Drying of Drill Cuttings: Emphasis on Energy Consumption and Thermal Analysis

Abstract

:1. Introduction

- Process 1—the transfer of energy (mostly as heat) from the surrounding environment to evaporate surface moisture;

- Process 2—the transfer of internal moisture to the surface of the solid and its subsequent evaporation due to Process 1 [9].

2. Materials and Methods

2.1. Material Characterization

2.2. Experimental Setup

2.3. Experimental Procedure

3. Results and Discussion

3.1. Drying Characteristics

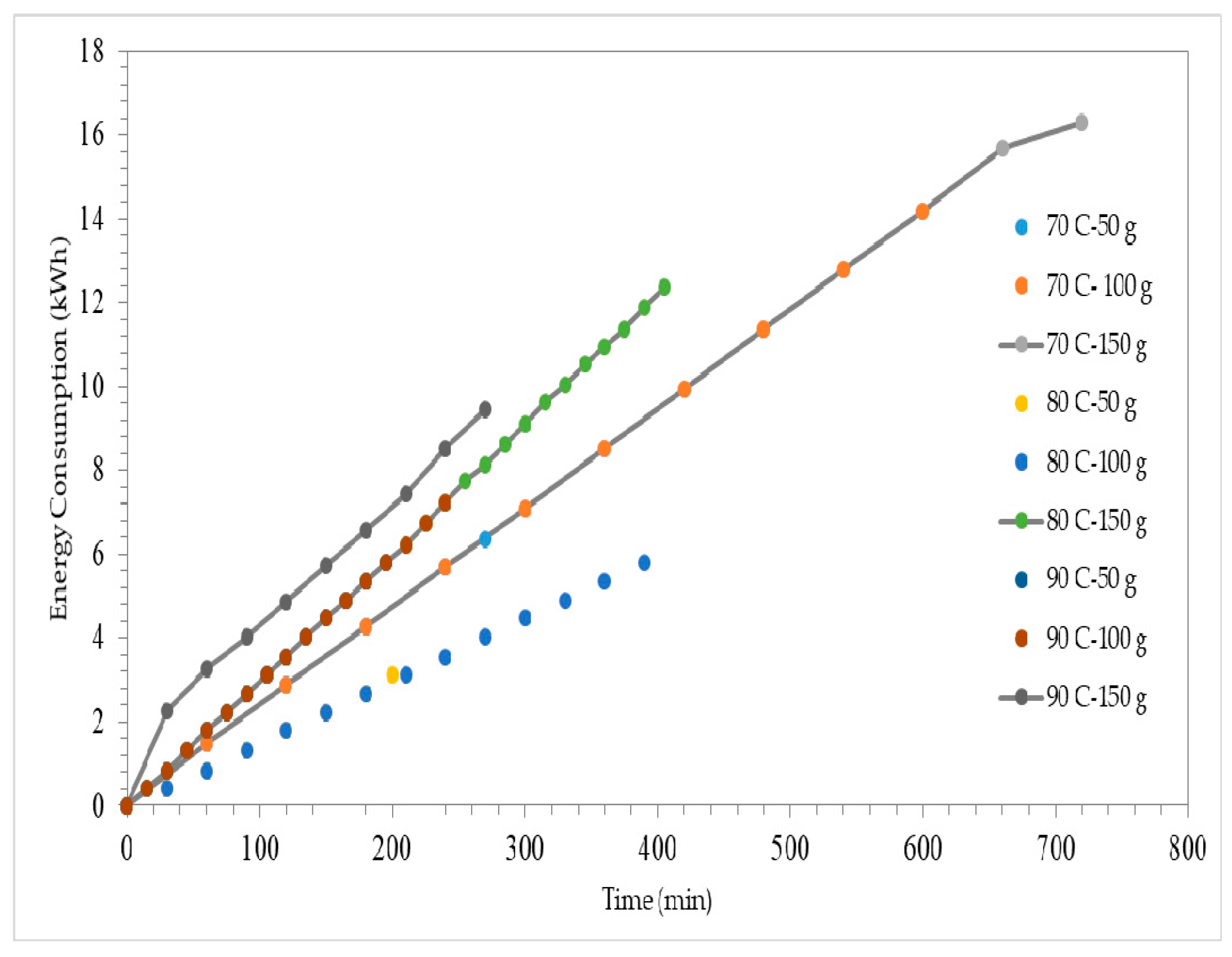

3.2. Energy Consumption

3.3. Thermal Analysis

4. Conclusions

Supplementary Materials

Supplementary File 1Funding

Conflicts of Interest

References

- Geology Information Page, Environmental Geology, Drilling Fluid (Drilling Sludge). Available online: http://www.jeolojitr.com/2014/09/sondaj-sivilari-sondaj-camuru.html#more (accessed on 12 December 2018).

