Evolution of Dried Food Texturization: A Critical Review of Technologies and Their Impact on Organoleptic and Nutritional Properties

Abstract

1. Introduction

2. Popping Expansion

2.1. Amaranth Grain Popping and Flour Applications

2.2. Diverse Popping Methods of Maize (Popcorn)

2.3. Process Optimization of Popped Sorghum and Genotype Selection

2.4. Popped Rice Applications

2.5. Grain Applications in Snack Production

2.6. Economic Feasibility and Scalability Considerations

3. Frying Expansion

3.1. Impact of Frying Parameters on Expansion

3.2. Influence of Ingredient Composition on Product Quality

3.3. Textural and Sensory Evaluation of Fried Snacks

3.4. Health Considerations and Future Directions

4. Mechanical Extrusion Expansion

4.1. Process Parameters and Modeling Approach

4.2. Ingredient Interactions and Production Optimization

4.3. Rheological Properties and Structural Optimization

5. Puffing Expansion

5.1. Barley Puffing Techniques

5.2. HTST Air Puffing for RTE Snacks

5.3. Puffing Process Evaluation in Fruits and Vegetables

5.4. Microwave and IR Puffing Applications

5.5. Other Puffing Technologies and Novel Applications

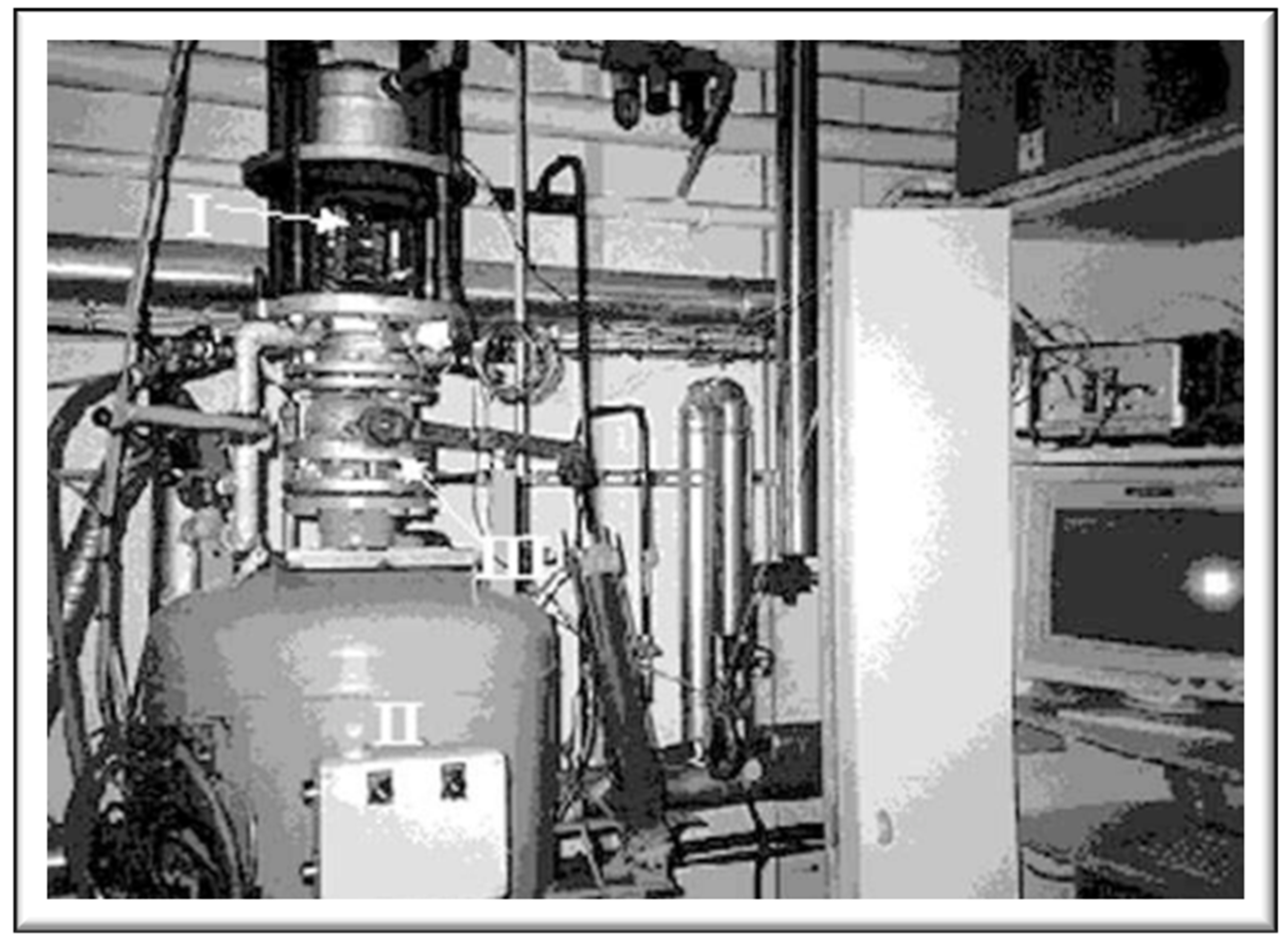

6. Controlled Sudden Decompression (DIC Process)

6.1. DIC Texturization and Quality Enhancement

6.2. DIC Applications in Powder Modification

6.3. Industrialization and Future Considerations

7. Intensification of Vaporization by Decompression to the Vacuum (IVDV)

7.1. IVDV Applications in Processing Legumes and Cereals

7.2. IVDV in Processing Defatted Peanut

7.3. IVDV for Sprout Preservation and Nutrient Retention

7.4. IVDV Applications in Fruit Processing

8. Advantages and Disadvantages of the Expansion Methods

9. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviation List

| AA | Acrylamide |

| AP | Apple pomace |

| Aw | Water activity |

| DIC | Controlled Sudden Decompression/Détente Instantanée Contrôlée |

| DF | Deep frying |

| EF | Expansion factor |

| ER | Expansion ratio |

| HARD | Hardness |

| HTST | High-Temperature Short-Time |

| HAD | Hot-air drying |

| IR | Infrared |

| IVDV | Intensification of Vaporization by Decompression to the Vacuum |

| ME | Mechanical extrusion |

| RTE | Ready-to-eat |

| RSM | Response surface methodology |

| SME | Specific Mechanical Energy |

| SD | Spray drying |

| TSE | Twin-Screw Extrusion |

References

- Nummer, B.A. Historical Origins of Food Preservation. National Center for Home Food Preservation. Available online: https://nchfp.uga.edu/resources/entry/historical-origins-of-food-preservation#:~:text=In%20ancient%20times%20the%20sun,B.C.%20in%20the%20hot%20sun (accessed on 3 October 2024).

- Delgado, J.M.P.Q.; da Silva, M.V. Food dehydration: Fundamentals, modelling and applications. Adv. Struct. Mater. 2014, 48, 69–94. [Google Scholar] [CrossRef]

- Heldman, D.R.; Singh, R.P. (Eds.) Food Dehydration BT—Food Process Engineering; Springer: Dordrecht, The Netherlands, 1981; pp. 261–331. [Google Scholar] [CrossRef]

- Noomhorm, A. Overview of dehydration method on quality of fruit and vegetables. SWU Sci. J. 2007, 23, 9–22. [Google Scholar]

- Mayor, L.; Sereno, A.M. Modelling shrinkage during convective drying of food materials: A review. J. Food Eng. 2004, 61, 373–386. [Google Scholar] [CrossRef]

- Mohapatra, D.; Mishra, S. Current trends in drying and dehydration of foods. Food Eng. 2011, 2011, 311–351. [Google Scholar]

- Zhang, M.; Chen, H.; Mujumdar, A.S.; Tang, J.; Miao, S.; Wang, Y. Recent developments in high-quality drying of vegetables, fruits, and aquatic products. Crit. Rev. Food Sci. Nutr. 2017, 57, 1239–1255. [Google Scholar] [CrossRef]

- Louka, N. Maîtrise de la Qualité des Produits Agro-Alimentaires Séchés: Modification Texturale et Réduction du Coût énergétique par Détente Instantanée Contrôlée ‘DIC’ vers le Vide: Conception et Réalisation d’un Nouveau Procédé Industriel. Université de Technologie de Compiègne. 1996. Available online: https://www.theses.fr/1996COMPD897 (accessed on 7 March 2024).

- Bi, J.-F.; Wang, X.; Chen, Q.-Q.; Liu, X.; Wu, X.-Y.; Wang, Q.; Lv, J.; Yang, A.-J. Evaluation indicators of explosion puffing Fuji apple chips quality from different Chinese origins. LWT 2015, 60, 1129–1135. [Google Scholar] [CrossRef]

- Lyu, J.; Yi, J.; Bi, J.F.; Gao, H.; Zhou, M.; Liu, X. Impacts of Explosion Puffing Drying Combined with Hot-Air and Freeze Drying on the Quality of Papaya Chips. Int. J. Food Eng. 2017, 13, 20160250. [Google Scholar] [CrossRef]

- Lisiecka, K.; Wójtowicz, A.; Samborska, K.; Mitrus, M.; Oniszczuk, T.; Combrzyński, M.; Soja, J.; Lewko, P.; Drozd, K.K.; Oniszczuk, A. Structure and Texture Characteristics of Novel Snacks Expanded by Various Methods. Materials 2023, 16, 1541. [Google Scholar] [CrossRef]

- Louka, N.; Juhel, F.; Allaf, K. Quality studies on various types of partially dried vegetables texturized by Controlled Sudden Decompression general patterns for the variation of the expansion ratio. J. Food Eng. 2004, 65, 245–253. [Google Scholar] [CrossRef]

- Liu, C.-J.; Xue, Y.-L.; Guo, J.; Ren, H.-C.; Jiang, S.; Li, D.-J.; Song, J.-F.; Zhang, Z.-Y. Citric acid and sucrose pretreatment improves the crispness of puffed peach chips by regulating cell structure and mechanical properties. LWT 2021, 142, 111036. [Google Scholar] [CrossRef]

- Wang, D.; Han, W.; Shi, L.; Guo, X.; Chen, S.; Chen, L.; Qiao, Y.; Wu, W.; Li, J.; Wang, L. Effects of explosion puffing on surimi-starch blends: Structural characteristics, physicochemical properties, and digestibility. LWT 2023, 183, 114902. [Google Scholar] [CrossRef]

- Raikham, C.; Prachayawarakorn, S.; Nathakaranakule, A.; Soponronnarit, S. Influences of Pretreatments and Drying Process Including Fluidized Bed Puffing on Quality Attributes and Microstructural Changes of Banana Slices. Dry. Technol. 2015, 33, 915–925. [Google Scholar] [CrossRef]

- Raza, H.; Zaaboul, F.; Shoaib, M.; Zhang, L. An Overview of Physicochemical Composition and Methods used for Chickpeas Processing. Int. J. Agric. Innov. Res. 2019, 7, 1473–2319. [Google Scholar]

- Sahyoun, W.; Adenier, H.; Barbotin, J.N.; Louka, N.; Chaveron, H.; Thomas, D.; Allaf, K. Deshydratation de la carotte (Daucus carota L.): Effet d’un nouveau procede sur les composes lipidiques et la microstructure. Sci. Aliment. 1996, 16, 491–503. Available online: https://agris.fao.org/search/en/providers/123819/records/64735b0653aa8c8963084167 (accessed on 20 March 2024).

