Pore Structure Characteristics and Controlling Factors of an Interbedded Shale Oil Reservoir—A Case Study of Chang 7 in the HSN Area of the Ordos Basin

Abstract

:1. Introduction

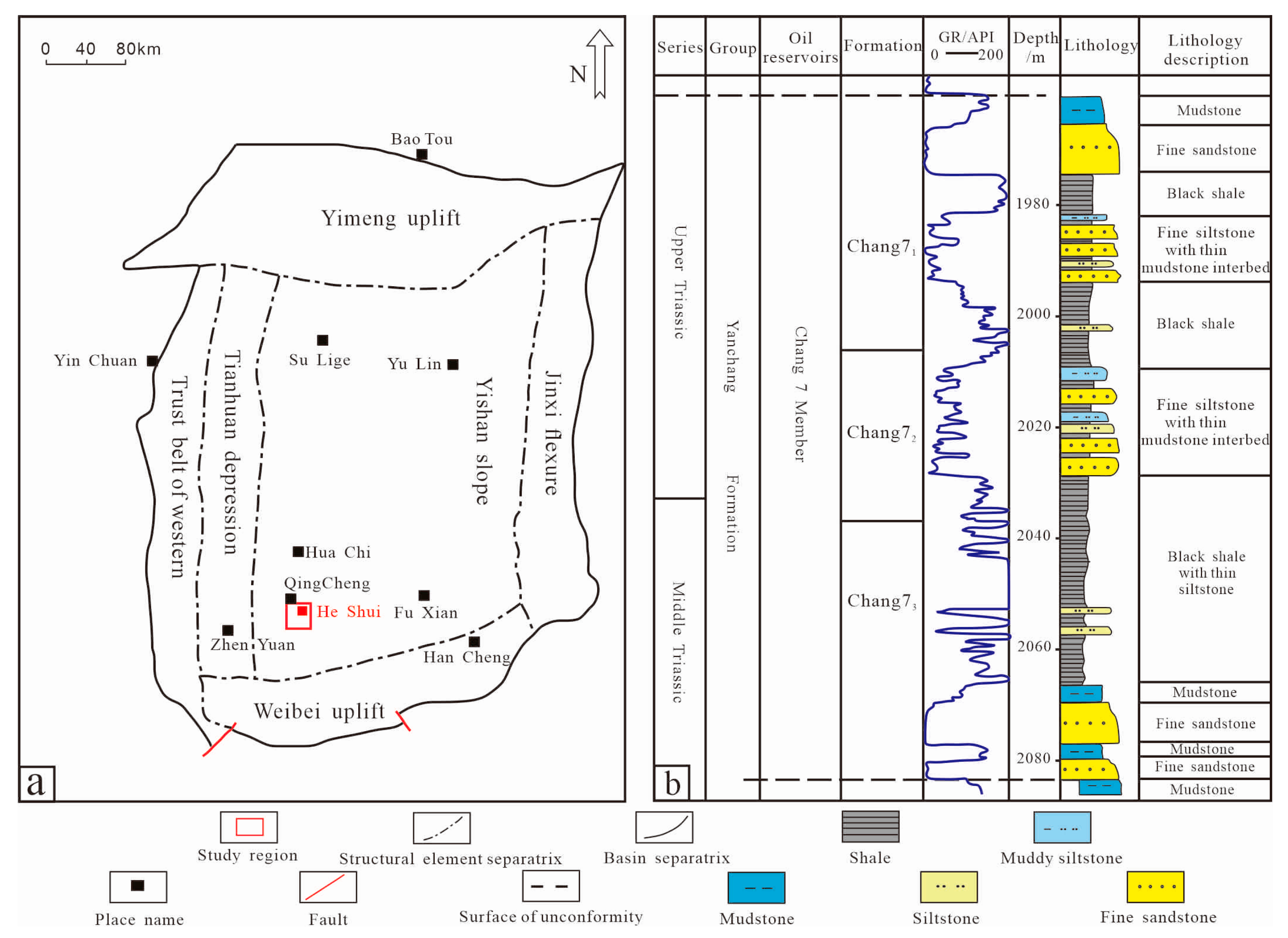

2. Geological Background

3. Experiments and Methods

3.1. Samples

3.2. Petrographic Observation

3.3. Experimental Measurement

4. Results

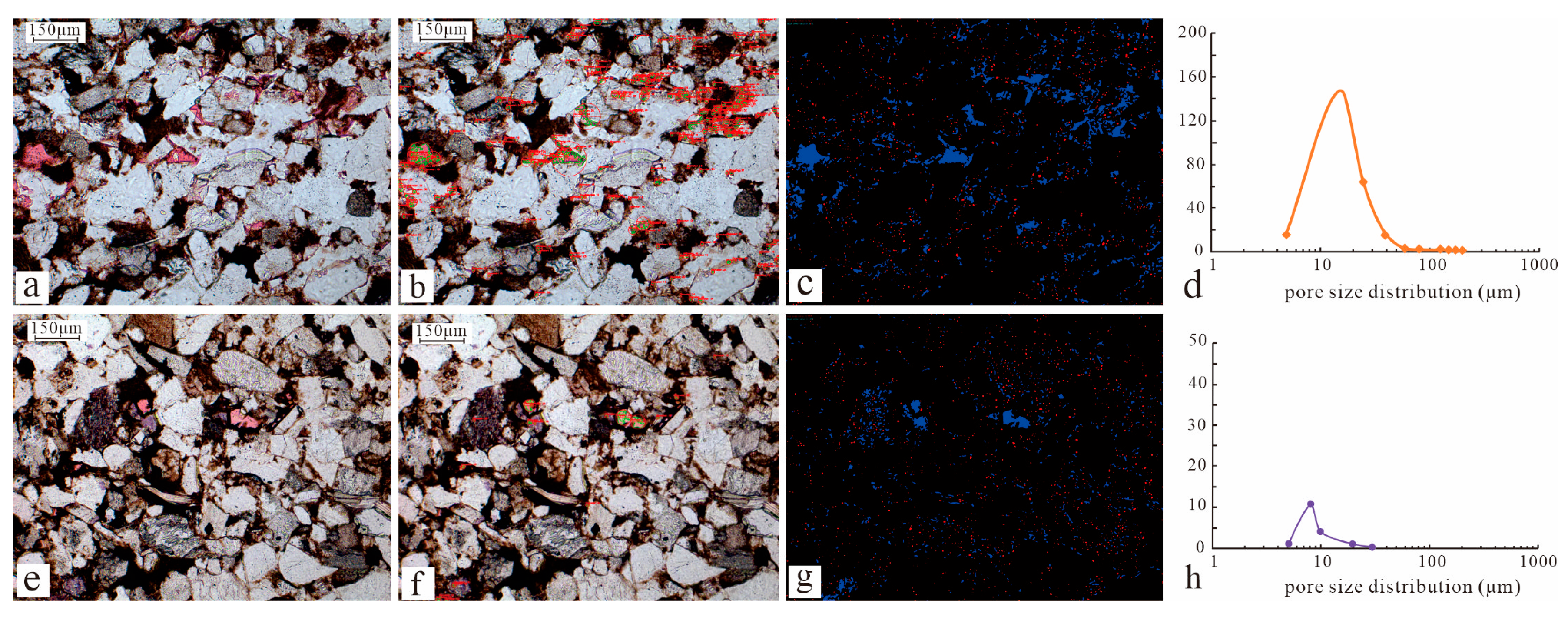

