Life Cycle Assessment and Economic Analysis of an Innovative Biogas Membrane Reformer for Hydrogen Production

Abstract

:1. Introduction

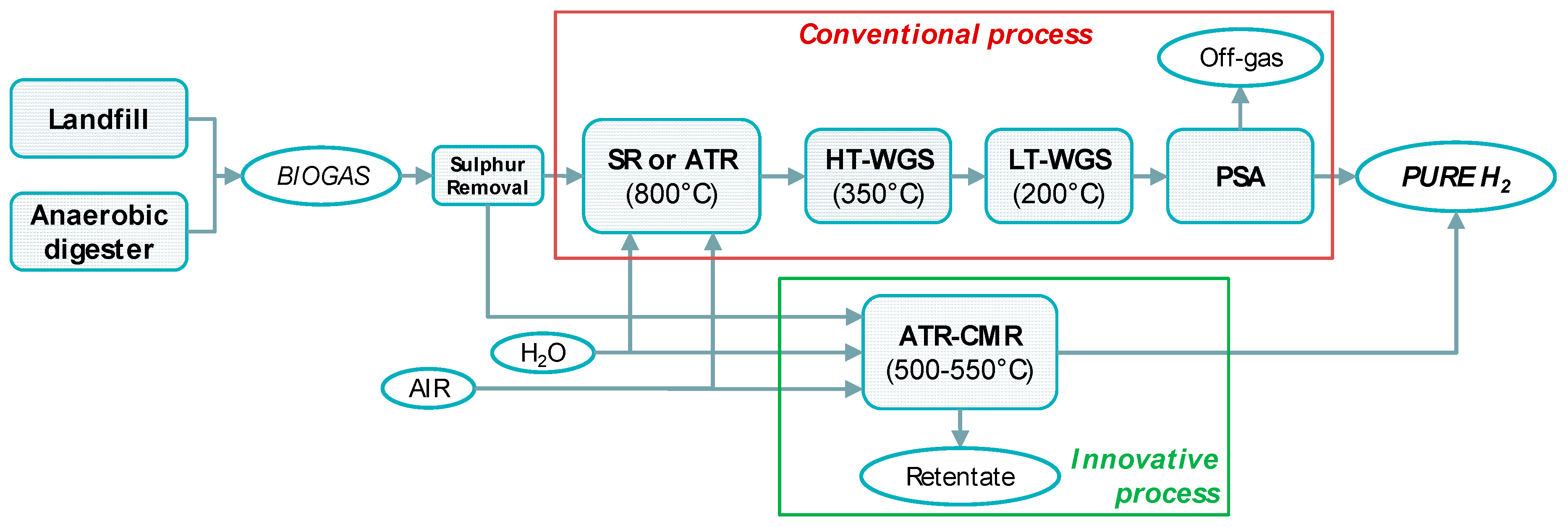

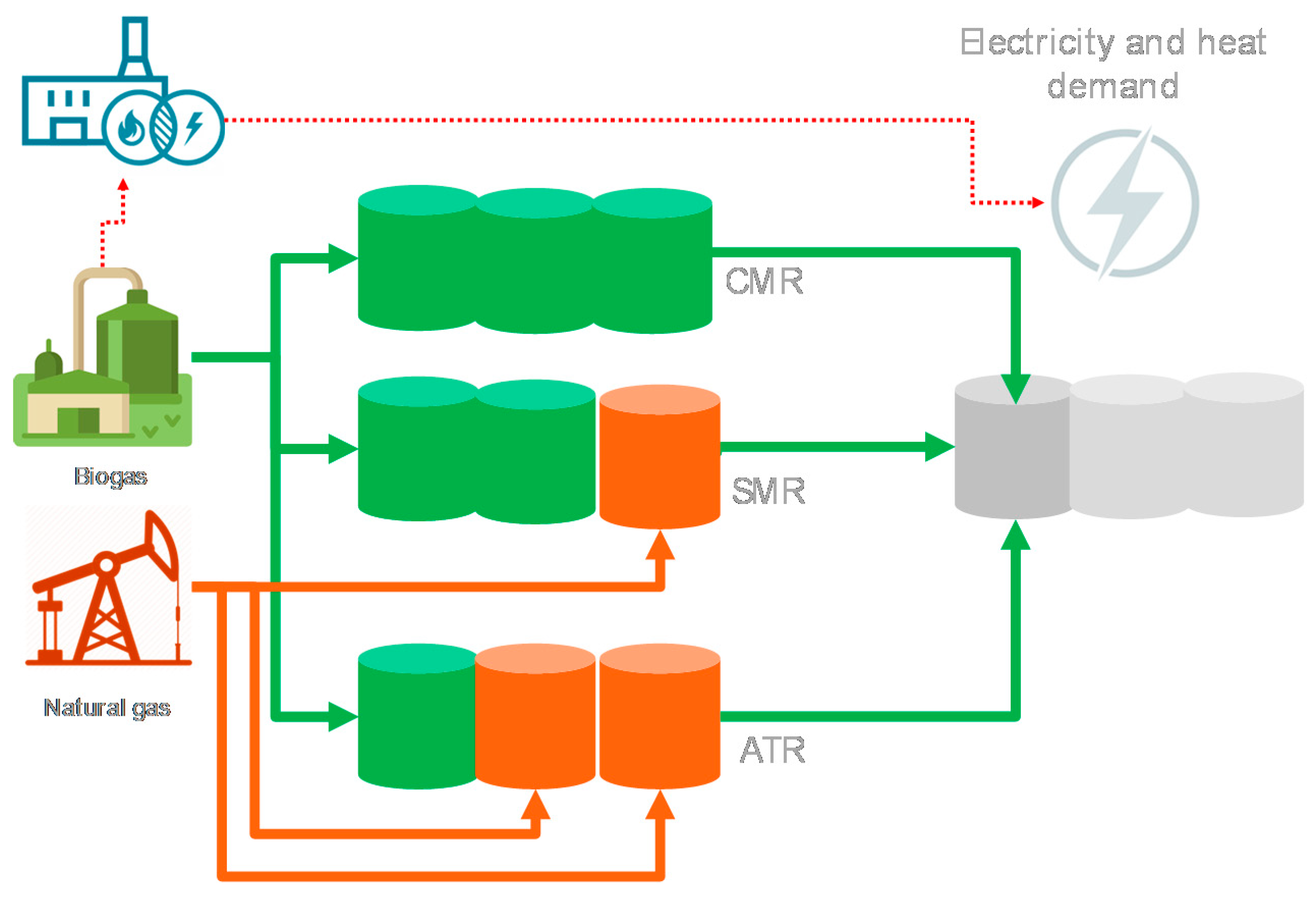

2. Case Studies

2.1. System Layouts

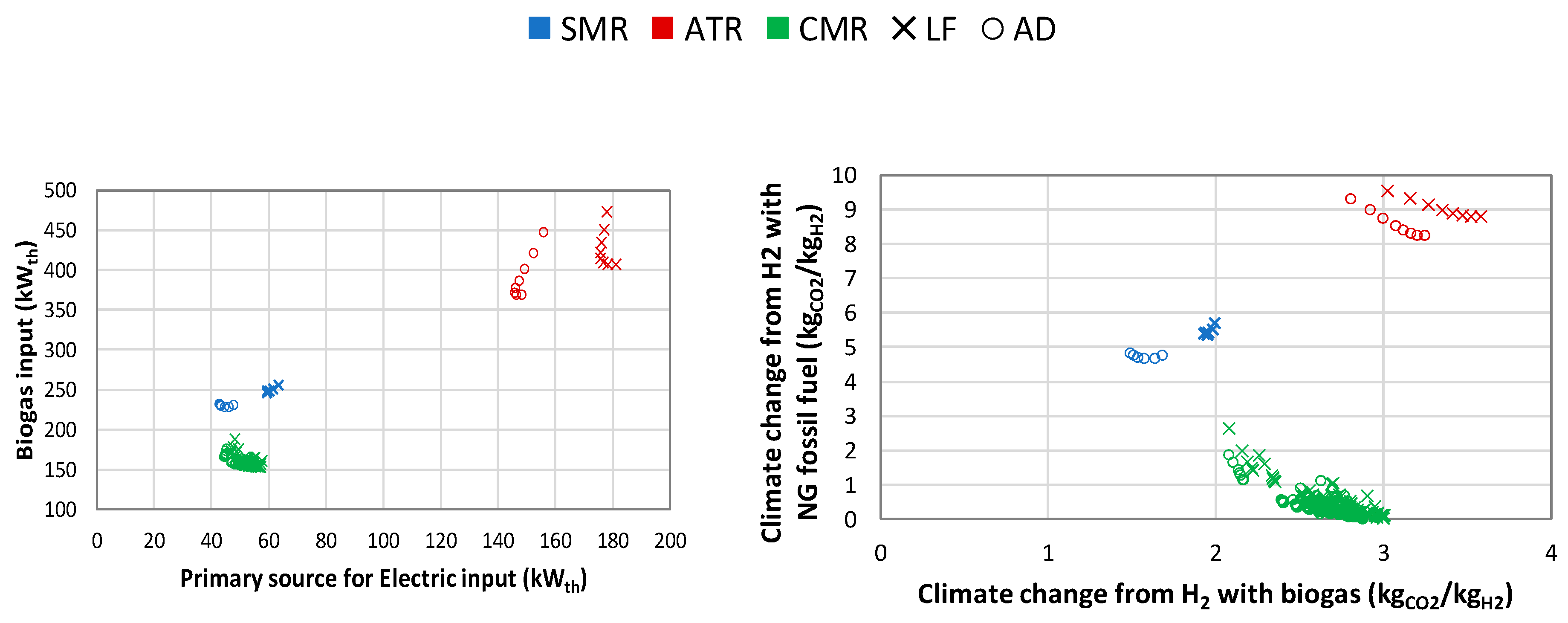

2.2. Techno-Economic Results

3. Lifecycle Assessment (LCA) Methodology

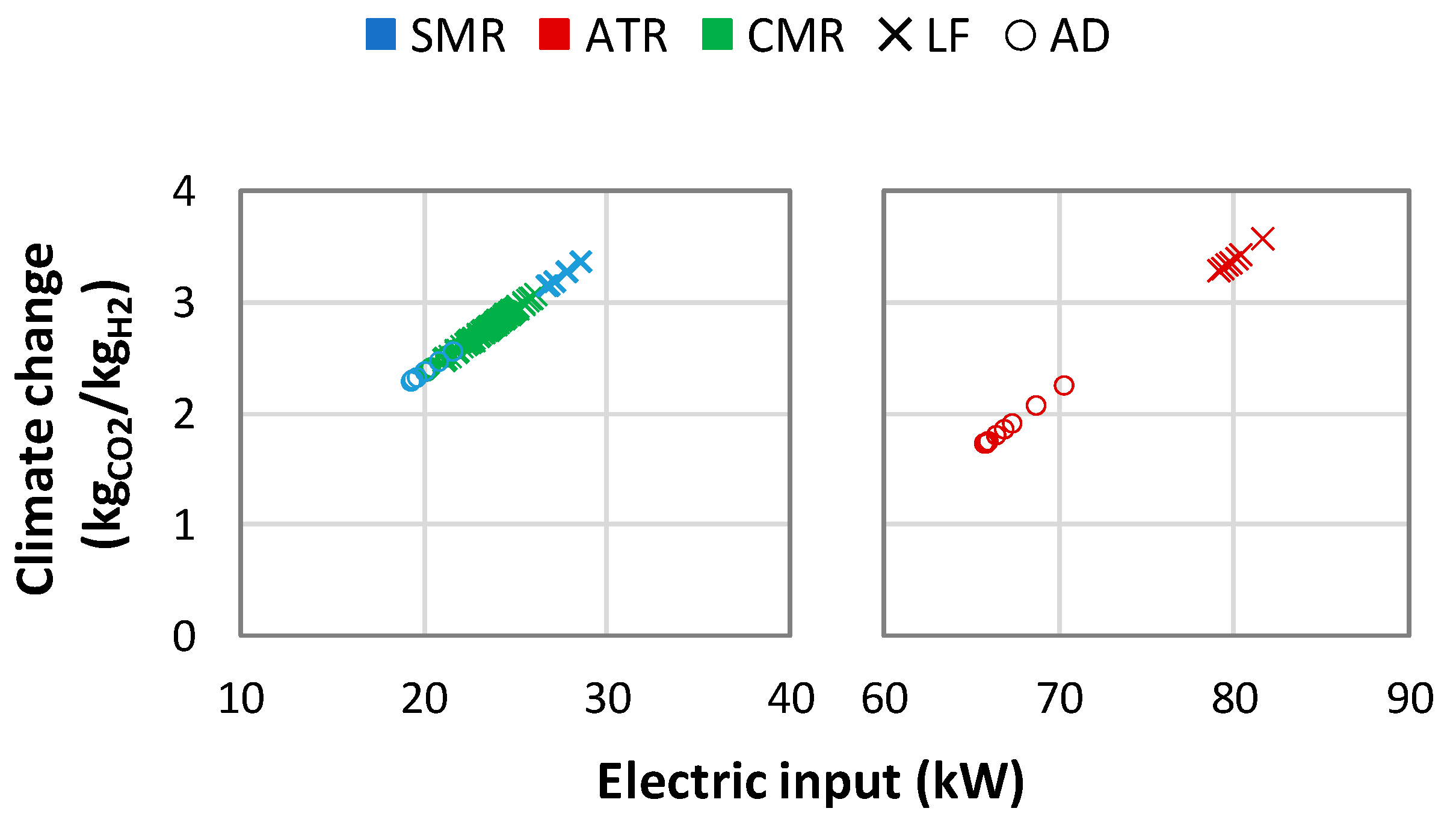

- Biogas availability for H2 production is limited. Under this scenario, a system with a higher biogas conversion efficiency (i.e., BIONICO process) can supply more H2 to the market. Choosing a technology with lower efficiency means it will require a certain amount of H2 produced from conventional process (such as natural gas steam reforming) to meet the same demand, as shown in Figure 5.

- Biogas production is abundant, thus there is a surplus of biogas which is simply flared. In this scenario, biogas utilization is not competing with other potential uses.

- For scenario 1, the energy recovery of biogas is assumed to be cogeneration of electricity and heat. The electric and heat efficiencies are assumed to be 39% and 46%, respectively, with a total CHP efficiency of 85% [31]. The impact of biogas production is excluded from the cogeneration impact. The marginal replacing technology for the lost energy resulting from biogas diversion are assumed to be the European average for electricity generation and natural gas cogeneration for heat production;

- The European average grid mix is assumed to be the marginal electricity generation technology demanded for hydrogen production;

- The only relevant air emission during the H2 production process is CO2, which is considered to be carbon neutral in this study;

