Quantitative Prediction Method for Post-Fracturing Productivity of Oil–Water Two-Phase Flow in Low-Saturation Reservoirs

Abstract

:1. Introduction

2. Methodology

2.1. Establishment of Post-Fracturing Oil–Water Two-Phase Productivity Prediction Model

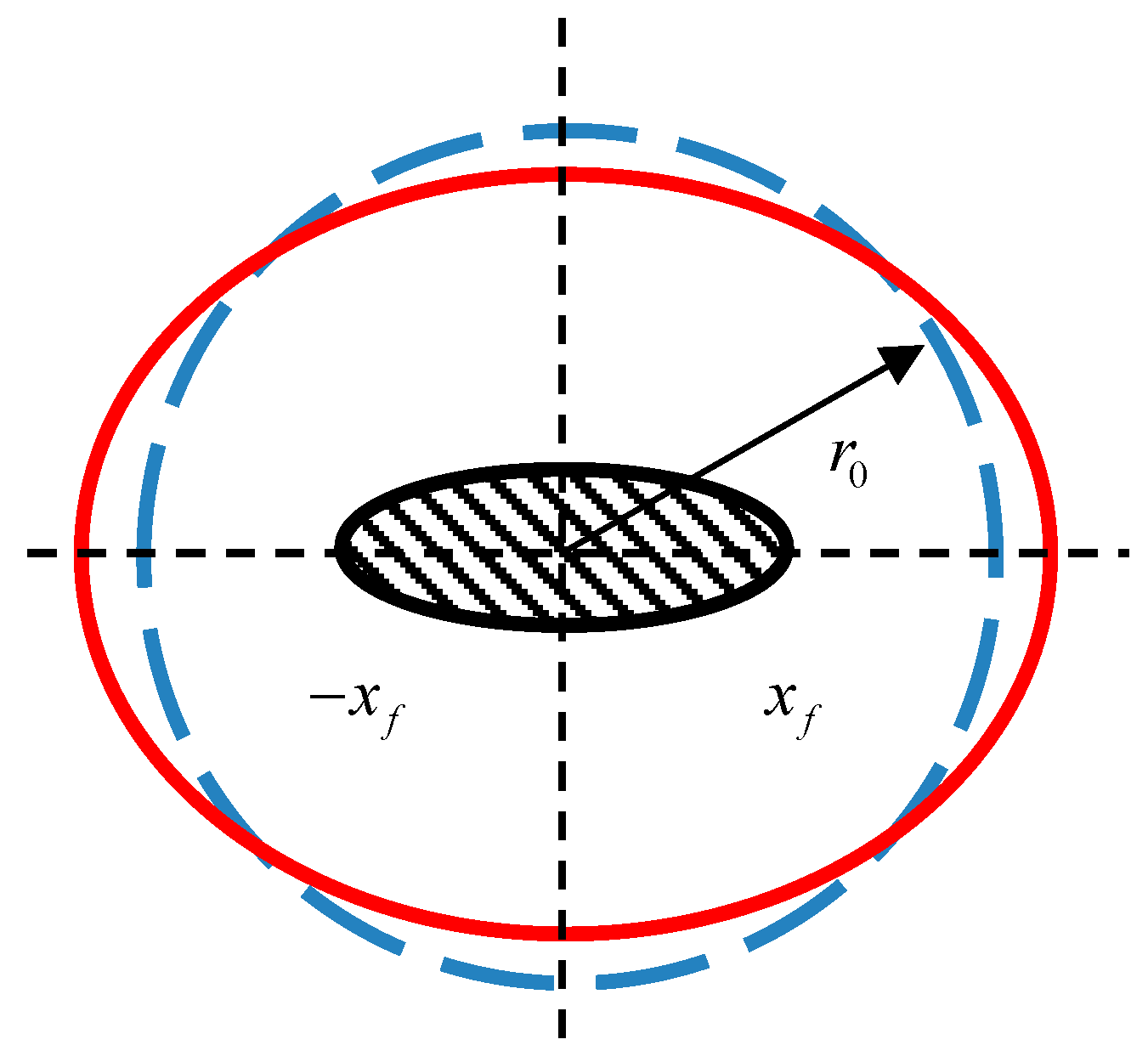

2.1.1. Establishment of Steady-State Productivity Prediction Model Based on Elliptical Fracture

2.1.2. Establishment of Post-Fracturing Productivity Prediction Model Considering Starting Pressure Gradient

- (1)

