An Efficient Scheduling Method in Supply Chain Logistics Based on Network Flow

Abstract

:1. Introduction

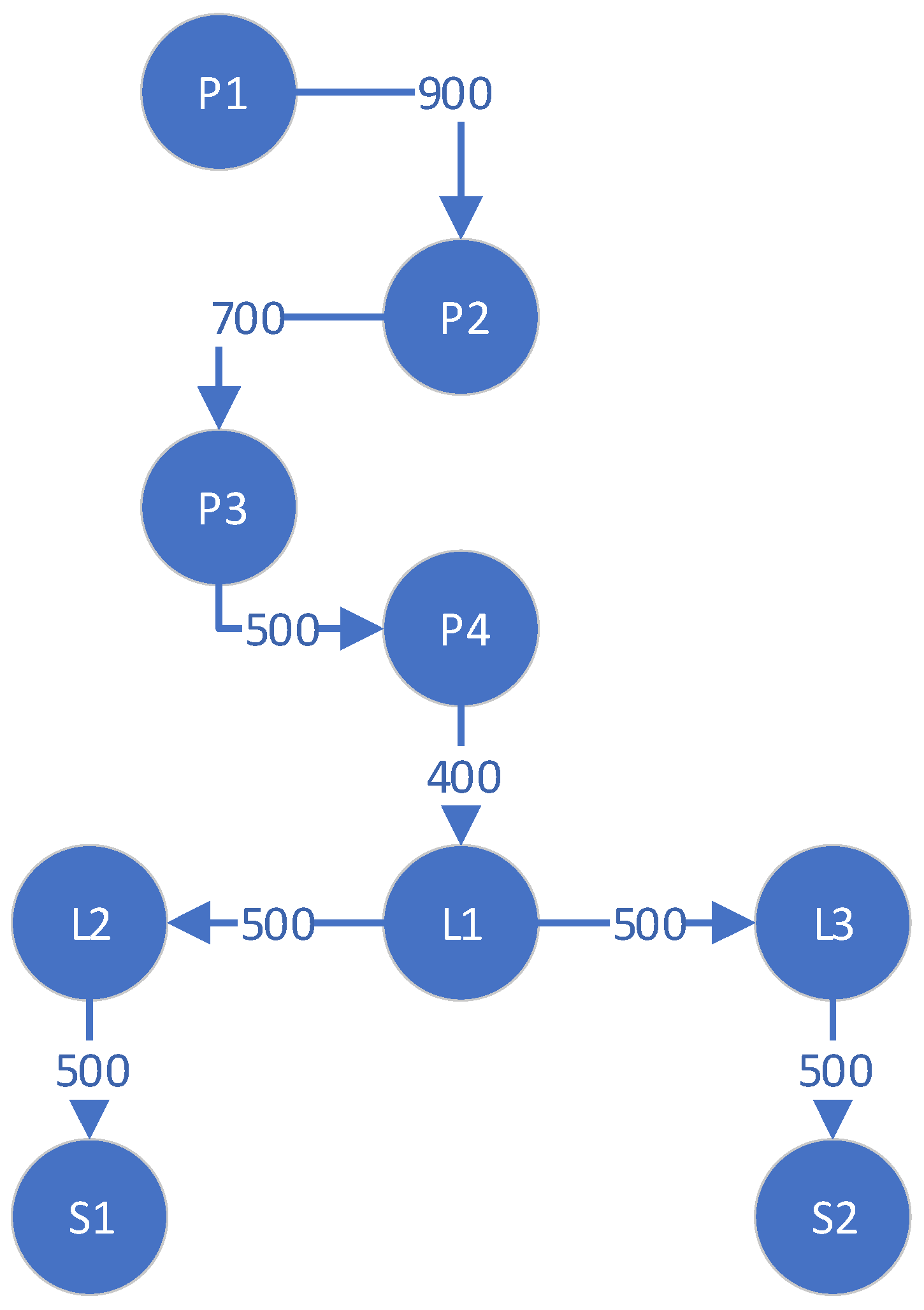

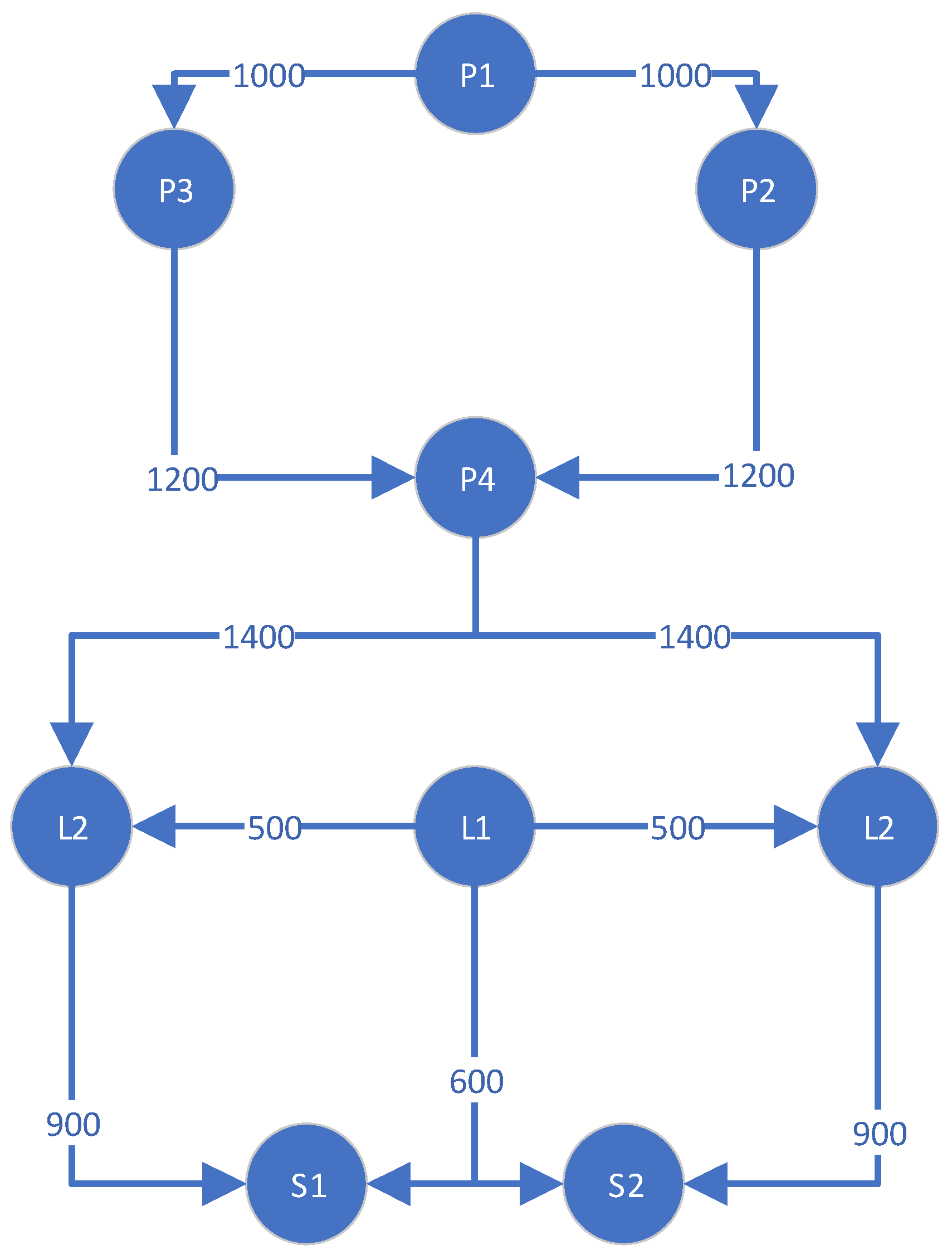

2. Building a Network Flow Model

2.1. Specific Problem Description

- (1)

- WLTP: probability of wafer lot transfer between different production areas;

- (2)

- WIP: average number of wafer lots in process within the system;

- (3)

- Vehicle count: number of automated vehicles for wafer transportation.

2.2. Mathematical Model Formulation

- (1)

- WLTP vector , where represents the probability of a wafer being transferred from one production area to another;

- (2)

- WIP level , which is the average WIP level given the number of vehicles and transition probability ;

- (3)

- Directional derivative , which is the rate of change of the WIP level with respect to WLTPs;

- (4)

- The number of vehicles , that is, the total number of vehicles used to transport wafers in the AMHS;

- (5)

- Maximum WIP Fluctuation , which is the maximum change in the WIP level under the worst-case scenario;

- (6)

- Upper limit , which is the upper limit of the allowed WIP level.

