Cooling Performance Assessment of a Slinky Closed Loop Lake Water Heat Pump System under the Climate Conditions of Pakistan

Abstract

:1. Introduction

2. Mathematical Modelling

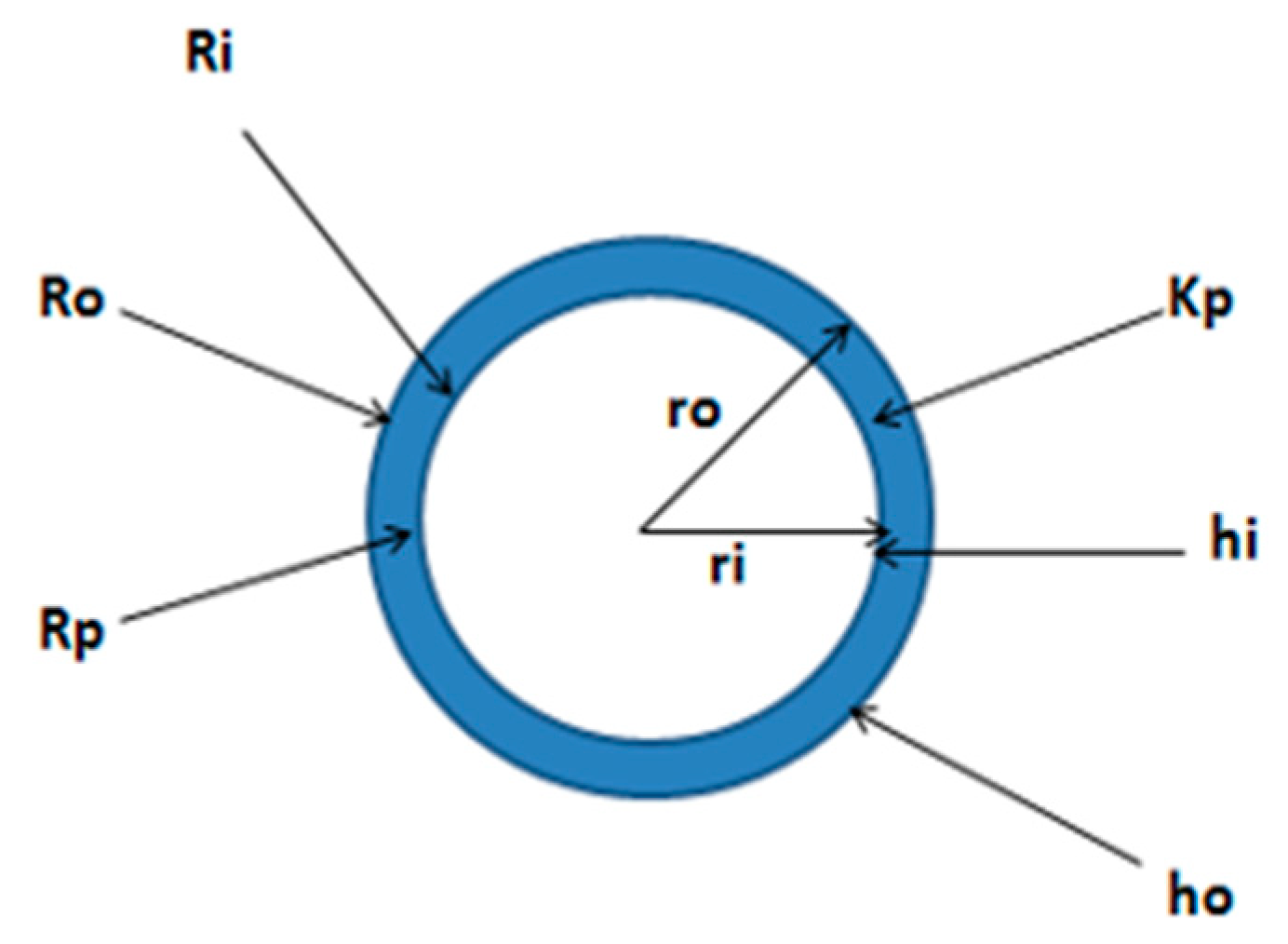

2.1. Heat Transfer Model of Submerged Heat Exchanger (HX)

2.1.1. External Convection Heat Transfer Coefficient of Coil

2.1.2. Internal Convection Heat Transfer Coefficient of Coil

