Optimization of Combustion Parameters in the Fire Tube of Water Jacket Heating Furnace Based on FLUENT

Abstract

:1. Introduction

2. Simulation Setup

2.1. Physical Model of the Fire Tube

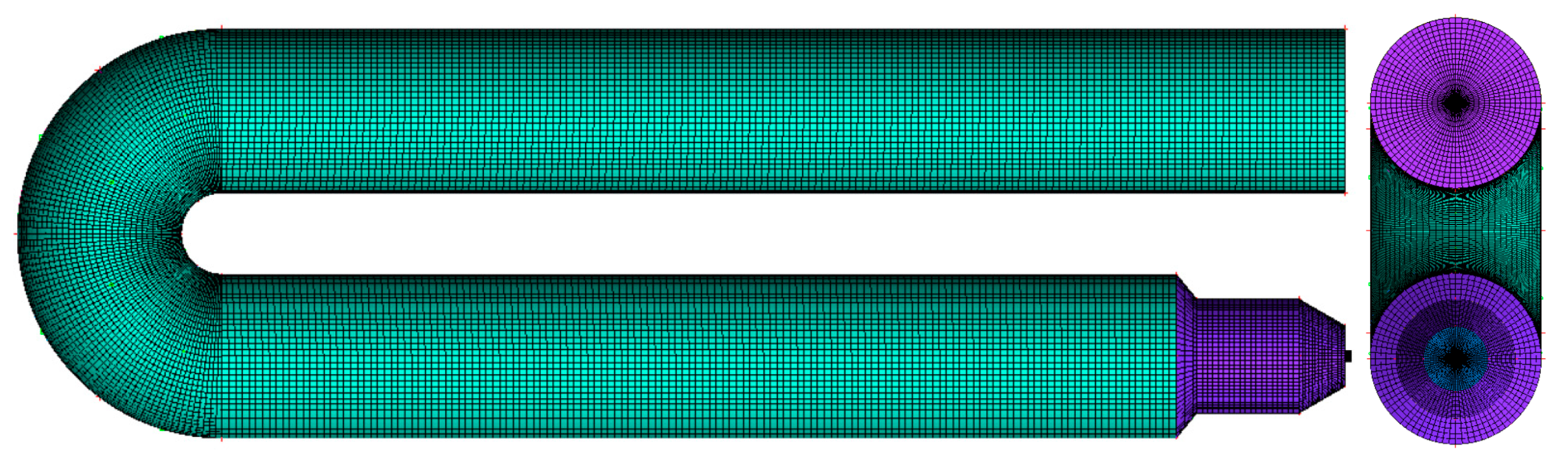

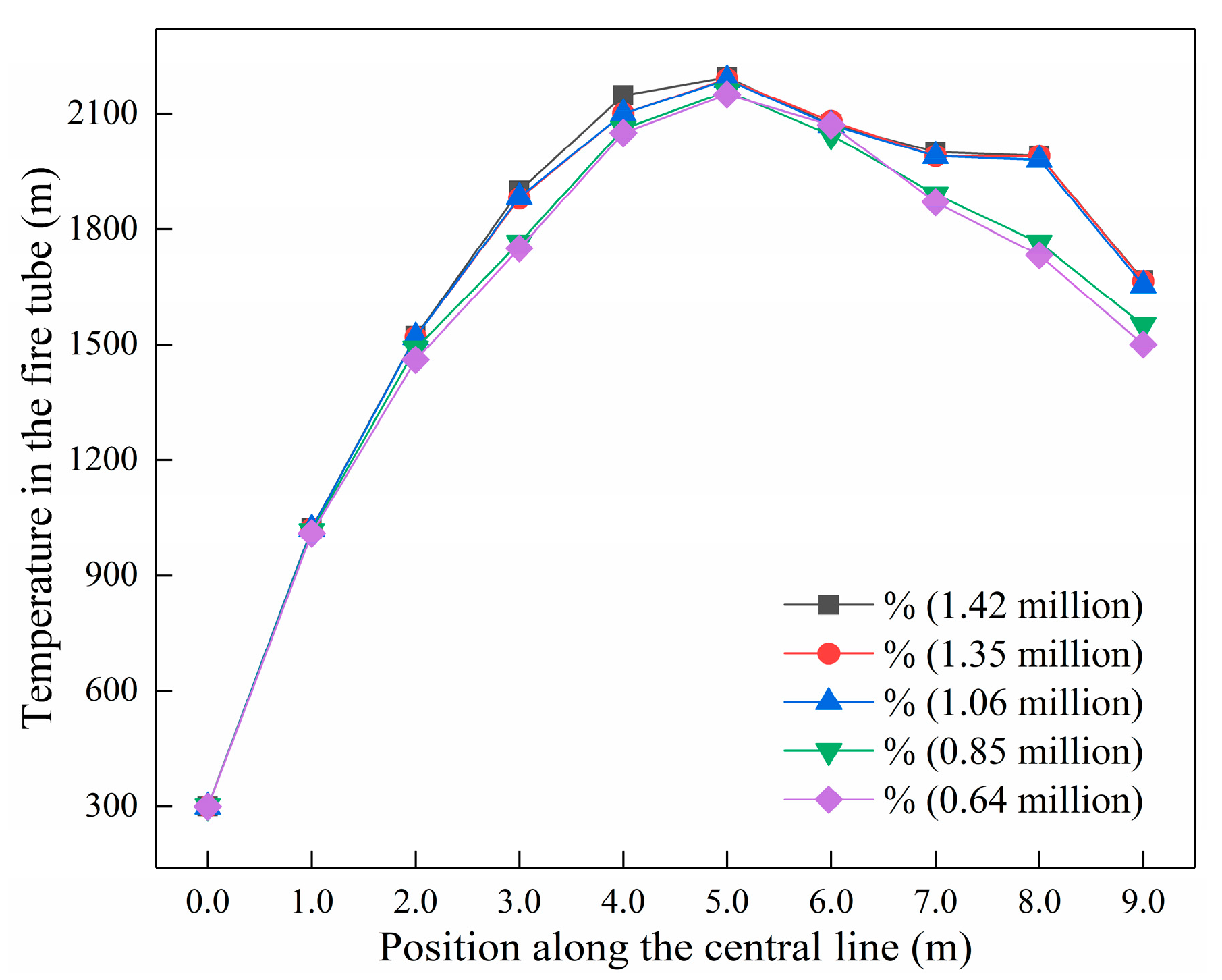

2.2. Mesh Division and Independence Verification

- Grid division

- 2.

- Mesh independence verification

2.3. Subsection

- Boundary conditions

- 2.

- Computational models

- 3.