2.2.1. Notation and Assumptions

- : set of production nodes (e.g., processing area , inspection area , and warehouse );

- : set of transportation paths, where denotes a feasible path from node to ;

- : index of AGV types (classified by load capacity and speed).

- : maximum number of AGVs that the system can accommodate;

- : upper limit of the allowed work-in-process (WIP) level at each node;

- : maximum transportation capacity of path (in wafer lots);

- : external wafer arrival rate at node (Poisson-distributed);

- : service rate at node (exponentially distributed).

- : the number of type- AGVs allocated;

- : binary path selection variable ( if path is activated).

- : probability of wafer transfer from node to (WLTP);

- : transportation volume of type- AGVs on path ;

- : average WIP level at node .

- (1)

- AGVs operate without failure and tasks are executed sequentially;

- (2)

- The transportation time is linearly proportional to the distance, with AGVs moving at constant speeds;

- (3)

- Wafer loading/unloading times are fixed, and equipment switching costs are negligible.

2.2.2. Lower-Level Model: WLTP Allocation and WIP Sensitivity Analysis

- (a)

- WLTP probability normalization:

- (b)

- Path capacity constraints:

- (c)

- AGV task assignment:

- (d)

- WIP dynamic balance:

2.2.3. Upper-Level Model: AGV Configuration and Path Selection

- (e)

- AGV fleet size limit:

- (f)

- WIP upper bound:

- (g)

- Path activation logic:

