Enhancing the Quality and Sustainability of Laser Cutting Processes in Laser-Assisted Manufacturing Using a Box–Behnken Design

Abstract

:1. Introduction

2. Experimental Methodology

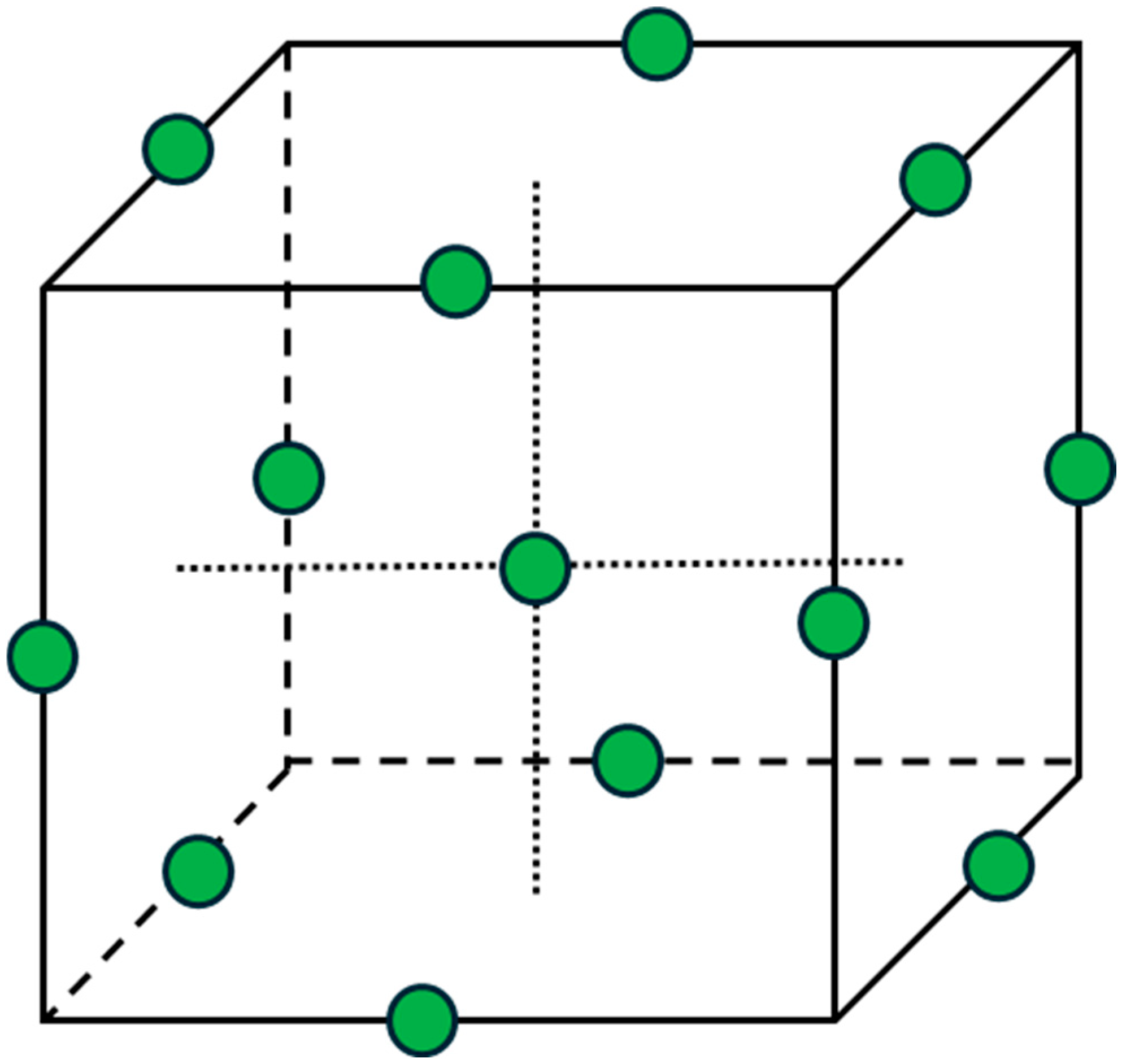

2.1. Box–Behnken Design

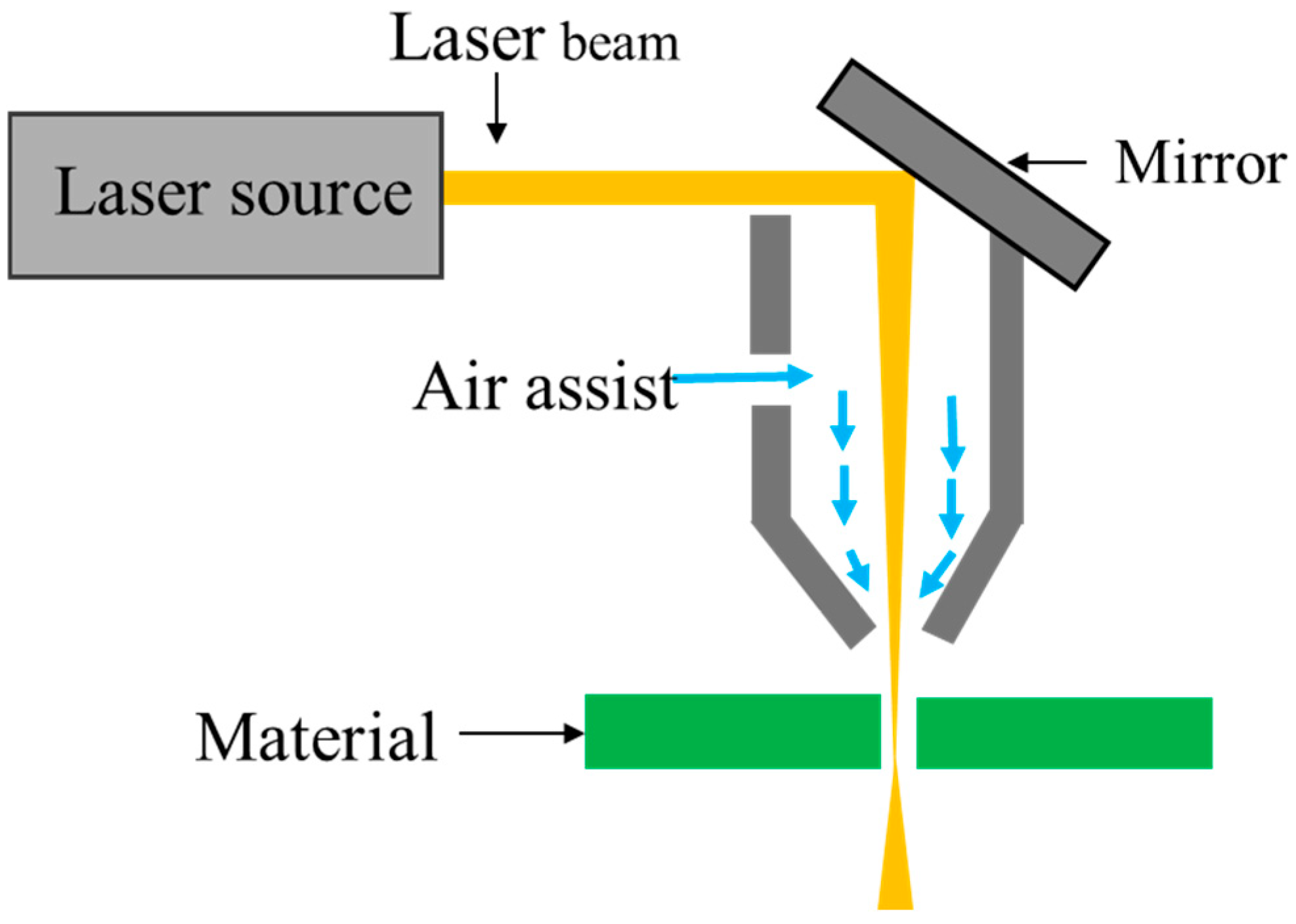

2.2. Experimental Work

3. Results and Discussion

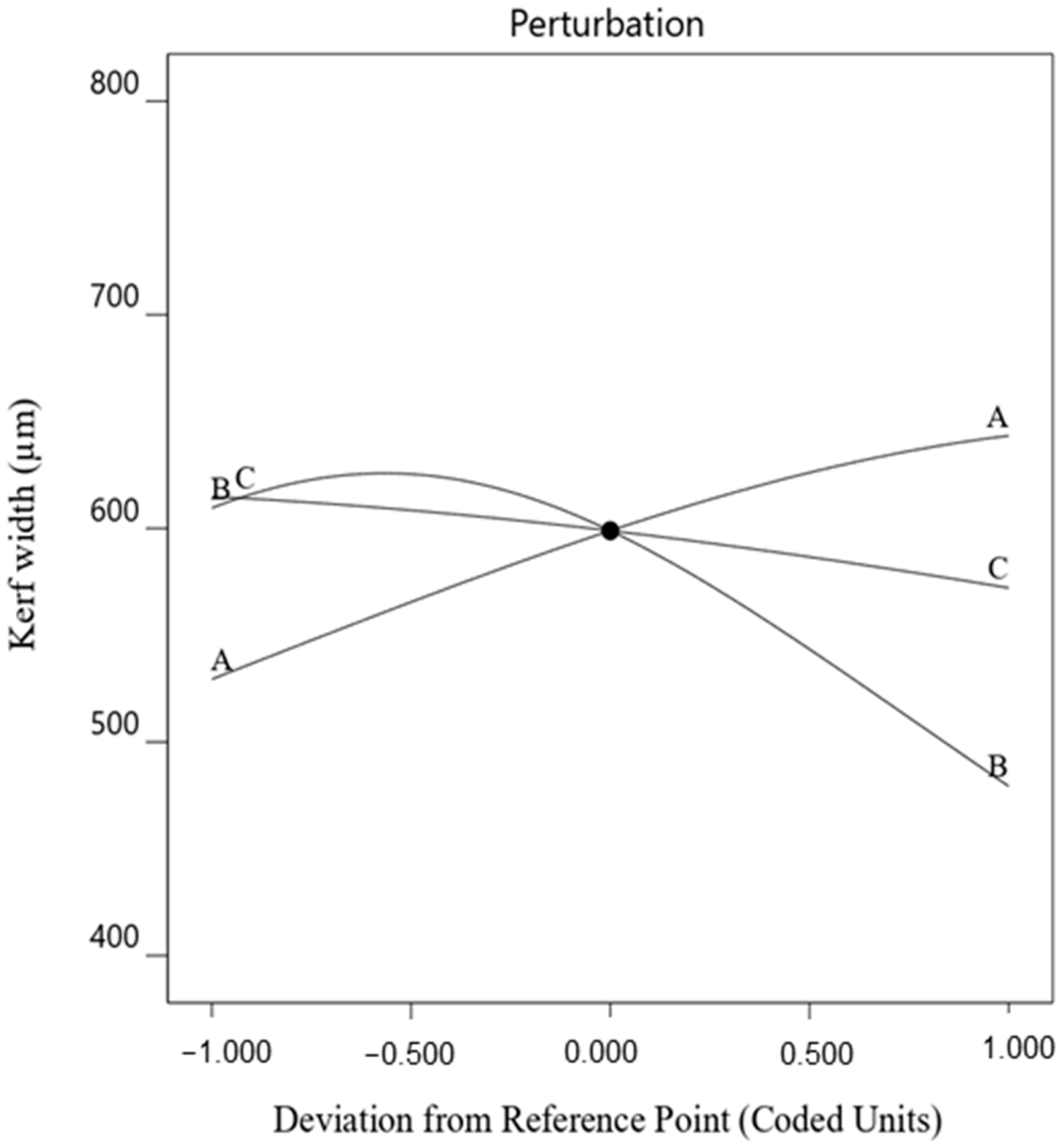

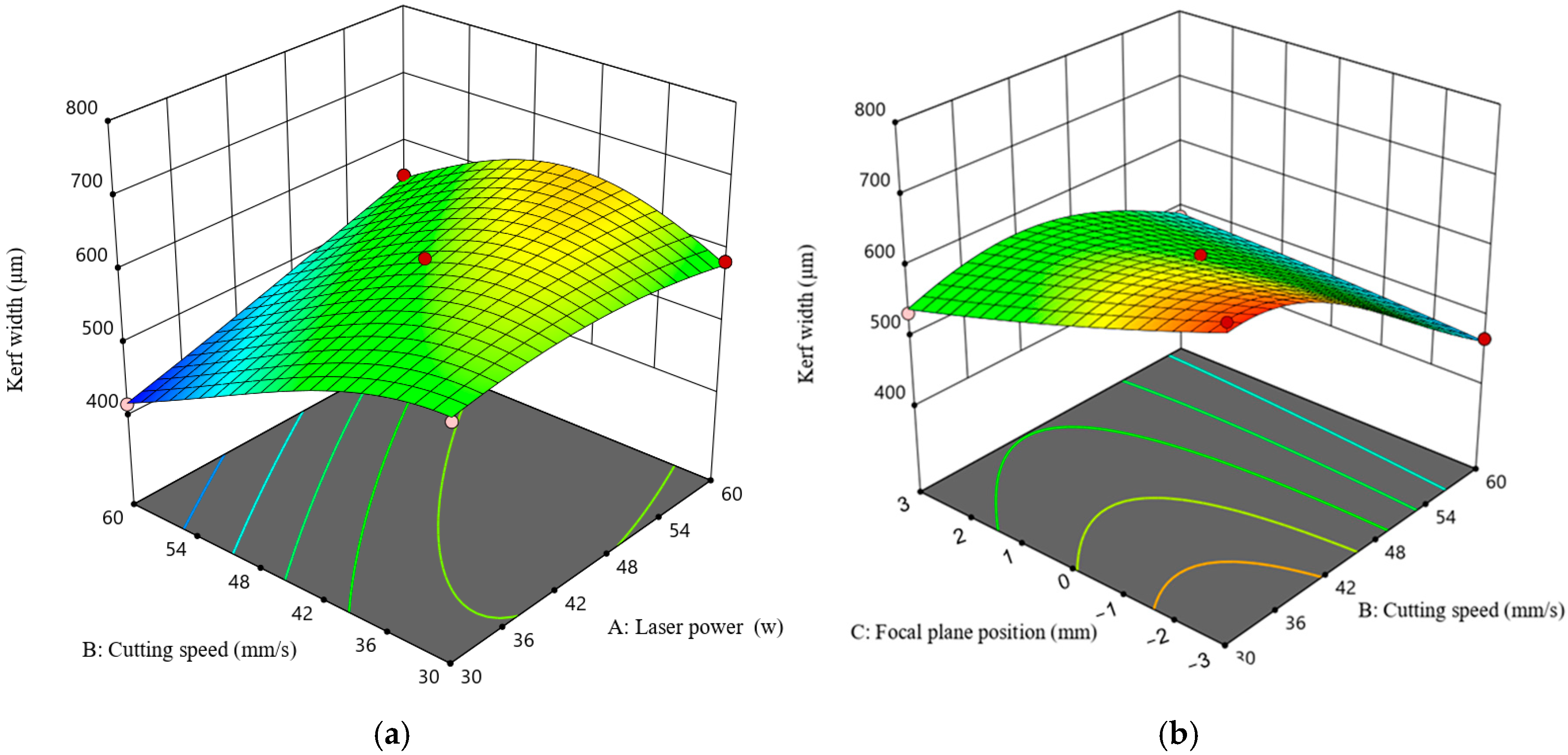

3.1. Analysis of the Width of the Kerf

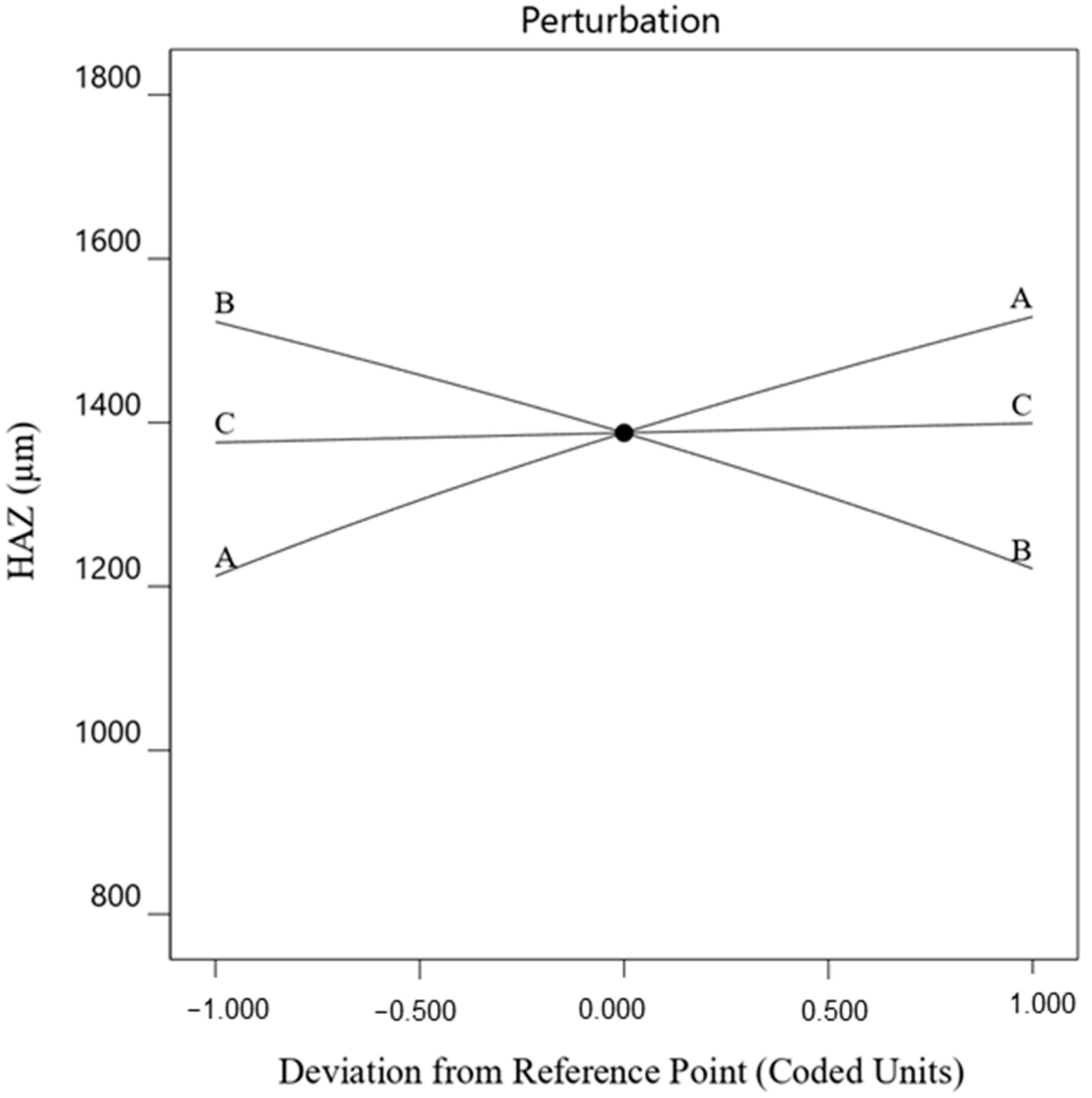

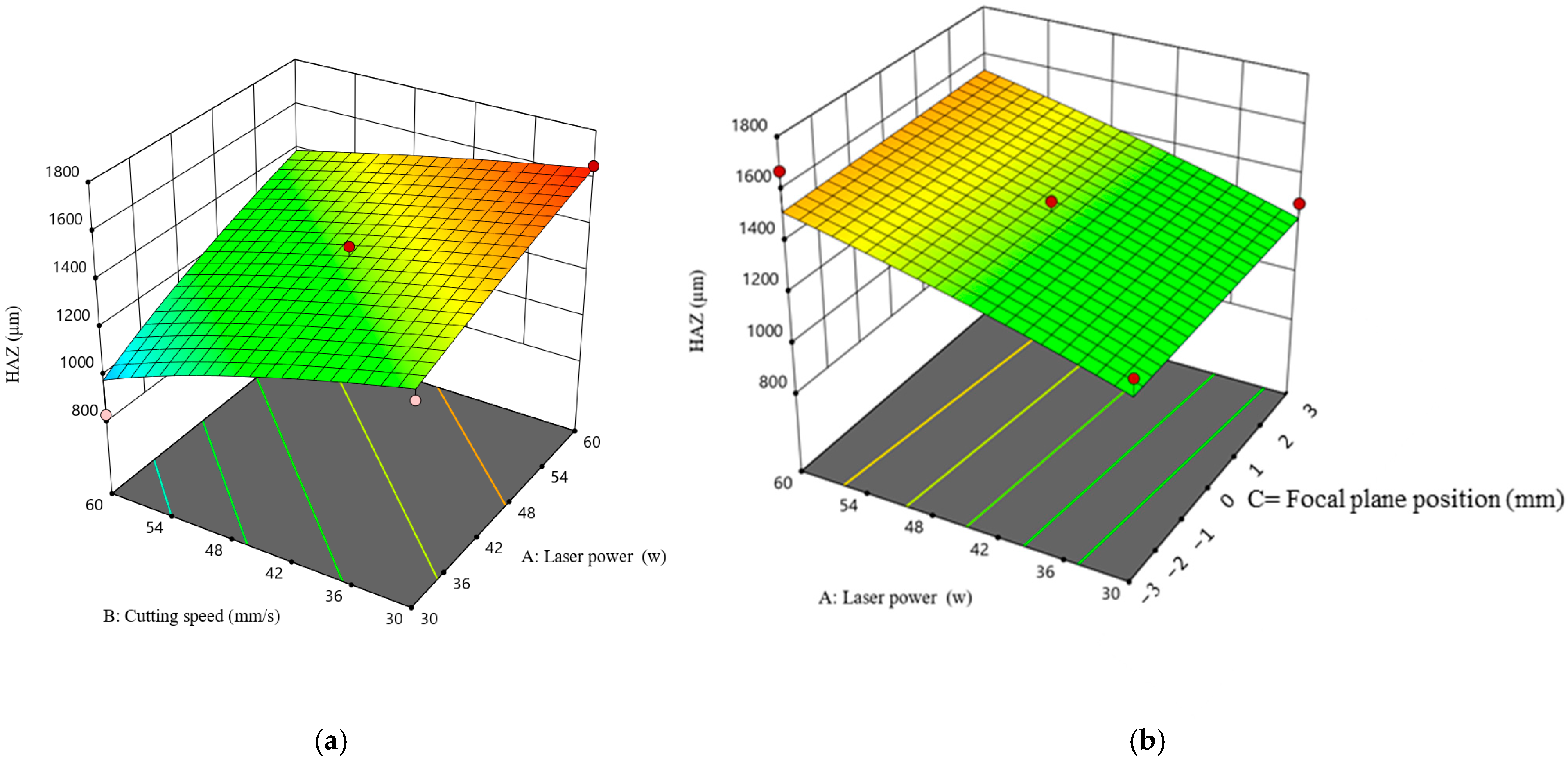

3.2. Analysis of Heat-Affected Zone (HAZ)

4. Optimization

5. Conclusions

- -

- The experiments conducted using the response surface methodology (RSM) show that cutting speed and laser power have a significant influence on both kerf width and HAZ. In