Tools of Theory of Inventive Problem Solving Used for Process Improvement—A Systematic Literature Review

Abstract

:1. Introduction

2. Methods

- The study must include a practical case study;

- There must be application of TRIZ to process improvement;

- The used TRIZ tools must be clearly described (just TRIZ is not enough);

- Optionally, the rate of achieved improvement is mentioned.

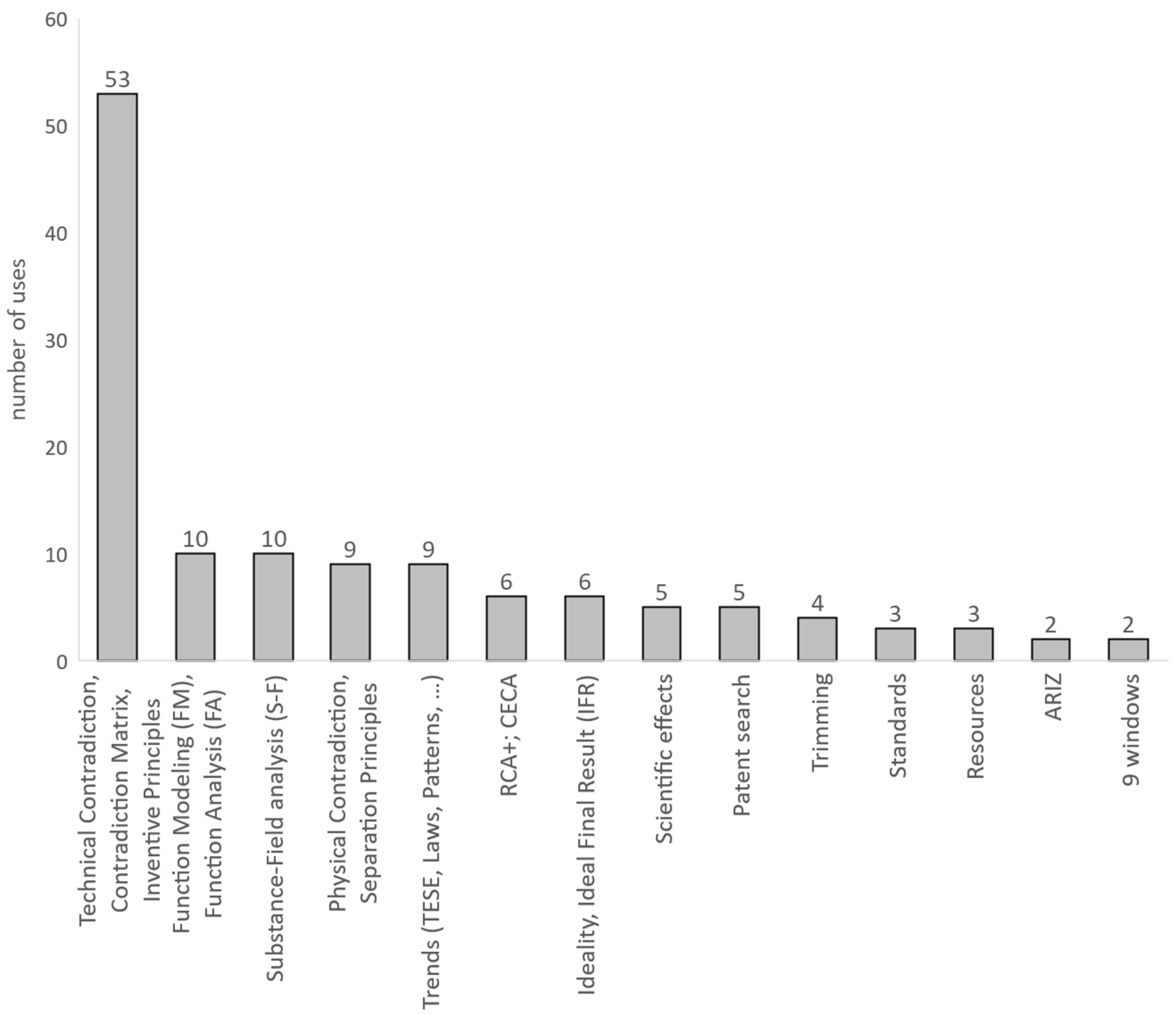

- Technical contradiction, contradiction matrix, and inventive principles;

- Physical contradiction and separation principles;

- Function modeling (FM) and function analysis (FA);

- Trimming;

- Trends (TESE—trends of engineering system evolution, laws, patterns, …);

- Substance-field analysis (S-F);

- RCA+ (root cause contradiction), and CECA (cause and effect chains analysis);

- Ideality and ideal final result (IFR);

- Standards;

- Scientific effects;

- Resources;

- ARIZ (algorithm for inventive problem solving);

- 9 windows;

- Patent search.

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Boisjoly, R.P.; Conine, T.E.; McDonald, M.B. Working Capital Management: Financial and Valuation Impacts. J. Bus. Res. 2020, 108, 1–8. [Google Scholar] [CrossRef]

- Cohen, M.A.; Kouvelis, P. Revisit of AAA Excellence of Global Value Chains: Robustness, Resilience, and Realignment. Prod. Oper. Manag. 2021, 30, 633–643. [Google Scholar] [CrossRef]

- Genin, A.; Ma, W.; Bhagwat, V.; Bernile, G. Board Experiential Diversity and Corporate Radical Innovation. Strateg. Manag. J. 2023, 44, 2634–2657. [Google Scholar] [CrossRef]

- Leon, R.-D.; Rodríguez-Rodríguez, R.; Gómez-Gasquet, P.; Mula, J. Business Process Improvement and the Knowledge Flows That Cross a Private Online Social Network: An Insurance Supply Chain Case. Inf. Process. Manag. 2020, 57, 102237. [Google Scholar] [CrossRef]

- Liu, W.; He, Y.; Dong, J.; Cao, Y. Disruptive Technologies for Advancing Supply Chain Resilience. Front. Eng. Manag. 2023, 10, 360–366. [Google Scholar] [CrossRef]

- Mayer, K.J.; Xing, Z.; Mondal, P. Contracting for Innovation: Designing Contracts That Account for Exchange Hazards and the Need for Innovation. Strateg. Manag. J. 2022, 43, 2253–2278. [Google Scholar] [CrossRef]