- Hoke, K.; Houšová, J.; Houška, M. Optimum conditions of rice puffing. Czech J. Food Sci. 2005, 23, 1–11. [Google Scholar] [CrossRef]

- Saha, S.; Roy, A. Puffed rice: A materialistic understanding of rice puffing and its associated changes in physicochemical and nutritional characteristics. J. Food Process Eng. 2020, 43, e13479. [Google Scholar] [CrossRef]

- Brennan, M.A.; Derbyshire, E.; Tiwari, B.K.; Brennan, C.S. Ready-to-eat snack products: The role of extrusion technology in developing consumer acceptable and nutritious snacks. Int. J. Food Sci. Technol. 2013, 48, 893–902. [Google Scholar] [CrossRef]

- Köprüalan, Ö.; Elmas, F.; Bodruk, A.; Arıkaya, Ş.; Koç, M.; Koca, N.; Kaymak-Ertekin, F. Impact of pre-drying on the textural, chemical, color, and sensory properties of explosive puffing dried white cheese snacks. LWT—Food Sci. Technol. 2021, 154, 112665. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, H.; Li, X.; Han, X.; Qu, X.; Chen, P.; Wang, H.; Wang, L. Effect of waxy rice starch on textural and microstructural properties of microwave-puffed cheese chips. Int. J. Dairy Technol. 2018, 71, 501–511. [Google Scholar] [CrossRef]

- Tentu, R.D.; Dabir, S.; Specialist, F.I.; Ishwarya, P.; Specialist, T. Technological Review of High-Moisture Extrusion for Creating Whole-Cut Meat Analogs; Good Food Institute: Washington, DC, USA, 2023. [Google Scholar]

- Nawaz, A.; Xiong, Z.; Li, Q.; Xiong, H.; Irshad, S.; Chen, L.; Wang, P.; Zhang, M.; Hina, S.; Regenstein, J.M. Evaluation of physicochemical, textural and sensory quality characteristics of red fish meat-based fried snacks. Soc. Chem. Ind. J. Sci. Food Agric. 2019, 99, 5771–5777. [Google Scholar] [CrossRef]

- Farzana, W.; Patel, S.; Palanimuthu, V. Effect of processing parameters on puffing quality of Kodo millet (Paspalum scrobiculatum). Pharma Innov. J. 2022, 11, 1009–1018. [Google Scholar]

- Sweley, J.C.; Rose, D.J.; Jackson, D.S. Quality Traits and Popping Performance Considerations for Popcorn (Zea mays Everta). Food Rev. Int. 2013, 29, 157–177. [Google Scholar] [CrossRef]

- Cabrera-Ramírez, A.; Morales-Sánchez, E.; Méndez-Montealvo, G.; Velazquez, G.; Rodríguez-García, M.; Villamiel, M.; Gaytán-Martínez, M. Structural changes in popped sorghum starch and their impact on the rheological behavior. Int. J. Biol. Macromol. 2021, 186, 686–694. [Google Scholar] [CrossRef] [PubMed]

- Castro-Giráldez, M.; Fito, P.J.; Prieto, J.M.; Andrés, A.; Fito, P. Study of the puffing process of amaranth seeds by dielectric spectroscopy. J. Food Eng. 2012, 110, 298–304. [Google Scholar] [CrossRef][Green Version]

- Mahfoud, F.; Assaf, J.C.; Elias, R.; Debs, E.; Louka, N. Defatting and Defatted Peanuts: A Critical Review on Methods of Oil Extraction and Consideration of Solid Matrix as a By-Product or Intended Target. Processes 2023, 11, 2512. [Google Scholar] [CrossRef]

- Lloyd, L. The Origin and History of Chapati & Roti. Desiblitz. Available online: https://www.desiblitz.com/content/history-of-chapati (accessed on 2 October 2024).

- Shaikh, I.M.; Ghodke, S.K.; Ananthanarayan, L. Staling of chapatti (Indian unleavened flat bread). Food Chem. 2007, 101, 113–119. [Google Scholar] [CrossRef]

- Spaeth, S.C.; Debouck, D.G. Microstructure of ñuñas: Andean popping beans (Phaseolus vulgaris L.). Food Microstruct. 1989, 35, 263–269. [Google Scholar] [CrossRef]

- Swarnakar, A.K.; Mohapatra, M.; Das, S.K. A review on processes, mechanisms, and quality influencing parameters for puffing and popping of grains. J. Food Process. Preserv. 2022, 46, 2022. [Google Scholar] [CrossRef]

- Sankar, R.; Pandav, C.S.; Sripathy, G. Ethics and public health policy: Lessons from salt iodization program in India. Compr. Rev. Food Sci. Food Saf. 2008, 7, 386–389. [Google Scholar] [CrossRef]

- Bertman, S. Handbook to Life in Ancient Mesopotamia; Infobase Publishing: New York, NY, USA, 2003. [Google Scholar]

- King, F.B. The Relative Value of Various Lards and Other Fats for the Deep-Fat Frying of Potato Chips. Journal of Washington, US: Journal of Agricultural Research. 1937. Available online: https://books.google.com.lb/books?hl=en&lr=&id=7uLUAAAAMAAJ&oi=fnd&pg=PA369&dq=deep+frying+1937&ots=OeRnhkWgs4&sig=JDT2tI6gsz8h08NPJWtle3GvzHs&redir_esc=y#v=onepage&q=deep frying 1937&f=false (accessed on 2 June 2024).

- Lawton, B.T.; Henderson, G.A.; Derlatka, E.J. The effects of extruder variables on the gelatinisation of corn starch. Can. J. Chem. Eng. 1972, 50, 168–172. [Google Scholar] [CrossRef]

- Bookwalter, G.N.; MUSTAKAS, G.C.; Kwolek, W.F.; Mcghee, J.E.; Albrecht, W.J. Full-Fat Soy Flour Extrusion Cooked: Properties and Food Uses. J. Food Sci. 1971, 36, 5–9. [Google Scholar] [CrossRef]

- Launay, B.; Lisch, J.M. Twin-screw extrusion cooking of starches: Flow behaviour of starch pastes, expansion and mechanical properties of extrudates. J. Food Eng. 1983, 2, 259–280. [Google Scholar] [CrossRef]

- Singh, R.; Guerrero, M.; Nickerson, M.T.; Koksel, F. Effects of extrusion screw speed, feed moisture content, and barrel temperature on the physical, techno-functional, and microstructural quality of texturized lentil protein. J. Food Sci. 2024, 89, 2040–2053. [Google Scholar] [CrossRef] [PubMed]

- Santi, T.D.N.E.; Yuniati, S. From traditional recipes to biologically complete food products: Review on snacks extrusion. Russ. J. Agric. Socio-Econ. Sci. 2017, 12, 239–245. [Google Scholar]

- Webb, D.; Dogan, H.; Li, Y.; Alavi, S. Physico-Chemical Properties and Texturization of Pea, Wheat and Soy Proteins Using Extrusion and Their Application in Plant-Based Meat. Foods 2023, 12, 1586. [Google Scholar] [CrossRef]

- Adekola, K.A. Engineering Review Food Extrusion Technology and Its Applications. J. Food Sci. Eng. 2016, 6, 149–168. [Google Scholar] [CrossRef][Green Version]

- Rathod, S. Development and Performance Evaluation of Rice Puffing Machine; University of Agricultural Sciences: Raichur, India, 2019. [Google Scholar]

- Harrington, W.O.; Griffiths, F. Puffs Potatoes. Food Ind. 1950, 22, 2005–2006. [Google Scholar]

- Sullivan, J.F.; Konstance, R.P.; Aceto, N.C.; Heiland, W.K.; Craig, J.C., Jr. Continuous explosion-puffing of potatoes. J. Food Sci. 1977, 42, 1462–1463. [Google Scholar] [CrossRef]

- Sullivan, J.F.; Konstance, R.P.; Egoville, M.J.; Craig, J.C., Jr. Storage stability of continuous explosion-puffed potatoes. Leb. + Technol. 1983, 16, 76–80. Available online: https://pascal-francis.inist.fr/vibad/index.php?action=getRecordDetail&idt=PASCAL83X0291620 (accessed on 1 June 2024).

- Chandrasekhar, P.R.; Chattopadhyay, P.K. Studies on microstructural changes of parboiled and puffed rice. J. Food Process. Preserv. 1990, 14, 27–37. [Google Scholar] [CrossRef]

- Kim, M.H.; Toledo, R.T. Effect of osmotic dehydration and high temperature fluidized bed drying on properties of dehydrated rabbiteye blueberries. J. Food Sci. 1987, 52, 980–984. [Google Scholar] [CrossRef]

- Tabeidie, Z.; Payne, F.A. Hydrogen and calcium ion concentrations affect volume of CO2 puffed diced green bell peppers. J. Food Sci. 1992, 57, 1149–1151. [Google Scholar] [CrossRef]

- Payne, F.A.; Taraba, J.L.; Saputra, D. A review of puffing processes for expansion of biological products. J. Food Eng. 1989, 10, 183–197. [Google Scholar] [CrossRef]

- Louka, N.; Allaf, K. New process for texturizing partially dehydrated biological products using controlled sudden decompression to the vacuum: Application on potatoes. J. Food Sci. 2002, 67, 3033–3038. [Google Scholar] [CrossRef]

- Louka, N.; Allaf, K. Expansion ratio and color improvement of dried vegetables texturized by a new process ‘Controlled Sudden Decompression to the vacuum’: Application to potatoes, carrots and onions. J. Food Eng. 2004, 65, 233–243. [Google Scholar] [CrossRef]

- Mrad, R.; Debs, E.; Saliba, R.; Maroun, R.G.; Louka, N. Multiple optimization of chemical and textural properties of roasted expanded purple maize using response surface methodology. J. Cereal Sci. 2014, 60, 397–405. [Google Scholar] [CrossRef]

- Mrad, R.; El Rammouz, R.; Maroun, R.G.; Louka, N. Effect of intensification of vaporization by decompression to the vacuum as a pretreatment for roasting australian chickpea: Multiple optimization by response surface methodology of chemical, textural and color parameters. J. Food Qual. 2015, 38, 139–152. [Google Scholar] [CrossRef]

- Mandhare, L.; More, D.; Nagulwar, M. Effect of popping methods on popping characteristics of quinoa seed. J. Pharmacogn. Phytochem. 2020, 9, 1943–1945. [Google Scholar]

- Mounir, S.; Ghandour, A.; Farid, E.; Shatta, A. Popped and Puffed Cereal Products. In Cereal-Based Food Products; Springer: Berlin/Heidelberg, Germany, 2023; pp. 169–195. [Google Scholar]

- Malik, M.; Sindhu, R.; Dhull, S.B.; Bou-Mitri, C.; Singh, Y.; Panwar, S.; Khatkar, B.S. Nutritional Composition, Functionality, and Processing Technologies for Amaranth. J. Food Process. Preserv. 2023, 2023, 1753029. [Google Scholar] [CrossRef]

- Lara, N.; Ruales, J. Popping of amaranth grain (Amaranthus caudatus) and its effect on the functional, nutritional and sensory properties. J. Sci. Food Agric. 2002, 82, 797–805. [Google Scholar] [CrossRef]

- Ceylan, M.; Karababa, E. The effects of ingredients on popcorn popping characteristics. Int. J. Food Sci. Technol. 2004, 39, 361–370. [Google Scholar] [CrossRef]

- Gökmen, S. Effects of moisture content and popping method on popping characteristics of popcorn. J. Food Eng. 2004, 65, 357–362. [Google Scholar] [CrossRef]

- Gaul, J.A.; Rayas-Duarte, P. Effect of moisture content and tempering method on the functional and sensory properties of popped sorghum. Cereal Chem. 2008, 85, 344–350. [Google Scholar] [CrossRef]

- de la Barca, A.M.C.; Rojas-Martínez, M.E.; Islas-Rubio, A.R.; Cabrera-Chávez, F. Gluten-Free Breads and Cookies of Raw and Popped Amaranth Flours with Attractive Technological and Nutritional Qualities. Plant Foods Hum. Nutr. 2010, 65, 241–246. [Google Scholar] [CrossRef]

- Shukla, S.; Gour, S. Evaluation of physical, nutritional and popping quality of some maize (Zea mays) varieties. Asian J. Dairy Food Res. 2014, 33, 285. [Google Scholar] [CrossRef]

- Mishra, G.; Joshi, D.C.; Mohapatra, D. Optimization of pretreatments and process parameters for sorghum popping in microwave oven using response surface methodology. J. Food Sci. Technol. 2015, 52, 7839–7849. [Google Scholar] [CrossRef]

- Mishra, G.; Joshi, D.C.; Mohapatra, D.; Babu, V.B. Varietal influence on the microwave popping characteristics of sorghum. J. Cereal Sci. 2015, 65, 19–24. [Google Scholar] [CrossRef]

- Chavan, U.D.; Dalvi, U.S.; Pawar, G.H.; Shinde, M.S. Selection of genotype and development of technology for sorghum pops production. Int. Food Res. J. 2015, 2, 100–105. [Google Scholar]

- Mir, S.A.; Bosco, S.J.D.; Shah, M.A.; Mir, M.M.; Sunooj, K.V. Process Optimization and Characterization of Popped Brown Rice. Int. J. Food Prop. 2016, 19, 2102–2112. [Google Scholar] [CrossRef]

- Gupta, M.; Bhattacharya, S. Effect of ingredients on the quality characteristics of gluten free snacks. J. Food Sci. Technol. 2017, 54, 3989–3999. [Google Scholar] [CrossRef]

- Khan, R.; Professor, A.D.; Khan, C.R.; Dutta, A. Effect of popping on physico-chemical and nutritional parameters of amaranth grain. J. Pharmacogn. Phytochem. 2018, 7, 954–958. [Google Scholar]

- Ishwarya, S.P.; Desai, K.M.; Naladala, S.; Anandharamakrishnan, C. Impact of wheat bran addition on the temperature-induced state transitions in dough during bread-baking process. Int. J. Food Sci. Technol. 2018, 53, 404–411. [Google Scholar] [CrossRef]

- Solanki, C.; Indore, N.; Nanda, K. Microwave vs conventional popping system: A comparative evaluation for maize popping. Int. J. Chem. Stud. 2018, 6, 176–181. [Google Scholar]

- Cañizares, L.d.C.C.; Timm, N.d.S.; Ramos, A.H.; Neutzling, H.P.; Ferreira, C.D.; de Oliveira, M. Effects of moisture content and expansion method on the technological and sensory properties of white popcorn. Int. J. Gastron. Food Sci. 2020, 22, 100282. [Google Scholar] [CrossRef]