2.1.3. Overall Heat Transfer between the Submerged Coil and Lake Water

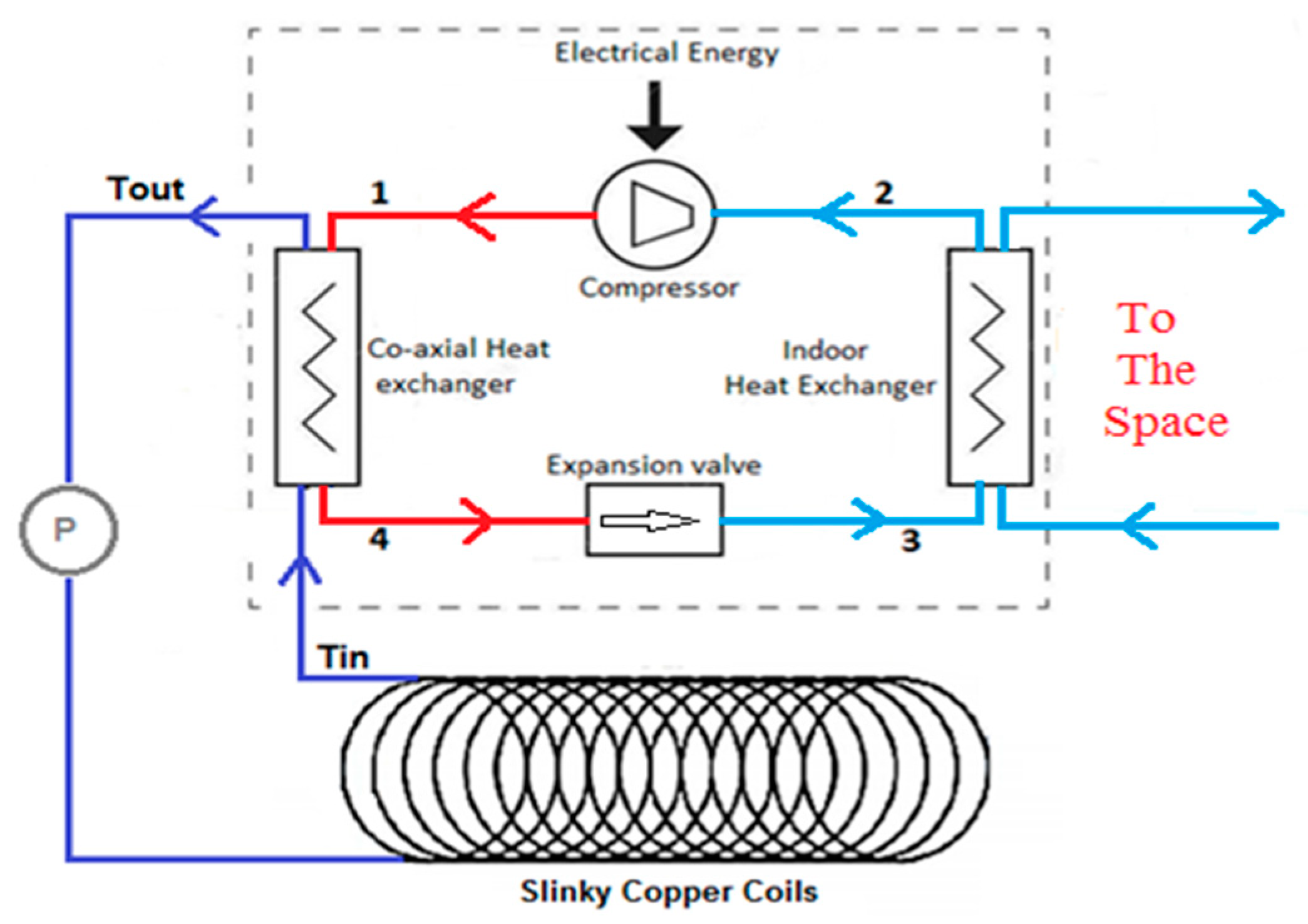

2.2. Heat Pump Performance Model

2.3. EES Modeling

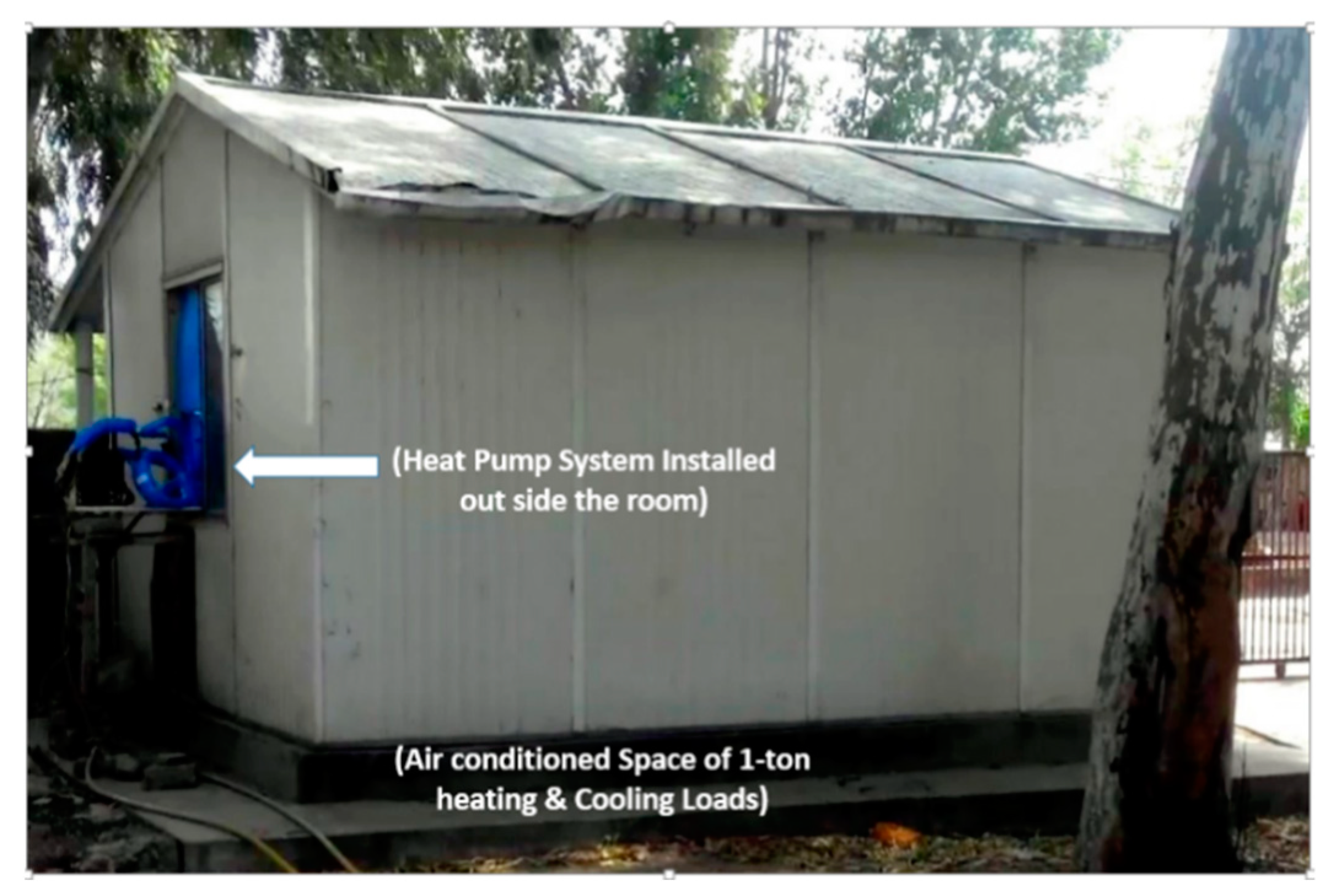

3. Experimental Setup

3.1. Test Room Used for Experimental Purposes

3.2. Heat Pump/Reversible Vapor Compression System

3.3. Lake Water Heat Exchanger

3.4. Sensors

3.4.1. Temperature Sensors

3.4.2. Flow Meter

