarios [14,52];

- ✓

- Lifecycle assessment: standards do not typically cover the complete valve lifecycle, while the literature urges the adoption of lifecycle cost analysis for optimized maintenance planning [12,48];

- ✓

- Cross-disciplinary approaches: standards emphasize mechanical design, whereas the literature argues for incorporating insights from fluid dynamics and materials science to enhance performance [51,53];

- ✓

- Chatter prevention: standards provide basic guidelines, but the existing literature presents in-depth studies on valve behavior related to chatter and offers novel design solutions [18,54];

- ✓

- Case studies of failures: standards may provide general guidelines for valve operation; the literature often includes detailed case studies and lessons learned from past failures to inform better practices [55,56];

- ✓

- Customization needs: standards suggest generic valve specifications, while the literature highlights the growing need for customized solutions to meet specific operational demands in various industries [1,8];

- ✓

- Simulation techniques: while standards offer basic testing procedures, the literature investigates complex simulation techniques that more accurately predict valve behavior [3,50];

- ✓

- Regulatory updates: standards are frequently static; however, the literature advocates for agile approaches that incorporate ongoing research findings and technological advancements into compliance updates [18,30];

- ✓

- Standard operating procedures: standards provide basic procedures for the operation of safety valves, while the literature emphasizes the need for specific guidelines tailored to individual operational contexts to ensure optimal performance [11,46];

- ✓

- Assessment of system risks: standards may outline general safety assessments; however, the literature advocates conducting detailed risk analyses that consider system-specific variables and historical data [6,19];

- ✓

- Energy efficiency considerations: standards often overlook energy consumption metrics; the literature discusses integrating efficiency guidelines into the design and operation of safety valves to minimize energy waste [21,22];

- ✓

- Role of computational fluid dynamics [CFDs]: while standards indicate basic testing methods, the literature strongly promotes the use of CFD simulations to gain insights into fluid dynamics affecting valve performance [50,57];

- ✓

- Temperature effects: OSHA and other standards typically address temperature limits but may lack thorough analysis; the literature reports that temperature fluctuations can significantly impact valve materials and performance, suggesting further study [1,51];

- ✓

- Post-failure analysis: standards may lack guidelines on conducting thorough post-failure assessments, whereas the literature stresses the importance of such analyses to derive insights for preventing future incidents [55,56];

- ✓

- Life cycle management: standards provide limited guidance on life cycle management of safety valves; the literature suggests a more proactive approach to evaluating long-term performance and maintenance needs [12,27];

- ✓

- Public safety regulations: while standards focus on compliance, the literature advocates for a broader view encompassing public safety regulations and social responsibility in safety valve designs [6,49];

- ✓

- User-friendly design: standards primarily focus on functionality; the literature suggests employing ergonomic designs that enhance user interaction to minimize operational errors [22,48];

- ✓

- Collaboration with regulatory bodies: standards are often developed independently, but the literature suggests ongoing collaboration between industry experts and regulatory bodies to keep standards relevant and effective [18,30];

- ✓

- Design specifications: standards typically provide minimum design specifications for safety valves, while the literature discusses advancements in design techniques that improve performance and reliability beyond minimum requirements [10,14];

- ✓

- Installation guidelines: many standards outline general installation practices, yet the literature emphasizes the importance of site-specific factors—such as ambient temperature and system dynamics—that can significantly affect valve function [11,25];

- ✓

- Failure mode analysis: while standards acknowledge common failure modes, the literature often presents detailed case studies that explore less frequent but critical failure scenarios, highlighting a need for broader failure analysis [55,56];

- ✓

- Calibration frequencies: standards may dictate calibration frequencies based on general operational environments; however, the existing literature indicates that calibration needs should reflect specific operational conditions and historical performance data [6,19];

- ✓

- Industry-specific regulations: occupational standards may offer generic guidelines; the literature often points out the necessity for tailored regulations that account for the unique challenges faced in specific industries, such as pharmaceuticals or nuclear power [12,19];

- ✓

- Innovations in valve technologies: standards typically endorse existing technology, while the recent literature advocates for the exploration of innovative technologies like automated monitoring systems that collect data for predictive maintenance [21,48];

- ✓

- Impact of design age: standards sometimes focus on modern systems, whereas the literature analyzes the performance of legacy systems, suggesting the need for updated evaluations and modifications to improve safety [1,5];

- ✓

- Risk management approaches: standards might present basic risk management principles, while the literature emphasizes more sophisticated methodologies that integrate probabilistic risk assessments for better decision making [22,49];

- ✓

- Hydraulic performance testing: though standards define testing protocols for hydraulic performance, the literature often highlights the limitations of these tests and suggests additional metrics for evaluating valve performance under diverse conditions [10,50];

- ✓

- Post-maintenance validation: standards may require post-maintenance checks, yet the literature strongly advises for comprehensive validation procedures to ensure that safety valves remain functional after maintenance activities [55,56].