- Pereira, M.S.; Panisset, C.M.A.; Martins, A.L.; Sá, C.H.M.; Barrozo, M.A.S.; Ataíde, C.H. Microwave treatment of drilled cuttings contaminated by synthetic drilling fluid. Sep. Purif. Technol. 2014, 124, 68–73. [Google Scholar] [CrossRef]

- Anonym, Waste Management Regulation, Official Gazette, Official Gazette Time: 02.04.2015 Official Gazette Number:29314. Available online: http://www.mevzuat.gov.tr/Metin.Aspx?MevzuatKod=7.5.20644&MevzuatIliski=0&sourceXmlSearch=at%C4%B1k%20y%C3%B6netimi (accessed on 15 December 2018). (In Turkish)

- Tao, T.; Peng, X.F.; Lee, D.J. Skin layer on thermally dried sludge cake. Drying Tech. 2006, 24, 1047–1052. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Chen, M.Q.; Huang, W.; Xue, F. Isothermal hot air drying behavior of municipal sewage sludge briquettes coupled with lignite additive. Fuel 2016, 171, 108–115. [Google Scholar] [CrossRef]

- Tınmaz Köse, E.; Çelen, S.; Çelik, S.Ö. Conventional and microwave drying of hydrocarbon cutting sludge. Environ. Prog. Sustain. Energy 2018. [Google Scholar] [CrossRef]

- Anonym, Mining Waste Regulation, Official Gazette, Official Gazette Time: 15.07.2015 Official Gazette Number: 29417. Available online: http://www.mevzuat.gov.tr/Metin.Aspx?MevzuatKod=7.5.20913&MevzuatIliski=0&sourceXmlSearch=maden%20at%C4%B1k (accessed on 15 December 2018). (In Turkish)

- Doğanay, G. 2018, Sondaj Atıkları ve Yönetmeliklere Göre Atık Yönetimi. Available online: http://medyaenerji.com/2018/02/14/sondaj-sektorunde-cevre-mevzuati/ (accessed on 15 December 2018). (In Turkish).

- Mujumdar, A.S. Handbook of Industrial Drying Industrial, Drying Handbook of Fourth Edition; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA; London, UK; New York, NY, USA, 2015. [Google Scholar]

- Parikh, D.M. Solids Drying: Basics and Applications, Website of Chemical Engineering. Available online: https://www.chemengonline.com/solids-drying-basics-and-applications/?printmode=1 (accessed on 14 December 2018).

- Rossi, A.S.; Faria, M.G.; Pereira, M.S.; Ataide, C.H. Kinetics of microwave heating and drying of drilling fluids and drill cuttings. Dry Technol. 2017, 35, 1130–1140. [Google Scholar] [CrossRef]

- Mujumdar, A.S. Drying: Principles and Practice. In Proceedings of the International Workshop on Drying of Food and Biomaterials, Bangkok, Thailand, 6–7 June 2011. [Google Scholar]

- Sahnia, E.K.; Chaudhuria, B. Contact drying: A review of experimental and mechanistic modeling approaches. Int. J. Pharm. 2012, 434, 334–348. [Google Scholar] [CrossRef] [PubMed]

- Júnior, I.J.; Pereira, M.S.; Santos, J.M.; Duarte, C.R.; Ataíde, C.H.; Panisset, C.M.S. Microwave remediation of oil well drill cuttings. J. Petrol. Sci. Eng. 2015, 134, 23–29. [Google Scholar]

- Júnior, I.P.; Leibsohn Martins, A.; Ataíde, C.H.; Duarte, C.R. Microwave drying remediation of petroleum-contaminated drill cuttings. J. Environ. Manag. 2017, 196, 659–665. [Google Scholar] [CrossRef] [PubMed]

