Mechanical and Failure Properties of Deep Grouted Fractured Rock Under Real-Time Coupling of Temperature and Dynamic Load

Abstract

1. Introduction

2. Experimental Materials and Methods

2.1. Preparation of Grout

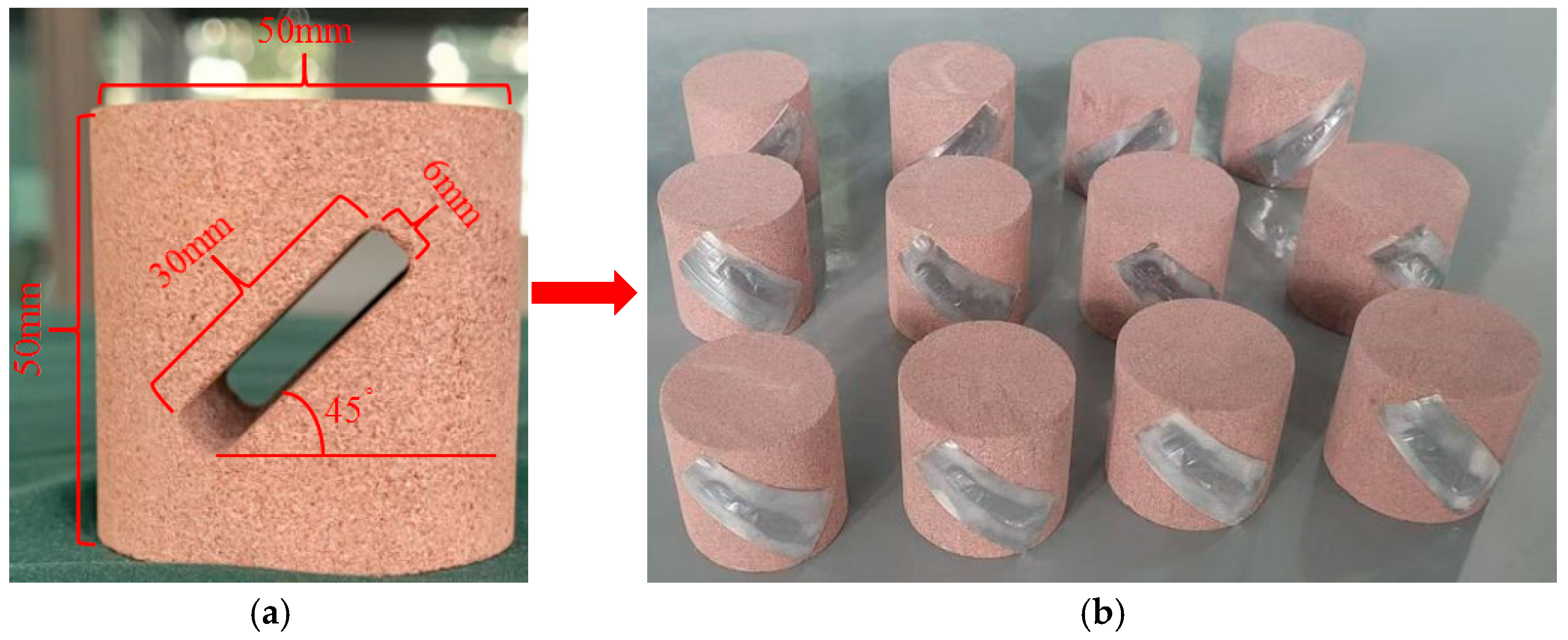