- Outer Flow Field (Matrix Region)

- (2)

- Inner Flow Field (Fracture Region)

2.1.3. Establishment of Post-Fracturing Productivity Prediction Model Considering Oil-Water Two-Phase Flow

2.2. Basic Parameter Calculation for Post-Fracturing Productivity Model

2.2.1. Starting Pressure Gradient

2.2.2. Calculation of Fracturing Fracture Parameters

Fracture Length

Fracture Permeability

Fracture Width

2.2.3. Calculation of Relative Permeability

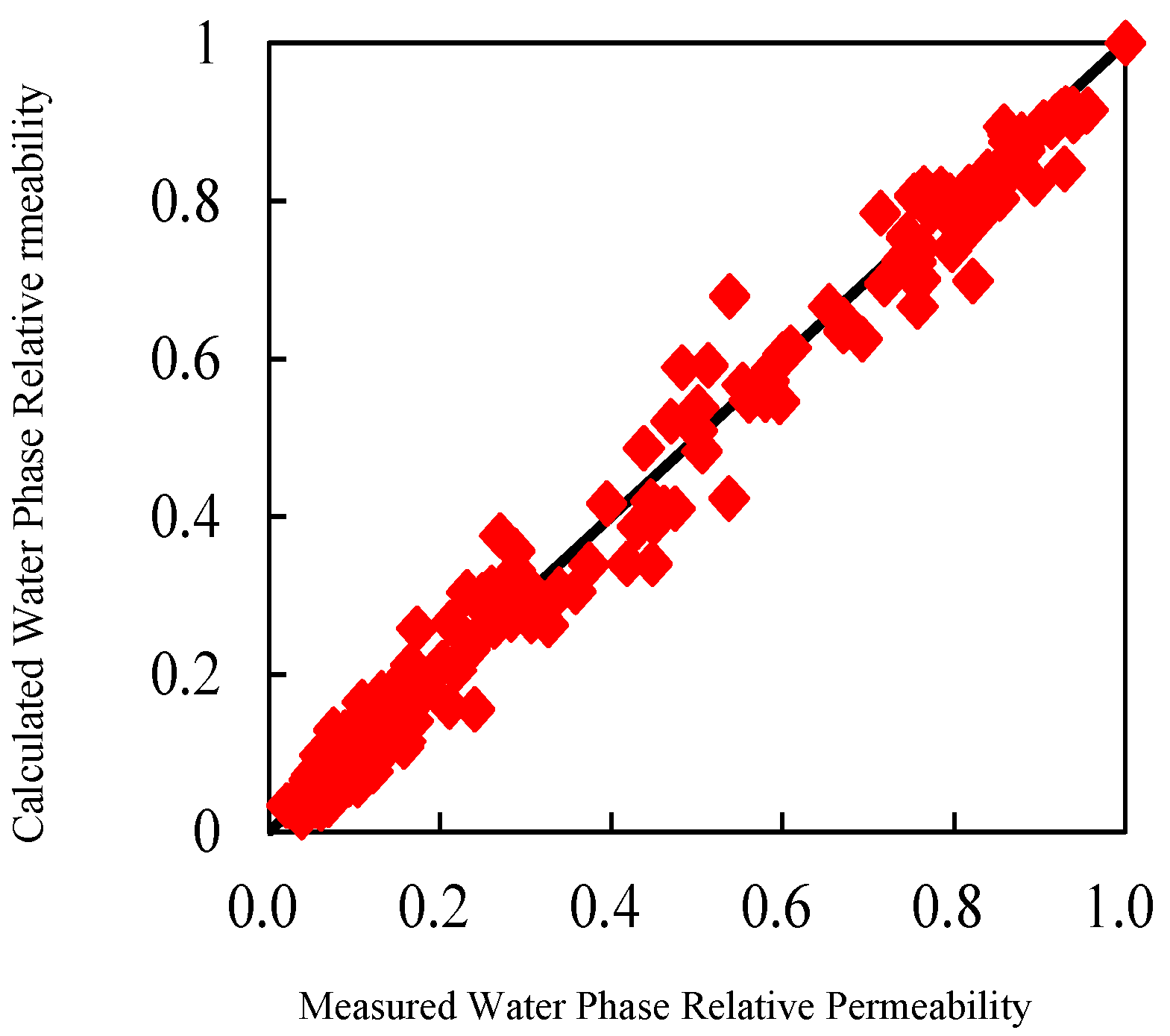

Calculation of Oil–Water Two-Phase Relative Permeability

Determination of Model Parameters

3. Results

4. Discussion

5. Conclusions

- (1)