4. Results and Discussion

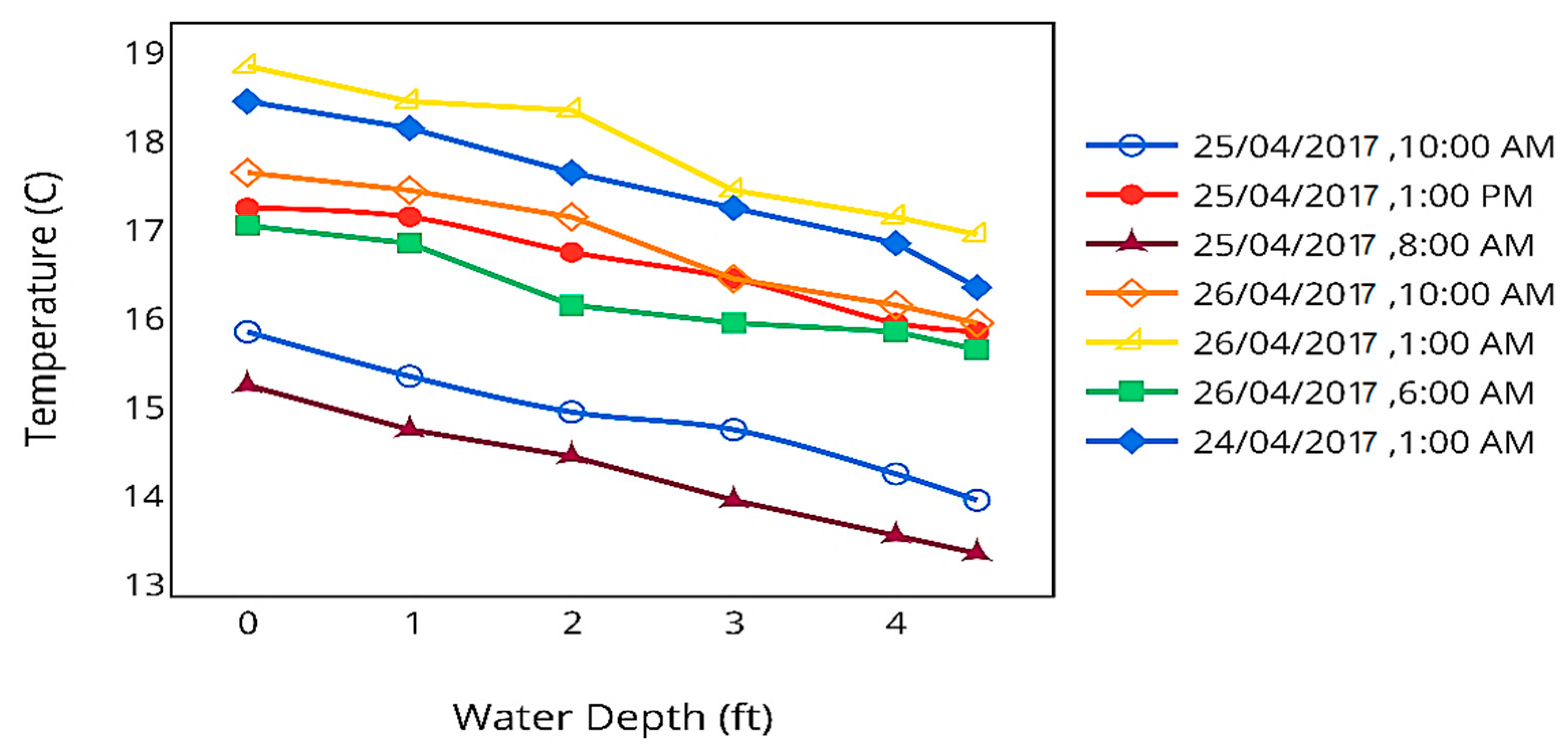

4.1. Effect of Lack Depth on Water Temperature

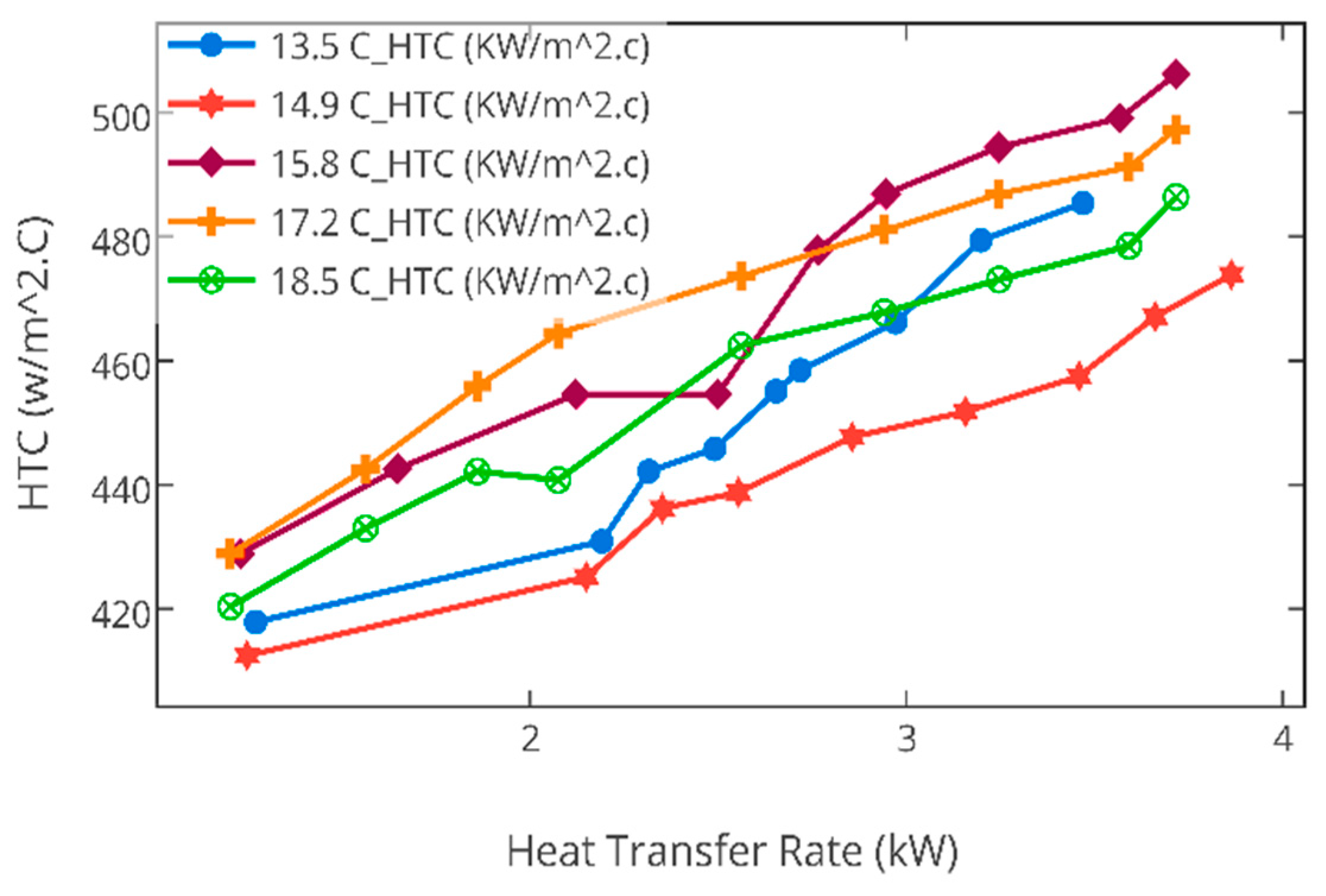

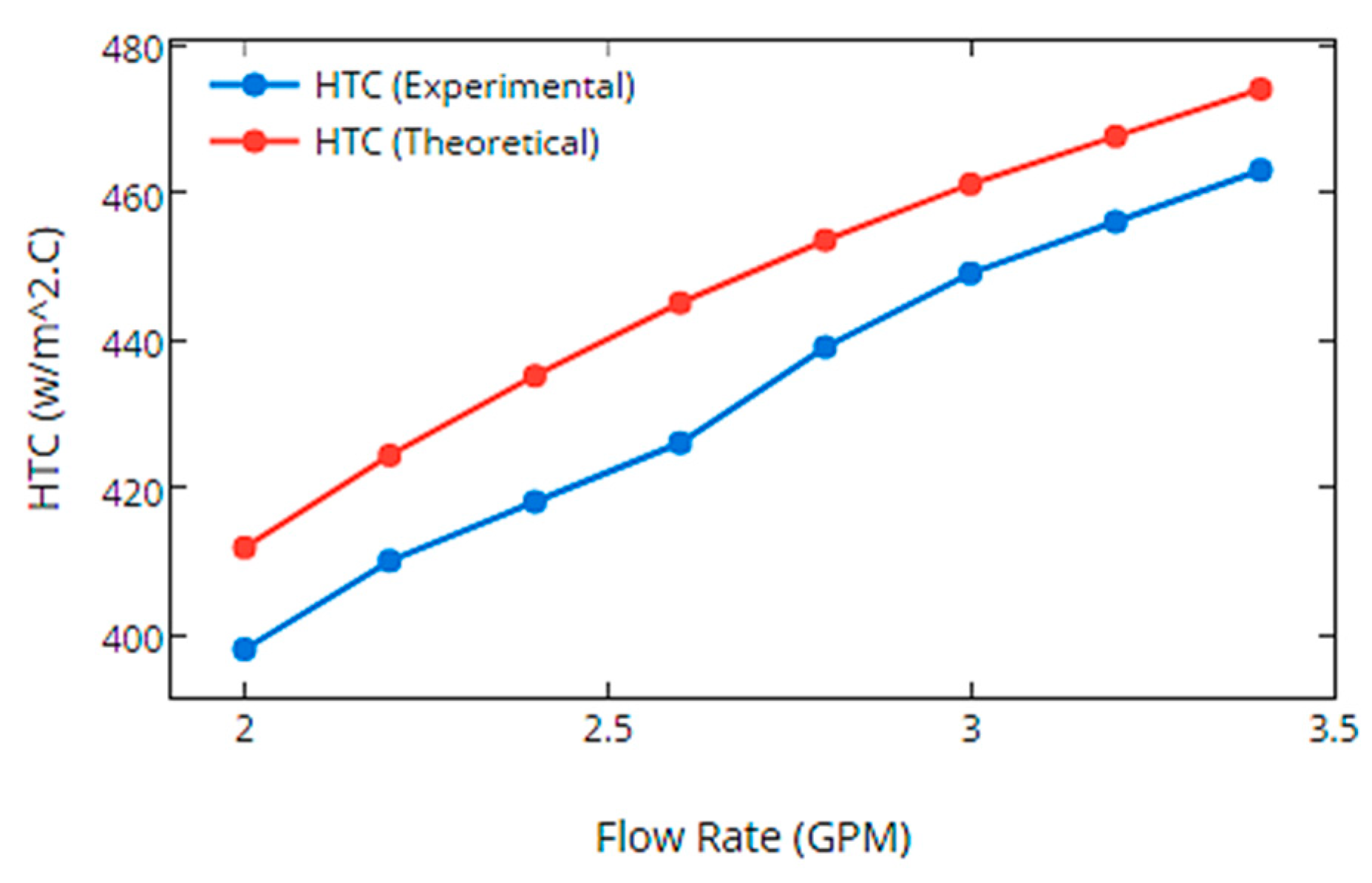

4.2. Effect of Heat Transfer Rate through Slinky Coils on Heat Transfer Coefficient

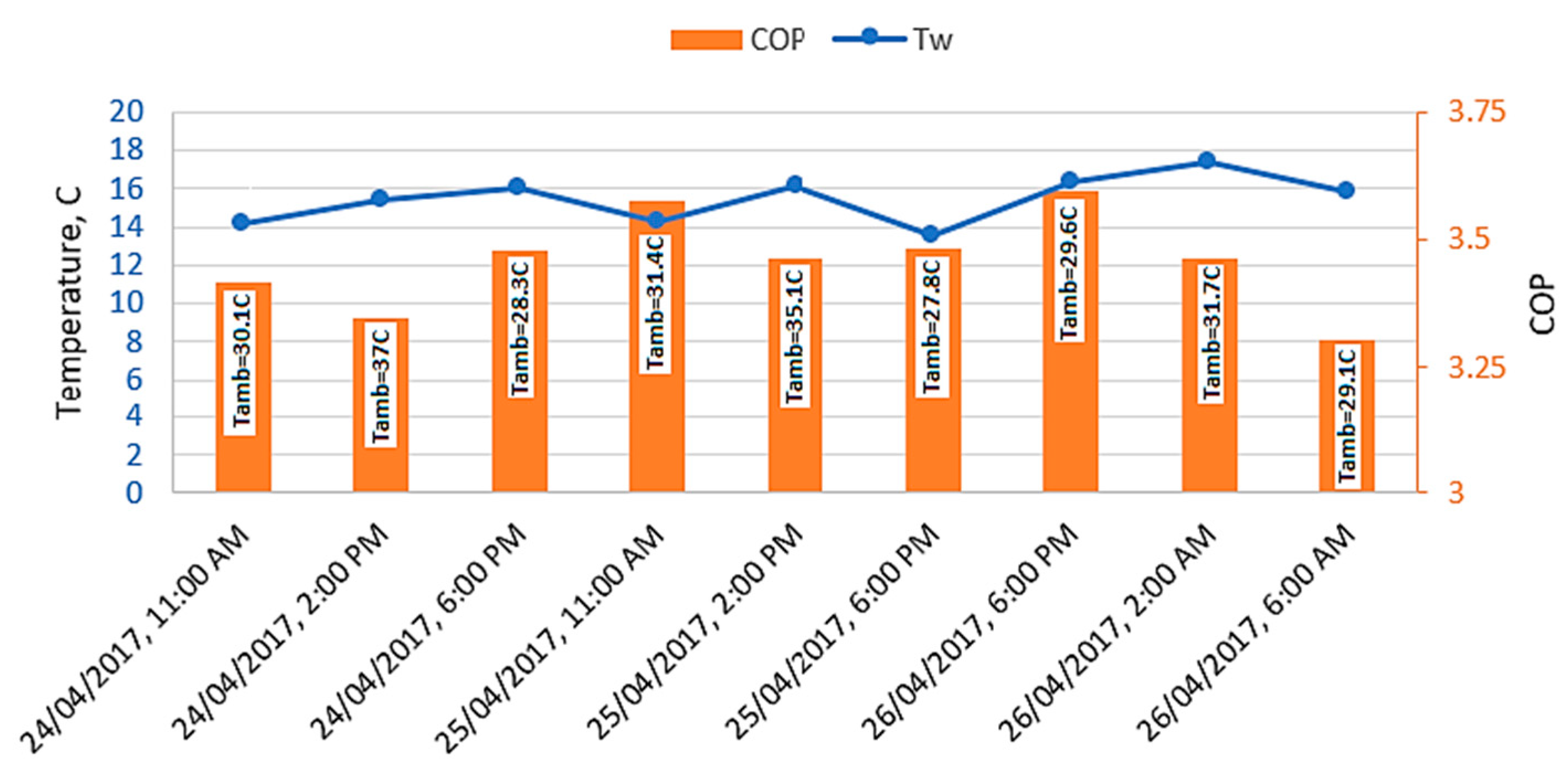

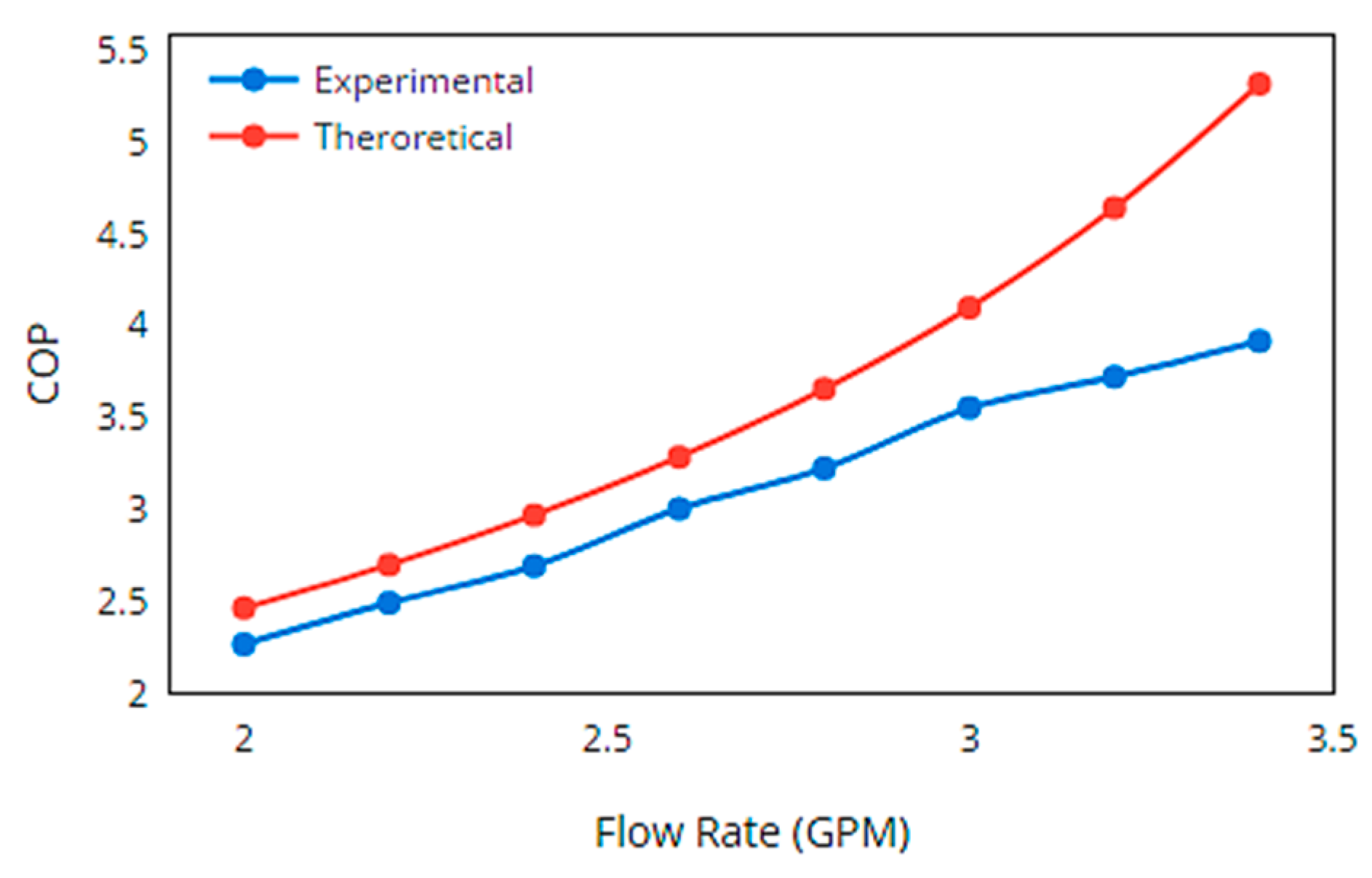

4.3. Performance Results of Heat Pump

