Abstract

CO2-enhanced gas recovery (EGR) has emerged as a promising method for improving hydrocarbon production and achieving carbon sequestration in offshore gas reservoirs. This study investigates the performance and influencing factors of CO2-based gas displacement using long core displacement experiments. Consolidated synthetic cores were prepared to replicate reservoir conditions, and experiments were conducted at formation pressure and temperature to evaluate the effects of permeability, injection pressure, CO2 concentration, and core length on gas recovery efficiency. The results reveal that (1) for a homogeneous porous medium, permeability and injection pressure have minimal correlation with recovery efficiency when sufficient gas is injected; (2) direct gas displacement after reservoir depletion outperforms pressure-boosting displacement methods; (3) higher CO2 concentrations delay gas breakthrough, enhance piston-like displacement behavior, and improve recovery efficiency; and (4) core length significantly affects recovery, with longer cores resulting in slower breakthroughs and more stable displacement. Cores of at least 1 m in length are essential for accurately simulating field conditions. For a CO2 injection with a pressure of 7 MPa and a temperature of 81 °C, when 0.87 PV of CO2 is injected, the current recovery can reach 87%, after which the displacement efficiency decreases sharply. The ultimate EGR can be as high as 50%. These findings provide valuable insights into optimizing CO2 injection strategies for enhanced gas recovery in offshore reservoirs, offering guidance for both experimental designs and practical applications in the field.

1. Introduction

CO2-enhanced gas recovery (CO2-EGR) is an innovative and promising technology with significant potential to enhance hydrocarbon recovery while simultaneously mitigating greenhouse gas emissions. By injecting CO2 into depleted or partially depleted gas reservoirs, this process displaces the remaining natural gas, improving recovery efficiency while also enabling long-term geological storage of CO2 [1,2,3,4,5,6]. This dual-purpose approach aligns with the urgent global need to address climate change and transition toward a low-carbon future. As the energy industry seeks sustainable solutions, CO2-EGR has garnered increasing attention as a key strategy to support carbon neutrality and enhance energy security [7,8,9,10].

The growing interest in CO2-EGR is driven by several key factors, particularly the increasing global focus on carbon management. Climate change is one of the most pressing challenges facing the world today, with rising concerns about greenhouse gas emissions intensifying the demand for effective mitigation technologies. CO2 capture, utilization, and storage (CCUS) technologies, including CO2-EGR, have been identified as essential components of global climate action plans [1,7,11,12]. By incorporating CO2 storage within productive gas reservoirs, CO2-EGR helps reduce atmospheric emissions while contributing to sustainable energy production [1,8,13].

Another advantage of CO2 injection lies in its dual functionality. In addition to enhancing gas recovery by displacing residual natural gas trapped within the reservoir’s porous rock, it also serves as a method of long-term CO2 sequestration. This synergy between enhanced resource utilization and climate action underscores the strategic importance of CO2-EGR, making it an attractive option for energy producers seeking both economic returns and environmental sustainability [2,5,13,14]. The process also offers economic advantages by offsetting the costs of CCUS operations through increased gas production, creating a dual revenue stream for energy companies and governments aiming to balance economic growth with carbon reduction commitments [2,13].

Offshore gas reservoirs are increasingly recognized as promising targets for CO2-EGR due to their strategic importance in the global energy landscape [15,16]. However, these reservoirs also present unique operational challenges that require tailored approaches for successful CO2 injection. Declining pressure in mature reservoirs is a significant obstacle to efficient gas production, as reduced reservoir energy limits gas mobilization [2,15]. CO2 injection can help restore reservoir pressure, mobilizing trapped natural gas and extending the productive lifespan of offshore gas fields. Additionally, water influx in offshore reservoirs can pose a serious challenge during late-stage gas production, as encroaching water reduces gas deliverability and raises operational costs [15]. CO2 injections can create a barrier to prevent water from entering the gas zone, maintaining reservoir integrity and preserving gas production efficiency.

Despite these advantages, several challenges must be addressed to optimize the performance of CO2-EGR in offshore reservoirs. One critical challenge involves managing the dispersion of injected CO2 with resident methane (CH4) [15]. Effective control of dispersion dynamics is essential to maximize gas recovery while ensuring efficient CO2 sequestration. If CO2 mixes too extensively with CH4, recovery efficiency declines, reducing both economic and environmental benefits. Similarly, gas composition and reservoir permeability significantly influence the displacement process. The physical characteristics of the reservoir rock, along with the concentration of CO2 in the injected gas, play key roles in determining how efficiently gas is displaced and stored [17,18]. Understanding these complex interactions is crucial for optimizing injection strategies and achieving successful CO2-EGR implementation.

While much research has been conducted on the potential of CO2-EGR, further investigation is required to develop practical solutions for managing gas dispersion and optimizing recovery in offshore environments. The present study addresses these gaps by conducting laboratory experiments under simulated conditions of Dongfang gas reservoir, which is a typical offshore gas reservoir in China. This research focuses on understanding the impact of key parameters such as injection pressure, gas composition, core length, and permeability on recovery efficiency and displacement stability. By exploring these interactions, the study aims to provide insights into effective injection strategies and contribute to the development of sustainable and economically viable solutions for enhanced gas recovery in offshore reservoirs. These insights will not only advance scientific understanding of CO2-EGR processes but also support global efforts to reduce carbon emissions and promote energy security in a low-carbon future.

2. Experimental Methodology

2.1. Experimental Cores and Fluids

The experimental core samples were consolidated synthetic cores designed to simulate the reservoir properties of the DF1-1 gas field. These cores were prepared using a mixture of rock fragments sieved through screens of varying mesh sizes to achieve a uniform distribution of particle sizes. The sieved fragments were combined in specific proportions, compacted into core molds, and subjected to multiple cycles of compression to create a bonded core model. This process ensured consistency in the core’s physical properties and mimicked the natural reservoir rock.

Key parameters of the core samples are presented in Table 1. These include core length, diameter, permeability, and porosity. The experimental cores varied in length to investigate the influence of core dimensions on gas recovery efficiency, with lengths of 31.97 cm, 95.37 cm, and 276.32 cm. The permeability of the cores ranged from 24.64 mD to 30.02 mD, while porosity values ranged from 9.71% to 12.26%. The permeability was measured under the original reservoir conditions of 14 MPa pressure and 81 °C temperature, using methane as the test gas.

Table 1.

Parameters of the core samples.

The fluids used in the experiments comprised simulated formation water and natural gas to replicate the in-situ conditions of the reservoir. The formation water was synthesized to match the ionic composition of the reservoir brine, as shown in Table 2. It included major ions such as Na+, K+, Ca2+, Mg2+, Cl−, HCO3−, and SO42−, with a total salinity of 32,760 mg/L. The formation gas composition is detailed in Table 3, consisting predominantly of methane (CH4), nitrogen (N2), and a small fraction of CO2.

Table 2.

Ionic composition of simulated formation water.

Table 3.

Composition of formation gas.

Injection gases with varying CO2 concentrations were prepared to study their effects on recovery efficiency. These compositions are provided in Table 4, with CO2 concentrations ranging from 50% to 100%, and corresponding CH4 concentrations adjusted accordingly. The gas mixtures were prepared at reservoir pressure (7 MPa) and temperature (81 °C) to ensure consistency with field conditions.

Table 4.

Composition of injection gas.