- Nguyen, T.M.N.; Nguyen, T.P.; Tran, G.B.; Le, P.T.Q. Effect of processing methods on foam properties and application of lima bean (Phaseolus lunatus L.) aquafaba in eggless cupcakes. J. Food Process. Preserv. 2020, 44, e14886. [Google Scholar] [CrossRef]

- Castro-Campos, F.; Cabrera-Ramírez, A.; Morales-Sánchez, E.; Rodríguez-García, M.; Villamiel, M.; Ramos-López, M.; Gaytán-Martínez, M. Impact of the popping process on the structural and thermal properties of sorghum grains (Sorghum bicolor L. Moench). Food Chem. 2021, 348, 129092. [Google Scholar] [CrossRef]

- Beech, D.; Beech, J.; Gould, J.; Hill, S. Effect of popping water content and amylose/amylopectin ratio on the physical properties of expanded starch products with different shear histories. Int. J. Food Sci. Technol. 2022, 57, 7368–7378. [Google Scholar] [CrossRef]

- Shavandi, M.; Javanmard, M.; Basiri, A. Novel popping through infrared: Effect on some physicochemical properties of popcorn (Zea mays L. var. Everta). LWT 2021, 155, 112955. [Google Scholar] [CrossRef]

- Han, H.M.; Koh, B.K. Gel properties of rice varieties in relation to bread baking potential. Int. J. Food Prop. 2023, 26, 833–841. [Google Scholar] [CrossRef]

- Nair, C.K.V.; Seow, C.C.; Sulebele, G.A. Effects of frying parameters on physical changes of tapioca chips during deep-fat frying. Int. J. Food Sci. Technol. 1996, 31, 249–256. [Google Scholar] [CrossRef]

- Vitrac, O.; Trystram, G.; Raoult-Wack, A.L. Deep-fat frying of food: Heat and mass transfer, transformations and reactions inside the frying material. Eur. J. Lipid Sci. Technol. 2000, 102, 529–538. [Google Scholar] [CrossRef]

- Arunachalam, S.; Rajan, D.; Giridharaprasad, S.; Subramani, D. Optimization of Texture and Quality of Deep-Fried Prawn Chips Using Response Surface Methodology. J. Culin. Sci. Technol. 2024, 1–19. [Google Scholar] [CrossRef]

- Sivaranjani, S.P.S.R.; Joshi, T.J.; Mukta, S.S. A comprehensive review of the mechanism, changes, and effect of deep fat frying on the characteristics of restructured foods. Food Chem. 2024, 450, 139393. [Google Scholar] [CrossRef]

- Maneerote, J.; Noomhorm, A.; Takhar, P.S. Optimization of processing conditions to reduce oil uptake and enhance physico-chemical properties of deep fried rice crackers. LWT 2009, 42, 805–812. [Google Scholar] [CrossRef]

- Saeleaw, M.; Schleining, G. Effect of frying parameters on crispiness and sound emission of cassava crackers. J. Food Eng. 2011, 103, 229–236. [Google Scholar] [CrossRef]

- Yamsaengsung, R.; Ariyapuchai, T.; Prasertsit, K. Effects of vacuum frying on structural changes of bananas. J. Food Eng. 2011, 106, 298–305. [Google Scholar] [CrossRef]

- Tiwari, U.; Gunasekaran, M.; Jaganmohan, R.; Alagusundaram, K.; Tiwari, B.K. Quality Characteristic and Shelf Life Studies of Deep-Fried Snack Prepared from Rice Brokens and Legumes By-Product. Food Bioprocess Technol. 2011, 4, 1172–1178. [Google Scholar] [CrossRef]

- Bertuzzi, T.; Mulazzi, A.; Rastelli, S.; Sala, L.; Pietri, A. Mitigation measures for acrylamide reduction in dough-based potato snacks during their expansion by frying. Food Addit. Contam. Part A 2018, 35, 1940–1947. [Google Scholar] [CrossRef]

- Nawaz, A.; Xiong, Z.; Xiong, H.; Chen, L.; Wang, P.; Ahmad, I.; Hu, C.; Irshad, S.; Ali, S.W. The effects of fish meat and fish bone addition on nutritional value, texture and microstructure of optimised fried snacks. Int. J. Food Sci. Technol. 2019, 54, 1045–1053. [Google Scholar] [CrossRef]

- Reyniers, S.; De Brier, N.; Ooms, N.; Matthijs, S.; Piovesan, A.; Verboven, P.; Brijs, K.; Gilbert, R.G.; Delcour, J.A. Amylose molecular fine structure dictates water–oil dynamics during deep-frying and the caloric density of potato crisps. Nat. Food 2020, 1, 736–745. [Google Scholar] [CrossRef]

- Odunlami, Y.O.; Sobukola, O.P.; Adebowale, A.A.; Sanni, S.A.; Sanni, L.O.; Ajayi, F.F.; Faloye, O.R.; Tomslin, K. Effect of Ingredient combination and post frying centrifugation on oil uptake and associated quality attributes of a fried snack. J. Culin. Sci. Technol. 2023, 21, 52–70. [Google Scholar] [CrossRef]

- Choi, Y.; Chae, J.; Kim, S.; Shin, E.-C.; Choi, G.; Kim, D.; Cho, S. Surimi for snacks: Physicochemical and sensory properties of fried fish snacks prepared from surimi of different fish species. Fish. Aquat. Sci. 2023, 26, 145–157. [Google Scholar] [CrossRef]

- Dana, D.; Saguy, I.S. Frying of Nutritious Foods: Obstacles and Feasibility. Food Sci. Technol. Res. 2001, 7, 265–279. [Google Scholar] [CrossRef]

- Oke, E.K.; Idowu, M.A.; Sobukola, O.P.; Adeyeye, S.A.O.; Akinsola, A.O. Frying of Food: A Critical Review. J. Culin. Sci. Technol. 2017, 16, 107–127. [Google Scholar] [CrossRef]

- Pandiselvam, R.; Süfer, Ö.; Özaslan, Z.T.; Gowda, N.N.; Pulivarthi, M.K.; Charles, A.P.R.; Ramesh, B.; Ramniwas, S.; Rustagi, S.; Jafari, Z.; et al. Acrylamide in food products: Formation, technological strategies for mitigation, and future outlook. Food Front. 2024, 5, 1063–1095. [Google Scholar] [CrossRef]

- Shelar, G.A.; Gaikwad, S.T. Extrusion in food processing: An overview. Pharma Innov. J. 2019, 562, 562–568. Available online: www.thepharmajournal.com (accessed on 19 June 2024).

- Sui, X.; Zhang, T.; Zhang, X.; Jiang, L. High-Moisture Extrusion of Plant Proteins: Fundamentals of Texturization and Applications. Annu. Rev. Food Sci. Technol. 2024, 15, 125–149. [Google Scholar] [CrossRef]

- Singh, S.; Gamlath, S.; Wakeling, L. Nutritional aspects of food extrusion: A review. Int. J. Food Sci. Technol. 2007, 42, 916–929. [Google Scholar] [CrossRef]

- Offiah, V.; Kontogiorgos, V.; Falade, K.O. Extrusion processing of raw food materials and by-products: A review. Crit. Rev. Food Sci. Nutr. 2019, 59, 2979–2998. [Google Scholar] [CrossRef]

- Ruiz-Armenta, X.A.; Zazueta-Morales, J.d.J.; Delgado-Nieblas, C.I.; Carrillo-López, A.; Aguilar-Palazuelos, E.; Camacho-Hernández, I.L. Effect of the extrusion process and expansion by microwave heating on physicochemical, phytochemical, and antioxidant properties during the production of indirectly expanded snack foods. J. Food Process. Preserv. 2019, 43, e14261. [Google Scholar] [CrossRef]

- Aguilar-Palazuelos, E.; Zazueta-Morales, J.D.J.; Martínez-Bustos, F. Preparation of high-quality protein-based extruded pellets expanded by microwave oven. Cereal Chem. 2006, 83, 363–369. [Google Scholar] [CrossRef]

- Raleng, A.; Singh, N.G.J.; Chavan, P.; Attkan, A.K. Opportunities in valorisation of industrial food waste into extruded snack products—A review. Indian J. Agric. Sci. 2022, 92, 1167–1174. [Google Scholar] [CrossRef]

- Sule, S.; Okafor, G.I.; Momoh, O.C.; Gbaa, S.T.; Amonyeze, A.O. Applications of food extrusion technology. MOJ Food Process. Technol. 2024, 12, 74–84. [Google Scholar] [CrossRef]

- Garber, B.W.; Hsieh, F.; Huff, H.E. Influence of Particle Size on the Twin-Screw Extrusion of Corn Meal. Cereal Chem. 1997, 74, 656–661. [Google Scholar] [CrossRef]

- Cheng, H.; Friis, A. Modelling extrudate expansion in a twin-screw food extrusion cooking process through dimensional analysis methodology. Food Bioprod. Process. 2010, 88, 188–194. [Google Scholar] [CrossRef][Green Version]

- Karkle, E.L.; Alavi, S.; Dogan, H. Cellular architecture and its relationship with mechanical properties in expanded extrudates containing apple pomace. Food Res. Int. 2012, 46, 10–21. [Google Scholar] [CrossRef]

- Saeleaw, M.; Dürrschmid, K.; Schleining, G. The effect of extrusion conditions on mechanical-sound and sensory evaluation of rye expanded snack. J. Food Eng. 2012, 110, 532–540. [Google Scholar] [CrossRef]

- Joshi, S.M.R.; Bera, M.B.; Panesar, P.S. Extrusion cooking of maize/spirulina mixture: Factors affecting expanded product characteristics and sensory quality. J. Food Process. Preserv. 2014, 38, 655–664. [Google Scholar] [CrossRef]

- Kristiawan, M.; Della Valle, G.; Kansou, K.; Ndiaye, A.; Vergnes, B. Validation and use for product optimization of a phenomenological model of starch foods expansion by extrusion. J. Food Eng. 2019, 246, 160–178. [Google Scholar] [CrossRef]

- Jain, R.; Goomer, S.; Singh, S.N. Mung-Oat snack of high protein content by twin screw extrusion using response surface methodology. Appl. Food Res. 2022, 2, 100099. [Google Scholar] [CrossRef]

- Jebalia, I.; Della Valle, G.; Kristiawan, M. Extrusion of pea snack foods and control of biopolymer changes aided by rheology and simulation. Food Bioprod. Process. 2022, 135, 190–204. [Google Scholar] [CrossRef]

- Li, R.; Wang, C.; Wang, Y.; Xie, X.; Sui, W.; Liu, R.; Wu, T.; Zhang, M. Extrusion Modification of Wheat Bran and Its Effects on Structural and Rheological Properties of Wheat Flour Dough. Foods 2023, 12, 1813. [Google Scholar] [CrossRef] [PubMed]

- Attenborough, E.; Creado, J.; Tiong, A.; Michalski, P.; Dhital, S.; Desai, K.; Hag, L.V. Feed composition and particle size affect the physicochemical properties of jackfruit-corn extrudates. LWT 2023, 185, 115148. [Google Scholar] [CrossRef]

- Rózanska-Boczula, M.; Wójtowicz, A.; Piszcz, M.; Soja, J.; Ignaciuk, K.K.-D.S.; Milanowski, M.; Kupryaniuk, K. Corn-Based Gluten-Free Snacks Supplemented with Various Dried Fruits: Characteristics of Physical Properties and Effect of Variables. Appl. Sci. 2023, 13, 10678. [Google Scholar] [CrossRef]

- Mitrus, M.; Wójtowicz, A.; Oniszczuk, T.; Combrzyński, M.; Bouasla, A.; Kocira, S.; Czerwińska, E.; Szparaga, A. Application of Extrusion-Cooking for Processing of White and Red Bean to Create Specific Functional Properties. Appl. Sci. 2023, 13, 1671. [Google Scholar] [CrossRef]

- Niu, Y.; Chen, H.; Zhang, Z.; Yuan, Y.; Dong, S.; Xu, Z. Effect of ethanol osmotic dehydration on CO2 puffing and drying mechanism of potato. Food Chem. X 2023, 18, 100715. [Google Scholar] [CrossRef]

- Katkar, K.C.; Pardeshi, I.L.; Swami, S.B.; Durgawati; Sutar, P.P.; Athmaselvi, K.A.; Sontakke, P.B. Study on high temperature short time (HTST) hot air puffing of rice. Dry. Technol. 2024, 42, 563–575. [Google Scholar] [CrossRef]

- Feng, L.; Xu, Y.; Xiao, Y.; Song, J.; Li, D.; Zhang, Z.; Liu, C.; Liu, C.; Jiang, N.; Zhang, M.; et al. Effects of pre-drying treatments combined with explosion puffing drying on the physicochemical properties, antioxidant activities and flavor characteristics of apples. Food Chem. 2021, 338, 128015. [Google Scholar] [CrossRef]