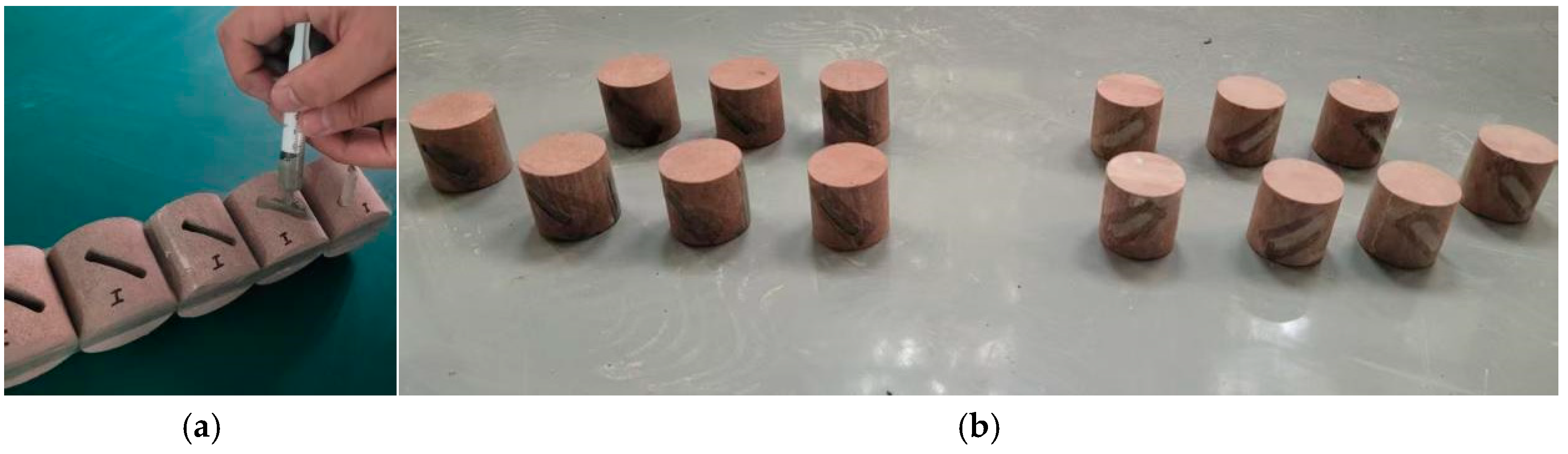

2.2. Preparation of Grouted Samples

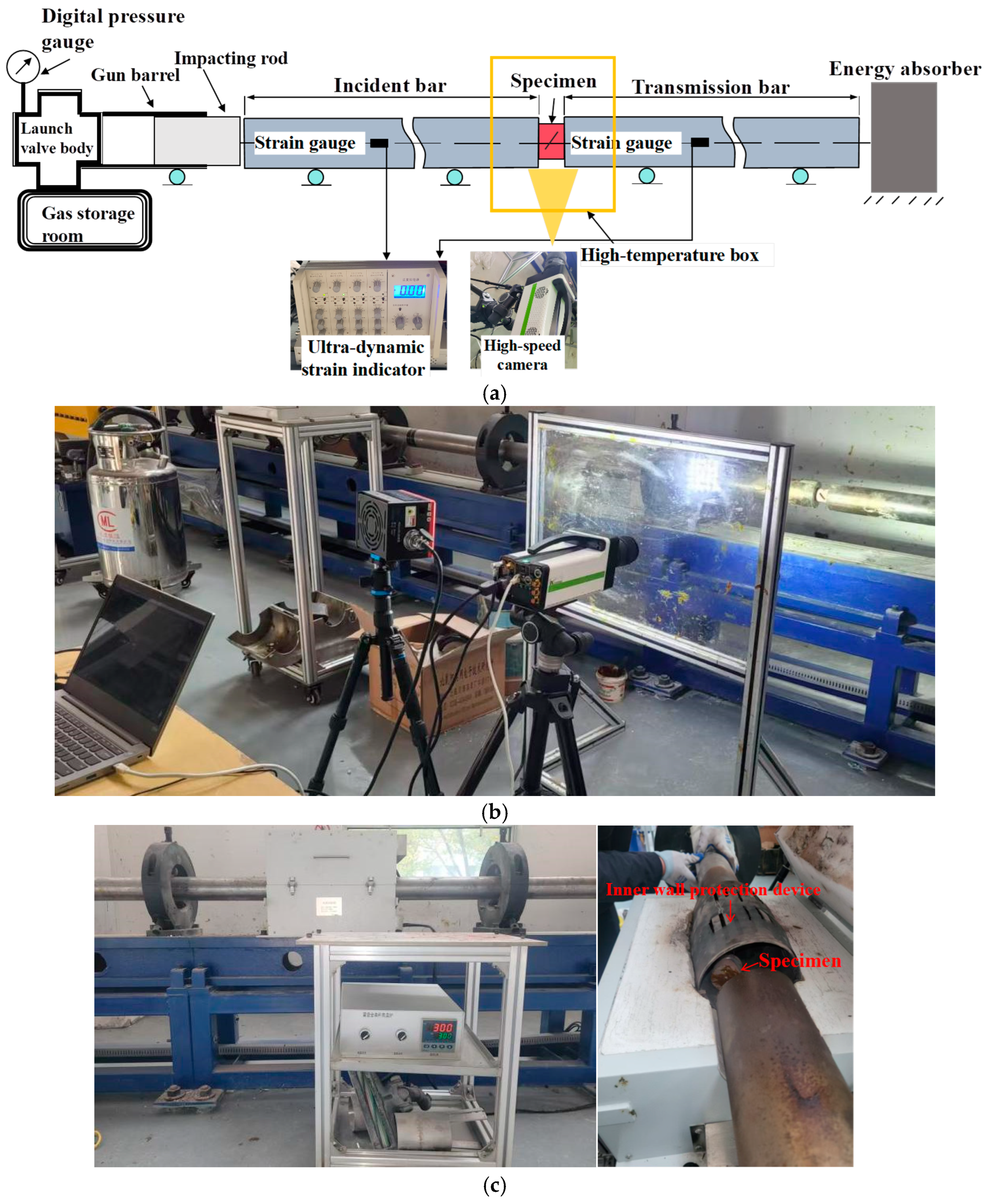

2.3. HT-SHPB Experimental System and Scheme

3. Dynamic Mechanical and Failure Properties of Grouted Fractured Rock Under Real-Time Temperature–Dynamic Load Coupling