contrast, within the range of focal plane position (FPP) examined in this study, FPP exhibits a negligible effect on kerf width and HAZ.

- -

- The findings show that a decrease in cutting speed and an increase in laser power increase both kerf width and HAZ.

- -

- The lowest kerf width (414.388 µm) and HAZ (827.338 µm) are observed at a cutting speed of 60 mm/s and a laser power of 30 W.

- -

- The results indicated that the optimal parameter settings for achieving the minimum kerf width and HAZ are a cutting speed of 60 mm/s, a laser power of 30 W, and a focal plane position of −3 mm.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chi, Y.; Dong, Z.; Cui, M.; Shan, C.; Xiong, Y.; Zhang, D.; Luo, M. Comparative study on machinability and surface integrity of γ-TiAl alloy in laser assisted milling. J. Mater. Res. Technol. 2024, 33, 3743–3755. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, Q.; Li, X.; Wang, Y.; Guan, Y. Mechanical performance of laser-textured metallic surface. J. Mater. Res. Technol. 2024, 33, 6084–6089. [Google Scholar] [CrossRef]

- Luo, W.; Yuan, X.; Zhang, Z.; Cheng, C.; Liu, H.; Qiu, H.; Cheng, X. Effect of volumetric energy density on the mechanical properties and corrosion resistance of laser-additive-manufactured AlCoCrFeNi2.1 high-entropy alloys. J. Alloys Compd. 2025, 1010, 178032. [Google Scholar] [CrossRef]

- Mehrabi, O.; Seyedkashi, S.; Moradi, M. Effect of the Laser Power on the Geometrical Features of 316L Stainless Steel Additively Manufactured by Direct Laser Metal Deposition (DLMD). Lasers Eng. 2023, 56, 127–141. [Google Scholar]