- Hypothetical conditions

3. Analysis of Calculation Results

3.1. Optimization of Fuel Dosage

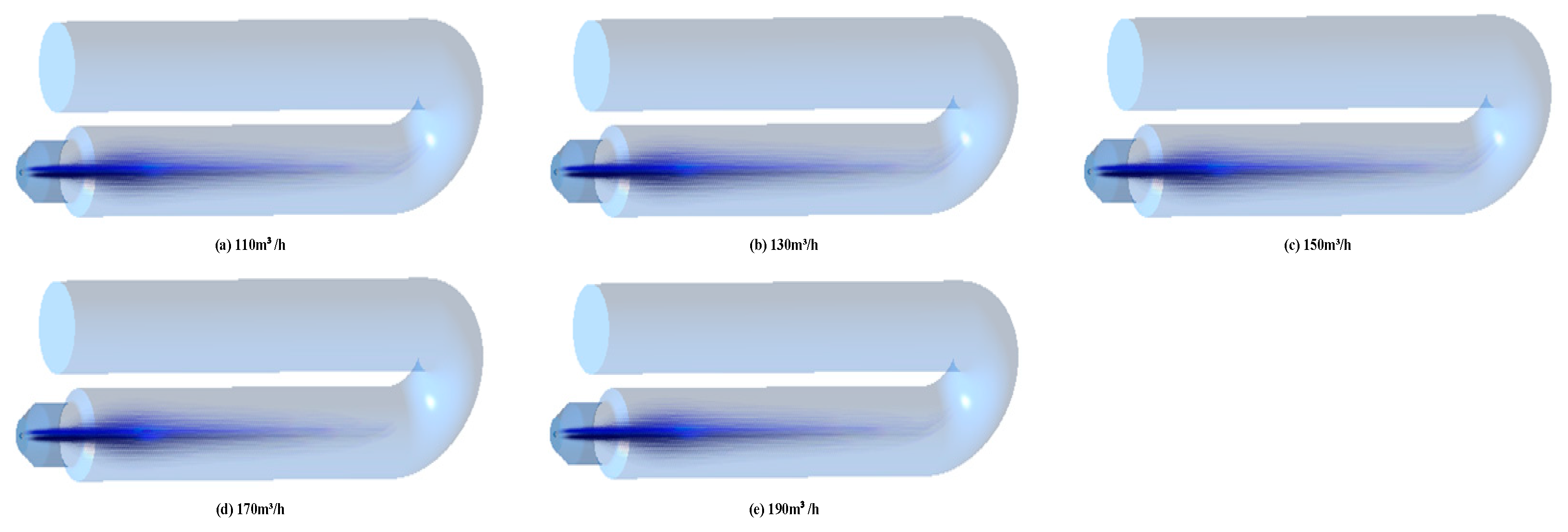

3.1.1. Analysis of Velocity Field Characteristics

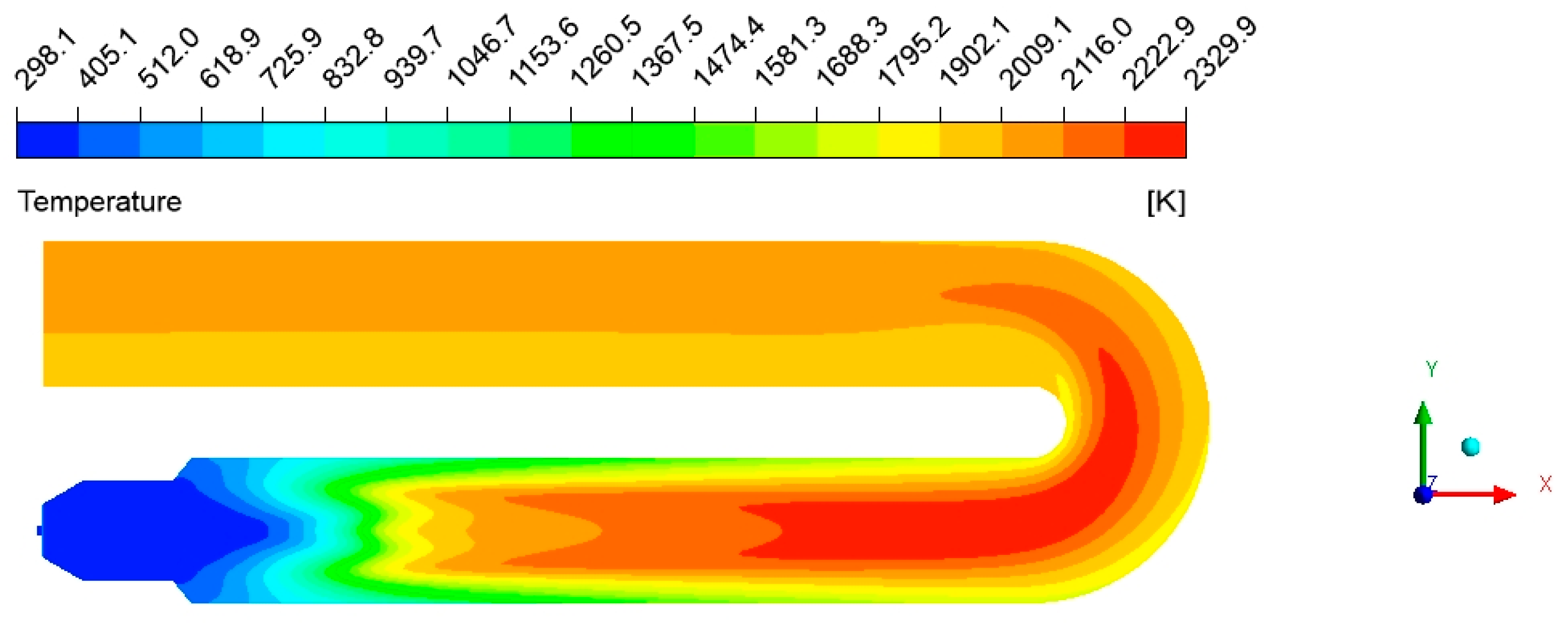

3.1.2. Analysis of Temperature Field Characteristics

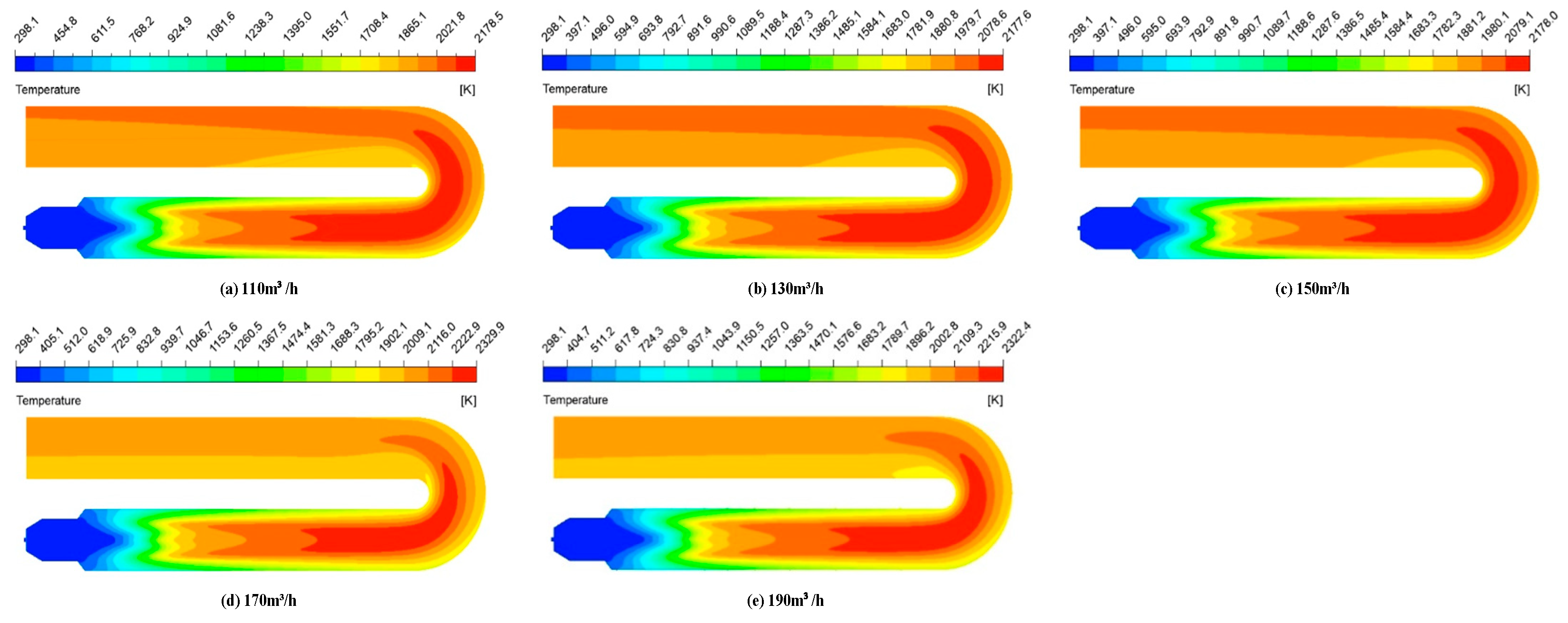

- Influence on the temperature field in the fire tube

- 2.