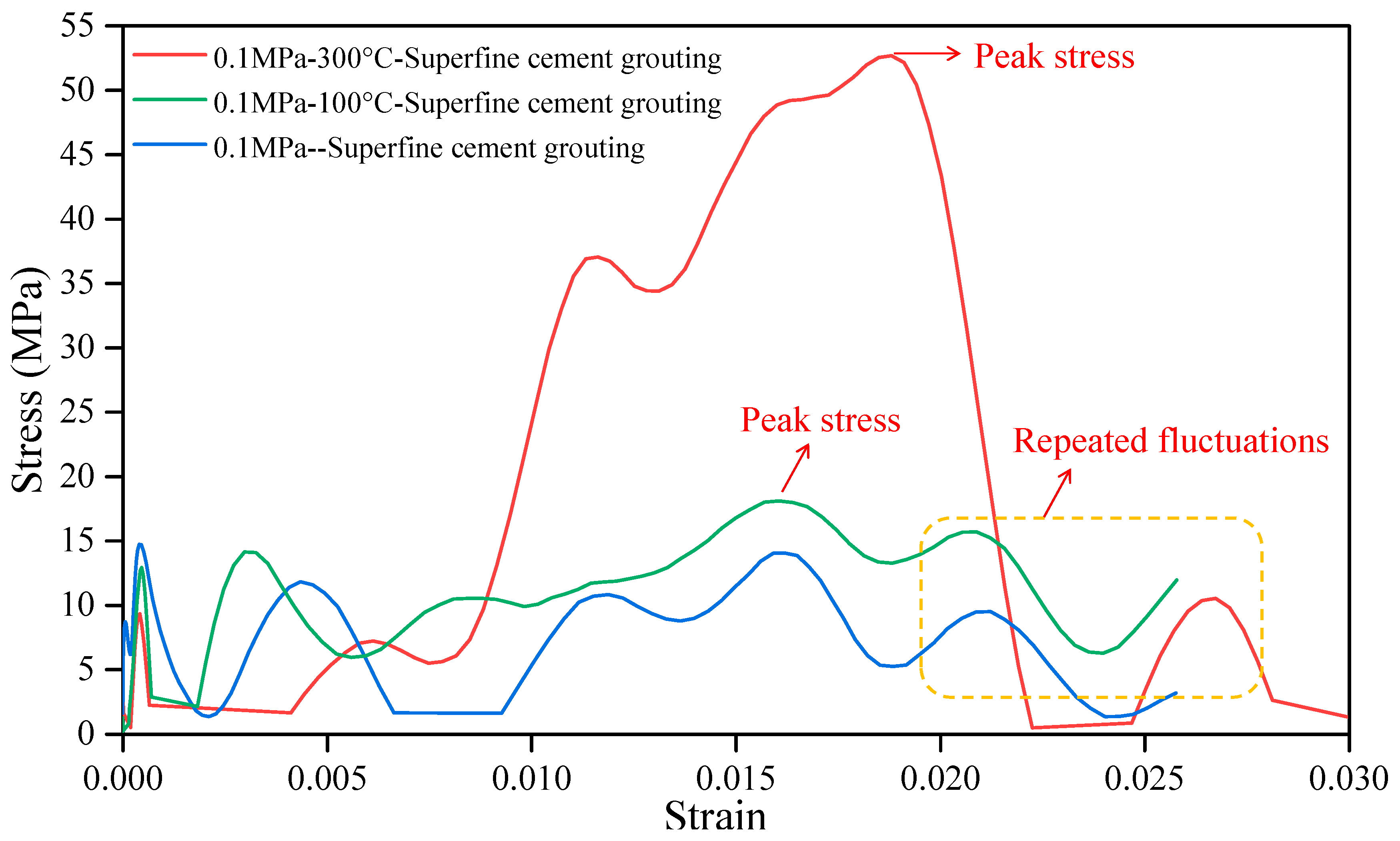

3.1. Dynamic Mechanical Properties

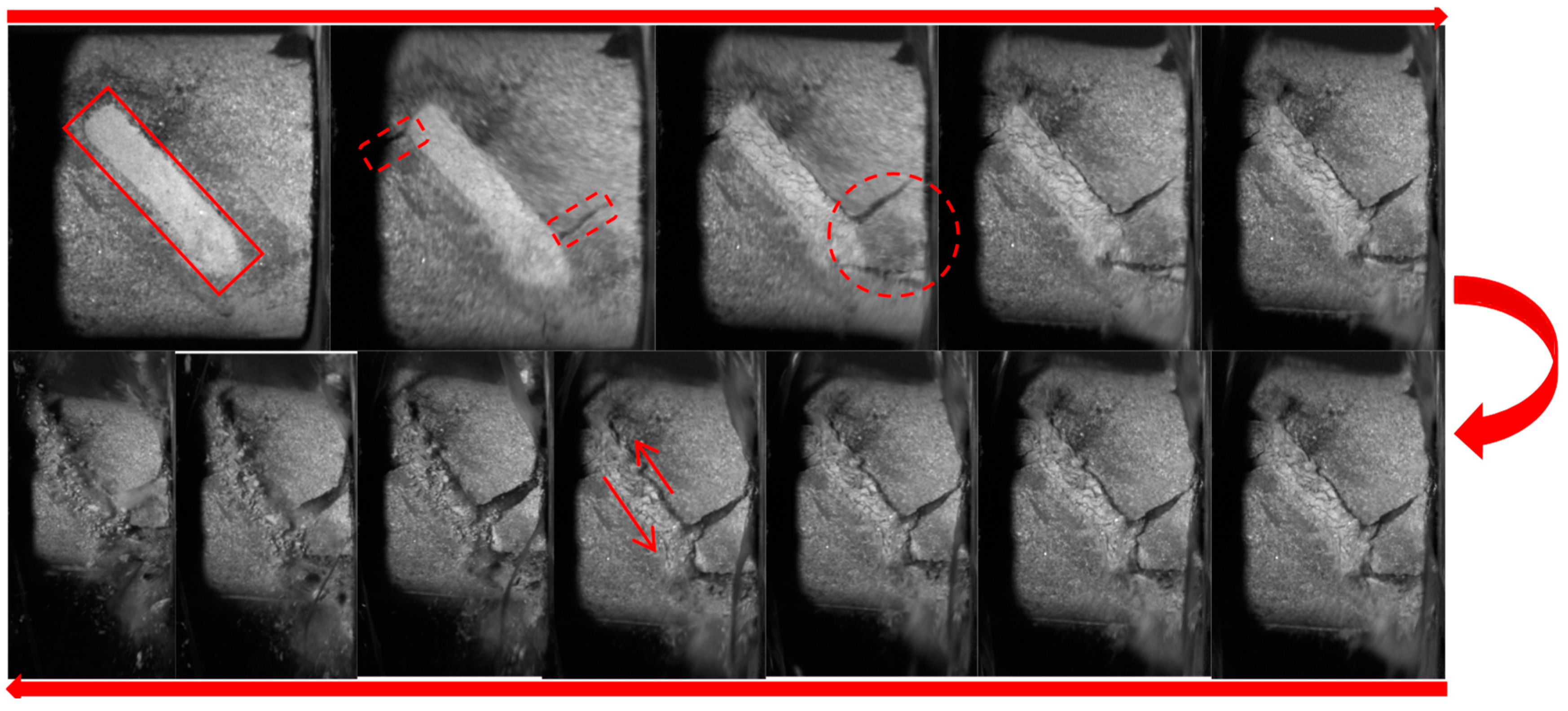

3.2. Macroscopic Dynamic Deformation and Failure Properties of Samples at Indoor Temperature