4.1. Pore Type and Pore Shape

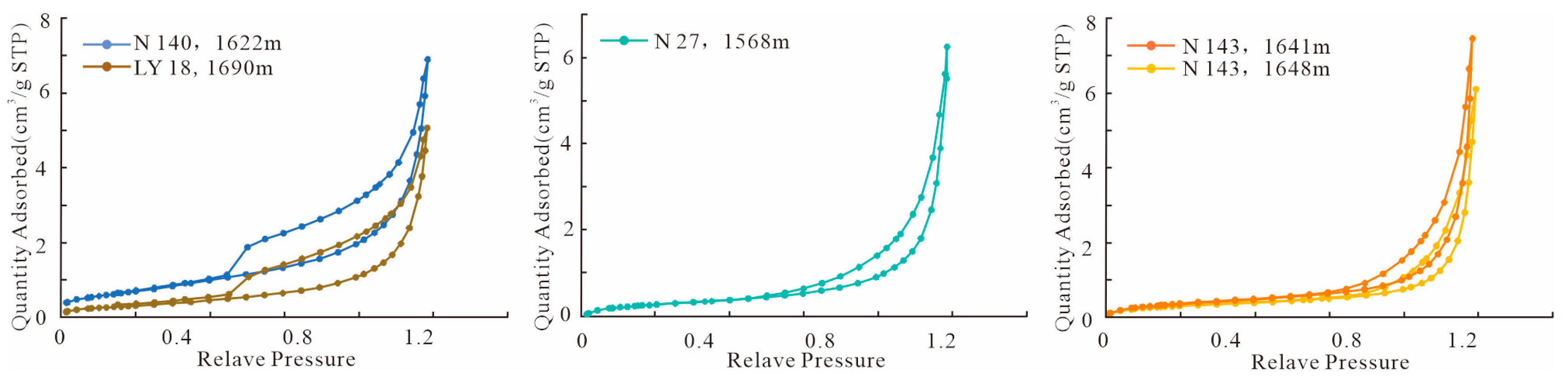

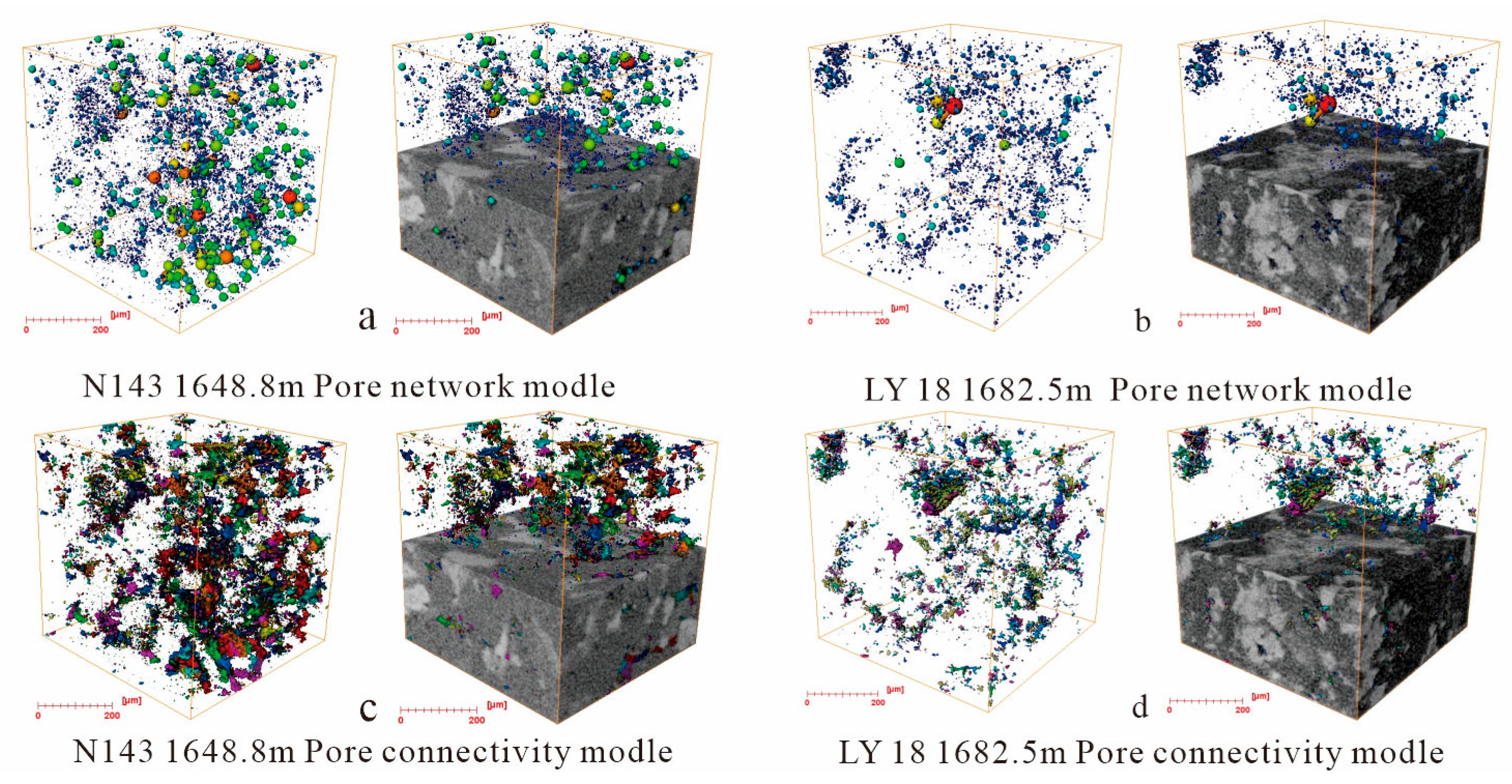

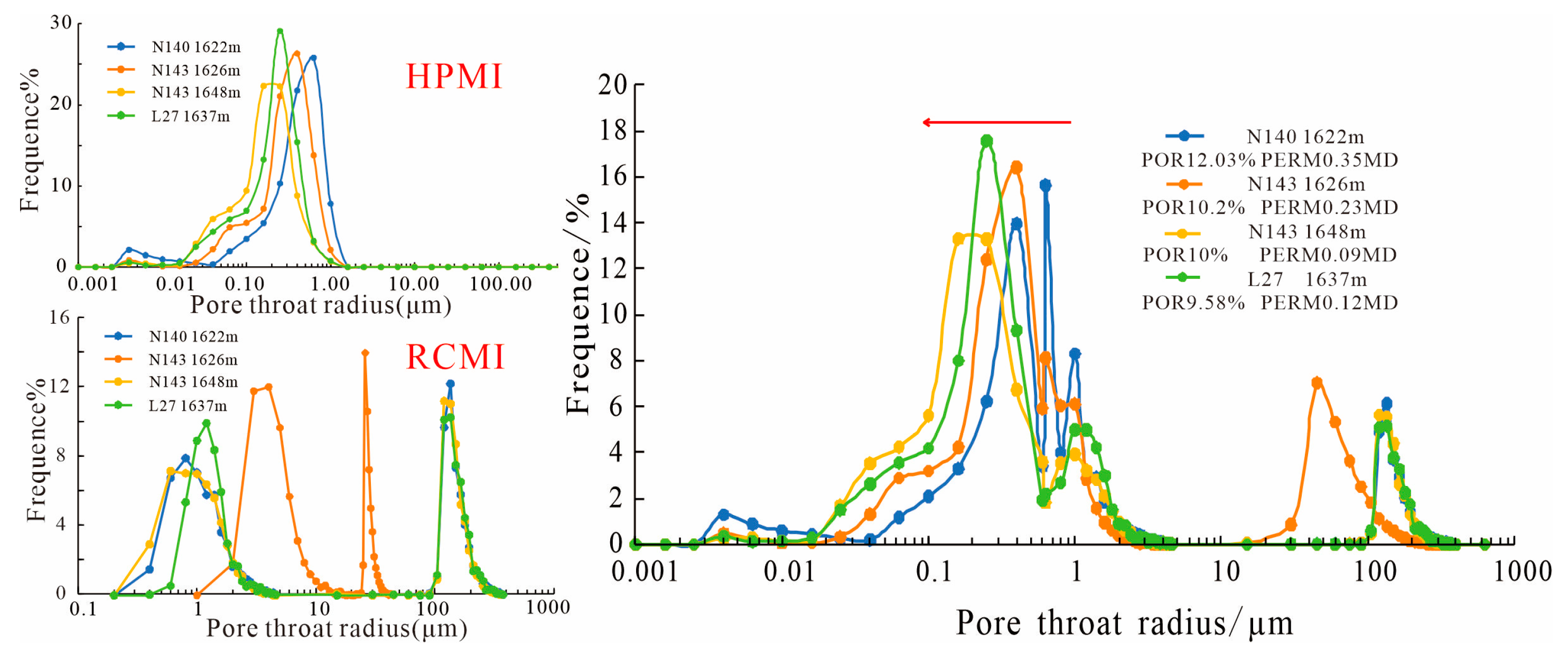

4.2. Pore Structure and Pore Radius

5. Discussion

5.1. Control of Pore Structure by Sedimentation

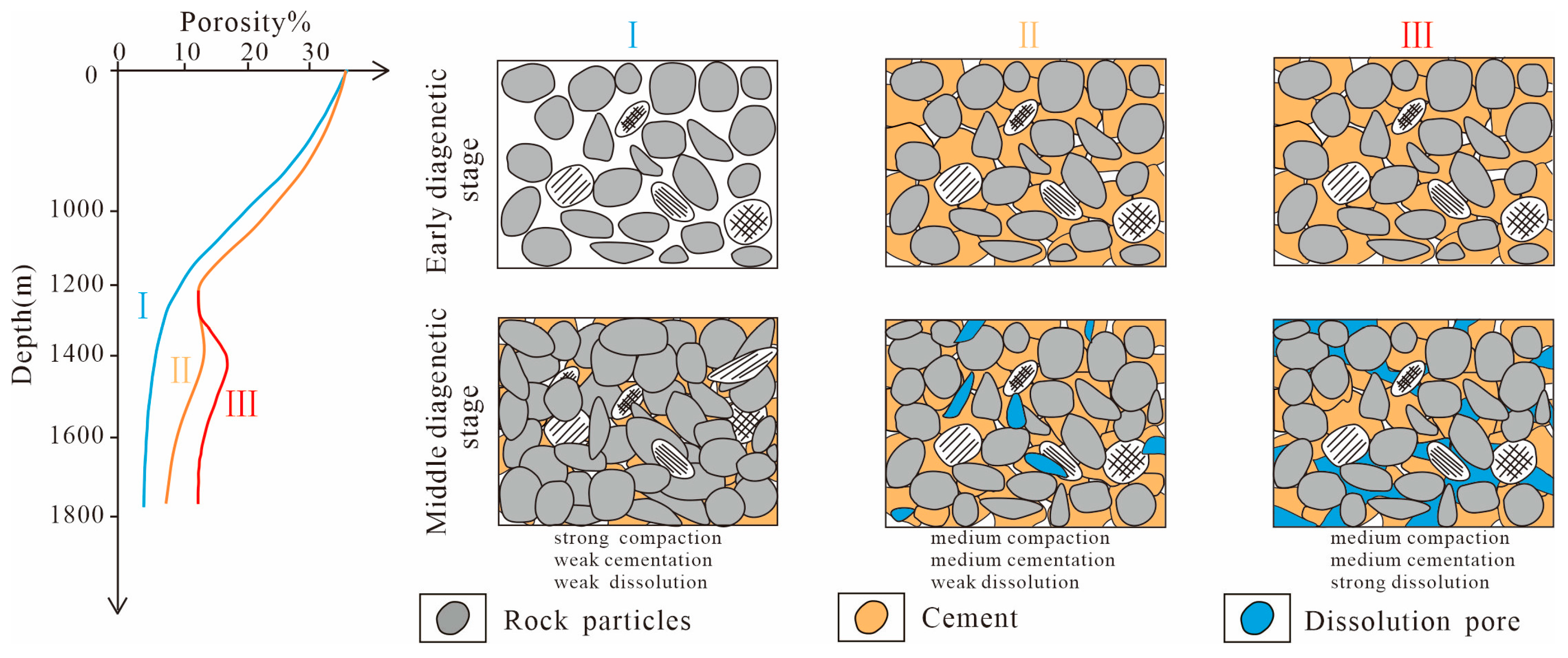

5.2. Control of Pore Structure by Diagenesis

5.2.1. Diagenesis

Compaction

Cementation

- (1)

- Carbonate cementation

- (2)

- Clay cementation

Dissolution

5.3. Advantageous Reservoir Forming Mechanism

6. Conclusions

- (1)

- The Chang 7 interbedded shale oil reservoir in the HSN area has extremely strong heterogeneity and extremely low porosity and permeability. The pore types are diverse, mainly feldspar and debris dissolution pores, residual intergranular pores, and a small number of microcracks are developed.

- (2)

- The pore shapes are mainly parallel-slit and ink-bottle shapes. The pore radius is mainly distributed in the range of 30 to 200 µm, and the throat radius is mainly distributed in the range of 0.3 to 2 µm.

- (3)

- The pore structure of interbedded shale oil reservoirs in the HSN area is controlled by sedimentation and diagenesis. Sedimentation determines the material basis of fine size and high matrix clay content. Compaction and cementation are the main factors for reducing pores in the study area. The effect of sand debris flow is reduced by cementation. The effect of turbidity current is reduced by compaction. The strength of dissolution is the key to the development of high-quality reservoirs.