4. Results and Discussion

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

Nomenclature

| p | Pressure (bar) |

| T | Temperature (°C) |

| Acronyms | |

| AD | Anaerobic digester |

| ATR | Autothermal reformer |

| ATR-CMR | Autothermal catlytic membrane reformer |

| BG | Biogas |

| CCF | Carrying charge factor |

| CHP | Combined heat and power |

| GWP | Global warming potential |

| HT | High temperature |

| HX | Heat exchanger |

| LCA | Life cycle assessment |

| LCOH | Levelised cost of hydrogen |

| LF | Landfill |

| LHV | Low heating value |

| LT | Low temperature |

| MR | Membrane reactor |

| NG | Natural Gas |

| O/C | Oxygen to carbon molar ratio |

| P | Pump |

| PSA | Pressure swing adsorption |

| S/C | Steam to carbon molar ratio |

| SMR | Steam methane reformer |

| WGSR | Water gas shift reformer |

| Greek letters | |

| ηsys | System efficiency in terms of LHV of hydrogen |

Appendix A

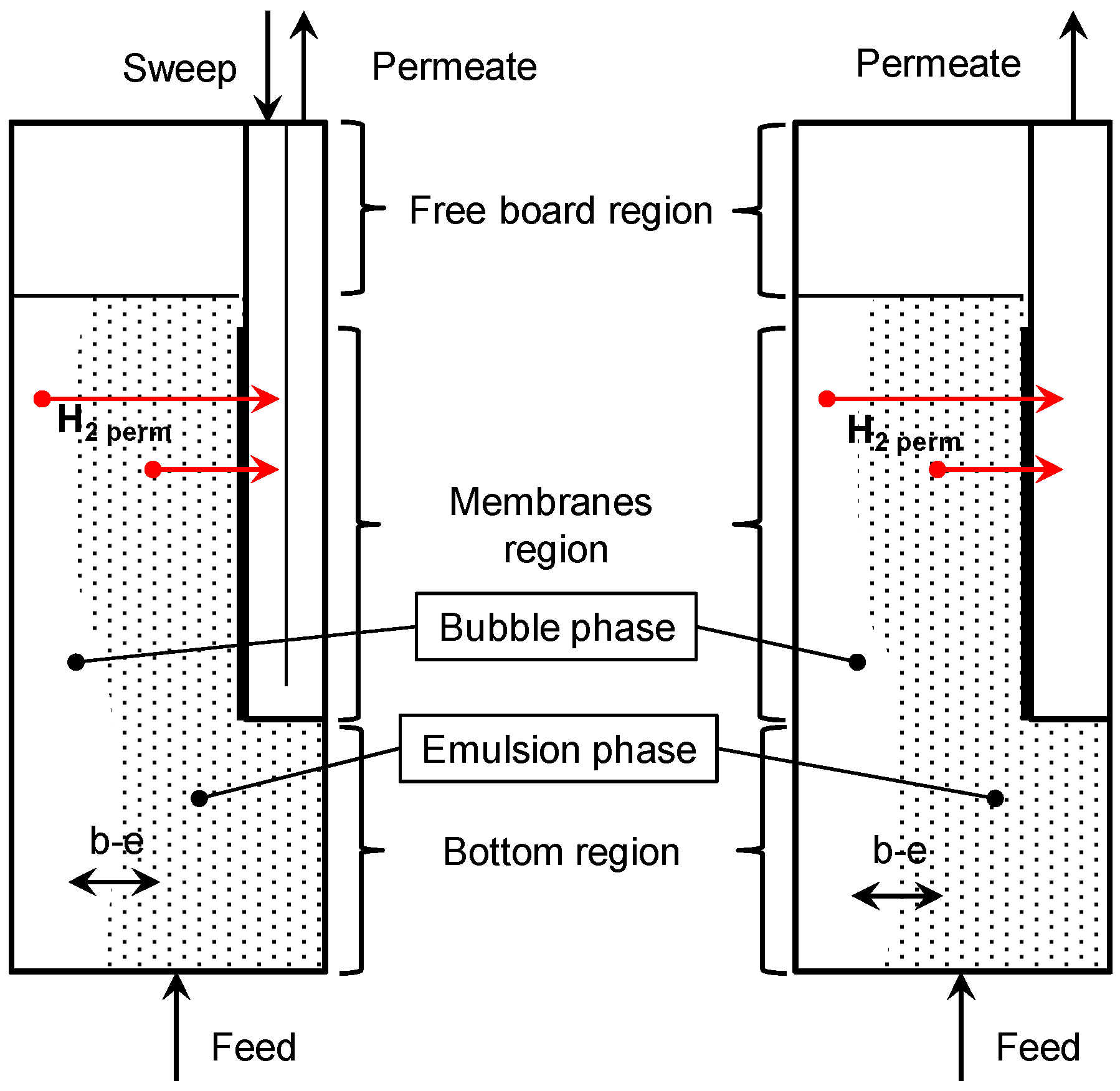

Membrane Reactor

| Parameter | Units | Value |

|---|---|---|

| Membrane reactor geometry | ||

| L reactor | m | 1 |

| L bottom region (from distributor to membrane) | m | 0.1 |

| L free board region | m | 0.45 |

| D reactor | m | 0.44‒0.6 |

| Membrane distance | m | 0.01‒0.026 |

| Membrane parameters | ||

| OD/ID | m | 0.014/0.007 |

| Support thickness | m | 0.0035 |

| Length | m | 0.45 |

| Membrane thickness () | µm | 4.5 |

| k0 | mol s−1 m−1 Pa−n | 3.93 × 10−8 |

| Ea | kJ mol-1 | 9.26 |

| n | - | 0.5 |

References

- Albrecht, U.; Altmann, M.; Barth, F.; Bünger, U.; Fraile, D.; Lanoix, J.-C.; Pschorr-Schoberer, E.; Vanhoudt, W.; Weindorf, W.; Zerta, M.Z.; et al. Study on hydrogen from renewable resources in the EU. Final. Rep. 2015. [Google Scholar] [CrossRef]

- Sheet, H.F. Hydrogen Production–Steam Methane Reforming (SMR). New York State Energy Res. Dev. Authority New York 2005. [Google Scholar]

- Nikolaidis, P.; Poullikkas, A. A comparative overview of hydrogen production processes. Renew. Sustain. Eng. Rev. 2017, 67, 597–611. [Google Scholar] [CrossRef]

