Abstract

As Malaysia is a fast-developing country, its prospects of sustainable energy generation are at the center of debate. Malaysian municipal solid waste (MSW) is projected to have a 3.3% increase in annual generation rate at the same time an increase of 3.3% for electricity demand. In Malaysia, most of the landfills are open dumpsite and 89% of the collected MSW end up in landfills. Furthermore, huge attention is being focused on converting MSW into energy due to the enormous amount of daily MSW being generated. Sanitary landfill to capture methane from waste landfill gas (LFG) and incineration in a combined heat and power plant (CHP) are common MSW-to-energy technologies in Malaysia. MSW in Malaysia contains 45% organic fraction thus landfill contributes as a potential LFG source. Waste-to-energy (WTE) technologies in treating MSW potentially provide an attractive economic investment since its feedstock (MSW) is collected almost for free. At present, there are considerable issues in WTE technologies although the technology employing MSW as feedstock are well established, for instance the fluctuation of MSW composition and the complexity in treatment facilities with its pollutant emissions. Thus, this study discusses various WTE technologies in Malaysia by considering the energy potentials from all existing incineration plants and landfill sites as an effective MSW management in Malaysia. Furthermore, to promote local innovation and technology development and to ensure successful long-term sustainable economic viability, social inclusiveness, and environmental sustainability in Malaysia, the four faculties of sustainable development namely technical, economic, environmental, and social issues affiliated with MSW-to-Energy technologies were compared and evaluated.

1. Introduction

The aim of this paper is to provide readers with a better picture on the current environmental and energy issues arising from the continuous municipal solid waste (MSW) generation and economic development in Malaysia. The paper addresses how MSW-to-energy can play an important role in achieving the United Nation’s sustainable development goals (UN-SDGs) and showcases the available MSW-to-energy plants in Malaysia. Moreover, a holistic analysis involving the four faculties in sustainable development, namely technical, economic, environmental, and social, together with the SWOT (strength, weakness, opportunity, and threat) analysis is discussed to select the most appropriate waste-to-energy (WTE) technology for ensuring long-term sustainability of WTE implementation and waste management practices in Malaysia can be achieved.

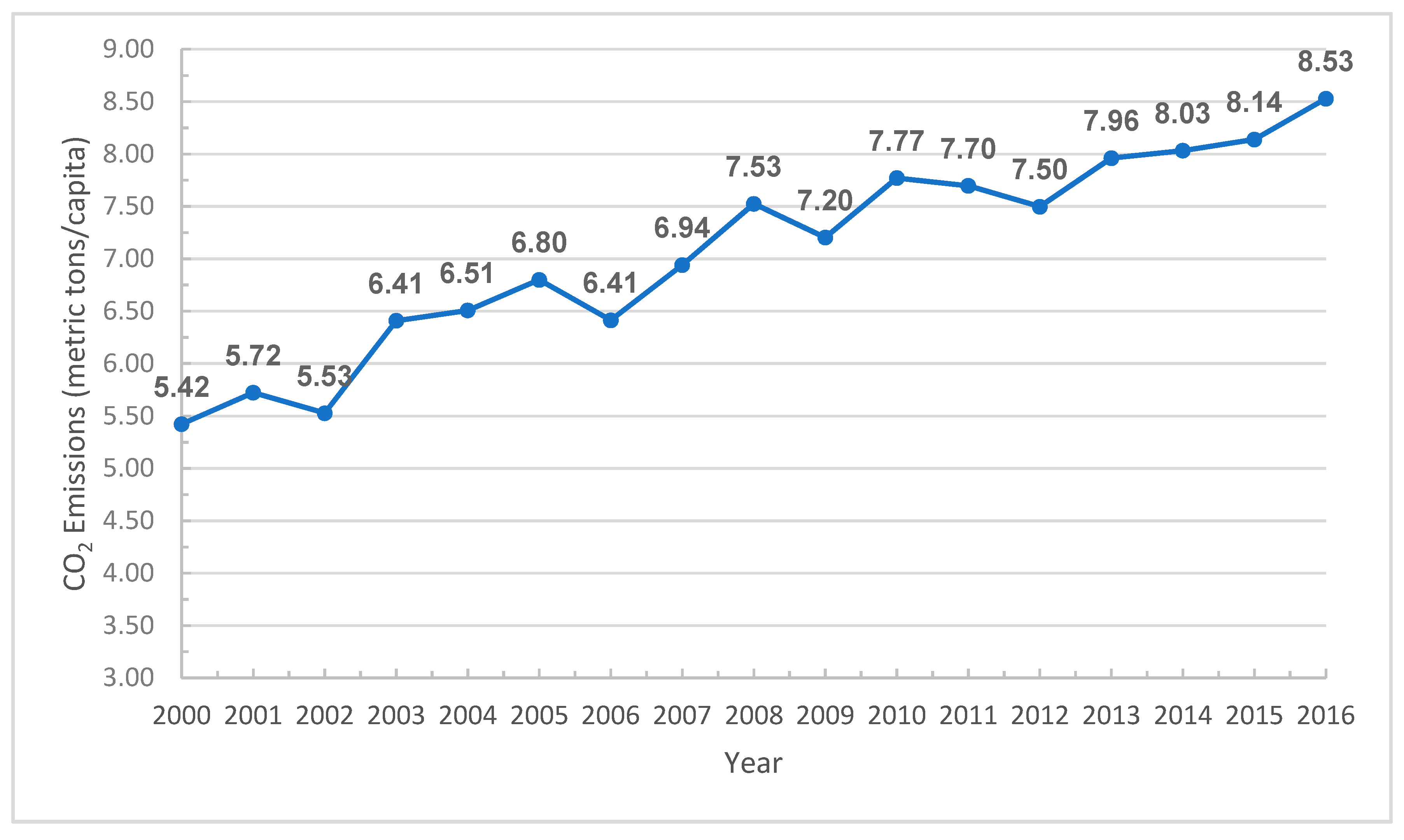

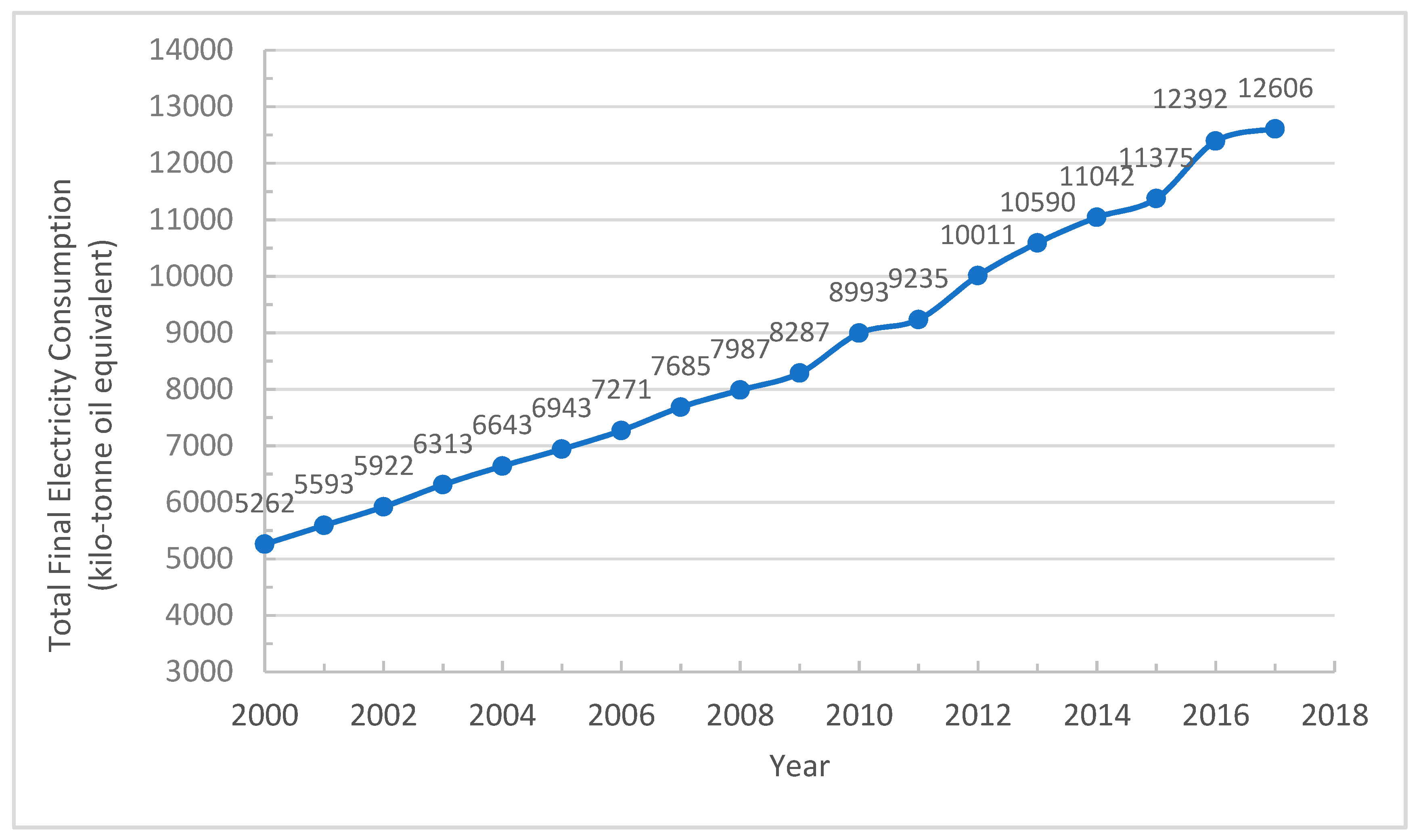

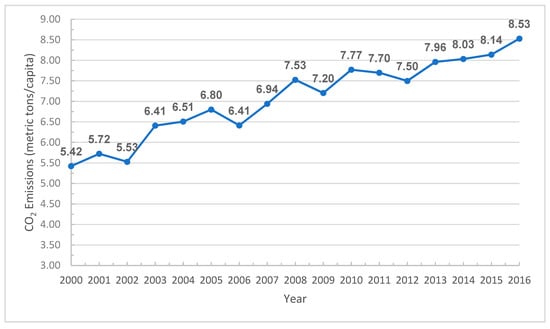

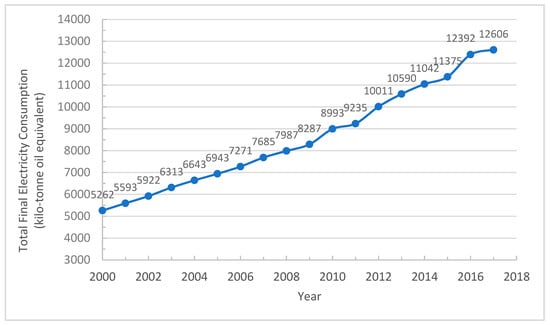

As the population increases, the need for more material and energy consumption increases. This contributes significantly to the amount of anthropogenic municipal solid waste (MSW) generation and greenhouse gases (GHGs) emissions resulting from electricity production to support the ever-increasing services needed by the growing population. Malaysia, as an emerging developing country, is currently facing the dilemma of MSW management with increasing GHGs especially methane gas resulting from the degradation of organic waste within landfills and the need for more energy (electricity) and material consumption to support the growing Malaysian population. Currently, the Malaysia’s average solid waste generation per capita is 1.17 kg/day [1]. Major cities contribute toward higher waste generation per capita due to mass consumption and higher purchasing power. For instance, the capital of Malaysia, Kuala Lumpur, has an average generation rate of 1.35 kg/person/day and Penang has waste generation rate ranging from 1.5 to 1.8 kg/person/day [1,2]. The carbon dioxide (CO2) emission per capita in Malaysia has increased from 5.42 metric tons in 2000 to 8.53 metric tons (MT) in 2016 which had an increase of 57.38% as shown in Figure 1; while the final electricity consumption combining agriculture, commercial, transport, industry, and residential in 2016 was 12,392 kilo-ton oil equivalent (ktoe)/person/year, which had increased 70.43% from the level in 2006 at 7271 ktoe/person/year as indicated in Figure 2. At present, the total solid waste generation in Malaysia is 33,130 tonnes per day, and is expected to increase further to 49,670 tonnes per day by 2030 [1]. The energy demand is expected to increase by 4.7% and there is an average annual growth of 8.1% in the final electricity consumption which will eventually contribute to more GHG emissions if the energy sector in Malaysia is still largely dependent on fossil fuel resources, namely diesel, coal, and natural gas for electricity generation [3]. Hence there is an urgent need to resolve multiple issues and dilemmas towards a more sustainable waste management, lowering per capita CO2 emissions and clean energy production in Malaysia.

Figure 1.

The increasing trend of CO2 emissions per capita in Malaysia from 2000 to 2016 [4].

Figure 2.

Final electricity consumption, kilo-tonne oil equivalent (ktoe) in Malaysia [8].

