Integrated Component Optimization and Energy Management for Plug-In Hybrid Electric Buses

Abstract

1. Introduction

2. Preparing for Integrated Optimization

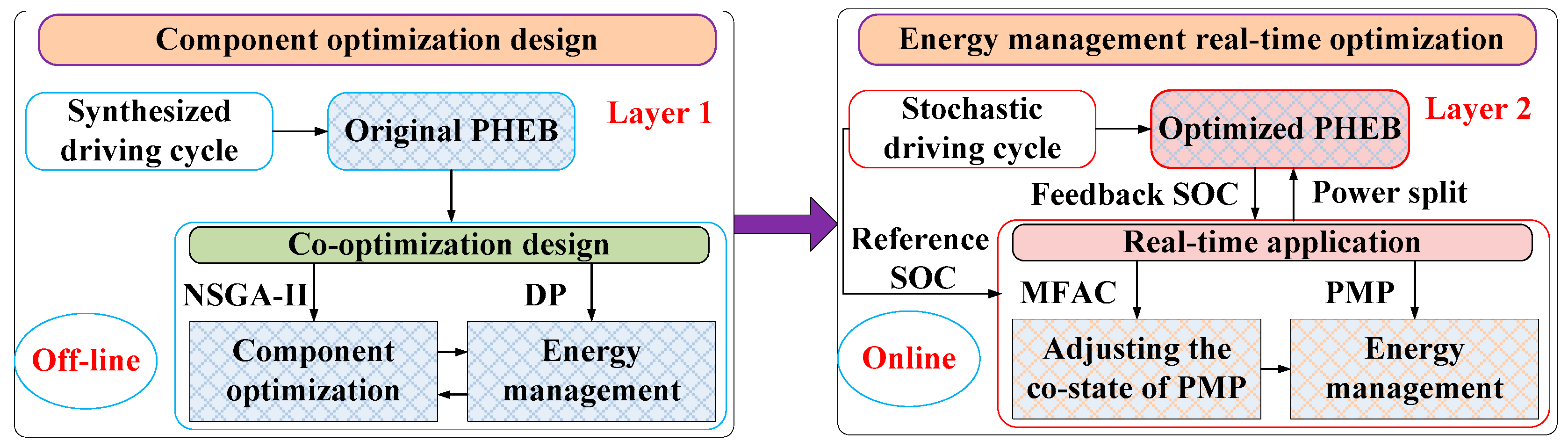

2.1. Architecture of Integrated Optimization

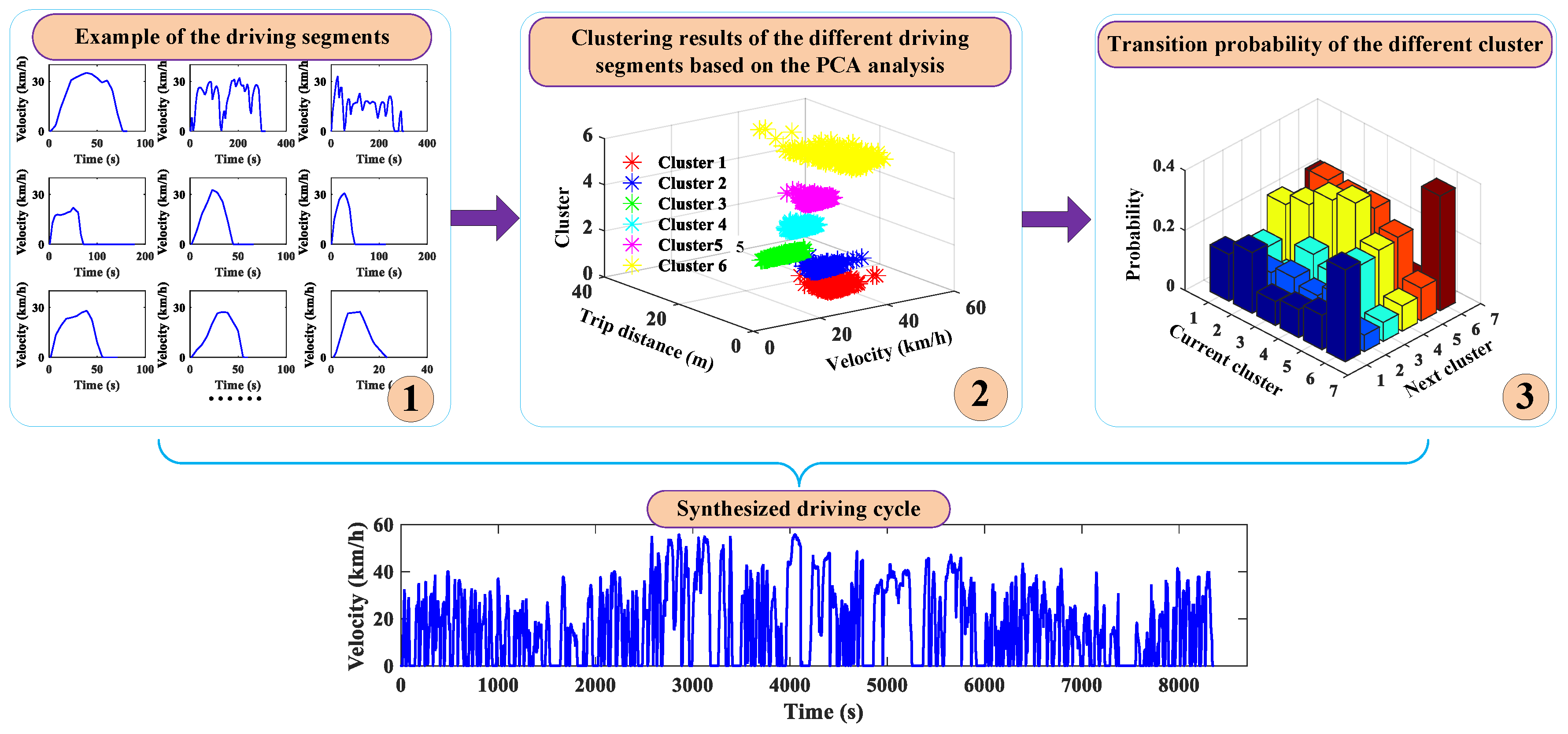

2.2. Synthesis of the Representative Driving Cycle

3. PHEB Models

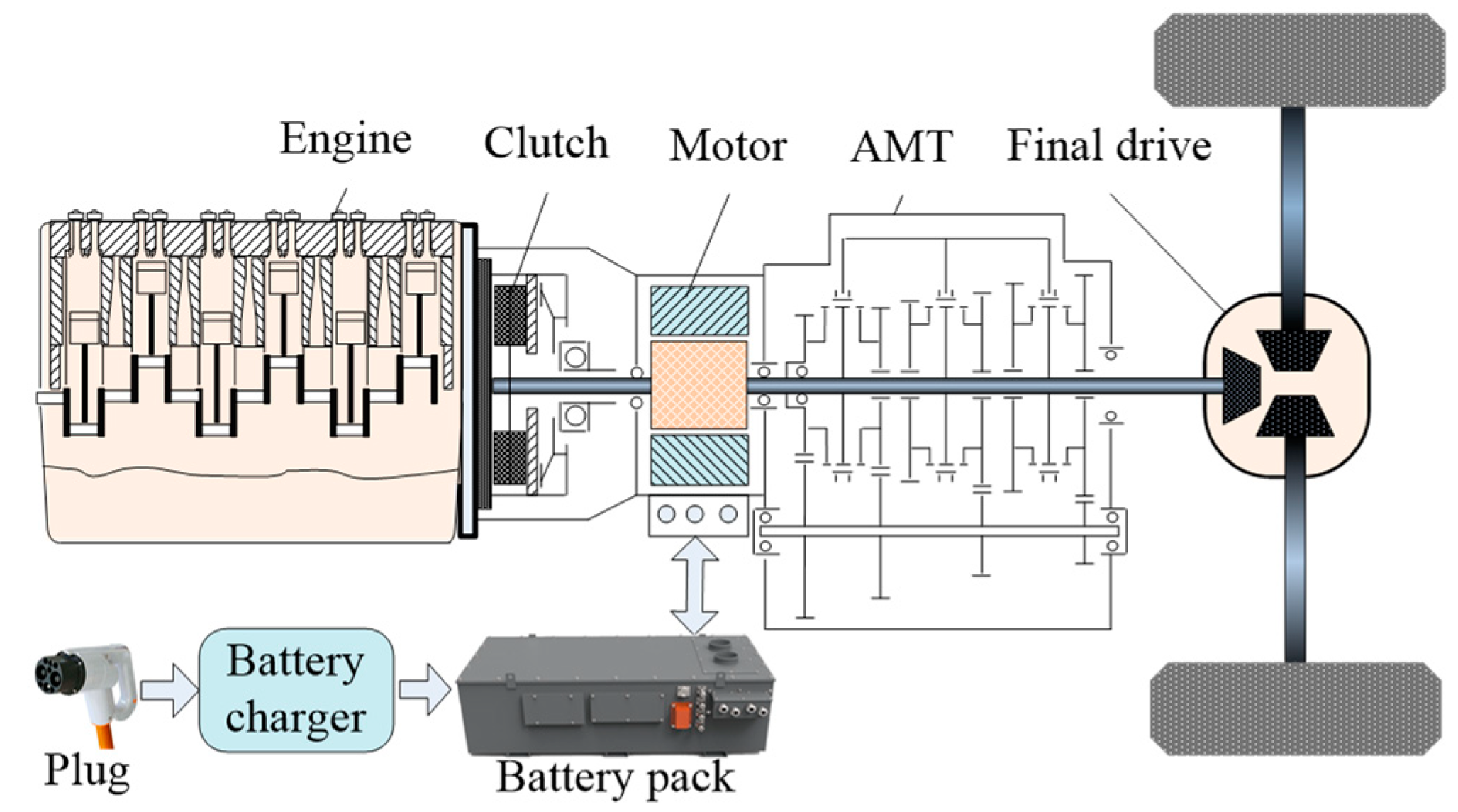