- Cui, M.; Shi, G.; Deng, L.; Guo, H.; Xiong, S.; Tan, L.; Yao, C.; Zhang, D.; Deguchi, Y. Microstructure classification of steel samples with different heat-treatment processes based on laser-induced breakdown spectroscopy (LIBS). J. Anal. At. Spectrom. 2024, 39, 1361–1374. [Google Scholar] [CrossRef]

- Cui, M.; Shilei, X.; Nan, Y.; Yuanbin, W.; Zhenzhen, W.; Ming, L.; Changfeng, Y. Deguchi Applications of laser-induced breakdown spectroscopy in industrial measurement and monitoring: Multi-technology combination. Appl. Spectrosc. Rev. 2025, 60, 243–291. [Google Scholar] [CrossRef]

- Moradi, M.; Mehrabi, O.; Azdast, T.; Benyounis, K.Y. Enhancement of low power CO2 laser cutting process for injection molded polycarbonate. Opt. Laser Technol. 2017, 96, 208–218. [Google Scholar] [CrossRef]

- Alsaadawy, M.; Dewidar, M.; Said, A.; Maher, I.; Shehabeldeen, T.A. A comprehensive review of studying the influence of laser cutting parameters on surface and kerf quality of metals. Int. J. Adv. Manuf. Technol. 2024, 130, 1039–1074. [Google Scholar] [CrossRef]

- Naresh; Khatak, P. Laser cutting technique: A literature review. Mater. Today Proc. 2022, 56, 2484–2489. [Google Scholar] [CrossRef]

- Moradi, M.; Mehrabi, O.; Azdast, T.; Benyounis, K.Y. Effect of the focal plane position on CO2 laser beam cutting of injection molded polycarbonate sheets. Second. Int. Semin. Photonics Opt. Its Appl. 2016, 10150, 56–65. [Google Scholar]

- Adin, M.Ş. Investigation of the Effects of Machining Parameters on Kerf Widths during Laser Beam Machining of Medium Carbon Steels. J. Mater. Eng. Perform. 2025, 34, 5304–5315. [Google Scholar] [CrossRef]