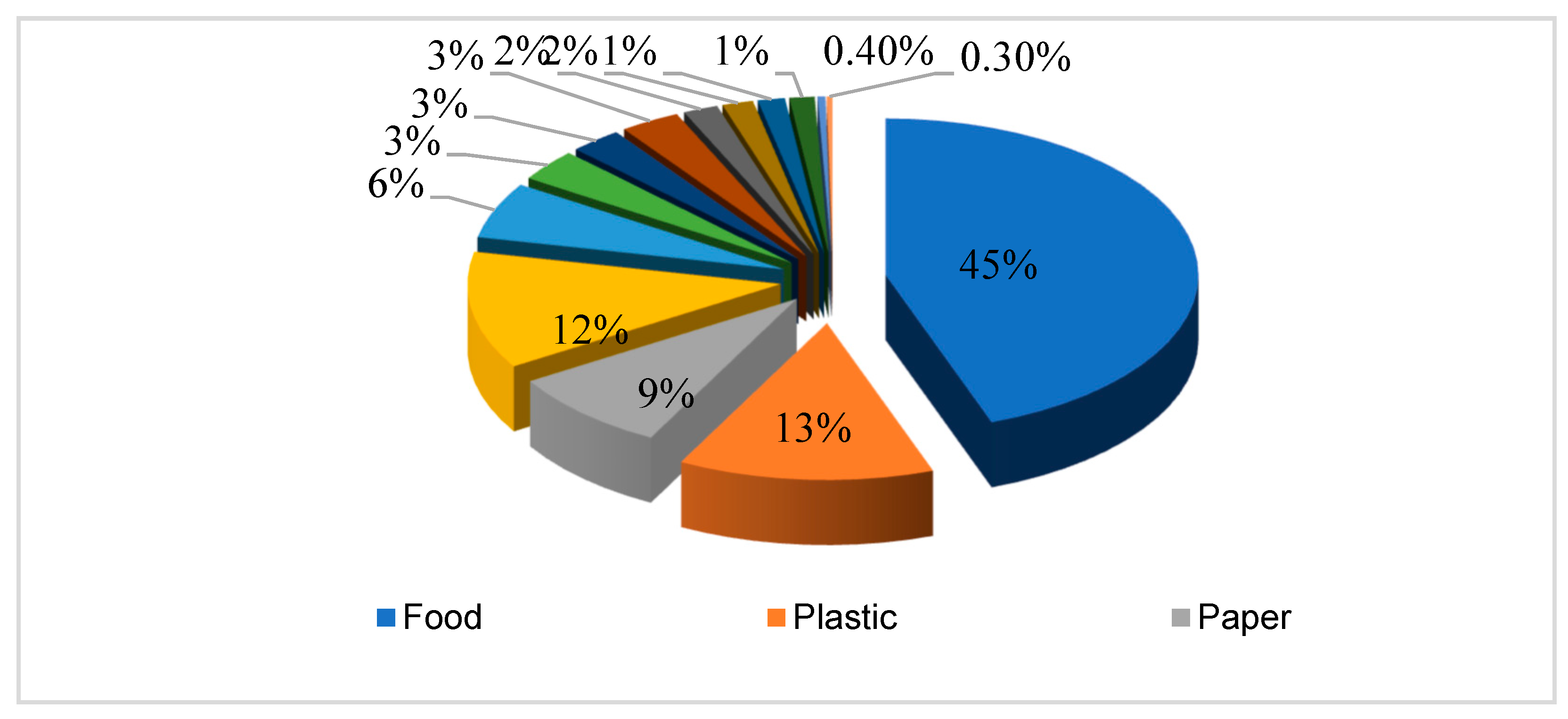

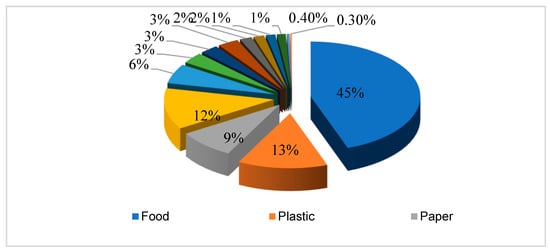

A total of 89% of the Malaysian MSW generated directly enter into landfills with minimal treatment, where only 1% of the total incoming MSW receive proper treatment [1]. In Malaysia, 50% of landfills are open dumping sites; 30% use-controlled tipping; 12% are controlled landfills with daily cover; 5% are sanitary landfills without leachate treatment facility; and the other 5% are sanitary landfills with leachate treatment. Within the coming 10 years (by 2030), over 80% of the Malaysian open dumping landfill sites are to be shut down due to reaching full capacity. The major MSW fractions generated in Malaysia are 45% organic material, 13% plastics, 12% diapers, 9% paper, 3% glass, 3% metal and others [1,5]. Figure 3 shows the composition of solid waste in Malaysia. It can be concluded that organic waste represents the largest portion of the total solid waste produced by Malaysians therefore making landfills a potential source of landfill gas (LFG) [6]. Nevertheless, decommissioning a landfill involves the process of obtaining other lands and is an environmentally challenging process. This will make land scarcer in the future. Employing MSW to energy can solve two problems at once, namely the demand for more energy and the continuous increase in MSW generation. Hence, waste is no longer an undesired product from the society but a new resource by treating non-recyclables and non-reusables from MSW to generate a substantial amount of energy for urban use while preserving scarce lands [7].

Figure 3.

Malaysian waste fraction [8].

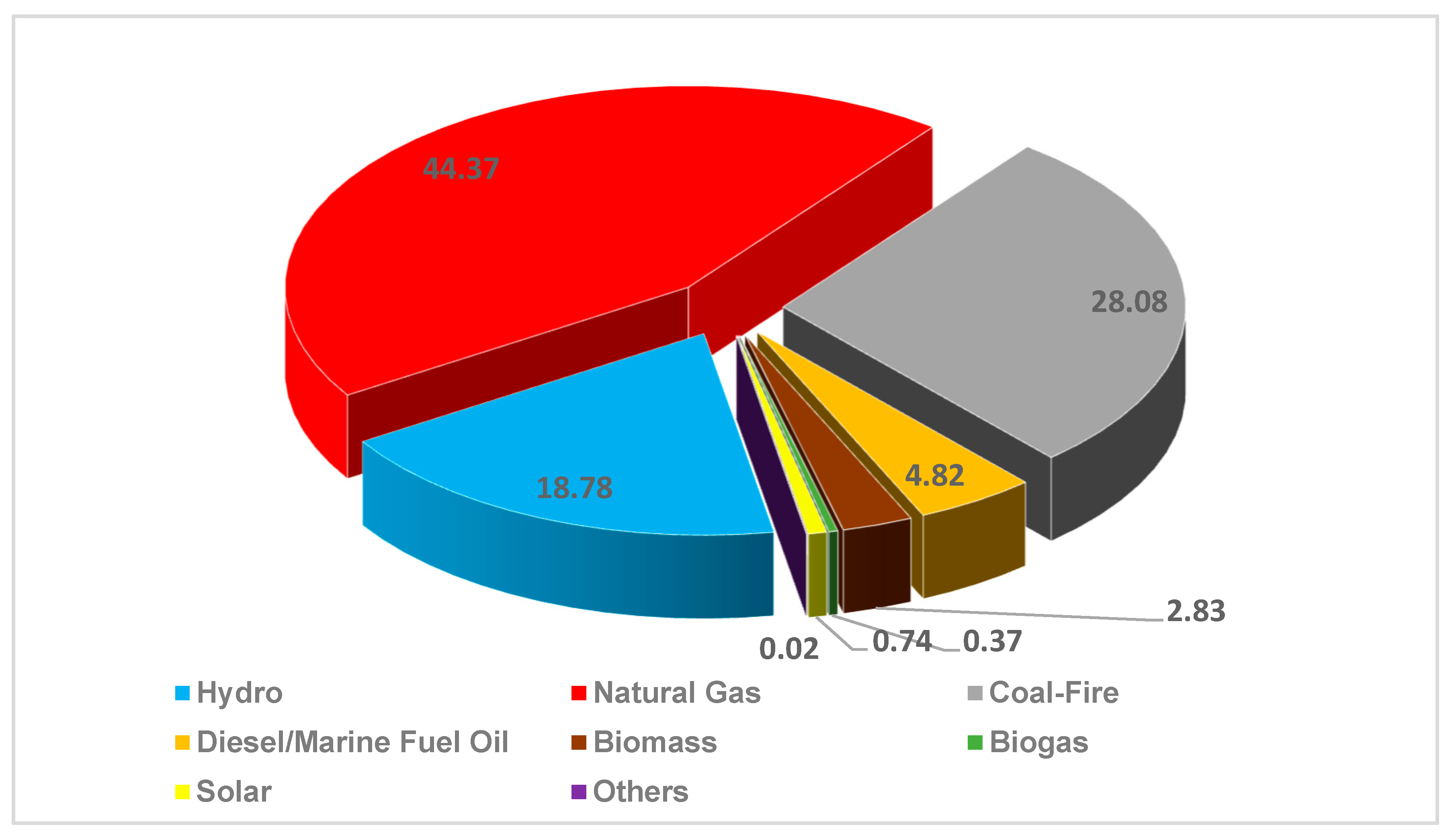

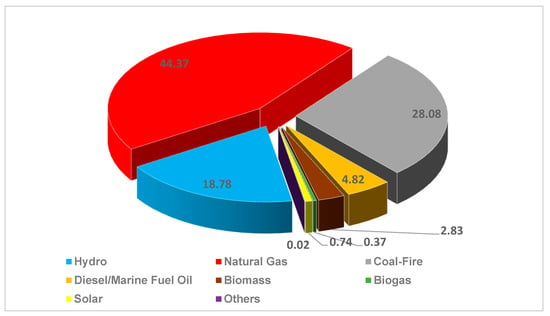

Malaysian electricity generation is still largely dependent on fossil fuel-based resources for which accounts for 77.27% or 23,518.10 MW installed capacity source from natural gas, coal, and diesel/Marine Fuel Oil (MFO) while large-hydro power contributes 18.78% or 5716.10 MW. Only a small fraction of 3.96% or 1205.20 MW are from renewable energy (RE) resources by excluding large-hydro namely biomass, biogas, solar, and geothermal as indicated in Figure 4.

Figure 4.

The percentage, %, of share in installed capacity of energy resources in the production of electricity [11].

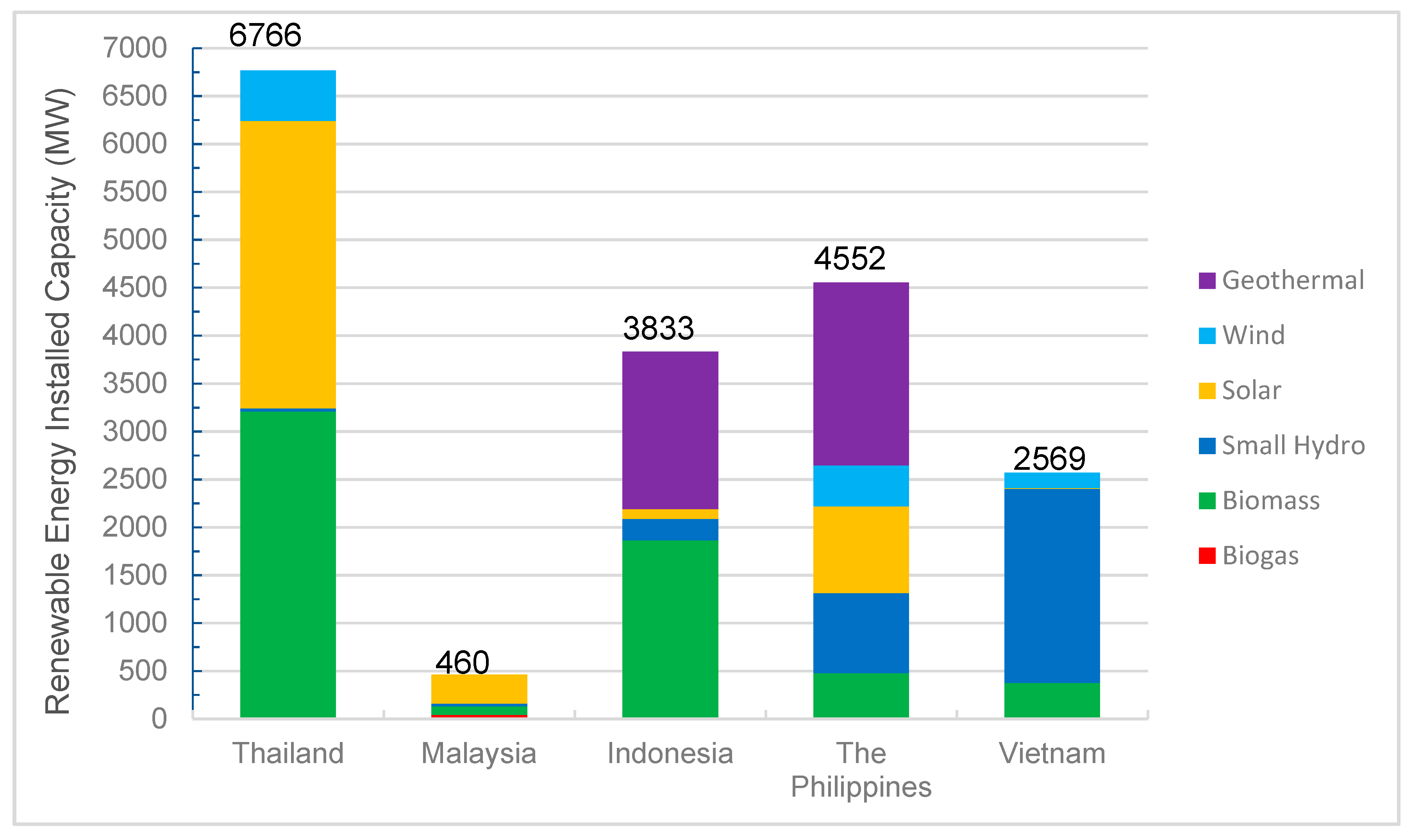

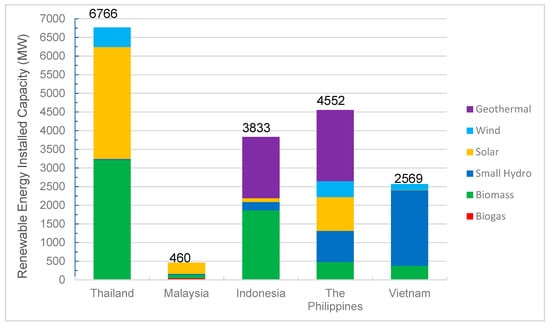

Furthermore, the renewable energy installed capacity via the Feed-in Tariff (FiT) mechanism scheme, which only applies in Peninsular and Sabah set by the Sustainable Energy Development Authority (SEDA) Malaysia, is relatively low compared to other neighboring countries in terms of installed capacity as shown in Figure 5. According to Joshi [9], in 2015 the renewable energy installed capacity (excluding Sarawak) in Malaysia totaled 446 MW which has a short-fall of 45% of the aim to achieve 975 MW of RE targets in 2015 laid out in the Malaysian National Renewable Energy Policy and Action Plan (NREPAP). Within the same year, the electricity produced from renewable energy resources which is being fed into the electricity grid is well under 3%. At present, the total commissioned renewable energy installations as of the end of March 2019 in Malaysia is 604.44 MW which is still lower than the target fixed in 2015 [10].

Figure 5.

The renewable energy installed capacity in Mega-Watts (MW) of five Southeast Asia countries as of 31 March 2017 [12].

For instance, the Feed-in Tariff renewables installed capacity as of 2017 in Malaysia totaled 528.06 MW [10] while in Vietnam is 2569 MW; Indonesia is 3833 MW, and Thailand is 6766 MW [12].

Lastly, this study investigates the key technical, economic, environmental, and social issues within Malaysia while realizing various WTE technologies. The opportunities and challenges in the implementation of MSW-to-energy are considered.