- (4)

- We established the formation mode of the high-quality reservoir of the Chang 7 interbedded shale in the HSN area. The formation of the sandy debris flow is attributed to medium compaction, medium cementation, and medium dissolution, which results in good physical properties and large pore sizes. It is the main factor for high-quality reservoirs in the study area.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, W.X. Development and prospect of oil and gas resource evaluation. Fault-Block Oil Gas Field 1994, 38–40+49. [Google Scholar]

- Zou, C.; Pan, S.; Jing, Z.; Gao, J.; Yang, Z.; Wu, S.; Zhao, Q. Shale oil and gas revolution and its impact. Acta Pet. Sin. 2020, 41, 1–12. [Google Scholar]

- Wang, X.; Hou, J.; Li, S.; Dou, L.; Song, S.; Kang, Q.; Wang, D. Insight into the nanoscale pore structure of organic-rich shales in the Bakken Formation, USA. J. Pet. Sci. Eng. 2020, 191, 107182. [Google Scholar] [CrossRef]

- Li, G.X.; Zhu, R.K. Progress, challenges and key issues of uncoventional oil and gas development of CNPC. China Pet. Explor. 2020, 25, 1–13. [Google Scholar]

- Tanguang, F.; Xiongfei, X.; Liang, F.; Yaqin, F.; Wenhui, L.; Juntian, L.; Meiyan, W.; Guoqiang, J. Geological characteristics and exploration prospect of shale oil in Permian Lucaogou Formation, Santanghu Basin. China Pet. Explor. 2021, 26, 125–136. [Google Scholar]

- Yang, H.; Li, S.X.; Liu, X.Y. Characteristics and resource prospects of tight oil and shale oil in Ordos Basin. Acta Pet. Sin. 2013, 34, 1–11. [Google Scholar]

- Ma, W.Z.; Wang, Y.H.; Zhang, S.; Fe, S.B.; Ha, B.Y.; Cu, X.L. Microscopic characteristics and controlling factors of Chang 7 Member shale oil reservoir in northern Shanxi area, Ordos Basin. Nat. Gas Geosci. 2021, 32, 1810–1821. [Google Scholar]

- Wang, Z.; Li, Z.; Xi, K.; Wu, Y. Analysis of main control factor of Mesozoic oil and gas accumulation in Ordos Basin of Zhenjing rejion. Fault-Block Oil Gas Field 2007, 14, 25–27+90. [Google Scholar]

- Fu, J.H.; Yu, J.; Xu, L.M.; Niu, X.B.; Feng, S.B.; Wang, X.J.; You, Y.; Li, T. New Progress in Exploration and Development of Tight Oil in Ordos Basin and Main Controlling Factors of Large-scale Enrichment and Exploitable Capacity. China Pet. Explor. 2015, 20, 9–19. [Google Scholar]

- Li, W.; Wen, Z.G. Characterisitics and distribution of Chang7 source rocks of Yangchang Formation in Maling Area of Ordos Basin. Fault-Block Oil Gas Field 2014, 21, 24–27. [Google Scholar]

- Zhao, W.Z.; Hu, S.Y.; Hou, L.H. Connotation and strategic role of in-situ conversion processing of shale oil underground in the onshore China. Pet. Explor. Dev. 2018, 45, 537–545. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.C.; Cao, H.; Wu, J.; Wang, F.; Wang, Y. The Crack Propagation Behaviour of CO2 Fracturing Fluid in Unconventional Low Permeability Reservoirs: Factor Analysis and Mechanism Revelation. Processes 2025, 13, 159. [Google Scholar] [CrossRef]

- Li, Q.C.; Li, Q.; Wu, J.; Li, X.; Li, H.; Cheng, Y. Wellhead Stability During Development Process of Hydrate Reservoir in the Northern South China Sea: Evolution and Mechanism. Processes 2025, 13, 40. [Google Scholar] [CrossRef]

- Wang, X.; Yu, S.; Li, S.; Zhang, N. Two parameter optimization methods of multi-point geostatistics. J. Pet. Sci. Eng. 2022, 208, 109724. [Google Scholar] [CrossRef]

- Tang, H.P.; Chen, S.J.; Zhang, X.W.; Huang, Y.L.; Yao, Y.T. Influence of physical property and pore throat structure on oiliness of tight sandatone reservoir: Taking Chang7 oil-bearing formation in Huachi-Heshui Area of Ordos Basin as an example. Fault-Block Oil Gas Field 2015, 22, 198–201. [Google Scholar]

- Zhao, J.R.; Zhu, H.H.; Feng, X.Z.; Ma, X.Q. Characteristics of Member 7 mica of Yangchang Formation in Ordos Basin and its effetcs on reservoirs. Fault-Block Oil Gas Field 2021, 28, 194–199. [Google Scholar]