- Scarlat, N.; Dallemand, J.-F.; Fahl, F. Biogas: Developments and perspectives in Europe. Renew. Energy. 2018, 129, 457–472. [Google Scholar] [CrossRef]

- Alves, H.J.; Bley Junior, C.; Niklevicz, R.R.; Frigo, E.P.; Frigo, M.S.; Coimbra-Araújo, C.H. Overview of hydrogen production technologies from biogas and the applications in fuel cells. Int. J. Hydrogen Eng. 2013, 38, 5215–5225. [Google Scholar] [CrossRef]

- Gallucci, F.; Fernandez, E.; Corengia, P.; van Sint Annaland, M. Recent advances on membranes and membrane reactors for hydrogen production. Chem. Eng. Sci. 2013, 92, 40–66. [Google Scholar] [CrossRef]

- Di Marcoberardino, G.; Vitali, D.; Spinelli, F.; Binotti, M.; Di Marcoberardino, G.; Vitali, D.; Spinelli, F.; Binotti, M.; Manzolini, G. Green Hydrogen Production from Raw Biogas: A Techno-Economic Investigation of Conventional Processes Using Pressure Swing Adsorption Unit. Processes 2018, 6, 19. [Google Scholar] [CrossRef]

- Di Marcoberardino, G.; Foresti, S.; Binotti, M.; Manzolini, G. Potentiality of a biogas membrane reformer for decentralized hydrogen production. Chem. Eng. Process Process Intensif. 2018, 129, 131–141. [Google Scholar] [CrossRef]

- Whiting, A.; Azapagic, A. Life cycle environmental impacts of generating electricity and heat from biogas produced by anaerobic digestion. Energy 2014, 70, 181–193. [Google Scholar] [CrossRef]

- Bacenetti, J.; Sala, C.; Fusi, A.; Fiala, M. Agricultural anaerobic digestion plants: What LCA studies pointed out and what can be done to make them more environmentally sustainable. Appl. Eng. 2016, 179, 669–686. [Google Scholar] [CrossRef]

- Van Stappen, F.; Mathot, M.; Decruyenaere, V.; Loriers, A.; Delcour, A.; Planchon, V.; Goffart, J.-P.; Stilmant, D. Consequential environmental life cycle assessment of a farm-scale biogas plant. J. Environ. Manag. 2016, 175, 20–32. [Google Scholar] [CrossRef] [PubMed]

- Hijazi, O.; Munro, S.; Zerhusen, B.; Effenberger, M. Review of life cycle assessment for biogas production in Europe. Renew. Sustain. Eng. Rev. 2016, 54, 1291–1300. [Google Scholar] [CrossRef]