2. Municipal Solid Waste (MSW)-to-Energy in Malaysia

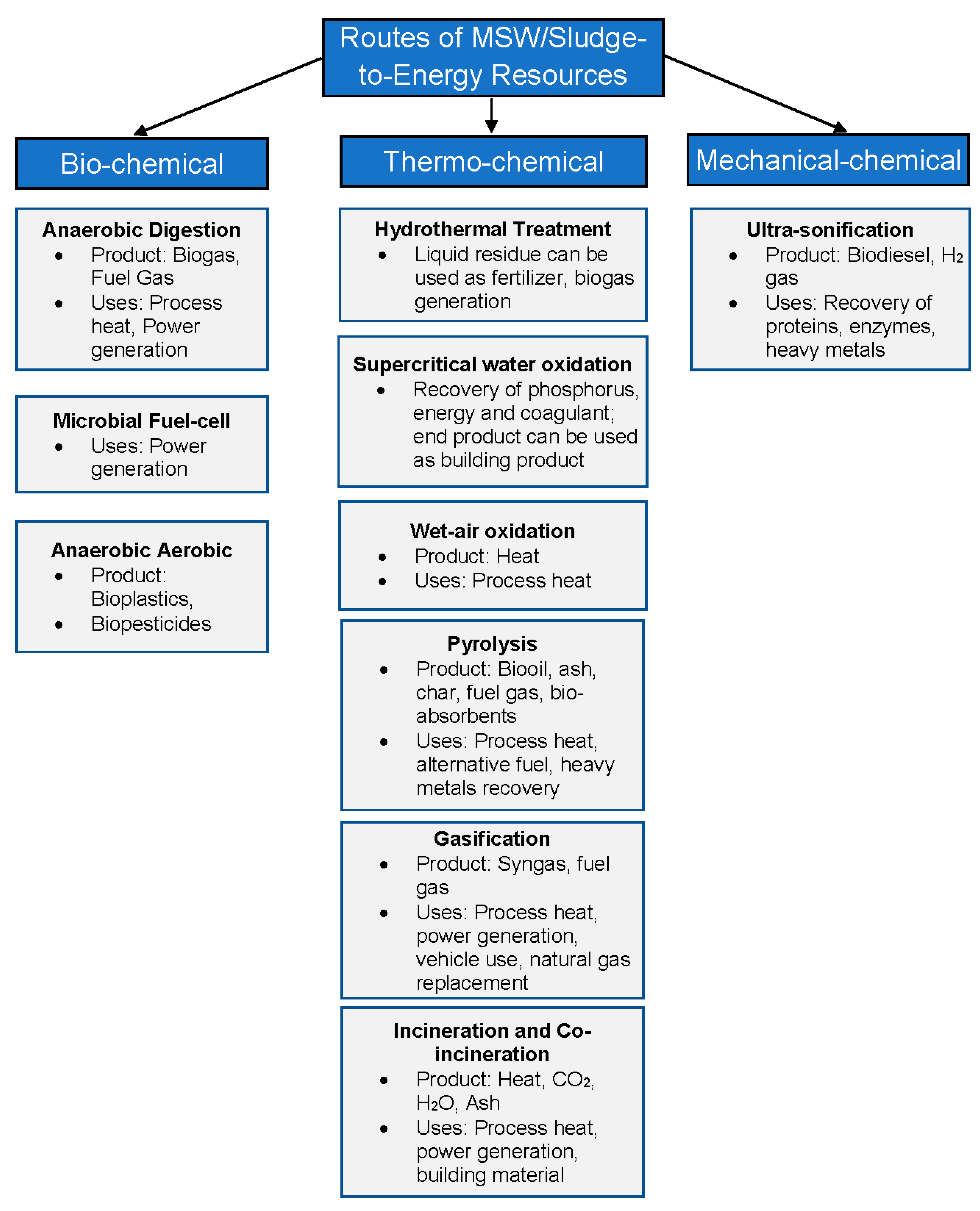

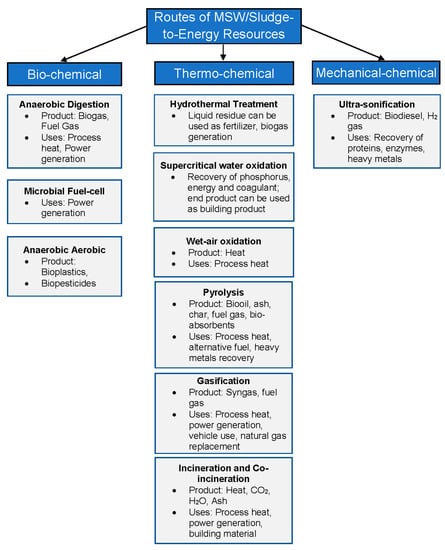

The government of Malaysia has included “waste minimization”, “promotion of reuse”, “developing a recycling-oriented”, and “implementation of pilot projects for recycling” as some of its main policy goals, starting from the 8th Malaysian Plan. The continuation of waste reduction, recycling, reuse, and recovery with the focus of greater use of environmentally friendly products were emphasized in the 9th Malaysia Plan (2006–2010). Consequently, the National Solid Waste Management Department was established under the Ministry of Housing and Local Government [13]. Meanwhile, a new bill has been developed to implement the new Solid Waste and Public Cleansing Management Corporation Act 2007 (SWPCMC Act 2007) [14] which later in 2011 was followed by the enforcement and restructuring of the SWM Act [15]. This act also provides executive power to the Federal Government to implement municipal solid waste management and public cleansing activities throughout Peninsula Malaysia, Federal Territories of Putrajaya, and Labuan. Various small-scale technologies to recover material and energy from waste including composting, recycling, and burning have been identified and utilized for municipal solid waste management. Malaysia, like any other developing countries, is concerned about the increasing need for more energy to sustain the continuous economic and industry development. In search for a more holistic waste management at the same time towards the need for renewable energy, the government of Malaysia proposes the utilization of waste-to-energy technologies to recover energy from municipal solid waste [16]. This makes municipal solid waste as a new form of renewable source for energy production. WTE technology is an energy recovery process that converts chemicals from waste residues into practical forms of usable energy like electricity, heat, or steam. In general, Figure 6 shows the three main routes of MSW to energy recovery, namely bio-chemical, thermo-chemical, and mechanical-chemical.

Figure 6.

The various routes of waste-to-energy (WTE) treatment available [17].

The aim of WTE technology is to minimize the solid waste volume to be disposed into existing landfills despite the many differences of WTE technologies that are available in today’s market. The WTE process can reduce the solid waste biodegradable fraction to zero, while at the same time generates valuable electricity and heat from non-recyclable waste. The major classifications of WTE technology are biological and thermal. Pyrolysis, plasma gasification, or gasification and combustion are a few examples of thermal treatment of waste where the waste is subjected to high temperatures with varying oxygen concentrations. Anaerobic digestion (AD) and microbial fuel-cell are examples of biological treatment of waste. Anaerobic digestion is normally used to recover energy to both forms of electricity and heat. Furthermore, anaerobic digestion produces nutrient rich fertilizer in the form of digestate from the wet and biodegradable waste streams (food and kitchen waste, sludge from wastewater treatment plants, manure from live-stock farming, high-energy yield crop from agricultural waste, and farm slurry). In addition, WTE involves the conversion of landfill gas (LFG) into energy through landfill technologies [18]. WTE technology is also one of many potential alternatives which can produce electricity from RE resources from the utilization of re-cycling potential of the degradable organic waste portion from various sources like household, commercial, and industrial and municipal wastewater treatment plants. Furthermore, energy extraction from waste can simultaneously increase the life-span of existing landfills and reduce the emissions of GHGs into the atmosphere as the energy produced from waste is a potential replacement to the equivalent sum of energy produced from fossil fuel resources. WTE technologies were established in consideration of the push towards a more sustainable and clean solid waste management together with the need for sustainable energy development. In Malaysia, the degradation of organic waste within landfill to produce biogas via LFG, incineration, and co-incineration of mixed MSW are present in converting waste into energy. In Malaysia, the idea of WTE resulted in the construction of an incineration plant at Langkawi and the establishment of biogas power plants within Peninsular Malaysia to convert MSW to electricity [16]. At the moment, Malaysia has four mini incinerators under various stages of implementation in Langkawi, Tioman, and Pangkor Island plus one in Cameron Highlands and one WTE plant located at the central region. Recently in 2018 within the 10th Malaysia Plan timeframe, another WTE plant is to be built and completed in Negeri Sembilan [19]. Energy can be recovered from MSW in Malaysia through one of the three ways in WTE treatment namely thermal, biological, and landfilling via LFG.

2.1. Complementing the United Nations Sustainable Development Goals (SDGs)

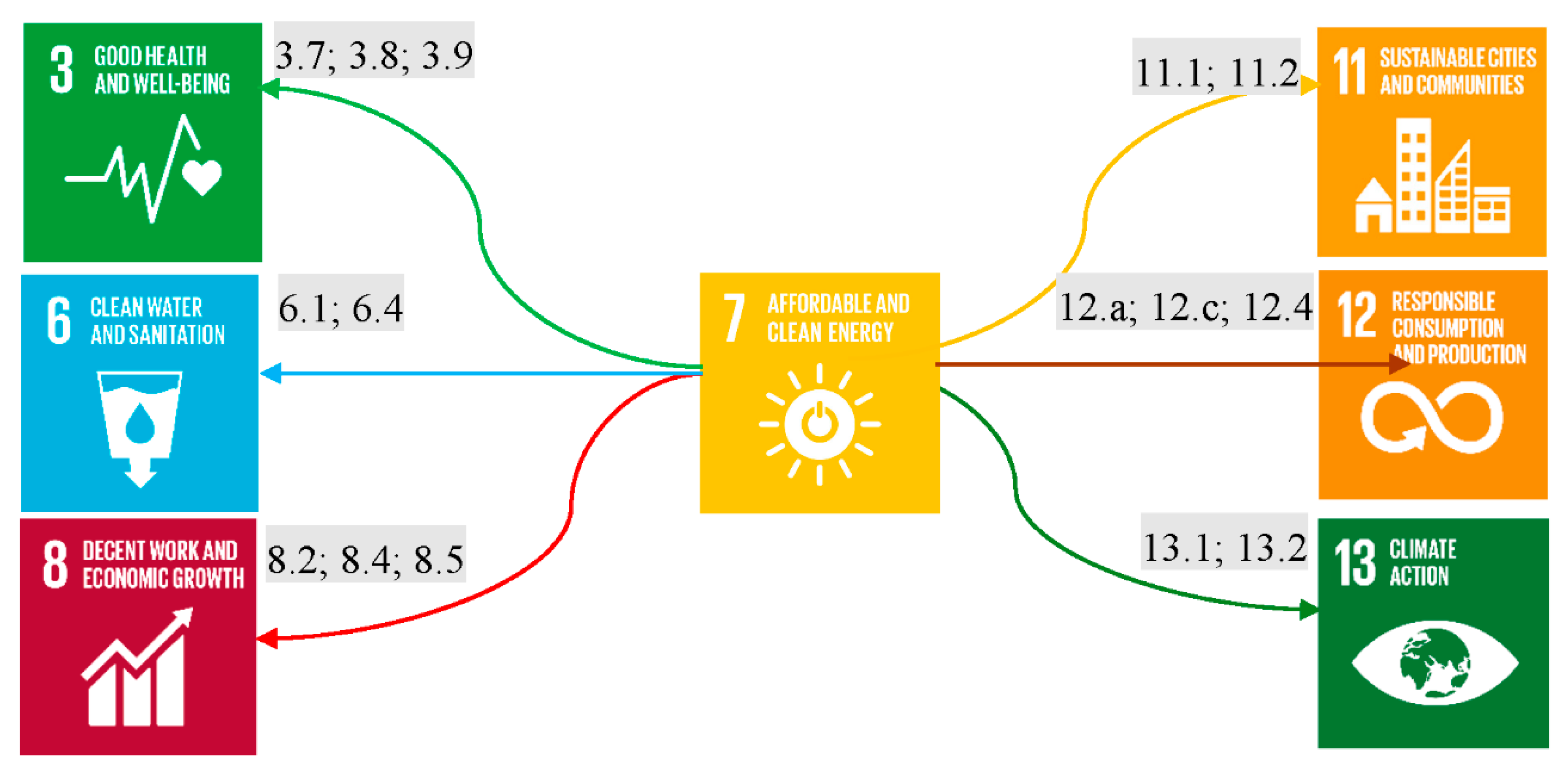

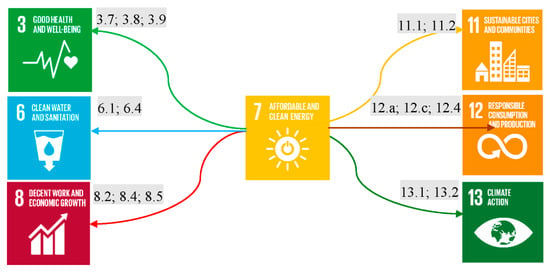

The implementation of WTE technologies and strategies contribute significantly in reducing total waste volume entering landfills, increasing the lifespan of existing landfills, and offsetting large repercussions associated with the burning of fossil fuels to generate electricity. This enables Malaysia to play a positive role internationally in offsetting the world’s carbon emission by generating electricity from waste and to push towards a greater share of RE in the national electricity generation mix. WTE falls under SDG 7 for affordable and clean energy where technology advancement in WTE can provide the human race with sustainable, safe, low-cost, renewable, and secure energy sources in the future [20]. It is of utmost important to understand the targets involved in SDG 7 and to be able to link towards other appropriate SDGs to see how achieving SDG 7 can concurrently complement towards other SDGs. Table 1 indicates the five targets in SDG 7. Moreover, there are six identified SDGs which have a more direct relationship with SDG 7 in regards to the implementation of WTE in Malaysia, as represented in Figure 7 [21].

Table 1.

All the five energy targets consisting of three substantive targets and two additional targets which are identified as a means of implementation in contributing towards achieving Sustainable Development Goal (SDG) No. 7 [22].

Figure 7.

The relationship and interlinked of targets between SDG 7 with SDG 3, 6, 8, 11, 12, and 13 (Yong Zi Jun, 2019).

- SDG 3 for good health and well-being for all can be achieved, as employing WTE can significantly reduce MSW entering landfills. This helps to prevent and reduce the generation of hazardous leachate containing persistent, carcinogenic compounds, and other pathogens from complex mixed waste within the landfill. Hence, this reduce the chances of water contamination from leachate infiltrating into nearby groundwater and surface water sources which maybe the source of water supply for downstream populations. This significantly reduces the impact on the number of cases of deaths and illness related to water pollution and water borne diseases (target 3.9). Moreover, WTE plants are usually located off city centers. The government can plan to integrate these WTE plants to provide a stable baseload electricity towards many remote clinics and hospitals located in sub-urban and rural areas. This can provide both rural and sub-urban residents access to universal health care (targets 3.7 and 3.8).

- SDG 6 for ensuring access to water and sanitation for all can be secured via WTE process as WTE plants can supply clean electricity to both raw water and wastewater treatment plants for water related treatment processes such as blowers, aerators, pumping, chemical dosing equipment, meters, sensors etc., as well as to supply electricity to the treatment plant’s centralized control and monitoring room. Hence, WTE plants power treatment plants to provide people adequate access to clean drinking water and sanitation, especially those who are living in remote areas (target 6.1). Moreover, preservation of water resources can be achieved via these advanced WTE plants. This is because WTE plants use the latest efficient boiler technology which has a higher efficiency in terms of using less water from tube-wells and rivers to produce the same amount of kWh of electricity (target 6.4).

- SDG 8 for promoting sustained, inclusive, and sustainable economic growth, full and productive employment, and decent work for all. Embarking on WTE to produce electricity helps to diversify the energy industry and giving back value to MSW as a new resource to generate energy to drive the nation’s economy (target 8.2). WTE plants help to decouple the economy in the energy and production sector from environmental degradation (target 8.4) as part of the fossil fuel-based resources in generating electricity is being substituted by WTE plants. Moreover, WTE can stimulate and generate more job opportunities in various stages of planning, design, constructing, commissioning, operating, and maintaining such WTE power plants (target 8.5).