2.2.4. Linearization Techniques

3. Instance Validation

3.1. Cost Comparison Before and After Network Flow Model Optimization

3.2. Comparison of the Completion Time of Different Tasks Using the Network Flow Model

| Algorithm 1: Simulated Annealing Algorithm (SA) | |

| 1: | S_initial |

| 2: | S_current |

| 3: | |

| 4: | while T > T_final do |

| 5: | for i = 1 to Max_Iterations do |

| 6: | Generate_Neighbor(S_current) |

| 7: | Cost(S_new) − Cost(S_current) |

| 8: | if Delta_E < 0 then |

| 9: | S_new |

| 10: | if Cost(S_new) < Cost(S_best) then |

| 11: | S_new |

| 12: | Else |

| 13: | exp(−Delta_E/T) |

| 14: | if Random(0,1) < P_accept then |

| 15: | S_new |

| 16: | alpha × T |

| 17: | end while |

| 18: | return S_best |

| Algorithm 2: Ant Colony Optimization Algorithm (ACO) | |

| 1: | |

| 2: | |

| 3: | for iter = 1 to N do |

| 4: | for each ant m = 1 to M do |

| 5: | |

| 6: | |

| 7: | |

| 8: | for all edges (i, j) do |

| 9: | |

| 10: | end for |

| 11: | ) then |

| 12: | < ) |

| 13: | end if |

| 14: | end for |

| 15: | |

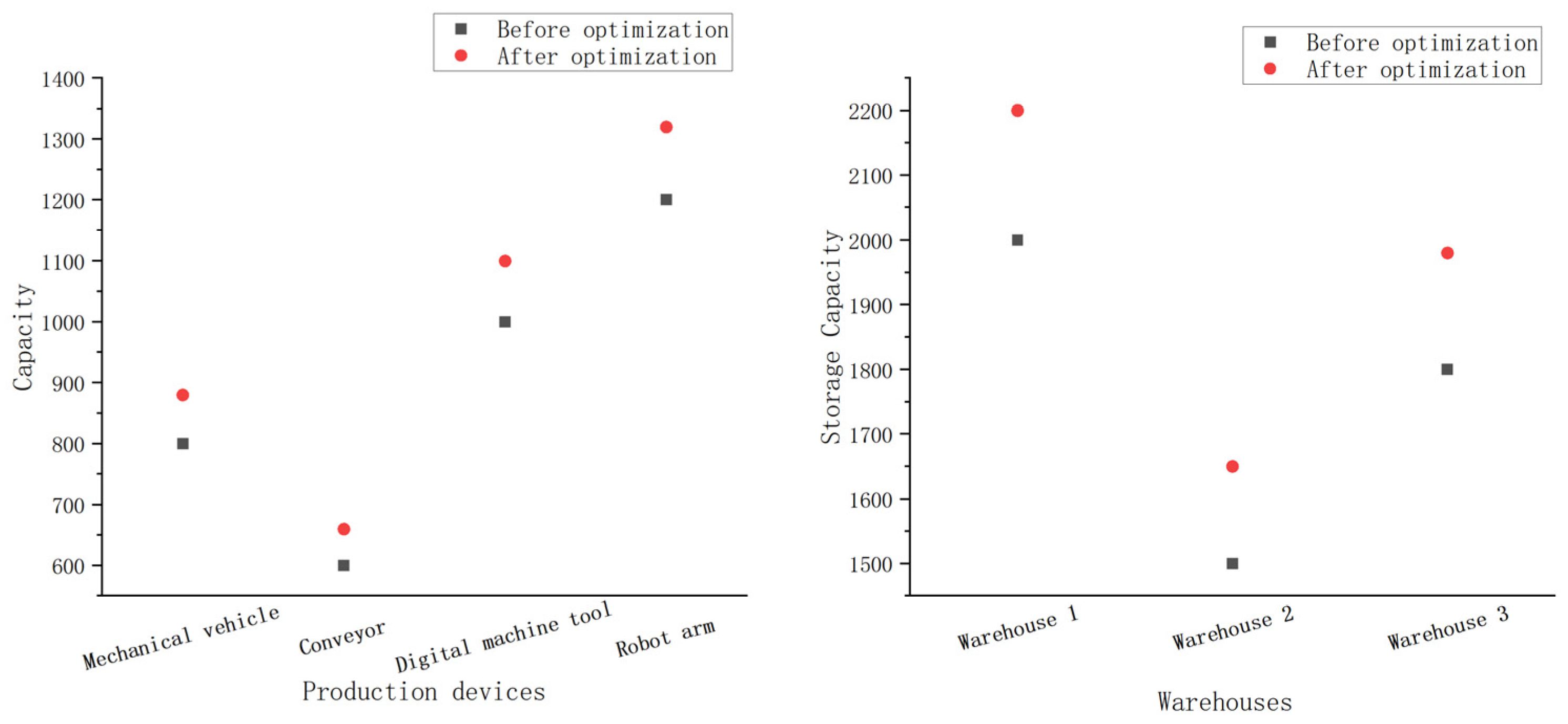

3.3. Comparison of Productivity of Production Equipment and Storage Rate of Warehouses Before and After Optimization Using Network Flow Models