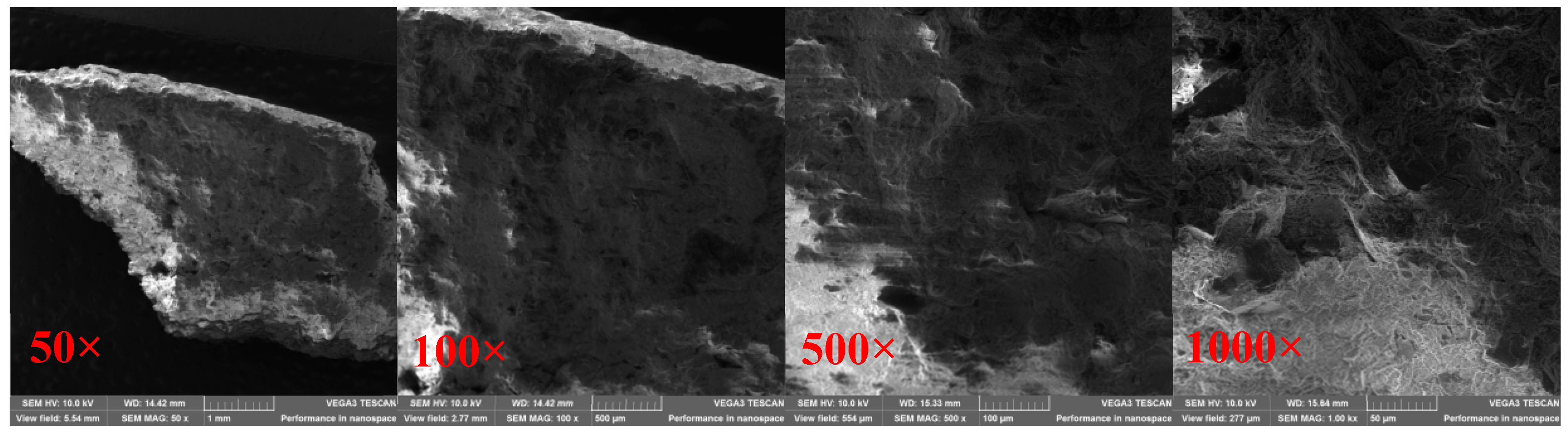

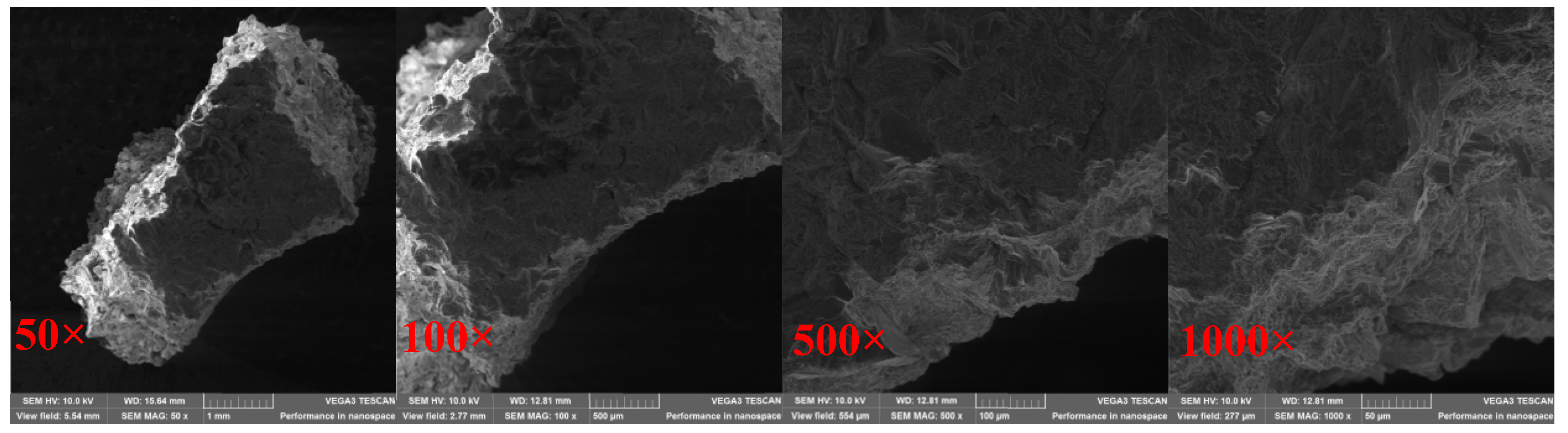

3.3. Micro-Structure Characteristics of Samples at Temperature of 300 °C

4. Discussion

5. Conclusions

- The dynamic compressive strength of grouted fractured rock increases with the increase of temperature. The dynamic strength increases by 23% from indoor temperature to 100 °C and by 192.01% from 100 to 300 °C. The trend of dynamic strength increasing with the temperature is verified to a certain extent by the existing references.