- SDG 11 for making cities and human settlements inclusive, safe, resilient, and sustainable. WTE has the potential to gradually substitute some of the nation’s coal-fired and diesel power plants to provide adequate base-load power supply to residential housing, hence providing access to adequate and safe housing to the people (target 11.1). Since WTE is decarbonizing the energy sector by replacing the conventional high air polluting coal-fired and diesel power plants, WTE emits lower GHGs allowing better urban air quality in cities. The carbon dioxide, sulfur dioxide, and nitrogen oxides emissions by WTE using MSW as fuel are 837, 0.8, and 5.4 pounds/MWh respectively which is much lower than coal-fired power plants which emits 2249, 13, and 6 pounds/MWh of electricity produced respectively [23]. Moreover, the implementation of WTE can divert away mixed MSW from entering landfills. This reduces the collective release of hazardous bad odor gases from landfills in Malaysia which result from the complex chemical reaction and degradation of waste within landfills. Hence, this reduces the adverse per capita environmental impact of cities by paying special attention to air quality and MSW management via WTE (target 11.6).

- SDG 12 for ensuring sustainable consumption and production patterns. This is closely related to circular economy where the main intention of SDG 12 is to maximize the use of natural resources and to minimize the harmful waste generation and disposal towards the environment. WTE support this by reusing the waste stream to generate electricity hence (target 12.5) at the same time reducing the contamination of hazardous chemicals emitted by landfills into air, water, and land (target 12.4).

- SDG 13 for climate action by taking urgent action to combat climate change and its impacts can be achieved via the use of more WTE as RE resources (target 7.2). At the same time, the use of more WTE plants to generate electricity for urban use crucially strengthen the adaptive capacity and resilience of cities towards climate-related hazards (target 13.1) as the burning of fossil fuel for energy is replaced with the conversion of municipal solid waste to energy. WTE technologies like LFG and AD capture and burn methane gas (CH4) where methane is 21 times more potent in global warming potential (GWP) than CO2 to generate heat and electricity. Hence, this contributes towards reducing GHGs emissions (targets 13.2). According to AlQattan [17], it was reported that ¼ of a ton of high-quality coal or a barrel of oil can be offset for every metric ton of waste used in WTE to produce the same amount of electricity.

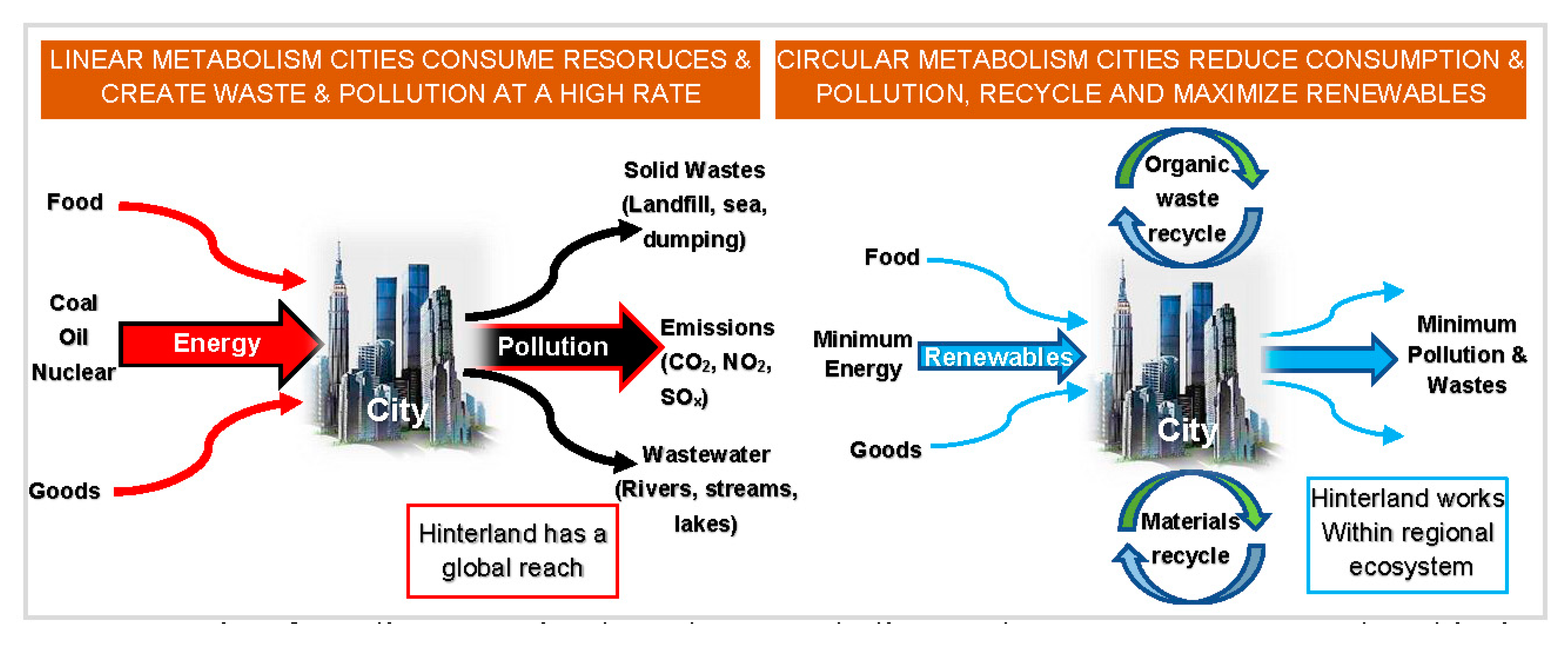

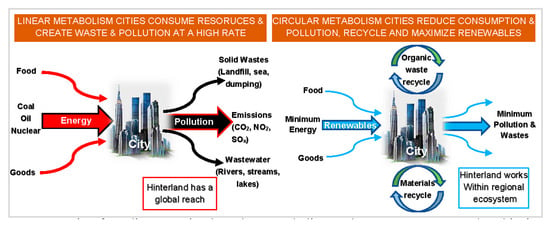

2.2. Complementing the Malaysian Low Carbon Cities Framework (LCCF) Initiative: From Linear to Circular Cities Metabolism

Currently, cities worldwide are responsible for consuming 70% of earth’s energy and resources hence are the main source of generating solid waste and the generation of 70% of global carbon emission [24]. Moreover, half of the world’s current population are already living in cities and the number is expected to rise to 60% by 2030 and up to 66% by 2050 [24]. Malaysia had voluntarily pledged to reduce 40% of the country’s GHG emissions by 2020 compared to levels in 2005 during the 15th Conference of Parties (COP 15) at Copenhagen in Denmark, and pledged to reduce carbon emissions by 45% compared to levels in 2005 levels during the Paris UN Climate Change Conference in 2015 [25]. Turning MSW into energy is a key in creating a sustainable city by recycling all organic and inorganic waste streams, and at the same time serves as a key complement towards the Malaysian pledge during the COP 15 and moving towards a circular economy enabling value of products, materials, and resources to be maintained. WTE supports the initiative of moving from a linear to circular urban metabolism to minimize waste and pollution output to the environment as illustrated in Figure 8. Unfortunately, according to Abushammala et al. [26], Malaysia has a grand total of 212 disposal sites and only 14 sites are classified as sanitary landfills, as indicated in Table 2. This indicates that most Malaysian cities are currently adopting the conventional linear metabolism rather than a more environmentally sound approach of a closed-loop circular city metabolism where the reuse of waste into energy and new materials dominates the waste management practices. Non-sanitary landfills and open dumping are implemented as a main disposal method of MSW due to its low operating cost and convenience to dispose MSW, although this practice brings tremendous negative implications to the economy, environment, and towards the health of the people. With that in mind, according to the Sustainable Energy Development Authority (SEDA) Malaysia, there are a few MSW-to-energy plants or LFG-to-energy sites registered with SEDA for the biogas (landfill) Feed-in Tariff (FiT) scheme to produce and sell green electricity back to Tenaga National Berhad (TNB) which is later on fed into the national grid for urban electricity consumption.

Figure 8.

Moving from a linear to circular urban metabolism as a key component towards achieving sustainable cities, which assures the most efficient possible resource use and least generation of waste back into the biosphere [27].

Table 2.

The types and number of disposal sites in Malaysia in respect to the amount of waste received [2,26].

Moreover, WTE plants compliment the Malaysian Low Carbon Cities Framework (LCCF) and assessment system which was launched and adopted in 2009 by the Ministry of Energy, Green Technology, and Water (KeTTHA) and later had a LCCF version 2. This is part of Malaysia’s initiative in playing a positive role in the world’s climate agenda during the (COP) 15 in Copenhagen, Denmark in 2009. In general, there are four main performance aspects under the LCCF which can be quantified under the LCCF in the effort to lower and to keep track of the city’s carbon emissions. The four LCCF aspects are:

- Urban Environment;

- Urban Transport;

- Urban Infrastructure;

- Urban Building.

Waste management has been classified as part of a component under the urban infrastructure, besides water management, energy, and other infrastructure provisions such as urban storm water management and flood mitigation, earth work management etc. In Malaysia, households are the main source of total solid waste generation which accounts for 65% compared to commercial and institutional at 28% and industry at 7% [1]. Therefore, WTE through the thermo-chemical waste treatment pathways like incineration, gasification, etc., plays a crucial role in household solid waste management in reducing nearly up to 95% of MSW by volume entering landfills.

3. WTE in Malaysia

3.1. Incineration Plant

In Malaysia, the use of incineration as WTE is only present in a very limited quantity at a small scale. A total of 80%–95% of MSW volume can be reduced by incineration. Back in 2011, several incineration projects with the expenditure of RM 187.74 million had been commenced by the Ministry of Local Government and Housing (MHLG) Malaysia to manage MSW. These included five units of small-scale incinerators of rotary kiln type that were erected in five tourism spots: Pulau Langkawi (100 ton/day), Pulau Labuan (60 ton/day), Cameron Highlands (40 ton/day), Pulau Pangkor (20 ton/day), and Pulau Tioman (10 ton/day) [28]. Table 3 summarizes the incineration plants in Malaysia, current status, and energy production rate.

Table 3.

The summary of the five incineration plants which are funded by the Ministry of Local Government and Housing (MHLG) in Malaysia [28].

In June 2011, XCN Technology Sdn Bhd constructed an incineration plant located on a 0.8 ha land area at Teluk Cempedak, Pangkor Island. The plant can reduce incoming waste volume up to 94% using the Autogenous Combustion Technology (ACT). In January 2012, the plant commenced operation and was handed over to MHLG. The plant is capable of combusting up to 20 tonnes of MSW per day. Two more mini incinerators located at Tioman Island’s facility is capable of incinerating 3221 tons of MSW per year. Two other mini incinerators each were constructed in Cameron Highland and Labuan, where each incinerator has a capacity of combusting 15 and 60 tonnes of MSW per day respectively. None of the four-mentioned incinerator could utilize the MSW to produce energy and generate electricity rather than only to minimize the volume of the incoming MSW. The Langkawi incineration plant is the most comprehensive plant and was the first waste incineration plant in Malaysia to utilize the concept of WTE technology. The Langkawi plant was constructed at a cost of RM68 million and the plant is estimated to process 100 tons per-day of waste to generate one megawatt of electricity. There were two units of mini incinerator installed where the model of the incinerator is Hoval GG42. The operation of the two mini incinerators was monitored by the local authority of Langkawi Town Council. So far, the incinerator plant in Langkawi is the only incinerator plant in Malaysia to practice solid waste segregation at the site before the waste stream was fed into the incinerator. Waste which is not suitable for the incineration process due to high moisture content such as food waste and other wet waste was later dumped into a nearby landfill. The efficiency of the of Langkawi’s plant is estimated to be around 80%–90% [29]. The incinerator disposes approximately 100 tons of waste per day and runs on power generated from the WTE technology. The waste heat generated from the incineration process is converted to 1 MW of electricity. The main features of the plant included waste separation systems, rotary kilns, waste heat recovery boilers, air pollution control systems, and a fully condensing steam turbine generator.

The Kajang WTE plant, which consists of a refuse-derived fuel (RDF) facility, is the most comprehensive incinerator as the system incorporates the refused-derived-facility (RFD) operation in Malaysia. WTE or refuse-derived-fuel technologies are both energy recovery initiatives currently emerging at Malaysia and are given priority in solid waste management. In 2008, the Kajang WTE facility was commissioned and has the capacity to process approximately 1100 tons of MSW daily into RDF which is used to produce approximately 8 MW of electricity daily. A total of 3 MW of electricity produced from the RDF plant is used to power the plant and the remainder 5 MW is fed and sold into the national electricity grid via the Feed-in-Tariff (FiT) mechanism [30]. At present, there is a plan to increase the export capacity of electricity generation from 5 to 6 MW. In addition, the current RFD technology only allows 77% of the energy stored within the MSW to be recovered in the form of fuel. It is anticipated that the energy recovered from MSW is targeted to increase to 83% by mixing biogas produce from organic waste via AD into the process, hence making the overall operation more efficient [30]. The increase in MSW generation from 6.37 to 13.38 Mt from year 2010 to 2030 greatly increases the potential of MSW application of WTE. The calorific value of the MSW at Malaysia is estimated between 1500 to 2600 kcal/kg, with energy potential from the incineration plant operating based on the provided calorific value incinerator plant at Malaysia which will have the potential to generate 640 kW/per day. Their study stated that there will be an increase of 60% in electrical generation from 2010 to 2030 by incineration plants as it is estimated that the increasing MSW as renewable source of energy in Malaysia has the potential to produce 5000 Gwh/year by 2020 and further increase to 6200 Gwh/y by year 2030 [16].