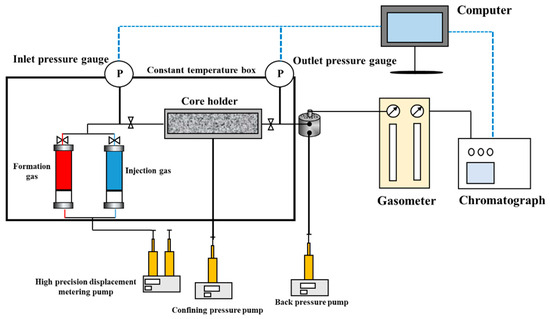

2.2. Experimental Procedures

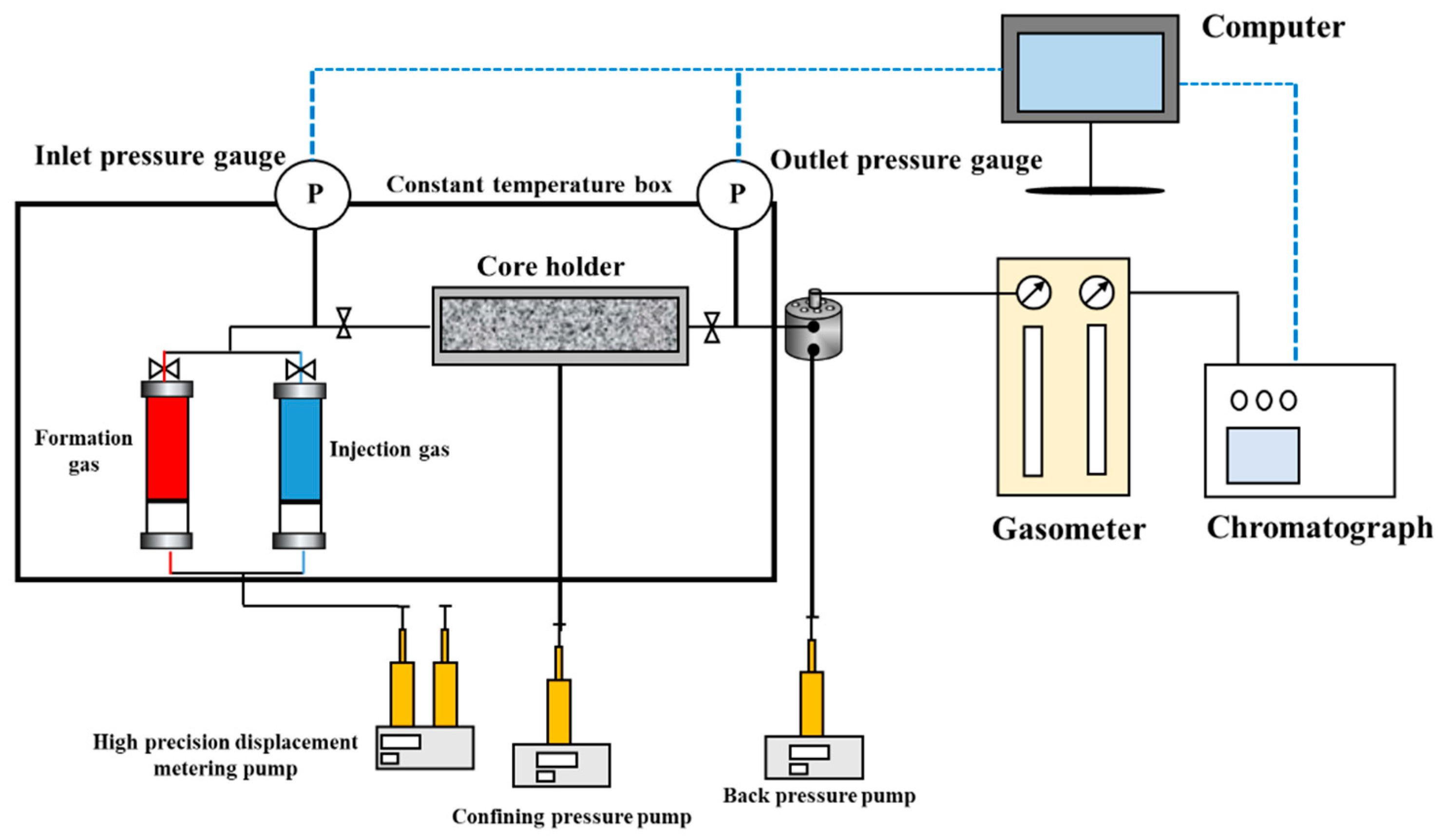

The experiment was conducted using a setup designed to replicate in-situ reservoir conditions, ensuring precise control over key parameters such as pressure, temperature, and fluid flow. The injection equipment comprises a high-precision displacement pump (P11-03-03, self-develop, Chengdu, China) with a pressure accuracy of 0.5%; a multifunctional long core displacement device (NSPTHX-1203 self-develop, Chengdu, China) with a pressure accuracy of ±1 psi and a temperature accuracy of ±0.1 °C; a gas meter (NSPTQLY self-develop, Chengdu, China) for collecting the produced gas at the outlet end, with a volumetric error of 5%; and a gas chromatograph (7890B, Agilent Technologies, Chengdu, China) for analyzing the components of the collected gas. The core holder, equipped with heating and pressure control systems, maintained the reservoir pressure (14 MPa) and temperature (81 °C) throughout the experiments. A schematic diagram of the experimental apparatus, detailing the flow pathways and instrumentation, is shown in Figure 1.

Figure 1.

Experiment apparatus.

The cores were oven-dried at 105 °C for 24 h to remove residual moisture, followed by vacuuming for an additional 24 h to eliminate trapped air. Each core was placed in the core holder, and an initial confining pressure of 3 MPa was applied to secure it. Simulated formation water, replicating the ionic composition of reservoir brine, was injected using the displacement pump. The injection was performed gradually, while increasing the confining pressure and backpressure to ensure complete saturation. The water saturation is 53%, controlled by injecting a specified volume of water. Once the core pressure reached 14 MPa and water uptake ceased, saturation was confirmed.

The pressure depletion phase simulated natural reservoir production. A backpressure regulator was used to incrementally reduce the pressure by 0.5 MPa at a time, while monitoring gas production. This process continued until the pressure reached either 7 MPa or 5 MPa. Produced gas volumes were measured, and periodic samples were analyzed using the gas chromatograph to determine the CH4 and CO2 content.

Following depletion, CO2-rich gas mixtures were injected into the core to study the displacement dynamics and recovery efficiency. The injection gases, with CO2 concentrations ranging from 50% to 100%, were introduced at a constant pressure of 7 MPa and a flow rate of 0.5 mL/min. Produced gas was collected and analyzed at regular intervals to monitor the breakthrough behavior and displacement efficiency. Injection continued until the outlet gas composition stabilized, indicating full displacement of the original reservoir gas.

All experiments were conducted at a constant temperature of 81 °C, replicating the thermal conditions of the reservoir. The confining pressure and injection parameters were carefully controlled to simulate realistic field scenarios. Data from the experiment provided insights into the effects of CO2 concentration, core length, and injection modes on gas recovery and displacement efficiency.

2.3. Data Analysis and Recovery Efficiency Determination

The recovery efficiency (R) of methane (CH4) from the formation gas was determined using a material balance approach based on the following equations.

Here, a represents molar fraction of CO2 in the formation gas; b denotes molar fraction of CO2 in the injected gas; A signifies molar fraction of CO2 in the produced gas; x denotes moles of formation gas in the produced gas; y represents moles of injected gas in the produced gas; V represents total volume of produced gas (L); and 22.4 represents the molar volume of gas (L/mol) under experimental conditions.

These equations account for the contributions of both formation gas and injected gas in the produced stream. Solving these equations simultaneously yields the individual molar contributions of formation gas (x) and injected gas (y).

The volume of CH4 recovered from the formation gas is determined by multiplying x by the CH4 molar fraction in the formation gas. Finally, the recovery efficiency of CH4 is expressed as follows.

where V1 is the CH4 volume produced in the gas reservoir; V2 is the initial volume of CH4 in the reservoir.

The breakthrough behavior of injected gas was analyzed by monitoring the CO2 concentration (A) in the produced gas over time. Gas chromatography was used to measure the molar fractions of CO2, CH4, and other components. The following parameters were evaluated:

- Breakthrough time: Defined as the time or injected pore volume (PV) at which CO2 was first detected in the produced gas. This indicates the arrival of the displacement front.

- Breakthrough concentration: The molar fraction of CO2 in the produced gas at the breakthrough point, reflecting the sharpness of the displacement front.

- Transition zone: The rate at which CO2 concentration increases after breakthrough, which is indicative of the efficiency and stability of the displacement process.

The analysis also considered the influence of CO2 concentration, injection pressure, and core length on displacement efficiency. A sharp increase in CO2 concentration following breakthrough suggests efficient piston-like displacement, while a gradual increase indicates significant diffusion and mixing. These metrics were used to evaluate the impact of experimental parameters on gas recovery performance.