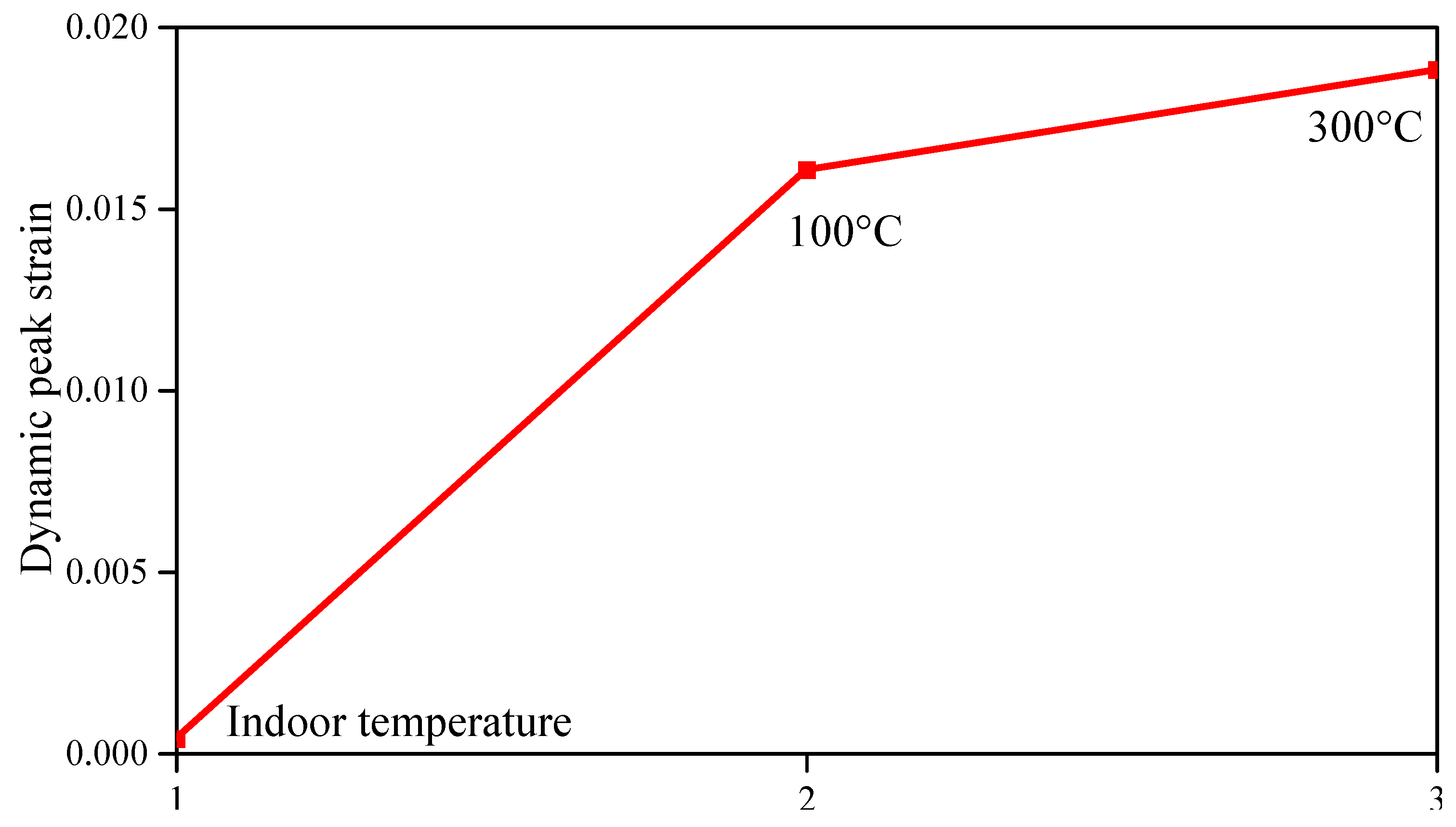

- The dynamic peak strain shows the increasing trend with the increase in temperature. The peak strain increases by 38.80 times from indoor temperature to 100 °C and by 0.17 times from 100 to 300 °C, which is in contrast to the degree of increase in dynamic strength during different stages of increasing temperature.

- The macroscopic failure properties show that the impact fractures first occur at the two ends of the pre-existing grouted fracture and are a pair of parallel lines. Micro-structure characteristics indicate that the existence of grouting material restrains the generation and development of micro-cracks at 300 °C, explaining the variation of the macroscopic dynamic strength with temperature from a microscopic perspective.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, M.; Zhang, Y.; Zhang, G.; Zhou, G.; Wang, Z. Discrete element study on mechanical response and pressure relief effect of rock containing variable hole. Theor. Appl. Fract. Mech. 2023, 127, 103976. [Google Scholar] [CrossRef]

- Chen, M.; Zhang, Y.; Zang, C.; Zhang, G.; Li, Q.; Jiang, B. Experimental Investigation on Pressure Relief Mechanism of Specimens with Prefabricated Reaming Boreholes. Rock. Mech. Rock. Eng. 2023, 56, 2949–2966. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, H.; Liu, Y.; Ding, L. Effect of fracture parameters on the thermal recovery performance of enhanced geothermal system. Energy Sources Part A Recovery Util. Environ. Eff. 2025, 47, 44–60. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, H.; Wang, J.; Sun, X.; Shi, F.; He, L.; Miao, C.-Y.; Ding, J.-X. Research on the mechanical characteristics and precursor patterns of failure in sandstone under different water contents. KSCE J. Civ. Eng. 2025, 29, 100051. [Google Scholar] [CrossRef]