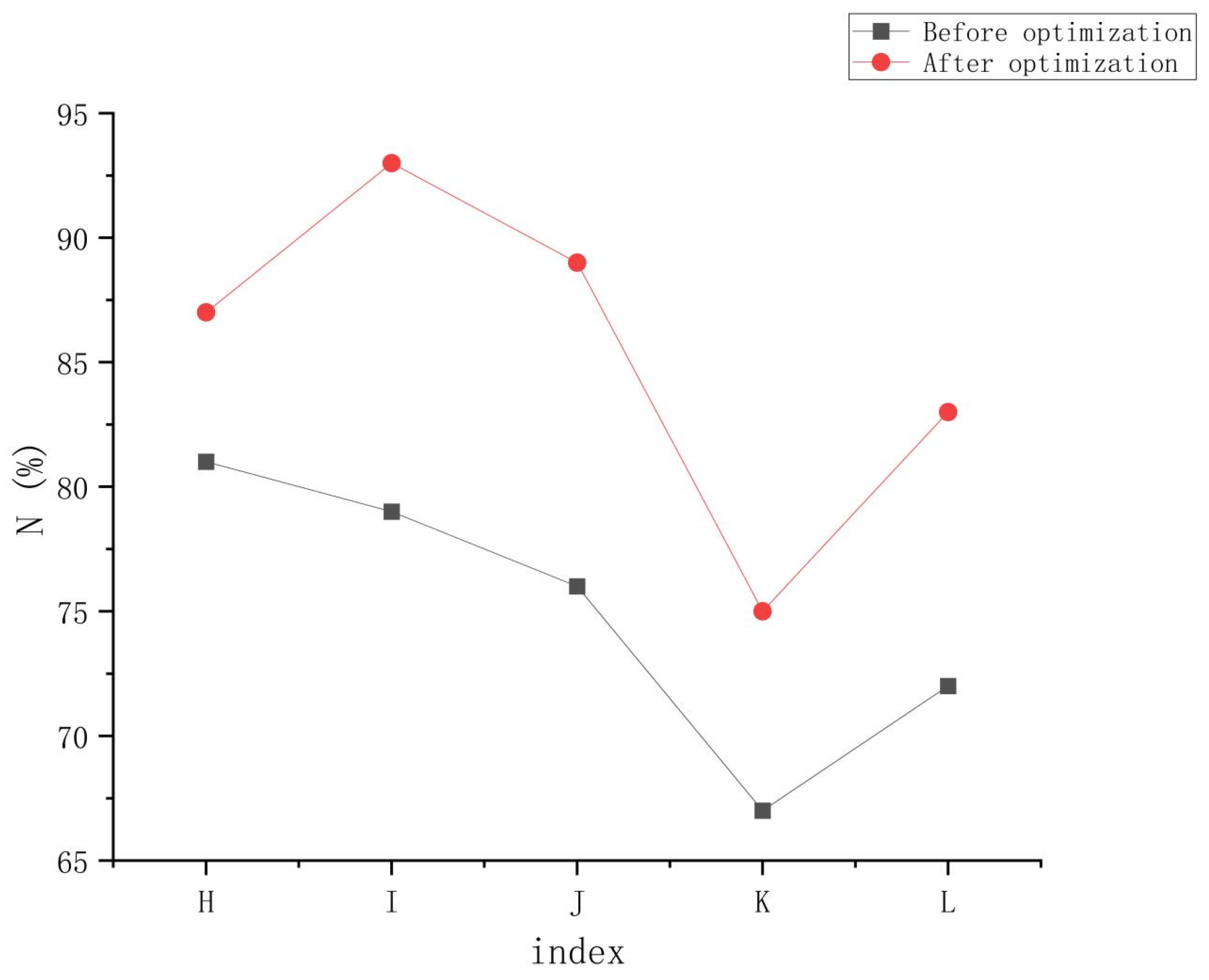

3.4. Comparison of the Resource Utilization Efficiency of Production Logistics Scheduling Before and After Optimization Using Network Flow Models