4. Types of Safety Valves

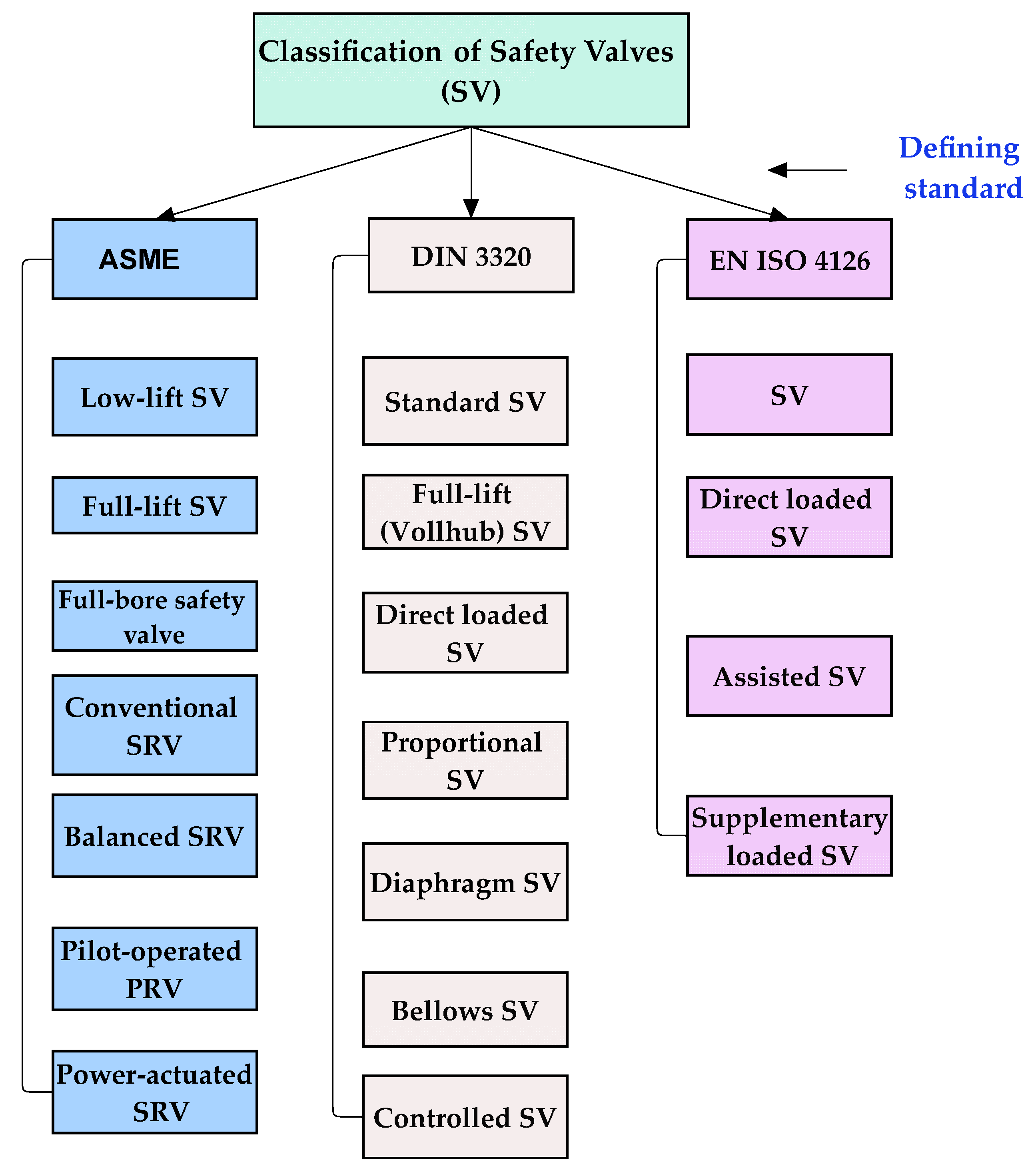

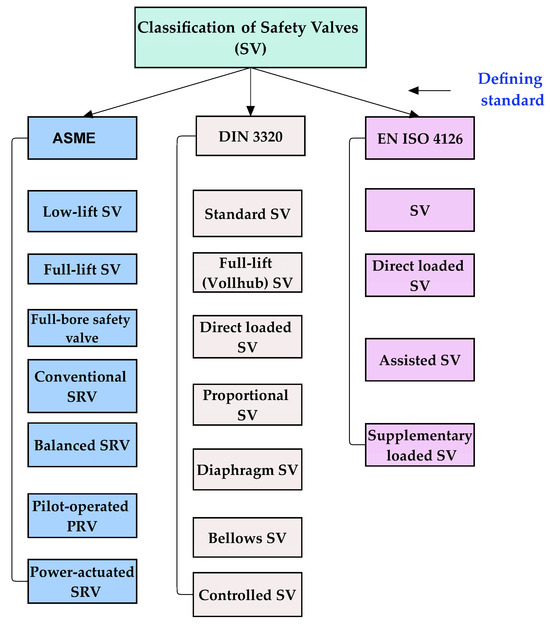

This section provides an overview of the different types of safety valves, focusing on their distinct designs, functions, and applications across various industries. Each type of safety valve—such as spring-loaded, pilot-operated, and balanced-bellows valves—offers unique advantages suited to specific pressure ranges, environmental conditions, and fluid types. Table 3 [54] and Figure 4 are presenting different types of safety valves according to the standards ASME [58], DIN 3320 [59], and EN ISO 4126 [60].

Table 3.

Characteristics of different types of safety valves.

Figure 4.

Classification of safety valves.

5. Design and Operation Principles

5.1. Discussion on the Working Principles of Safety Valves

Safety valves are critical components in various systems, especially in pressure vessels and boilers, ensuring safety by preventing overpressure; the working principles of safety valves are the followings:

- Pressure monitoring: safety valves are designed to monitor the pressure inside a vessel or system. As the pressure rises, it is compared against the valve’s set point for different conditions.

- Spring mechanism: most safety valves employ a spring-loaded mechanism. The spring exerts a force that keeps the valve closed under normal operating conditions.

- Set pressure: When the internal pressure exceeds a predetermined “set pressure”, it overcomes the force exerted by the spring.

- Opening Mechanism: once the set pressure is reached, the valve opens, allowing excess fluid (gas or liquid) to escape. This release of pressure prevents the system from reaching dangerous levels.

- Full lift: as the internal pressure increases further, the valve will fully open, allowing maximum flow to disperse the excess pressure efficiently.

- Closing mechanism: once the pressure drops back to a safe level (below the set pressure), the spring closes the valve again, sealing the system and restoring its normal operating conditions.

- Types of safety valves: there are different types of safety valves based on their application, such as pop-off valves, balanced bellows valves, and pilot-operated valves, each having specific features to suit various system requirements.

- Regular testing: safety valves should be regularly tested and maintained to ensure reliability and proper functioning. Table 4 provides a clear and organized overview of the different types of safety valves, outlining their working principles, key components, and common applications [18,22,28,52,59,60,61,62,63].

Table 4. Working principles, key components, and common applications for common safety valves.

Table 4. Working principles, key components, and common applications for common safety valves.

5.2. Pressure Settings and Valve Response Under Different Conditions

Safety valves are vital safety devices commonly used to prevent overpressure in various applications such as boilers, pressure vessels, gas systems, and hydraulic systems. They consist of key components, including a body, spring, disc, seat, adjustment mechanism, and guide, designed to operate effectively under varying pressure conditions. Under normal operation, the internal system pressure remains below the valve’s set pressure, keeping the valve closed due to the spring force. However, as pressure increases, it eventually overcomes the spring force, causing the valve to open and allowing excess fluid to vent, thereby reducing system pressure. This quick response and simplicity of design make spring-loaded safety valves reliable and compact, suitable for numerous applications. Once pressure falls back to a safe level, the valve re-seats to prevent leakage, ensuring the system is sealed. Various applications of spring-loaded safety valves include relieving pressure in boilers, protecting chemical processing equipment from dangerous overpressures, managing safe operation levels in gas pipelines, and preventing equipment damage in hydraulic systems.

To maintain their efficiency and safety, spring-loaded safety valves require regular testing to ensure they open at the correct set pressure and close fully afterward. Calibration of the spring tension is essential to maintain precise pressure settings. Additionally, thorough inspections should be conducted to identify any signs of wear, corrosion, or damage that could compromise functionality. Keeping detailed records of maintenance activities, testing, and any adjustments made can help track performance and ensure compliance with safety regulations. Understanding the design and operational principles of spring-loaded safety valves is crucial for engineers and maintenance personnel in managing pressure safely and effectively, as these valves act as essential protectors in various pressurized systems.