3.2. Landfill Gas (LFG)

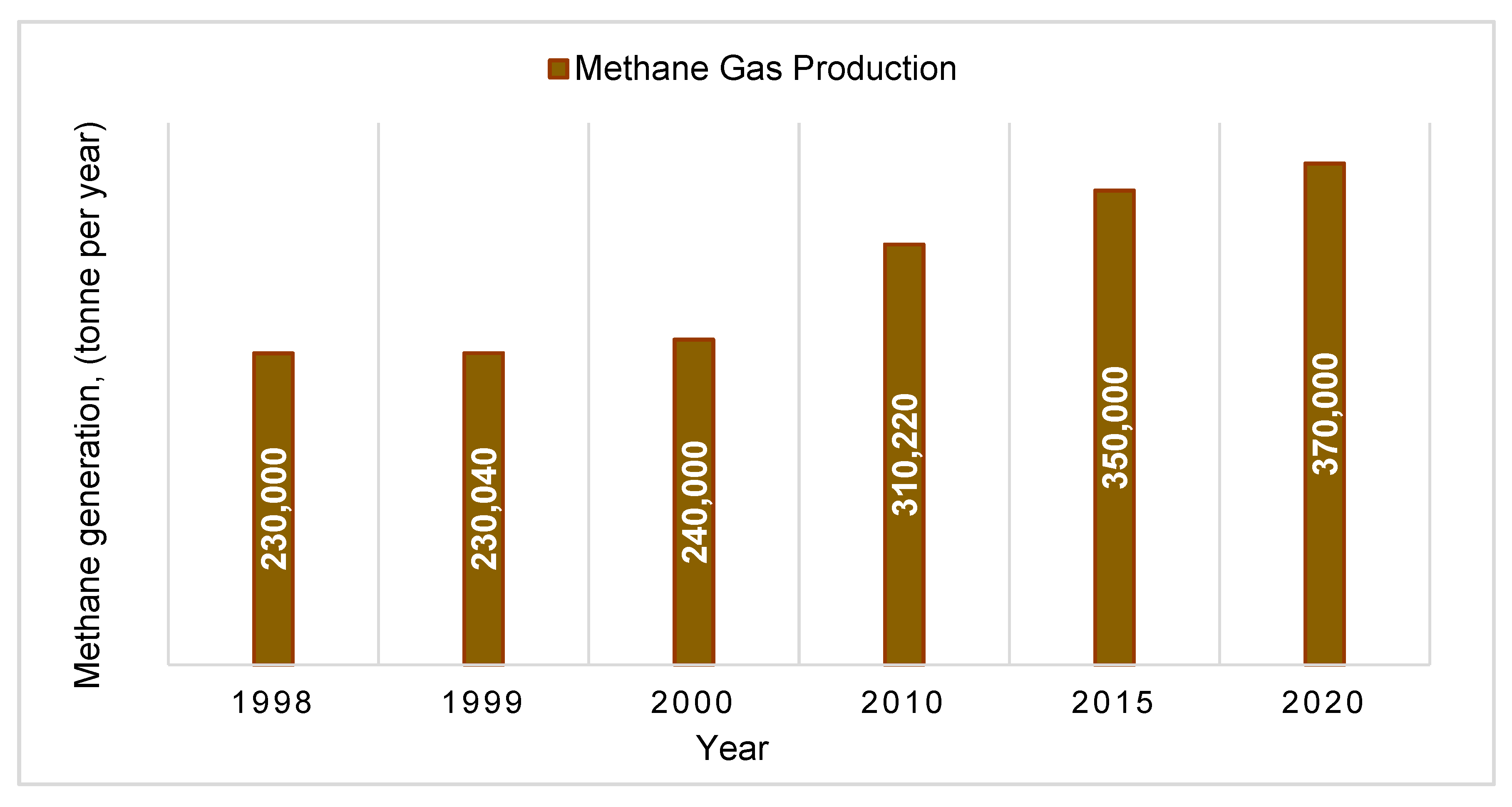

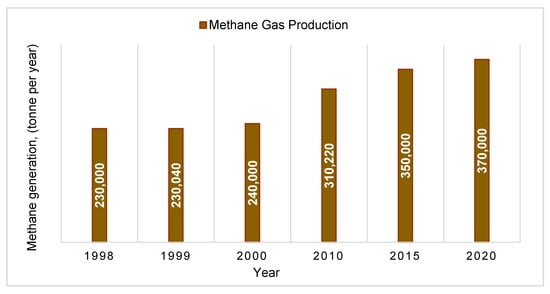

MSW is one of the well-known biomass resources. By year 2020, the MSW generation is estimated to exceed 30,000 tones/day with 45% of the MSW to be processed at sanitary landfills. Decomposition of biodegradable components of MSW roughly produces 55%–65% of Methane (CH4), 35%–45% of Carbon Dioxide (CO2), 0%–3% of Nitrogen (N2), 0%–2% of Oxygen (O2), 0%–1% of hydrogen sulphide (H2S), Hydrogen (H2), and Ammonia (NH3) [31]. In Malaysia, landfills are the major source of methane emission (53%); palm-mill effluent generates 38%; swine manure 6%; and other methane gas from industrial effluent 3% [32]. Figure 9 summarizes the generation of methane gas from landfill in Malaysia (ton/year). With that amount of potential methane gas estimated to be generated, there is great potential to harness energy from methane gas for renewable energy in Malaysia.

Figure 9.

The generation of methane gas from 1998 to 2015 and the predicted value for 2020 [33].

The Bukit Tagar Sanitary Landfill (BTSL) is a practical example, which consist of 18 separate waste cells, which was developed under a parcel of s700-ha area at Hulu Selangor with a 120 million metric ton of waste capacity. At present, BTSL collects 2500 tons of MSW daily (with capacity to handle 5000 tons MSW daily) from Kuala Lumpur and Selayang and the landfill is projected to have a life span of another 130 years. At present, BSTL captures and harvests methane gas generated through horizontal wells from the first and second cell which contain 1.45 million tons and 2 million tons of MSW respectively. Both cells generate approximately 3600 cubic meters of LFG per hour with 60% methane concentration to generate 6 MW of electrical power. A 1.2 MW gas power engine to generate electricity was being installed in BTSL facility where the energy is produced to collected the methane gas. Currently, only part of the methane gas is captured and converted into electricity while the remaining gas is being flared. Currently, BSTL is one of the largest WTE projects which consist of a total of 10.5 MW gas engine capacity combined to generate electricity from LFG. Electricity generated from the site is sold and supplied back to Tenaga National Berhad (TNB), a utility company in Malaysia via FiT mechanism. Another example is the Air Hitam sanitary landfill which is located at Puchong. The landfill currently known as Worldwide Landfill Park (WLP) generates LFG containing a high concentration of methane gas from the degradation of organic waste which had accumulated over the past 10 years. The collected LFG is used to generate 2 MW of electricity monthly whereby 2 MW of capacity is able to power around 2000 houses. In 2006, the landfill was closed and rehabilitated and renamed as Worldwide Landfills Park, with the renewable energy project undertaken by Worldwide Landfills Sdn Bhd. The landfill is projected to continuously produce 2 MW of electrical capacity for at least another 16 years from the saturated 6.2 million metric tons of MSW from its past decade-old operations. According to Worldwide Landfills Sdn Bhd, the generated electric supply was sold to TNB at cost of RM 0.40 per kilowatt-hour (kWh). In addition, Jeram landfill with 160 acres of land area and MSW capacity of 2500 tons per day was established with a capacity to hold 6 million tons of MSW. Currently, the landfill collects approximately 2000 tons of waste daily and to date 4.1 million tons of waste has been added to the landfill. The landfill caters MSW from city councils of Shah Alam and Petaling Jaya, the municipal councils of Subang Jaya and Klang, the district council of Kuala Selangor, and private waste collectors. To date, the gas power plants at Air Hitam and Jeram sanitary landfills produce combined generated power of 6 MW which can power up to 6000 homes. The energy production from LFG is expected to increase from 3000 GWh/year in 2010 to 3300 GWh/year in 2020 and further increase to 5000 GWh/year by year 2030 [16]. An anaerobic digestion system can be combined with an LFG system to increase the total methane gas output hence increasing the efficiency of waste to energy production. Food waste has the higher percentage of MSW content, and a study on the food waste in Malaysia indicate the average food waste generated in year 2010 was a staggering 7600 Metric Ton/day, about 45% of the total MSW generated in 2016.

There are upcoming new LFG-to-Energy projects according to Table 4. At present, part of the biogas installed capacity in the BTSL will increase its capacity to 6.06 MW by installing new units of MWM (A Caterpillar Company) biogas engines on the same site, with each engine having a total electricity output of 2000 kW and electrical efficiency of 43%. Jeram landfill on the other hand will install the new biogas systems with an install capacity of 3.6 MW.

Table 4.

List of operating and upcoming landfill biogas plants registered under the Feed-in-Tariff (FiT) scheme associated with municipal solid waste (MSW) landfill to energy (Source: SEDA, Sustainable Energy Development Authority Malaysia).

4. Assessment the Factors Affecting the Sustainability of MSW-To-Energy in Malaysia

4.1. Technical, Economic, Environmental, and Social Issues

Table 5 shows the factors which need to be considered holistically in terms of the four main categories, namely technology or technical, economic and finance, environment, as well as social and political factors. These factors and issues affect the final decision of selecting the appropriate WTE methods to deploy best suited to the Malaysian context.

Table 5.

Summary of the technical, economic, environmental, and social issues relating to the MSW-to-Energy.

4.1.1. Technical Issues

Quality of Waste

- There are different types of wastes that can be used as a potential source for renewable energy to achieve sustainable sound MSW management and towards the use of WTE [34]. A study indicates that MSW in Malaysia has a high calorific value of approximately 23,000 kJ/kg which is suitable and ready to be used as feedstock for energy production. However, non-organic waste which has lower moisture content is suitable for thermal treatment while MSW containing high organic waste which contributes towards higher moisture content in the overall MSW is not suitable for thermal treatment.

- The Malaysian MSW contains a high level of moisture as the largest 45% constituents is organic waste (food and kitchen waste), which reduces the calorific value for thermal incineration treatment between the range of only 1500 and 2600 kcal/kg, hence making the incineration process ineffective [35]. For example, the use of small-scale incinerators operating in the tourist islands in Malaysia were discontinued due to the unsorted MSW as feedstock which contains high moisture content as the presence of wet organic waste like food waste was reported in 2008 [36]. This results in a higher operational and maintenance cost in operating the incinerator in the long run as the incinerator is not functioning within the optimal condition which needs frequent maintenance.

Quantity of Waste

- Periathamby et al. [37] stated that in Malaysia, most landfills are small in capacity. These landfills hence were insufficient to generate adequate LFG volume viable for gas extraction. In addition, most of the Malaysian landfills are non-sanitary landfills and often open dumping sites which rely mainly on only natural clay lining. Furthermore, there is no proper infrastructure for the collection of LFG and leachate. Hence, the establishment of these disposal sites were mainly based on the most traditional and economical at the same time non-environmentally sound and responsible way of disposing of MSW. Therefore, although Malaysia has sufficient MSW for power generation, however, the previous MSW management style of these landfills are not designed with the intention to generate resources such as methane to profit the landfill owners and operators. Thus, most of the LFG generated escapes naturally from cracks and crevices within waste-cells in the landfill into the atmosphere.

Consistency Supply of Waste

- The consistency in supply of waste resources is of utmost importance to keep MSW-to-energy plants, particularly those associated with thermo-chemical treatment, operating optimally to supply a steady state of electricity into the grid [16]. Any fluctuation in the supply of waste would greatly reduce the plant’s efficiency hence leading to technical and economic issues which will result in the reduction and affect the stability, hence the quality, of the electricity produced by these WTE plants. Incineration, pyrolysis, and plasma gasification WTE plants need huge volumes of waste, for instance a minimal of 100 tons per day (TPD) and best at 500 TPD of waste, to sustain the continuous combustion in the furnace of boilers to produce consistent heat to supply to boilers for steam production. For the bio-chemical pathway of WTE plants, particularly the AD biogas-to-energy plant, it is encouraged that other types of organic waste from other sources like the industry, agriculture, or live-stock farming can be incorporated with MSW as feedstock to reduce its susceptibility to fluctuating waste resources. The type of organic waste from various sources that can be mixed with MSW are palm oil residue, agriculture crop residue, tropical forest and garden waste, pulp and paper mill waste, animal manure etc. Moreover, the one advantage of AD WTE plants compared to any other WTE treatment methods is that AD process can accept a wide range of MSW volumes, ranging from 25 TPD to above 500 TDP, yet maintain a similar amount of efficiency in converting waste into energy. However, for LFG-to-energy applications at landfill sites, this will need at least a consistent volume of MSW of above 500 TPD to produce a steady stream of electricity supply for the grid [38].

4.1.2. Economic Issues

Investment in waste management systems and electricity generation systems

- In Malaysia, per-capita rate of MSW generation is ever increasing, whereas the energy demand by 2050 increases by a factor of four. In addition, there is an imbalance of existing energy production to the energy demand due to the increasing Malaysian population. According to Oh et al. [32] for each 1% growth on Malaysian GDP (Gross Domestic Product), there will be a 1.2%–1.5% increase in national energy demand. Thus, there is an urgent need to develop WTE technology to minimize MSW disposing to landfills, at the same time produce sufficient energy from MSW as an alternative resource to support the economic development in the coming decade in Malaysia.

Initial and operational cost

- An incineration project requires huge capital costs as the cost is mainly attributed to the need for advanced air pollution control technologies to filter the complex and hazardous flue gas from incinerator plants. In European nations, about two-thirds of the capital cost is spent on air pollution control systems and devices. Furthermore, higher fuel consumption and the need for professional and skilled employees required to operate and to maintain the incineration facility are the main contributors towards the high operational costs of incinerators. Kathirvale and Ahnathakrisnan. [39] reported that in Malaysia, the capital expenditure (CAPEX) and operational expenditure (OPEX) for an incinerator facility with capacity of 800–1000 tons of MSW per day is estimated within the range of RM 500–800 million and USD 40–100/tons of MSW respectively. Similarly, Yahaya. [40] reported that the CAPEX and OPEX of a 1000 ton/day capacity mass burn incinerator WTE facility is RM 360–550 million and RM 102–110 million/ton of MSW respectively. While, the CAPEX and OPEX for a plasma gasification WTE facility is RM650 million and 120 million/ton of MSW respectively. Moreover, the cost required to construct an incinerator compared to a sanitary landfill is estimated to be around 10 times and three times in terms of capital expenditure and operational expenditure, respectively.

- According to AlQattan et al. [17] more environmental efficient WTE systems have a co-generation or combined heat and power (CHP) system, although plants overall improve efficiency but have a lower profit margin due to high equipment and operation cost. Hence, this leaves a dilemma conflict between economic benefit and environmental sustainability, as the most environmentally efficient WTE systems may not always be the most financially prudent. For instance, the net profit generated by a 150 kilo-tonne (kt) plant with electricity configuration is 25.4 Euro/kt of treated waste, which is significantly higher than a 300 kt plant with co-generative configuration where the profit generated was just 4 Euro/kt of treated waste.

- The cost for installing and running an LFG site is considerably high. In the case of LFG plants, the total cost for a plant are categorized into two categories with the listed details:

- (i)

- Total Initial Capital Cost

- -

- Digester equipment;

- -

- Gas engine;

- -

- Generator;

- -

- Balance of System (BOS);

- -

- Installation Cost;

- -

- Design and Consultancy;

- -

- Interconnection Cost (from plant to nearest TNB substation);

- -

- Preliminary Cost;

- -

- Other Capital Cost.

- (ii)

- Annual Operation and Maintenance Cost

- -

- Insurance Premium;

- -

- Operation and Maintenance Cost;

- -

- Fuel Cost at Site;

- -

- Other Operating Cost.

Table 6 indicates the typical total initial capital and operation and maintenance cost for an LFG WTE plant in Malaysia per MW of installation capacity. Comparing to the cost of other RE resource RM/MW installation, the total initial capital of LFG is lower than solar. However, the cost of LFG is becoming lower annually as more and more projects are being developed in Malaysia.