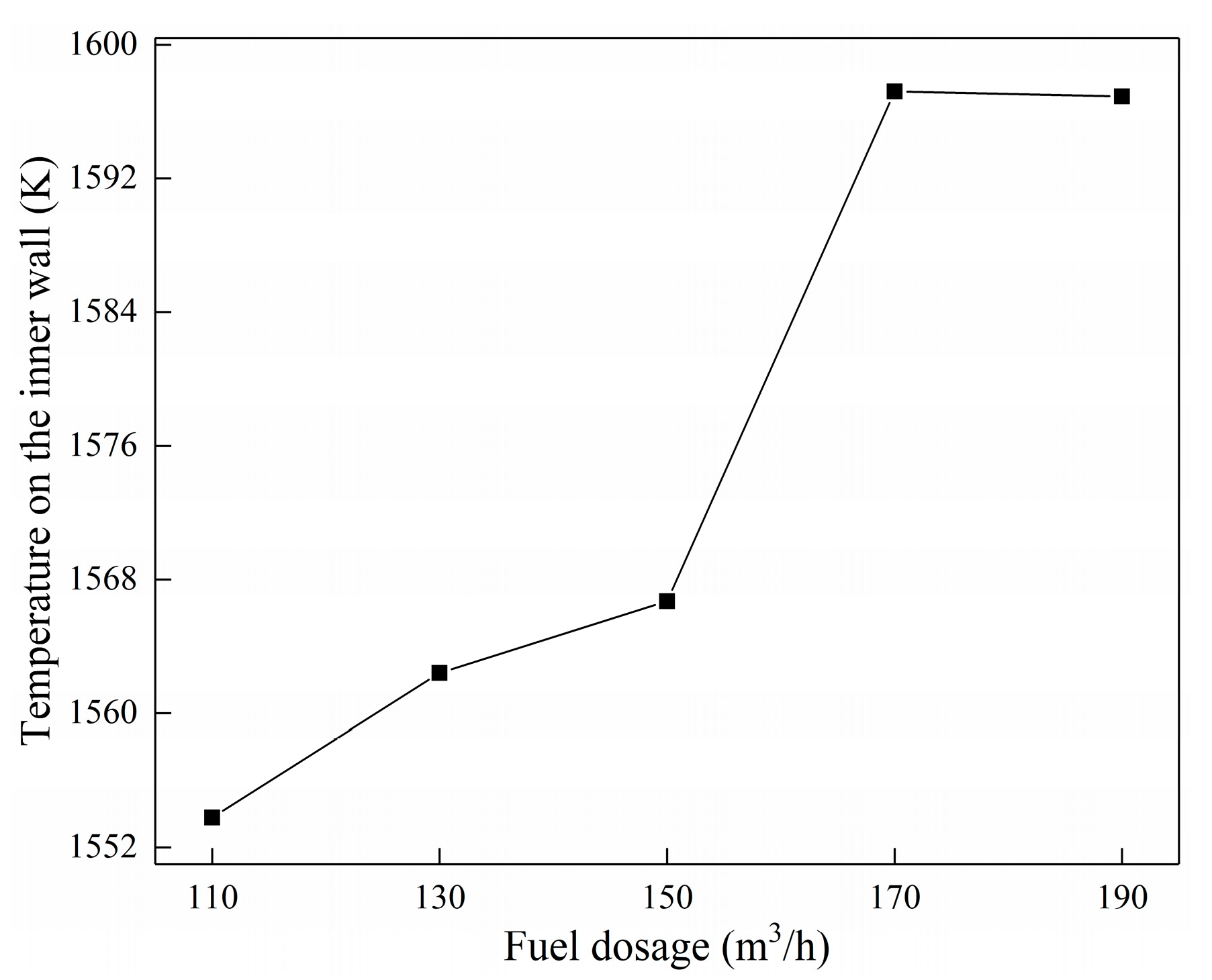

- Influence on the inner wall temperature of the fire tube

3.1.3. Analysis of Concentration