3.1. Configuration and Parameters

3.2. Engine Model

3.3. Motor Model

3.4. Battery Model

3.5. Vehicle Longitudinal Dynamics

4. Co-Optimization Framework

4.1. Problem Formulation

4.2. Boundaries

4.3. Optimization Results Analysis

5. Real-Time Application of the Energy Management Strategy

5.1. PMP Problem Formulation

5.2. Reference SOC

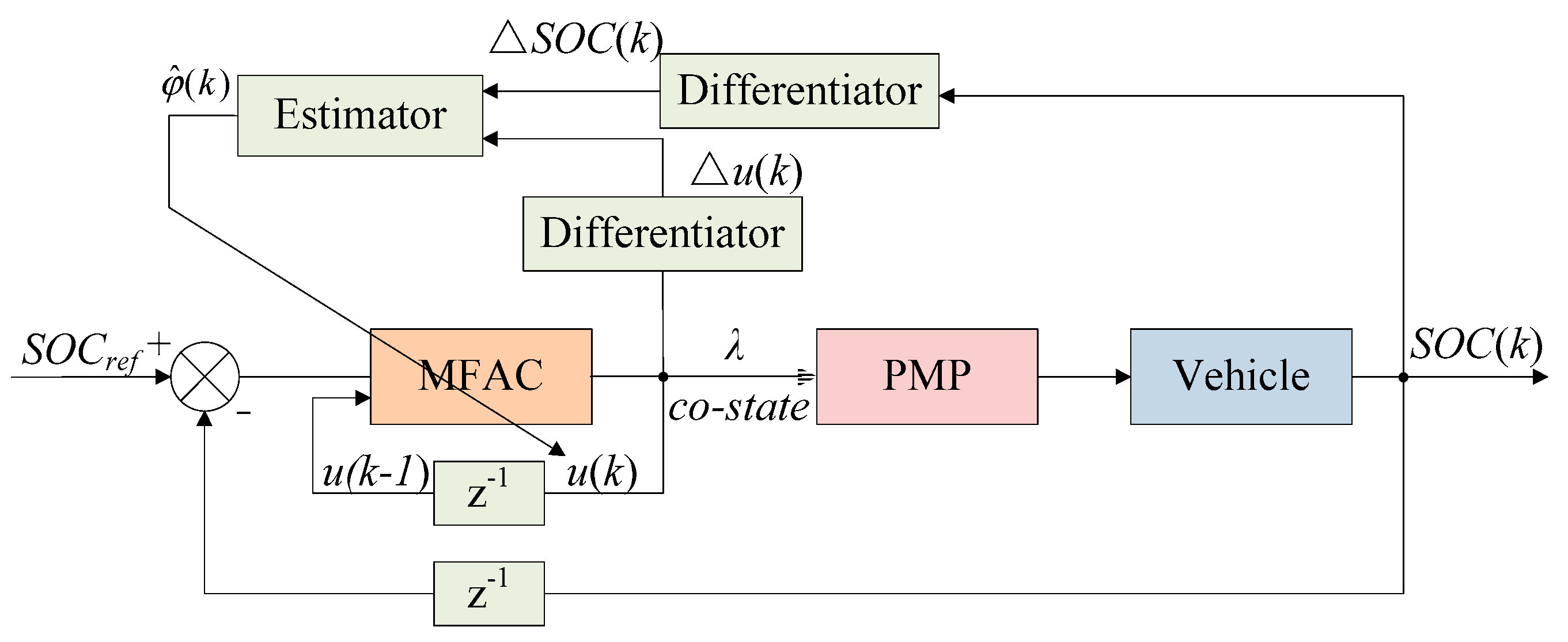

5.3. MFAC Controller Design