- Abul-Fadl, M.; Ghanem, T.; EL-Badry, N.; Nasr, A. Effect of puff drying on seedless grape fruits quality criteria compared to convective air drying. Al-Azhar J. Agric. Res. 2020, 45, 55–66. [Google Scholar] [CrossRef]

- Turkot, V.A.; Eskew, R.K.; Sullivan, J.F.; Cording, J., Jr.; Heiland, W.K. Explosion puffed dehydrated carrots. III. Estimated cost of commercial production using shortened cycle. U.S. Dept. Agric. Agric. Res. Serv. 1965, 73, 49. [Google Scholar]

- Sullivan, J.F.; Cording, J.R.; Eskew, R.K.; Heiland, W.K. Superheated steam aids explosion puffing. Food Eng. 1965, 37, 116. [Google Scholar]

- Xiaoping, F.; Yajun, W.; Zijue, Z.; Fangying, W.; Danyang, Y. A Review on Explosion Puffing Technology for Fruits and Vegetables. ETP Int. J. Food Eng. 2018, 4, 332–336. [Google Scholar] [CrossRef][Green Version]

- Hoke, K.; Houška, M.; Průchová, J.; Gabrovská, D.; Vaculová, K.; Paulíčková, I. Optimisation of puffing naked barley. J. Food Eng. 2007, 80, 1016–1022. [Google Scholar] [CrossRef]

- Nath, A.; Chattopadhyay, P.K. Effect of process parameters and soy flour concentration on quality attributes and microstructural changes in ready-to-eat potato-soy snack using high-temperature short time air puffing. LWT 2008, 41, 707–715. [Google Scholar] [CrossRef]

- Pardeshi, I.L.; Chattopadhyay, P.K. Hot air puffing kinetics for soy-fortified wheat-based ready-to-eat (RTE) snacks. Food Bioprocess Technol. 2010, 3, 415–426. [Google Scholar] [CrossRef]

- Minati, M.; Das, S.K. Effect of Process Parameters and Optimization on Microwave Puffing Performance of Rice. Res. J. Chem. Environ. 2011, 15, 454–461. [Google Scholar]

- Tabtiang, S.; Prachayawarakon, S.; Soponronnarit, S. Effects of osmotic treatment and superheated steam puffing temperature on drying characteristics and texture properties of banana slices. Dry. Technol. 2012, 30, 20–28. [Google Scholar] [CrossRef]

- Zou, K.; Teng, J.; Huang, L.; Dai, X.; Wei, B. Effect of osmotic pretreatment on quality of mango chips by explosion puffing drying. LWT 2013, 51, 253–259. [Google Scholar] [CrossRef]

- Raikham, C.; Prachayawarakorn, S.; Nathakaranakule, A.; Soponronnarit, S. Optimum Conditions of Fluidized Bed Puffing for Producing Crispy Banana. Dry. Technol. 2013, 31, 726–739. [Google Scholar] [CrossRef]

- Dhumal, C.V.; Pardeshi, I.L.; Sutar, P.P.; Babar, O.A.; Scholar, P.D. Optimization of Process Parameters for Development of Microwave Puffed Product. J. Ready Eat Food 2014, 1, 111–119. Available online: https://www.researchgate.net/publication/277197629_Optimization_of_Process_Parameters_for_Development_of_Microwave_Puffed_Product (accessed on 10 June 2024).

- Sharma, V.; Champawat, P.; Mudgal, V. Process development for puffing of Sorghum. Int. J. Curr. Res. Acad. Rev. 2014, 2, 164–170. Available online: https://citeseerx.ist.psu.edu/document?repid=rep1&type=pdf&doi=a9acd8ae9a7789eba0e3d78970b87db0032e39fc (accessed on 10 June 2024).

- Altan, A. Effects of pretreatments and moisture content on microstructure and physical properties of microwave expanded hull-less barley. Food Res. Int. 2014, 56, 126–135. [Google Scholar] [CrossRef]

- Nath, A.; Swain, K.C.; Khan, M.K. Development of ready-to-eat puffed carrot (Daucuscarota) cubes using HTST whirling bed. Int. Agric. Eng. J. 2015, 24, 1–9. [Google Scholar]

- Yi, J.Y.; Zhou, L.Y.; Bi, J.F.; Wang, P.; Liu, X.; Wu, X.Y. Influence of number of puffing times on physicochemical, color, texture, and microstructure of explosion puffing dried apple chips. Dry. Technol. 2016, 34, 773–782. [Google Scholar] [CrossRef]

- Rahman, H.A.; Salleh, M.H.M.; Salim, N.S. Effect of moisture content and microwave power on puffed yield and expansion volume of Malaysian paddy variety MR297. Malays. Appl. Biol. 2019, 48, 139–143. [Google Scholar]

- Yuan, Y.; Zhao, Z.; Wang, L.; Xu, Y.; Chen, H.; Kong, L.; Wang, D. Process optimization of CO2 high-pressure and low-temperature explosion puffing drying for apple chips using response surface methodology. Dry. Technol. 2020, 40, 100–115. [Google Scholar] [CrossRef]

- Deepak, S.; Sharmila, T.; Maheswari, M.; Shivaswamy, M.S. Optimization of variables that influence puffing quality of hot air oven puffed quinoa. Int. J. Pharm. Res. 2020, 12, 736–743. [Google Scholar] [CrossRef]

- Rajha, H.N.; Debs, E.; Rached, R.A.; El Khoury, K.; Al-Kazzi, M.; Mrad, R.; Louka, N. Innovation in cannon puffing technology for the homogenization of bulk treatment: Half-popped purple corn, a new healthy snack. J. Food Process Eng. 2021, 44, e13695. [Google Scholar] [CrossRef]

- Köprüalan, Ö.; Altay, Ö.; Bodruk, A.; Kaymak-Ertekin, F. Effect of hybrid drying method on physical, textural and antioxidant properties of pumpkin chips. J. Food Meas. Charact. 2021, 15, 2995–3004. [Google Scholar] [CrossRef]

- He, Y.; Ye, F.; Li, S.; Wang, D.; Chen, J.; Zhao, G. Effect of sand-frying-triggered puffing on the multi-scale structure and physicochemical properties of cassava starch in dry gel. Biomolecules 2021, 11, 1872. [Google Scholar] [CrossRef]

- Kumar, M.; Bharti, A.; Dhumketi, K.; Ansari, F.; Patidar, S.; Tiwari, P.N. Comparative Study of Nutritional and Physical Characteristics of Raw and Puffed Quinoa. Agric. Mech. Asia 2022, 53. Available online: https://www.researchgate.net/profile/Priyanka-Chauhan-27/publication/362090919_Comparative_Study_of_Nutritional_and_Physical_Characteristics_of_Raw_and_Puffed_Quinoa_Corresponding_author_1/links/62d648ded624055892756ab3/Comparative-Study-of-Nutritional-and-Physical-Characteristics-of-Raw-and-Puffed-Quinoa-Corresponding-author-1.pdf (accessed on 10 June 2024).

- Shavandi, M.; Javanmard, M.; Basiri, A. Novel infrared puffing: Effect on physicochemical attributes of puffed rice (Oryza sativa L.). Food Sci. Nutr. 2022, 11, 2141–2151. [Google Scholar] [CrossRef] [PubMed]

- Sompong, R.; Songsermpong, S. Production method and optimization of puffing tofu skin snack using home microwave oven. Agric. Nat. Resour. 2022, 56, 525–536. [Google Scholar] [CrossRef]

- Bahrani, S.A.; Monteau, J.-Y.; Rezzoug, S.-A.; Loisel, C.; Maache-Rezzoug, Z. Physics-based modeling of simultaneous heat and mass transfer intensification during vacuum steaming processes of starchy material. Chem. Eng. Process. Process Intensif. 2014, 85, 216–226. [Google Scholar] [CrossRef]

- Cheng, X.; Zhao, Y.; Shi, Q.; Barani, Y.H. Instant controlled pressure drop (DIC) as an effective pretreatment to intensify drying efficiency and enhance quality attributes of heat pump dried scallop adductors. Innov. Food Sci. Emerg. Technol. 2024, 94, 103701. [Google Scholar] [CrossRef]

- Rezzoug, S.A.; Maache-Rezzoug, Z.; Mazoyer, J.; Jeannin, M.; Allaf, K. Effect of instantaneous controlled pressure drop process on the hydration capacity of scleroglucan: Optimisation of operating conditions by response surface methodology. Carbohydr. Polym. 2000, 42, 73–84. [Google Scholar] [CrossRef]

- Tienda-Vazquez, M.A.; Perez-Herrera, M.; Carrasco-Morales, O.; Tellez-Perez, C.; Alonzo-Macias, M.; Cardador-Martínez, A. Techno-functional properties of Camelina sativa cake proteins treated with the instant controlled pressure drop (DIC) technology. Innov. Food Sci. Emerg. Technol. 2024, 95, 103741. [Google Scholar] [CrossRef]

- Pliego-Cortés, H.; Boy, V.; Bourgougnon, N. Instant Controlled Pressure Drop (DIC) as an innovative pre-treatment for extraction of natural compounds from the brown seaweed Sargassum muticum (Yendo) Fensholt 1955 (Ochrophytina, Fucales). Algal Res. 2024, 83, 103705. [Google Scholar] [CrossRef]

- Rezzoug, S.A.; Baghdadi, M.W.; Louka, N.; Boutekedjiret, C.; Allaf, K. Study of a new extraction process: Controlled instantaneous decompression. Application to the extraction of essential oil from rosemary leaves. Flavour Fragr. J. 1998, 13, 251–258. [Google Scholar] [CrossRef]

- Rezzoug, S.A.; Louka, N. Thermomechanical process intensification for oil extraction from orange peels. Innov. Food Sci. Emerg. Technol. 2009, 10, 530–536. [Google Scholar] [CrossRef]

- Rakotozafy, H.; Louka, N.; Thérisod, M.; Thérisod, H.; Allaf, K. Drying of baker’s yeast by a new method: Dehydration by Successive Pressure Drops (DDS). Effect on cell survival and enzymatic activities. Dry. Technol. 2000, 18, 2253–2271. [Google Scholar] [CrossRef]

- Haddad, J.; Juhel, F.; Louka, N.; Allaf, K. A study of dehydration of fish using successive pressure drops (DDS) and controlled instantaneous pressure Drop (DIC). Dry. Technol. 2004, 22, 457–478. [Google Scholar] [CrossRef]

- Louka, N.; Juhel, F.; Fazilleau, V.; Loonis, P. A novel colorimetry analysis used to compare different drying fish processes. Food Control 2004, 15, 327–334. [Google Scholar] [CrossRef]

- Arias, C.; Rodríguez, P.; Cortés, M.; Soto, I.; Quintero, J.; Vaillant, F. Innovative Process Coupling Short Steam Blanching with Vacuum Flash-Expansion Produces in One Single Stage High-Quality Purple Passion Fruit Smoothies. Foods 2022, 11, 832. [Google Scholar] [CrossRef]

- Iguedjtal, T.; Louka, N.; Allaf, K. Sorption Isotherms of Granny Smith Apples Hot-Air Dried and Texturized by “Controlled Sudden Decompression to the Vacuum “Sorption Isotherms of Granny Smith Apples Hot-Air Dried and Texturized by “Controlled Sudden Decompression to the Vacuum”. Int. J. Food Eng. 2007, 3. [Google Scholar] [CrossRef]

- Iguedjtal, T.; Louka, N.; Allaf, K. Sorption isotherms of potato slices dried and texturized by controlled sudden decompression. J. Food Eng. 2008, 85, 180–190. [Google Scholar] [CrossRef]

- Mounir, S.; Schuck, P.; Allaf, K. Structure and attribute modifications of spray-dried skim milk powder treated by DIC (instant controlled pressure drop) technology. Dairy Sci. Technol. 2010, 90, 301–320. [Google Scholar] [CrossRef]

- Alonzo-Macías, M.; Montejano-Gaitán, G.; Allaf, K. Impact of drying processes on strawberry (Fragaria var. Camarosa) texture: Identification of crispy and crunchy features by instrumental measurement. J. Texture Stud. 2014, 45, 246–259. [Google Scholar] [CrossRef]

- Mounir, S.; Allaf, T.; Sulaiman, I.; Allaf, K. Instant Controlled Pressure Drop (DIC) Texturing of Heat-Sensitive Spray-Dried Powders: Phenomenological Modeling and Optimization. Dry. Technol. 2015, 33, 1524–1533. [Google Scholar] [CrossRef]

- Mrad, R.; Rouphael, M.; Maroun, R.G.; Louka, N. Effect of expansion by ‘Intensification of Vaporization by Decompression to the Vacuum’ (IVDV) on polyphenol content, expansion ratio, texture and color changes of Australian chickpea. LWT 2014, 59, 874–882. [Google Scholar] [CrossRef]

- Hammoud, M.; Debs, E.; Broek, L.A.v.D.; Rajha, H.N.; Safi, C.; van Erven, G.; Maroun, R.G.; Chokr, A.; Rammal, H.; Louka, N. Intensification of extraction process through IVDV pretreatment from Eryngium creticum leaves and stems: Maximizing yields and assessing biological activities. Heliyon 2024, 10, e27431. [Google Scholar] [CrossRef] [PubMed]