Field Characteristics

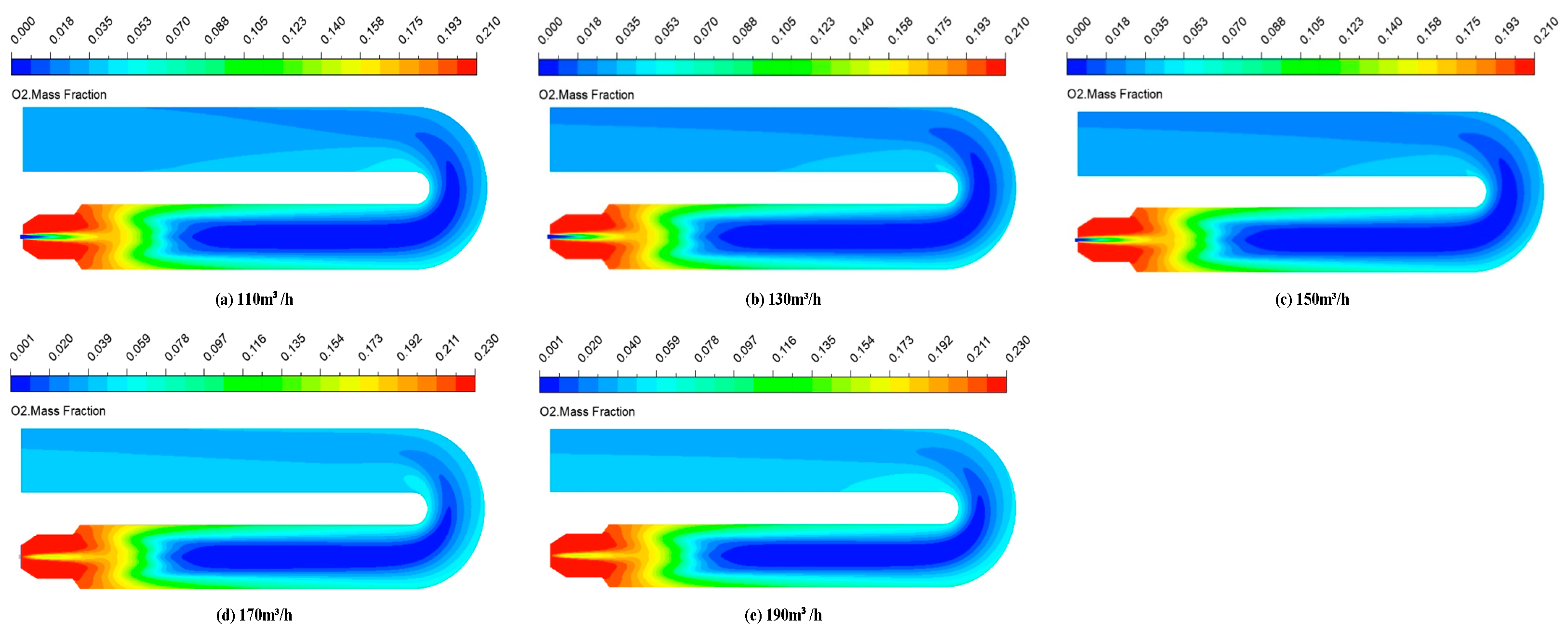

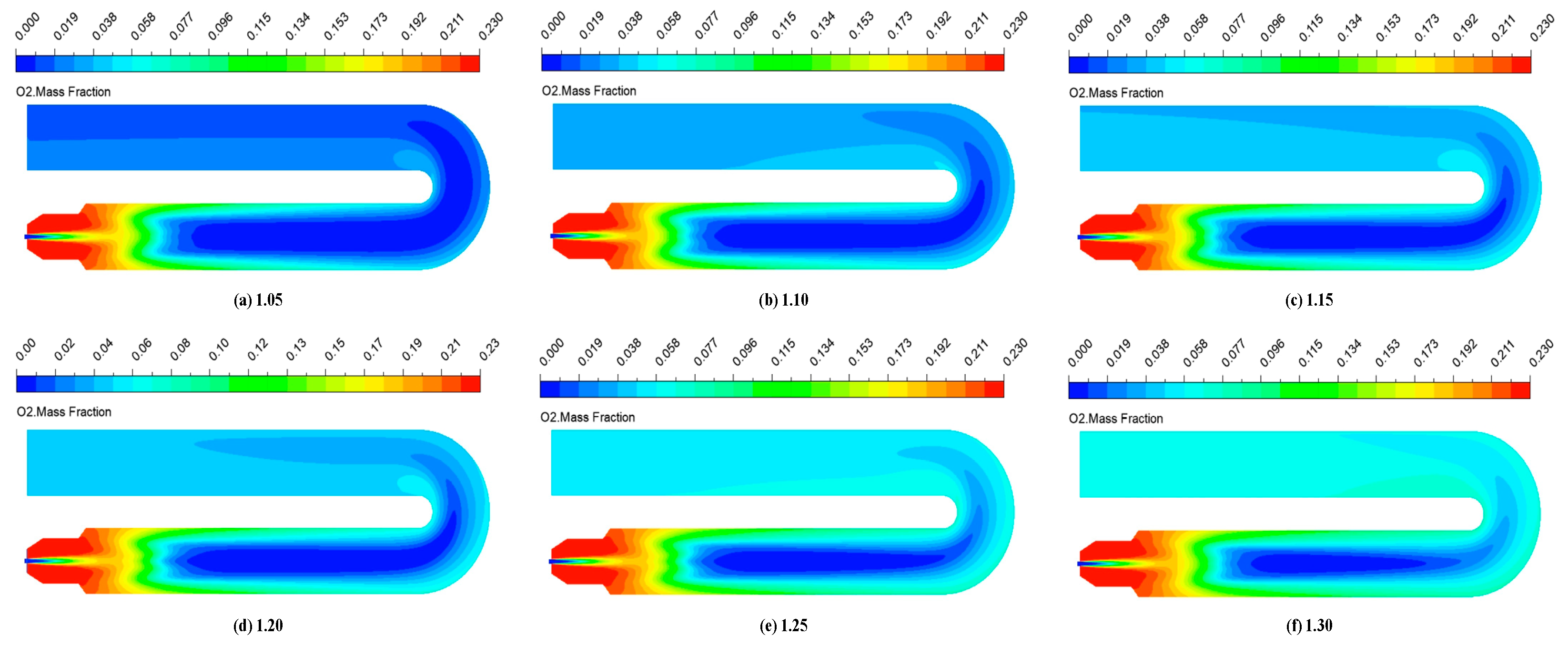

- O2 concentration field

- 2.