Operating principle: normal operation: under normal operating conditions, the pressure inside the system remains below the safety valve’s set pressure, which is typically set at about 75–90% of the maximum allowable working pressure (MAWP). The force exerted by the spring keeps the valve closed, ensuring system integrity. For example, if the MAWP is 1034 kPa (150 psi), the set pressure might range from 775 to 930 kPa (112.5 to 135 psi). Pressure increase: as system pressure rises due to factors such as heating, fluid expansion, or operational anomalies, this increased pressure acts directly on the disc area of the valve. In steam systems, for instance, pressure could rise to over 1034 kPa (150 psi) under conditions of low water levels or high heat input. Opening point: when the internal pressure exceeds the predetermined set pressure (e.g., a safety valve may be set to open at 827 kPa (120 psi)), the force from the internal pressure acting on the disc surpasses the opposing spring force. This threshold is critical for activating the safety mechanism. Flow regulation: once the valve opens, it allows excess fluid (either gas or liquid) to escape, thereby reducing the pressure within the system. The amount of flow that escapes correlates with how far the valve opens. For example, a valve may be designed to allow a flow rate of several hundred to several thousand liters per minute, depending on its size and application. Re-seating: after the system pressure decreases back to a safe level, typically around 10% below the set pressure, the spring re-closes the valve. This action ensures that the system is sealed and can safely resume normal operations. The reliability of the spring’s function is essential to prevent leakage, as any failure to re-seat could lead to pressure loss and operational inefficiency.

Table 5.

Responses under specific conditions for different safety valve types.

5.3. Materials Used for Valve Components Based on Application

Table 6 provides a comprehensive overview of the materials used for different components in various types of safety valves [22,59,60,61,62,63,64,65]. The choice of materials is essential as it affects the valve’s performance, durability, and compatibility with various fluids or gases.

Table 6.

Common materials used for different safety valve components.

In addition to the commonly used materials for safety valves (see Table 7 [15,18,33,58,59,60]), there are special materials that are utilized under specific conditions to ensure optimal performance, reliability, and safety.

Table 7.

Special materials for safety valves to operate under extreme conditions.

6. Testing and Maintenance

Several significant industrial accidents have been attributed to the failure of safety valves, underscoring the critical importance of proper valve design, maintenance, and operational practices in ensuring safety in high-pressure environments. The “Piper Alpha disaster” in 1988, located in the North Sea, resulted in a catastrophic series of explosions and fires, leading to the tragic loss of 167 lives [55]. Investigations revealed that modifications to the platform had led to the failure of key safety relief systems, including improperly functioning safety valves, which exacerbated the situation by allowing pressure to build uncontrollably. Similarly, the “Bhopal gas tragedy” in 1984 remains one of the worst industrial disasters in history, where a catastrophic leak of methyl isocyanate (MIC) gas at the Union Carbide pesticide plant exposed more than 500,000 people to toxic substances [56]. The incident was significantly worsened by the lack of functional safety systems, including safety valves, which were inadequately designed and maintained, resulting in thousands of deaths and long-term health consequences for the affected population.

Another significant incident occurred at the “Chevron Richmond refinery” in California in 2012, where a fire erupted due to a corroded pipe that led to a failure in the safety valve mechanisms [66]. This incident not only resulted in injuries but also prompted a shelter-in-place order for nearby residents due to thick plumes of smoke. Additionally, a gas leak during maintenance work at “Hyundai Heavy Industries” in South Korea in 2012 led to multiple worker fatalities, primarily due to safety valves that were not properly calibrated or maintained, highlighting the need for better training and protocols in handling high-risk operations [67].

The infamous “Deepwater Horizon oil spill” in 2010, one of the largest marine oil spills in history, was linked to failures in blowout preventer (BOP) systems that include safety valves designed to prevent blowouts during drilling [68]. When these valves failed to operate effectively during a critical moment, it resulted in an explosive blowout that caused the tragic loss of 11 crew members and the release of approximately 4.9 million barrels of oil into the Gulf of Mexico, with devastating environmental impacts. Lastly, the “ExxonMobil Torrance refinery explosion” in 2015 was attributed to the failure of a safety valve that allowed for pressure buildup, resulting in a violent explosion that injured workers and caused extensive property damage and operational disruption [69].

These significant incidents highlight the dire consequences of inadequate safety valve performance and the essential need for rigorous testing, maintenance, and compliance with safety regulations across industries. They serve as poignant reminders of the importance of implementing robust quality assurance measures, adherence to regulatory standards, and a culture of continuous improvement in industrial safety practices to prevent similar tragedies in the future. The overarching lessons from these events stress the critical role that safety valves play in protecting workers, the environment, and the integrity of industrial operations.

To maintain their efficiency and safety, safety valves require regular testing. Guidelines suggest testing intervals can vary from annual to every five years based on the application and regulations. It is crucial that they open at the correct set pressure and fully close afterward.

Calibration of the spring tension is essential, typically adjusted in increments of 5 psi until the desired opening pressure is achieved. Additionally, thorough inspections should be conducted to identify any signs of wear, corrosion, or damage, which can impact functionality.

For example, visual inspections can be performed on a semi-annual basis, while more in-depth evaluations may be conducted annually.

Regular testing according to different standards ensures compliance and the effective functioning of safety valves in various applications, a comprehensive list of tests for safety valve reliability, along with specific names and their corresponding international standards is presented:

- (a)

- Set pressure test:

- ■

- Purpose: verifies that the safety valve opens at the specified set pressure;

- ■

- Standard: ASME Boiler and Pressure Vessel Code (BPVC) Section I or VIII;

- ■

- Reference: ASME PTC 25 for testing methods;

- (b)

- Leakage test:

- ■

- Purpose: ensures the valve does not leak when closed;

- ■

- Standard: API 527 (for blow-off and seat leakage tests);

- ■

- Reference: ISO 5208 (Industrial valves—Pressure testing of valves) for methods;

- (c)

- Capacity test:

- ■

- Purpose: determines whether the safety valve can discharge the required flow rate;

- ■

- Standard: ASME PTC 25 or API 520/521;

- ■

- Reference: ASME BPVC Section I for setting capacity testing procedures;

- (d)

- Re-seating test:

- ■

- Purpose: confirms that the valve properly closes after venting;

- ■

- Standard: ASME BPVC Section I and VIII;

- ■

- Reference: API 527 for guidelines on reseating tests;

- (e)

- Functional test:

- ■

- Purpose: ensures the valve operates as intended under specified conditions;

- ■

- Standard: API 526 or ASME BPVC;

- ■

- Reference: ISO 4126 (safety devices for protection against excessive pressure);

- (f)

- Cycle test:

- ■

- Purpose: assesses the durability and reliability of the safety valve through repeated cycles;

- ■

- Standard: ASME BPVC Section I or VIII;