- Hajjaji, N.; Martinez, S.; Trably, E.; Steyer, J.-P.; Helias, A. Life cycle assessment of hydrogen production from biogas reforming. Int. J. Hydrogen Eng. 2016, 41, 6064–6075. [Google Scholar] [CrossRef]

- Valente, A.; Iribarren, D.; Dufour, J. Harmonised life-cycle global warming impact of renewable hydrogen. J. Clean. Prod. 2017, 14, 762–772. [Google Scholar] [CrossRef]

- Battista, F.; Montenegro Camacho, Y.S.; Hernández, S.; Bensaid, S.; Herrmann, A.; Krause, H.; Trimis, D.; Fino, D. LCA evaluation for the hydrogen production from biogas through the innovative BioRobur project concept. Int. J. Hydrogen Eng. 2017, 42, 14030–14043. [Google Scholar] [CrossRef]

- AspenTech. Available online: http://www.aspentech.com/products/aspen-plus.aspx (accessed on 15 May 2018).

- Foresti, S.; Manzolini, G. Performances of a micro-CHP system fed with bio-ethanol based on fluidized bed membrane reactor and PEM fuel cells. Int. J. Hydrogen Eng. 2016, 41, 9004–9021. [Google Scholar] [CrossRef]

- Foresti, S.; Di Marcoberardino, G.; Manzolini, G.; De Nooijer, N.; Gallucci, F.; van Sint Annaland, M. A comprehensive model of a fluidized bed membrane reactor for small-scale hydrogen production. Chem. Eng. Process. 2018, 127, 136–144. [Google Scholar] [CrossRef]

- NIST Chemistry webbook. Available online: https://webbook.nist.gov/chemistry (accessed on 15 May 2018).

- European Environment agency. Available online: https://www.eea.europa.eu/data-and-maps/indicators/overview-of-the-electricity-production-2/assessment-4 (accessed on 15 May 2018).

- Gerdes, K.; Summers, W.M.; Wimer, J. Cost Estimation Methodology for NETL Assessments of Power Plant Performance; Report No. DOE/NETL-2011/1455; US Department of Energy, National Energy Technology Laboratories, 2011.

- Spallina, V.; Pandolfo, D.; Battistella, A.; Romano, M.C.; van Sint Annaland, M.; Gallucci, F. Techno-economic assessment of membrane assisted fluidized bed reactors for pure H2 production with CO2 capture. Eng. Convers. Manag. 2016, 120, 257–273. [Google Scholar] [CrossRef]

- Manzolini, G.; Macchi, E.; Gazzani, M. CO2 capture in natural gas combined cycle with SEWGS. Part B: Economic assessment. Int. J. Greenh. Gas Control 2013, 12, 502–509. [Google Scholar] [CrossRef]

- International Renewable Energy Agency (IRENA). Available online: https://www.irena.org/ (accessed on 15 May 2018).

- European Commission. EuroStat, Statistics Explained. Available online: http://ec.europa.eu/eurostat/statistics-explained/index.php/Main_Page (accessed on 15 May 2018).

- FERRET. Available online: http://www.ferret-h2.eu (accessed on 15 May 2018).

- ISO 14040. Available online: https://www.iso.org/standard/37456.html (accessed on 15 May 2018).

- ISO 14044. Available online: https://www.iso.org/standard/38498.html (accessed on 15 May 2018).

- Masoni, P.; Zamagni, A. Guidance Document for performing LCAs on Fuel Cells and H2 Technologies. Available online: https://www.fch.europa.eu/project/guidance-document-performing-lcas-hydrogen-and-fuel-cell-technologies (accessed on 15 May 2018).

- DEMCAMER. Available online: http://www.demcamer.org/ (accessed on 15 May 2018).

- European Environment Agency, Combined heat and power (CHP). Available online: https://www.eea.europa.eu/data-and-maps/indicators/combined-heat-and-power-chp-1 (accessed on 15 May 2018).