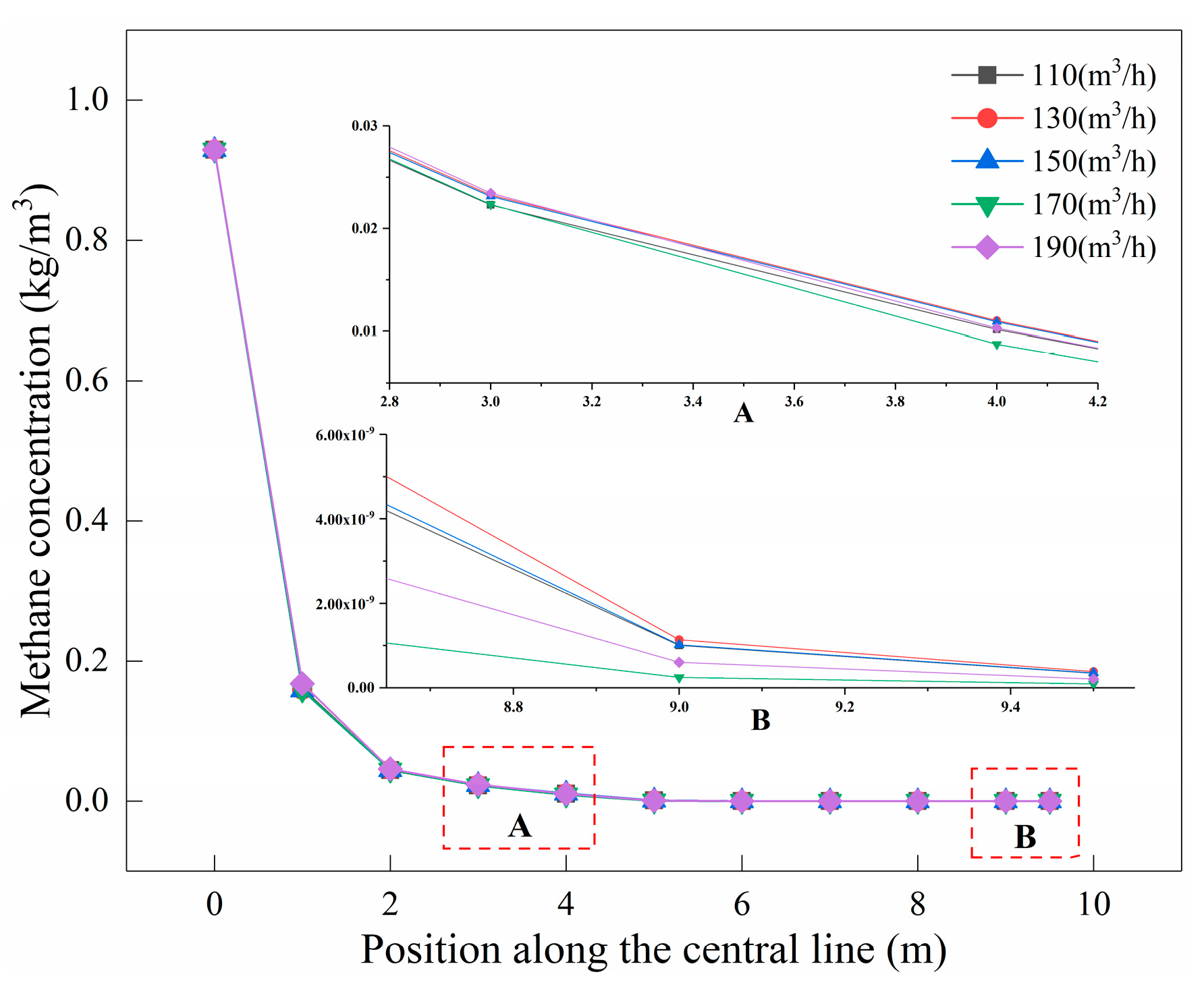

- CH4 concentration field

3.2. Optimization of Air Dosage

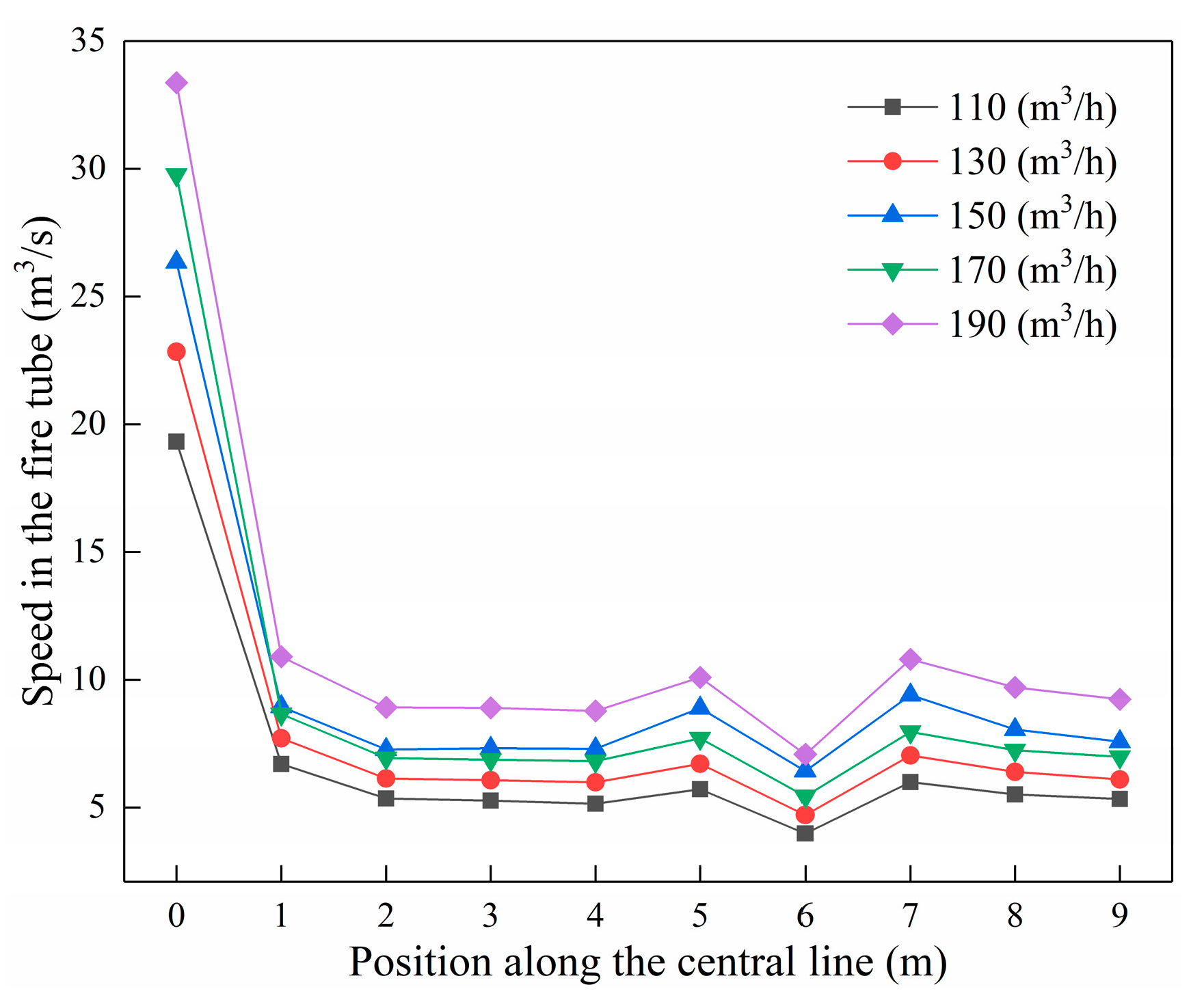

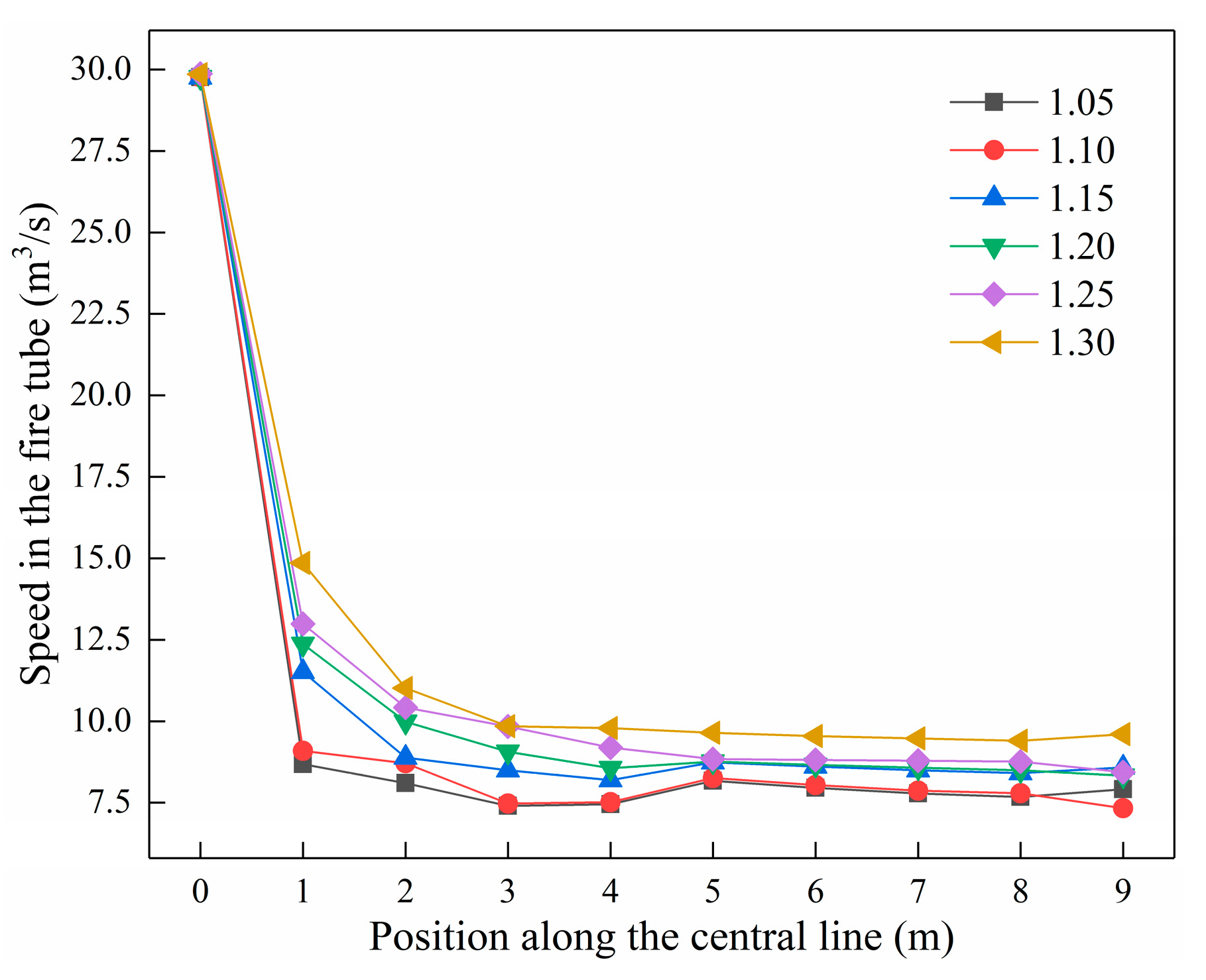

3.2.1. Analysis of Velocity Field Characteristics

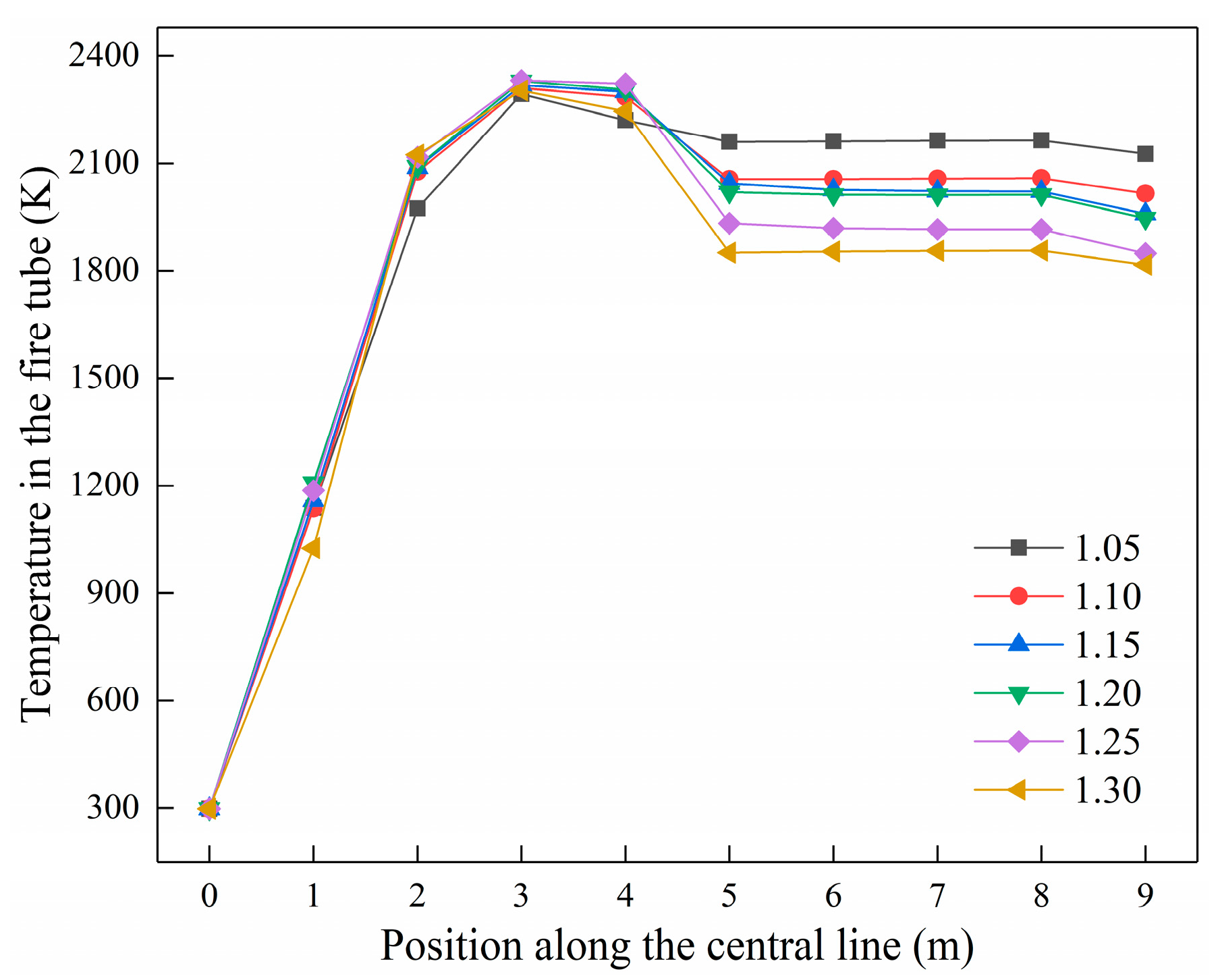

3.2.2. Analysis of Temperature Field Characteristics

- Influence on the temperature field in the fire tube

- 2.

- Influence on the inner wall temperature of the fire tube

3.2.3. Analysis of Concentration Field Characteristics

- O2 concentration field

- 2.

- CH4 concentration field

4. Conclusions