- Abi-Khattar, A.-M.; Rajha, H.N.; Abdel-Massih, R.M.; Habchi, R.; Maroun, R.G.; Debs, E.; Louka, N. ‘Intensification of Vaporization by Decompression to the Vacuum’ (IVDV), a novel technology applied as a pretreatment to improve polyphenols extraction from olive leaves. Food Chem. 2021, 342, 128236. [Google Scholar] [CrossRef] [PubMed]

- Tannir, H.; Debs, E.; Mansour, G.; Neugart, S.; El Hage, R.; Khalil, M.I.; El Darra, N.; Louka, N. Microbial Decontamination of Cuminum cyminum Seeds Using ‘Intensification of Vaporization by Decompression to the Vacuum’: Effect on Color Parameters and Essential Oil Profile. Foods 2024, 13, 2264. [Google Scholar] [CrossRef] [PubMed]

- Lakkis, J.; Louka, N.; Haidar, E.; Kattour, N.; Karam, M.; Debs, E. Breakthrough in allergy mitigation using an innovative steam pressure-based processing technique. Appl. Food Res. 2024, 4, 100562. [Google Scholar] [CrossRef]

- Haidar, E.; Lakkis, J.; Karam, M.; Koubaa, M.; Louka, N.; Debs, E. Peanut Allergenicity: An Insight into Its Mitigation Using Thermomechanical Processing. Foods 2023, 12, 1253. [Google Scholar] [CrossRef]

- Haidar, E.; Mhasseb, C.; Khalil, J.; Saleh, S.; Al Rassy, G.; Louka, N.; Debs, E. A Journey through Peanut Processing Techniques for Mitigating Allergenicity: Unveiling Hypoallergenic Alternatives for Peanut-Allergic Patients. In Food Allergies; CRC Press: Boca Raton, FL, USA, 2024; pp. 68–96. [Google Scholar]

- Mrad, R.; Maroun, R.G.; Louka, N. Study of Intensification of Vaporization by Decompression to the Vacuum (IVDV) as an environment-friendly process on the expansion of maize. In Proceedings of the International Conference on Renewable Energies for Developing Countries 2014, Beirut, Lebanon, 26–27 November 2014; pp. 60–65. [Google Scholar] [CrossRef]

- Nader, J.; Afif, C.; Louka, N. A new eco-friendly defatting process of peanuts by mechanical expression preserving structure integrity (MEPSI). In Proceedings of the International Conference on Renewable Energies for Developing Countries 2014, REDEC, Beirut, Lebanon, 26–27 November 2014; pp. 54–59. [Google Scholar] [CrossRef]

- Mrad, R.; Debs, E.; Maroun, R.G.; Louka, N. Multiple optimization of chemical components and texture of purple maize expanded by IVDV treatment using the response surface methodology. Food Chem. 2014, 165, 60–69. [Google Scholar] [CrossRef]

- Mrad, R.; Assy, P.; Maroun, R.G.; Louka, N. Multiple optimization of polyphenols content, texture and color of roasted chickpea pre-treated by IVDV using response surface methodology. LWT 2015, 62, 532–540. [Google Scholar] [CrossRef]

- Nader, J.; Afif, C.; Louka, N. Expansion of partially defatted peanuts by a new texturizing process called ‘Intensification of Vaporization by Decompression to the Vacuum’ (IVDV). Innov. Food Sci. Emerg. Technol. 2017, 41, 179–187. [Google Scholar] [CrossRef]

- Nader, J.; Louka, N. Development of a novel technology entitled ‘Intensification of Vaporization by Decompression to the Vacuum’ (IVDV) for reconstitution and texturing of partially defatted peanuts. Innov. Food Sci. Emerg. Technol. 2018, 45, 455–466. [Google Scholar] [CrossRef]

- Francis, H.; Debs, E.; Maroun, R.; Louka, N. An eco-friendly process for the preservation of natural nutritious sprouts. In Proceedings of the 2020 5th International Conference on Renewable Energies for Developing Countries (REDEC), Marrakech, Morocco, 29–30 June 2021; pp. 3–8. [Google Scholar] [CrossRef]

- Rajha, H.N.; Azoury, J.; Debs, E.; El Azzi, E.; Louka, N. Optimization of peanuts’ defatting using Ired- Irrad®, a newly-patented green and low-cost technology. In Proceedings of the 2020 5th International Conference on Renewable Energies for Developing Countries (REDEC), Marrakech, Morocco, 29–30 June 2020; pp. 1–4. [Google Scholar] [CrossRef]

- Raza, H.; Ameer, K.; Zaaboul, F.; Shoaib, M.; Pasha, I.; Nadeem, M.; Ren, X.; Zhang, L. Effects of intensification of vaporization by decompression to the vacuum (IVDV) and frying on physicochemical, structural, thermal, and rheological properties of chickpea (cicer arietinum l.) powder. Food Sci. Technol. 2021, 41, 669–677. [Google Scholar] [CrossRef]

- Francis, H.; Debs, E.; Maroun, R.G.; Louka, N. Enhancing Wheat Sprout Attributes Using ‘Intensification of Vaporization by Decompression to the Vacuum’, an Innovative Drying—Texturizing Technology. Agriculture 2024, 14, 515. [Google Scholar] [CrossRef]

- Labaky, P.; Dahdouh, L.; Grosmaire, L.; Rajha, H.N.; Ricci, J.; Delpech, C.; El Khoury, A.; Debs, E.; Wisniewski, C.; Louka, N. Improving dried mango physicochemical properties using conventional hot-air drying coupled with a novel technology ‘intensification of vaporization by decompression to the vacuum’. Innov. Food Sci. Emerg. Technol. 2024, 95, 103739. [Google Scholar] [CrossRef]

- Ziaiifar, A.M.; Achir, N.; Courtois, F.; Trezzani, I.; Trystram, G. Review of mechanisms; conditions, and factors involved in the oil uptake phenomenon during the deep-fat frying process. Int. J. Food Sci. Technol. 2008, 43, 1410–1423. [Google Scholar] [CrossRef]

- Asokapandian, S.; Swamy, G.J.; Hajjul, H. Deep fat frying of foods: A critical review on process and product parameters. Crit. Rev. Food Sci. Nutr. 2020, 60, 3400–3413. [Google Scholar] [CrossRef]

- Alam, M.S.; Kaur, J.; Khaira, H.; Gupta, K. Extrusion and Extruded Products: Changes in Quality Attributes as Affected by Extrusion Process Parameters: A Review. Crit. Rev. Food Sci. Nutr. 2016, 56, 445–473. [Google Scholar] [CrossRef]

- Choton, S.; Gupta, N.; Bandral, J.D.; Anjum, N.; Choudary, A. Extrusion technology and its application in food processing: A review. Pharma Innov. 2020, 9, 162–168. [Google Scholar] [CrossRef]

- Bordoloi, R.; Ganguly, S. Extrusion Technique in Food Processing and a Review on Its Various Technological Parameters. J. Sci. Res. Technol. 2014, 2, 1–3. Available online: https://www.researchgate.net/publication/263535708_EXTRUSION_TECHNIQUE_IN_FOOD_PROCESSING_AND_A_REVIEW_ON_ITS_VARIOUS_TECHNOLOGICAL_PARAMETERS?enrichId=rgreq-029c89b118010b7d56c5d0172981149a-XXX&enrichSource=Y292ZXJQYWdlOzI2MzUzNTcwODtBUzoxMTQxNDUwOTM0OTI3MzhAMTQwNDIyNTcxOTgzNA%3D%3D&el=1_x_3&_esc=publicationCoverPdf (accessed on 28 May 2024).

- Mishra, G.; Joshi, D.C.; Panda, B.K. Popping and Puffing of Cereal Grains: A Review. J. Grain Process. Storage 2014, 1, 34–46. Available online: https://www.researchgate.net/profile/Gayatri-Mishra-4/publication/283355236_Popping_and_Puffing_of_Cereal_Grains_A_Review/links/5637441d08aebc004000e0d6/Popping-and-Puffing-of-Cereal-Grains-A-Review.pdf?__cf_chl_tk=MdCX8hCVHatHskparleCSGfY2D2Y2I0r2BzsTIIwzeg-1741254117-1.0.1.1-.J7VECoflhPEUkgxXcy8G828h7mfEifqNnRqy3bm5II (accessed on 28 May 2024).

- Mounir, S.; Allaf, T.; Mujumdar, A.S.; Allaf, K. Swell Drying: Coupling Instant Controlled Pressure Drop DIC to Standard Convection Drying Processes to Intensify Transfer Phenomena and Improve Quality—An Overview. Dry. Technol. 2012, 30, 1508–1531. [Google Scholar] [CrossRef]

| Methods/Year/Reference | Target Product(s) | EFs (Ratio, mL/g) | Pre-Treatment | Post-Treatment | Parameters and Outcomes |

|---|---|---|---|---|---|

| Popping (2002) [59] | Popped amaranth snacks | 5.2 | -Drying: 30 °C → W = 10–11% d.b. -Hydration → W = 12% d.b. -Storage: 48 h | N/A | -T = 240 °C -Load = 22 g -Airflow = 0.013 m3/s -Crunching = 13 ± 3.7 |

| Popping (2004) [60] | Popcorn | Specific volume: -Microwave popping: 33.1 mL/g -Conventional popping: 37.3 mL/g | -Moisture: 12.2% d.b. -Mixing of coating ingredients -Corn coating | Cooling: 3 min | Microwave popping: -Coating mixture: 4.4% salt, 5.9% vegetable oil, 0% sodium bicarbonate, and 16.4% butter -P (microwave) = 715 W/t = 2 min -Un-popped kernel ratio = 4.2%. Conventional popping: -Coating mixture: 3.5% salt, 6% vegetable oil, 0.10% sodium bicarbonate, and 12.9% butter -Un-popped kernel ratio = 0.2% |

| Microwave Popping (2004) [61] | Popcorn | Specific volume: 42.1 mL/g | -Drying -Hydration: distilled water -Storage: 5 °C, 35–40 days | N/A | -W = 14% d.b. -P (microwave) = 1200 W/t = 2.5–3 min -Flake size = 4.81 cm3 -Popping yield = 97.61% |

| Popping (2008) [62] | Popped sorghum | Specific volume: 16 mL/g | -Cleaning -Tempering: 25 °C, 4 h and 4 °C, 44 h -Drying → W = 12, 14 or 17% d.b. -Storage: 4 °C | -Separation of un-popped kernels. -Storage: plastic zip bags | -T = 200.3 °C/W = 17% d.b. -Popping yields ≥ 80% -Foam: L* = 75.8 ± 6.31 -Husk: L* = 27.3 ± 5.13 |

| Baking Popping (2010) [63] | Popped amaranth flour, gluten-free breads and cookies | -Cookies: 5.84 -Bread: 3.4 | -Mixing dough -Molding dough -Fermentation: 52 min, 86% relative humidity, 36 °C | N/A | -T = 205 °C/t = 17 min -HARD (cookies) = 10.88 N -Amaranth bread composition: 60:40 (popped/raw) |

| Popping (2014) [64] | Protein-rich popcorn | Specific volume: 5.63 ± 2 mL/g | -Overnight dipping in salt solution -Draining -Drying: 3–4 h, 150 °C | -Cooling -Packaging: polythene bags | -T = 250 °C/t = 5 min -15% salt in solution -Bulk density = 0.19 g/mL -L* = 54.13/a* = 10.79/b* = 22.3 |

| Microwave Popping (2015) [65] | Popped sorghum | 14.56 | -Hydration → W = 12, 16, and 20% w.b. -Storage: microwavable paper bag, room temperature | N/A | -W = 16.62% w.b. -Microwave power density = 18 W/g -P = 900 W/t = 140 s -Mixture: 0.55% salt and 10% oil -Popping yield = 82.3% |

| Microwave Popping (2015) [66] | Popped sorghum | 14.5 | -Hydration → 16.5 ± 0.5% w.b. -Coating: salt solution (0.5%) -Drying -Coating: oil 10 mL/100 g of grain -Packaging: microwave paper bags | -Cooling of chamber: 3 min -Handpicking of un-popped grains | -P = 900 W/t = 140 s -Grain size = 3.04 mm -Bulk density = 833.4 kg/m3 -Popping yield = 81.2% ± 0.6 -HARD = 103.46 N |

| Popping (2015) [67] | Popped sorghum | Specific volume: 6.5 mL/g | Hydration → 14% d.b. | N/A | -Popping yield = 87.4% -Processing losses < 3.7% -Size: extra-large white fully opened and excellent |

| Popping (2016) [68] | Popped brown rice snacks | 6.85 | -Soaking: water, 80 °C, 4 h -Autoclaving: 1.47 bar, 10 min -Drying: 40 °C -Mixing: salt solution -Drying | Sieving | -Salt content = 1.75 g/100 g raw material -W = 15% d.b./T = 225 °C -HARD = 15.68 ± 1.3 N -L*= 67.78/a* = 7.13/b* = 23.27 -Bulk density = 137.85 ± 2.8 kg/m3 |