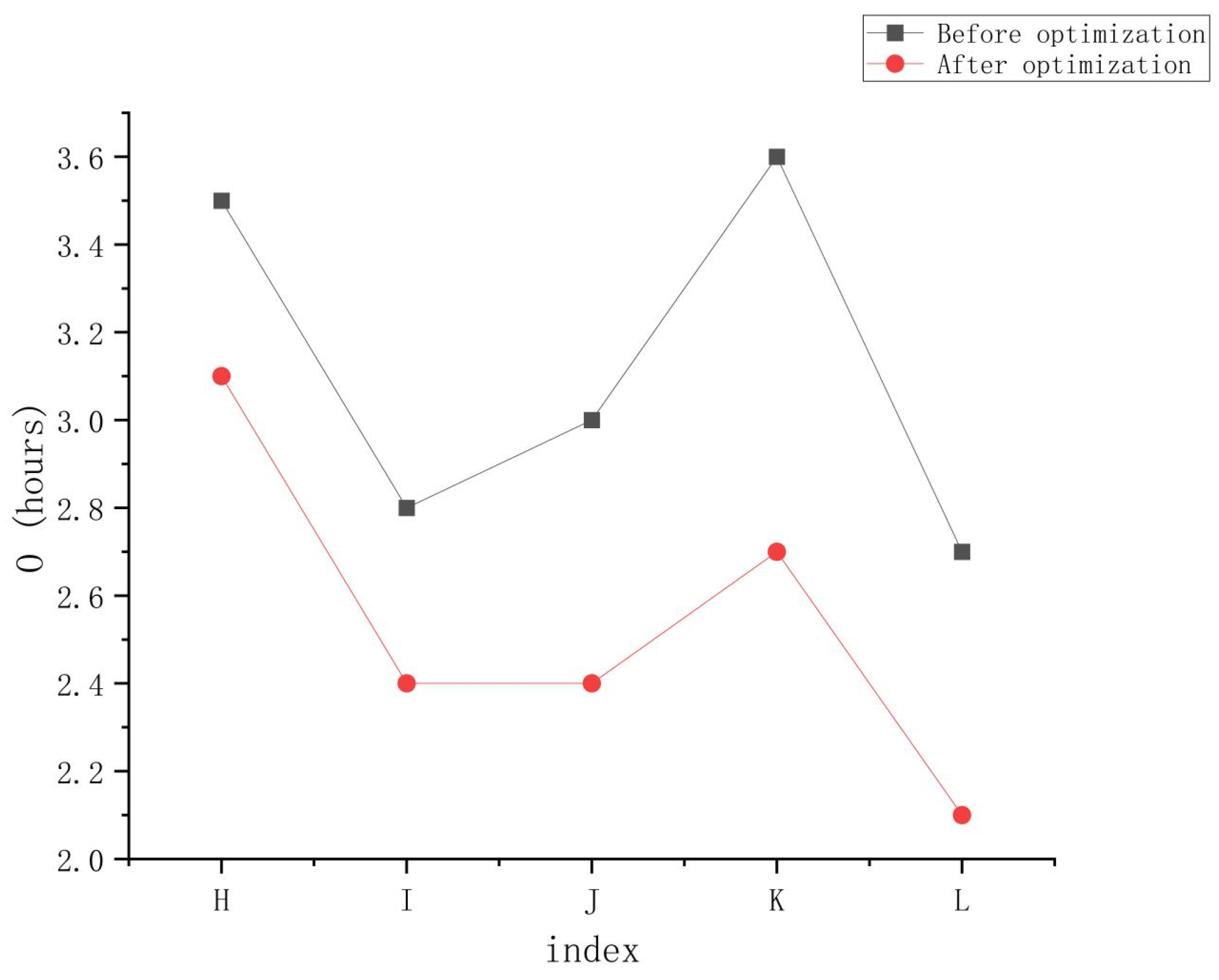

3.5. Comparison of the Transportation Volume of Semiconductor Wafers Before and After Optimization Using the Network Flow Model

3.6. Comparison of Network Flow Models in Production Logistics Scheduling Before and After Semiconductor Optimization

3.7. Comprehensive Model Performance Comparison Test

3.8. Sensitivity Analysis and Model Robustness

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bishutin, S.G.; Alekhin, S.S. Crack Formation Reduction on Diamond-Paste Abrasive Processing of Silicon-Carbide Semiconductor Wafers. Glass Ceram. 2023, 80, 201–204. [Google Scholar]

- Dong, J.; Ye, C. Joint optimisation of uncertain distributed manufacturing and preventive maintenance for semiconductor wafers considering multi-energy complementary. Int. J. Prod. Res. 2023, 61, 3029–3050. [Google Scholar]

- Wu, Y.; Chen, S. Machine Allocation in Semiconductor Wafer Fabrication Systems: A Simulation-Based Approach. J. Syst. Sci. Syst. Eng. 2023, 32, 372–390. [Google Scholar]

- Shin, E.; Yoo, C.D. Efficient Convolutional Neural Networks for Semiconductor Wafer Bin Map Classification. Sensors 2023, 23, 1926. [Google Scholar] [CrossRef]

- Harada, S.; Nishigaki, T.; Kitagawa, N.; Ishiji, K.; Hanada, K.; Tanaka, A.; Morishima, K. Development of High-Resolution Nuclear Emulsion Plates for Synchrotron X-Ray Topography Observation of Large-Size Semiconductor Wafers. J. Electron. Mater. 2023, 52, 2951–2956. [Google Scholar]

- Azadi Moghaddam Arani, A.; Jolai, F.; Nasiri, M.M. A multi-commodity network flow model for railway capacity optimization in case of line blockage. Int. J. Rail Transp. 2019, 7, 297–320. [Google Scholar]

- Li, B.; Wang, Y.; Cheng, L. Adaptive and augmented active anomaly detection on dynamic network traffic streams. Front. Inf. Technol. Electron. Eng. 2024, 25, 446–460. [Google Scholar]

- Xin, F.; Feng, C.; Chengbin, C.; Yufei, H. Crowdsource-enabled integrated production and transportation scheduling for smart city logistics. Int. J. Prod. Res. 2021, 59, 2157–2176. [Google Scholar]