- ■

- Reference: API 526 for testing protocols;

- (g)

- Temperature test:

- ■

- Purpose: checks valve performance at specified temperature ranges;

- ■

- Standard: ASTM E1952 (standard guide for the testing of pressure relief valves);

- ■

- Reference: specific temperature ratings can reference ASME fittings or valve temperature classes;

- (h)

- Vibration test:

- ■

- Purpose: evaluates valve performance under vibrational conditions typical in the operating environment;

- ■

- Standard: ISO 10816 (mechanical vibration—evaluation of machine vibration by measurements on non-rotating parts);

- ■

- Reference: API 610 for pumps may provide context for dynamic conditions, applicable to safety valves on pumps;

- (i)

- Visual inspection:

- ■

- Purpose: identifies any visible signs of wear, corrosion, or damage;

- ■

- Standard: ASME B31.3 (Process Piping)—includes inspection requirements;

- ■

- Reference: NACE RP0188 for corrosion assessment;

- (j)

- Documentation and traceability:

- ■

- Purpose: maintains records of pressure tests, repairs, and maintenance history;

- ■

- Standard: ISO 9001 (Quality Management Systems);

- ■

- Reference: API Spec Q1 (Specification for Quality Management System Requirements);

- (k)

- Calibration check:

- ■

- Purpose: verifies that the pressure settings and indications are accurate;

- ■

- Standard: ISO 17025 (general requirements for the competence of testing and calibration laboratories);

- ■

- Reference: ASME PTC 19.1 (Test Codes);

- (l)

- Dynamic response test:

- ■

- Purpose: evaluates how quickly and effectively the valve reacts to system pressure changes;

- ■

- Standard: IEC 61508 (functional safety of electrical/electronic/programmable electronic safety-related systems) for controlled systems;

- ■

- Reference: API 520 for guidelines.

Table 8 provides a comprehensive overview of the tests, the equipment used, and notable manufacturers of the equipment necessary for ensuring the reliability and performance of safety valves [1,22,33,58,59,60,61,63,65]. By combining this information, you can gain insights into the practical application of testing safety valves in real-world scenarios.

Table 8.

Equipment and manufactures for testing safety valves.

A well-structured maintenance plan for safety valves is essential to ensure their reliable operation and compliance with relevant standards and codes. A comprehensive overview of a maintenance plan, including recommended frequencies, procedures, and references to industry standards and codes must contain the following:

- ■

- Routine inspections. Frequency—at least annually or according to the manufacturer’s recommendations and specific regulations applicable to the industry. Activities—visual inspection for signs of damage, wear, or corrosion. Check for proper valve identification and labeling. Inspect for leaks or signs of pressure loss around the valve. Standards/references—ASME Boiler and Pressure Vessel Code (BPVC) Section I for boilers and Section VIII for pressure vessels. API Recommended Practice 576 for inspection of pressure-relief devices;

- ■

- Operational testing. Frequency—annually or more frequently as required by specific applications or regulatory mandates. Activities—conduct a set pressure test to verify that the valve opens at specified pressure settings. Perform a leakage test to ensure the valve properly seals in the closed position. Operational tests to ensure the valve functions correctly under various conditions. Standards/references—API 526 for steam relief valves. ASME PTC 25 for performance testing of pressure relief devices;

- ■

- Calibration. Frequency—every 3 to 5 years or according to specific service demands and conditions. Activities—calibrate the valve’s set pressure using calibrated test equipment. Document the calibration process and results in maintenance records. Standards/references—ISO 17025 for calibration and testing laboratory standards. ASME PTC calibration guidelines;

- ■

- Maintenance and repairs. Frequency—as required based on inspection or testing findings. Activities—repairs to seals, gaskets, or any damaged components should be performed as needed. For valves that have been removed for maintenance, perform checks for corrosion damage or wear. Reassemble and conduct functional checks after repairs. Standards/references—API 527 for repair procedures and guidelines for pressure relief devices. Manufacturer guidelines for specific maintenance practices;

- ■

- Documentation. Frequency—ongoing, with records updated after each maintenance activity. Activities—maintain records of inspections, tests, repairs, and calibrations. Document any changes made to the valve settings or configurations. Standards/references—ISO 9001 for maintaining quality management systems and documentation practices. API Recommended Practice 580 for risk-based inspection and management of equipment;

- ■

- Replacement. Frequency—as necessary or based on performance and age of the valve. Activities—evaluate the performance history and condition; if the valve routinely fails tests or shows excessive wear, consider replacement. Follow manufacturer guidelines for selecting and installing replacement valves. Standards/references—ASME BPVC for guidelines regarding the retirement of equipment. Industry best practices for the disposal of old valves and installation of new devices.

The standards and tools mentioned were chosen based on their global recognition, relevance to the diverse applications of safety valves, and their ability to address industry-specific needs effectively. For instance, the ASME Boiler and Pressure Vessel Code (BPVC) is widely adopted for its rigorous guidelines ensuring safety valve reliability across critical sectors like power generation and oil and gas. Similarly, ISO and API standards provide specialized testing protocols, such as ISO 5208 for leakage testing and API 526 for cycle testing, which address both general and niche operational requirements. These standards are prioritized because they ensure compliance with regulatory norms while supporting the safe and efficient functioning of safety valves under varying industrial conditions.