3. Results and Discussion

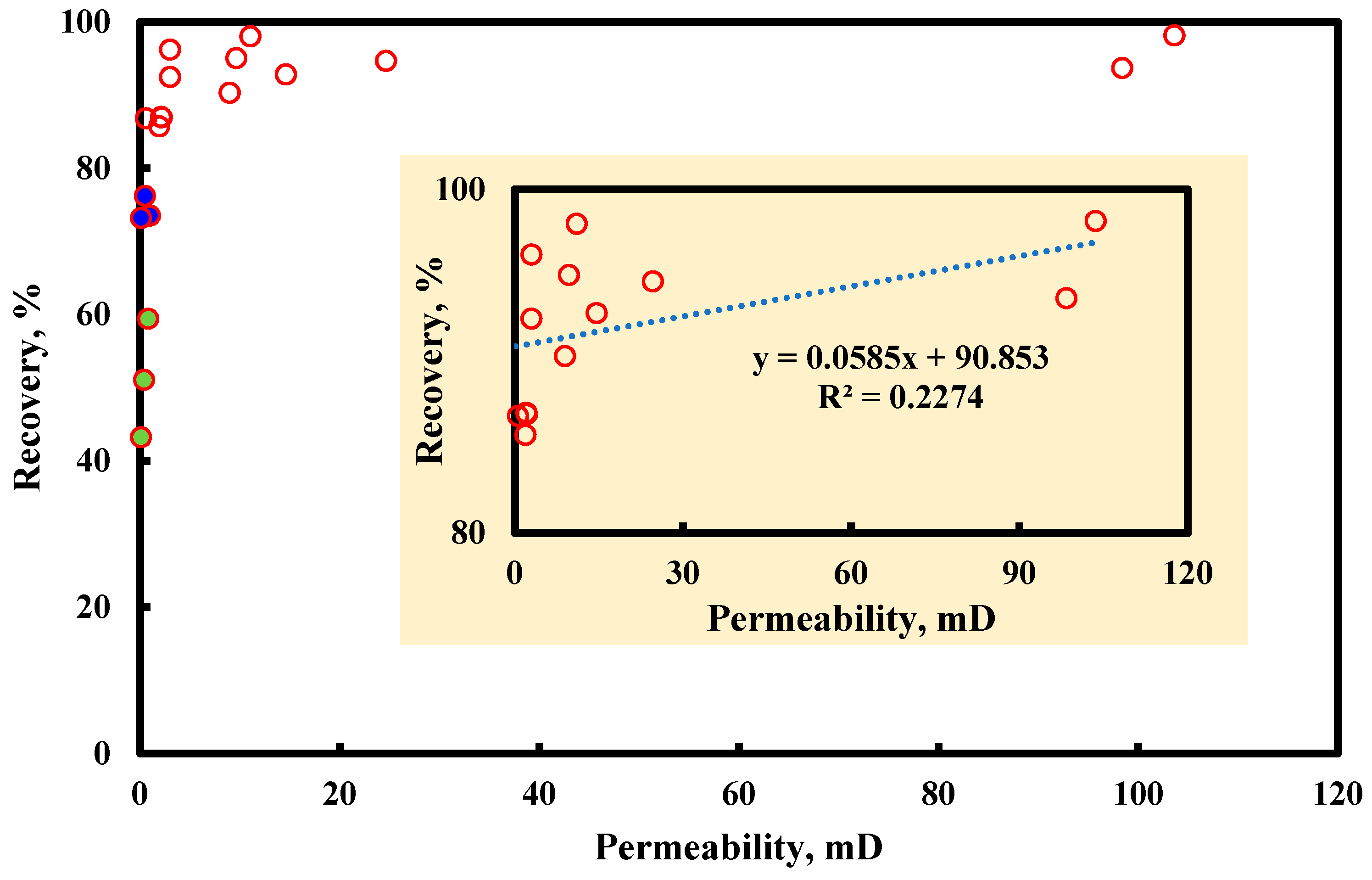

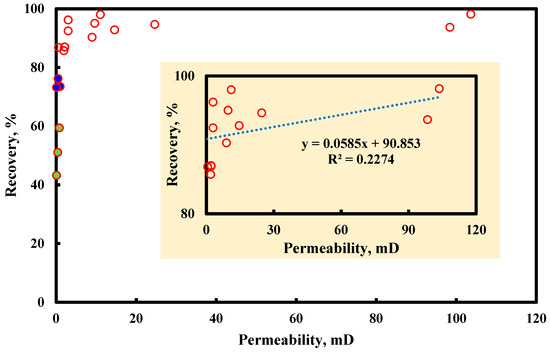

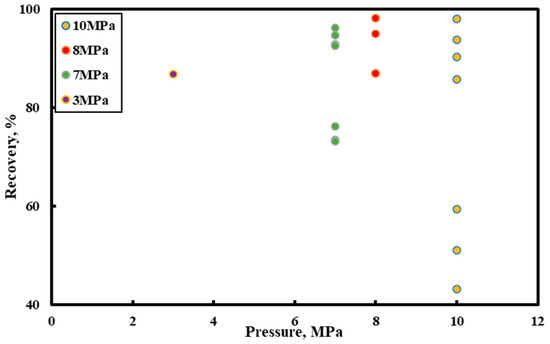

3.1. Impact of Permeability and Injection Pressure on Gas Recovery Efficiency

The relationship between reservoir permeability, injection pressure, and gas recovery efficiency was analyzed to understand the factors affecting CO2-enhanced gas recovery. The experimental results indicated that under conditions of sufficient CO2 injection, the permeability of the reservoir rock did not exhibit a significant correlation with the ultimate recovery efficiency. As shown in Table 5 and Figure 2, the recovery efficiencies remained consistent across permeability values ranging from 0.1 mD to 100 mD. The linear regression analysis yielded a low R2 value of 0.2274, suggesting that the impact of permeability on recovery efficiency is minimal under these conditions.

Table 5.

Summary of CO2 injection experiments in gas reservoirs.

Figure 2.

Effect of permeability on gas recovery efficiency for long-core CO2 injection experiments.

The weak dependence between permeability and recovery efficiency may be attributed to the high mobility of the injected CO2, which allows it to effectively displace the resident gas regardless of the reservoir rock’s permeability. This observation is consistent with findings from previous studies, which suggest that CO2’s high diffusivity and miscibility with methane (CH4) mitigate the influence of reservoir heterogeneity on displacement performance. However, extreme permeability variations, such as those found in fractured reservoirs or ultra-low-permeability formations, may introduce complexities not addressed in this study.

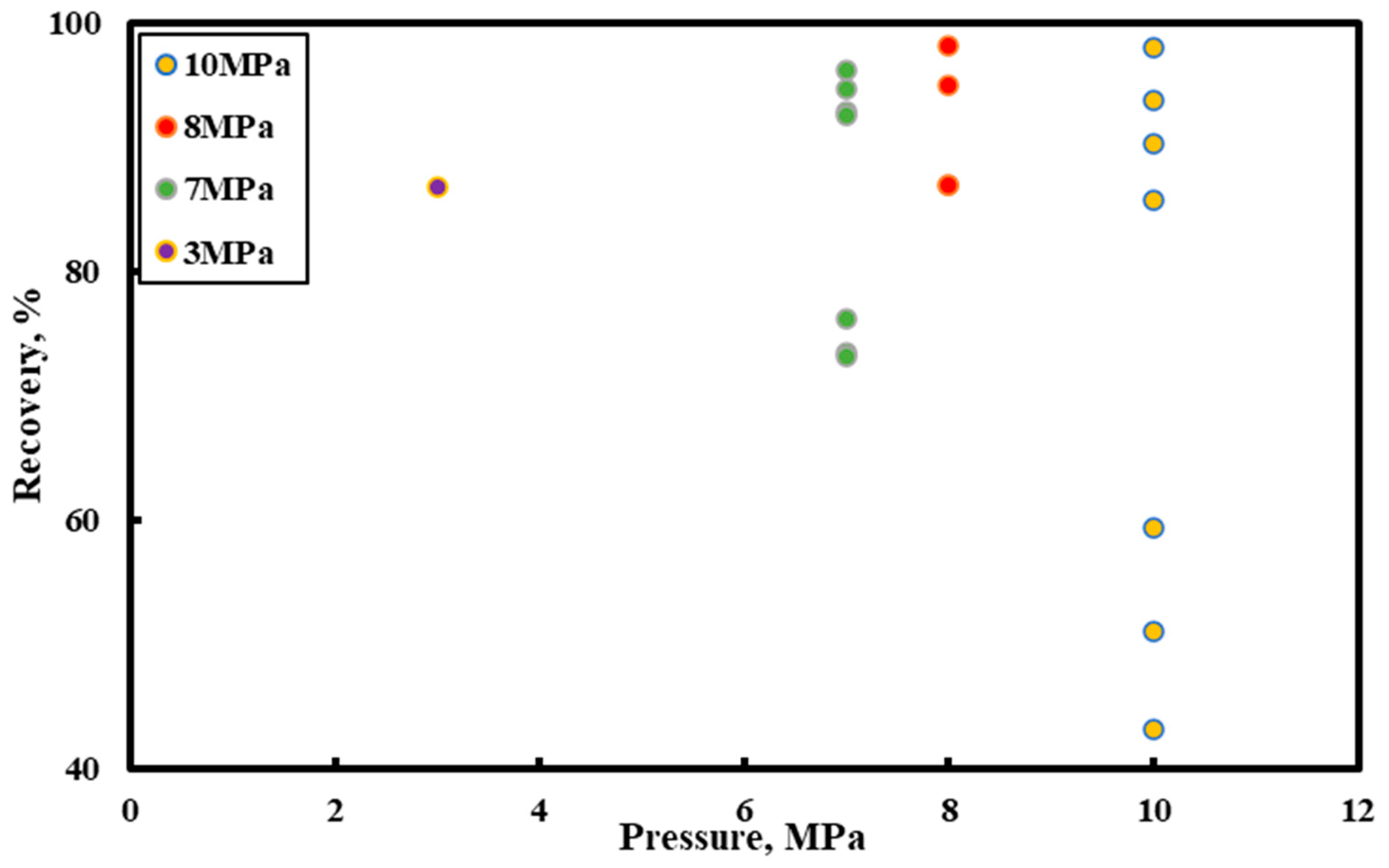

Injection pressure was also found to have limited influence on ultimate recovery efficiency, as shown in Figure 3. Recovery efficiencies were similar across injection pressures ranging from 7 MPa to 14 MPa, demonstrating that the magnitude of injection pressure is not a critical determinant of the final recovery performance. However, the dynamics of the displacement process were affected by injection pressure. Higher injection pressures resulted in delayed CO2 breakthrough and more uniform displacement fronts, which is likely due to reduced diffusion and dispersion effects. The higher pressures enhanced the piston-like displacement characteristics of CO2, reducing the mixing zone between CO2 and CH4 and improving the overall stability of the displacement process.

Figure 3.

Analysis of injection pressure impact on recovery efficiency.

These findings suggest that ultimate recovery efficiency is primarily influenced by the availability and distribution of the injected gas rather than the permeability of the reservoir or the magnitude of injection pressure. The ability of CO2 to achieve effective displacement at moderate pressures and across varying permeability ranges highlights its versatility as a gas recovery agent. For practical applications, this implies that operators can optimize CO2 injection strategies to balance operational efficiency and cost without compromising recovery performance.

The results of this study were compared with data from the literature to contextualize the findings and validate the experimental observations [13,21]. As summarized in Table 5, the recovery efficiencies achieved in this study are consistent with those reported for similar reservoirs, particularly for permeability ranges between 0.5 mD and 100 mD. The majority of studies show recovery efficiencies exceeding 85%, further supporting the conclusion that permeability and injection pressure are secondary factors when sufficient CO2 injection is achieved.

Outliers in the literature, such as recovery efficiencies below 60%, were associated with incomplete depletion stages or excessive residual water saturation [13,21]. For example, studies where the depletion phase was prematurely terminated often resulted in lower recovery efficiencies due to the presence of unrecovered gas in poorly connected pore spaces. Similarly, residual water saturation can impede the flow of both CO2 and CH4, reducing the efficiency of the displacement process. These observations highlight the importance of ensuring adequate reservoir preparation prior to CO2 injection to maximize recovery potential.

