New Techniques of Meat Quality Assessment for Detecting Meat Texture

Abstract

:1. Introduction

2. The Relationship Between Rheological Properties and Meat Quality

2.1. The Impact of Rheological Properties on Processing and Sensory Characteristics

2.2. The Impact of Rheological Properties on Texture and Mouthfeel

3. The Research Progress of the Assessment of Rheological Properties in the Field of Meat Quality Detection

4. Integrated Application of Rheological Characterization and Emerging Technologies

4.1. Advantages and Disadvantages of Different Assessments of Rheological Properties

4.2. Possibilities and Effects of Combined Application of Multiple Technologies

4.2.1. Combination of Hyperspectral Imaging (HSI) and Computer Vision Techniques

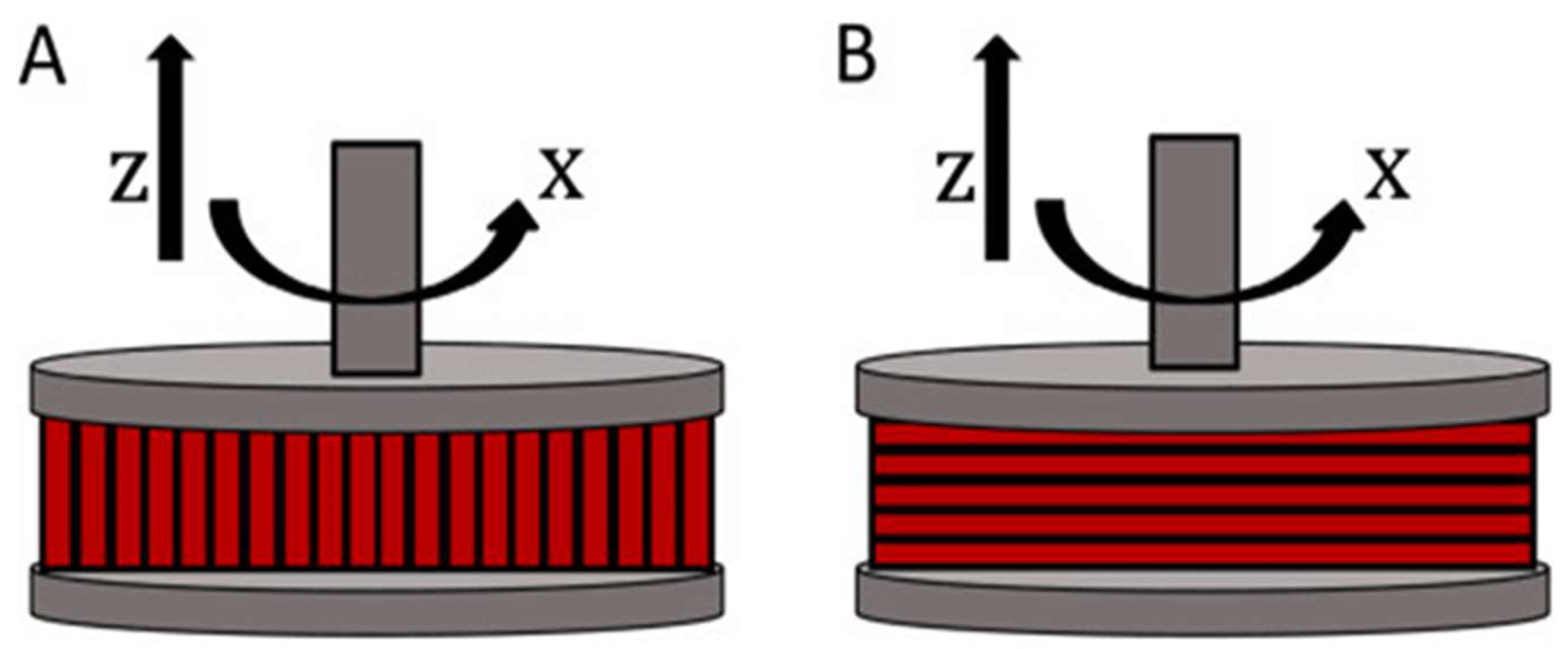

4.2.2. Airflow and Laser Fusion Detection Technology

4.2.3. Fusion of Airflow Pulse and 3D Structured Light Imaging

4.3. The Potential Applications of Emerging Technologies in the Detection of Rheological Properties of Meat

4.3.1. Nanotechnology

4.3.2. Biosensor Technology

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pathare, P.B.; Roskilly, A.P. Quality and Energy Evaluation in Meat Cooking. Food Res. Int. 2012, 45, 1449–1452. [Google Scholar] [CrossRef]