- Jin, Y.; Yang, S.; Guo, H.; Han, L.; Su, S.; Shan, H.; Zhao, J.; Wang, G. A Novel Visual System for Conducting Safety Evaluations of Operational Tunnel Linings. Appl. Sci. 2024, 14, 8414. [Google Scholar] [CrossRef]

- Ren, C.; Sun, X.; He, M.; Liu, D. Experimental Simulation Investigation on Slab Buckling Rockburst in Deep Tunnel. Appl. Sci. 2025, 15, 1682. [Google Scholar] [CrossRef]

- Liu, S.; Cheng, Z.; Wang, H.; Bao, J. Experimental and Numerical Study on Grouting Reinforcement of a Broken Rock Mass. Int. J. Geomech. 2025, 25, 04024357. [Google Scholar] [CrossRef]

- Ding, W.; Lei, B.; Duan, C.; Zhang, Q. Grout diffusion model for single fractures in rock considering influences of grouting pressure and filling rate. Tunn. Undergr. Space Technol. 2025, 158, 106392. [Google Scholar] [CrossRef]

- Liu, Y.; Wu, Z.; Weng, L.; Wu, L.; Zhou, Y.; Liu, Q. Grouting diffusion characteristics in rough sandstone fracture with flowing water: Insights from NMR experimental investigation. Tunn. Undergr. Space Technol. 2025, 157, 106372. [Google Scholar] [CrossRef]

- Liu, X.; Tao, W.; Liu, B.; Wang, S.; Deng, W.; Fan, Y. Study on direct shear mechanical characteristics of grouted-filled jointed coal using discrete element method. Eng. Anal. Bound. Elem. 2024, 169, 106048. [Google Scholar] [CrossRef]

- Yao, Z.; Li, M.; Huang, S.; Chang, M.; Yang, Z. Study on the impact of grouting reinforcement on the mechanical behavior of non-penetrating fracture sandstone. Constr. Build. Mater. 2024, 453, 139079. [Google Scholar] [CrossRef]

- Mathur, G.K.; Jha, A.K.; Tiwari, G.; Singh, T.N. Dynamic Response of Grouted Jointed Rock Mass to Cyclic Loading Under Extreme Temperature Conditions. Rock. Mech. Rock. Eng. 2025. [Google Scholar] [CrossRef]

- Mathur, G.K.; Jha, A.K.; Tiwari, G. Assessing fracture mechanics in thermally treated, uniaxial loaded grouted non-persistent medium-hard rock: A digital image correlation and FracPaQ analysis. Bull. Eng. Geol. Environ. 2025, 84, 172. [Google Scholar] [CrossRef]

- Shams, G.; Moradian, O.; Li, B.Q.; Rivard, P. Microcracking and fracture behavior of cement grout under tensile loading. Constr. Build. Mater. 2025, 467, 140395. [Google Scholar] [CrossRef]

- Rojas, C.; Anani, A.; Cordova, E.; Nyaaba, W.; Wellman, E.; Adewuyi, S.O. Analysis of Raise Boring with Grouting as an Optimal Method for Ore Pass Construction in Incompetent Rock Mass-A Case Study. Min. Metall. Explor. 2024, 41, 2177–2191. [Google Scholar] [CrossRef]

- Jin, Y.; Han, L.; Meng, Q.; Ma, D.; Wen, S.; Wang, S. Experimental investigation of the mechanical behaviors of grouted crushed coal rocks under uniaxial compression. Geomech. Eng. 2018, 16, 273–284. [Google Scholar]

- Le, H.; Weng, M.; Li, H.; Li, J. Evaluating the Effect of Grouting on the Strength of Foliation of Metamorphic Rocks. Rock. Mech. Rock. Eng. 2024, 57, 2061–2079. [Google Scholar] [CrossRef]

- Li, X.; Luo, Q.; Yan, F.; Qi, C. Dynamic compressive micro-macro fracture mechanism with the water-saturated strengthening and weakening effect in brittle rocks. Theor. Appl. Fract. Mech. 2025, 137, 104871. [Google Scholar] [CrossRef]

- Li, F.; Wang, C.; Xu, B.; Liang, D.; Li, Z.; Zhang, T.; Tian, B. Research on dynamic damage path of multi-layered combined coal mass under impact load. Phys. Chem. Earth 2025, 138, 103872. [Google Scholar] [CrossRef]

- Luo, H.; Tao, M.; Hong, Z.; Xiang, G.; Wu, C. Analysis of the dynamic response and damage characteristic for the tunnel under near-field blasts and far-field earthquakes. Undergr. Space 2025, 21, 331–351. [Google Scholar] [CrossRef]