- Shao, Y.; Xu, K.; Shan, Y.G. Leveraging Corporate Digitalization for Green Technology Innovation: The Mediating Role of Resource Endowments. Technovation 2024, 133, 102999. [Google Scholar] [CrossRef]

- Terra, J.D.R.; Berssaneti, F.T.; Quintanilha, J.A. Challenges and Barriers in Integrating Industry 4.0 and Continuous Improvement into an Operational Excellence Plan. Prod. Manuf. Res. 2023, 11, 2288175. [Google Scholar] [CrossRef]

- Azaria, S.; Ronen, B.; Shamir, N. Justice in Time: A Theory of Constraints Approach. J. Ops. Manag. 2023, 69, 1202–1208. [Google Scholar] [CrossRef]

- Lu, K.-K.; Zhang, M.-M.; Zhu, Y.-L.; Ye, C.; Li, M. Improving the Quality of Emergency Intrahospital Transport for Critically Ill Patients by Using Toyota Production System Methods. J. Multidiscip. Healthc. 2022, 15, 1111–1120. [Google Scholar] [CrossRef]

- Miric, M.; Ozalp, H.; Yilmaz, E.D. Trade-offs to Using Standardized Tools: Innovation Enablers or Creativity Constraints? Strateg. Manag. J. 2023, 44, 909–942. [Google Scholar] [CrossRef]

- Mourtzis, D. Simulation in the Design and Operation of Manufacturing Systems: State of the Art and New Trends. Int. J. Prod. Res. 2020, 58, 1927–1949. [Google Scholar] [CrossRef]

- Niñerola, A.; Sánchez-Rebull, M.-V.; Hernández-Lara, A.-B. Quality Improvement in Healthcare: Six Sigma Systematic Review. Health Policy 2020, 124, 438–445. [Google Scholar] [CrossRef] [PubMed]

- Pacheco, D.A.D.J.; Antunes Junior, J.A.V.; De Matos, C.A. The Constraints of Theory: What Is the Impact of the Theory of Constraints on Operations Strategy? Int. J. Prod. Econ. 2021, 235, 107955. [Google Scholar] [CrossRef]

- Ram Kumar, S.; Nimesh Nathan, V.; Mohammed Ashique, S.I.; Rajkumar, V.; Arun Karthick, P. Productivity Enhancement and Cycle Time Reduction in Toyota Production System through Jishuken Activity—Case Study. Mater. Today Proc. 2021, 37, 964–966. [Google Scholar] [CrossRef]

- Wadho, W.; Chaudhry, A. Measuring Process Innovation Outputs and Understanding Their Implications for Firms and Workers: Evidence from Pakistan. Technovation 2024, 136, 103085. [Google Scholar] [CrossRef]

- Kucharavy, D.; Damand, D.; Barth, M. Technological Forecasting Using Mixed Methods Approach. Int. J. Prod. Res. 2023, 61, 5411–5435. [Google Scholar] [CrossRef]

- Meissner, D.; Harms, R.; Kratzer, J.; Zhou, J. The Dead End of Classical Innovation Management and Unsustainable Innovation. Technovation 2024, 129, 102916. [Google Scholar] [CrossRef]

- Pontikes, E.G. Category Innovation in the Software Industry: 1990–2002. Strateg. Manag. J. 2022, 43, 1697–1727. [Google Scholar] [CrossRef]

- Silva, L.E.N.; Gomes, L.A.D.V.; Faria, A.M.D.; Borini, F.M. Innovation Processes in Ecosystem Settings: An Integrative Framework and Future Directions. Technovation 2024, 132, 102984. [Google Scholar] [CrossRef]

- Yu, F.; Fu, J.; Guo, J.; Tan, R.; Yang, B. An Approach for Radical Innovative Design Based on Cross-Domain Technology Mining in Patents. Int. J. Prod. Res. 2023, 61, 7502–7523. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, W. Breakthrough Invention and Problem Complexity: Evidence from a Quasi-experiment. Strateg. Manag. J. 2022, 43, 2510–2544. [Google Scholar] [CrossRef]

- Chiarini, A.; Kumar, M. Lean Six Sigma and Industry 4.0 Integration for Operational Excellence: Evidence from Italian Manufacturing Companies. Prod. Plan. Control 2021, 32, 1084–1101. [Google Scholar] [CrossRef]

- Patel, A.S.; Patel, K.M. Critical Review of Literature on Lean Six Sigma Methodology. Int. J. Lean Six Sigma 2021, 12, 627–674. [Google Scholar] [CrossRef]

- Bag, S.; Wood, L.C.; Xu, L.; Dhamija, P.; Kayikci, Y. Big Data Analytics as an Operational Excellence Approach to Enhance Sustainable Supply Chain Performance. Resour. Conserv. Recycl. 2020, 153, 104559. [Google Scholar] [CrossRef]

- Dev, N.K.; Shankar, R.; Qaiser, F.H. Industry 4.0 and Circular Economy: Operational Excellence for Sustainable Reverse Supply Chain Performance. Resour. Conserv. Recycl. 2020, 153, 104583. [Google Scholar] [CrossRef]

- Francisco, M.G.; Canciglieri Junior, O.; Santanna, A.M.O. Roadmap for Product Development Based on Design for Six Sigma Method. Int. J. Lean Six Sigma 2023, 14, 989–1009. [Google Scholar] [CrossRef]

- Gholami, H.; Jamil, N.; Mat Saman, M.Z.; Streimikiene, D.; Sharif, S.; Zakuan, N. The Application of Green Lean Six Sigma. Bus. Strat. Environ. 2021, 30, 1913–1931. [Google Scholar] [CrossRef]

- Gupta, S.; Modgil, S.; Gunasekaran, A. Big Data in Lean Six Sigma: A Review and Further Research Directions. Int. J. Prod. Res. 2020, 58, 947–969. [Google Scholar] [CrossRef]

- Haktanır, E.; Kahraman, C. Design for Six Sigma and Process Capability Using Penthagorean Fuzzy Sets. In Intelligent and Fuzzy Techniques: Smart and Innovative Solutions; Advances in Intelligent Systems and Computing; Kahraman, C., Cevik Onar, S., Oztaysi, B., Sari, I.U., Cebi, S., Tolga, A.C., Eds.; Springer International Publishing: Cham, Switzerland, 2021; Volume 1197, pp. 1385–1395. ISBN 978-3-030-51155-5. [Google Scholar]