- Patel, A.; Bhavsar, S.N. Experimental investigation to optimize laser cutting process parameters for difficult to cut die alloy steel using response surface methodology. Mater. Today Proc. 2021, 43, 28–35. [Google Scholar] [CrossRef]

- Wang, J.; Sun, Z.; Gu, L.; Azimy, H. Investigating the effect of laser cutting parameters on the cut quality of Inconel 625 using Response Surface Method (RSM). Infrared Phys. Technol. 2021, 118, 103866. [Google Scholar] [CrossRef]

- Agarwal, J.; Sahoo, S.; Mohanty, S.; Nayak, S.K. Progress of novel techniques for lightweight automobile applications through innovative eco-friendly composite materials: A review. J. Thermoplast. Compos. Mater. 2020, 33, 978–1013. [Google Scholar] [CrossRef]

- Huang, P.; Su, Y.; Luo, H.; Lan, X.; Chong, Y.; Wu, F.; Zheng, W. Facile one-step method to manufacture polypropylene bead foams with outstanding thermal insulation and mechanical properties via supercritical CO2 extrusion foaming. J. CO2 Util. 2022, 64, 102167. [Google Scholar] [CrossRef]

- Der, O.; Ordu, M.; Basar, G. Optimization of cutting parameters in manufacturing of polymeric materials for flexible two-phase thermal management systems. Mater. Test. 2024, 66, 1700–1719. [Google Scholar] [CrossRef]

- Choudhury, I.A.; Shirley, S. Laser cutting of polymeric materials: An experimental investigation. Opt. Laser Technol. 2010, 42, 503–508. [Google Scholar] [CrossRef]

- Deepa, A.; Padmanabhan, K.; Kuppan, P. Analysis and optimization of machining parameters of laser cutting for polypropylene composite. In IOP Conference Series: Materials Science and Engineering, Vellore, India, 2–3 May 2017; IOP Publishing: Bristol, UK, 2017; Volume 263, p. 062043. [Google Scholar] [CrossRef]

- Wu, C.; Rong, Y.; Li, M.; Zhang, G.; Huang, Y.; Zhang, T. High-quality cutting of polypropylene (PP) film by UV nanosecond laser based on thermal ablation. Opt. Laser Technol. 2022, 147, 107600. [Google Scholar] [CrossRef]

- Singh, Y.; Singh, J.; Sharma, S.; Aggarwal, V.; Pruncu, C.I. Multi-objective Optimization of Kerf-taper and Surface-roughness Quality Characteristics for Cutting-operation On Coir and Carbon Fibre Reinforced Epoxy Hybrid Polymeric Composites During CO2-Pulsed Laser-cutting Using RSM. Lasers Manuf. Mater. Process. 2021, 8, 157–182. [Google Scholar] [CrossRef]

- Singh, Y.; Singh, J.; Sharma, S.; Sharma, A.; Chohan, J.S. Process parameter optimization in laser cutting of Coir fiber reinforced Epoxy composite—A review. Mater. Today Proc. 2022, 48, 1021–1027. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Muthuramalingam, T.; Elaziz, M.A.; Ibrahim, A.M.M.; Showaib, E.A. Minimization of fume emissions in laser cutting of polyvinyl chloride sheets using genetic algorithm. Int. J. Environ. Sci. Technol. 2022, 19, 6331–6344. [Google Scholar] [CrossRef]

- Sabri, H.; Mehrabi, O.; Khoran, M.; Moradi, M. Leveraging CO2 laser cutting for enhancing fused deposition modeling (FDM) 3D printed PETG parts through postprocessing. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2024. [Google Scholar] [CrossRef]

- Basar, G.; Der, O. Multi-objective optimization of process parameters for laser cutting polyethylene using fuzzy AHP-based MCDM methods. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2025. [Google Scholar] [CrossRef]

- Aydın, K.; Uğur, L. Prediction of Kerf and Groove Widths in CO2 Laser Cutting Process of PMMA Using Experimental and Machine Learning Methods. Exp. Tech. 2025, 1–14. [Google Scholar] [CrossRef]

- Kechagias, J.D.; Ninikas, K.; Petousis, M.; Vidakis, N.; Vaxevanidis, N. An investigation of surface quality characteristics of 3D printed PLA plates cut by CO2 laser using experimental design. Mater. Manuf. Process. 2021, 36, 1544–1553. [Google Scholar] [CrossRef]

- Kechagias, J.D.; Fountas, N.A.; Ninikas, K.; Petousis, M.; Vidakis, N.; Vaxevanidis, N. Surface characteristics investigation of 3D-printed PET-G plates during CO2 laser cutting. Mater. Manuf. Process. 2022, 37, 1347–1357. [Google Scholar] [CrossRef]

- Moradi, M.; Mehrabi, O.; Rasoul, F.A.; Mattie, A.A.; Schaber, F.; Khandan, R. Enhancing 3D Printing Copper-PLA Composite Fabrication via Fused Deposition Modeling through Statistical Process Parameter Study. Micromachines 2024, 15, 1082. [Google Scholar] [CrossRef] [PubMed]

- Jensen, W.A. Response Surface Methodology: Process and Product Optimization Using Designed Experiments, 4th ed.; Taylor & Francis, Ed.; Wiley: Hoboken, NJ, USA, 2017. [Google Scholar]