| Popping (2017) [69] | Grain-based gluten-free snacks | N/A | Manual cleaning: remove impurities | -Grinding (T < 40 °C) → flour -Dough preparation -Cutting: cubes -Drying: 60 °C → W = 20% d.b. -Flake toasting: 180 °C, 3 min | -T = 260 °C -t = 30 s -HARD = 13.6 N -L* = 44.8/a* = 8.3/b* = 21.2/ΔE* = 56.9 |

| Popping (2018) [70] | Pseudo-cereal based on popped amaranth flour | 4.36 | -Cleaning and washing -Drying: 50 °C, 4 h -Grinding raw seeds → flour | -Sieving: 20 mesh size -Milling: popped seeds → flour | -T = 190 °C/t = 15 s -Popping yield = 76.2% -Flour recovery yield = 74.3% -Bulk density = 0.36 g/mL |

| Baking Popping (2018) [71] | Wheat bran-based bread | N/A | -Wheat bran addition: 5% flour basis -Water addition: 66.5, 67.75, and 69 mL | N/A | -Mean bubble size = 31.4 ± 1.1 µm -T (gelatinization) = 73.2 °C -HARD = 32 N |

| Microwave Popping (2018) [72] | Popcorn | 9.57 | -Drying → W = 11% w.b. -Placing grains in glass beaker -Covering glass beaker: aluminum foil -Puncturing aluminum: 2–3 holes | N/A | -Popping yield = 87.81% -T = 200 °C/t = 150 s -P (microwave) = 720 W |

| Microwave Popping (2020) [73] | Popcorn snacks | 13.5 | -Sieving and cleaning -Drying: 40 °C, V (air) = 0.5 m/s | N/A | -P (Microwave) = 1600 W/t = 2.9 min -Residue: 11% -11.39 ≤ W ≤ 12.91% d.b. -Toughness = 61 kg.s -L* = 86.8/a* = −0.6/b* = 4.5 |

| Baking Popping (2020) [74] | Lima bean aquafaba-infused eggless cupcakes | N/A | -Drying → 16% d.b. -Storage: 30 °C -Soaking: 2 L water, 12 h, room temperature -Air drying -Cooking: bean/water ratio 1:4) -Microwave: 840 W, 15 min -pH adjustment > 4 | N/A | -t (baking) = 60 min -Springiness = 8.79 mm -Gumminess = 2.47 g -Chewiness = 21.76 mJ Crumb: -HARD = 4.03 ± 0.55 N -L* = 79.54/a* = −1.20/b* = 26.13 Crust: -HARD = 3.3 ± 0.5 N -L* = 76.65/a* = −0.92/b* = 25.68 |

| Popping (2021) [75] | Popped sorghum | 4.3 | -Drying → 11% w.b. -Equilibration: 4 °C, 48 h | Cooling: 27 °C, 30 s | -T = 210 °C/t = 90 s -Popping yield = 71% -Peak temperature = 76.8 °C -ΔH (gelatinization) = 5.07 J/g -Double-helix degree = 0.987 |

| Popping (2022) [76] | Air-popped starch snacks | N/A | -Drying: 105 °C, 2 h -Grinding -Sieving: 106 µm -Rehydration: steam water 50 °C | -Molding: diameter 45 mm, depth 10 mm -Heat pressing: 230 °C, 4 s, 4 bar | -15 ≤ W ≤ 21% d.b. -T = 210 °C/t = 10 s -Density < 100 kg/m3 |

| Infrared (IR) Popping (2022) [77] | Popcorn | 22.5 | -Cleaning and sieving -Drying → 14% d.b. | N/A | -P (IR) = 550 W/d (lamp-grain) = 10 cm -Popping yield = 100% -Bulk density = 0.03 ± 0.01 g/cm3 -L* = 76.297/a* = −2.566/b* = 9.502 |

| Popping (2023) [78] | Rice flour-based bread | Specific volume: -Milyang260: 4.39 mL/g -Milyang261: 3.19 mL/g -Goamibyeo: 2.96 mL/g -Suweon: 2.18 mL/g | Preparation of rice flour: -Centrifugal disk dry-milling -Sieving < 125 μm -Storage: plastic bag, 4 °C Gelatinization of rice flour: -Hydration -Heating phase 1: 50 °C, 1 min -Heating phase 2: 95 °C, 3.8 min -Holding heat: 7 min and 18 s -Cooling: 30 min -Storage: 4 °C for 1 day | N/A | -20.82 ± 1.03 ≤ Amylose content ≤ 31.79 ± 1.48 -3.85 ≤ Crumb firmness ratio ≤ 6.25 |

| Methods/Year/Reference | Target Product(s) | EFs (Ratio, mm) | Pre-Treatment | Post-Treatment | Parameters and Outcomes |

|---|---|---|---|---|---|

| DF (1996) [79] | Tapioca starch crisps | 1 | -Mixture of tapioca starch and water -Steaming: 30 min -Cooling: room temperature -Conditioning: 5 °C, 21 h -Drying: 50 °C for 7 h | -Cooling -Surface de-oiling using filter paper | -T = 200 °C/t = 40 s/W = 15% d.b. |

| DF (2009) [83] | Rice crackers | 6.55 | -Soaking: 20 °C water, 16–18 h → W = 38% w.b. -Crushing -Steaming: 115 °C, 12–13 min -Resting and kneading -Mixing with fish powder -Cooling: 2–4 °C, 3 days -Cutting to pieces -Drying: 50–60 °C → 16% w.b. | -Centrifugation: 500 rpm, 30 s -Storage: 4 °C | -T = 220 °C/t = 60 s -Oil content: 20.22% -Fish powder: 10% -HARD = 6.27 N |

| DF (2011) [84] | Cassava-starch based crackers | 1.2 | -Boiling with water: 5 min -Drying: 96–98 °C, 50 min -Cooling: room temperature -Refrigeration: 4 °C, 12 h -Cut into slices -Drying: 60 °C, 4 h | -Cooling: 1 h, room temperature -Storage: plastic bags | -T = 160 °C/t = 30 s -HARD = 2.943 N |

| Vacuum Frying (2011) [85] | Banana snacks | 0.2 | -Ripening: 1–4 days -Peeling -Cutting: 3.5–4.5 mm slices | -Centrifugation (de-oiling): 5 min, 450 rpm | -P = 8.0 kPa/T = 110 °C/t = 20 min -Ripeness: 2nd day -HARD = 12.17 N |

| DF (2011) [86] | Snack products (legumes and cereal byproduct flours) | 0.71 | -Dehulling -Milling -Sieving: 100 µm -Cooling and storage | -Cooling: room temperature -Storage: 29 °C, humidity (67%), sealed polypropylene pouches | -T = 165 ± 2 °C/t = 3 min -Flour blend: red gram (20%), green gram (20%), black gram (20%), rice (40%) -Maximum shelf life: 24 days -Bulk density = 0.4 g/mL -HARD = 0.477 N -1st fracture deformation = 0.363 mm |

| DF (2018) [87] | Dough-based potato snacks | N/A | -Extrusion: 90 °C → square-tube potatoes -Drying: 10 ≤ W ≤ 12% d.b. | N/A | -T = 185 °C/t = 8 s -W (after frying) = 3% d.b AA concentration: Yellow square-tube potatoes: 20 µg/kg Green square-tube potatoes: 28 µg/kg Red square-tube potatoes: 92 µg/kg. |

| DF (2019) [88] | Wheat- and fish-based snacks | Thickness increase: 3.6 mm | Fish meat: -Grinding -Storage: polyethylene bags, –20 °C Fish bone: -Thawing and cutting -Cooking: pressure cooker (15 psi, 121 °C, 1 h) -Rinsing and mincing -Adding to bone: distilled ice water at a 0.9:1 ratio -High-pressure dispersion: 20 min, 7500 and 10,000 rpm -Milling: 5 min -Storage: 20 °C Dough: -Hydration -Shaping: 3 × 3 squares -Drying: 50 °C, 2 h | -Cooling -Storage: room temperature | Blend: wheat flour: 35.71%/potato powder: 28.57%/fish meat: 21.42%/fish bone: 14.28% -Bioavailable calcium: 37% -T = 165 °C/t = 30–35 s -HARD = 40.87 N -Water-holding capacity = 3.45 mL/g |

| DF (2020) [89] | Deep-fried potato crisps | N/A | Potato flakes production: -Boiling and mashing -Drying Potato crisp production: -Blending: parboiled rice flour and extruded rice flour, 2 min -Mixing and sheeting -Cutting: oval dough pieces | -Draining: 12 s. -Cooling: room temperature | -13.3 ≤ HARD ≤ 19.7 N. -0.199 ≤ density ≤ 0.241 g/cm3 -T = 180 °C/t = 12 s |

| DF (2023) [11] | Potato-based snacks | N/A | Grinding of carrots → pulp: particle size < 400 µm | Draining: oil with paper towels | -T = 180 °C/t = 15 s -Fresh carrot pulp: 10% -Total porosity = 67.30 ± 4.4% -Fracturability = 21.13 ± 2.91 N -Crispiness = 16.63 ± 1.72 N -HARD = 74.27 ± 6.36 N |

| DF (2023) [90] | Fried snacks (wheat flour, cassava flour, and corn bran) | 1.48 | -Mixing: 2 min -Hydration: W = 37.8% w.b. -Dough rest: 1 h -Sheeting -Cutting into disks | Centrifugation (de-oiling): 1400 rpm, 3 min | -Blend: wheat flour = 92%/cassava flour = 8% -Oil: refined bleached deodorized palm olein (2 L) -T = 170 °C/t = 5 min |

| DF (2023) [91] | Surimi-based deep-fried fish snacks | 1.75 | -Cutting: 600 g blocks -Storage: −80 °C -Hand blending: 1 min -Blending: 5 min -Molding dough -Drying: 50 °C, 4 h → 8.3 ≤ W ≤ 10.9% d.b. | N/A | -T = 190 °C/t = 40 s -Oil content: 32% -HARD = 350 N -L* = 68/a* = 16/b* = 38 |

| Methods/Year/Reference | Target Product(s) | ER | Pre-Treatment | Post-Treatment | Parameters and Outcomes |

|---|---|---|---|---|---|

| Twin-Screw Extrusion (TSE) (1997) [103] | Corn-based extrudates | -Fine flour: 4.69 -Flour: 4.51 -Meal: 4.45 -Grits: 4.47 -Coarse grits: 3.99 | Dry-milling into different granulations (50 → 1622 µm) | -Drying: W = 7% d.b. -Storage: polyethylene bags | -50 ≤ Particle size ≤ 1622 µm -19 ≤ W ≤ 22% d.b. -200 ≤ V (screw) ≤ 400 rpm |

| TSE (2010) [104] | Whole-wheat flour product and fish feed | N/A | N/A | -Drying: 100 °C, 12 min → 5 ≤ W ≤ 8% d.b. -Storage: 4 °C | -101 ≤ T ≤ 149 °C -9.2 ≤ W ≤ 15.8% d.b. -208 ≤ V (screw) ≤ 393 rpm |

| TSE (2012) [105] | Corn flour and apple pomace-based extruded snacks | 17% AP: 6.1 22% AP: 5.5 28% AP: 4.3 | -Blend preparation of corn starch: AP: 0% AP, 17% AP, 22% AP, and 28% AP. -Hydration: 17.5, 20 and 25% d.b. | -Manual cutting -Drying: 103 °C, 10 min | -d (screw) = 18 m/feed rate = 2.1 kg/h -V (screw) = 350 rpm -Addition 17% AP: W = 17.5% d.b./Specific Mechanical Energy (SME) = 840 kJ/kg/Density = 210 kg/m3 -Addition 22% AP: W = 17.5% d.b./SME = 550 kJ/kg/density = 190 kg/m3 -Addition 28% AP: W = 17.5% d.b./SME = 580 kJ/kg/density = 195 kg/m3 |

| TSE (2012) [106] | Rye-based snacks | 4.49 | N/A | -Cooling: room temperature -Storage in sealed polyethylene bags | -T (barrel) = 190 °C/W = 12% d.b. -Density = 0.08 g/cm3/Force = 15.98 N -Number of force peaks = 47.96 -Number of sound peaks = 339.77 -Mean of sound = 52.88 dB |

| TSE (2014) [107] | Maize-based extruded product | 1.61 | -Blend preparations: spirulina powder (7.5%) and maize flour (92.5%) -Hydration → 16% d.b. | -Cooling: room temperature, 20 min -Drying: 60 °C, 12 h -Storage: polyethylene bags, room temperature | -T (barrel) = 109.2 °C/V (screw) = 280 rpm -Overall acceptability = 6.12 -Desirability = 0.809 |