- By applying the linear flow seepage formula for elliptical fractures and considering the influence of the SPG in low-permeability reservoirs, a theoretical model for predicting the PFP of oil–water two-phase flow was established. Through the interpretation and verification of the productivity of 111 small horizons in 34 actual wells, the conformity rate for oil production was 77.5%, and the conformity rate for water production was 73.2%, with an improvement of over 15% in the interpretation conformity rate. Compared with actual well test productivity, the mean absolute error of oil productivity prediction is 3.51 t/d, and the mean absolute error of water productivity prediction is 12.37 t/d, which can fully meet the evaluation requirements for field PFP prediction.

- (2)

- Using formation parameters, logging parameters and fracturing operation parameters, formulas were established for calculating basic parameters such as fracture length, fracture width and fracture permeability. The results of processing actual well data indicate that these basic parameters can meet the accuracy requirements for quantitative productivity prediction.

- (3)

- By introducing an empirical coefficient and improving the empirical relationship between relative permeability and saturation, a model for the relationship between relative permeability and saturation was established. Using experimental data from simultaneous relative permeability and resistivity measurements as well as supporting experimental data, formulas for calculating each parameter in the model were provided, which improved the accuracy of calculating the relative permeability of oil and water in the reservoir.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, X.Y.; Wan, Q.S.; Wang, F.L. Interpretation method of oil-water layer in low oil-saturation reservoirs: A case study in Putaohua reservoirs in Gu628 Block of Xinzhao Oilfield. J. Prog. Geophys. 2021, 36, 1088–1094. (In Chinese) [Google Scholar]

- He, A.T.; Yan, J.P.; Huang, L.S. Oil heterogeneity characteristics of low oil saturation sandstone reservoirs in M area of junggar basin. J. Well Logg. Technol. 2023, 47, 476–485. (In Chinese) [Google Scholar]

- Xu, X.C. Genesis of low oil-saturated reservoir of Putaohua oil layer in Gulong Sag. J. Fault Bl. Oil Gas Fld. 2017, 24, 320–323. (In Chinese) [Google Scholar]

- Liu, G.Q.; Yuan, C. Refined log evaluation method for recoverable reserves and production enhancement on low saturation oil-bearing reservoirs. J. World Pet. Ind. 2025, 32, 27–42. (In Chinese) [Google Scholar]

- Zou, C.N.; Zhu, R.K.; Wu, S.T. Types, characteristics, genesis and prospect of conventional and unconventional hydrocarbon accumulations: Taking tight oil and tight gas in China as an instance. J. Acta Pet. Sin. 2012, 33, 173–187. (In Chinese) [Google Scholar]

- Ji, T.L.; Lu, S.F.; Tang, M.M. Productivity predicting method of the fractured horizontal wells in the tight oil reservoirs. J. Daqing Pet. Geol. Dev. 2016, 35, 165–169. (In Chinese) [Google Scholar]

- Liu, K.; Sun, J.M.; Wang, Y. Tight oil reservoir productivity prediction after fracturing in horizontal wells. J. Sci. Technol. Eng. 2017, 35, 165–169. (In Chinese) [Google Scholar]

- Zhang, L.H.; Pan, B.Z.; Zhuang, H. Productivity log forecasting method for Post-frac reservoir with low porosity and low permeability. J. Well Logg. Technol. 2012, 36, 101–105. (In Chinese) [Google Scholar]

- Guo, J.C.; Liu, H.; Zeng, F.H. Influence of varying fracture width on fractured wells long-term productivity. J. China Univ. Pet. 2015, 39, 111–115. (In Chinese) [Google Scholar]

- Xiong, J.; Yu, L.J.; Guo, P. Analysis on productivity equation of fractured well in low permeability gas reservoir with Non-Linear seepage. J. Nat. Gas Oil. 2012, 30, 42–45+4. (In Chinese) [Google Scholar]