- Bohacs, G.; Gyorvary, Z.S.; Gaspar, D. Integrating scheduling and energy efficiency aspects in production logistic using AGV systems. IFAC Pap. 2021, 54, 294–299. [Google Scholar]

- Wu, Q.; Xu, H.; Liu, M. Applying an Improved Dung Beetle Optimizer Algorithm to Network Traffic Identification. Comput. Mater. Contin. 2024, 78, 4091–4107. [Google Scholar]

- Gaba, S.; Budhiraja, I.; Kumar, V.; Makkar, A. Advancements in enhancing cyber-physical system security: Practical deep learning solutions for network traffic classification and integration with security technologies. Math. Biosci. Eng. MBE 2024, 21, 1527–1553. [Google Scholar] [PubMed]

- Cai, L.; Li, W.; Luo, Y.; He, L. Real-time scheduling simulation optimisation of job shop in a production-logistics collaborative environment. Int. J. Prod. Res. 2023, 61, 1373–1393. [Google Scholar]

- Li, W.; Yang, W.; Luo, G. A real-time collaborative scheduling method of production-logistics resources based on cluster consistency. Comput. Integr. Manuf. Syst. 2022, 28, 2953–2969. [Google Scholar]

- Wang, X.; Cheng, X.; Liang, X. Research on intelligent scheduling and collaborative control technology of Electronic product production logistics system. Mod. Manuf. Technol. Equip. 2020, 6, 183–185. [Google Scholar]

- Resop, P.J.; Cundiff, S.J. Optimization of herbaceous feedstock delivery to a network of supply depots for a biorefinery in the Piedmont, USA. Biofuels Bioprod. Biorefin. 2023, 17, 1528–1540. [Google Scholar]

- Tadeusz, S.; Bartosz, S. Risk-averse decision-making to maintain supply chain viability under propagated disruptions. Int. J. Prod. Res. 2024, 62, 2853–2867. [Google Scholar]

- Hridoy, S.I.; Tabassum, N.; Ethen, D.Z.; Mahfuza, E.J.; Hasif MA, M.; Hasan, M.M.; Palash, M.S. A Study on Supply Chain Analysis and Marketing Margin of Catfish Seed in Mymensingh District, Bangladesh. Asian J. Econ. Bus. Account. 2024, 24, 219–229. [Google Scholar]

- Sheetal, B.R.S. Maximize resource utilization based channel access model with presence of reactive jammer for underwater wireless sensor network. Int. J. Electr. Comput. Eng. (IJECE) 2020, 10, 3284–3294. [Google Scholar]

- Kyagante, F.; Tukamuhabwa, B.; Makepu, J.N.; Mutebi, H.; Waiswa, C. The mediating role of information integration: Information technology capabilities and supply chain resilience in Ugandan agro-food processing firms. Contin. Resil. Rev. 2024, 6, 28–47. [Google Scholar]

- He, Y.; Chen, L.; Xu, Q. Optimal pricing decisions for a global fresh product supply chain in the blockchain technology era. Int. J. Logist. Res. Appl. 2024, 27, 649–666. [Google Scholar]

- Iswanto, A.H.; Alazzawi, F.J.I.; Guerrero, J.W.G.; Ahmed, A.A.A.; Chetthamrongchai, P.; Vladimirovich, K.O.; Kadhim, M.M.; Jawad, M.A.; Surendar, A. Design of a Supply Chain-Based Production and Distribution System Based on Multi-Stage Stochastic Programming. Found. Comput. Decis. Sci. 2023, 48, 357–370. [Google Scholar]

- Zhou, L.; Jiang, Z.; Geng, N.; Niu, Y.; Cui, F.; Liu, K.; Qi, N. Production and operations management for intelligent manufacturing: A systematic literature review. Int. J. Prod. Res. 2022, 60, 808–846. [Google Scholar]

- Wang, Y. Research on the relationship between international trade and modern supply chain. Chin. Bus. Theory 2024, 7, 53–56. [Google Scholar]

- Zhu, C.; Yu, H. Multi-commodity network flow model and discrete particle swarm algorithm for parking space allocation. Sci. Technol. Eng. 2023, 23, 4417–4425. [Google Scholar]

- Qian, C.; Xu, X.; Peng, F. Single-line bus driver scheduling planning network flow model and solving algorithm. Transp. Technol. Econ. 2022, 24, 8–15. [Google Scholar]