While ultimate recovery efficiency was largely unaffected by injection pressure, the findings underscore the importance of pressure management during the injection process. Higher injection pressures were found to enhance the stability of the displacement front by reducing the impact of diffusion and dispersion effects. This improvement in displacement stability is critical during the initial phases of injection, where breakthrough behavior has a significant impact on the efficient utilization of the injected CO2.

Moreover, higher injection pressures may also facilitate better control over water influx in offshore reservoirs. By creating a pressure gradient that opposes water encroachment, CO2 injection at elevated pressures can help maintain reservoir integrity and prolong the productive life of the field. However, excessive injection pressures may lead to operational challenges, including increased risk of caprock failure or the formation of preferential flow pathways, which could compromise CO2 storage integrity.

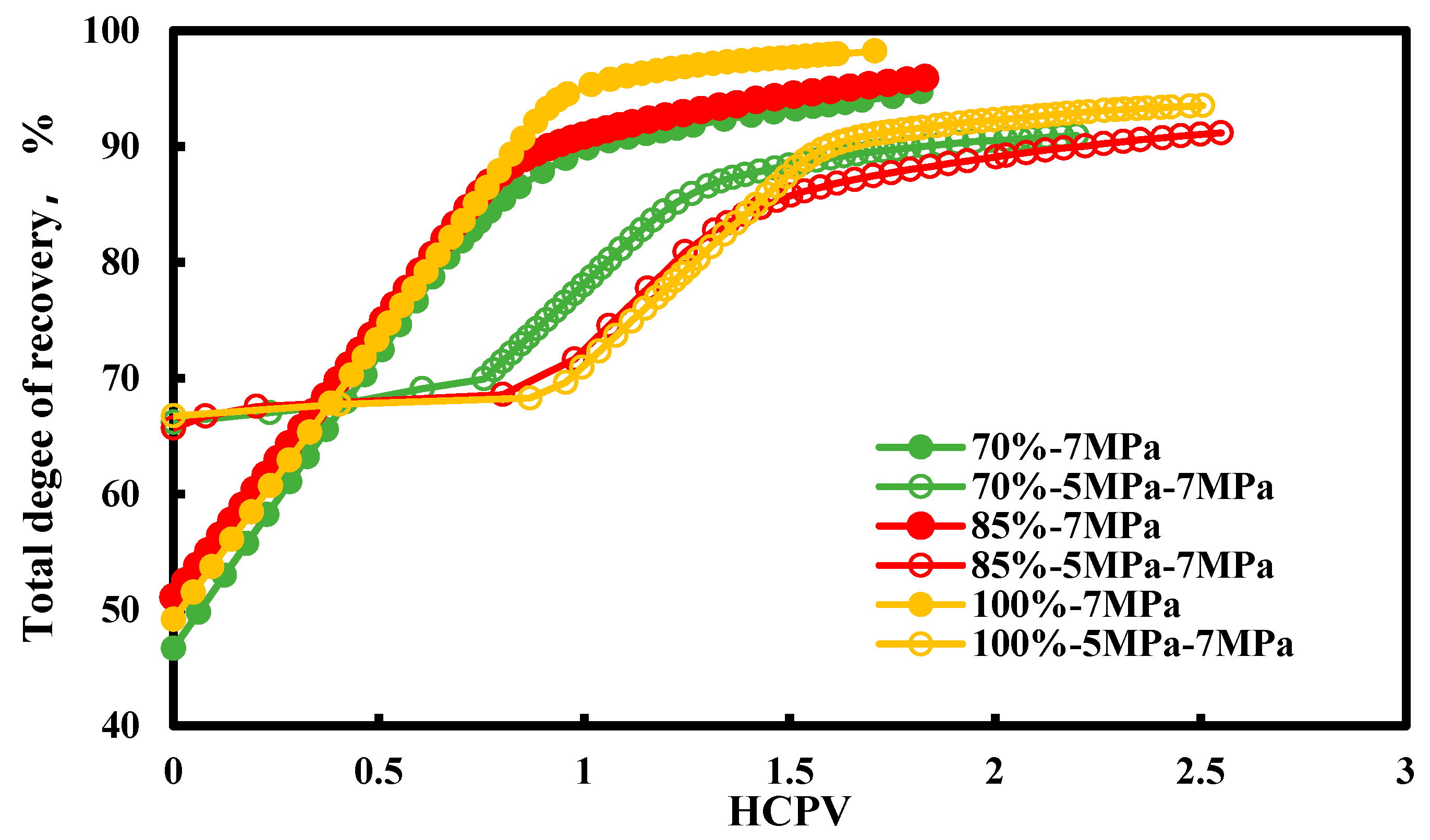

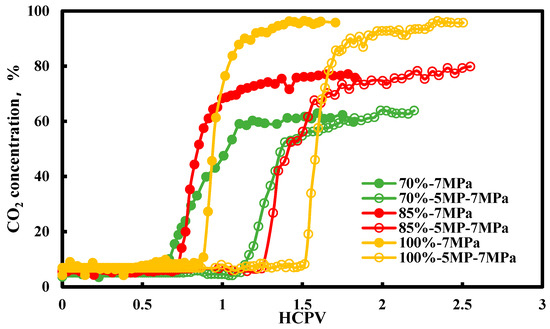

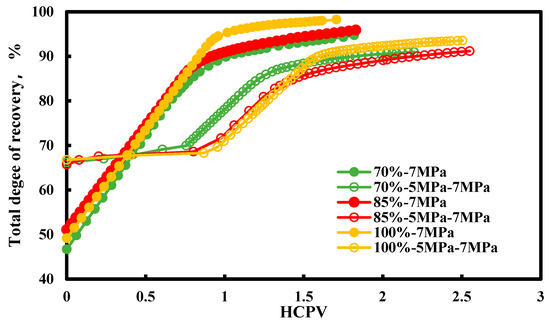

3.2. Effect of Displacement Mode on Gas Recovery Efficiency

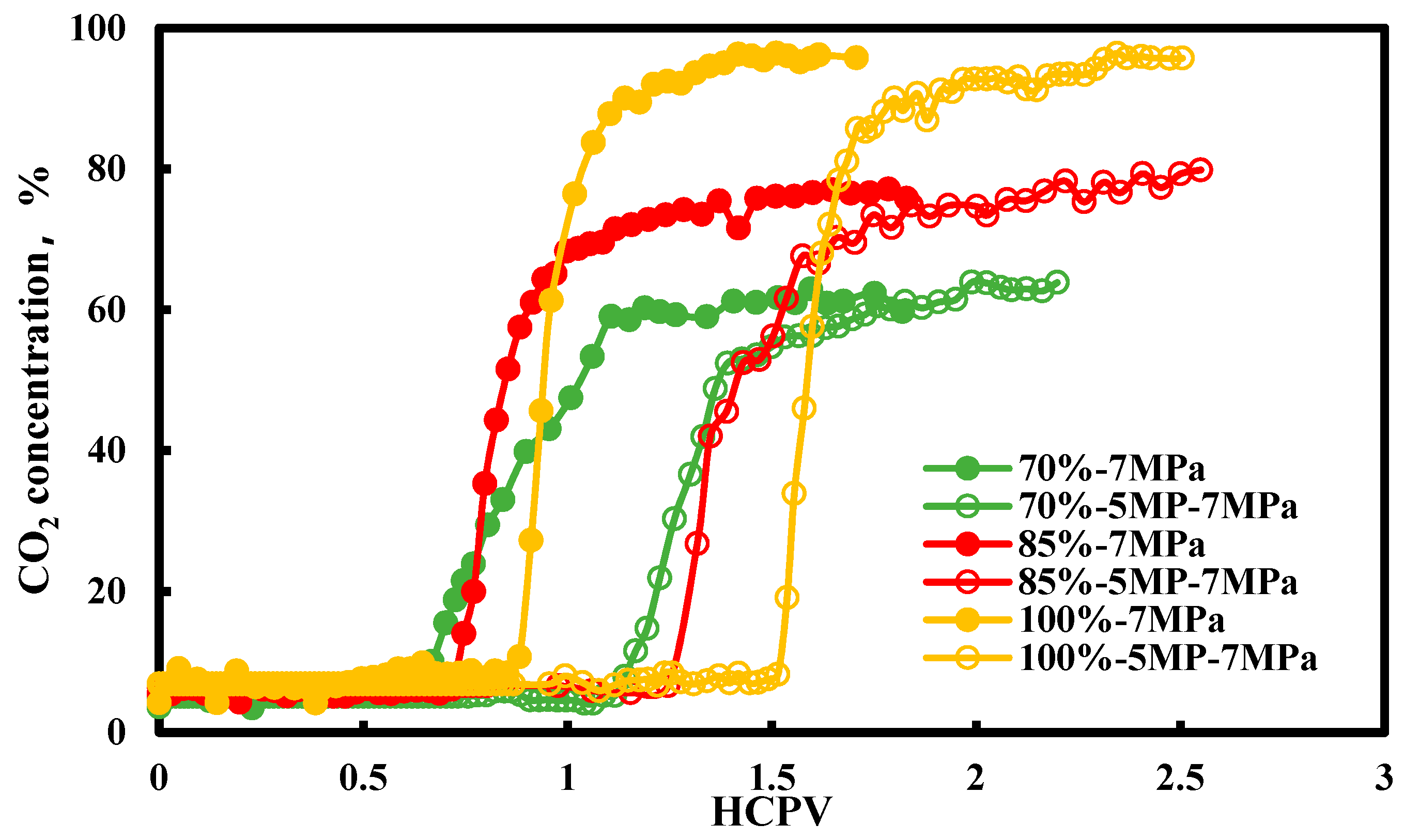

The mode of displacement significantly influenced the recovery efficiency and breakthrough dynamics of CO2 injection. Two displacement modes were compared: direct displacement and pressurized displacement following reservoir depletion. The results, illustrated in Figure 4 and Figure 5, show that direct displacement achieved superior recovery performance compared to the pressurized displacement method.