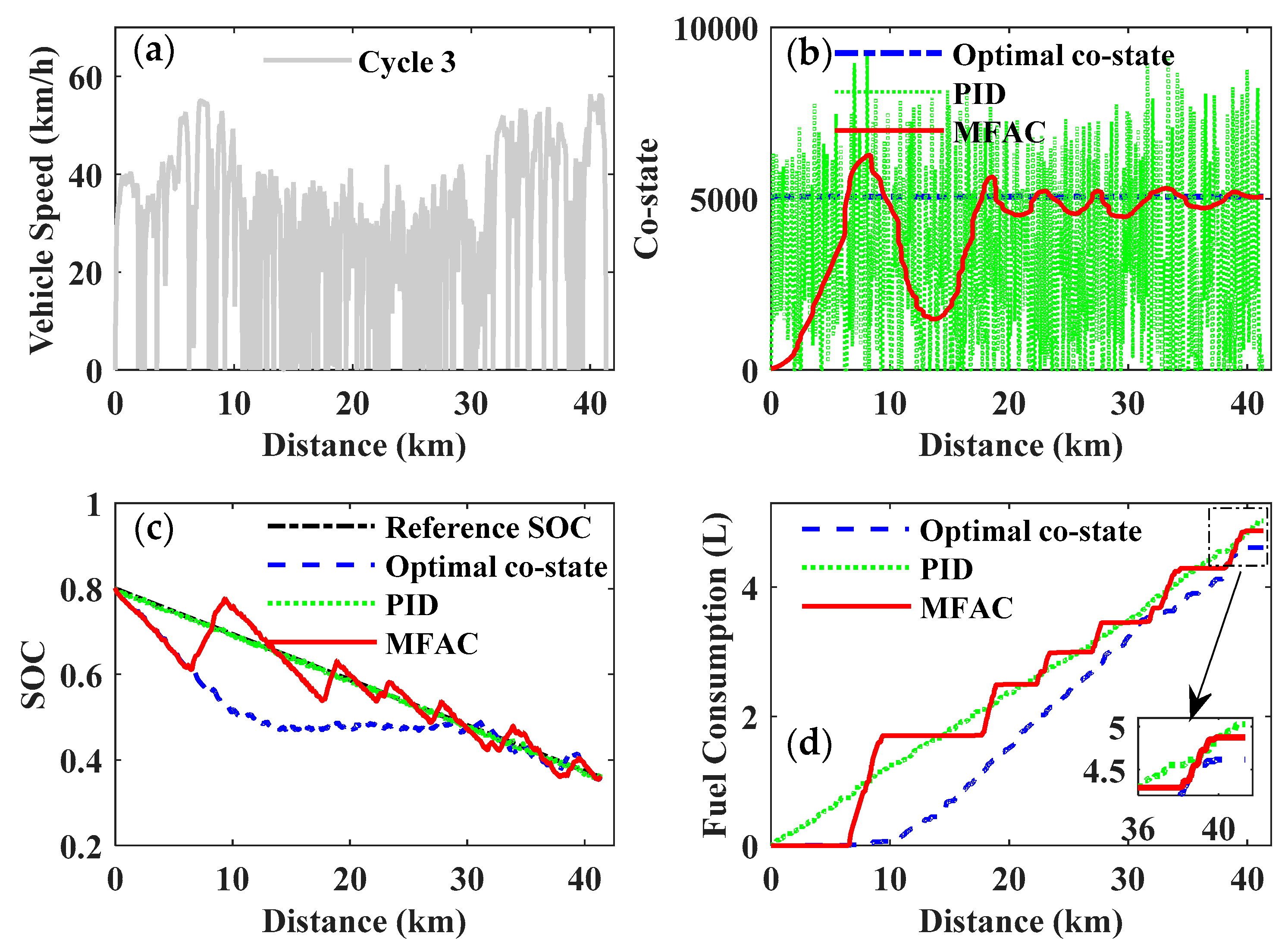

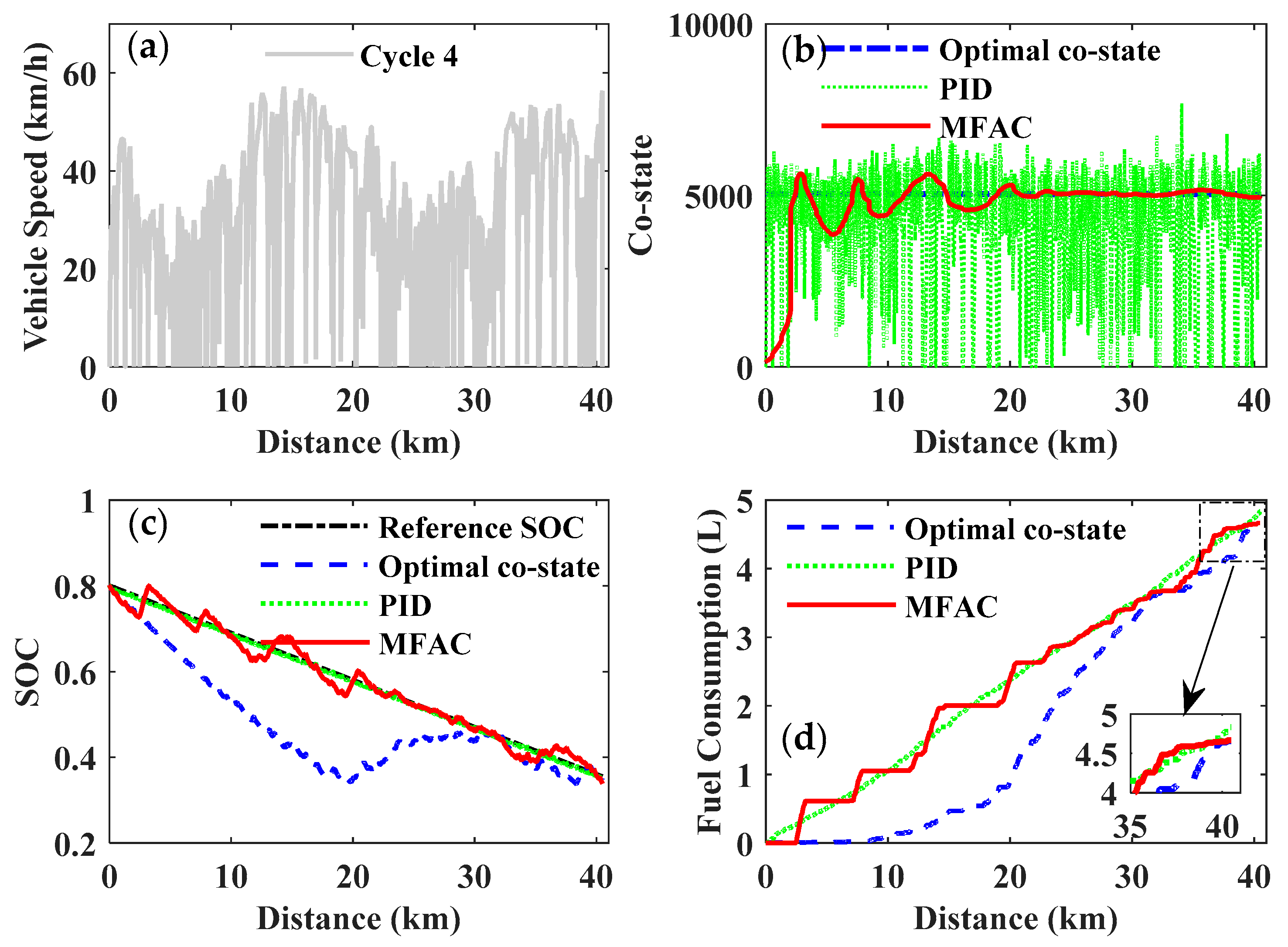

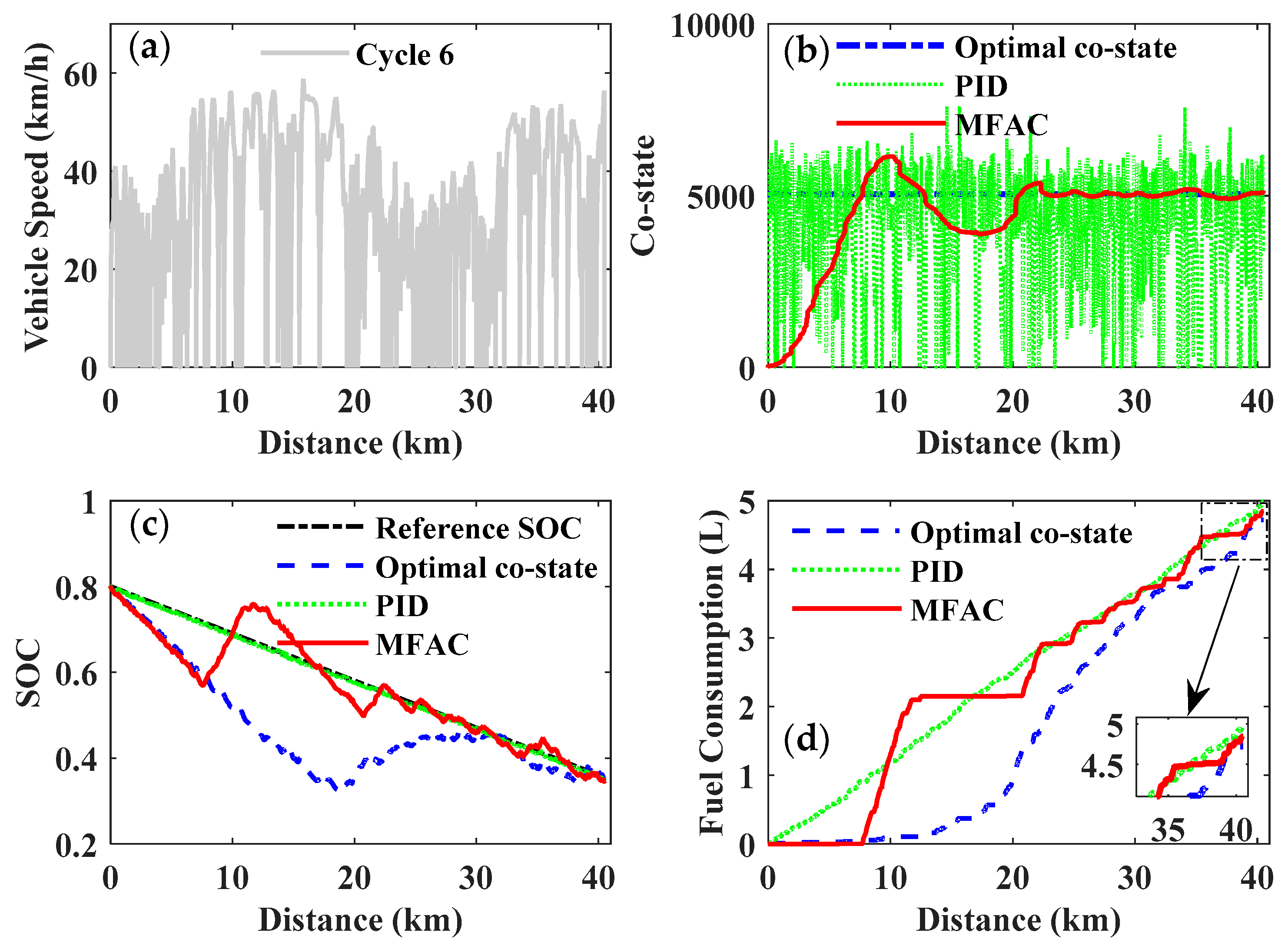

5.4. Results and Discussion

6. Conclusions

- (1)

- To decouple the interaction between the component design and the EMS, a co-optimization method that combines an NSGA-II with a DP algorithm was proposed for simultaneous optimization of the driveline parameters and EMS, based on a synthesized real-road driving cycle. The results indicated that fuel consumption and an acceleration performance of 0–50 km/h could be respectively improved by 4.71% and 4.59%. Most significantly, the optimized driveline was on the basis of a global optimal EMS;

- (2)

- To develop an optimal real-time EMS after the component was optimized, a novel MFAC controller was utilized for the online adjustment of the co-state to realize PMP-based energy management by tracking the properly defined reference SOC. Moreover, the solutions for the optimal co-state control and the PID control were both compared to the proposed method. Then, a validation of the proposed EMS was carried out through six different driving conditions containing one typical driving cycle and five stochastic driving cycles;

- (3)