Table 6.

The total initial capital and operation and maintenance cost per MW of LFG installation (Source: SEDA, Sustainable Energy Development Authority Malaysia).

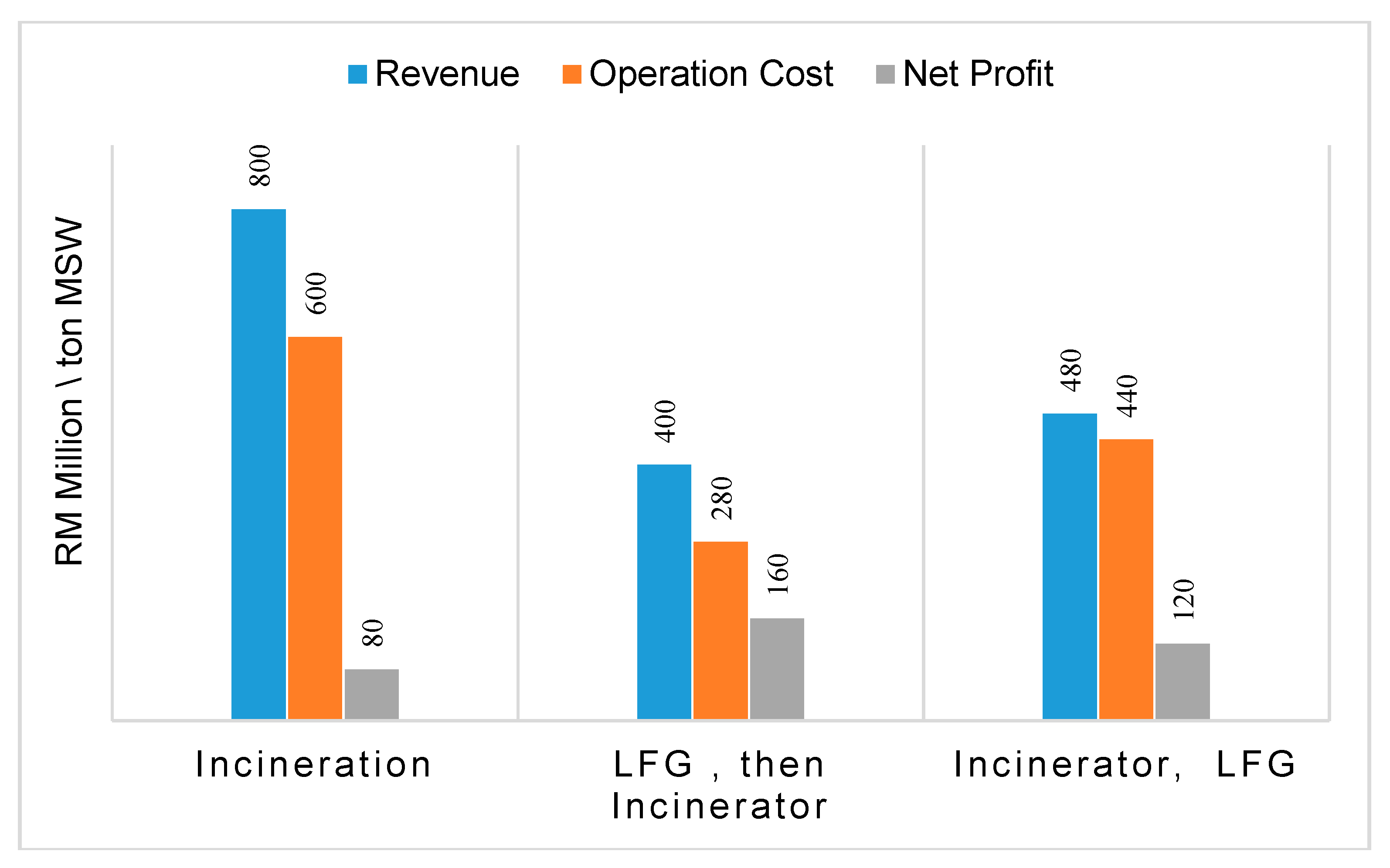

Revenue, profit, and carbon credits

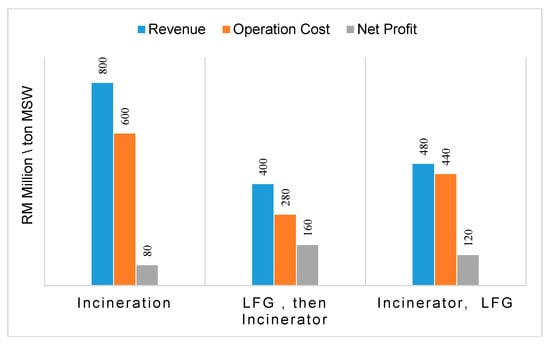

- The economic benefit from the operation of incineration plants which use MSW to produce energy were estimated through the sales of electricity and carbon credits. The revenue generated from the sale of electricity for these MSW incineration plants was around RM 5440 M/y (million/year) in year 2006 and RM 6280, and the amount is estimated to increase to RM 1800 M/y by 2020 and further increase to RM 2500 M/y by year 2030. Table 7 summarizes the potential revenue obtained from the operation of incinerator plants in Malaysia. The cost analysis of incineration in Malaysia is shown in Figure 10, where the figure indicates the net profit from the operation of incineration plant to generate energy from MSW. Based on Figure 10, MSW-to-energy via incineration has the potential to generate a net profit of RM 80 M/ton MSW while the combined process of using incineration together with LFG recovery system has the potential to generate RM 120–160 M/ton MSW [16].

Table 7. The potential revenue from the operation of incineration plants in Malaysia.

Table 7. The potential revenue from the operation of incineration plants in Malaysia. Figure 10. Summary of cost analysis of incineration operation [33].

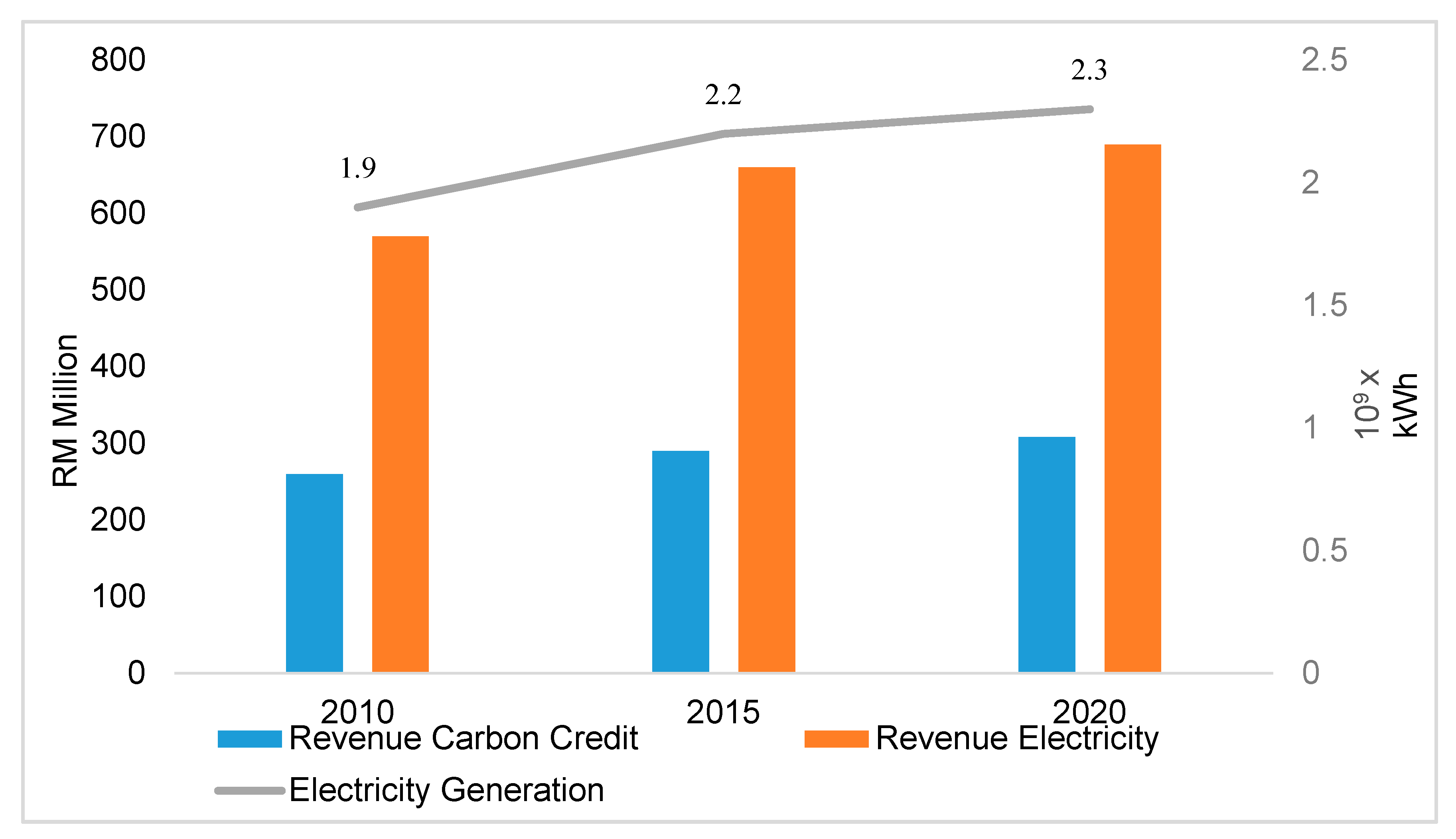

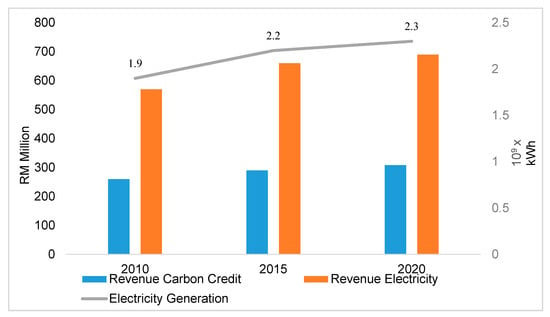

Figure 10. Summary of cost analysis of incineration operation [33]. - Johari et al. [33] reported that in Malaysia, 44.4% and 55.6% of methane emissions are from sanitary landfills and dumpsites, respectively. The usage of LFG technology promises low-operational cost and significantly lower emissions compared to incineration in generating the same amount electricity. According to Johari et al. [33], the revenue generated from converting LFG into energy is RM 998 million from selling both electricity and carbon credits by year 2020. The total revenue from LFG through the sales of carbon credit and electricity are shown in Figure 11.

Figure 11. Electricity generation and revenue via landfill gas for the years 2010, 2015, and 2020 [33].

Figure 11. Electricity generation and revenue via landfill gas for the years 2010, 2015, and 2020 [33]. - The economic analysis based on the net profit and revenue generated from the sales of electricity and carbon credits. From the year 2010 to 2030, LFG applications show an increase in electricity and carbon credit sales. In 2010, electricity generated from LFG has a revenue of RM 1600 M/year and is estimated to increase to RM 2000 M/year and RM 2140 M/year by 2020, respectively. Similarly, the sale of carbon credits are estimated to increase the revenue generated from RM 160 M/year to RM 200 M/year by year 2010 and 2030, respectively. The study performs cost analysis of the LFG system where it shows the operation of LFG power plants may reach a net profit of RM 120 M/ton of MSW from the sale of electricity within the next 10 years (by year 2030).

Lack of financial support to construct sanitary landfills

- The use of LFG technology in biogas sectors potentially mitigate various environmental issues and resolve energy resource shortages, however, this technology requires huge initial capital investment. The lack of financial support from the Government and from bank loans for waste management in Malaysia results in the lack of sustainable sanitary landfill practices. Moreover, due to this factor, only a few large operators and companies are more financially independent to construct and operate sanitary landfills with adequate landfill gas recovery systems and WTE technology from gas collection. This leaves the small-scale waste operators to not have the adequate initial capital to construct and improve their existing landfill facilities for LFG applications. Furthermore, the increase in land price poses a significant impact to the government and private companies in opening new sites for landfilling [41,42].

4.1.3. Environmental Issues

Residue management

- The incineration process plays a major role in effectively reducing the volume of MSW entering landfills and efficiently recovering energy from waste. The mass and volume of MSW could be reduced up to 75% and 90% respectively [38]. However, the retrieved ash needs to be handled after the incineration process whereby the ash consists of 10% by weight relative to the weight of the initial MSW fed into the incinerator before the combustion. These ashes are later disposed into the landfill. The disposal of ash into landfills remains a serious environmental issue as these ashes sourced from the incinerator’s bottom ash and fly ash (from flue gas cleaning systems) contains 8%–12% ferrous metals and 0.5%–1.5% non-ferrous metals. This potentially brings great harm to the environment if there is no implementation towards the recycling and recovery of these precious yet hazardous heavy metals namely Zinc (Zn), Nickel (Ni), Lead (Pb), Mercury (Hg), Cadmium (Cd) and, among others, trace heavy metals which might be present [17].

- Compared to recovering LFG from landfill to generate energy, incineration (with energy recovery) has several environmental advantages and benefits, namely smaller plant footprint which requires a smaller area of land to operate, lower carbon emissions, minimal land contamination, by-product from incineration ash is inert (chemically stable without odor), and higher density of energy recovery per ton of MSW. Yet, the operation of incinerators in Malaysia encounters difficulties due to several issues. These issues comprise the opposition from non-governmental organizations and public against the health issues relating to the operation of incineration plants; unsuitability of available technology for incineration of local MSW; high capital expenditure; and stringent emission standards compared to other combustion equipment. Additional difficulties encountered by present incinerator operators were failure to comply to environmental impact assessment standards; insufficient local expertise; incompetent local operators; and higher cost for incinerator maintenance and parts.

Emissions management

- There was no available emission standard for incinerators in Malaysia until the release of Environmental Quality (Dioxin and Furan) Regulation in 2004 by Department of Environment (DOE) Malaysia. However, the need for such regulation to be established in Malaysia must be grounded on the United States Environmental Protection Agency (USEPA) Method 23 and USEPA Method 8290 which are used for analysis in accordance with strict dioxin and furan discharge criteria (EQA,1974). Furthermore, stricter requirement needs for other pollutant release from the incinerator include heavy metals. As the laws can change and updates may be required in the air pollution controls, this could lead to much higher costs in the future [43].