- Agha, H.M.; Abdulhameed, A.S.; Jawad, A.H.; Alothman, Z.A.; Wilson, L.D.; Algburi, S. Fabrication of glutaraldehyde crosslinked chitosan/algae biomaterial via hydrothermal process: Statistical optimization and adsorption mechanism for MV 2B dye removal. Biomass Convers. Biorefinery 2025, 15, 1105–1119. [Google Scholar] [CrossRef]

- Khan, M.K.A.; Abdulhameed, A.S.; Alshahrani, H.; Algburi, S. Development of chitosan biopolymer by chemically modified orange peel for safranin O dye removal: A sustainable adsorbent and adsorption modeling using RSM-BBD. Int. J. Biol. Macromol. 2024, 261, 129964. [Google Scholar] [CrossRef]

- Agha, H.M.; Abdulhameed, A.S.; Jawad, A.H.; Sidik, N.J.; Aazmi, S.; ALOthman, Z.A.; Wilson, L.D.; Algburi, S. Physicochemical fabrication of chitosan and algae with crosslinking glyoxal for cationic dye removal: Insight into optimization, kinetics, isotherms, and adsorption mechanism. Int. J. Biol. Macromol. 2023, 253, 127112. [Google Scholar] [CrossRef]

- Li, M. Evaluation of the effect of process parameters on the cut quality in fiber laser cutting of duplex stainless steel using response surface method (RSM). Infrared Phys. Technol. 2021, 118, 103896. [Google Scholar] [CrossRef]

- Rajesh, K.; Raju, V.V.M.K.; Rajesh, S.; Varma, N.S.K. Effect of process parameters on machinability characteristics of CO2 laser process used for cutting SS-304 Stainless steels. Mater. Today Proc. 2019, 18, 2065–2072. [Google Scholar] [CrossRef]

- Leone, C.; Mingione, E.; Genna, S. Laser cutting of CFRP by Quasi-Continuous Wave (QCW) fibre laser: Effect of process parameters and analysis of the HAZ index. Compos. Part B Eng. 2021, 224, 109146. [Google Scholar] [CrossRef]

- Son, S.; Lee, D. The Effect of Laser Parameters on Cutting Metallic Materials. Materials 2020, 13, 4596. [Google Scholar] [CrossRef]

- Tao, Z.; Li, W.; Guo, Z.; Chen, Y.; Song, L.; Li, J. Aerothermal optimization of a turbine rotor tip configuration based on free-form deformation approach. Int. J. Heat Fluid Flow 2024, 110, 109644. [Google Scholar] [CrossRef]

- Long, X.; Lu, C.; Su, Y.; Dai, Y. Machine learning framework for predicting the low cycle fatigue life of lead-free solders. Eng. Fail. Anal. 2023, 148, 107228. [Google Scholar] [CrossRef]

- Peng, X.; Chen, K.; Jia, W.; Li, K.; Huang, C.; Liu, X. Stacking sequence optimization of variable thickness composite laminated plate based on multi-peak stacking sequence table. Compos. Struct. 2025, 356, 118886. [Google Scholar] [CrossRef]

- Guo, X.; Tian, D.; Li, C.; Li, X.; Li, W.; Cao, M.; Zhang, F.; Wang, B. Optimization for the Process Parameters of Nickel–Titanium Nitride Composites Fabricated via Jet Pulse Electrodeposition. Nanomaterials 2024, 14, 2034. [Google Scholar] [CrossRef]

| Variables | Notation | Unit | −1 | 0 | +1 |

|---|---|---|---|---|---|

| Laser power | P | w | 30 | 45 | 60 |

| Cutting speed | S | mm/s | 30 | 45 | 60 |

| Focal plane position | FPP | mm | −3 | 0 | 3 |

| NO | Input Variables | Output Variables | ||||||

|---|---|---|---|---|---|---|---|---|

| Coded Values | Actual Values | Kerf with (µm) | HAZ (µm) | |||||

| P (W) | S (mm/s) | FPP (mm) | P (W) | S (mm/s) | FPP (mm) | |||

| #1 | −1 | −1 | 0 | 30 | 30 | 0 | 588.5 | 1335.3 |

| #2 | −1 | 0 | 1 | 30 | 45 | +3 | 499.3 | 1287.8 |

| #3 | 1 | 0 | 1 | 60 | 45 | +3 | 651.8 | 1383.5 |

| #4 | 0 | 0 | 0 | 45 | 45 | 0 | 604.3 | 1430.2 |

| #5 | 0 | −1 | 1 | 45 | 30 | +3 | 535.3 | 1517.3 |

| #6 | 0 | −1 | −1 | 45 | 30 | −3 | 703.6 | 1522.3 |

| #7 | 0 | 1 | 1 | 45 | 60 | +3 | 485 | 1509.4 |

| #8 | 0 | 0 | 0 | 45 | 45 | 0 | 595.7 | 1427.3 |

| #9 | 0 | 1 | −1 | 45 | 60 | −3 | 466.9 | 1019.4 |

| #10 | 1 | 0 | −1 | 60 | 45 | −3 | 607.9 | 1671.9 |

| #11 | −1 | 0 | −1 | 30 | 45 | −3 | 562.6 | 1264.8 |

| #12 | 1 | 1 | 0 | 60 | 60 | 0 | 551.1 | 1313.7 |

| #13 | 0 | 0 | 0 | 45 | 45 | 0 | 595.7 | 1385.6 |

| #14 | −1 | 1 | 0 | 30 | 60 | 0 | 414.4 | 827.3 |

| #15 | 1 | −1 | 0 | 60 | 30 | 0 | 585.6 | 1654.7 |

| Property | Unite | Value |

|---|---|---|

| Density | g/cm3 | 0.91 |

| Melting point | °C | 160 |

| Modulus of Elasticity | GPa | 0.9–1.1 |

| Electrical Resistivity | Ω/cm | 1016–1018 |

| Thermal Coefficient | --- | 72–90 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 1.686 × 10−11 | 9 | 1.873 × 10−12 | 100.20 | <0.0001 |