- Kaswan, M.S.; Rathi, R. Green Lean Six Sigma for Sustainable Development: Integration and Framework. Environ. Impact Assess. Rev. 2020, 83, 106396. [Google Scholar] [CrossRef]

- Neligan, A.; Baumgartner, R.J.; Geissdoerfer, M.; Schöggl, J. Circular Disruption: Digitalisation as a Driver of Circular Economy Business Models. Bus. Strat. Environ. 2023, 32, 1175–1188. [Google Scholar] [CrossRef]

- Toh, P.K.; Ahuja, G. Integration and Appropriability: A Study of Process and Product Components within a Firm’s Innovation Portfolio. Strateg. Manag. J. 2022, 43, 1075–1109. [Google Scholar] [CrossRef]

- Bligh, A. The Overlap Between TRIZ and Lean; University of Rhode Island: Kingston, RI, USA, 2006. [Google Scholar]

- Ikovenko, S.; Bradley, J. TRIZ as a Lean Thinking Tool. In Proceedings of the 2004 ETRIA TRIZ Future Conference, Florence, Italy, 3–5 November 2004. [Google Scholar]

- Sojka, V.; Lepšík, P. TRIZ Tools for Manufacturing Processes Improvement. In Proceedings of the DOKBAT 2020—16th International Bata Conference for Ph.D. Students and Young Researchers, Zlín, Czech Republic, 20–21 May 2020; Tomas Bata University in Zlín: Zlín, Czech Republic, 2020; pp. 484–491. [Google Scholar]

- Coulibaly, S. The Contribution of TRIZ Integration with Others Design Tools In the Engineering Design Process. Int. J. Innov. Res. Sci. Eng. Technol. 2017, 6, 684–693. [Google Scholar]

- Ghane, M.; Ang, M.C.; Cavallucci, D.; Abdul Kadir, R.; Ng, K.W.; Sorooshian, S. Semantic TRIZ Feasibility in Technology Development, Innovation, and Production: A Systematic Review. Heliyon 2024, 10, e23775. [Google Scholar] [CrossRef]

- Hua, Z.; Yang, J.; Coulibaly, S.; Zhang, B. Integration TRIZ with Problem-Solving Tools: A Literature Review from 1995 to 2006. Int. J. Bus. Innov. Res. 2006, 1, 111–128. [Google Scholar] [CrossRef]

- Lin, C.C.; Lin, H.-H.; Huang, K.-C. TRIZ Retrospect and Prospect. In Proceedings of the 2016 3rd International Conference on Systems and Informatics (ICSAI), Shanghai, China, 19–21 November 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1072–1076. [Google Scholar]

- Maia, L.C.; Alves, A.C.; Leão, C.P. How Could the TRIZ Tool Help Continuous Improvement Efforts of the Companies? Procedia Eng. 2015, 131, 343–351. [Google Scholar] [CrossRef]

- Rupani, M.M.; Lotfi, M.R.; Nejat, A.; Bakar, N.A.; Othman, F. A Review on TRIZ Approach in Service Industry. J. Eng. Appl. Sci. 2017, 12, 7815–7823. [Google Scholar]

- Sojka, V.; Lepsik, P. Use of TRIZ, and TRIZ with Other Tools for Process Improvement: A Literature Review. Emerg. Sci. J. 2020, 4, 319–335. [Google Scholar] [CrossRef]

- Mann, D.; Stratton, R. Physical Contradictions and Evaporating Clouds (Case Study Applications of TRIZ and the Theory of Constraints. TRIZ J. 2000. Available online: https://the-trizjournal.com/physical-contradictions-evaporating-clouds/ (accessed on 6 January 2024).

- Winkless, B.; Mann, D. Product and Process Improvement Using TRIZ: A Case Study in Increasing Innovative Options. In Proceedings of the TRIZ Future Conference, Strasbourg, France, 6–8 November 2002. [Google Scholar]

- Kumar, G.P. Software Process Improvement—TRIZ and Six Sigma (40 Principles Usage for Level 2 Inventions). TRIZ J. 2005. Available online: https://the-trizjournal.com/software-process-improvement-triz-six-sigma-40-principles-usage-level-2-inventions/ (accessed on 6 January 2024).

- Robles, G.C.; Negny, S.; Le Lann, J.M. Innovation and Knowledge Management: Using the Combined Approach TRIZ-CBR in Process System Engineering. In 16th European Symposium on Computer Aided Process Engineering and 9th International Symposium on Process Systems Engineering; Marquardt, W., Pantelides, C., Eds.; Elsevier: Amsterdam, The Netherlands, 2006; Volume 21, pp. 2237–2242. [Google Scholar]

- Ru, H.; Ru, H. Applying TRIZ in Process Improvement. TRIZ J. 2006. Available online: https://the-trizjournal.com/applying-triz-process-improvement/ (accessed on 6 January 2024).

- Domb, E.; Kling, T.J. How to Reduce Cost in Product and Process Using TRIZ. TRIZ J. 2006, 6. [Google Scholar]

- Duflou, J.R.; D’hondt, J. Applying TRIZ for Systematic Manufacturing Process Innovation: The Single Point Incremental Forming Case. Procedia Eng. 2011, 9, 528–537. [Google Scholar] [CrossRef]

- Jin, Y.T.; San, Y.T.; Li, S.C. TRIZ: Systematic Innovation towards Factory Operational Efficiency. In Proceedings of the 2008 33rd IEEE/CPMT International Electronics Manufacturing Technology Conference (IEMT), Penang, Malaysia, 4–6 November 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–4. [Google Scholar]

- Brad, S.; Fulea, M.; Emilia, B.; Mocan, B. Systematic Integration of Innovation in Process Improvement Projects Using the Enhanced Sigma-TRIZ Algorithm and Its Effective Use by Means of a Knowledge Management Software Platform. Inform. Econ. J. 2009, 13, 75–89. [Google Scholar]

- Lee, L.J.H.; Leu, J.-D. Using Value Engineering and TRIZ for Better Business Process Management. In Proceedings of the 40th International Conference on Computers & Indutrial Engineering, Awaji City, Japan, 25–28 July 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 1–5. [Google Scholar]