- Shang, H.; Snape, C.E.; Kingman, S.W.; Robinson, J.P. Microwave treatment of oil-contaminated north sea drill cuttings in a high power multimode cavity. Sep. Purif. Technol. 2006, 49, 84–90. [Google Scholar] [CrossRef]

- Rossi, A.S.; Pereira, M.S.; dos Santos, J.M.; Petri, I.; Ataíde, C.H. Fundemantals of microwave heating and drying of drilled cuttings. Mater. Sci. Forum 2017, 899, 528–533. [Google Scholar] [CrossRef]

- Chien, Y. Field study of in situ remediation of petroleum hydrocarbon contaminated soil on site using microwave energy. J. Hazard. Mater. 2012, 199–200, 457–461. [Google Scholar] [CrossRef] [PubMed]

- Robinson, J.P.; Kingman, S.W.; Onobrakpeya, O. Microwave-assisted stripping of oil contaminated drill cuttings. J. Environ. Manag. 2008, 88, 211–218. [Google Scholar] [CrossRef] [PubMed]

- Robinson, J.P.; Kingman, S.W.; Snape, C.E.; Barranco, R.; Shang, H.; Bradley, M.S.A.; Bradshaw, S.M. Remediation of oil-contaminated drill cuttings using continuous microwave heating. Chem. Eng. J. 2009, 152, 458–463. [Google Scholar] [CrossRef]

- Proestos, C.; Komaitis, M. Application of microwave-assisted extraction to the fast extraction of plant phenolic compounds. Food Sci. Technol. 2008, 41, 652–659. [Google Scholar] [CrossRef]

- Meredith, R.J. Introduction and fundamental concepts. In Institution of Electrical Engineers, Engineers’ Handbook of Industrial Microwave Heating; IET: London, UK, 1998; pp. 1–16. [Google Scholar]

- Fernandez, Y.; Arenillas, A.; Menendez, J.A. Microwave heating applied to pyrolysis. In Advances in Induction and Microwave Heating of Mineral and Organic Materials; Grundas, S., Ed.; IntechOpen: London, UK, 2011; pp. 723–751. [Google Scholar]

- Haghi, A.K.; Amanifard, N. Analysis of heat and mass transfer during microwave drying of food products. Braz. J. Chem. Eng. 2008, 25, 491–501. [Google Scholar] [CrossRef]

- Ingvarsson, M.K. Airflow and Energy Analysis in Geothermally Heated Conveyor Drying of Fishbone. MSc Thesis, Faculty of Industrial Engineering, Mechanical Engineering and Computer Science School of Engineering and Natural Sciences University of Iceland, Reykjavik, Iceland, June 2014. [Google Scholar]

- Alamia, A.; Ström, H.; Thunman, A. Design of an integrated dryer and conveyor belt for woody biofuels. Biomass Bioenergy 2015, 77, 92–109. [Google Scholar] [CrossRef] [Green Version]

- Tınmaz Köse, E.; Akyildiz, A.; Çelik, S.Ö.; Engin, E. Treatment of Hydrocarbon Drilling Waste Sludge, Recovery and Recovery In The Construction Sector, Scientific Research Project, NKUBAP.06.GA.17.100 2017; Tekirdağ Namık Kemal University: Tekirdağ, Turkey, December 2017. [Google Scholar]

- Akcay, G. Drilling Fluid and Duties. 2013. Available online: http://geopazar.com/forum.asp?d23/Sondaj-Sivisi-ve-Gorevleri (accessed on 4 February 2019).