- Dioxin emissions have stringent regulations in other developing and developed countries for instance China, Taiwan, Germany, and Japan, where dioxin emissions are limited to 1 ng/m3 toxic equivalent for incinerators [44]. Furthermore, during the thermo-chemical treatment of MSW the complex composition of unsorted waste material may result in the formation of carcinogenic, complex, and environmentally persistent acidic gas pollutants, namely Sulphur Dioxide (SO2), Polychlorinated biphenyls (PCBs), Volatile Organic Compounds (VOCs), Carbon Monoxide (CO), Hydrofluoric acid (HF), Hydrochloric Acid (HCl), and Hydrobromic acid (HBr), among others. If these gaseous pollutants were untreated or accidentally leaked into the environment, this will result in a long-term unforeseen negative impact to the people and the entire ecosystem [17]. These unforeseen negative impacts include the bioaccumulation of these carcinogenic compounds in the food chain and the development of diseases like lymphoma and sarcoma [45]. The emission standard of dioxin and furans is at 80 pg TEQ/m3 and for mercury is at 20 µg/m3 according to the department of Environmental Government of Nunavut [46].

Location of facility

- Currently, there is no standard listed in the Malaysian Environmental Quality Act, 1974 Act (127) and the Clean Air Regulation 2014 by the Department of Environment Malaysia (DOE) specifically stating the distance of incineration or WTE plants from and city centers or housing areas or having how many kilometers, in radius, of buffer zone to prevent the breach of toxic flue gas containing dioxin and furans. In the case of thermo-chemical treatment of MSW via incineration, gasification, and pyrolysis, according to Elliott et al. [38], the facility distance of up to 10 km threshold for exposed population for all MSW incinerators still gives a negative health impacts in the long-term. Table 8 below shows the adverse health outcomes associated with the distance of facility and dioxin emission level from various case studies in regards with WTE incinerators. The World Health Organization (WHO) recommended a minimum of 500–750 m buffer zone surrounding the facility to have a sufficient flue gas dilution ratio above 1000 which is based on ideal condition of relatively flat and unobstructed terrain. In reality, a more serious and holistic environmental impact assessment has to be conducted to determine the safe buffer zone as well as the distance of facility from residential housing area.

Table 8. The relation of peak dioxin levels from various incineration plants studies associated with health effects [44,45,46,47,48,49,50].

Table 8. The relation of peak dioxin levels from various incineration plants studies associated with health effects [44,45,46,47,48,49,50].

4.1.4. Social Issues

Public health and safety management

- Incineration can contribute positively to public health by eliminating harmful pathogens, bacteria, and other hazardous micro-organisms which accumulate in MSW. However, the byproducts from the incineration process, namely fly ash, bottom ash, and other residues from the incinerator’s air-pollution control (APC) system in the form of sludge and slags from wet scrubber treatment process, pose an existential threat to public health via the carriage of toxic pollutants containing heavy metals such as lead, mercury, cadmium, along with other pollutants.

- In the case of MSW-to-energy via the route of thermo-chemical pathway, there were several studies which confirmed significant health effects. Giusti [50] reported that the flue gases from incinerators containing acidic gases (SO2, NOx, N2O, HCl, HF), certain metals (arsenic, beryllium, chromium, cadmium, lead and mercury), carbon monoxide (CO), carbon dioxide (CO2), dioxins, furans, polyaromatic hydrocarbons (PAHs), polychlorinated biphenyls (PCBs), volatile organic carbons (VOCs), and odor, increases the chance of acquiring non-Hodgkin’s lymphomas and soft tissue sarcoma. According to National Research Council [51], other potential health effects from incineration flue gas exposure are chest pain, dizziness, irritative symptoms, and poor coordination.

- From Table 8, it can be seen that infant and neonatal death occurs when the peak dioxin emission level from incineration plant is at 80,000 pg/m3 in Japan [46]. Incineration plants will have to be situated far and must have least a 10 km buffer zone from cities centers and away from any residential and inhabitants’ areas to prevent any risk of negative health implications caused by the release and exposure of toxic flue gases which contain furan, dioxin, and other heavy metals which is being blended in the emission stacks of these WTE plants.

Government Initiative and Political Will

- At present, the 11th Malaysia Plan (2016–2020) embraces the concept of responsible consumption and production which is the United Nations SDG 12 where the focus area is treating solid waste as a new resource which can be recovered materially via bio-chemical path (AD) or thermo-chemical path (Incineration, Pyrolysis, Plasma Gasification) for electrical generation and secondary fuel resources for energy production. Furthermore, the 11th MP aims to transform the Malaysian society towards a more energy and resource efficient society by managing waste holistically, increasing the percentage of RE in energy sector, as well as in the national electrical generation mix, creating a green market etc.

- The Renewable Energy Act in 2011 was designed to support the FiT mechanism to promote the use of RE. In the act, a 1.6% surcharge is imposed to the electricity bill of all consumers except for domestic consumers who consume electricity less than 300 kWh/month. The 1.6% surcharge is collected to fund the RE quota and development in Malaysia.

- The national renewable energy policy and action plan (2010) under thrust 1 where the FiT mechanism is implemented together with the establishment of the RE Fund and SEDA Malaysia is responsible as an authority to implement FiT projects for RE developers. The FiT mechanisms allow RE producers to generate income via the selling of electricity generated from RE resources (solar, biomass, biogas, and small hydro) to the national electricity grid based on different FiT premium rates over a certain period of tenure [46]. Table 9 shows the most updated FiT rates for biogas (landfill/waste) and biomass (solid waste) RE resources.

Table 9. The FiT rates for biogas and biomass as of 1 January 2019 [10].

Table 9. The FiT rates for biogas and biomass as of 1 January 2019 [10]. - In 2009, the Malaysia’s National Green Technology Policy (GT) was established to promote and integrate sustainable development into the national economic development. GT is defined as technology that promotes the use of RE which has zero or lower GHG emissions, improves environmental outcome by minimizing the degradation of the environment, conserves natural resources, and maximizes energy use by increasing efficiency.

4.2. Assessing the Suitability and Sustainability Aspect of WTE in the Malaysian Context

According to Aich and Ghosh. [38] any WTE project has long-term implications towards the sustainability aspect of the society and the development of a nation. It may contribute positively, and some may have an adverse effect towards the local economy, society, and the environment if selecting the wrong or not suitable technicality of the WTE systems to treat MSW. Hence, a SWOT (strength, weakness, opportunity, and treat) analysis of various WTE systems is required to be done for the selection of the most suitable technology to be adopted by the local context in Malaysia. By conducting SWOT analysis, this can help to reduce uncertainties and risk of WTE project by identifying weaknesses and threats of a WTE technology. Furthermore, the identification of new or alternative feed mix and the establishment of raw material supply chain can be done by identifying the strengths and opportunities of the WTE technology. Table 10 shows the general elements and guideline used to conduct the SWOT analysis for WTE technologies. In terms of technical, Aich and Ghosh [38] provide the technical parameter indicative chart which will help local authorities and decision makers identify the most suitable WTE technology. The main consideration in choosing the right technology must be based on both the waste characteristics as well as the local climatic condition in Malaysia.

Table 10.

The general outline of the SWOT (strength, weakness, opportunity, threat) analysis to be used for WTE (Waste-to-Energy) projects [38].

To better understand the Malaysia climatic condition, presented below is the Malaysian climate information [46]:

- Average Daily Temperature (°C) = 27–28;

- Average Annual Rainfall (mm/year) = 3318;

- Average Daily Wind Speed (km/h) = 5.5–8.6;

- Average Daily Humidity (%) = 79–80;

Table 11 shows the technical parameters indicative for various municipal solid waste (MSW)-to-energy technologies [38]. Hence, based on Malaysia’s weather and climate conditions, the most suitable thermo-chemical treatment will be pyrolysis or plasma gasification. However, this needs a huge amount of funding assistance or initial capital either from the government or foreign investors as the initial capital cost in building up such plant is very high, as indicated. As indicated in Table 11, it must be noted that both pyrolysis and plasma gasification WTE plants require a consistent supply of waste to be fed into the system of a minimum 100 tonnes per day to maintain the facility operation in generating electricity. Regarding the most flexible system based on the plant size, anaerobic digestion is the best option in harnessing biogas for electricity production from organic waste in MSW. Malaysia can consider anaerobic digestion as the future WTE bio-chemical route while at the same time converting all possible open dump sites into LFG for methane capturing and energy generation.

Table 11.

The technical parameter indicative chart for various MSW-to-Energy projects [38].

5. Challenges and Future Prospects

In the effort of making WTE a profitable and effective project to support the decarbonization of the energy sector and the development of RE production in Malaysia, the following are some of the related improvements which can be considered.

- The government is responsible for playing crucial role in translating policies in papers into actual implementation by initiating behavior changes via a top to bottom approach. There are numerous policies related to solid waste management that have been established throughout the Malaysia Plan, however, there is a lack in the implementation and enforcement in both WTE policy and MSW in Malaysia. The stakeholders, mainly industrial players and academic institutions, must deliver adequate awareness and knowledge on the plans and initiatives developed in WTE policies.

- Effective and good communication, understanding, and cooperation is needed between the local and federal authorities regarding the planning and establishment of SWM policies. Furthermore, there is also the need to establish an efficient governance in SWM policy and legislation. Creating a strong and reliable task force to which the authority can enforce the policy and legislative measure is greatly needed.

- To effectively treat and to maximize the energy potential from MSW and at the same time to save cost of constructing a facility to segregate MSW, both the government and local authorities need to educate and implement effective and practical household and commercial source segregation to separate organic waste and inorganic waste for WTE treatment processes. The organic waste can be treated via the AD biological process to recover both electricity and organic waste while inorganic waste can be treated thermally via pyrolysis and gasification to recover energy and secondary fuel and other products.

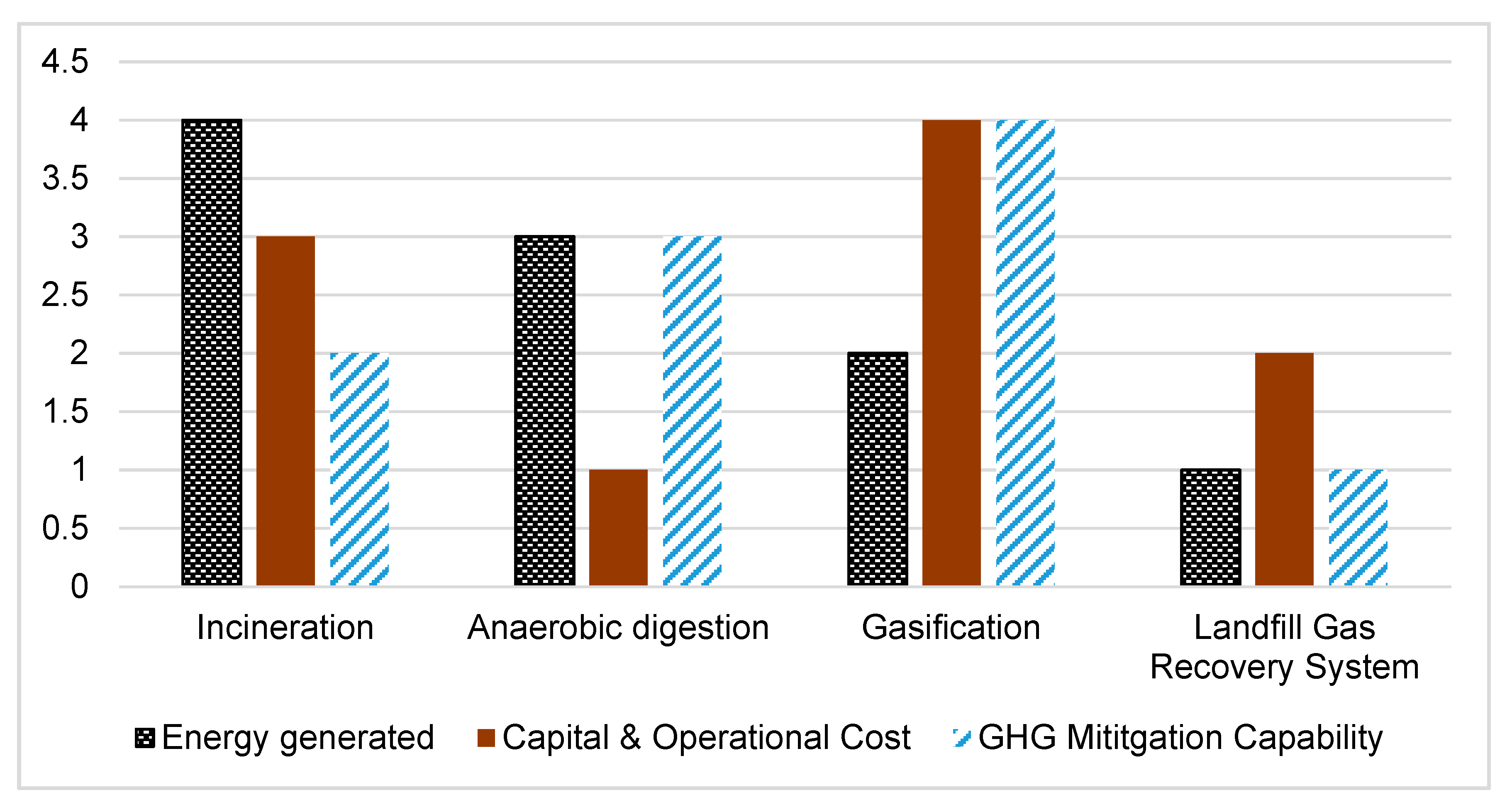

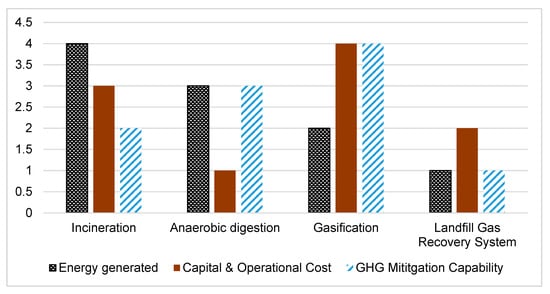

- The use of alternative approaches is encouraged, such as gasification and pyrolysis, rather than mass burn or incineration to treat either mixed waste or inorganic waste. Pyrolysis and gasification processes generate several useful secondary fuels, and at the same time heat and energy, which can be turned into electricity by reacting organic material fractions from the MSW at high temperature. Both processes treat MSW without direct combustion with precisely controlling the amount of oxygen and steam entering into the system. Syngas is produced at first in both processes where pollutants are removed before it is combusted, hence resulting in a cleaner emission level. Energy recovery from MSW via gasification and pyrolysis produces cleaner emissions compared to incineration and does not possess any threat to public health. Though the initial construction cost for gasification is higher compare to incineration, at 1.5 times the initial capital cost, however, gasification in terms of converting waste to energy is 30% more efficient than incineration [48]. Figure 12 compares different WTE technologies in terms of energy potential, cost, and GHG mitigation ability.

Figure 12. Comparison of different WTE technologies in terms of energy potential, cost, and greenhouse gas (GHG) mitigation ability [16].

Figure 12. Comparison of different WTE technologies in terms of energy potential, cost, and greenhouse gas (GHG) mitigation ability [16].