- Xu, Y.; Dong, H.; Zeng, X.; Li, Y.; Wang, H.; Zhang, X.; Liu, Y. Research progress on meat quality assessment methods. J. Food Saf. Qual. Test. 2017, 8, 1967–1972. [Google Scholar]

- Fadeyibi, A. Modeling Rheological Behavior of Beef based on Time-Dependent Deformation and Packaging. J. Rheol. 2021, 65, 547–563. [Google Scholar] [CrossRef]

- Liu, L.-Y.; Liu, Y.; Liu, D.-M.; Zhang, X.-Y.; Wang, Y.-J.; Chen, J.-H. Experimental study on the correlation between water-holding capacity and stress relaxation properties of fresh pork. J. Food Sci. Technol. 2014, 35, 123–130. [Google Scholar]

- Wang, H.X.; Lin, X.Y.; Zhu, J.C.; Yang, Y.X.; Qiao, S.H.; Jiao, B.; Ma, L.; Zhang, Y.H. Encapsulation of lutein in gelatin type A/B-chitosan systems via tunable chains and bonds from tweens: Thermal stability, rheologic property and food 2D/3D printability. Food Res. Int. 2023, 173, 113392. [Google Scholar] [CrossRef]

- Li, X.; Liu, X. Research on quality attribute evaluation method of meat and meat product. China Food Ind. 2021, 8, 18–19. [Google Scholar]

- Zhang, Y. Application of new nondestructive testing technology in meat quality inspection. Mod. Food 2023, 29, 104–106. [Google Scholar]

- Fan, B.; Qian, J.; Liu, S. Progress in the application of electronic sensory evaluation system in meat quality analysis. J. Food Saf. Qual. Test. 2014, 5, 2440–2447. [Google Scholar]

- Tura, M.; Gagliano, M.A.; Valli, E.; Petracci, M.; Toschi, T.G. A methodological review in sensory analyses of chicken meat: Sensory analyses of chicken meat: A review. Poult. Sci. 2024, 103, 104083. [Google Scholar] [CrossRef]

- Aaslyng, M.D.; Meinert, L.; Bejerholm, C.; Warner, R. Sensory assessment of meat. In Encyclopedia of Meat Sciences, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 267–278. [Google Scholar]

- Bourne, M.C. Food Texture and Viscosity: Concept and Measurement; Academic Press: Cambridge, MA, USA, 2002. [Google Scholar]

- Gallego, M.; Grau, R.; Toldrá, F. Use of texture analyzer to study the behavior of meat treated with proteolytic enzymes during vitro gastrointestinal digestion simulating elderly alterations. Meat Sci. 2018, 143, 67–73. [Google Scholar]

- Giménez-Ribes, J.; Oostendorp, M.; van der Goot, A.J.; van der Linden, E.; Habibi, M. Effect of fiber properties and orientation on the shear rheology and Poynting effect in meat and meat analogues. Food Hydrocoll. 2024, 149, 109509. [Google Scholar] [CrossRef]

- Szczesniak, A.S. Texture is a sensory property. Food Qual. Prefer. 2002, 13, 215–225. [Google Scholar] [CrossRef]

- Wang, S.; Das, A.K.; Pang, J.; Laing, P. Real-time monitoring the color changes of large yellow croaker (Larimichthys crocea) fillets based on hyperspectral imaging empowered with artificial intelligence. Food Chem. 2022, 382, 132343. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Wang, W.; Long, Y.; Peng, Y.; Li, Y.; Chao, K.; Tang, X. A feasibility study of rapid nondestructive detection of total volatile basic nitrogen (TVB-N) content in beef based on airflow and laser ranging technique. Meat Sci. 2018, 145, 367–374. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Zhao, Q.; He, K.; Li, Y.; Peng, Y.; Tang, X. Chicken tenderness assessment method based on controlled airflow-laser detection technology. J. Agric. Mach. 2020, 51 (Suppl. S2), 457–465. [Google Scholar]

- Lu, W.; Hu, Q.-Y.; Dai, D.-J.; Zhang, C.-Y.; Deng, Y. Beef tenderness detection method based on airflow pulse and structured light imaging. J. Agric. Mach. 2020, 12, 324–331. [Google Scholar]