- Yuan, Y.; Haoxin, Z. Multi-objective optimization model of downtime allocation based on network flow theory. Sci. Technol. Eng. 2020, 20, 12204–12210. [Google Scholar]

- Li, K.; Chen, X.; Han, X. Research on intelligent logistics scheduling in photovoltaic cell production workshop. Ind. Eng. Manag. 2022, 27, 159–169. [Google Scholar]

- Lin, Z.; Yuanyuan, Z.; Xing, L. A redundancy elimination routing strategy to minimize network energy consumption. J. Cap. Norm. Univ. (Nat. Sci. Ed.) 2023, 44, 37–40. [Google Scholar]

- Setiawan, F.; Bektaş, T.; Iris, Ç. The hub location problem with comparisons of compact formulations: A note. Transp. Res. Part E: Logist. Transp. Rev. 2025, 194, 103902. [Google Scholar]

| Task Type | Objective Function Value (h) | Gap(%) | |

|---|---|---|---|

| The model of this paper | A | 41.0 | - |

| B | 21.3 | - | |

| C | 13.1 | - | |

| D | 5.0 | - | |

| E | 13.2 | - | |

| Simulated annealing model | A | 43.5 ± 2.1 | 6.1% |

| B | 25.1 ± 1.5 | 17.8% | |

| C | 16.2 ± 1.0 | 23.7% | |

| D | 6.2 ± 0.6 | 14.0% | |

| E | 14.3 ± 0.9 | 8.3% | |

| Ant colony model | A | 49.2 ± 2.8 | 20.0% |

| B | 26.4 ± 1.8 | 23.9% | |

| C | 15.1 ± 1.3 | 18.2% | |

| D | 4.7 ± 0.5 | 5.7% | |

| E | 14.5 ± 1.0 | 9.8% |

| Model | Total Cost (Million CNY) | Task Time (h) | Equipment Utilization (%) | Capacity Loss (%) |

|---|---|---|---|---|

| LP | 520 | 55 ± 6.3 | 75 | 22 |

| Dynamic-NF | 480 | 48 ± 5.1 | 82 | 15 |

| MIP | 465 | 45 ± 4.8 | 88 | 12 |

| GA | 458 | 43 ± 3.9 | 85 | 10 |

| PSO | 442 | 42 ± 3.5 | 87 | 9 |

| DRL | 433 | 41 ± 2.8 | 90 | 8 |

| Proposed | 429 | 41 ± 2.1 | 93 | 8 |

| Parameter | Sensitivity Index | Impact on WIP | Impact on Transport Time |

|---|---|---|---|

| WLTP () | 0.79 | High (+68% variance) | Moderate (+22% variance) |

| AGV Fleet () | 0.51 | Low (+9% variance) | High (+61% variance) |

| Service Rate () | 0.11 | Negligible | Negligible |

| Scenario | WIP Increase | Transport Time Increase | Throughput Retention |

|---|---|---|---|

| Baseline (No Perturbation) | 0% | 0% | 100% |

| Demand Surge (+30%) | 8.2% | 11.7% | 94% |

| AGV Fleet Reduction (−25%) | 13.5% | 17.3% | 87% |

| Combined Perturbation (±20%) | 21.7% | 24.5% | 79% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Zhang, H.; Yuan, C.; Li, X.; Jiang, Z. An Efficient Scheduling Method in Supply Chain Logistics Based on Network Flow. Processes 2025, 13, 969. https://doi.org/10.3390/pr13040969

Wang Y, Zhang H, Yuan C, Li X, Jiang Z. An Efficient Scheduling Method in Supply Chain Logistics Based on Network Flow. Processes. 2025; 13(4):969. https://doi.org/10.3390/pr13040969

Chicago/Turabian StyleWang, Yichen, Huanbo Zhang, Chunhong Yuan, Xiangyu Li, and Zuowen Jiang. 2025. "An Efficient Scheduling Method in Supply Chain Logistics Based on Network Flow" Processes 13, no. 4: 969. https://doi.org/10.3390/pr13040969

APA StyleWang, Y., Zhang, H., Yuan, C., Li, X., & Jiang, Z. (2025). An Efficient Scheduling Method in Supply Chain Logistics Based on Network Flow. Processes, 13(4), 969. https://doi.org/10.3390/pr13040969