- The research results demonstrated that the MFAC controller could recognize the optimal co-state of the PMP in real time while facilitating the feedback SOC in generating favorable fluctuations around the reference SOC, thereby improving fuel economy compared to the PID controller. The MFAC-based method was not an optimal solution to enhance fuel economy, contrasted to the optimal co-state control. Nevertheless, it could achieve a suboptimal performance on a real-time application of the PMP-based EMS for unknown driving cycles. Furthermore, the optimal co-state of the PMP obtained from an offline iteration calculation could be approximately identified by the MFAC in real time.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fathabadi, H. Plug-in hybrid electric vehicles (PHEVs): Replacing internal combustion engine with clean and renewable energy based auxiliary power sources. IEEE Trans. Power Electron. 2018, 33, 9611–9618. [Google Scholar] [CrossRef]

- Chen, H.; Li, J.; Zhong, X. Effects of gasoline and polyoxymethylene dimethyl ethers blending in diesel on the combustion and emission of a common rail diesel engine. Energy 2019, 171, 981–999. [Google Scholar] [CrossRef]

- Hu, X.; Moura, S.J.; Murgovski, N. Integrated optimization of battery sizing, charging, and power management in plug-in hybrid electric vehicles. IEEE Trans. Contr. Syst. Technol. 2016, 24, 1036–1043. [Google Scholar] [CrossRef]

- Li, L.; Zhang, Y.; Yang, C. Hybrid genetic algorithm-based optimization of powertrain and control parameters of plug-in hybrid electric bus. J. Frankl. Inst. 2015, 352, 776–801. [Google Scholar] [CrossRef]

- Li, L.; Zhou, L.; Yang, C. A novel combinatorial optimization algorithm for energy management strategy of plug-in hybrid electric vehicle. J. Frankl. Inst. 2017, 354, 6588–6609. [Google Scholar] [CrossRef]

- Guo, H.; Sun, Q.; Wang, C. A systematic design and optimization method of transmission system and power management for a plug-in hybrid electric vehicle. Energy 2018, 148, 1006–1017. [Google Scholar] [CrossRef]

- Silvas, E.; Hofman, T.; Murgovski, N. Review of optimization strategies for system-level design in hybrid electric vehicles. IEEE Trans. Veh. Technol. 2017, 66, 57–70. [Google Scholar] [CrossRef]

- Bayrak, A.; Kang, N.; Papalambros, P. Decomposition-based design optimization of hybrid electric powertrain architectures: Simultaneous configuration and sizing design. J. Mech. Des. 2016, 138, 071405. [Google Scholar] [CrossRef]

- Trovao, J.; Pereirinha, P.; Jorge, H. A multi-level energy management system for multi-source electric vehicles–an integrated rule-based meta-heuristic approach. Appl. Energy 2013, 105, 304–318. [Google Scholar] [CrossRef]

- Zhang, S.; Xiong, R.; Zhang, C. An optimal structure selection and parameter design approach for a dual-motor-driven system used in an electric bus. Energy 2016, 96, 437–448. [Google Scholar] [CrossRef]

- Chen, Z.; Xiong, R.; Cao, J. Particle swarm optimization-based optimal power management of plug-in hybrid electric vehicles considering uncertain driving conditions. Energy 2016, 96, 197–208. [Google Scholar] [CrossRef]

- Hu, X.; Murgovski, N.; Johannesson, L. Comparison of three electrochemical energy buffers applied to a hybrid bus powertrain with simultaneous optimal sizing and energy management. IEEE Trans. Intell. Transp. 2014, 15, 1193–1205. [Google Scholar] [CrossRef]

- Tazelaar, E.; Shen, Y.; Veenhuizen, P. Sizing stack and battery of a fuel cell hybrid distribution truck. Oil Gas Sci. Technol. 2012, 67, 563–573. [Google Scholar] [CrossRef]

- Millo, F.; Zhao, J.; Rolando, L. Optimizing the design of a plug-in hybrid electric vehicle from the early phase: An advanced sizing methodology. Comput.-Aided Des. 2015, 12, 22–32. [Google Scholar] [CrossRef][Green Version]

- Ebbesen, S.; Dönitz, C.; Guzzella, L. Particle swarm optimisation for hybrid electric drivetrain sizing. Int. J. Veh. Des. 2012, 58, 181–199. [Google Scholar] [CrossRef]

- Gao, W.; Mi, C. Hybrid vehicle design using global optimisation algorithms. Int. J. Electr. Hybrid Veh. 2007, 1, 57–70. [Google Scholar] [CrossRef]

- Hu, X.; Martinez, C.; Yang, Y. Charging, power management, and battery degradation mitigation in plug-in hybrid electric vehicles: A unified cost-optimal approach. Mech. Syst. Signal Process. 2017, 87, 4–16. [Google Scholar] [CrossRef]

- Pourabdollah, M.; Murgovski, N.; Grauers, A. Optimal sizing of a parallel PHEV powertrain. IEEE Trans. Veh. Technol. 2013, 62, 2469–2480. [Google Scholar] [CrossRef]

- Martinez, C.; Hu, X.; Cao, D.; Velenis, E.; Gao, B. Energy management in plug-in hybrid electric vehicles: Recent progress and a connected vehicles perspective. IEEE Trans. Veh. Technol. 2017, 66, 4534–4549. [Google Scholar] [CrossRef]

- Peng, J.; He, H.; Xiong, R. Rule based energy management strategy for a series-parallel plug-in hybrid electric bus optimized by dynamic programming. Appl. Energy 2016, 185, 1633–1643. [Google Scholar] [CrossRef]