- Çelen, S.; Aktaş, T.; Karabeyoğlu, S.S.; Akyıldız, A. Drying of prina using microwave energy and determination of appropriate thin layer drying model. JOTAF 2015, 12, 21–31. [Google Scholar]

- Çelen, S.; Aktaş, T.; Karabeyoğlu, S.S.; Akyildiz, A. Drying Behaviour of Prina (Crude Olive Cake) Using Different Type of Dryers. Dry Technol. 2016, 34, 843–853. [Google Scholar] [CrossRef]

- Tınmaz Köse, E.; Çelen, S.; Çelik, S.Ö.; Akın, G.; Akyıldız, A. Drying of drilling sludge: Conventional and microwave drying. HJSE 2019, in press. [Google Scholar]

- Huang, J.; Zhang, M.; Adhikari, B.; Yang, Z. Effect of microwave air spouted drying arranged in two and three-stages on the drying uniformity and quality of dehydrated carrot cubes. J. Food Process. Eng. 2016, 177, 80–89. [Google Scholar] [CrossRef]

| Criterion | Types |

|---|---|

| Mode of operation | Batch, continuous |

| Heat input type | Convection, conduction, radiation, electromagnetic fields, combination of heat transfer modes intermittent or continuous adiabatic or non-adiabatic |

| State of material in dryer | Stationary moving agitated, dispersed |

| Operating pressure | Vacuum, atmospheric |

| Drying medium (convection) | Air, superheated steam flue gases |

| Drying temperature | Below boiling temperature, above boiling temperature, below freezing point |

| Relative motion between drying medium and solids | Co-current countercurrent mixed flow |

| Number of stages | Single multistage |

| Residence time | Short (60 min) |

| Parameter | Analytical Method |

|---|---|

| DOC (Dissolved organic carbon) | SM-5310 B High-temperature combustion method |

| TDS (Total dissolved solid) | SM-2540 C gravimetric method |

| TOC (Total organic carbon) | SM-5310 B High-temperature combustion method |

| Conductivity | ASTM D1125-14 |

| BTEX | EPA-8015C Nonhalogenated organics using GC/FID |

| PCBs | ISO 10382 GC method with electron capture detection |

| Mineral oil (C10–C40) | BS EN 14039 |

| Chemical properties moisture content | X-Ray fluorescent spectrometer (XRF) ASTM 3173 |

| Element | % | Oxide | % | Element | % | Oxide | % |

|---|---|---|---|---|---|---|---|

| O | 41.590 | Ti | 0.362 | TiO2 | 0.605 | ||

| Na Mg | 2.150 | Na2O3 | 2.898 | Cr | 0.041 | Cr2O3 | 0.060 |

| Mg | 2.482 | MgO | 4.115 | Mn | 0.084 | MnO | 0.108 |

| Al | 7.150 | Al2O33 | 13.509 | Fe | 3.952 | Fe2O3 | 5.650 |

| Si | 21.482 | SiO2 | 45.958 | Co | 0.012 | Co3O4 | 0.016 |

| P | 0.070 | P2O5 | 0.161 | Ni | 0.017 | NiO | 0.022 |

| S | 0.506 | SO3 | 1.263 | Cu | 0.042 | CuO | 0.053 |

| Cl | 3.009 | Cl | 3.009 | Zn | 0.011 | ZnO | 0.014 |

| K | 4.565 | K2O | 5.499 | Ba | 1.394 | BaO | 1.557 |

| Ca | 11.080 | CaO | 15.503 |

| Parameter | Unit | Value |

|---|---|---|

| BTEX | mg/kg | <0.5 |

| PCBs | mg/kg | <0.1 |

| Mineral oil (C10–40) | mg/kg | 1247 |

| TOC | % | 0.7228 |

| DOC | mg/L | 209.79 |

| TDS | mg/L | 2.810 |

| Conductivity | S/cm | 4380 |

| Moisture content | % | 45 ± 2 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tınmaz Köse, E. Drying of Drill Cuttings: Emphasis on Energy Consumption and Thermal Analysis. Processes 2019, 7, 145. https://doi.org/10.3390/pr7030145

Tınmaz Köse E. Drying of Drill Cuttings: Emphasis on Energy Consumption and Thermal Analysis. Processes. 2019; 7(3):145. https://doi.org/10.3390/pr7030145

Chicago/Turabian StyleTınmaz Köse, Esra. 2019. "Drying of Drill Cuttings: Emphasis on Energy Consumption and Thermal Analysis" Processes 7, no. 3: 145. https://doi.org/10.3390/pr7030145

APA StyleTınmaz Köse, E. (2019). Drying of Drill Cuttings: Emphasis on Energy Consumption and Thermal Analysis. Processes, 7(3), 145. https://doi.org/10.3390/pr7030145