| TSE (2019) [108] | Expanded maize starches | 7 | N/A | N/A | -W = 22% d.b./T = 175 °C -SME = 120 kWh/t -η = 250 Pa.s |

| TSE (2022) [109] | Extruded mung–oat snacks | 3.79 | -Milling to particle size of >100 mm -Hydration → W = 14.797% d.b. -Homogenization of W: refrigeration overnight | -Drying: 100 °C, 30 min -Storage: polyethylene pouches | -V (screw) = 220 rpm/V (cutter) = 25 rpm -Die diameter = 3 mm -T (barrel) = 193.85 °C -Desirability = 0.793 -Bulk density = 0.021 g/cm3 (minimum) |

| TSE (2022) [110] | Pea flour snacks | Expansion avoided | N/A | N/A | -Starch/protein ratio = 2/1 -Flow rate (powder): QF = 0.24 kg/h -T (die) = 95 °C/W = 18–35% d.b. -V (screw) = 120–700 rpm -SME = 150–2000 kJ/kg |

| TSE (2023) [111] | Wheat bran-based flour dough | N/A | -Dough preparation -Sealing of dough: 30 min | -Drying: 50 °C, overnight -Grinding -Passing through a 60-mesh screen (particle size < 250 µm) | -rRtio length/diameter = 25 -V (screw) = 600 rpm -W = 25% d.b. -Stability ratio increase: 4.82 -Degree of softening decrease: 25.81% |

| TSE (2023) [112] | Extrudate expanded dried ripe jackfruit powder cornmeal | 2.8 | Jackfruit: within 7 days of harvest: storage in vacuum-sealed packs at 19 °C | Drying in oven: 2 h, 60 °C | -V (screw) = 150 rpm/feed rate = 400 g/h -Particle size = 500–1000 µm -W < 16% d.b. -30/70% (w/w%) ripe jackfruit/cornmeal -HARD = 23.8 N |

| Single-Screw Extrusion (2023) [113] | Corn-based crisps supplemented with fruits | Addition of -Apple: 4.05 -White mulberry: 3.85 -Goji berry: 4.14 -Elderberry: 4.21 -Blackberry: 3.74 | Grinding: dried fruits to powder | N/A | -Apple: addition 5%/V (screw) = 80 rpm/L* = 81.14/a* = 6.75/b* = 24.16 -White mulberry: addition 5%/V (screw) = 100 rpm/L* = 81.55/a* = 6.63/b* = 24.14 -Goji berry: addition 5%/V (screw) = 100 rpm/L* = 78.70/a* = 8.15/b* = 34.10 -Elderberry: addition 5%, V (screw) = 120 rpm/L* = 68.00/a* = 8.76/b* = 13.71 -Blackberry: addition 5%/V (screw) = 120 rpm/L* = 73.98/a* = 8.21/b* = 18.13 |

| TSE (2023) [114] | Extruded white and red beans | -Toska red bean: 4.4 -Aura white bean: 5.25 | -Grinding -Sieving: d = 1 mm | Cooling: room temperature | -V (screw) = 700 rpm -Feeding rate: 20 kg/h -Water addition: 0.8 L/h |

| Methods/Year/Reference | Target Product(s) | EFs (Ratio, mL/g) | Pre-Treatment | Post-Treatment | Parameters and Outcomes |

|---|---|---|---|---|---|

| Barrel Puffin (2007) [122] | Puffed naked barley | 4.7 | -Grinding -Polishing -Hydration -Storage: 20 °C, 48–72 h | N/A | -T = 550 °C/P = 0.9 MPa/W = 16.5% d.b. |

| High-Temperature Short-Time (HTST) Air Puffing (2008) [123] | Potato–soy snacks | 3.69 | Mixture preparation: -Mixing: soy flour with potato flour, water (5 °C) and salt -Kneading: 10–15 min -Shaping the dough | N/A | -W (initial) = 36.74% d.b. -T = 230 °C/t = 25.5 s -V (air) = 3.99 m/s -HARD = 27.02 N -Flour ratio: 10.31% soy flour: 89.69% potato flour |

| HTST Whirling-Bed Puffing (2010) [124] | Soy-fortified wheat-based snacks | 4.42 | -Blend of wheat and soy flour (ratio of soy: 7.5%) -Addition: 5 °C, salt water: 2% -Kneading: 12–15 min -Cutting: rectangles -Steaming: 70 kPa, 11 min | N/A | -W = 46.17% d.b./t = 30 s/T = 220 °C -V (air) = 3.95 m/s -Diffusivity = 1.15 × 10−9–2.58 × 10−9 m2/s -Activation energy = 2341.8 kJ/kg |

| Microwave Puffing (2011) [125] | Puffed rice snacks | 6.2 | -Parboiling milled rice -Addition of salt -Packaging and sealing | N/A | -P (microwave) = 850 W/t = 35 s -Salt content in rice = 5% -Puffing yield = 99.27% -Input energy = 29.75 KJ |

| Superheated Steam Puffing (2012) [126] | Puffed banana crisps | 0.675 | -Slicing: 3.5 mm thick -Blanching: 95 °C, 60 s -Osmotic treatment: 310 min -Drying: 90 °C, V (air) = 2 m/s | Drying: 90 °C → W (final) = 4% d.b. | -W (initial) = 30% d.b. -t = 150 s/T = 220 °C -V (air) = 2 m/s/P = 200 kPa -L* = 54.19/a* = 5.27/b* = 17.7 |

| Explosion Puffing Drying (2013) [127] | Puffed mango chips snacks | 1.88 | -Washing, peeling -Slicing: 26 × 26 × 5 mm pieces -Hot-air drying: 50 °C, V (air) = 2 m/s → W = 30% d.b. -Storage: 4 °C, 24 h | Vacuum drying: 180 min | -T = 95 °C/t = 5 min/W = 7.5% d.b. -Water activity (aw) = 0.470 ± 0.005 -HARD = 16.4 N ± 6.0 -Crispness = 7 N ± 3.1 -L* = 47.4/a* = 15.7/b* = 37.8/∆E* = 22.9 -Odor = 5.6/overall quality = 5.4 -Texture = 4.9/flavor = 4.9 |

| Fluidized-Bed Puffing (2013) [128] | Puffed banana crisps | N/A | -Peeling and slicing -Soaking sodium metabisulfite solution: 700 mg/L, 5 min -Drying: 90 °C, V (air) = 2 m/s → 26% d.b. | Drying: W (final) = 4% d.b. | -T = 163 °C/t = 1 min -V (air) = 3.5 m/s -HARD = 22.3 N -Number of peaks = 16 -L* = 44.3 ± 0.9 |

| Microwave Puffing (2014) [129] | RTE food based on millet flour and potato or sweet potato mash | 2.04 | -Steaming -Cooking: 98,066.5 Pa, 15 min | N/A | -P (microwave) = 1080 W/t = 60 s -W = 19.22% d.b. -HARD = 15.89 N -Number of peaks = 22 |

| Microwave Puffing (2014) [130] | Pre-cooked puffed sorghum | 8.67 | -Cleaning -Soaking: water, 150 min -Surface drying: 10 min | N/A | -W = 21% d.b./t = 3 min -P (microwave) = 100% -Flake size = 0.28 mL/grain -Puffing yield = 89% |

| Microwave Puffing (2014) [131] | Expanded hull-less barley snacks | 3.3 | -IR treatment: 200 °C, 2 min -Hydration -Storage: 4 °C overnight | -Drying: 100 °C, 5 min → W < 4.7% w.b. -Storage: room temperature | -W = 29.5% d.b. -P (microwave) = 850 W/t = 45–75 s -HARD = 10 N -L* = 68.4/a* = 6.7/b* = 18.2/ΔE* = 3.7 |

| HTST Whirling-Bed Treatment (2015) [132] | Puffed carrot cubes | 2.14 | -Dicing -Steam branching -Solution treatment: K2S2O5 and NaHSO3 -Partial drying: 70 °C, V (air) = 1.1 m/s | Toasting: 125 °C, 15 min | -T = 175 °C/t = 30 s -W (final) = 0.0456 d.b. -HARD = 2.231 N -a* = 24.65 |

| Explosion Puffing Drying (2016) [133] | Puffed apple chip snacks | 1.09 | -Refrigerating red Fuji apples: 4 °C, 2 weeks -Peeling, slicing -Drying: vacuum dryer, 60 °C -Sample equilibration: 4 °C, 12 h | Drying: 60 °C → W < 5% d.b. | -W (initial) = 90.32 ± 0.57% d.b. -W (final) = 5.7% d.b. -L* = 53/a* = 1/b* = 15.5/∆E* = 7.5 -HARD = 40.8 ± 2.3 N -Crispness = 8.8 ± 0.7 N/mm |

| Microwave Oven Puffing (2019) [134] | Puffed rice snacks | Specific volume: 2.22 mL/g | -Cleaning -Soaking: distilled water, 24 h | Cooling: 2 min | -W = 14% w.b. -P (microwave) = 800 W/t = 60 s |

| CO2 High-Pressure and Low-Temperature Explosion Puffing (2020) [135] | Puffed apple chips snacks | 1.7 | -Soaking: 1 g apples/10:6:7:7 mL (citric acid–ascorbic acid–sodium chloride–distilled water), 20 min. -Agitating every 5 min -Rinsing: distilled water -Hot-air drying (HAD): V (air) =2 m/s, 60 °C, 15 ≤ W ≤ 20% d.b. -Storage: 4 °C, 6–12 h | N/A | -T = 74 °C/W = 17% d.b./ΔP = 1.25 MPa -t (vacuum drying) = 33 min -Quantity of fractures = 29.3 |

| Hot-Air Puffing (2020) [136] | Puffed white quinoa | 4.20 | -Hydration: spraying salt solution -Tempering: 27 °C, 30 min | N/A | -W = 2% d.b./T = 253.8 °C/t = 60 s -Desirability = 0.962 -Flake size = 11.43 mm3 -Bulk density = 0.34 g/mL |

| Vacuum Cannon Puffing (VCP) (2021) [137] | Half-puffed purple corn snacks | 2.18 | Soaking methods: -Water, room temperature, 48 h -Boiling water, 40 min, ratio: 1 g kernels: 5 mL water | Drying: 185 °C, 5 min, V (fan) = 3.4 m/s | -P = 7.7 × 105 Pa/t = 14 s/W = 32.8% d.b. |

| Explosion Puffing Drying (2021) [138] | Puffed pumpkin chips | 4.97 | -Washing and peeling -Slicing -First freeze-drying: –18 °C, 24 h -Second freeze-drying: –55 °C, P (vacuum) = 0.10 mbar, W = 45%, 120 min | Vacuum drying: 25 kPa, 70 °C, 70 min | -T = 90 °C./t = 10 min/P = 190 kPa -W initial = 88.73% ± 0.90 w.b. -W final < 10% w.b. -Total phenolic content (TPC) = 1375.86 mg 100 g/DM -Bulk density = 26.98 ± 9.91 kg/m3 -HARD = 200 N -L* = 67.72/a* = 17.23/b* = 49.74 -∆E* = 19.47 |

| Sand-Frying Puffing (2021) [139] | Puffed–dried cassava starch gel and snacks | 10.69 | -Suspension of starch in 50 mL water -Steaming: 15 s -Boiling: 30 s -Cooling: 15 s -Storage: 4 °C, 24 h -Shaping: disk -Drying: 50 °C → W = 12% d.b. | -Packaging: polyethylene bags -Cooling: room temperature -Storage: desiccator | -W = 3.25% -Porosity = 89.04% -Surface temperature = 181.67 °C -L* = 66.84/a* = 1.35/b* = 4.64/∆E* = 29.13 -Bulk density = 0.21 g/mL -True density = 1.95 g/mL -HARD = 24.55 N -First peak force = 9.98 N |

| Puffing (2022) [140] | Puffed quinoa snacks | 8.2 | N/A | N/A | -T = 230 °C/t = 30 s/W = 6.70% d.b. -Density = 0.29 g/mL -Water absorption = 260% -L* = 81.30/a* = 1.90/b* = 19.45 |

| IR Radiation Puffing (2022) [141] | Puffed rice snacks | 2.24 | -Cleaning -Sieving -Storage -Hydration → W = 14% d.b. | N/A | -Distance (lamp) = 10 cm/P (IR) = 550 W -TPC = 0.06 mg GAE/g -Peroxide value = 0.9 mEq O2/kg oil -Bulk density = 0.29 ± 0.03 g/cm3 -L* = 72.56/a* = 1.27/b* = 16.51 -ΔE* = 10.98 |

| Microwave Oven Puffing (2022) [142] | Puffed tofu skin snacks | 4 | -Heating: 80 °C, 20 min -Rolling along the Teflon belt -Storage: 4 °C -Cutting: rectangles -Pre-drying: 40 °C → W = 55% w.b. | Drying: 135 °C, 2 h → 3.31% w.b. | -P = 1071 W/t = 111 s -HARD = 4.78 N -L* = 59.27/a* = 0.49/b* = 27.09 |

| Methods/Year/Reference | Target Product(s) | ER | Pre-Treatment | Post-Treatment | Parameters and Outcomes |