- Spath, P.L.; Mann, M.K. Life Cycle Assessment of Hydrogen Production via Natural Gas Steam Reforming; National Renewable Energy Lab.: Golden, CO, USA, 2000. [CrossRef]

- Ecoinvent. Available online: www.ecoinvent.ch (accessed on 15 May 2018).

- De Nooijer, N.; Gallucci, F.; Pellizzari, E.; Melendez, J.; Pacheco Tanaka, D.A.; Manzolini, G. On concentration polarisation in a fluidized bed membrane reactor for biogas steam reforming: Modelling and experimental validation. Chem. Eng. J. 2018, 348, 232–243. [Google Scholar] [CrossRef]

| Species | Units | LF | AD |

|---|---|---|---|

| CH4 | % mol | 44.2 | 58.1 |

| CO2 | 34.0 | 33.9 | |

| N2 | 16.0 | 3.8 | |

| O2 | 2.7 | 1.1 | |

| H2 | 0.0165 | - | |

| CO | 0.0006 | - | |

| H2O | Saturated | Saturated | |

| p, T | bar, °C | 1.013, 25 | 1.013, 25 |

| LHV | MJ/kg | 12.7 | 17.8 |

| Parameter | Units | SMR | ATR | BIONICO ATR-CMR |

|---|---|---|---|---|

| Biogas (BG) | - | LF‒AD | LF‒AD | LF‒AD |

| Reactors operating conditions | ||||

| T max reactors | °C | 800 | 800 | 550‒600 |

| S/C | - | 4 | 3 | 3‒3.5 |

| P feed | bar | 4‒20 | 4‒20 | 8‒16 |

| Reactor geometry | ||||

| D reactor | m | - | - | 0.44‒0.6 |

| Membrane distance | m | - | - | 0.01‒0.026 |

| Parameter | Units | SMR | ATR | BIONICO ATR-CMR | |||

|---|---|---|---|---|---|---|---|

| BG | - | LF | AD | LF | AD | LF | AD |

| T max reactors | °C | 800 | 800 | 800 | 800 | 550 | 550 |

| (S/C)/pfeed | - | 4/14 | 4/12 | 3/18 | 3/18 | 3/12 | 3/12 |

| H2 flow/pressure | kg/day/bar | 100/20 | 100/20 | 100/20 | 100/20 | 100/20 | 100/20 |

| BG Input | kW | 247 | 229 | 407 | 368 | 154.6 | 154.8 |

| Tot aux cons. | kW | 24.3 | 17.9 | 73.0 | 60.0 | 24.8 | 24.1 |

| ƞsys | % | 46.2 | 51.7 | 24.5 | 27.8 | 65.1 | 66.1 |

| LCOH | €/kg | 4.29 | 4.21 | 6.60 | 6.41 | 4.11 | 4.01 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Marcoberardino, G.; Liao, X.; Dauriat, A.; Binotti, M.; Manzolini, G. Life Cycle Assessment and Economic Analysis of an Innovative Biogas Membrane Reformer for Hydrogen Production. Processes 2019, 7, 86. https://doi.org/10.3390/pr7020086

Di Marcoberardino G, Liao X, Dauriat A, Binotti M, Manzolini G. Life Cycle Assessment and Economic Analysis of an Innovative Biogas Membrane Reformer for Hydrogen Production. Processes. 2019; 7(2):86. https://doi.org/10.3390/pr7020086

Chicago/Turabian StyleDi Marcoberardino, Gioele, Xun Liao, Arnaud Dauriat, Marco Binotti, and Giampaolo Manzolini. 2019. "Life Cycle Assessment and Economic Analysis of an Innovative Biogas Membrane Reformer for Hydrogen Production" Processes 7, no. 2: 86. https://doi.org/10.3390/pr7020086

APA StyleDi Marcoberardino, G., Liao, X., Dauriat, A., Binotti, M., & Manzolini, G. (2019). Life Cycle Assessment and Economic Analysis of an Innovative Biogas Membrane Reformer for Hydrogen Production. Processes, 7(2), 86. https://doi.org/10.3390/pr7020086