- Wirasingha, S.; Emadi, A. Classification and review of control strategies for plug-in hybrid electric vehicles. IEEE Trans. Veh. Technol. 2011, 60, 111–122. [Google Scholar] [CrossRef]

- Xie, S.; Hu, X.; Qi, S.; Lang, K. An artificial neural network-enhanced energy management strategy for plug-in hybrid electric vehicles. Energy 2018, 163, 837–848. [Google Scholar] [CrossRef]

- Wang, X.; He, H.; Sun, F. Application study on the dynamic programming algorithm for energy management of plug-in hybrid electric vehicles. Energies 2015, 8, 3225–3244. [Google Scholar] [CrossRef]

- Li, L.; Yang, C.; Zhang, Y. Correctional DP-based energy management strategy of plug-in hybrid electric bus for city-bus route. IEEE Trans. Veh. Technol. 2015, 64, 2792–2803. [Google Scholar] [CrossRef]

- Onori, S.; Tribioli, L. Adaptive Pontryagin’s Minimum Principle supervisory controller design for the plug-in hybrid GM Chevrolet Volt. Appl. Energy 2015, 147, 224–234. [Google Scholar] [CrossRef]

- Rezaei, A.; Burl, J.; Zhou, B. Estimation of the ECMS equivalent factor bounds for hybrid electric vehicles. IEEE Trans. Control Syst. Technol. 2017, 99, 2198–2205. [Google Scholar] [CrossRef]

- Zhang, S.; Xiong, R.; Sun, F. Model predictive control for power management in a plug-in hybrid electric vehicle with a hybrid energy storage system. Appl. Energy 2017, 185, 1654–1662. [Google Scholar] [CrossRef]

- Xie, S.; Hu, X.; Xin, Z.; Li, L. Time-efficient stochastic model predictive energy management for a plug-in hybrid electric bus with adaptive reference state-of-charge advisory. IEEE Trans. Veh. Technol. 2018, 67, 5671–5682. [Google Scholar] [CrossRef]

- Li, L.; Yan, B.; Yang, C. Application-oriented stochastic energy management for plug-in hybrid electric bus with AMT. IEEE Trans. Veh. Technol. 2016, 65, 4459–4470. [Google Scholar] [CrossRef]

- Xiong, R.; Cao, J.; Yu, Q. Reinforcement learning-based real-time power management for hybrid energy storage system in the plug-in hybrid electric vehicle. Appl. Energy 2018, 211, 538–548. [Google Scholar] [CrossRef]

- Xie, S.; Li, H.; Xin, Z. A Pontryagin Minimum Principle-based adaptive equivalent consumption minimum strategy for a plug-in hybrid electric bus on a fixed route. Energies 2017, 10, 1379. [Google Scholar] [CrossRef]

- Zhou, W.; Zhang, C.; Li, J.; Fathy, H. A pseudospectral strategy for optimal power management in series hybrid electric powertrains. IEEE Trans. Veh. Technol. 2016, 65, 4813–4825. [Google Scholar] [CrossRef]

- Zhang, J.; Zheng, C.; Cha, S. Co-state variable determination in Pontryagin’s Minimum Principle for energy management of hybrid vehicles. Int. J. Precis. Eng. Manuf. 2016, 17, 1215–1222. [Google Scholar] [CrossRef]

- Zhang, F.; Liu, H.; Hu, Y.; Xi, J. A Supervisory control algorithm of hybrid electric vehicle based on adaptive equivalent consumption minimization strategy with fuzzy PI. Energies 2016, 9, 919. [Google Scholar] [CrossRef]

- Tang, L.; Rizzoni, G.; Onori, S. Energy management strategy for HEVs including battery life optimization. IEEE Trans. Transp. Electrif. 2015, 1, 211–222. [Google Scholar] [CrossRef]

- Yang, C.; Du, S.; Li, L. Adaptive real-time optimal energy management strategy based on equivalent factors optimization for plug-in hybrid electric vehicle. Appl. Energy 2017, 203, 883–896. [Google Scholar] [CrossRef]

- Sun, C.; Hu, X.; Moura, S.; Sun, F. Velocity predictors for predictive energy management in hybrid electric vehicles. IEEE Trans. Control Syst. Technol. 2015, 23, 1197–1204. [Google Scholar]

- Ouddah, N.; Adouane, L.; Abdrakhmanov, R. From offline to adaptive online energy management strategy of hybrid vehicle using Pontryagin’s Minimum Principle. Int. J. Automot. Technol. 2018, 19, 571–584. [Google Scholar] [CrossRef]

- Lin, C.C.; Peng, H.; Grizzle, J.W.; Kong, J.-M. Power management strategy for a parallel hybrid electric truck. IEEE Trans. Control Syst. Technol. 2003, 11, 839–849. [Google Scholar]

- Sundstrom, O.; Ambuhl, D.; Guzzella, L. On implementation of Dynamic Programming for optimal control problems with final state constraints. Oil Gas Sci. Technol. 2010, 65, 91–102. [Google Scholar] [CrossRef]

- Kim, N.; Cha, S.; Peng, H. Optimal control of hybrid electric vehicles based on Pontryagin’s Minimum Principle. IEEE Trans. Control Syst. Technol. 2011, 19, 1279–1287. [Google Scholar]