7. Technological Advancements in Safety Valves

7.1. Recent Innovations and Smart Safety Valves

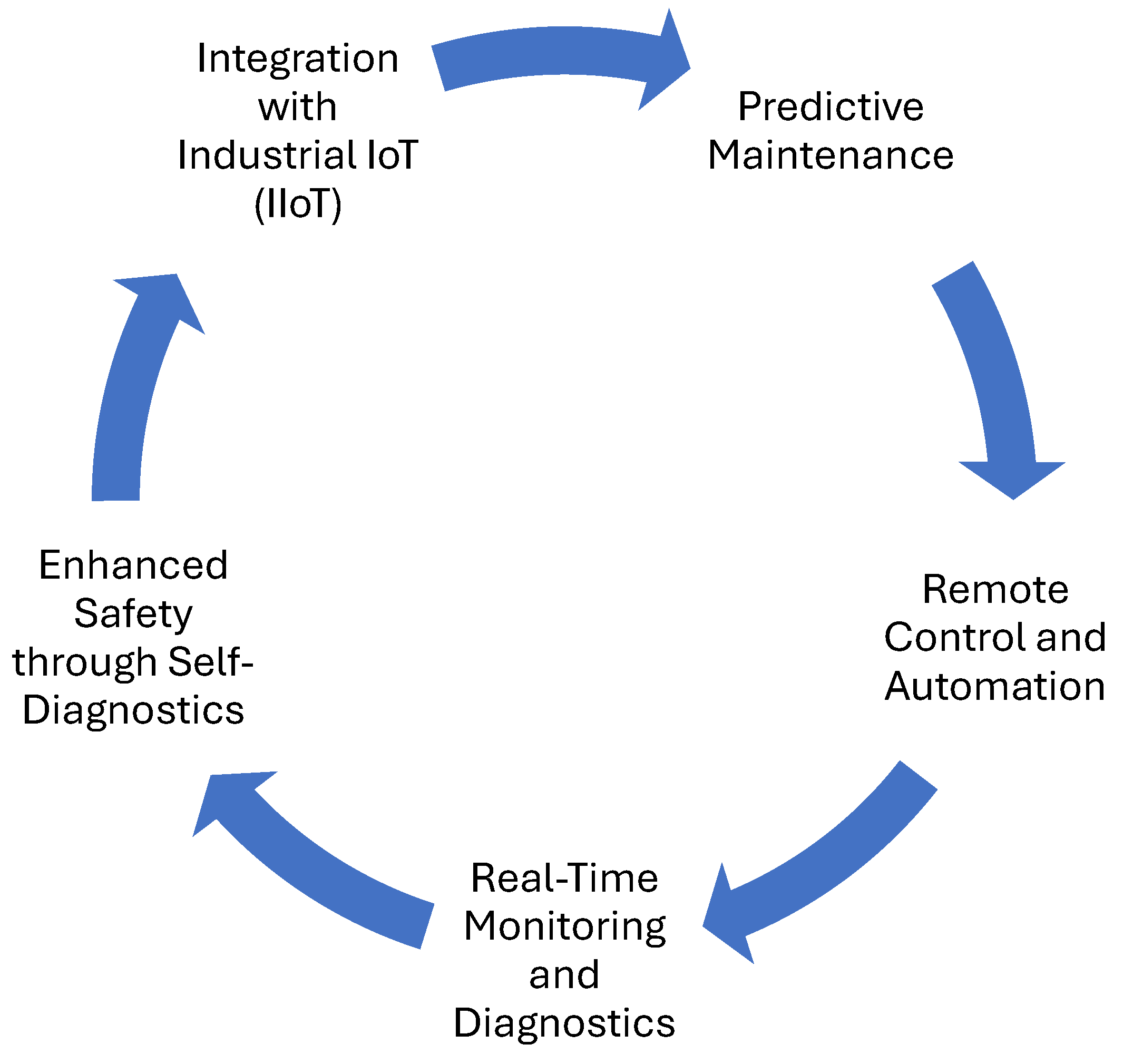

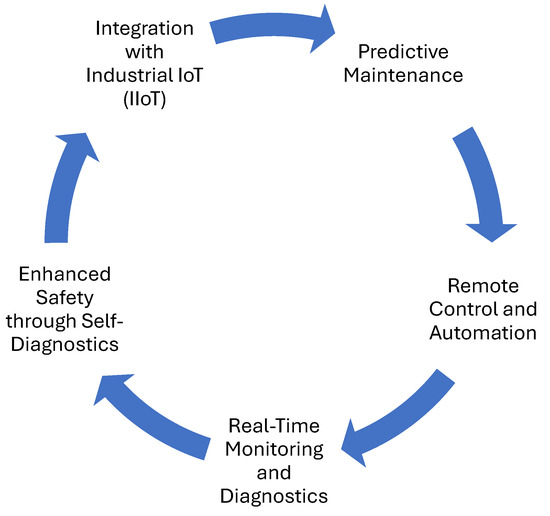

Studies considered for analyzing the technological advancement themes collectively emphasize the development of advanced fault diagnosis methods, the application of machine learning techniques to enhance diagnostic accuracy, and the rigorous performance evaluation of these models. These advancements contribute significantly to improving the reliability and efficiency of various hydraulic and control systems. Smart safety valves represent a significant advancement in industrial safety and automation [21,70]. The SmOP system [71] involve valves integrated with sensors, control systems, and connectivity features that enable real-time monitoring, automatic adjustments, and predictive maintenance capabilities. The production of basic and specialty chemicals is foundational for nearly all commercially produced goods. These chemicals are synthesized in reactors, often involving hazardous reactants or solvents. Operational disruptions—such as cooling failure, incorrect reactant dosing, agitator malfunction, or premature catalyst activation—can lead to “runaway” reactions, where rising reactor temperatures significantly accelerate reaction rates. In exothermic processes, this can result in rapid energy release, causing potentially hazardous temperature and pressure increases. To safeguard equipment and maintain safe operating conditions, industries employ mechanical safety devices alongside safety-related programmable logic controllers (sPLCs) [47]. The following paragraph reveals a classification regarding their functionalities and benefits (Figure 5).

Figure 5.

Recent innovations and functionality of smart safety valves.

- A.

- Real-Time Monitoring and Diagnostics

Smart safety valves continuously collect data on pressure, temperature, flow rate, and other critical parameters and can detect early signs of wear, leaks, or blockages, helping operators intervene before issues escalate. This real-time feedback loop allows for immediate adjustments to maintain safe and efficient operation.

- B.

- Predictive Maintenance

With the integration of machine learning algorithms [61], smart safety valves can analyze historical and real-time data to predict potential failures, so this predictive capability reduces unplanned downtime by enabling scheduled maintenance before critical parts reach failure points, predictive maintenance also reduces maintenance costs and extends the lifespan of the valve, contributing to more sustainable industrial practices. As computing technology advanced, traditional machine learning methods like support vector machine (SVM), K-nearest neighbor (KNN), and random forest (RF) were introduced in valve fault diagnosis, as depicted in Table 9.

Table 9.

Machine learning methods used valve fault diagnosis.

- C.

- Remote Control and Automation

Smart safety valves are often connected to centralized control systems, allowing operators to remotely adjust valve settings or shut down systems in emergencies.

Automated response protocols can be programmed into the system to close or open valves based on preset thresholds, minimizing human intervention and reaction time. This remote accessibility is particularly valuable in hazardous or hard-to-reach environments.

- D.

- Enhanced Safety through Self-Diagnostics

Smart valves perform regular self-diagnostics, identifying issues such as incorrect positioning, sensor malfunctions, or software errors. They ensure that the valve operates within safe parameters, reducing the likelihood of catastrophic failures.

These diagnostics improve compliance with safety standards and reduce liability risks associated with equipment malfunction.

- E.

- Integration with Industrial IoT (IIoT)

Smart safety valves are compatible with Industrial Internet of Things (IIoT) networks, allowing seamless integration with other smart devices and systems within a facility. This integration enables comprehensive data analysis across the entire plant, leading to optimized system performance and resource usage. IIoT connectivity also supports cloud-based monitoring, providing remote access to valve data and enabling advanced analytics [62].

- F.