- Ozimek, L.; Pospiech, E.; Narine, S. Nanotechnologies in food and meat processing. Acta Sci. Pol.-Technol. Aliment. 2021, 9, 401–412. [Google Scholar]

- Sionek, B.; Przybylski, W.; Tambor, K. Application of biosensors in the quality assessment of meat and meat products—A review. Ann. Anim. Sci. 2020, 20, 783–802. [Google Scholar] [CrossRef]

- Li, Y. Food Physical Properties; China Light Industry Press: Beijing, China, 2013. [Google Scholar]

- Purslow, P.P. The structure and functional significance of variations in the connective tissue within different muscles of mammals. J. Anim. Sci. 2005, 83, 544–552. [Google Scholar]

- Gao, R.-S.; Zhang, C.-X.; Zhao, H.-Y. Relationship between muscle histological characteristics and meat quality. Meat Res. 2009, 23, 11–15. [Google Scholar]

- Hu, J.-W.; Yu, F.-M.; Wang, Y.-J.; Cheng, Y.-M. Advances in the nutritional regulation of intramuscular fat and its relationship with meat quality. Shandong Agric. Sci. 2010, 42, 23–26. [Google Scholar]

- Khalid, M.; Maggiolino, J.; Waseem, A. Dynamic alterations in protein, sensory, chemical, and oxidative properties occurring in meat during thermal and non-thermal processing techniques: A comprehensive review. Front. Nutr. 2022, 9, 1057457. [Google Scholar] [CrossRef] [PubMed]

- Offer, G.; Knight, P. The structural basis of water-holding capacity in meat: The role of drip and its loss in conditioning. In Developments in Meat Science; Lawrie, R.A., Ed.; Elsevier: Amsterdam, The Netherlands, 1988; Volume 4, pp. 155–177. [Google Scholar]

- Bouton, P.E.; Harris, P.V. The role of connective tissue in determining the tenderness of meat. J. Texture Stud. 1972, 3, 40–52. [Google Scholar]

- Fu, Y.; Cao, S.; Yang, L.; Li, Z. Flavor formation based on lipid in meat and meat products: A review. J. Food Biochem. 2022, 46, e14439. [Google Scholar] [CrossRef] [PubMed]

- Xiong, Y.L. Protein interactions and their effects on thermal and pH-induced gelation of myofibrillar proteins. J. Food Sci. 2004, 69, C615–C622. [Google Scholar]

- Zhou, Q.; Zhang, J.; Wang, B.; Wang, W.; Liu, Y.; Zhong, Z. Research progress on the flavor formation mechanism of meat products and the effect of processing methods on flavor. Process. Storage Agric. Prod. 2024, 43, 74–84. [Google Scholar]

- López-Pedrouso, A.; Lorenzo, J.M.; Gagaoua, M.; Franco, D. Insights on meat quality from combining traditional studies and proteomics. Meat Sci. 2020, 170, 108207. [Google Scholar]

- Tornberg, E. Effects of heat on meat proteins—Implications on structure and quality of meat products. Meat Sci. 2005, 70, 493–508. [Google Scholar] [CrossRef] [PubMed]

- Funami, T.; Yada, H.; Nakao, Y. Thermal and rheological properties of curdlan gel in minced pork gel. Food Hydrocoll. 1998, 54, 1378–1385. [Google Scholar] [CrossRef]

- Kang, X.-L.; Li, Y.-L.; Dong, J.; Wang, W.-J.; Peng, Y.-K.; Tang, X.-Y. Research progress on viscoelasticity detection of edible meat. J. Food Saf. Qual. 2016, 7, 3265–3269. [Google Scholar]

- Shao, C.-F. Development of study on sensory evaluation in food. Meat Ind. 2006, 6, 35–37. [Google Scholar]

- Hansen, T.; Petersen, M.A.; Byrne, D.V. Sensory based quality control utilising an electronic nose and GC-MS analyses to predict end-product quality from raw materials. Meat Sci. 2005, 69, 621–634. [Google Scholar] [CrossRef] [PubMed]

- Tong, Y.; Chen, D.; Shi, Z.; Tong, J. Relationship between pressure characteristic curve and freshness of chicken. J. Jilin Univ. (Eng. Technol. Ed.) 2010, 40, 492–495. [Google Scholar]