Figure 4.

CO2 concentration at the outlet of long core under different PVs of CO2 injection. In the legend, 70% refers to the CO2 concentration in the injected gas, and 7 MPa refers to the gas injection pressure. For 5 MPa–7 MPa mode, 5 MPa refers to the pressure at the end of depletion development. After depletion ends, the pore pressure is increased to 7 MPa by injecting CO2. CO2 gas injection is then carried out.

Figure 5.

Relationship between gas injection volume and recovery under different injection modes.

In the direct displacement mode, CO2 reached breakthrough earlier but achieved stable production more quickly. The CH4 recovery efficiency was higher, with final recovery values exceeding 96.5% in most cases. This enhanced performance can be attributed to the continuous pressure gradient established during direct displacement, which facilitated a more uniform and efficient displacement front. In contrast, the pressurized displacement mode introduced an intermediate phase where CO2 was injected to raise the reservoir pressure before initiating displacement. This additional phase led to delayed gas recovery and reduced overall efficiency, with recovery values approximately 5% lower than those of the direct displacement method. The differences in breakthrough behavior were also notable. Direct displacement resulted in sharper CO2 breakthroughs and shorter transition zones, indicating better displacement stability and reduced mixing between CO2 and CH4. The pressurized displacement method, however, exhibited a more gradual breakthrough and extended transition zones, reflecting less efficient gas displacement. These findings emphasize the advantages of direct displacement for CO2-EGR applications, particularly in scenarios where maximizing recovery efficiency is a priority. The simplicity of the direct displacement process also makes it more practical for field operations, reducing the time and complexity associated with pressure-boosting phases.