- Application Areas

- ✓

- Oil and gas industry: smart valves enhance safety in high-pressure environments, preventing leaks [78] and blowouts;

- ✓

- Chemical processing: they monitor toxic or corrosive materials, ensuring safe containment and handling;

- ✓

- Water treatment plants: smart valves help regulate water pressure and flow, optimizing resource usage;

- ✓

- Manufacturing: they support automation and quality control, ensuring precise control over production processes.

7.2. Technological Innovations and Industrial Impacts

Chevron implemented smart safety valves equipped with real-time monitoring and control systems in their offshore drilling platforms. These valves reduce the risk of blowouts by detecting pressure anomalies early and enabling remote emergency shutdowns. This enhances operational safety and cuts costs associated with manual checks and downtime [46].

BP Deepwater Operations uses advanced safety valves integrated with predictive maintenance systems. By leveraging IoT connectivity, they reduced unplanned shutdowns by 15%, saving millions in operational costs annually [46].

BASF Chemical plants integrated automated safety valves with predictive maintenance algorithms in their production lines. This setup prevents chemical leaks by detecting early wear in valve seals, reducing environmental risks and avoiding penalties for non-compliance with safety regulations [64].

Siemens Energy installed smart safety valves in power plants to optimize steam flow management. The valves are connected to central control systems that automatically adjust operation parameters for peak efficiency, reducing energy consumption and maintenance costs [65].

Thames Water uses smart safety valves to regulate the flow of water and chemicals in treatment processes. These valves minimize resource waste, reduce operational costs, and enhance the reliability of water delivery systems [79].

In their manufacturing plants, Toyota implemented smart valves in pressurized systems for paint and coating applications. The valves’ real-time feedback system reduced paint waste by 20%, resulting in significant material savings and environmental benefits [48].

These examples illustrate the diverse applications and tangible benefits of adopting modern safety valve technologies across industries.

The use of additive manufacturing (3D printing) has revolutionized the production of valve components. By allowing for the creation of complex geometries and reducing material waste, 3D printing enhances customization and reduces inventory costs. This technology not only speeds up production but also reduces costs related to storage and delivery [80].

The ongoing development in AI and machine learning could make smart safety valves even more autonomous, potentially handling complex decisions without human input.

Cybersecurity remains a key challenge, as connectivity increases vulnerability to cyber-attacks. Enhanced encryption and security protocols are essential.

Standardization of smart valve technology across industries will also be critical, as compatibility issues could limit widespread adoption. Table 10 presents key technical specifications of smart safety valves, including inflow and outflow rate volumes, dimensions, weights, energy consumption, and material choices. It highlights the suitability of these valves for various industrial sectors, with a particular focus on renewable energy infrastructure such as wind, solar, and biogas plants. Additionally, it covers the environmental and safety considerations relevant to each application.

Table 10.

Specifications of smart safety valves for industrial and renewable energy applications.

Smart safety valves offer several advantages over traditional systems [22,53,78,81,82]. For instance, they respond much more quickly due to integrated sensors that detect pressure changes almost immediately, whereas traditional valves rely on mechanical mechanisms that are slower to react. Additionally, smart valves are equipped with predictive maintenance features, which continuously monitor performance and alert operators when maintenance is needed, reducing the risk of unexpected failures and minimizing downtime. In contrast, traditional valves often require manual inspections and are prone to undetected malfunctions. Furthermore, smart valves integrate seamlessly into automated control systems, allowing for real-time adjustments based on operational conditions, which enhances both safety and efficiency compared to traditional valves.

7.3. Practical Impact of Safety Valves in Various Industries

Oil and gas industry: pressure relief valves (PRVs). In oil refineries and natural gas processing plants, pressure relief valves are crucial for safety. They are strategically placed on vessels and pipelines to automatically release gases or liquids when pressure exceeds set thresholds due to equipment failure or operational changes. For instance, during an emergency shutdown or an unexpected chemical reaction resulting in a pressure spike, PRVs prevent catastrophic failures by safely releasing the excess pressurized fluid to a flare, where it is burned off safely.

Chemical manufacturing: rupture discs and relief valves. Chemical plants handle volatile substances that require precise pressure control. A rupture disc is a non-reclosing pressure relief device that acts as a safety barrier until an overpressure incident occurs, at which point it bursts open. This device is often used in tandem with relief valves, allowing for an immediate release that avoids the buildup of dangerous pressure levels. This setup is essential in chemical reactors or storage tanks containing reactive or hazardous chemicals, ensuring a secondary layer of protection.

Power generation: steam safety valves in boilers. Boilers in power plants operate under high pressure to generate steam for turbines. Safety valves are installed to open at predetermined pressures, permitting the discharge of steam into the atmosphere or a condensing unit. These valves are designed in accordance with stringent standards such as those set by ASME, which specify rigorous testing and material requirements. In the event of a failure in the control system preventing proper pressure regulation, these valves avert potential catastrophic explosions, protecting both equipment and personnel.

Pharmaceutical industry: aseptic safety valves. Cleanliness and pressure control are critical in pharmaceutical manufacturing, where contamination can render entire batches unusable. Aseptic safety valves are employed in systems handling sterile liquids or gases, ensuring any pressure relief maintains the sterile environment. Such valves are typically designed with smooth surfaces and minimal crevices to prevent bacterial growth and are integrated into sterilization-in-place and cleaning-in-place systems.

Food and beverage industry: vacuum relief valves in storage tanks. During processes such as cooling after pasteurization, the pressure inside storage tanks can change rapidly. Vacuum relief valves are installed to protect the structural integrity of these tanks by allowing air to enter if a vacuum condition arises due to a temperature drop. This prevents tank implosion and maintains product integrity. These valves are critical for maintaining hygiene standards and preventing mechanical failure.

Automotive industry: fuel tank safety valves. In vehicles, fuel tanks are equipped with safety valves to manage pressure variations caused by temperature changes or fuel expansion. These valves protect the tank from rupturing under high-pressure conditions, such as those generated by intense heat during driving or when parked in the sun. This functionality not only ensures vehicle safety by mitigating burst risks but also helps in controlling evaporative emissions, making vehicles more environmentally friendly.

These detailed examples demonstrate how safety valves are integral to operational safety and efficiency across different industries, adhering to specific regulatory standards that ensure their reliability and effectiveness in preventing accidents.

7.4. Future Research Directions Associated with Safety Valves

Analyzing the available bibliography, the main recommendations for future research directions in the field of safety valves were extracted.