|---|---|---|---|---|---|

| DIC (2002) [52] | Expanded potatoes | 2 | -Washing and peeling -Cutting -Blanching: 95 °C, 7 min -Drying → W = 25% d.b. -Equilibration of water | Drying → W < 5% d.b. | -P = 5 bar/t = 45 s -Decompression → P = 0.15 bar -Drying kinetics: 400% time reduction |

| DIC (2004) [12] | Expanded potatoes, carrots, onions, broccoli, and tomatoes | -Potatoes: 2.3 -Carrots: 2.6 -Onions: 2.65 -Broccoli: 2.25 -Tomatoes: 4.55 | -Washing and peeling -Cutting -Blanching -Partial drying -Equilibration of water | Drying → W < 5% d.b. | Potatoes: -P = 10 bar/t = 40 s/W = 28% db. Carrots: -P = 5 bar/t = 25 s/W = 20% d.b. Onions: -P = 4.5 bar/t = 15 s/W = 10% d.b. Broccolis: -P = 7 bar/t = 10 s/W = 30% d.b. Tomatoes: -P = 7 bar/t = 15 s/W = 20% d.b. |

| DIC (2004) [53] | Expanded potatoes, carrots, and onions | Trial 1: -Potatoes: 2.05 -Carrots: 2.42 -Onions: 2.75 Trial 2: -Potatoes: 2.35 -Carrots: 2.3 -Onions: 2.8 | -Washing and peeling -Dicing -Blanching: potatoes (95 °C, 7 min) and carrots (95 °C, 5 min) -Drying → W (potatoes) = 13% d.b.; W (carrots) = 18% d.b.; W (onions) = 8.5% d.b. -Equilibration of water | Drying → W < 5% d.b. | Trial 1: Potatoes: -Step 1: 3 bar, 30 s/Step 2: 6 bar, 10 s Carrots: -Step 1: 2 bar, 30 s/Step 2: 6 bar, 6 s Onions: -Step 1: 2 bar, 20 s/Step 2: 6 bar, 8 s Trial 2 (with atmospheric air injection): Potatoes: -P = 7 bar/t = 45 s/W = 15% d.b. Carrots: -P = 6 bar/t = 20 s/W = 20% d.b. Onions: -P = 6 bar/t = 15 s/W = 10% d.b. |

| DIC (2007) [154] | Expanded apples | N/A | -Washing and peeling -Cutting: 1 cm cubes -Blanching: diluted lemon 50%, 10 min -Drying: 50 °C | Drying → W = 3% d.b. | -P = 5 bar/t = 20 s/W = 8% d.b. -Surface area = 466 m2/g |

| DIC (2008) [155] | Expanded potatoes | 1.45 | -Cutting -Blanching: 7 min, 95 °C -Drying: 60 °C | Drying → W = 3% d.b. | -P = 6 bar/t = 20 s/W = 15% d.b. |

| DIC (2010) [156] | Expanded spray-dried skimmed milk powder | N/A | -Spray drying (SD) -Rehydration: 6 °C, 24 h | Drying: 50 °C → W = 3% d.b. | -P = 5.7 bar/t = 16 s/W = 18% d.b. -Bulk density = 390 kg/m3 -Compressibility = 14.47% -Porosity = 71% |

| DIC-Assisted HAD (2014) [157] | Strawberry snacks | 3.62 | -HAD: 50 °C, 8 h → W = 18% d.b. -Storage/homogenization: 5 °C, 24 h | N/A | -P = 5.3 bar/t = 13 s -HARD = 7.65 N -Work done = 1.79 J |

| DIC (2015) [158] | Expanded powder granules | N/A | SD | -Drying: 50 ± 2 °C, 1.2 ± 0.2 m/s air stream -Storage | Skim milk powders: -P = 6 bar/t = 30 s/W = 12% d.b. -Specific surface area = 200 m2/kg Whey protein powders: -P = 6 bar/t = 30 s/W = 16% d.b. -Specific surface area = 320 m2/kg |

| Method/Year/Reference | Target Product(s) | ER | Pre-Treatment | Post-Treatment | Parameters and Outcomes |

|---|---|---|---|---|---|

| IVDV (2014) [159] | Expanded chickpeas | 1.65 | -Soaking: distilled water, 25 °C -Homogenization: 3 to 4 days, 4 °C | Drying: 50 °C, 24 h | -P = 8.5 bar/t = 20 s/W = 42% d.b. -TPC = 32.3 ± 0.6 mg GAE/100 mg DM -HARD = 10.9 N -Work done = 18 ± 2.3 mJ |

| IVDV (2014) [166] | Expanded maize | 2.65 | -Soaking: distilled water, 25 °C -Homogenization: 3 to 4 days, 4 °C | -Drying: 50 °C, 24 h -Roasting: 3 min, 220 °C | -P = 10 bar/t = 20 s/W = 25% d.b. |

| IVDV (2014) [167] | Partially defatted peanuts | 1.5 | -Cleaning and sieving -Air roasting: 140 °C for 15 min -Hydration -Homogenization: 2 days, 4 °C -Mechanical pressing: 97 bar, 4 min | -Drying: 50 °C, 1.5 h → 7 ≤ W ≤ 10% d.b. -Roasting: 180 °C, 3.5 min | -Defatting ratio = 56% -P = 9 bar/t = 10 s/W = 10% d.b. |

| IVDV (2014) [168] | Purple maize snacks | 2.97 | -Soaking: distilled water, 25 °C -Homogenization: 3 to 4 days, 4 °C | Drying: 50 °C, 24 h | -P = 10 bar/t = 20 s/W = 25% d.b. -TAC = 29.43 mg GAE/100 mg DM -TPC = 510.87 mg GAE/100 mg DM -HARD = 44.17 N -Work done = 137.9 mJ |

| IVDV (2014) [54] | Purple maize snacks | 3.13 | -Soaking: distilled water, 25 °C -Homogenization: 3 to 4 days, 4 °C | -Drying: 50 °C, 24 h -Roasting: 3 min, 220 °C | -P = 10 bar/t = 20 s/W = 25% d.b. -TAC = 38.35 ± 3.3 mg GAE/100 mg DM -TPC = 602.87 ± 22 mg GAE/100 mg DM -HARD = 58.78 ± 1.61 N -Work done = 240.7 ± 7.6 mJ |

| IVDV (2015) [55] | Expanded chickpeas | 1.61 | -Soaking: distilled water, 25 °C -Homogenization: 3 to 4 days, 4 °C | -Drying: 50 °C, 24 h. -Roasting: 3 min, 190 °C | -P = 8.5 bar/t = 20 s/W = 42% d.b. -HARD = 10.9 ± 0.78 N -Work done = 11.8 ± 2.8 mJ -L* = 46.39/a* = 12.86/b* = 24.28 -ΔE* = 5.35 -TPC = 53.9 ± 1.5 mg GAE/100 mg DM |

| IVDV (2015) [169] | Expanded chickpeas | 1.63 | -Soaking: distilled water, 25 °C -Homogenization: 4 days, 4 °C | -Drying: 50 °C, 24 h -Roasting: 3 min, 190 °C | -P = 6.5 bar/t = 75 s/W = 42% d.b. -HARD = 12.29 N -Work done = 10.6 mJ -L* = 43.43/a* = 15.21/b* = 24.51 -TPC = 43.94 mg GAE/100 mg DM |

| IVDV (2017) [170] | Partially defatted peanuts | 1.9 | -Dehulling -Drying: 2–3 days → W = 5.56 ± 0.24% d.b. -Cleaning and sieving -Light roasting: 140 °C, 15 min -Homogenization: PVC bags, 3 days, 4 °C -Mechanical pressing: bar, 240 s -Rehydration and homogenization | -Drying: 50 °C → 7.5 ≤ W ≤ 11% d.b. -Roasting: 180 °C, 210 s | -P = 11.9 bar/t = 17.4 s/W = 7.1% d.b. -Defatting ratio = 45% |

| IVDV (2018) [171] | Partially defatted peanuts | N/A | -Drying: 140 °C, 15 min → 2.48% d.b. -Hydration → 5% d.b. -Storage: PVC bags, 4 °C, 3 days -Mechanical pressing: 62 bar, 240 s -Rehydration: 25 °C -Homogenization: 4 °C, 3 days | -Drying: 50 °C → 7.5 ≤ W ≤ 11% d.b. -Roasting: 180 °C, 210 s | -P = 9.1 bar/t = 17.1 s/W = 19.9% d.b. -Defatting ratio = 45.02% -HARD = 5.94 N -1st fracture deformation = 6.72% -Work done = 5.76 mJ -Quantity of fractures = 14 |

| IVDV (2020) [172] | Sprouts | N/A | -Soaking and germination. -Partial drying → W = 25% d.b. | -Drying: 50 °C → W = 4% d.b. | -P = 4.5 bar/t = 12 s/W = 25% d.b. -Energy consumption decrease = 55% |

| IVDV (2020) [173] | Partially defatted peanuts | N/A | -IR treatment: 88.5 °C, 56 min -Hydraulic pressing: 80 bar, 1 min | N/A | -Defatting ratio = 45% -IR treatment = 88.5 °C, 56 min -Pressing: 80 bar, 1 min |

| IVDV (2021) [174] | Expanded chickpeas | N/A | -Hydration -Homogenization: PVC bags at 4 °C for 1–2 days | -Drying: 50 °C, 24 h -Roasting: 200 °C, 6 min | -L* = 83.43/a* = 3.09/b* = 24.58 -aw = 0.08 |

| IVDV (2024) [175] | Sprouts | 1.6 | -Soaking: 3 h, mineral water, mass-to-volume ratio of 1:5 (g/mL) -Germination: 22 °C ± 1 °C, 7 days | N/A | -P = 5.5 bar/t = 15.4 s/W = 8.8% d.b. -Vit. B2 = 2.05 mg/kg -Vit. B6 = 5.02 mg/kg -Vit. E = 14.08 mg/kg |

| IVDV (2024) [176] | Expanded mangos | 3.82 | -Washing -Cutting: cubes 1 cm3 -Hydration: <30 s → W = 880% d.b. -Drying: 60 °C → W = 22.5% d.b. -Homogenization: 4 °C, 4 days | -Drying: 60 °C → W = 5.5% d.b. | -P = 4.5 bar/t = 22.5 s -HARD = 8.49 N -Work done = 66.85 mJ -Drying time decrease: 50% -Phenolic content increases 9 times -Antioxidant activities increase 11 times |

| Methods | Advantages | Disadvantages |

|---|---|---|

| DF | Rich, savory flavor; crispy texture; reduced cooking time [177] | Health risks associated with fried food consumption [178] |

| ME | Cost-effective; scalable [179]; handles diverse raw materials [180]; produces various textures [181] | Inconsistent expansion; potential flavor/color changes [180] |

| Popping | Minimal oil usage; low-calorie; airy snacks [33,182] | High energy consumption; risk of nutrient degradation [33] |

| Puffing | Convenient and versatile [33]; preserves many original organoleptic qualities [182] | Degradation at high temperatures and pressures; potential undesirable changes [33] |

| DIC | Significant microbial reduction [183]; extended shelf life [52]; improved color and texture [153] | Risk of additional thermal degradation during the initial pressure-increase phase [174] |

| IVDV | Rapid high-pressure treatment [159]; low degradation risk [176]; extended shelf life; improved color and texture [171] | Requires further improvements in the treatment of powdered products |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahfoud, F.; Frem, J.; Assaf, J.C.; Maache-Rezzoug, Z.; Rezzoug, S.-A.; Elias, R.; Debs, E.; Louka, N. Evolution of Dried Food Texturization: A Critical Review of Technologies and Their Impact on Organoleptic and Nutritional Properties. Processes 2025, 13, 799. https://doi.org/10.3390/pr13030799

Mahfoud F, Frem J, Assaf JC, Maache-Rezzoug Z, Rezzoug S-A, Elias R, Debs E, Louka N. Evolution of Dried Food Texturization: A Critical Review of Technologies and Their Impact on Organoleptic and Nutritional Properties. Processes. 2025; 13(3):799. https://doi.org/10.3390/pr13030799

Chicago/Turabian StyleMahfoud, Freddy, Jessica Frem, Jean Claude Assaf, Zoulikha Maache-Rezzoug, Sid-Ahmed Rezzoug, Rudolph Elias, Espérance Debs, and Nicolas Louka. 2025. "Evolution of Dried Food Texturization: A Critical Review of Technologies and Their Impact on Organoleptic and Nutritional Properties" Processes 13, no. 3: 799. https://doi.org/10.3390/pr13030799

APA StyleMahfoud, F., Frem, J., Assaf, J. C., Maache-Rezzoug, Z., Rezzoug, S.-A., Elias, R., Debs, E., & Louka, N. (2025). Evolution of Dried Food Texturization: A Critical Review of Technologies and Their Impact on Organoleptic and Nutritional Properties. Processes, 13(3), 799. https://doi.org/10.3390/pr13030799