- The fuel dosage can improve the heating efficiency of the fire tube heating furnace. The fuel consumption was set at 110 m3/h, 130 m3/h, 150 m3/h, 170 m3/h, and 190 m3/h for the simulation and comparative analysis. It was found that when the fuel dosage is 170 m3/h, the fuel combustion in the fire tube is the most intense, the fuel combustion temperature is the highest, and the average temperature of the inner wall of the fire tube is the highest under the fuel dosages, so the thermal efficiency is the highest when the fuel dosage is 170 m3/h.

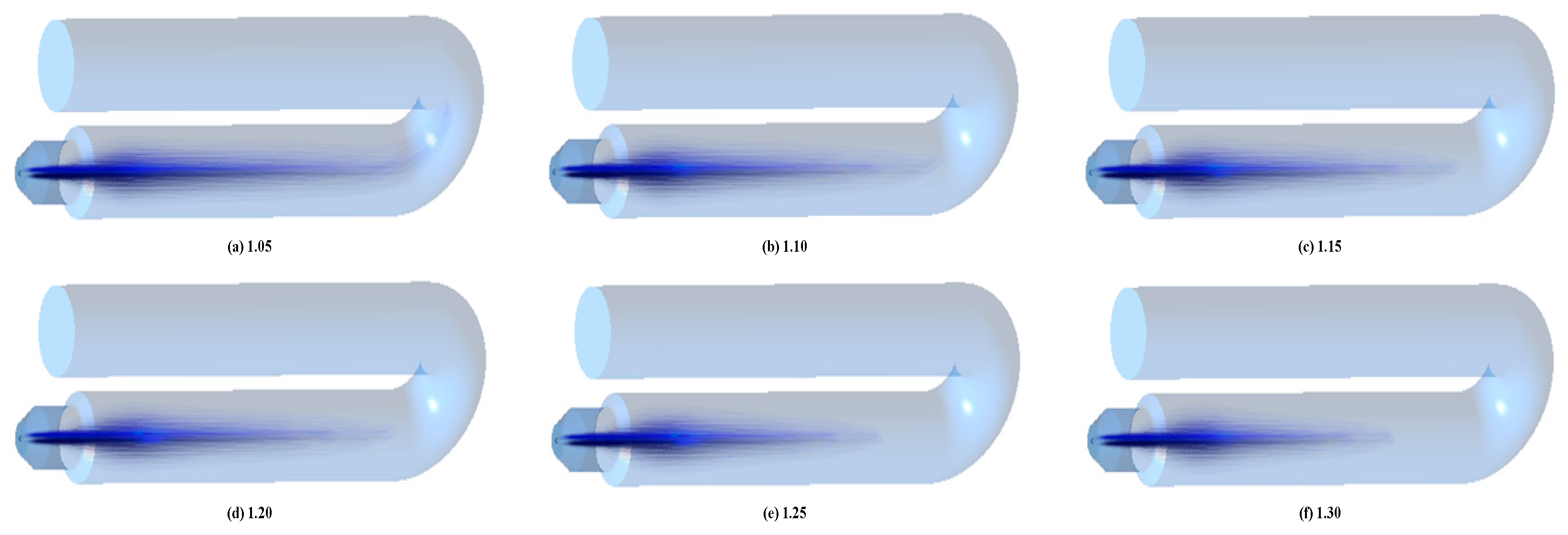

- The air dosage can increase the fuel diffusion combustion speed and significantly improve the heating efficiency. In this paper, the air dosage is represented by the excess air coefficient, which adopts values of 1.05, 1.10, 1.15, 1.20, 1.25, and 1.30 for the simulation and comparative analysis. It is found that when the excess air coefficient is 1.25, the flame temperature in the fire tube is the highest, and the fuel combustion is the most intense. However, when the excess air coefficient is 1.25, the inner wall temperature of the fire tube is low, and the heat transfer effect is not good. When the air coefficient is 1.15, the inner wall temperature of the fire tube is the highest and the heat transfer effect is the best, so the air coefficient is 1.15 and the heat efficiency is the highest.