- ✓

- Material innovations: investigate the development and application of advanced materials that can withstand extreme temperatures and corrosive environments, enhancing the longevity and reliability of safety valves;

- ✓

- Enhanced pressure-release mechanisms: explore innovative designs for pressure-release mechanisms that can improve response times and accuracy in high-stress situations, thereby increasing overall safety;

- ✓

- Integration of fail-safe features: study the implementation of fail-safe designs that ensure safety valves can still operate effectively even in the event of a primary system failure;

- ✓

- Agile manufacturing practices: analyze how agile manufacturing methodologies can improve the production efficiency and customization of safety valves to meet evolving industry needs;

- ✓

- Digital solutions and automation: research the impact of automation technologies and digital tools, such as IoT sensors, on monitoring safety valves’ performance, facilitating real-time data analysis, and optimizing operational efficiency;

- ✓

- Simulation and modeling advances: develop advanced computational fluid dynamics (CFDs) and modeling techniques to better predict the behavior of safety valves under varied operational conditions, enabling improved designs;

- ✓

- Predictive maintenance techniques: investigate predictive maintenance methodologies that leverage data analytics and machine learning to forecast potential failures and minimize downtime in valve operations;

- ✓

- Environmental impact assessments: conduct research into the environmental effects of safety valve materials and operations, aiming to enhance sustainability in manufacturing and product design;

- ✓

- Integration of smart technologies: explore the integration of smart technologies, such as machine learning algorithms, for adaptive control of safety valves in response to changing operational parameters;

- ✓

- Standardization of testing protocols: advocate for the development and standardization of testing protocols across manufacturers to ensure consistency in safety valve performance evaluation;

- ✓

- User training and awareness programs: develop training programs that educate users and maintenance personnel on emerging technologies and best practices for safety valve management;

- ✓

- Market trends and user needs: research market trends to align safety valve development with user needs and regulatory requirements, ensuring that innovations effectively address current industry challenges.

By delving into these areas, future research can contribute significantly to technological advancements and improvements in safety valve performance and reliability across various applications.

8. Finite Element Method and Experimental Analysis in Relief Valves Working Process

The finite element method, as a powerful computational tool, allows for detailed simulation and analysis of stress distribution, deformation, and flow dynamics in relief valve components under different operating conditions. Coupling FEM with experimental analysis enhances the accuracy and reliability of these simulations, providing valuable insights into valve behavior under high-stress scenarios. Experimental validation is essential to ensure that FEM models accurately replicate real-world performance, thereby informing design optimizations and improving the valve’s reliability and safety across its operational lifespan. This section explores the integration of FEM with experimental approaches to capture a comprehensive understanding of relief valve functionality.

According to [3], the total force acting on the disk (Fx) is a result of the pressure on the upstream side of the disk at the nozzle exit (pN), the backpressure on the downstream side of the disk (pB), and the momentum transfer from the fluid stream impacting on the disk. The nozzle pressure (pN) is related to the vessel pressure (p0) through the fluid dynamics in the upstream piping (including friction loss, acoustic coupling inertia, and dynamic capacitance).

It is presented in studies [45,50] that the total force acting on the disk can be calculated by relation (1), where F0 represents the pretension force.

where p is the pressure acting on the disk, and x is the displacement, [MPa]. The other forces involved in relation (1) are presented below.

Pressure force: the force given by the static pressure difference Δp across the valve between the variable upstream pressure p and the downstream pressure p0. It depends on the volumetric flow rate, and it generates a pressure force given by the relation (2):

where Ap is the total area on the valve upon which the fluid pressure (p) acts, [mm2] [50].

Impact force: the effect of impact at the lower and upper bounds x1 and x2 is modeled by a force term given by relation (3) [50,57]. According to these sources, the impact force models the repulsion during impact using a stiff spring constant ki = 109…1010 N/m, much larger than the system stiffness (ki ≫ k).

Momentum force: due to the redirection of the fluid jet by the valve surface, a momentum change is considered by the force given by relation (4) [50]:

where Cf is an empirically determined momentum coefficient which controls the relative amount of transferred momentum. Cd,v and Cd,b are accurately chosen to reflect the transition from laminar to turbulent flow. The valve opening section Av(x) is a direct function of the flow perimeter of the valve and the displacement which gives a generated surface for the flow given by relation (5) [50,57,83]. The flow proportionality coefficient α is used to adjust the actual flow area depending on the geometry.

where dv is the flow diameter of the valve, [mm].

For a constant driving force, the dynamic response of the system is described by the angular frequency which is given by the relation (6), regarding the undamped working conditions, and is expressed as follows:

With respect to the units previously presented, the angular frequency is expressed as rad/sec.

Considering the real environment of the valve, and with any mechanical system having its own damping, the damp factor is given by the relation (7):

The valve is over-damped if ν > 1, critically damped if ν = 1, and will oscillate if ν < 1. The valve opens when Fx > F0 and closes when Fx < F0, where F0 is the force on the disk corresponding to the spring compression at the set pressure (x0). Regarding relations (1) and (2), and according to [3,4], the displacement of one degree of freedom in the system describes a waveform modulated in amplitude.

When the disc oscillates slightly, the mass-spring system can be regarded as a linear system, and the principle can be used to simplify complex problems. Considering that the excitation force on the disk is described by the harmonic law (8), the differential equation of displacement can be put in form (9) [83].

where capital A refers to the equivalent displacement of the excitation force, [mm].

The solution of the Equation (9) can be put in the form given by (10) regarding the complex nature of problem.

where θ is phase shift of the oscillation given by relation (11), [rad].

Table 11 provides a summary of different studies that analyze the behavior and performance of safety relief valves using both computational and experimental techniques.

Table 11.

Overview on safety valves experimental and numerical analyses.

While the literature extensively addresses traditional safety valve designs and regulatory standards, emerging trends such as smart safety valves with integrated sensors and predictive maintenance capabilities remain underexplored. These technologies, aligned with Industry 4.0 principles, represent a transformative shift in industrial safety by enabling real-time monitoring and automated adjustments.

Additionally, a notable research gap exists in the application of advanced computational tools like CFDs and FEA for optimizing safety valve performance under extreme conditions, such as high-pressure and corrosive environments. Addressing these challenges through innovative materials and robust designs can significantly enhance reliability. In addition to the analyzed standards, the computational tools analyzed—ANSYS Flo® CFDs software, OLGA software, and Fluent software—were selected for their advanced capabilities in modeling and simulating fluid dynamics in complex systems. ANSYS Flo® is highly regarded for its precision in assessing valve performance under various flow conditions, OLGA excels in simulating transient multiphase flow scenarios relevant to the oil and gas industry, and Fluent offers versatile solutions for optimizing valve designs through detailed CFD analysis. These tools complement the standards by providing a robust platform for evaluating safety valve behavior, enabling a more comprehensive understanding of their performance under real-world conditions. Together, these standards and computational tools form a cohesive framework for ensuring the reliability and effectiveness of safety valves in diverse industrial applications.

Future research should focus on developing standardized frameworks for smart valve technologies and exploring novel materials capable of withstanding demanding environments. By bridging these gaps, the field can advance toward more efficient and sustainable industrial safety solutions.