- Wu, H.; Zhang, C.; Ji, Y.; Liu, R.E.; Cao, S.; Chen, S.; Zhang, Y.; Wang, Y.; Du, W.; Liu, G. Pore-throat size characterization of tight sandstone and its control on reservoir physical proper Formation, eastern Gansu, Ordos Basin. Acta Pet. Sin. 2017, 38, 876–887. [Google Scholar]

- Giffin, S.; Littke, R.; Klaver, J.; Urai, J.L. Application of BIB–SEM technology to characterize macropore morphology in coal. Int. J. Coal Geol. 2013, 114, 85–95. [Google Scholar] [CrossRef]

- Zhao, J.Z.; Wang, R.; Er, C. Adsorption characteristics of Chang7 shale from the Triassic Yanchang Formation in Ordos Basin, and its controlling factor. Earth Sci. Front. 2016, 23, 146–153. [Google Scholar]

- Wang, X.; Zhou, X.; Li, S.; Zhang, N.; Ji, L.; Lu, H. Mechanism study of hydrocarbon differential distribution controlled by the activity of growing faults in faulted basins: Case study of Paleogene in the Wang Guantun Area, Bohai Bay Basin, China. Lithosphere 2022, 2021, 7115985. [Google Scholar] [CrossRef]

- Zhong, D.K.; Zhu, H.H.; Sun, H.T.; Cai, C.; Yao, J.L.; Liu, X.Y.; Deng, X.Q.; Luo, A.X. Diagenesis and Porosity evolution of sandstone in Longdong Area,Ordos Basin. Earth Sci. Front. 2013, 20, 61–68. [Google Scholar]

- Fu, J.H.; Niu, X.B.; Dan, W.D.; Feng, S.B.; Liang, X.W.; Xin, H.G.; You, Y. The geological characteristics and the progress on exploration and development of shale oil in Chang7 Member of Mesozoic Yanchang Formation,Ordos Basin. China Pet. Explor. 2019, 24, 601–614. [Google Scholar]

- Deng, X.; Fu, J.; Yao, J.; Pang, J.; Sun, B. Sedimentary facies of the Middle-Upper Triassic Yanchang Formation in Ordos Basin and breakthrough in petroleum exploration. J. Palaeogeogr. 2011, 13, 443–455. [Google Scholar]

- Li, S.; Zhu, R.k.; Cui, J.w.; Liu, H. Paleoenvironment and controlling factors of organic matter enrichment:a case of Chang7 oil reservoir in southern margin of Ordos Basin. Lithol. Reserv. 2019, 31, 87–95. [Google Scholar]

- Fu, J.H.; Guo, W.; Li, S.X.; Liu, X.Y.; Cheng, D.X.; Zhou, X.P. Characteristics and exploration potential of muti-type shale oil in the 7th Member of Yanchang Formation, Ordos Basin. Nat. Gas Geosci. 2021, 32, 1749–1761. [Google Scholar]

- Zou, C.N.; Zhao, Z.Z.; Yang, H.; Fu, J.H.; Zhu, R.K.; Yuan, X.J.; Wang, L. Genetic Mechanism and Distribution of Sandy Debris Flows in Terrestrial Lacustrine Basin. Acta Sedimentol. 2009, 27, 1065–1075. [Google Scholar]

- GB/T 29172-2012; Practices for Core Analysis. Standardization Administration of the People’s Republic of China: Beijing, China, 2012.

- Lu, C.; Wang, X.; Ma, S.; Li, S.; Xue, T.; Li, Q. The Classification and Evaluation of an Interlayer Shale Oil Reservoir Based on the Fractal Characteristics of Pore Systems: A Case Study in the HSN Area, China. Fractal Fract. 2024, 8, 167. [Google Scholar] [CrossRef]

- Xiao, D.S.; Zhao, R.W.; Yang, X.; Fang, D.Z.; Li, B.; Kong, X.X. Characterization, classification and contribution of marine shale gas reservoirs. Oil Gas Geol. 2019, 40, 1215–1225. [Google Scholar]

- Xiao, Y.; Xiao, H.; Jiang, Z. Analysis on difference of pore-throat structure of tight sandstone reservoirs characterized by constant-rate mercury intrusion and high-pressure mercury intrusion experiments. China Energy Environ. Prot. 2021, 43, 59–63. [Google Scholar]