- Shen, Y.; Zhang, R.; Ma, D. Energy evolution characteristics and mechanical properties of freeze-thawed red sandstone under repeat impact loading. Mech. Time Depend. Mater. 2025, 29, 2. [Google Scholar] [CrossRef]

- Xu, Q.; Peng, S.; Xu, J.; Jiao, F.; Yang, Y.; Qin, C.; Nong, X.; Li, M. The Physical Simulation Study on Impact Damage Characteristics of Deep Elliptical Roadway. Rock. Mech. Rock. Eng. 2025. [Google Scholar] [CrossRef]

- Gao, Y.; Chen, M.; Pang, H. Experimental investigations on elastoplastic deformation and permeability evolution of terrestrial Karamay oil sands at high temperatures and pressures. J. Pet. Sci. Eng. 2020, 190, 107124. [Google Scholar] [CrossRef]

- Gao, Y.; Chen, M. Influence of temperature-viscosity behaviors of Karamay oil sand bitumen on the geomechanics in the SAGD process. J. Pet. Explor. Prod. Technol. 2021, 11, 747–767. [Google Scholar] [CrossRef]

- Zhang, L.; Li, B.; Wu, P.; Guo, S.; Zheng, Y.; Li, M.; Zhu, F. Experimental Study on the Dynamic Mechanical Properties and Crashing Behaviors of Limestone Under High Temperatures in Real-Time. Appl. Sci. 2024, 14, 10486. [Google Scholar] [CrossRef]

- Liang, W.; Han, F.; Li, M.; Xu, M.; Tan, W. Study on dynamic mechanical properties and energy dissipation of cyclic impact high temperature bedding sandstone. Geothermics 2025, 127, 103246. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhou, L.; Zhu, Z.; Ma, L.; Chen, J.; Li, Y. Research on dynamic cracking properties of cracked rock mass under the effect of thermal treatment. Theor. Appl. Fract. Mech. 2022, 122, 103580. [Google Scholar] [CrossRef]

- Zhang, J.Z.; Li, M.; Lin, G.; Zhang, L.; Yu, H.; Di, K. Study on Dynamic Mechanical Properties and Failure Mechanism of Sandstones under Real-Time High Temperature. Geofluids 2021, 2021, 9628675. [Google Scholar] [CrossRef]

- Wen, S.; Zhang, C.; Chang, Y.; Hu, P. Dynamic compression characteristics of layered rock mass of significant strength changes in adjacent layers. J. Rock. Mech. Geotech. Eng. 2020, 12, 353–365. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, Q. Dynamic Crack Propagation and Fracture Behavior of Pre-cracked Specimens under Impact Loading by Split Hopkinson Pressure Bar. Adv. Mater. Sci. Eng. 2019, 2019, 2383861. [Google Scholar] [CrossRef]

- Zhao, E.; Wang, E.; Zang, Z.; Feng, X.; Shen, R. Dynamic Mechanical Characteristics of Impact Rock under the Combined Action of Different Constant Temperatures and Static and Dynamic Loads. Shock Vib. 2021, 2021, 8484391. [Google Scholar] [CrossRef]

- Gao, W.; Deng, G.; Sun, G.; Deng, Y.; Li, Y. Dynamic Mechanical Properties of Heat-Treated Shale under Different Temperatures. Appl. Sci. 2023, 13, 12288. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, Y.; Yang, S.; Guo, H.; Han, L.; Huang, L.; Su, S.; Huang, P.; Shan, H.; He, Q. Mechanical and Failure Properties of Deep Grouted Fractured Rock Under Real-Time Coupling of Temperature and Dynamic Load. Processes 2025, 13, 1249. https://doi.org/10.3390/pr13041249

Jin Y, Yang S, Guo H, Han L, Huang L, Su S, Huang P, Shan H, He Q. Mechanical and Failure Properties of Deep Grouted Fractured Rock Under Real-Time Coupling of Temperature and Dynamic Load. Processes. 2025; 13(4):1249. https://doi.org/10.3390/pr13041249

Chicago/Turabian StyleJin, Yuhao, Shuo Yang, Hui Guo, Lijun Han, Lanying Huang, Shanjie Su, Pengcheng Huang, Hao Shan, and Qian He. 2025. "Mechanical and Failure Properties of Deep Grouted Fractured Rock Under Real-Time Coupling of Temperature and Dynamic Load" Processes 13, no. 4: 1249. https://doi.org/10.3390/pr13041249

APA StyleJin, Y., Yang, S., Guo, H., Han, L., Huang, L., Su, S., Huang, P., Shan, H., & He, Q. (2025). Mechanical and Failure Properties of Deep Grouted Fractured Rock Under Real-Time Coupling of Temperature and Dynamic Load. Processes, 13(4), 1249. https://doi.org/10.3390/pr13041249