9. Conclusions

This review comprehensively addresses the critical role, standards, and advancements associated with safety valves in industrial applications. Safety valves are indispensable for maintaining safe operational pressures across sectors like oil and gas, chemical manufacturing, and power generation, protecting systems from catastrophic overpressure events. The performed analysis includes an extensive overview of different valve types, such as spring-loaded, pilot-operated, and specialized valves, each adapted to specific industrial needs. Adhering to stringent standards set by regulatory bodies like ASME, API, and ISO, safety valves are subject to rigorous design, testing, and maintenance requirements to ensure optimal performance under diverse operational conditions.

Also, it explored the historical development of safety valves, from early mechanisms used in steam engines to contemporary designs that accommodate increasingly complex industrial demands. The introduction of advanced materials, including corrosion-resistant alloys and high-strength composites, has significantly improved the durability and reliability of valves, particularly in harsh environments with high pressures and corrosive fluids. These material advancements are essential for industries where extended operational lifetimes and minimal maintenance intervals are critical. A major focus of this review is the shift towards smart safety valves, a development that aligns with Industry 4.0 initiatives. Equipped with sensors and diagnostic systems, smart valves provide real-time data on pressure, temperature, and flow rate, enabling predictive maintenance and early detection of potential failures. Integrated with machine learning algorithms, these valves can forecast issues based on historical and real-time data, reducing unplanned downtime and extending the equipment’s lifecycle.

The review highlights several recent incidents, underscoring the importance of regular testing, rigorous maintenance, and adherence to safety protocols. Failures in safety valve performance have historically led to significant industrial accidents, such as the Piper Alpha disaster and the Bhopal tragedy. These cases emphasize the need for stringent quality assurance practices, including set pressure tests, leakage tests, functional tests, and cycle tests, which are integral to maintaining reliable safety mechanisms.

Furthermore, this review addresses ongoing challenges within the field, such as optimizing valve designs for high-performance settings, including cryogenic applications and extreme-temperature operations. Innovations like finite element modeling and computational fluid dynamics (CFDs) simulations are discussed as powerful tools for refining valve designs, enabling engineers to predict how valves will behave under various operational stresses. Experimental validation remains an essential step in confirming these simulations and ensuring that designs meet real-world demands.

Looking ahead, the development of smart safety valves with enhanced cybersecurity features will be essential as industrial systems become increasingly connected. The integration of safety valves into the Industrial Internet of Things presents new opportunities for comprehensive monitoring and control across plant systems, but it also introduces vulnerabilities that require robust security protocols.

The implementation of smart safety valves equipped with advanced technologies across various industries demonstrates significant advancements in operational efficiency, safety, and cost savings. Chevron’s offshore drilling platforms utilize real-time monitoring valves to mitigate blow-out risks and enhance emergency responses, while BP’s predictive maintenance systems in safety valves have led to a 15% reduction in unplanned shutdowns, saving millions annually. Similarly, BASF’s automated safety valves prevent chemical leaks, reducing environmental risks and ensuring compliance with regulations. Siemens Energy optimizes steam flow management in power plants through smart valves, cutting energy consumption and maintenance costs. In water treatment, Thames Water’s smart valves improve resource efficiency and system reliability, and Toyota’s implementation in manufacturing plants has reduced paint waste by 20%, yielding significant material and environmental benefits. These diverse applications underscore the transformative impact of modern safety valve technologies. Furthermore, advancements in additive manufacturing have revolutionized valve production, enabling the creation of complex designs, reducing material waste, and cutting storage and delivery costs. Together, these innovations highlight the critical role of safety valve technologies and manufacturing advancements in driving industrial progress.

Future in the digital domain could significantly transform the functionality and effectiveness of safety valves across industries. Advanced sensors would enable continuous real-time monitoring of critical parameters such as pressure and temperature, allowing for immediate detection of anomalies. The integration of the Internet of Things would facilitate remote monitoring and control, offering a comprehensive view of system health and enhancing coordination across industrial sites. Predictive analytics and machine learning could analyze data patterns to foresee potential failures, enabling proactive maintenance strategies that reduce downtime and extend valve lifespan. Digital twin technology could simulate and test safety valve designs under various conditions, optimizing performance and enhancing resilience without physical risk. Enhanced automation would allow valves to react autonomously to sudden changes, improving both safety and efficiency. Additionally, blockchain technology could ensure secure data integrity and traceability for compliance and maintenance records. Collectively, these advancements promise to transform safety valves into intelligent components within an interconnected industrial ecosystem, leading to improved safety outcomes and operational efficiency.

Safety can be classified based on their utilization across different domains as follows: Oil and gas industry (pressure relief valves: used to release excess pressure in pipelines, vessels, and storage tanks. Blowdown valves: specialized for drilling operations to control well pressure. Emergency shutdown valves: automatically actuated valves to isolate sections of a plant during emergency situations); medical industry (gas regulator safety valves: used in medical gas systems to ensure safe delivery of oxygen and other gases. Pressure relief valves in sterilizers: maintain safe pressure levels in autoclaves and sterilization equipment); agriculture (irrigation system relief valves: protect irrigation lines and pumps from pressure surges. Fertilizer applicator safety valves: ensure safe dispensing of liquid fertilizers by managing pressure levels effectively); military/army (fuel tank relief valves: protect fuel tanks from pressure fluctuations and potential ruptures. Explosive ordinance disposal valves: used in controlled practices to prevent accidental detonation from pressure changes); industrial manufacturing (control valves in chemical processing: for managing reactor and pipeline pressures to prevent leaks and explosions. Thermal relief valves: used in heat exchangers and boilers to control pressures due to thermal expansion); aerospace (cabin pressure valves: maintain safe pressure levels in aircraft cabins. Propellant vent valves: used in spacecraft to release propellant gases safely); food and beverage industry (vacuum relief valves: protect storage tanks during cooling processes following pasteurization. Pressure safety valves in beverage production: regulate pressure in carbonation processes). By categorizing safety valves based on their application in these key domains, we can better understand their specific roles in maintaining safety and operational efficiency across various industries.

While this review provides a comprehensive synthesis of current knowledge, it has certain limitations. The findings are based on secondary sources, without empirical data or experimental validation, which may limit the direct applicability of the conclusions. Furthermore, the diversity of industrial practices and standards across sectors poses challenges for generalizing the insights presented. Addressing these gaps through targeted empirical studies and sector-specific investigations would further strengthen the understanding of safety valve performance and advancements. Future research should prioritize experimental validation of safety valve designs under extreme conditions, such as cryogenic environments and high-temperature operations, to bridge the gap between theoretical models and real-world performance. Additionally, investigations into the integration of smart safety valves with advanced cybersecurity protocols are essential to address vulnerabilities introduced by Industrial Internet of Things (IIoT) connectivity. Specific studies could also explore the long-term reliability of new materials, particularly in corrosive environments, and the development of standardized frameworks for predictive maintenance algorithms adapted to various industrial settings.