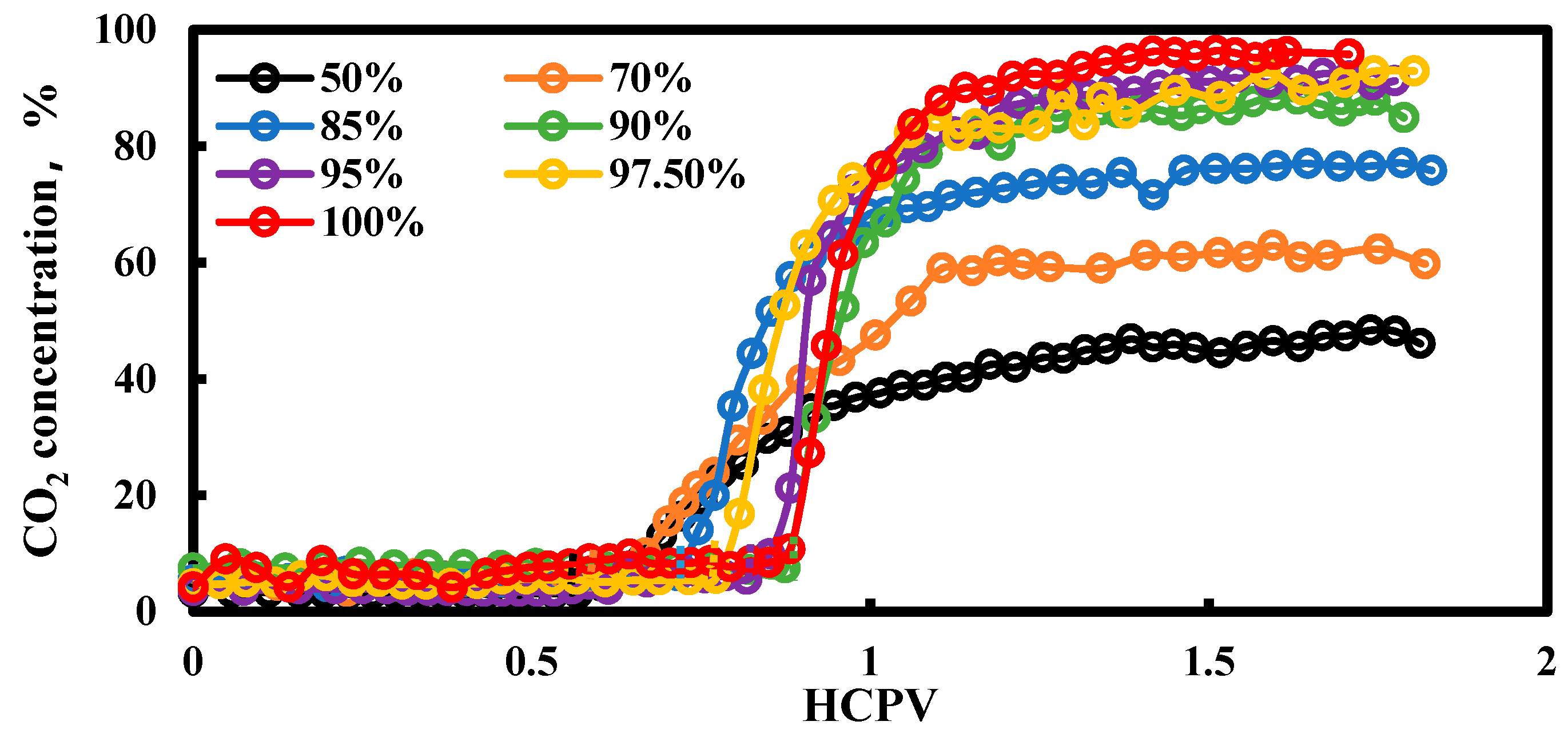

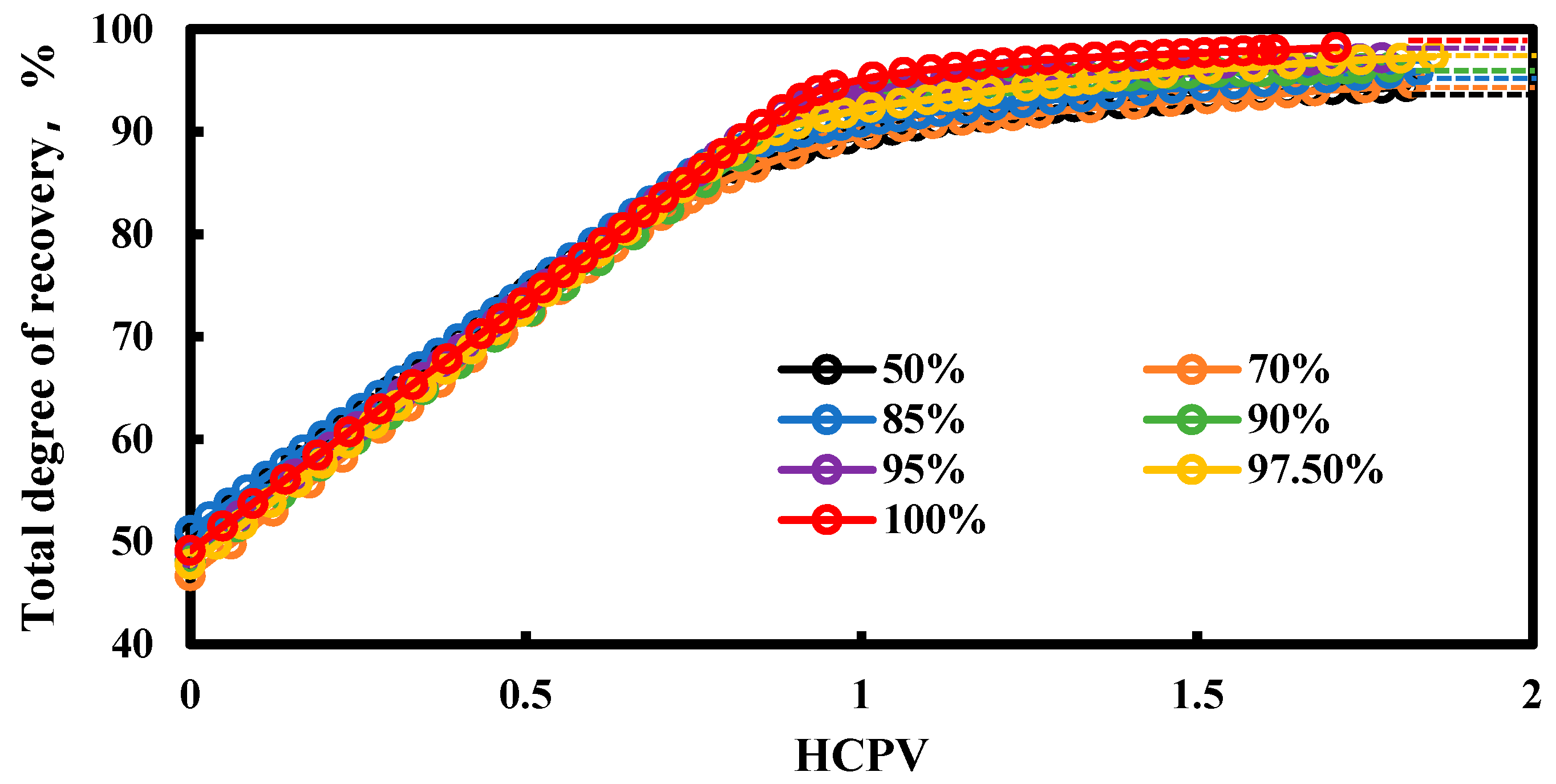

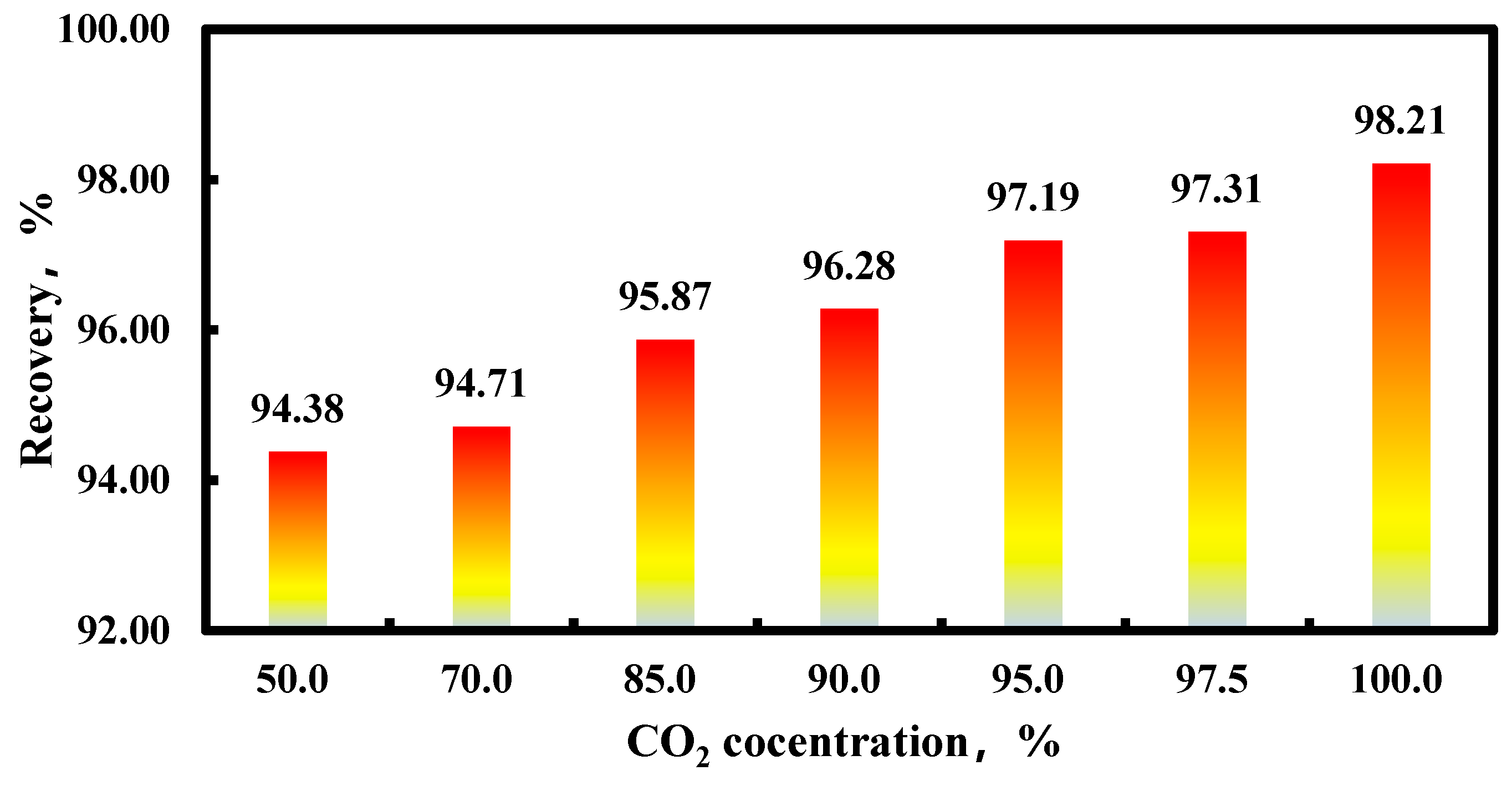

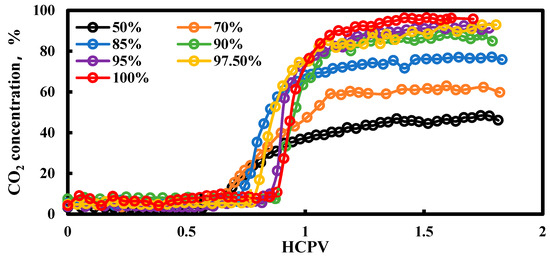

3.3. Influence of CO2 Concentration in Injected Gas

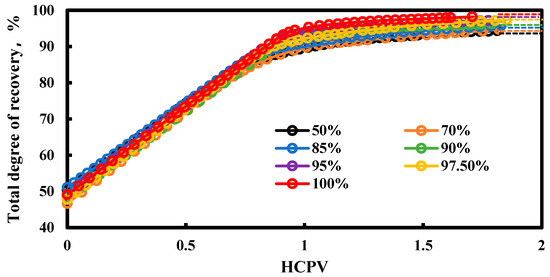

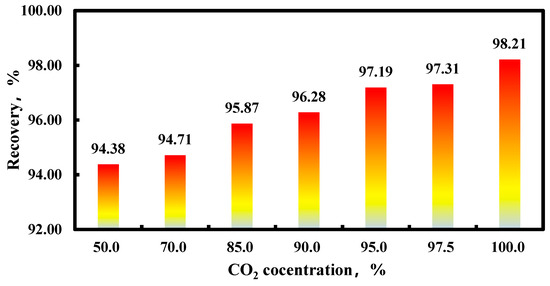

The concentration of CO2 in the injected gas was found to have a significant impact on recovery efficiency and displacement behavior. Seven gas mixtures with varying CO2 concentrations (50–100%) were tested, and the results are presented in Figure 6, Figure 7 and Figure 8. Higher CO2 concentrations consistently resulted in delayed breakthroughs and improved recovery efficiencies. The increase in impurity levels in CO2 leads to an increase in gas diffusion. [15,26,27].

Figure 6.

CO2 breakthrough curves for different injection gases.

Figure 7.

CH4 recovery for different injection gases.

Figure 8.

The relationship between final recovery and injected gas.

As the CO2 concentration in the injection gas increased, the viscosity of the injection fluid also increased, leading to more piston-like displacement behavior. This reduced the mixing and diffusion between CO2 and CH4, shortening the transition zone and enhancing displacement efficiency. For example, injection with 100% CO2 delayed breakthrough to 1.2 PV of injection and achieved a final recovery efficiency of 96.5%. In contrast, mixtures with lower CO2 concentrations exhibited earlier breakthroughs and lower recoveries due to the reduced displacement stability caused by increased mixing and dispersion effects.

These results highlight the importance of optimizing the composition of injected gas to maximize recovery and storage efficiency. While higher CO2 concentrations improve performance, practical considerations, such as gas availability, cost, and environmental factors, must also be taken into account when designing injection strategies.