- Civille, M.V.; Carr, B.T. Sensory Evaluation Techniques; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Lawless, H.T.; Heymann, H. Sensory Evaluation of Food: Principles and Practices; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Gunasekaran, S.; Ak, M.M. Dynamic oscillatory shear testing of foods—Selected applications. Trends Food Sci. Technol. 2000, 11, 115–127. [Google Scholar] [CrossRef]

- Culioli, J. Meat tenderness: Mechanical assessment. In Expression of Tissue Proteinases and Regulation of Protein Degradation as Related to Meat Quality; ECCEAMST: Utrecht, The Netherlands, 1995. [Google Scholar]

- Rosenau, J.; Mauer, L.J. Food Texture, Viscosity and Pigments; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Huidobro, F.R.D.; Miguel, E.; Blazquez, B.; Onega, E. A comparison between two methods (warner-bratzler and texture profile analysis) for testing either raw meat or cooked meat. Meat Sci. 2005, 69, 527–536. [Google Scholar] [CrossRef] [PubMed]

- Zhu, D.S.; Li, H.; Cao, X.H.; Liu, H.; Li, J.R.; Meng, X.J. Research Progress in Quality Evaluation of Fresh Foods by Texture Analyze. Food Sci. 2014, 35, 6. [Google Scholar]

- Wu, D.; Liping, K.; Jing, Z.; Sheguo, S. Quantitative evaluation of meat tenderness by penetration method of texture analyzer. Trans. Chin. Soc. Agric. Eng. 2005, 21, 138–141. [Google Scholar]

- Lin, F.; Jiang, Z.; Liao, S.; You, J.; Li, C. The summary of texture analyzer and its application in the evaluation for food quality. Life Sci. Instrum. 2009, 7, 61–63. [Google Scholar]

- Wang, X.-D.; Liu, A.-Y.; Sun, Y.-H.; Wang, Y.; Han, Y.-X.; Wang, H.-M. Beef tenderness evaluation method based on self-organizing neural network model and textural properties. Trans. Chin. Soc. Agric. Eng. 2015, 31, 262–268. [Google Scholar]

- Jiang, Y.J.; Zhou, Y. The study of meat elasticity measurement method. Food Sci. 2002, 23, 99–101. [Google Scholar]

- Dong, X.; Song, L.-Y.; Quan, L.-Z.; Li, Z.-H. Research on classification algorithm of pork breeds based on rheological properties of meat. J. Northeast Agric. Univ. 2013, 44, 107–110. [Google Scholar]

- Li, X. Correlation analysis between sensory evaluation and mechanical measurement of blood tofu texture. Food Res. Dev. 2016, 37, 5. [Google Scholar]

- Han, B.-Z.; Tong, H.-R.; Du, S.-K. Sensory Evaluation of Foods; China Forestry Press: Beijing, China, 2016. [Google Scholar]

- Capozzi, B.; Atkins, S. Relationship between mood change, odor and its psychophysiological responses in humans in terms of the sensory evaluation spectrum. In Proceedings of the 18th AIAA Aviation Technology, Integration, and Operations Conference (ATIO), Atlanta, GA, USA, 25–29 June 2018; American Institute of Aeronautics and Astronautics (AIAA) AIAA 2013-3035: Reston, VA, USA, 2018. [Google Scholar]

- AMSA. Guidelines for Meat Color Measurement. In Proceedings of the 44th Proceedings of the Reciprocal Meat Conference, Manhattan, KS, USA, 9–12 June 1991; American Meat Science Association: Savoy, IL, USA, 1991. [Google Scholar]

- Xu, B.-C.; Sun, J.-Q.; Han, Y.-Q.; Zhou, H.; Li, J.-J.; Wang, X.-X. The effect of mechanical pre-processing of raw meat on the quality of sliced ham. Trans. Chin. Soc. Agric. Eng. 2012, 28, 250–255. [Google Scholar]

- Fan, Y.-X. Experimental Study on Rapid Detection Methods for Pork Meatball Quality and Safety Using Visible/Near-Infrared Spectroscopy. Ph.D. Dissertation, Zhejiang University, Hangzhou, China, 2011. [Google Scholar]

- Hu, Y.-Y. Application status of texture analyzer in food research. Food Res. Dev. 2013, 34, 101–104. [Google Scholar]

- Bourne, M.C. Texture analysis. Food Technol. 1978, 32, 61–65. [Google Scholar]