- Wang, F.-K.; Chen, K.-S. Applying Lean Six Sigma and TRIZ Methodology in Banking Services. Total Qual. Manag. Bus. Excell. 2010, 21, 301–315. [Google Scholar] [CrossRef]

- Hsia, T.-C.; Huang, S.-C. Using the Theory of Inventive Problem-Solving (TRIZ) to Implement Safety Improvements in Foundry Engineering Pouring Procedures. In Proceedings of the 2011 International Conference on Management and Service Science, Wuhan, China, 12–14 August 2011; IEEE: Piscataway, NJ, USA, 2011; pp. 1–4. [Google Scholar]

- Hsia, T.C.; Chen, S.C.; Tsai, R.K.; Huang, S.C. Using Systematic Innovation Process (TRIZ Method) to Improve the Manufacturing Technology of Platelet Agitators. In Proceedings of the Flexible Automation and Intelligent Manufacturing, Porto, Portugal, 27–29 June 2011; Springer: Berlin/Heidelberg, Germany, 2011; Volume 44. [Google Scholar]

- Kumaresan, K.S.; Saman, M.Z.M. Integration of SMED and TRIZ in Improving Productivity at Semiconductor Industry. J. Mek. 2011, 33, 40–55. [Google Scholar]

- Wang, C.-N.; Hsiung, W.-M. Application of TRIZ to Improve the Layout for a Screw Packaging Factory. In Proceedings of the 2011 IEEE 18th International Conference on Industrial Engineering and Engineering Management, Changchun, China, 3–5 September 2011; IEEE: Piscataway, NJ, USA, 2011; pp. 62–66. [Google Scholar]

- Soti, A.; Shankar, R.; Kaushal, O.P. Six Sigma with Innovation Tool Kit of TRIZ. Int. J. Bus. Innov. Res. 2012, 6, 220–237. [Google Scholar] [CrossRef]

- Ferrer, J.B.; Negny, S.; Robles, G.C.; Le Lann, J.M. Eco-Innovative Design Method for Process Engineering. Comput. Chem. Eng. 2012, 45, 137–151. [Google Scholar] [CrossRef]

- Kim, S.; Yoon, B. Developing a Process of Concept Generation for New Product-Service Systems: A QFD and TRIZ-Based Approach. Serv. Bus. 2012, 6, 323–348. [Google Scholar] [CrossRef]

- Moreira, D. Component Misplacement Prevention on the ICOS Tape & Reel Process Using TRIZ & Lean. In Proceedings of the IPC APEX EXPO Proceedings, San Diego, CA, USA, 28 February–1 March 2012. [Google Scholar]

- Regazzoni, D.; Pezzotta, G.; Persico, S.; Cavalieri, S.; Rizzi, C. Integration of TRIZ Problem Solving Tools in a Product-Service Engineering Process. In The Philosopher’s Stone for Sustainability; Shimomura, Y., Kimita, K., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 399–404. [Google Scholar]

- Petrović, M.; Miljković, Z.; Babić, B. Integration of Process Planning, Scheduling, and Mobile Robot Navigation Based on TRIZ and Multi-Agent Methodology. FME Trans. 2013, 41, 97–106. [Google Scholar]

- Lanke, A.; Ghodrati, B. Reducing Defects and Achieving Business Profitability Using Innovative and Lean Thinking. In Proceedings of the 2013 IEEE International Conference on Industrial Engineering and Engineering Management, Bangkok, Thailand, 10–13 December 2013; IEEE: Piscataway, NJ, USA, 2013; pp. 1026–1030. [Google Scholar]

- Muruganantham, V.R.; Krishnan, P.N.; Arun, K.K. Performance Improvement and Cost Minimisation for Manufacturing Components in a Fabrication Plant by the Application of Lean with TRIZ Principles. Int. J. Product. Qual. Manag. 2013, 12, 449–465. [Google Scholar] [CrossRef]

- Sheu, D.D.; Hou, C.T. TRIZ-Based Trimming for Process-Machine Improvements: Slit-Valve Innovative Redesign. Comput. Ind. Eng. 2013, 66, 555–566. [Google Scholar] [CrossRef]

- Annamalai, N.; Kamaruddin, S.; Azid, I.A.; Yeoh, T.S. Clustered Model TRIZ and Application in Industries. Int. J. Innov. Manag. Technol. 2014, 5, 368–373. [Google Scholar] [CrossRef]

- Cabrera, B.R.; Li, G.J. A Lean-TRIZ Approach for Improving the Perfomance of Construction Projects. In Proceedings of the Proceedings IGLC-22 The International Group for Lean Construction, Oslo, Norway, 25–27 June 2014; Volume 22, pp. 883–894. [Google Scholar]

- Guo, Y.; Sun, M.-G.; Xu, M. Using TRIZ to a Quality Improvement—Case Study of Foxbro in Shanghai. Int. J. Bus. Econ. Dev. 2014, 2, 61–69. [Google Scholar]

- Muruganantham, V.R.; Krishnan, P.N.; Arun, K.K. Integrated Application of TRIZ with Lean in the Manufacturing Process in a Machine Shop for the Productivity Improvement. Int. J. Product. Qual. Manag. 2014, 13, 414–429. [Google Scholar] [CrossRef]

- Jiang, J.-C.; Nguyen, T.-A.-T. Process Improvement by Application of Lean Six Sigma and TRIZ Methodology—Case Study in Coffee Company. Int. J. Appl. Or Innov. Eng. Manag. 2015, 4, 208–219. [Google Scholar]

- Li, M.; Ming, X.; Zheng, M.; He, L.; Xu, Z. An Integrated TRIZ Approach for Technological Process and Product Innovation. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 231, 1062–1077. [Google Scholar] [CrossRef]

- Pokhrel, C.; Cruz, C.; Ramirez, Y.; Kraslawski, A. Adaptation of TRIZ Contradiction Matrix for Solving Problems in Process Engineering. Chem. Eng. Res. Des. 2015, 103, 3–10. [Google Scholar] [CrossRef]

- Arcidiacono, G.; Bucciarelli, L. TRIZ: Engineering Methodologies to Improve the Process Reliability: TRIZ in Process Reliability. Qual. Reliab. Engng. Int. 2016, 32, 2537–2547. [Google Scholar] [CrossRef]