- Yan, C.; Wang, X.; Li, S.; Duan, D.; Liu, Y.; Zhao, B. Sand architecture interpretation and modeling with few wells in the offshore—Case study of X36 area in the Xihu Depression, East China Sea, China. Interpretation 2023, 11, SA1–SA11. [Google Scholar] [CrossRef]

- Liu, K.; Xia, M.; Yang, X.M. An Effective 2D Convex Hull Algorithm. Adv. Eng. Sci. 2017, 49, 109–116. [Google Scholar]

- Wang, X.; Zhang, F.; Li, S.; Dou, L.; Liu, Y.; Ren, X.; Chen, D.; Zhao, W. The architectural surfaces characteristics of sandy braided river reservoirs, case study in Gudong Oil Field, China. Geofluids 2021, 2021, 8821711. [Google Scholar] [CrossRef]

| Test Method | Sample | Enter Pressure (MPa) | Average Radius (µm) | Maximum Mercury Saturation (%) | Maximum Mercury Removal Efficiency (%) |

|---|---|---|---|---|---|

| HPMI | N140 1622 m | 0.465 | 0.428 | 82.585 | 22.103 |

| N143 1626 m | 0.675 | 0.278 | 84.989 | 17.123 | |

| N143 1648 m | 0.675 | 0.209 | 83.891 | 15.334 | |

| L27 1637 m | 0.674 | 0.245 | 82.892 | 15.461 | |

| N23 1605 m | 5.501 | 0.040 | 74.294 | 30.556 | |

| N23 1613.2 m | 1.364 | 0.162 | 78.259 | 9.275 | |

| N27 1568.5 m | 1.361 | 0.125 | 83.752 | 30.890 | |

| N27 1572.6 m | 0.675 | 0.189 | 87.058 | 22.570 | |

| N142 1712 m | 2.047 | 0.114 | 84.767 | 22.901 | |

| N142 1792 m | 0.671 | 0.244 | 83.553 | 12.539 |

| Test Method | Sample | Enter Pressure (MPa) | Average Pore Radius (µm) | Average Pore-Throat Radius (µm) | Maximum Mercury Saturation (%) |

|---|---|---|---|---|---|

| RCMI | N140 1622 m | 0.433 | 158.992 | 1.331 | 71.956 |

| N143 1626 m | 0.406 | 151.311 | 0.998 | 67.922 | |

| N143 1648 m | 0.585 | 155.251 | 1.245 | 63.620 | |

| L27 1637 m | 0.610 | 159.674 | 0.722 | 65.138 |

| Sample | Pore Number | Throat Number | Average Pore Radius (um) | Average Throat Radius (um) | Pore Main Peak Distribution (um) | Average Pore Volume (um3) |

|---|---|---|---|---|---|---|

| N143 1648.8 m | 10,349 | 958 | 2.11 | 1.68 | 0~2 | 181.15 |

| LY18 1682.5 m | 6030 | 464 | 1.78 | 1.67 | 0~2 | 145 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, L.; Wang, X.; Zhao, B.; Ma, S. Pore Structure Characteristics and Controlling Factors of an Interbedded Shale Oil Reservoir—A Case Study of Chang 7 in the HSN Area of the Ordos Basin. Processes 2025, 13, 1331. https://doi.org/10.3390/pr13051331

Fu L, Wang X, Zhao B, Ma S. Pore Structure Characteristics and Controlling Factors of an Interbedded Shale Oil Reservoir—A Case Study of Chang 7 in the HSN Area of the Ordos Basin. Processes. 2025; 13(5):1331. https://doi.org/10.3390/pr13051331

Chicago/Turabian StyleFu, Linpu, Xixin Wang, Bin Zhao, and Shuwei Ma. 2025. "Pore Structure Characteristics and Controlling Factors of an Interbedded Shale Oil Reservoir—A Case Study of Chang 7 in the HSN Area of the Ordos Basin" Processes 13, no. 5: 1331. https://doi.org/10.3390/pr13051331

APA StyleFu, L., Wang, X., Zhao, B., & Ma, S. (2025). Pore Structure Characteristics and Controlling Factors of an Interbedded Shale Oil Reservoir—A Case Study of Chang 7 in the HSN Area of the Ordos Basin. Processes, 13(5), 1331. https://doi.org/10.3390/pr13051331