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| v | Kinematic Viscosity of lake water ] |

| Rayleigh number | |

| Parantal Number | |

| Specific heat of water | |

| μ | Dynamic viscosity of fluid [kg.m−1.s−1] |

| Thermal Conductivity of water [W.m−1.K−1] | |

| Outside Nusstlet Number | |

| Internal Nusselt Number | |

| Outside diameter of pipe [inch] | |

| K | Thermal Conductivity of copper pipe |

| Darcy friction factor | |

| Renoyld Number | |

| External convective coefficient of slinky coils | |

| Internal convective coefficient of slinky coils | |

| Effectiveness of submerged copper coils | |

| g | Acceleration due to gravity ] |

| α | Thermal diffusivity ] |

| Internal thermal resistance of pipe | |

| Thermal resistance of copper pipe | |

| Thermal resistance outside the pipe |

Abbreviation

| HDPE | High Density Polyethylene |

| HVAC | Heating Ventilation and Air Conditioning |

| LWHP | Lake water Heat Pump System |

| LWT | Lake water temperatures [C] |

| HTC | Overall heat transfer coefficient |

References

- Kavanaugh, S.P. Field test of vertical ground-coupled heat pump in Alabama. ASHRAE Trans. 1992, 98, 607–616. [Google Scholar]

- Kavanaugh, S.P. Development of design tools for ground-source heat pump piping. ASHRAE Trans. 1998, 104, 932–937. [Google Scholar]

- Sohail, M.; Qureshi, M.U.D. Ahmed Sohail and Moin ud Din Qureshi, Energy efficient buildings in Pakistan. Sci. Vis. 2010, 16–17, 27–38. [Google Scholar]

- American Society of Heating Refrigerating and Air-Conditioning Engineers. ASHRAE Handbook-HVAC Applications; American Society of Heating Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 2011. [Google Scholar]