- Alves, J.F.; Navas, H.V.G.; Nunes, I.L. Application of TRIZ Methodology for Ergonomic Problem Solving in a Continuous Improvement Environment. In Advances in Safety Management and Human Factors; Arezes, P., Ed.; Springer International Publishing: Cham, Switzerland, 2016; pp. 473–485. [Google Scholar]

- Pacheco, D.A.d.J.; Caten, C.S.; Navas, H.V.G.; Jung, C.F.; Machado, V.A.C.; Lopes, G.H.N. Systematic Eco-Innovation in Lean PSS Environment: An Integrated Model. Procedia CIRP 2016, 47, 466–471. [Google Scholar] [CrossRef]

- Ghani, J.A.; Natasha, A.R.; Hassan, C.H.C.; Syarif, J. TRIZ Approach for Machining Process Innovation in Cryogenic Environment. Int. J. Mater. Prod. Technol. 2016, 53, 286–297. [Google Scholar] [CrossRef]

- Lin, C.-H.; Lin, W.-T.; Jou, Y.-T.; Wu, W.-T.; Yan, Z.-H. A Study of Process Optimization for Roasting Taiwanese Coffees by Applying Six Sigma. In Proceedings of the 2016 International Conference on Fuzzy Theory and Its Applications (iFuzzy), Taichung, Taiwan, 9–11 November 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1–8. [Google Scholar]

- Karaulova, T.; Bashkite, V. Decision-Making Framework for Used Industrial Equipment. Eng. Econ. 2016, 27, 23–31. [Google Scholar] [CrossRef]

- Su, C.-T.; Su, F.-M. Yield Improvement in Color Filter Manufacturing Using Taguchi Methods and TRIZ’s Substance–Field Analysis. IEEE Trans. Compon. Packag. Manufact. Technol. 2018, 8, 2198–2212. [Google Scholar] [CrossRef]

- Chan, C.K.; Chin, W.C. Housing Manufacturing Process Optimization via TRIZ Approach. In Proceedings of the MyTRIZ Conference, Penang, Malaysia, 3 December 2020; pp. 87–96. [Google Scholar]

- Indrawati, S.; Azzam, A.; Adrianto, E.; Miranda, S.; Prabaswari, A.D. Lean Concept Development in Fast Food Industry Using Integration of Six Sigma and TRIZ Method. IOP Conf. Ser. Mater. Sci. Eng. 2020, 722, 012044. [Google Scholar] [CrossRef]

- Lepšík, P. Innovation of Device for Nanofibers Production Using TRIZ. In Current Methods of Construction Design; Lecture Notes in Mechanical Engineering; Medvecký, Š., Hrček, S., Kohár, R., Brumerčík, F., Konstantová, V., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 605–610. ISBN 978-3-030-33145-0. [Google Scholar]

- Purnomo, D.H.; Lukman, M. Reduce Waste Using Integration of Lean Six Sigma and TRIZ Method: A Case Study in Wood Industry. J. Tek. Ind. 2020, 21, 139–152. [Google Scholar] [CrossRef]

- Yu, S.; Wang, J. An Empirical Study on the Model of Aged Home-Care Service Process Improvement for the Elders. J. Inf. Optim. Sci. 2020, 41, 1269–1290. [Google Scholar] [CrossRef]

- Boangmanalu, E.; Abigail, T.; Sembiring, A.; Tampubolon, J. Minimizing Damage of Product Using Six Sigma and Triz Methods. IOP Conf. Ser. Mater. Sci. Eng. 2020, 801, 012101. [Google Scholar] [CrossRef]

- Gamboa, P.; Singgih, M.L. Waste Minimization in a Concrete Block Company Using Lean Six Sigma, ECRS, and TRIZ Methods. In Proceedings of the Second Asia Pacific International Conference on Industrial Engineering and Operations Management, Surakarta, Indonesia, 14–16 September 2021; IEOM Society International: Southfield, MI, USA, 2021; p. 9. [Google Scholar]

- Araújo, S.; Lopes, J.; Alves, A.C.; Navas, H. The Synergetic Effect of Lean Six Sigma and TRIZ on the Improvement of an Electronic Component. In Industrial Engineering and Operations Management; Springer Proceedings in Mathematics & Statistics; Tavares Thomé, A.M., Barbastefano, R.G., Scavarda, L.F., Gonçalves dos Reis, J.C., Amorim, M.P.C., Eds.; Springer International Publishing: Cham, Switzerland, 2021; Volume 367, pp. 409–420. ISBN 978-3-030-78569-7. [Google Scholar]

- Ucipto, S.; Ria, D.R.; Effendi, U. Controlling of Pasteurized Milk Production Using SPC and TRIZ. IOP Conf. Ser. Earth Environ. Sci. 2021, 733, 012038. [Google Scholar] [CrossRef]

- Sojka, V.; Lepsik, P. Innovation by Increasing Ideality—A New Method for Overcoming Process Related Problems. Qual. Innov. Prosper. 2021, 25, 78–94. [Google Scholar] [CrossRef]

- Wang, C.-N.; Hsueh, M.-H.; Lai, C.-J.; Wang, C.-F.; Wang, S.-H. Improvement of the Welding Process for Fillet Air Test for the Biggest Taiwan Shipyard. J. Mar. Sci. Eng. 2021, 9, 80. [Google Scholar] [CrossRef]

- Wang, C.-N.; Tibo, H.; You, C.-J. Noise and Work Reduction through Remodeling of Stern Tube Assembly in a Shipbuilding Process by Applying TRIZ Theory. J. Mar. Sci. Eng 2021, 9, 1059. [Google Scholar] [CrossRef]

- Wang, C.-N.; Hsueh, M.-H.; Lai, C.-J.; Chung, C.-C.; Chen, W.-C.; Wang, S.-H. Improve Chip Side Wall Crack Issue in Nanometer Packing Process of Semiconductor. IEEE Trans. Compon. Packag. Manufact. Technol. 2021, 11, 173–180. [Google Scholar] [CrossRef]

- Kandukuri, S.; Günay, E.E.; Al-Araidah, O.; Okudan Kremer, G.E. Inventive Solutions for Remanufacturing Using Additive Manufacturing: ETRIZ. J. Clean. Prod. 2021, 305, 126992. [Google Scholar] [CrossRef]