- Zhao, X.; Ma, J.; Wang, S. Developing an electric vehicle urban driving cycle to study differences in energy consumption. Environ. Sci. Pollut. Res. 2019, 26, 13839–13853. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Yu, Q.; Ma, J. Development of a representative EV urban driving cycle based on a k-means and SVM hybrid clustering algorithm. J. Adv. Transp. 2018, 2018, 18. [Google Scholar] [CrossRef]

- Lee, T.; Adornato, B.; Filipi, Z. Synthesis of real-world driving cycles and their use for estimating PHEV energy consumption and charging opportunities: Case study for midwest/U.S. IEEE Trans. Veh. Technol. 2011, 60, 4153–4163. [Google Scholar] [CrossRef]

- Pires, D.; Antunes, C.; Martins, A. NSGA-II with local search for a multi-objective reactive power compensation problem. Int. J. Electr. Power 2012, 43, 313–324. [Google Scholar] [CrossRef]

- Zhao, W.; Luan, Z.; Wang, C. Parametric optimization of novel electric-hydraulic hybrid steering system based on a shuffled particle swarm optimization algorithm. J. Clean. Prod. 2018, 186, 865–876. [Google Scholar] [CrossRef]

- Li, Y.; Lu, X.; Kar, N. Rule-Based control strategy with novel parameters optimization using NSGA-II for power-split PHEV operation cost minimization. IEEE Trans. Veh. Technol. 2014, 63, 3051–3061. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A Fast and Elitist Multiobjective Genetic Algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Xie, S.; Hu, X.; Xin, Z.; James, B. Pontryagin’s minimum principle based model predictive control of energy management for a plug-in hybrid electric bus. Appl. Energy 2019, 236, 893–905. [Google Scholar] [CrossRef]

- Hou, Z.; Jin, S. Data-driven model-free adaptive control for a class of MIMO nonlinear discrete-time systems. IEEE Trans. Neural Netw. 2011, 22, 2173–2188. [Google Scholar]

- Dong, Z.; Pan, Y.; Zhang, Z. Model-free adaptive control law for nuclear superheated-steam supply systems. Energy 2017, 135, 53–67. [Google Scholar] [CrossRef]

| Items | Description |

|---|---|

| Vehicle | Curb mass: 12,500 kg, gross mass: 16,500 kg |

| Engine | Max torque: 850 Nm, max power: 162 kW |

| Motor | Max torque: 850 Nm, max power: 130 kW |

| AMT | Four-speed, speed ratio: 3.64/2.29/1.32/0.75 |

| Final drive | Speed ratio: 5.785 |

| Battery | Capacity: 50 Ah, voltage: 384 V |

| Speed Ratios | Gear 1 | Gear 2 | Gear 3 | Gear 4 | Final Drive |

|---|---|---|---|---|---|

| The current ratios | 3.64 | 2.29 | 1.32 | 0.75 | 5.785 |

| The upper boundary | 4.2 | 3.0 | 1.8 | 1.0 | 6.5 |

| The lower boundary | 3.2 | 2.2 | 1.2 | 0.7 | 5.5 |

| Option | Value |

|---|---|

| Population size | 50 |

| Number of generations | 20 |

| Crossover probability | 0.9 |

| Mutation probability | 0.01 |

| Current | Best-Found Point | Improvement | |

|---|---|---|---|

| Gear 1 | 3.64 | 4.2 | — |

| Gear 2 | 2.29 | 2.26 | — |

| Gear 3 | 1.32 | 1.45 | — |

| Gear 4 | 0.75 | 1 | — |

| Final drive | 5.785 | 6.5 | — |

| Fuel consumption (L/100 km) | 12.226 | 11.765 | 4.71% |

| Acceleration time (s) | 19.74 | 18.834 | 4.59% |

| Improvement (%) | ||||||

|---|---|---|---|---|---|---|

| Cycle 1 | Cycle 2 | Cycle 3 | Cycle 4 | Cycle 5 | Cycle 6 | |

| MFAC versus optimal co-state | −2.42 | −2.18 | −5.65 | −0.20 | −2.91 | −2.57 |

| MFAC versus PID | 4.28 | 1.52 | 3.01 | 3.43 | 1.10 | 2.83 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Ma, J.; Zhao, X.; Zhang, Y.; Zhang, K.; He, Y. Integrated Component Optimization and Energy Management for Plug-In Hybrid Electric Buses. Processes 2019, 7, 477. https://doi.org/10.3390/pr7080477

Liu X, Ma J, Zhao X, Zhang Y, Zhang K, He Y. Integrated Component Optimization and Energy Management for Plug-In Hybrid Electric Buses. Processes. 2019; 7(8):477. https://doi.org/10.3390/pr7080477

Chicago/Turabian StyleLiu, Xiaodong, Jian Ma, Xuan Zhao, Yixi Zhang, Kai Zhang, and Yilin He. 2019. "Integrated Component Optimization and Energy Management for Plug-In Hybrid Electric Buses" Processes 7, no. 8: 477. https://doi.org/10.3390/pr7080477

APA StyleLiu, X., Ma, J., Zhao, X., Zhang, Y., Zhang, K., & He, Y. (2019). Integrated Component Optimization and Energy Management for Plug-In Hybrid Electric Buses. Processes, 7(8), 477. https://doi.org/10.3390/pr7080477