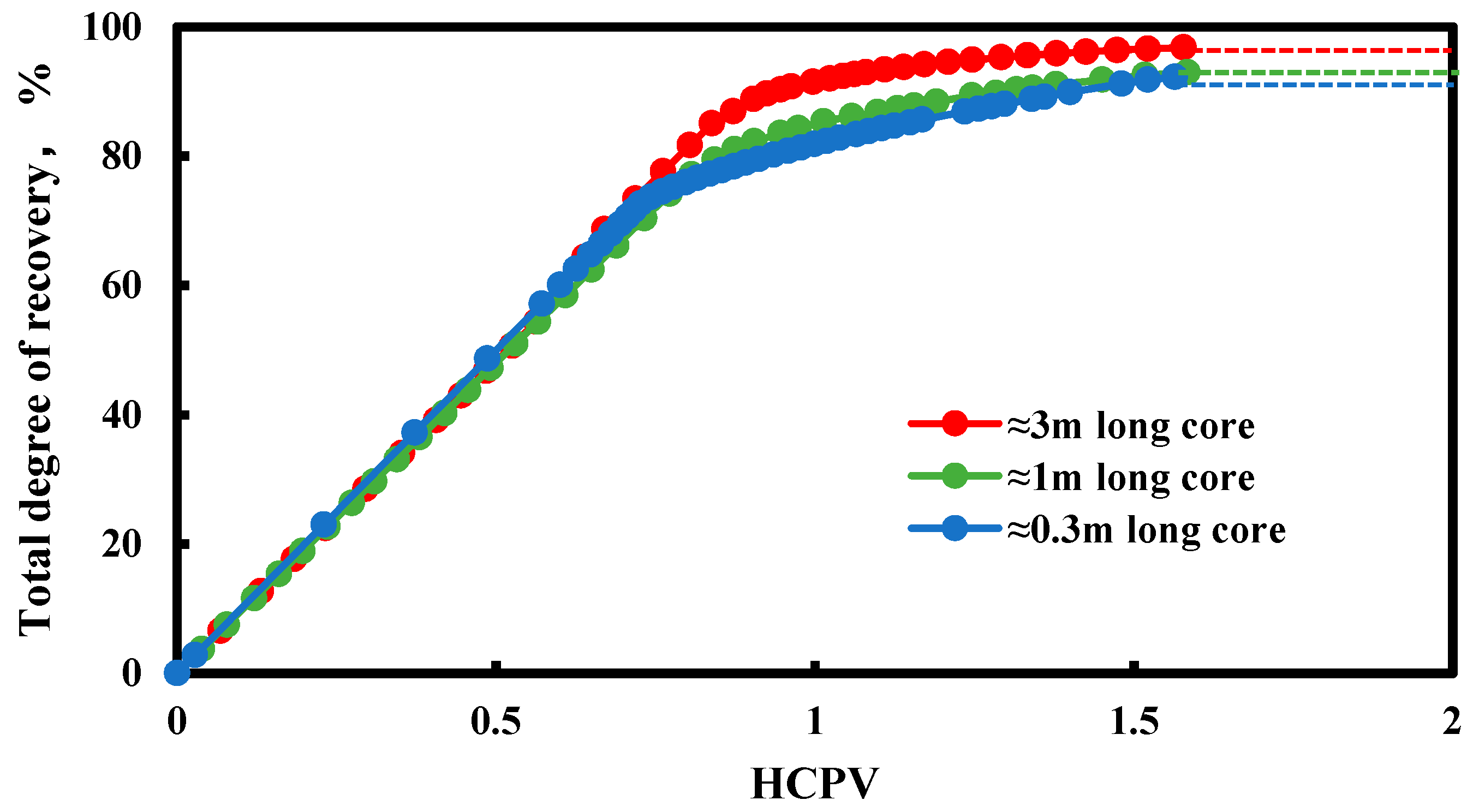

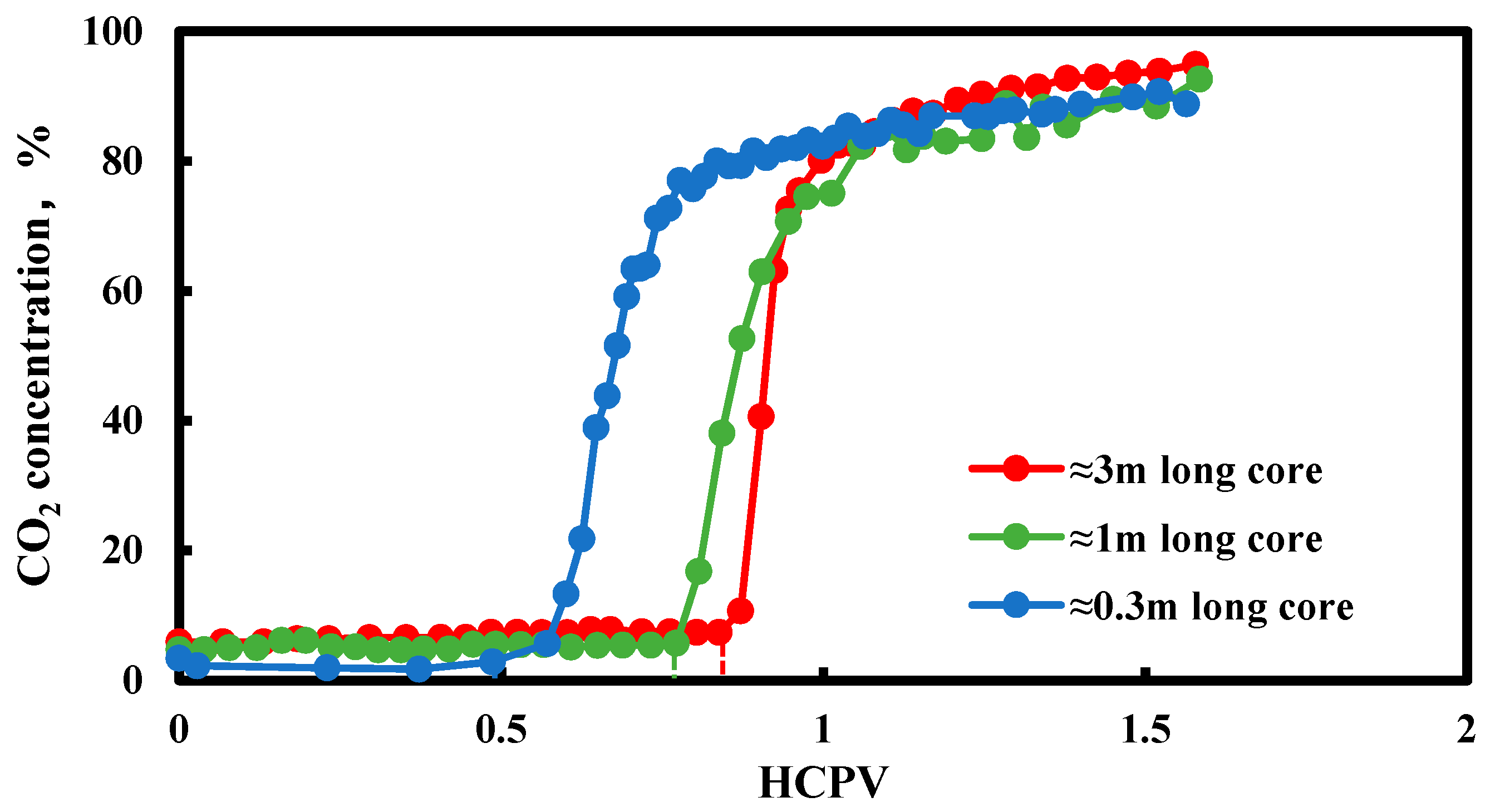

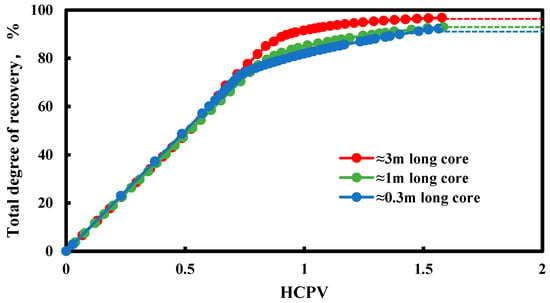

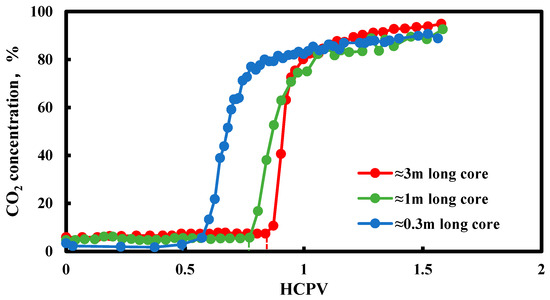

3.4. Effect of Core Length on Gas Recovery Efficiency

Core length was found to play a critical role in determining the displacement dynamics and overall recovery efficiency of CO2 injection. Experiments were conducted using cores of varying lengths (30 cm, 90 cm, and 270 cm) with a CO2 concentration of 100% to evaluate the influence of core dimensions on breakthrough behavior and recovery performance. The results are presented in Figure 9 and Figure 10.

Figure 9.

Influence of core length on gas recovery efficiency.

Figure 10.

CO2 breakthrough curves for experiments with different core lengths.

Longer cores exhibited delayed CO2 breakthroughs and shorter transition zones compared to shorter cores. For example, in the 270 cm core, breakthrough occurred significantly later than in the 30 cm core, and the transition to stable production was more abrupt. This is attributed to the extended displacement path in longer cores, which facilitates more uniform distribution of CO2 and reduces the effects of diffusion and dispersion. Consequently, the recovery efficiency was higher in longer cores, with values exceeding 98% in the longest core tested.

The results also indicate that the shorter cores experienced earlier CO2 breakthroughs and longer transition zones, leading to less efficient displacement and reduced recovery. This highlights the importance of core length in laboratory simulations of CO2-EGR, as shorter cores may not accurately represent the displacement dynamics observed in field-scale operations.

4. Conclusions

This study investigated the performance of CO2-enhanced gas recovery (CO2-EGR) under controlled laboratory conditions to evaluate the effects of key parameters, including reservoir permeability, injection pressure, gas composition, and core length, on recovery efficiency and displacement dynamics. The findings provide valuable insights into the mechanisms driving CO2-EGR and offer practical guidance for its implementation in offshore reservoirs. The key conclusions are summarized as follows.

For homogeneous porous media, reservoir permeability and injection pressure showed minimal influence on ultimate recovery efficiency under sufficient CO2 injection conditions. While permeability had a weak correlation with recovery performance, injection pressure primarily affected the displacement dynamics. Higher injection pressures improved displacement stability by delaying CO2 breakthrough and reducing diffusion effects but did not significantly alter the final recovery efficiency.

Direct displacement following reservoir depletion outperformed pressurized displacement in terms of recovery efficiency and breakthrough behavior. Direct displacement resulted in sharper CO2 breakthroughs, shorter transition zones, and higher recovery efficiencies, making it the preferred method for CO2-EGR operations.

Recovery efficiency and displacement stability improved with higher CO2 concentrations in the injection gas. Increased CO2 concentration delayed breakthroughs, enhanced piston-like displacement behavior, and reduced mixing and dispersion between CO2 and CH4. These findings emphasize the importance of optimizing gas composition for achieving both effective recovery and efficient CO2 sequestration.

Longer cores demonstrated delayed CO2 breakthroughs, shorter transition zones, and higher recovery efficiencies compared to shorter cores. These results highlight the necessity of using cores of sufficient length in laboratory experiments to ensure accurate simulation of field-scale displacement dynamics. For practical applications, reservoirs with longer flow paths are better suited for CO2-EGR due to enhanced displacement stability.