- Sojka, V.; Lepsik, P. Algorithm for Process Innovation by Increasing Ideality. Processes 2022, 10, 1283. [Google Scholar] [CrossRef]

- Ng, P.K.; Prasetio, M.D.; Liew, K.W.; Lim, B.K.; Oktafiani, A.; Salma, S.A.; Safrudin, Y.N. A TRIZ-Inspired Conceptual Development of a Roof Tile Transportation and Inspection System. Buildings 2022, 12, 1456. [Google Scholar] [CrossRef]

- Purushothaman, K.; Ahmad, R. Integration of Six Sigma Methodology of DMADV Steps with QFD, DFMEA and TRIZ Applications for Image-Based Automated Inspection System Development: A Case Study. Int. J. Lean Six Sigma 2022, 13, 1239–1276. [Google Scholar] [CrossRef]

- Sojka, V.; Lepsik, P. Radical Process Improvement by Systematic Approach to Overcome Problems on Custom Glass Eyes Manufacturing. Teh. Vjesn. 2023, 30, 348–353. [Google Scholar] [CrossRef]

- Števko, P.; Kohár, R.; Čechmánek, D.; Medvecká, D.; Nový, F. Optimization of the Tire Building Drum for Passenger Tires Using the TRIZ Methodology. Manag. Syst. Prod. Eng. 2023, 31, 361–372. [Google Scholar] [CrossRef]

- Soares, V.; Helena, V.G.N. New Model for Creating Innovative Solutions in Continuous Improvement Environments. Int. J. Syst. Innov. 2023, 7, 10–29. [Google Scholar] [CrossRef]

- Syu, S.-D.; Nhieu, N.-L.; Hoan, H.T.; Wang, C.-N.; Lin, G.-M.; Hung, Y.-A. TRIZ- Driven Product Quality Enhancement and Competitiveness in Electronic Manufacturing: A Practical Case Study and Strategic Investigation. In Proceedings of the 2023 5th International Conference on Control and Robotics (ICCR), Tokyo, Japan, 23–25 November 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 205–209. [Google Scholar]

- Reza, M.; Salim, M.A.; Masripan, N.A.; Yusof, N.M.; Purnomo, M.R.A. Improving the efficiency of operating the cone laying and collecting machine (C2L) using TRIZ method. J. Adv. Manuf. Technol. 2023, 17, 101–112. [Google Scholar]

- Vanko, K.; Pompáš, L.; Madaj, R.; Vicen, M.; Šutka, J. Optimization of Assembly Devices of Automated Workplaces Using the TRIZ Methodology. Prod. Eng. Arch. 2023, 29, 231–240. [Google Scholar] [CrossRef]

- Koay, F.T.; Tan, C.J.; Teh, S.Y.; Teoh, P.C.; Low, H.C. Supporting decision making with an ARIZ-based model for smart manufacturing. Malays. J. Comput. Sci. 2023, 36, 53–78. [Google Scholar] [CrossRef]

- Phuah, Z.Y.; Ng, P.K.; Prasetio, M.D.; Liew, K.W.; Lim, B.K.; Oktafiani, A.; Salma, S.A.; Safrudin, Y.N. A TRIZ-Supported Concept and Protocol Development for Roof Tile Transportation and Inspection Systems. Buildings 2023, 13, 197. [Google Scholar] [CrossRef]

| Study | Technical Contradiction, Contradiction Matrix, Inventive Principles | Physical Contradiction, Separation Principles | Function Modeling (FM), Function Analysis (FA) | Trimming | Trends (TESE, Laws, Patterns, …) | Substance-Field Analysis (S-F) | RCA+; CECA | Ideality, Ideal Final Result (IFR) | Standards | Scientific Effects | Resources | ARIZ | 9 Windows | Patent Search |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mann and Stratton, (2000) [44] | × | |||||||||||||

| Winkless and Mann, (2002) [45] | × | × | × | |||||||||||

| Kumar, (2005) [46] | × | |||||||||||||

| Robles et al., (2006) [47] | × | |||||||||||||

| Ru and Ru, (2006) [48] | × | |||||||||||||

| Domb and Kling, (2006) [49] | × | × | × | × | × | |||||||||

| Duflou and D’hondt, (2011) [50] (orig. 2007) | × | × | ||||||||||||

| Jin et al., (2008) [51] | × | × | × | × | ||||||||||

| Brad et al., (2009) [52] | × | × | ||||||||||||

| Lee and Leu, (2010) [53] | × | × | ||||||||||||

| Study | Technical Contr. | Physical Contr. | Function Analysis | Trimming | TESE | Su-Field | RCA+ | Ideality | Standards | Sci. Effects | Resources | ARIZ | 9 Windows | Patent Search |