- You, Y.; Peng, X.-B.; Yang, Y.-L.; Chen, X. Study on static rheological properties of chicken myofibrillar protein. J. Food Ind. Technol. 2013, 34, 4. [Google Scholar]

- Wan, G.; Liu, G.; He, J.; Luo, R. Feature wavelength selection and model development for rapid determination of myoglobin content in nitrite-cured mutton using hyperspectral imaging. J. Food Eng. 2020, 287, 110090. [Google Scholar] [CrossRef]

- Myhan, R.; Markowski, M.; Daszkiewicz, T.; Zapotoczny, P.; Sadowski, P. Non-linear stress relaxation model as a tool for evaluating the viscoelastic properties of meat products. J. Food Eng. 2015, 146, 107–115. [Google Scholar] [CrossRef]

- Tang, X.-Y.; Li, Y.-L.; Xu, Y.; Dong, X.-G.; Shen, Z.-X. A Method for Data Acquisition of Viscoelasticity Detection in Meat Based on Airflow and Laser Technology. Chinese Patent CN201810636026.3; Publication No. CN108801795A, 13 November 2018. [Google Scholar]

- He, K.; Luo, X.; Sun, Q.; Tang, X. Development of beef freshness detection device based on airflow and multipoint laser technology. J. Agric. Eng. 2021, 37, 278–286. [Google Scholar]

- Ding, Q.; Wang, Z.-Y.; Huang, L.; Wang, C.; Hou, R.-F.; Xu, Z.-L. Application of bioimpedance technology in meat quality detection. Transducer Microsyst. Technol. 2009, 28, 4–7. [Google Scholar]

- Zhang, L.Y.; Yu, Q.; Zhang, M.; Law, C.L.; Ma, Y.M. Intelligent detection of quality deterioration and adulteration of fresh meat products in the supply chain: Research progress and application. Food Biosci. 2023, 55, 103047. [Google Scholar] [CrossRef]

- Ramachandraiah, K.; Han, S.G.; Chin, K.B. Nanotechnology in Meat Processing and Packaging: Potential Applications—A Review. Asian-Australas J. Anim. Sci. 2015, 28, 290. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Liang, Y.; Li, X.; Kang, H. Effect of chitosangelatin coating containing nano-encapsulated tarragon essential oil on the preservation of pork slices. Meat Sci. 2020, 166, 108137. [Google Scholar] [CrossRef]

- Taheri-Garavand, A.; Fatahi, S.; Banan, A.; Makino, Y. Real-time nondestructive monitoring of common carp fish freshness using robust vision-based intelligent modeling approaches. Comput. Electron. Agric. 2019, 159, 16–27. [Google Scholar] [CrossRef]

- Wang, B.; Yang, H.; Yang, C.; Lu, F.; Wang, X.; Liu, D. Prediction of total volatile basic nitrogen (TVB-N) and 2-thiobarbituric acid (TBA) of smoked chicken thighs using computer vision during storage at 4 °C. Comput. Electron. Agric. 2022, 199, 107170. [Google Scholar] [CrossRef]

- Wang, H.-H.; Sheng, J.-S.; Liu, S.-L.; Shao, L.-T.; Sun, S.-Y.; Xu, X.-L. Construction and Application of a Colorimetric Biosensor for Meat Freshness Based on CRISPR/Cas12a. Chinese Patent CN202410369040.7, 6 September 2024. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Li, Y.; Sun, W.; Ma, F.; Wang, X.; Yang, Z. New Techniques of Meat Quality Assessment for Detecting Meat Texture. Processes 2025, 13, 640. https://doi.org/10.3390/pr13030640

Liu C, Li Y, Sun W, Ma F, Wang X, Yang Z. New Techniques of Meat Quality Assessment for Detecting Meat Texture. Processes. 2025; 13(3):640. https://doi.org/10.3390/pr13030640

Chicago/Turabian StyleLiu, Chang, Yanlei Li, Wenming Sun, Feiyu Ma, Xiangwu Wang, and Zihao Yang. 2025. "New Techniques of Meat Quality Assessment for Detecting Meat Texture" Processes 13, no. 3: 640. https://doi.org/10.3390/pr13030640

APA StyleLiu, C., Li, Y., Sun, W., Ma, F., Wang, X., & Yang, Z. (2025). New Techniques of Meat Quality Assessment for Detecting Meat Texture. Processes, 13(3), 640. https://doi.org/10.3390/pr13030640