- He, Y.F.; Xu, L.Y.; Lu, W.Y. Productivity analysis of fractured well in low permeability gas reservoir. J. Spec. Oil Gas Reserv. 2006, 13, 59–61+107. (In Chinese) [Google Scholar]

- Yin, H.J.; Liu, Y.; Fu, C.Q. Productive analysis of fractured well in low permeability reservoir. J. Xinjiang Pet. Geol. 2005, 26, 285–287. (In Chinese) [Google Scholar]

- Prats, M. Effect of vertical fractures on reservoir behavior incompressible fluid case. In Proceedings of the 35th Annual Fall Meeting of SPE, Denver, CO, USA, 2–5 October 1960. [Google Scholar]

- Raymond, L.R.; Binder, G.G., Jr. Productivity of wells in vertically fractured damaged formations. J. Pet. Technol. 1967, 19, 120–130. [Google Scholar]

- Agarwal, R.G.; Carter, R.D.; Pollock, C.B. Evaluation and performance prediction of low-permeability gas wells stimulated by massive hydraulic fracturing. J. Pet. Technol. 1979, 31, 362–372. [Google Scholar]

- Mao, C.H.; Huang, F.S.; Hu, Q.J. Optimization simulation of hydraulic fracture parameters for highly deviated wells in tight oil reservoirs, based on the reservoir fracture productivity coupling model. Processes 2024, 12, 179. [Google Scholar] [CrossRef]

- Poe, B.D. Production performance evaluation of hydraulically fractured wells. In Proceedings of the 2000 SPE/CERI Gas Technology Symposium, Calgary, AB, Canada, 3–5 April 2000. [Google Scholar]

- Wu, M.L.; Zhu, J.M.; Li, L.L. Calculation of perforated vertical and horizontal well productivity in low-permeablility reservoirs. SPE Drill. Compl. 2019, 35, 218–236. [Google Scholar]

- Zhao, Y.L.; Zhang, L.H.; He, Z.X. Productivity for horizontal wells in low permeability reservoir with oil/water two-phase flow. Math. Probl. Eng. 2014, 14, 364678. [Google Scholar]

- Sun, Y.T.; Wang, J.W.; Wang, T. Post-Fracture production prediction with production segmentation and well logging: Harnessing pipelines and hyperparameter tuning with GridSearchCV. Appl. Sci. 2024, 14, 3954. [Google Scholar] [CrossRef]

- Jiang, T.X.; Shan, W.W.; Yang, Y.L. The calculation of stable production capability of vertical fracture well. J. Pet. Explor. Dev. 2001, 28, 61–63. (In Chinese) [Google Scholar]

- Zhang, J.Q.; Lei, X.; Zhang, Q.L. Productivity evaluation of water-producing fractured horizontal wells in low permeability gas reservoir. Nat. Gas Geosci. 2019, 30, 1701–1708. (In Chinese) [Google Scholar]

- Li, S.Q.; Cheng, L.S.; Li, X.S. Non-linear seepage flow models of ultra-low permeability reservoirs. J. Pet. Explor. Dev. 2008, 35, 606–612. (In Chinese) [Google Scholar]

- Deng, Y.E.; Liu, C.Q. Theory of oil water flow through porous media and calculation of development indexes with starting pressure gradient included. J. Explor. Dev. 1998, 25, 36–39. (In Chinese) [Google Scholar]

- McGuire, W.J.; Sikora, V.J. The effect of vertical fractures on well productivity. J. Pet. Technol. 1960, 12, 72–74. [Google Scholar]

- Wang, R. Fracturing well productivity of low permeability reservoir with taking the oil-water two phase flow into consideration. J. Reserv. Eval. Dev. 2021, 11, 60–765. (In Chinese) [Google Scholar]

- Huang, S.J.; Hou, D.L.; Qiang, X.Y. A new method for evaluating the gas-water two-phase productivity of fractured straight wells in tight sandstone gas reservoirs. J. Unconv. Oil Gas. 2023, 10, 68–74. (In Chinese) [Google Scholar]

- Deng, M.Z.; Niu, N.; Yin, S. Gas-water two-phase productivity prediction model of multistage fractured horizontal wells in anisotropic tight sandstone gas reservoirs. J. Pet. Geol. Recovery Effic. 2024, 31, 99–111. (In Chinese) [Google Scholar]