| F.-K. Wang and Chen, (2010) [54] | × | |||||||||||||

| T.-C. Hsia and Huang, (2011) [55] | × | × | ||||||||||||

| T. C. Hsia et al., (2011) [56] | × | |||||||||||||

| Kumaresan and Saman, (2011) [57] | × | |||||||||||||

| C.-N. Wang and Hsiung, (2011) [58] | × | |||||||||||||

| Soti et al., (2012) [59] | × | × | × | × | × | × | × | × | ||||||

| Ferrer et al., (2012) [60] | × | × | × | × | ||||||||||

| Kim and Yoon, (2012) [61] | × | |||||||||||||

| Moreira, (2012) [62] | × | × | ||||||||||||

| Regazzoni et al., (2013) [63] | × | × | × | |||||||||||

| Petrović et al., (2013) [64] | × | |||||||||||||

| Lanke and Ghodrati, (2013) [65] | × | × | ||||||||||||

| Muruganantham et al., (2013) [66] | × | |||||||||||||

| Sheu and Hou, (2013) [67] | × | × | ||||||||||||

| Annamalai et al., (2014) [68] | × | × | × | |||||||||||

| Cabrera and Li, (2014) [69] | × | |||||||||||||

| Guo et al., (2014) [70] | × | |||||||||||||

| Muruganantham et al., (2014) [71] | × | |||||||||||||

| Jiang and Nguyen, (2015) [72] | × | |||||||||||||

| Li et al., (2017) [73] (orig. 2015) | × | × | ||||||||||||

| Pokhrel et al., (2015) [74] | × | |||||||||||||

| Arcidiacono and Bucciarelli, (2016) [75] | × | × | × | × | ||||||||||

| Alves et al., (2016) [76] | × | × | ||||||||||||

| de J. Pacheco et al., (2016) [77] | × | × | × | × | ||||||||||

| Ghani et al., (2016) [78] | × | |||||||||||||

| C.-H. Lin et al., (2016) [79] | × | |||||||||||||

| Karaulova and Bashkite, (2016) [80] | × | |||||||||||||

| Su and Su, (2018) [81] | × | |||||||||||||

| Chan and Chin, (2020) [82] | × | × | × | × | × | |||||||||

| Indrawati et al., (2020) [83] | × | |||||||||||||

| Lepšík, (2020) [84] | × | × | ||||||||||||

| Purnomo and Lukman, (2020) [85] | × | |||||||||||||

| S. Yu and Wang, (2020) [86] | × | |||||||||||||

| Boangmanalu et al., (2020) [87] | × | |||||||||||||

| Gamboa and Singgih, (2021) [88] | × | |||||||||||||

| Araújo et al., (2021) [89] | × | |||||||||||||

| Study | Technical Contr. | Physical Contr. | Function Analysis | Trimming | TESE | Su-Field | RCA+ | Ideality | Standards | Sci. Effects | Resources | ARIZ | 9 Windows | Patent Search |

| Sucipto et al., (2021) [90] | × | |||||||||||||

| Sojka and Lepsik, (2021) [91] | × | × | × | × | × | × | × | |||||||

| C.-N. Wang et al., (2021) [92] | × | |||||||||||||

| C.-N. Wang, Tibo, et al., (2021) [93] | × | × | × | |||||||||||

| C.-N. Wang et al., (2021) [94] | × | |||||||||||||

| Kandukuri et al., (2021) [95] | × | |||||||||||||

| Sojka and Lepsik, (2022) [96] | × | × | × | × | × | × | × | |||||||

| Ng et al., (2022) [97] | × | |||||||||||||

| Purushothaman and Ahmad, (2022) [98] | × | |||||||||||||

| Sojka and Lepsik, (2023) [99] | × | × | × | × | × | × | × | |||||||

| Števko et al., (2023) [100] | × | |||||||||||||

| Soares and Navas, (2023) [101] | × | |||||||||||||

| Syu et al., (2023) [102] | × | |||||||||||||

| Reza et al., (2023) [103] | × | |||||||||||||

| Vanko et al., (2023) [104] | × | × | ||||||||||||

| Koay et al., (2023) [105] | × | |||||||||||||

| Phuah et al., (2023) [106] | × |

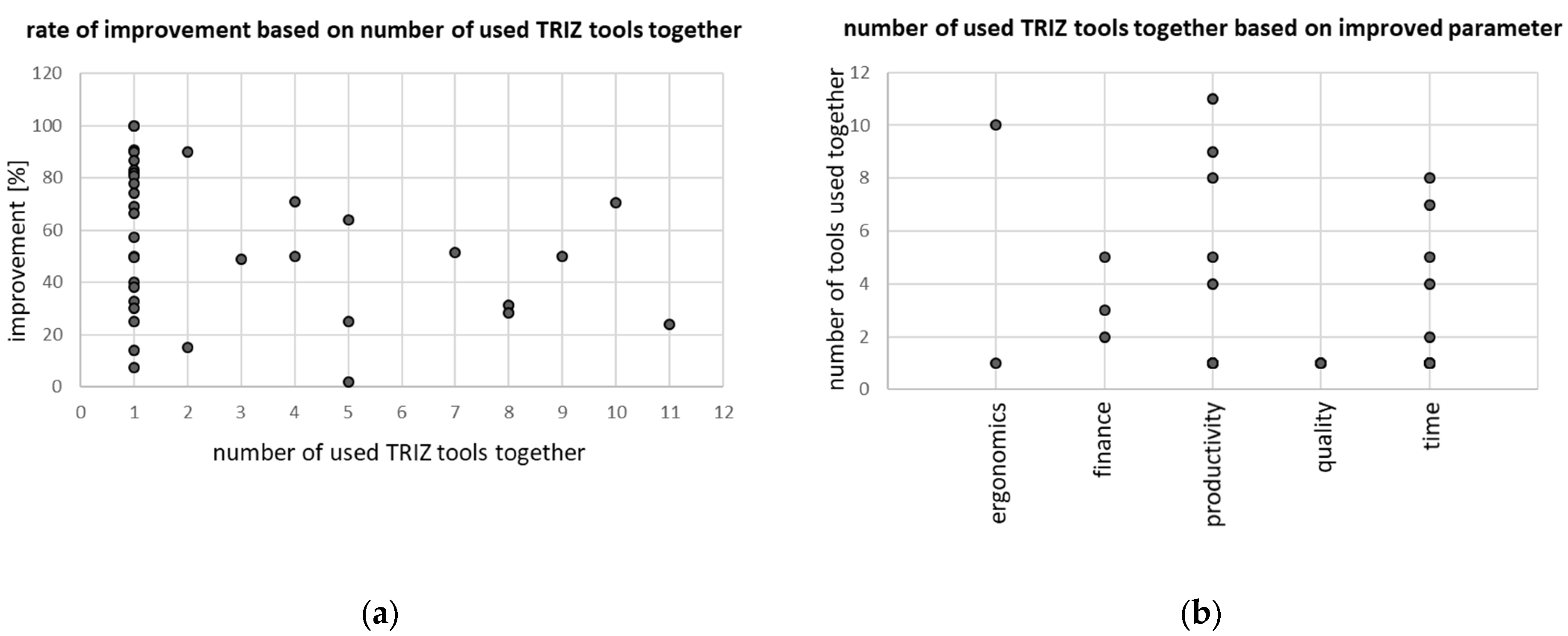

| Number of Samples | Mean | Median | Sample Standard Deviation (s) | Standard Deviation (σ) |