6. Conclusions

In brief, due to the escalating increase in the generation of municipal solid waste (MSW), carbon dioxide (CO2) emissions, and electricity consumption, there is an urgent need to develop and implement MSW-to-energy plants in Malaysia. MSW-to-energy plants can solve both environmental and energy issues by effectively minimizing waste volume, at the same time converting waste into energy. Hence, MSW as a renewable source of clean energy in generating electricity into the national electricity grid via the national Feed-in-Tariff (FiT) program has great potential to decarbonize the energy and waste sector in Malaysia. The implementation of waste-to-energy (WTE) as part of the solution towards Malaysia’s waste and energy problems contributes in achieving several of the 17 United Nations sustainable development goals (UN-SDGs). These goals include goal No. 3 (good health and wellbeing), 6 (clean water and sanitation), 7 (affordable and clean energy), 8 (decent work and economic growth, 11 (sustainable cities and communities), 12 (responsible consumption and production), and 13 (climate action). Moreover, WTE projects support the Malaysian Low Carbon Cities Framework (LCCF) which was launched and adopted in 2009 together with the voluntary pledge from the Malaysian government during the recent 15th conference of parties (COP) for the world’s climate agenda.

The aim of all waste-to-energy (WTE) technologies is to reduce waste volume entering landfills at the same time generating energy from waste. In general, although there are many types of WTE technologies in the market, the main WTE routes can be classified into bio-chemical and thermo-chemical treatment methods. In Malaysia, landfill gas (LFG) as a bio-chemical pathway and incineration as a thermo-chemical pathway are the two most widely used WTE technologies to treat MSW and to recover energy in the form of electricity and heat. There are a number of sanitary landfills with LFG application, namely Air Hitam, Bukit Tagar, Jeram, and Seelong sanitary landfills which are engineered to collect and harness methane gas generated from biodegradable contents within the waste cells for electricity production under the FiT scheme. There are four small-scale incinerators mainly at tourist islands in Malaysia namely Cameron Highlands, Pulau Tioman, Pulau Pangkor, and Labuan, however, these four incinerators do not produce electricity and are only intended to be used for minimizing MSW volume. Only one larger scale incinerator with a capacity of treating 100 tonne/day of MSW at Pulau Langkawi was used to generate electricity from burning MSW.

The application of MSW-to-energy has great potential to be implemented in Malaysia as 89% of MSW is being disposed to landfills without treatment or any WTE applications. In order to ensure a long-term sustainable development of WTE in Malaysia, the four faculties of technology (quality or characteristic of waste; quantity of waste; consistency supply of waste), economy (waste and electricity management; initial capital together with operation and maintenance costs; revenue and carbon credits; financial support), environment (residual and emissions management; location of facility), and social (public health and safety; government initiative and political will) are being considered holistically within the Malaysia context to ensure the suitability at the same time to minimize any business risk of selected WTE technology yet to be implemented in Malaysia. Moreover, a SWOT (strength, weakness, opportunity, and treat) analysis of various WTE systems is being discussed to further complement in terms of technicality towards the sustainability of selecting the best possible WTE in the context of Malaysia.

Therefore, the best WTE technology in dealing with wet MSW, which contains higher amount of organic waste (food waste), is anaerobic digestion (AD) as AD can fully utilize the feedstock by effectively converting organic waste into both form of biogas which later can be converted into electricity and bio-fertilizer. Hence, AD leaves almost no secondary by-product which is hazardous and persistent to the environment if compared to incineration which produces subsequent hazardous ashes. AD is considered as one of the most flexible systems compared to other systems. AD can adsorb a wide range of tonnage between 25 tons per day (TPD) to more than 500 TPD while maintaining its optimal operation. The initial capital expenditure (CAPEX) and operational expenditure (OPEX) of AD systems is the cheapest among all the mentioned WTE technologies in this paper, is most suitable to be utilized in Asia as the process is suited to the warm climate of most of the Asia region, and the initial capital cost as well as the operational cost is the lowest among all WTE technologies where AD suits the financial strength and climatic condition of most Asia countries. However, the main challenge to a successful long-term AD operation is that the MSW must be first sorted or segregated either at the source or at a sorting facility at the plant. This is to ensure only organic waste entering the digester, as other foreign non-organic substances like trace heavy metals and other carcinogenic and hazardous compounds which might bring toxicity possibly affect the biological process in the digestor.

The most sustainable WTE technology to treat mixed MSW containing higher amount of inorganic waste is plasma gasification rather than conventional incineration process. This is because plasma gasification generates high amount of energy, and heat at the same time can produce multiple secondary fuels which later can be turned into energy compared to incineration in which the process only generates heat. Moreover, plasma gasification can accept all kinds of mixed waste and the process generates flue gas which is much cleaner than in conventional incineration. Although the main challenge of plasma gasification is the initial capital costing, which is 1.5 times of that to an incinerator, however, in the long-run plasma gasification has 30% more efficiency compared to the incineration process, therefore generating more output out for the same amount of tonnage of MSW.

Lastly, Malaysia, as a developing country with a vision towards transitioning into a first world country and had pledged to contribute towards climate action and achieving the UN-SDGs, needs to embark towards a circular city metabolism where MSW-to-energy is widely used. National MSW-to-energy practices gives back value to waste as a renewable source for electricity production at the same time minimizing anthropogenic waste and pollutants entering the natural environment. Through nationwide MSW-to-energy implementation and realization, the socio-economic development in Malaysia can be more environmentally sound and efficient, hence enabling Malaysia to achieve sustainable development.

Author Contributions

Conceptualization, Z.J.Y. and M.J.K.B.; formal analysis, C.A.N.; resources, S.S.; writing—original draft preparation, Z.J.Y. and J.W.L.; writing—review and editing, P.L.S.; supervision, M.J.K.B.; funding acquisition, M.J.K.B. and J.W.L.

Funding

This research was funded by Universiti Tunku Abdul Rahman (UTAR), under the UTARRF research grant number PSR/RMC/UTARRF/2018 C1/M04. One of us, Jun Wei Lim also wishes to thank the funds received from Universiti Teknologi PETRONAS via YUTP-FRG (0153AA-E48) and Ministry of Education Malaysia under HICoE.

Acknowledgments

The authors would like to thank the colleagues Faculty of Engineering and Green Technology (FEGT), Universiti Tunku Abdul Rahman for their help.

Conflicts of Interest

The authors declare no conflict of interest.

References

- MHLG. Ministry of Housing and Local Government Malaysia, 2015; Final Lab Report: Solid Waste Management Lab; MHLG: Pemandu, Malaysia, 2015. Available online: http://www.kpkt.gov.my/resources/index/user_1/Attachments/hebahan_slider/slaid_dapatan_makmal.pdf (accessed on 25 April 2019).

- Mahamud, M.A.; Hidefumi, I.; Akio, O.; Chan, N.W.; Samat, N. A Strategic Partnership in Implementing Waste-To-Energy (Wte) Technology in Penang, Malaysia. Acad. Strateg. Manag. J. 2018, 17, 1–8. [Google Scholar]

- Bong, C.P.C.; Ho, W.S.; Hashim, H.; Lim, J.S.; Ho, C.S.; Tan, W.S.P.; Lee, C.T. Review on the renewable energy and solid waste management policies towards biogas development in Malaysia. Renew. Sustain. Energy Rev. 2017, 70, 988–998. [Google Scholar] [CrossRef]

- The World Bank Group. CO2 Emissions (Metric Tons Per Capita): Malaysia; The World Bank Group: Washington, DC, USA, 2019; Available online: https://data.worldbank.org/indicator/EN.ATM.CO2E.PC?locations=MY (accessed on 21 February 2019).

- Budhiarta, I.; Siwar CBasri, H. Current status of municipal solid waste generation in Malaysia. Int. J. Adv. Sci. Eng. Inf. Technol. 2012, 2, 129–134. [Google Scholar] [CrossRef]

- Noor, Z.Z.; Yusuf, R.O.; Abba, A.H.; Hassan, M.A.A.; Din, M.F.M. An overview for energy recovery from municipal solid wastes (MSW) in Malaysia scenario. Renew. Sustain. Energy Rev. 2013, 20, 378–384. [Google Scholar] [CrossRef]

- World Energy Council. World Energy Resources Waste to Energy; Report; World Energy Council: London, UK, 2016. [Google Scholar]

- Suruhanjaya Tenaga (Energy Commission Malaysia). Malaysia Energy Information Hub; Suruhanjaya Tenaga (Energy Commission Malaysia): Putrajaya, Malaysia, 2019. Available online: https://meih.st.gov.my/statistics (accessed on 3 February 2019).

- Joshi, D. Evaluating the Performance of the Sustainable Energy Development Authority (SEDA) and Renewable Energy Policy in Malaysia; Penang Institute: Pulau Pinang, Malaysia, 2018; Available online: https://penanginstitute.org/wp-content/uploads/2018/06/Evaluating-the-Performance-of-SEDA-and-RE-Policy-in-Malaysia_PI_Darshan_5-June-2018.pdf (accessed on 3 February 2019).

- SEDA. Sustainable Energy Development Authority Malaysia; SEDA: Putrajaya, Malaysia, 2019. Available online: http://www.seda.gov.my/ (accessed on 1 March 2019).

- Suruhanjaya Tenaga (Energy Commission Malaysia). Malaysia Energy Statistics Handbook; Suruhanjaya Tenaga (Energy Commission Malaysia): Putrajaya, Malaysia, 2017.

- Rohatgi, A. 2H 2017 Southeast Asia Renewables Market Outlook; Bloomberg New Energy Finance: UK, 2017. [Google Scholar]

- Nadzri, Y. The Way Forward: Solid Waste Managment in Malaysia. In Proceedings of the 10th Annual Waste Management Conference Exhibition, Putrajaya, Malaysia, 18–19 July 2012; pp. 10–19. [Google Scholar]

- Manaf, L.A.; Samah, M.A.A.; Zukki, N.I.M. Municipal solid waste management in Malaysia: Practices and challenges. Waste Manag. 2009, 29, 2902–2906. [Google Scholar] [CrossRef] [PubMed]

- Moh, Y.C.; Manaf, L.A. Overview of household solid waste recycling policy status and challenges in Malaysia. Resour. Conserv. Recycl. 2014, 82, 50–61. [Google Scholar] [CrossRef]

- Tan, S.T.; Ho, W.S.; Hashim, H.; Lee, C.T.; Taib, M.R.; Ho, C.S. Energy, economic and environmental (3E) analysis of waste-to-energy (WTE) strategies for municipal solid waste (MSW) management in Malaysia. Energy Convers. Manag. 2015, 102, 111–120. [Google Scholar] [CrossRef]

- AlQattan, N.; Acheampong, M.; Jaward, F.M.; Ertem, F.C.; Vijayakumar, N.; Bello, T. Reviewing the potential of Waste-to-Energy (WTE) technologies for Sustainable Development Goal (SDG) numbers seven and eleven. Renew. Energy Focus 2018, 27, 97–110. [Google Scholar] [CrossRef]

- Gumisiriza, R.; Hawumba, J.F.; Okure, M.; Hensel, O. Biomass waste-to-energy valorisation technologies: A review case for banana processing in Uganda. Biotechnol. Biofuels 2017, 10, 11. [Google Scholar] [CrossRef]

- Zainu, Z.A.; Songip, A.R. Policies, challenges and strategies for Municipal waste management in Malaysia. J. Sci. Technol. Innov. Policy 2017, 3, 18–22. [Google Scholar]

- Dada, O.; Mbohwa, C. Energy from waste: A possible way of meeting goal 7 of the sustainable development goals. Mater. Today Proc. 2018, 5, 10577–10584. [Google Scholar] [CrossRef]

- United Nations Economic and Social Commissions (UNESCAP). Visualization of Interlinkages for SDG 7; UNESCAP: New York, NY, USA, 2016; Available online: https://www.unescap.org/sites/default/files/Visualisation%20of%20interlinkages%20for%20SDG%207.pdf (accessed on 27 February 2019).

- UN Environment. GOAL 7: Affordable ad Clean Energy; UN Environment: Nairobi, Kenyan, 2019; Available online: https://www.unenvironment.org/explore-topics/sustainable-development-goals/why-do-sustainable-development-goals-matter/goal-7 (accessed on 4 February 2019).

- O’Brien, J.K. Comparison of Air Emissions from Waste-to-Energy Facilities to Fossil Fuel Power Plants. In Proceedings of the 14th Annual North American Waste-to-Energy Conference, Tampa, FL, USA, 1–3 May 2006; pp. 69–78. [Google Scholar]

- United Nations. Tracking Progress Towards Inclusive, Safe, Resilient and Sustainable Cities and Human Settlements. SDG 11 Synthesis Report: High Level Political Forum 2018; The United Nations: New York, NY, USA, 2018. [Google Scholar]

- KeTTHA. Ministry of Energy, Green Technology and Water Malaysia., Low Carbon Cities Framework; Version 2, KeTTHA: Putrajaya, Malaysia, 2017; Available online: https://www.greentechmalaysia.my/media/LCCF_Book-Version-2-2017.pdf (accessed on 23 February 2019).

- Abushammala, M.F.; Basri, N.E.A.; Basri, H.; El-Shafie, A.H.; Kadhum, A.A.H. Regional landfills methane emission inventory in Malaysia. Waste Manag. Res. 2011, 29, 863–873. [Google Scholar] [CrossRef] [PubMed]

- Girardet, H. Regenerative cities. In Green Economy Reader; Springer: Cham, Switzerland, 2017; pp. 183–204. [Google Scholar]

- Bashir MJ, K.; Ng, C.A.; Sethupathi, S.; Lim, J.W. Assessment of the Environmental, Technical and Economic Issues Associated with Energy Recovery from Municipal Solid Waste in Malaysia. IOP Conf. Ser. Earth Environ. Sci. 2019, 268, 012044. [Google Scholar] [CrossRef]

- Sulaiman, M.R.; Kadir, S.A.; Aishah, S.; Ibrahim, R.; Husin, M. A study on the problems of the usage of incinerators in Malaysia. Sci. Res. J. 2007, 4, 1–12. [Google Scholar] [CrossRef]

- Neville, A. Kajang Waste-to-Energy Plant, Semenyih, Malaysia. Power 2010, 154, 35–36. Available online: http://www.powermag.com/renewables/waste_to_energy/Top-Plant-Kajang-Waste-to-Energy-Plant-Semenyih-Malaysia_3225 (accessed on 23 February 2019).

- Balat, M.; Balat, H. Biogas as a renewable energy source—A review. Energy Sources Part A 2009, 31, 1280–1293. [Google Scholar] [CrossRef]

- Oh, T.H.; Pang, S.Y.; Chua, S.C. Energy policy and alternative energy in Malaysia: Issues and challenges for sustainable growth. Renew. Sustain. Energy Rev. 2010, 14, 1241–1252. [Google Scholar] [CrossRef]

- Johari, A.; Ahmed, S.I.; Hashim, H.; Alkali, H.; Ramli, M. Economic and environmental benefits of landfill gas from municipal solid waste in Malaysia. Renew. Sustain. Energy Rev. 2012, 16, 2907–2912. [Google Scholar] [CrossRef]