- Mohan, J. Effect of non-Dracy flow on well productivity for hydraulically fractured gas-condensate well. In Proceedings of the 2006 Annual Technical Conference and Exhibition, San Antonio, TX, USA, 24–27 September 2006. [Google Scholar]

- Nordgren, R.P. Propagation of a vertical hydraulic fracture. In Proceedings of the SPE 45th Annual Fall Meeting, Houston, TX, USA, 4–7 October 1970. [Google Scholar]

- Bird, R.B.; Stewart, W.E.; Lightfoot, E.N. Transport Phenomena; John Wiley & Sons: Hoboken, NJ, USA, 1960. [Google Scholar]

- Nolte, K.G. Determination of fracture parameters for fracturing pressure decline. In Proceedings of the 54th Annual Fall Technical Conference and Exhibition of the Society of Petroleum Engineers, Las Vegas, NV, USA, 23–25 September 1979. [Google Scholar]

- Li, K.W. An optimistic method for calculating oil-water relative permeability curves from dynamic displacement experimental data. J. Jianghan Pet. Inst. 1989, 11, 48–49. (In Chinese) [Google Scholar]

- Gao, Y.F.; Yang, D.; Han, H. Productivity evaluation modeling by numerical simulation for shale gas with variable dynamic viscosity in fractured horizontal wells. Processes. 2025, 13, 119. [Google Scholar]

- Zeng, J.; Wang, X.Z.; Guo, J.C. Composite linear flow model for multi-fractured horizontal wells in tight sand reservoirs with threshold pressure gradient. J. Pet. Sci. Eng. 2018, 165, 890–912. [Google Scholar]

| SizeRange (Mesh) | 8~12 | 10~20 | 10~30 | 20~40 | 40~60 | 10~20 |

| Sieve Diameter (mm) | 2.38~1.68 | 2.00~0.84 | 2.00~0.589 | 0.84~0.42 | 0.42~0.250 | 2.00~0.84 |

| Approximate Permeability (μm2) | 1722 | 321 | 188 | 119 | 44 | 321 |

| Porosity (%) | 36 | 32 | 32 | 35 | 32 | 32 |

| Oil Testing Productivity Base (t/d) | Control Relative Error (%) | Productivity Lower Limit (t/d) | Productivity Upper Limit (t/d) | Description |

|---|---|---|---|---|

| 100 | 30 | 70 | 130 | The productivity within the lower and upper limits matches the oil testing productivity base. |

| 50 | 50 | 25 | 75 | The productivity within the lower and upper limits matches the oil testing productivity base. |

| 20 | 70 | 6 | 34 | The productivity within the lower and upper limits matches the oil testing productivity base. |

| 10 | 80 | 2 | 18 | The productivity within the lower and upper limits matches the oil testing productivity base. |

| 1 | 100 | 0.13 | 2 | The productivity within the lower and upper limits matches the oil testing productivity base. |

| <1 | 0 | <1 | The order of magnitude matches while considering both the lower and upper limits of productivity. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, H.; Li, X.; He, X.; Sui, Q.; Xing, B.; Wang, C. Quantitative Prediction Method for Post-Fracturing Productivity of Oil–Water Two-Phase Flow in Low-Saturation Reservoirs. Processes 2025, 13, 1091. https://doi.org/10.3390/pr13041091

Wen H, Li X, He X, Sui Q, Xing B, Wang C. Quantitative Prediction Method for Post-Fracturing Productivity of Oil–Water Two-Phase Flow in Low-Saturation Reservoirs. Processes. 2025; 13(4):1091. https://doi.org/10.3390/pr13041091

Chicago/Turabian StyleWen, Huijian, Xueying Li, Xuchao He, Qiang Sui, Bo Xing, and Chao Wang. 2025. "Quantitative Prediction Method for Post-Fracturing Productivity of Oil–Water Two-Phase Flow in Low-Saturation Reservoirs" Processes 13, no. 4: 1091. https://doi.org/10.3390/pr13041091

APA StyleWen, H., Li, X., He, X., Sui, Q., Xing, B., & Wang, C. (2025). Quantitative Prediction Method for Post-Fracturing Productivity of Oil–Water Two-Phase Flow in Low-Saturation Reservoirs. Processes, 13(4), 1091. https://doi.org/10.3390/pr13041091