| A—Laser power | 3.347 × 10−12 | 1 | 3.347 × 10−12 | 179.06 | <0.0001 |

| B—Cutting speed | 6.942 × 10−12 | 1 | 6.942 × 10−12 | 371.40 | <0.0001 |

| C—Focal plane position | 4.234 × 10−13 | 1 | 4.234 × 10−13 | 22.65 | 0.0051 |

| AB | 2.053 × 10−12 | 1 | 2.053 × 10−12 | 109.83 | 0.0001 |

| AC | 4.575 × 10−13 | 1 | 4.575 × 10−13 | 24.48 | 0.0043 |

| BC | 1.029 × 10−12 | 1 | 1.029 × 10−12 | 55.05 | 0.0007 |

| A2 | 1.935 × 10−13 | 1 | 1.935 × 10−13 | 10.35 | 0.0235 |

| B2 | 2.502 × 10−12 | 1 | 2.502 × 10−12 | 133.87 | <0.0001 |

| C2 | 1.792 × 10−14 | 1 | 1.792 × 10−14 | 0.9589 | 0.3724 |

| Residual | 9.345 × 10−14 | 5 | 1.869 × 10−14 | ||

| Lack of Fit | 8.806 × 10−14 | 3 | 2.935 × 10−14 | 10.88 | 0.0853 |

| Pure Error | 5.395 × 10−15 | 2 | 2.697 × 10−15 | ||

| Cor Total | 1.695 × 10−11 | 14 | |||

| R2 = 0.99 | Adjusted R2 = 0.98 | ||||

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 2.297 × 1017 | 3 | 7.658 × 1016 | 7.34 | 0.0057 |

| A—Laser power | 1.200 × 1017 | 1 | 1.200 × 1017 | 11.50 | 0.0060 |

| B—Cutting speed | 1.091 × 1017 | 1 | 1.091 × 1017 | 10.46 | 0.0080 |

| C—Focal plane position | 6.900 × 1014 | 1 | 6.900 × 1014 | 0.0661 | 0.8018 |

| Residual | 1.148 × 1017 | 11 | 1.043 × 1016 | ||

| Lack of Fit | 1.139 × 1017 | 9 | 1.266 × 1016 | 29.91 | 0.0328 |

| Pure Error | 8.463 × 1014 | 2 | 4.232 × 1014 | ||

| Cor Total | 3.445 × 1017 | 14 | |||

| R2 = 0.66 | Adjusted R2 = 0.57 | ||||

| Parameter/Response | Goal | Lower | Upper | Importance | ||

|---|---|---|---|---|---|---|

| Parameter | Laser power | In range | 30 | 60 | - | |

| Cutting speed | In range | 30 | 60 | - | ||

| Focal plane position | In range | −3 | +3 | - | ||

| Response | Criteria Set 1 | Kerf width | Minimize | 414.388 | 703.597 | 3 |

| Heat-Affected Zone | Minimize | 827.338 | 1671.94 | 3 | ||

| Criteria Set 2 | Kerf width | Minimize | 414.388 | 703.597 | 2 | |

| Heat-Affected Zone | Minimize | 827.338 | 1671.94 | 5 | ||

| Criteria Set 3 | Kerf width | Minimize | 414.388 | 703.597 | 5 | |

| Heat-Affected Zone | Minimize | 827.338 | 1671.94 | 2 | ||

| Solution | Laser Power | Cutting Speed | Focal Plane Position | Kerf Width | HAZ | Desirability |

|---|---|---|---|---|---|---|

| 1 | 30.000 | 60.000 | −3.000 | 415.721 | 1001.314 | 0.935 |

| 2 | 30.000 | 60.000 | −2.999 | 415.720 | 1001.294 | 0.912 |

| 3 | 30.000 | 60.000 | −3.000 | 415.721 | 1001.293 | 0.958 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mehrabi, O.; Malekshahi Beiranvand, Z.; Rasoul, F.A.; Moradi, M. Enhancing the Quality and Sustainability of Laser Cutting Processes in Laser-Assisted Manufacturing Using a Box–Behnken Design. Processes 2025, 13, 1279. https://doi.org/10.3390/pr13051279

Mehrabi O, Malekshahi Beiranvand Z, Rasoul FA, Moradi M. Enhancing the Quality and Sustainability of Laser Cutting Processes in Laser-Assisted Manufacturing Using a Box–Behnken Design. Processes. 2025; 13(5):1279. https://doi.org/10.3390/pr13051279

Chicago/Turabian StyleMehrabi, Omid, Zeinab Malekshahi Beiranvand, Fakhir A. Rasoul, and Mahmoud Moradi. 2025. "Enhancing the Quality and Sustainability of Laser Cutting Processes in Laser-Assisted Manufacturing Using a Box–Behnken Design" Processes 13, no. 5: 1279. https://doi.org/10.3390/pr13051279

APA StyleMehrabi, O., Malekshahi Beiranvand, Z., Rasoul, F. A., & Moradi, M. (2025). Enhancing the Quality and Sustainability of Laser Cutting Processes in Laser-Assisted Manufacturing Using a Box–Behnken Design. Processes, 13(5), 1279. https://doi.org/10.3390/pr13051279