- Kavanaugh, S.P.; Rafferty, K. Ground-Source Heat Pumps-Design of Geothermal Systems for Commercial and Institutional Buildings; American Society of Heating Refrigerating and Air-Conditioning Engineers: Atlanta, GA, USA, 1997. [Google Scholar]

- Kavanaugh, S.P. Ground and Water Source Heat Pumps—A Manual for the Design and Installation of Ground-Coupled, Ground Water and Lake Water Heating and Cooling Systems in Southern Climates; University of Alabama: Tuscaloosa, AL, USA, 1991. [Google Scholar]

- Peer, T.; Joyce, W.S. Lake Source Cooling. ASHRAE J. 2002, 44, 37–39. [Google Scholar]

- Chen, X.; Zhang, G.; Peng, J.; Lin, X.; Liu, T. The performance of an open-loop lake water heat pump system in south China. Appl. Therm. Eng. 2006, 26, 2255–2261. [Google Scholar] [CrossRef]

- Chiasson, A.D.; Spitler, J.D.; Rees, S.J. A model for simulating the performance of a shallow pond as a supplemental heat rejecter with closed-loop ground source heat pump systems. ASHRAE Trans. 2002, 106, 107–121. [Google Scholar]

- Chen, X.; Zhang, G. On the study of closed-loop lake water heat pump applications in south China climates. Energy Build. 2013, 6. [Google Scholar]

- Liang, J.; Yang, Q.; Liu, L.; Li, X. Modeling and performance evaluation of shallow ground water heat pumps in Beijing plain, China. Energy Build. 2011, 43, 3131–3138. [Google Scholar] [CrossRef]

- Si, P.; Li, A.; Rong, X.; Feng, Y.; Yang, Z.; Gao, Q. New optimized model for water temperature calculation of river-water source heat pump and its application in simulation of energy consumption. Renew. Energy 2015, 84, 65–73. [Google Scholar] [CrossRef]

- Zaigham, N.A. Geothermal Energy Resources of Pakistan. In Proceedings of the World Geothermal Congress 2005, Antalya, Turkey, 24–29 April 2005. [Google Scholar]

- Bakht, M.S. An Overview of Geothermal Resources of Pakistan. In Proceedings of the World Geothermal Congress 2000, Kyushu, Japan, 28 May–10 June 2000. [Google Scholar]

- Churchill, S.W.; Chu, H.H.S. Correlating equations for laminar and turbulent free convection from a horizontal cylinder. Int. J. Heat Mass Transf. 1975, 18, 1049–1053. [Google Scholar] [CrossRef]

- Morton, A.C. Assessing the Performance of a Reservoir-Based Water Source Heat Pump; Renewable Energy Systems and the Environment; University of Strathclyde Engineering: Glasgow, UK, 2013. [Google Scholar]

- Hussen, H.M.; Hisham, A.H. Experimental model of ground source heat pump system. In Proceedings of the 7th Jordanian International Mechanical Engineering Conference (JIMEC’7), Amman, Jordan, 27–29 September 2010. [Google Scholar]

- Çağlar, A.; Yamali, C. Performance analysis of solar assisted heat pump with an evacuated collector for domestic heating. Energy Build. 2016, 54, 22–28. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shahzad, M.K.; Rehan, M.A.; Ali, M.; Mustafa, A.; Abbas, Z.; Mujtaba, M.; Akram, M.I.; Yousaf, M.R. Cooling Performance Assessment of a Slinky Closed Loop Lake Water Heat Pump System under the Climate Conditions of Pakistan. Processes 2019, 7, 553. https://doi.org/10.3390/pr7090553

Shahzad MK, Rehan MA, Ali M, Mustafa A, Abbas Z, Mujtaba M, Akram MI, Yousaf MR. Cooling Performance Assessment of a Slinky Closed Loop Lake Water Heat Pump System under the Climate Conditions of Pakistan. Processes. 2019; 7(9):553. https://doi.org/10.3390/pr7090553

Chicago/Turabian StyleShahzad, Muhammad Kashif, Mirza Abdullah Rehan, Muzaffar Ali, Azeem Mustafa, Zafar Abbas, Muhammad Mujtaba, Muhammad Imran Akram, and Muhammad Rabeet Yousaf. 2019. "Cooling Performance Assessment of a Slinky Closed Loop Lake Water Heat Pump System under the Climate Conditions of Pakistan" Processes 7, no. 9: 553. https://doi.org/10.3390/pr7090553

APA StyleShahzad, M. K., Rehan, M. A., Ali, M., Mustafa, A., Abbas, Z., Mujtaba, M., Akram, M. I., & Yousaf, M. R. (2019). Cooling Performance Assessment of a Slinky Closed Loop Lake Water Heat Pump System under the Climate Conditions of Pakistan. Processes, 7(9), 553. https://doi.org/10.3390/pr7090553