|---|---|---|---|---|

| 37 | 55.8451 | 51.4300 | 28.1554 | 27.7723 |

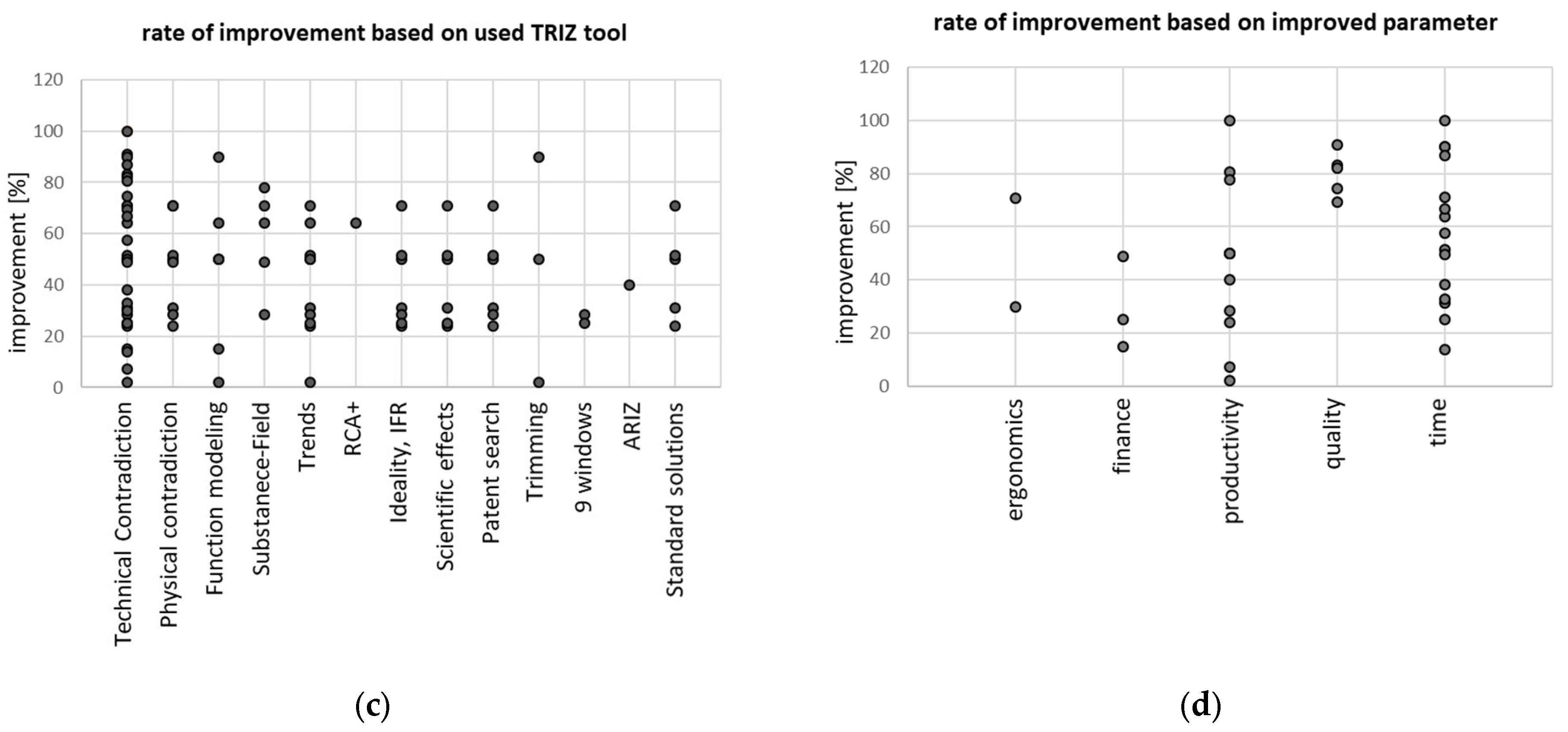

| TRIZ Tool | Number of Samples | Mean | Median | Sample Standard Deviation (s) | Standard Deviation (σ) |

|---|---|---|---|---|---|

| Technical Contradictions | 31 | 53.5439 | 51.4300 | 28.8015 | 28.3332 |

| Physical Contradictions | 8 | 46.9350 | 49.5000 | 18.1335 | 16.9623 |

| Function Modeling | 6 | 45.5816 | 50.0000 | 32.2020 | 29.3962 |

| Substance-Field | 5 | 67.0200 | 64.0000 | 19.7618 | 17.6755 |

| Trends | 10 | 39.6480 | 40.6050 | 21.0509 | 19.9707 |

| Ideality and IFR | 7 | 40.0686 | 31.2100 | 17.6516 | 16.3422 |

| Scientific Effects | 6 | 42.0333 | 40.6050 | 18.4789 | 16.8688 |

| Standard Solutions | 3 | 45.4400 | 50.0000 | 18.4335 | 16.4875 |

| Process Parameter | Number of Samples | Mean | Median | Sample Standard Deviation (s) | Standard Deviation (σ) |

|---|---|---|---|---|---|

| Ergonomics | 2 | 50.3300 | 50.3300 | 28.7510 | 20.3300 |

| Finance | 3 | 29.6667 | 25.0000 | 14.2673 | 17.4738 |

| Productivity | 11 | 46.3673 | 50.0000 | 30.7378 | 29.3073 |

| Quality | 5 | 79.9040 | 82.0000 | 8.3501 | 7.4686 |

| Time | 15 | 57.8707 | 57.5200 | 26.4559 | 25.5588 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sojka, V.; Lepsik, P. Tools of Theory of Inventive Problem Solving Used for Process Improvement—A Systematic Literature Review. Processes 2025, 13, 226. https://doi.org/10.3390/pr13010226

Sojka V, Lepsik P. Tools of Theory of Inventive Problem Solving Used for Process Improvement—A Systematic Literature Review. Processes. 2025; 13(1):226. https://doi.org/10.3390/pr13010226

Chicago/Turabian StyleSojka, Vladimir, and Petr Lepsik. 2025. "Tools of Theory of Inventive Problem Solving Used for Process Improvement—A Systematic Literature Review" Processes 13, no. 1: 226. https://doi.org/10.3390/pr13010226

APA StyleSojka, V., & Lepsik, P. (2025). Tools of Theory of Inventive Problem Solving Used for Process Improvement—A Systematic Literature Review. Processes, 13(1), 226. https://doi.org/10.3390/pr13010226