- In terms of improving thermal efficiency, this paper gives priority to optimizing operation parameters. A simulation analysis is carried out based on the actual operation parameters of an on-site heating furnace, and it is optimized that when the fuel consumption is 170 m3/h, the air consumption is based on the theoretical value of combustion, and the air excess coefficient is 1.15, the comparison is made with the actual operation parameters of the original site. The diffusion combustion speed is 2.25 m/s faster, the average temperature of the inner wall of the fire tube is 12 K higher, the heat transfer effect is the best, and the maximum combustion temperature in the fire tube is reduced by 11 K, reducing the risk of high temperature.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Patankar, S.V.; Spalding, D.B. A calculation procedure for heat, mass and momentum transfer in three-dimensional parabolic flows. Int. Heat Mass Transf. 1972, 15, 1787–1806. [Google Scholar] [CrossRef]

- Paul, A.; Deka, R.K. Unsteady natural convection flow past an infinite cylinder with thermal and mass stratification. Int. J. Eng. Math. 2017, 2017, 8410691. [Google Scholar] [CrossRef]

- Luo, X.; Wang, Z.; Deng, W. Optimization Model Design for Temperature Curve of Reflow Furnace. J. Phys.: Conf. Ser. 2021, 1802, 022020. [Google Scholar] [CrossRef]

- Xing, P.; Xiaogang, M. Analysis of flow and heat transfer characteristics of blast furnace heating gas. Ironmak. Steelmak. 2022, 49, 429–439. [Google Scholar]

- Qiaozhen, L. Multi-Field Coupling Mechanics Analysis of Furnace Tube for Heating Furnace. Ph.D. Thesis, Northeast Petroleum University, Daqing, China, 2011. [Google Scholar]

- Liu, J.; Zhu, Y.; Zhou, H. Numerical simulation study on combustion characteristics and NOx emission of COREX gas swirl burner and boiler. Fuel 2023, 352, 129128. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, C.; Yang, L.; Dai, S. Numerical simulation of coil heat transfer. Sci. Technol. Eng. 2011, 31, 7793–7796. [Google Scholar]

- Xuehu, L. Simulation study on combustion Heat Transfer Characteristics of water jacket Furnace. Pet. Chem. Equip. 2013, 16, 27–29. [Google Scholar]

- Zhang, X.; Yang, J. Discussion on Influencing Factors of heat loss in tubular heating furnace. Qilu Petrochem. Ind. 2015, 43, 317–320. [Google Scholar]

- Mengjiao, C. Numerical Simulation of Combustion and Heat Transfer in Tubular Heating Furnace. Ph.D. Thesis, Dalian University of Technology, Dalian, China, 2015. [Google Scholar]

- Huang, Y.; Bao, X.; Duan, L. Experimental and numerical investigation on heat transfer of supercritical CO2 in a horizontal U-tube under thermal boundary of immersed tube. Int. Commun. Heat Mass Transf. 2022, 138, 106364. [Google Scholar] [CrossRef]

- Xiao, Y. Experimental Study on Heat Load Distribution in Fire Cylinder Furnace. Ph.D. Thesis, Beijing University of Chemical Technology, Beijing, China, 2016. [Google Scholar]

- Tang, Z.; Zheng, W.; Hu, X.; Yang, X.; Li, W. Efficient operation analysis of water-jacket furnace in Shengli Oilfield Joint Station. Energy Conserv. Pet. Petrochem. Ind. 2017, 7, 15–17. [Google Scholar]

- Li, S.; Wang, Y. Transient simulation and minimum commutation time of high temperature air combustion in oil field water jacket furnace. J. East China Univ. Sci. Technol. (Nat. Sci. Ed.) 2019, 1, 1–12. [Google Scholar]

- Yuan, T.; Wang, C.; Feng, Q.; Sun, Y.; Fan, G.; Chen, M.; Che, D. Computational fluid dynamics simulation on oxy-fuel combustion performance of a multiple-burner furnace firing coking dry gas. Appl. Therm. Eng. 2024, 252, 123728. [Google Scholar] [CrossRef]

- Yao, G.; Han, X.; Tang, H.; Qu, J. Numerical and Experimental Study on Preheating Burner Characteristics for Peak Shaving. Processes 2024, 12, 346. [Google Scholar] [CrossRef]

- García, A.M.; López, Y.; Amell, A.A. Numerical analysis of oxygen enrichment in a self-recuperative radiant-tube burner. Int. J. Heat Mass Transf. 2024, 223, 125154. [Google Scholar] [CrossRef]

- Huang, M.; Li, R.; Xu, J.; Cheng, S.; Deng, H.; Zhang, B.; Rong, Z.; Li, Y. Effect of thermal input, excess air coefficient and combustion mode on natural gas MILD combustion in industrial-scale furnace. Fuel 2021, 302, 121179. [Google Scholar] [CrossRef]

- Lu, J.; Yang, S.; Wang, H. Investigation of the oxygen-methane combustion and heating characteristics in industrial-scale copper anode refining furnace. Energy 2024, 298, 131278. [Google Scholar] [CrossRef]

- Dong, L.; Huang, S.; Qian, B.; Wang, K.; Gao, N.; Lin, X.; Shi, Z.; Lu, H. Numerical Simulation of Hydrogen–Coal Blending Combustion in a 660 MW Tangential Boiler. Processes 2024, 12, 415. [Google Scholar] [CrossRef]

- Kim, N.; Guahk, Y.T.; Ko, C.-B. Numerical simulation of an industrial radiant tube burner using OpenFOAM. Fuel Commun. 2024, 19, 100119. [Google Scholar] [CrossRef]

- Knoll, M.; Gerhardter, H.; Hochenauer, C.; Tomazic, P. Influences of turbulence modeling on particle-wall contacts in numerical simulations of industrial furnaces for thermal particle treatment. Powder Technol. 2020, 373, 497–509. [Google Scholar] [CrossRef]

- Kiedrzyńska, A.; Lewtak, R.; Świątkowski, B.; Jóźwiak, P.; Hercog, J.; Badyda, K. Numerical study of natural gas and low-calorific syngas co-firing in a pilot scale burner. Energy 2020, 211, 118552. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, M.; Tian, Y.; Wang, J.; Lv, C. Optimization of Combustion Parameters in the Fire Tube of Water Jacket Heating Furnace Based on FLUENT. Processes 2025, 13, 190. https://doi.org/10.3390/pr13010190

Lu M, Tian Y, Wang J, Lv C. Optimization of Combustion Parameters in the Fire Tube of Water Jacket Heating Furnace Based on FLUENT. Processes. 2025; 13(1):190. https://doi.org/10.3390/pr13010190

Chicago/Turabian StyleLu, Mei, Yuan Tian, Jie Wang, and Congmin Lv. 2025. "Optimization of Combustion Parameters in the Fire Tube of Water Jacket Heating Furnace Based on FLUENT" Processes 13, no. 1: 190. https://doi.org/10.3390/pr13010190

APA StyleLu, M., Tian, Y., Wang, J., & Lv, C. (2025). Optimization of Combustion Parameters in the Fire Tube of Water Jacket Heating Furnace Based on FLUENT. Processes, 13(1), 190. https://doi.org/10.3390/pr13010190