The findings provide a scientific basis for designing CO2-EGR strategies in offshore reservoirs. The versatility of CO2 in achieving effective displacement across a range of permeability values and moderate injection pressures makes it particularly suitable for the heterogeneous and operationally challenging conditions of offshore reservoirs. By optimizing injection parameters and gas composition, CO2-EGR can enhance hydrocarbon recovery while contributing to global carbon sequestration goals.

This study underscores the potential of CO2-EGR as a sustainable and economically viable approach for improving gas recovery and mitigating greenhouse gas emissions. The insights gained can guide future laboratory studies and field-scale implementations, advancing the development of optimized CO2 injection strategies for offshore gas reservoirs. Further research into operational challenges, including dispersion control and water management, is recommended to maximize the effectiveness of CO2-EGR in complex reservoir systems.

Author Contributions

Conceptualization, Q.Y.; methodology, R.X. and B.L.; validation, M.L.; formal analysis, F.M. and N.Z.; investigation, Y.Z. (Yuqi Zeng) and R.X.; resources, Y.Z. (Yuqiang Zha) and Q.Y.; data curation, F.M.; writing—original draft preparation, R.X.; writing—review and editing, B.L.; visualization, N.Z.; supervision, Q.Y.; project administration, Y.Z. (Yuqiang Zha) and L.S.; funding acquisition, Q.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research is supported by Comprehensive Scientific Research of China National Offshore Oil Corporation (KJZH-2023-2203), which is also known as the Research Project of the CAS Workstation for South China Sea Oil and Gas Energy, China National Offshore Oil Corporation.

Data Availability Statement

Data will be available on request.

Conflicts of Interest

Qing Ye, Yuqiang Zha, Runfu Xiong, Nan Zhao, Fengyang Mo, and Minxuan Li are employed by the CNOOC China Limited. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Liu, S.; Ren, B.; Li, H.; Yang, Y.; Wang, Z.; Wang, B.; Xu, J.; Agarwal, R. CO2 storage with enhanced gas recovery (CSEGR): A review of experimental and numerical studies. Pet. Sci. 2022, 19, 594–607. [Google Scholar] [CrossRef]

- Narinesingh, J.; Alexander, D. CO2 enhanced gas recovery and geologic sequestration in condensate reservoir: A simulation study of the effects of injection pressure on condensate recovery from reservoir and CO2 storage efficiency. Energy Procedia 2014, 63, 3107–3115. [Google Scholar] [CrossRef]

- Khormali, A.; Ahmadi, S.; Kazemzadeh, Y. Inhibition of barium sulfate precipitation during water injection into oil reservoirs using various scale inhibitors. Arab. J. Sci. Eng. 2023, 48, 9383–9399. [Google Scholar] [CrossRef]

- Gong, W.; Liu, Y.; Xi, C.; Yang, G.; Ju, Y.; Wang, M. Dynamic characterization of residual oil during long-term waterflooding experiments in heterogeneous porous structures. Fuel 2024, 356, 129567. [Google Scholar] [CrossRef]

- Li, S.; Li, Z.; Dong, Q. Diffusion coefficients of supercritical CO2 in oil-saturated cores under low permeability reservoir conditions. J. CO2 Util. 2016, 14, 47–60. [Google Scholar] [CrossRef]

- Yang, Y.; Li, L.; Wang, X.; Qin, N.; Zhang, R.; Zhao, Y.; Tian, Y. Simulation study of hydrogen sulfide removal in underground gas storage converted from the multilayered sour gas field. Int. J. Coal Sci. Technol. 2023, 10, 71. [Google Scholar] [CrossRef]

- Hamza, A.; Ibnelwaleed, A.H.; Al-Marri, M.J.; Mahmoud, M.; Reyad, S.; Santiago, A. CO2 enhanced gas recovery and sequestration in depleted gas reservoirs: A review. J. Pet. Sci. Eng. 2021, 196, 107685. [Google Scholar] [CrossRef]

- Kai, J.; Ashworth, P.; Shiyi, Z.; Xi, L.; Yan, S.; Angus, D. China’s carbon capture, utilization and storage (CCUS) policy: A critical review. Renew. Sustain. Energy Rev. 2020, 119, 109601. [Google Scholar]

- Kai, J.; Ashworth, P. The development of Carbon Capture Utilization and Storage (CCUS) research in China: A bibliometric perspective. Renew. Sustain. Energy Rev. 2021, 138, 110521. [Google Scholar]

- Chen, S.; Liu, J.; Zhang, Q.; Teng, F.; McLellan, B.C. A critical review on deployment planning and risk analysis of carbon capture, utilization, and storage (CCUS) toward carbon neutrality. Renew. Sustain. Energy Rev. 2022, 167, 112537. [Google Scholar] [CrossRef]

- Liang, B.; Chen, C.; Jia, C.; Wang, C.; Wang, X.; Zha, Y.; Wang, R.; Meng, Z.; Wang, H. Carbon capture, utilization and storage (CCUS) in oil and gas reservoirs in China: Status, opportunities and challenges. Fuel 2024, 375, 132353. [Google Scholar] [CrossRef]

- Zhang, L.; Cao, C.; Wen, S.; Zhao, Y.; Peng, X.; Wu, J. Thoughts on the development of CO2-EGR under the background of carbon peak and carbon neutrality. Nat. Gas Ind. B 2023, 10, 383–392. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, S.; Chen, M.; Xu, S. Experimental study on dispersion characteristics and CH4 recovery efficiency of CO2, N2 and their mixtures for enhancing gas recovery. J. Nat. Gas Sci. Eng. 2022, 216, 110756. [Google Scholar]

- Omari, A.; Wang, C.; Li, Y.; Xu, X. The progress of enhanced gas recovery (EGR) in shale gas reservoirs: A review of theory, experiments, and simulations. J. Pet. Sci. Eng. 2022, 213, 110461. [Google Scholar] [CrossRef]

- Jiang, P.; Zha, Y.; Ye, Q.; Xiong, R.; Zhao, N.; Mo, F.; Sun, L.; Li, M.; Zeng, Y.; Liang, B. CO2-Enhanced Gas Recovery in Offshore Carbon-Rich Gas Reservoirs—Part 1: In Situ Gas Dispersion Behaviors. Processes 2024, 12, 2479. [Google Scholar] [CrossRef]

- Lin, Z.; Kuang, Y.; Li, W.; Zheng, Y. Research status and prospects of CO2 geological sequestration technology from onshore to offshore: A review. Earth Sci. Rev. 2024, 258, 104928. [Google Scholar] [CrossRef]

- Zhang, A.; Fan, Z.; Zhao, L. An investigation on phase behaviors and displacement mechanisms of gas injection in gas condensate reservoir. Fuel 2020, 268, 117373. [Google Scholar] [CrossRef]

- Liu, S.; Yuan, L.; Zhao, C.; Zhang, Y.; Song, Y. A review of research on the dispersion process and CO2 enhanced natural gas recovery in depleted gas reservoir. J. Pet. Sci. Eng. 2022, 208, 109682. [Google Scholar] [CrossRef]

- Cui, S.; Kong, J.; Lu, R.; Guo, M.; Wang, Y.; Zhong, H. Experiment on replacement of high carbon gas with high hydrocarbon gas and its mechanism evaluation. Spec. Oil Gas Reserv. 2023, 30, 114. [Google Scholar]

- Tang, Y.; Zhang, C.; Du, Z.; Cui, S.; Ma, Y.; Mi, H. Experiments on enhancing gas recovery and sequestration by CO2 displacement. Reserv. Eval. Dev. 2015, 5, 34–40. [Google Scholar]

- Turta, A.T.; Sim, S.S.K.; Singhal, A.K.; Hawkins, B.F. Basic investigations on enhanced gas recovery by gas-gas displacement. J. Can. Pet. Technol. 2008, 47, 39–44. [Google Scholar] [CrossRef]

- Zhang, L.; Bai, T.; Zhao, Q.; Zhang, X.; Cheng, H.; Li, Z. CO2 Injection for Enhanced Gas Recovery and Geo-Storage in Complex Tight Sandstone Gas Reservoirs. Processes 2023, 11, 2059. [Google Scholar] [CrossRef]

- Du, J.; Zhao, Y.; Guo, P.; Zhao, Q. Experiment research on recovery efficiency improvement by CO2 injection in tight gas reservoirs in northern Hubei. Sci. Tech. Eng. 2020, 20, 6459–6465. [Google Scholar]

- Guo, P.; Li, X.; Sun, Z.; Wang, S.; Du, J. The numerical simulation of CO2 displacement and storage in low-permeability gas reservoir. Sci. Tech. Eng. 2019, 19, 68–76. [Google Scholar]

- Yang, S. Mechanism of Supercritical-CO2 Storage with Enhanced Gas Recovery in The Natural Gas Reservoirs; Southwest Petroleum University: Chengdu, China, 2012. [Google Scholar]

- Liu, S.; Zhang, Y.; Xing, W.; Jian, W.; Liu, Z.; Li, T.; Song, Y. Laboratory experiment of CO2-CH4 displacement and dispersion in sandpacks in enhanced gas recovery. J. Nat. Gas. Sci. Eng. 2015, 26, 1585–1594. [Google Scholar] [CrossRef]

- Zhao, Z.; Wen, S.; Wang, M.; Zhang, L.; Cao, C.; Yang, C.; Li, L. Experimental and Numerical Simulation Study on Enhancing Gas Recovery with Impure CO2 in Gas Reservoirs. Processes 2024, 12, 1663. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).